A device and method for graded utilization of low-rank coal and biomass based on chemical chain

A low-rank coal and biomass technology, applied in chemical instruments and methods, chemical/physical processes, gasification processes, etc., can solve problems such as limited industrial applications, expensive hydrogen sources, and difficulty in recycling catalysts to reduce dust content Quantity, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

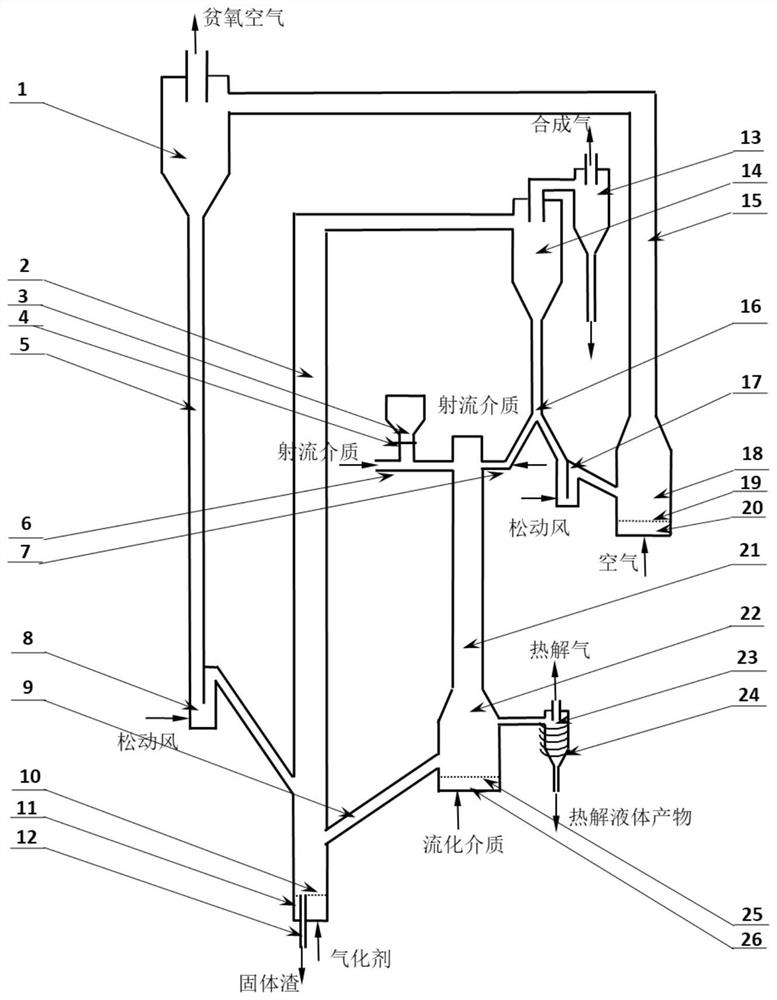

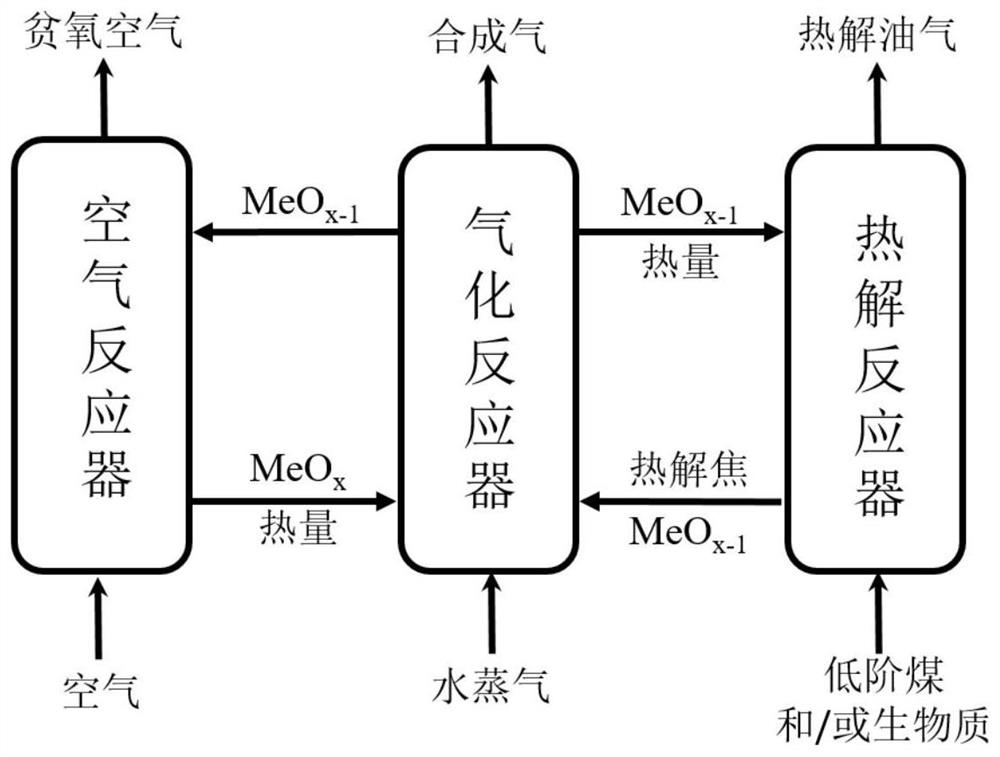

[0025]The main structure of the chemical chain-based low-rank coal and biomass graded utilization device described in this embodiment includes a main structure including a cyclone separator I 1, a gasification reactor 2, a stocker 3, a material control valve 4, a material leg 5, Jet pipe I 6, jet pipe II 7, return valve 8, flow control valve I 9, gas distribution plate I 10, gas distribution chamber I 11, solid slag outlet 12, cyclone separator III 13, cyclone separator II 14, Two-stage air reactor rapid lifting section 15, distributor 16, flow control valve II 17, two-stage air reactor dense phase section 18, gas distribution plate II 19, gas distribution chamber II 20, two-stage pyrolysis The fast descending section 21 of the reactor, the dense phase section 22 of the two-stage pyrolysis reactor, the gas-liquid separator 23, the quenching heat exchanger 24, the gas distribution plate III 25 and the gas distribution chamber III 26; the stocker 3 passes through the material con...

Embodiment 2

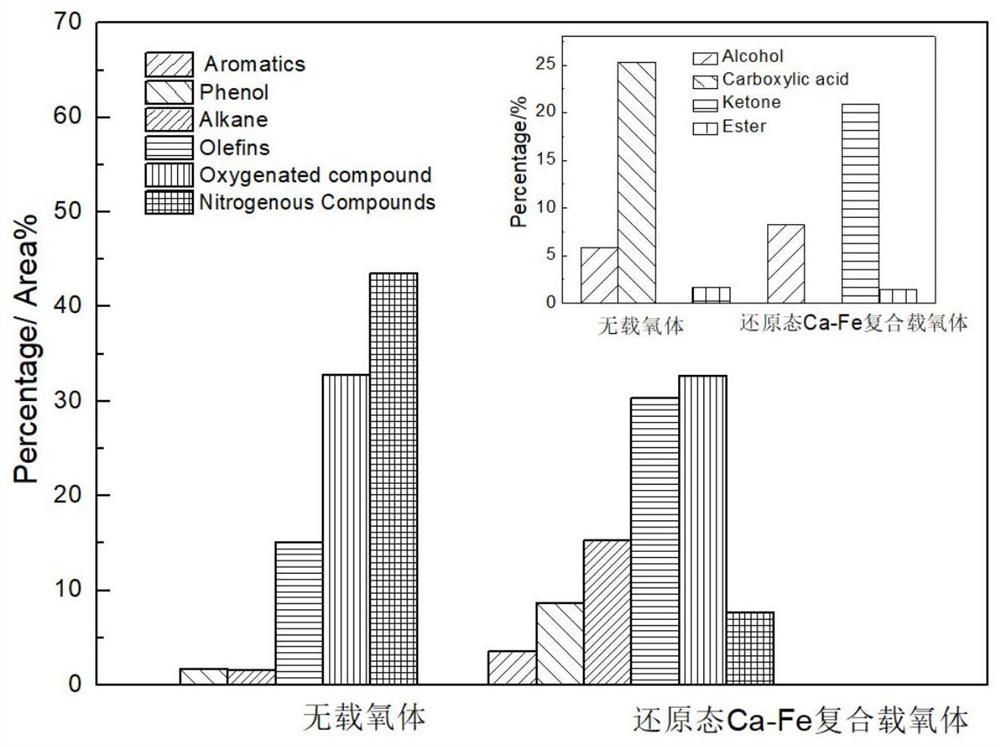

[0035] In this example, the device and method described in Example 1 are adopted, the Ca-Fe composite oxygen carrier is used as the oxygen carrier, and Zhaotong lignite is used as the reactant. The industrial analysis and elemental analysis of Zhaotong lignite are shown in Table 2, and the reduced Ca-Fe Composition distribution of liquid phase products of pyrolysis reaction between composite oxygen carrier and Zhaotong lignite see Figure 5 , Composition of syngas generated from gasification reaction between oxidized Ca-Fe composite oxygen carrier and Zhaotong lignite pyrolysis coke Image 6 ,

[0036] Table 2: Industrial analysis and elemental analysis of Zhaotong lignite (air-dried basis)

[0037]

[0038]

[0039] Depend on Figure 5 It can be seen that compared with conventional lignite pyrolysis, the addition of oxygen carrier plays an important role in adjusting the composition of the pyrolysis liquid phase, greatly increasing the relative content of benzene, tol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com