Fully sealed coal roadway tunneling and anchoring synchronous machine

A fully-sealed, synchronous machine technology, which is applied in the direction of cutting machinery, slitting machinery, and installation of anchor rods, can solve the problems of prolonged anchoring time, large dust volume, and extended empty head distance, so as to improve the safety operation factor and guarantee Physical health and the effect of improving tunneling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

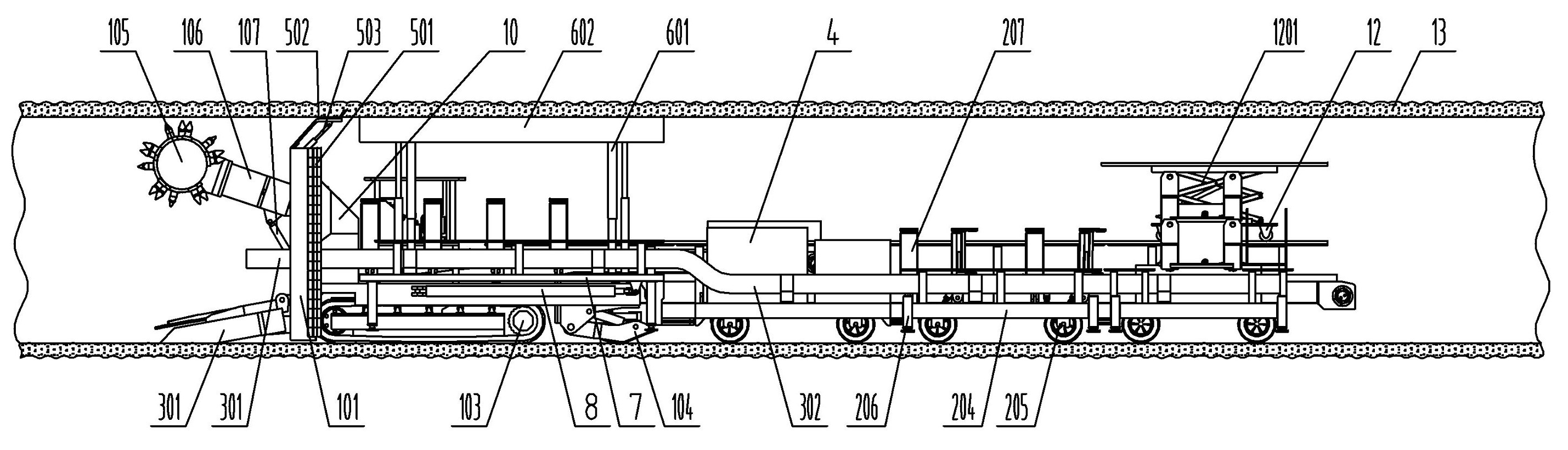

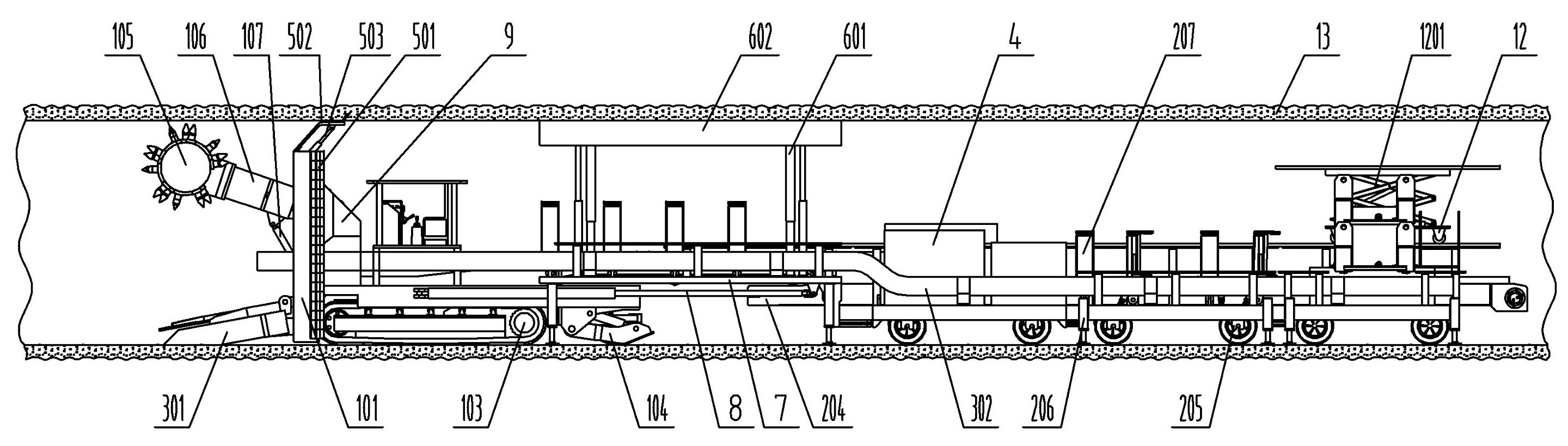

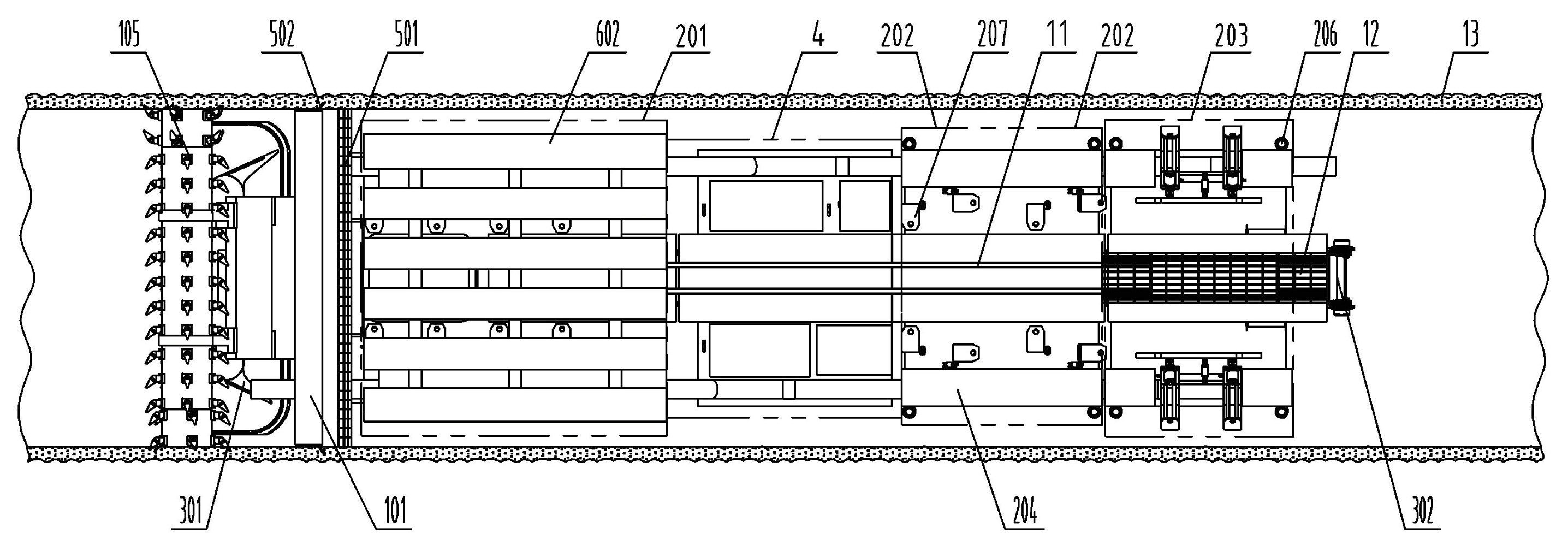

[0033] The working process of the fully sealed coal roadway bolt digging synchronous machine of the present invention is as follows:

[0034] The cutting drum 105 of the present invention cuts into the coal wall 13 to cut coal by extending the lifting cylinder 107 on the cantilever 106, and finally the cantilever 106 can be extended by a certain distance (tentatively 500mm), when the cantilever 106 reaches the limit position At this time, the cantilever 106 is recovered to the minimum length, and the crawler-type walking chassis drives the excavation device 1 to advance 500mm to carry out the next round of excavation; during the excavation process, the sealing device 5 moves forward close to the coal wall 13, and is constantly Draw air outwards so that the sealed space is in a state of negative pressure, so that the fresh air behind the sealing device 5 tends to pour into the sealed space to achieve a good dustproof effect; there is no structural dependence between the anchorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com