Vaporizing combustion turbulence incinerator

An incinerator and turbulent flow technology, applied in the field of gasification combustion turbulent flow incinerator, can solve the problems of high gasification temperature for catalytic hydrogen production or alcohol production, low direct utilization rate, complex equipment structure, etc., to achieve uniform and controllable reaction, Small dust content and high burnout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention and working process will be further described below in conjunction with accompanying drawing.

[0019] The orientation terms such as up, down, left, right, front and rear in this application document are established based on the positional relationship shown in the drawings. If the drawings are different, the corresponding positional relationship may also change accordingly, so this should not be understood as limiting the scope of protection.

[0020] The gasification combustion turbulent flow incinerator described in the present invention is suitable for the gasification and combustion of multiple industrial wastes disposed at the same time.

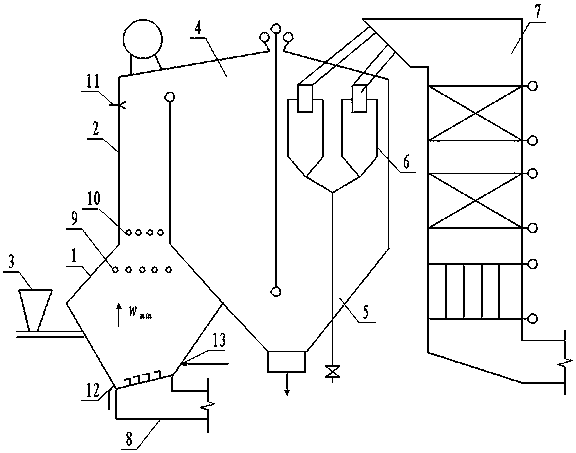

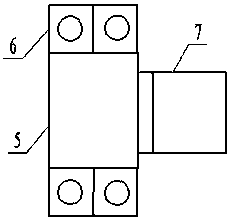

[0021] Such as figure 1 As shown, a gasification combustion turbulent flow incinerator includes a gasification combustion chamber, a burnout section 4 , a cooling section 5 , a separator 6 , a tail flue 7 and a feed device 3 . The gasification combustion chamber communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com