Patents

Literature

86results about How to "High thermoelectric figure of merit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of bismuth-tollurium base thromoelectric alloy

InactiveCN1757774AImprove performanceImprove thermoelectric performanceThermoelectric materialsHigh density

A process for preparing the BiTe-based electrothermal material includes such steps as proportionally mixing raw materials, vacuum smelting for alloying, quick cold quenching for non-crystalline treating, breaking, ball grinding, vacuum drying, hot pressing or hot shear extruding and machining. Its advantages are high density, thermoelectric performance, and machinability and low cost.

Owner:BEIJING CISRI GAONA TECH

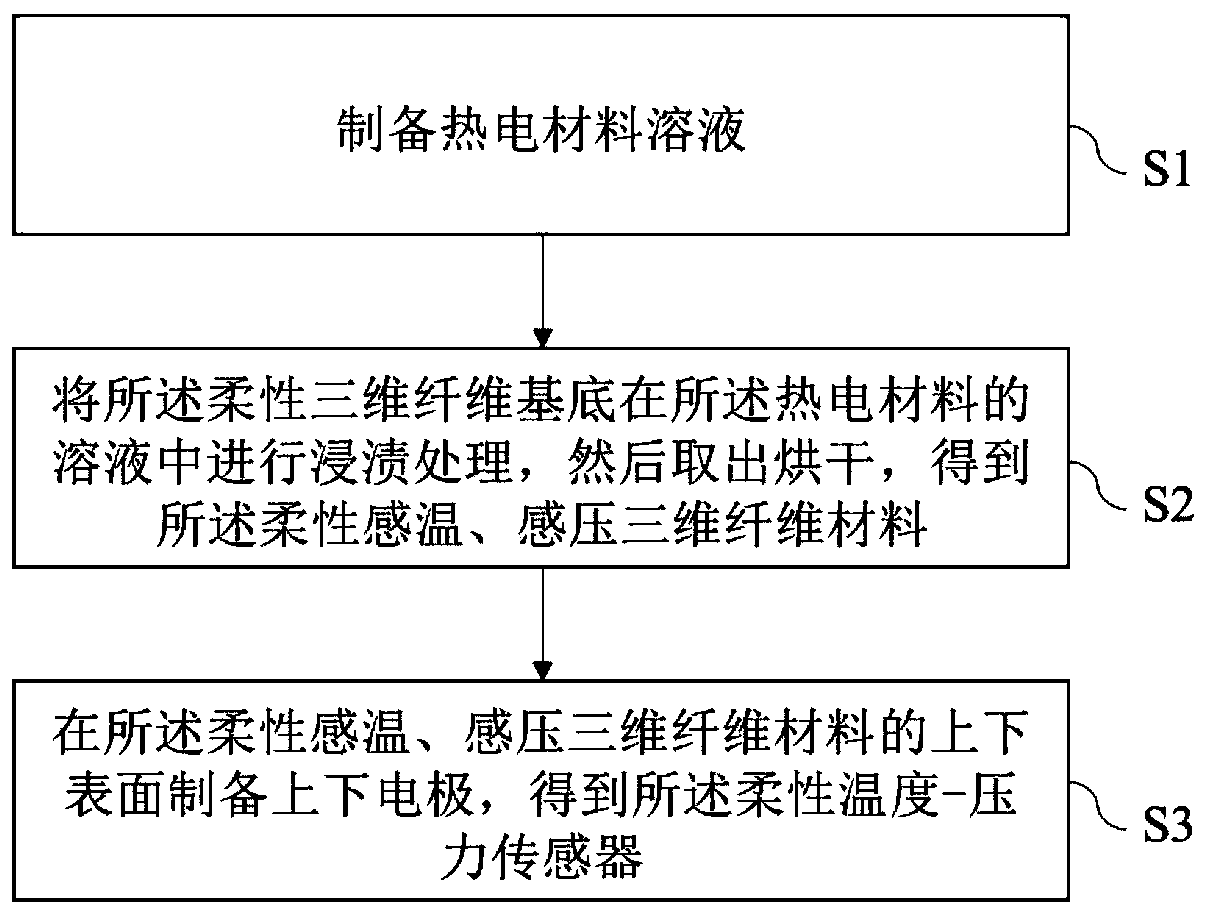

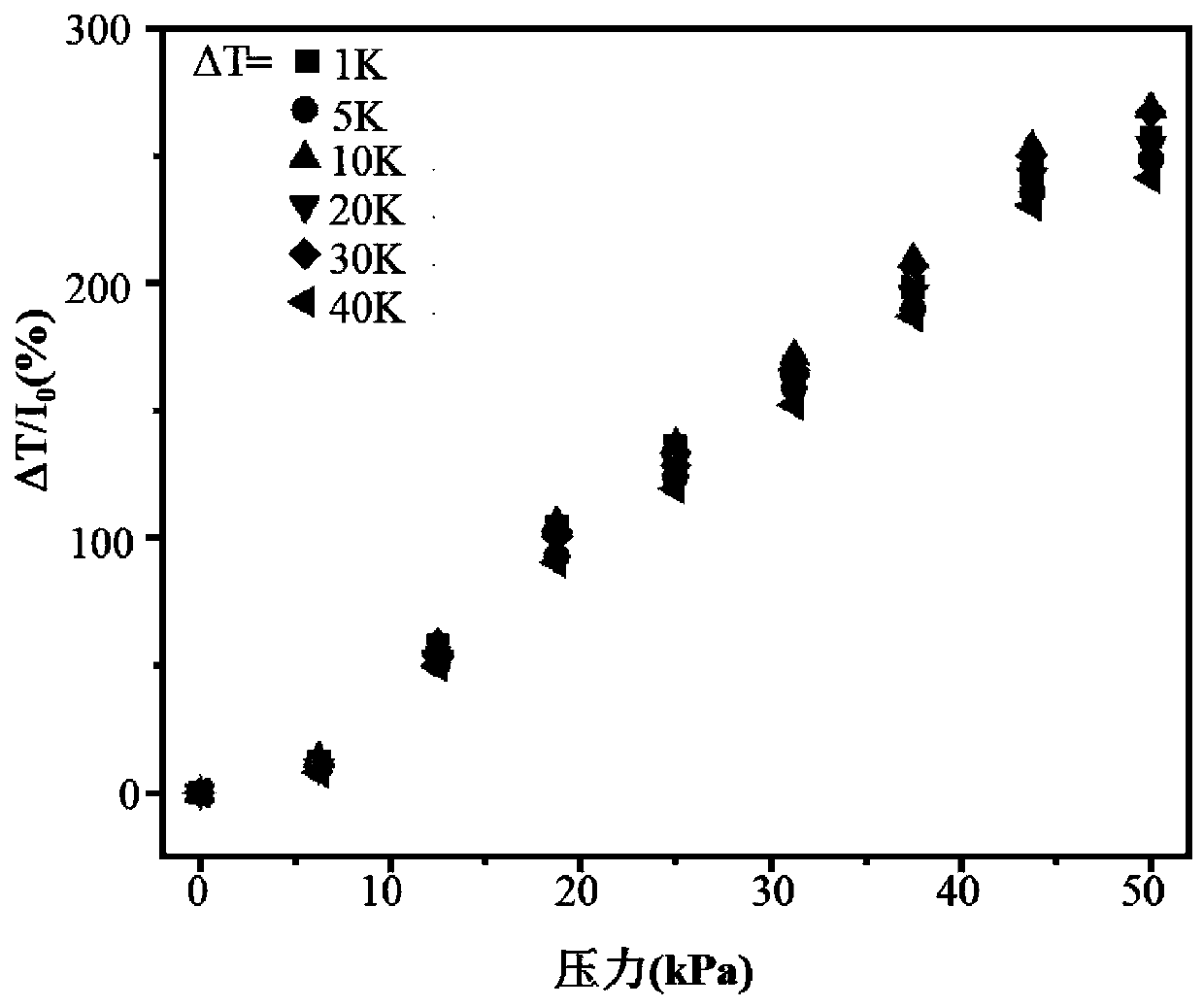

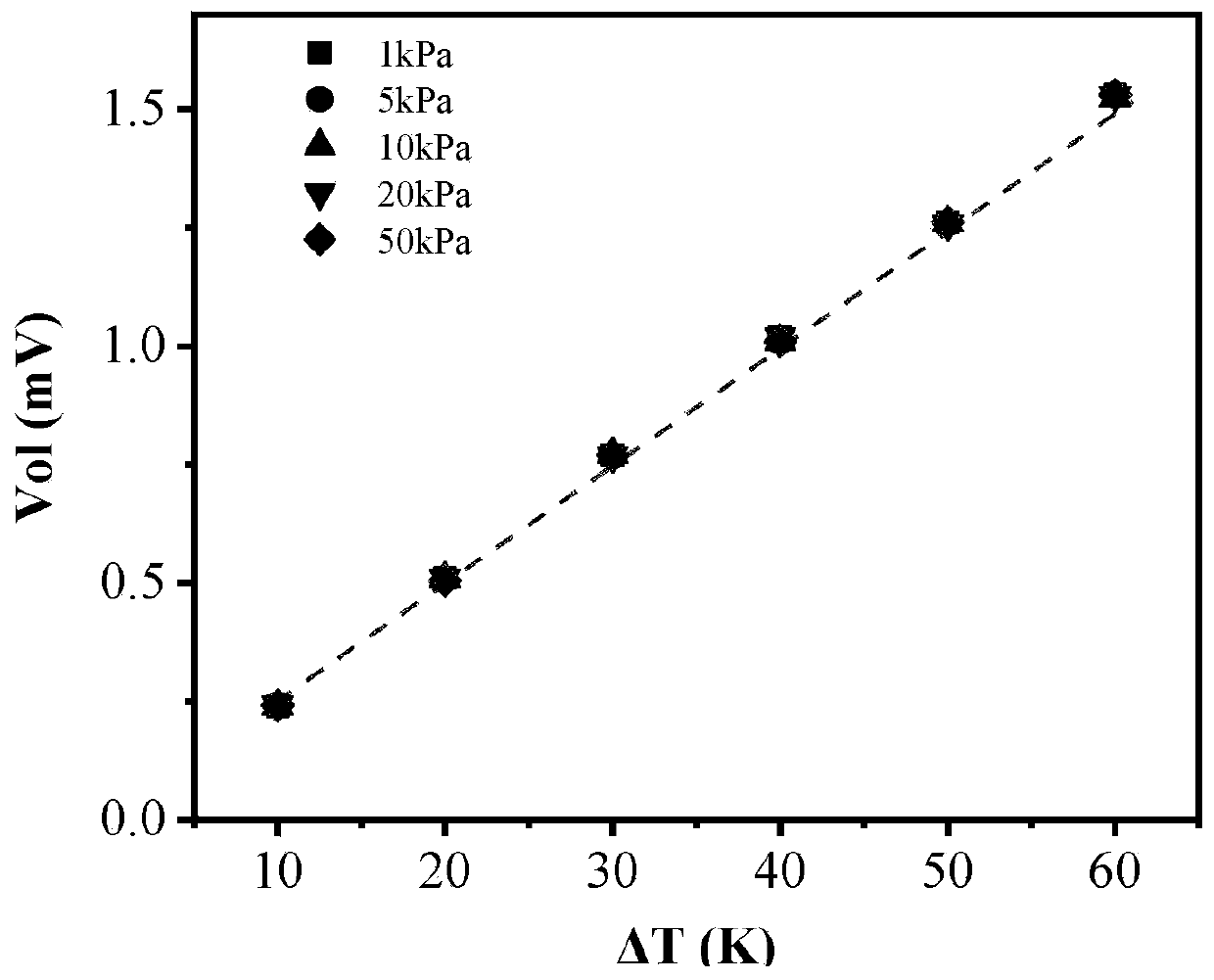

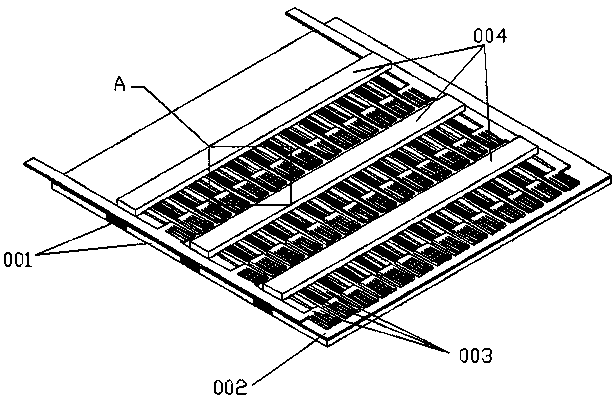

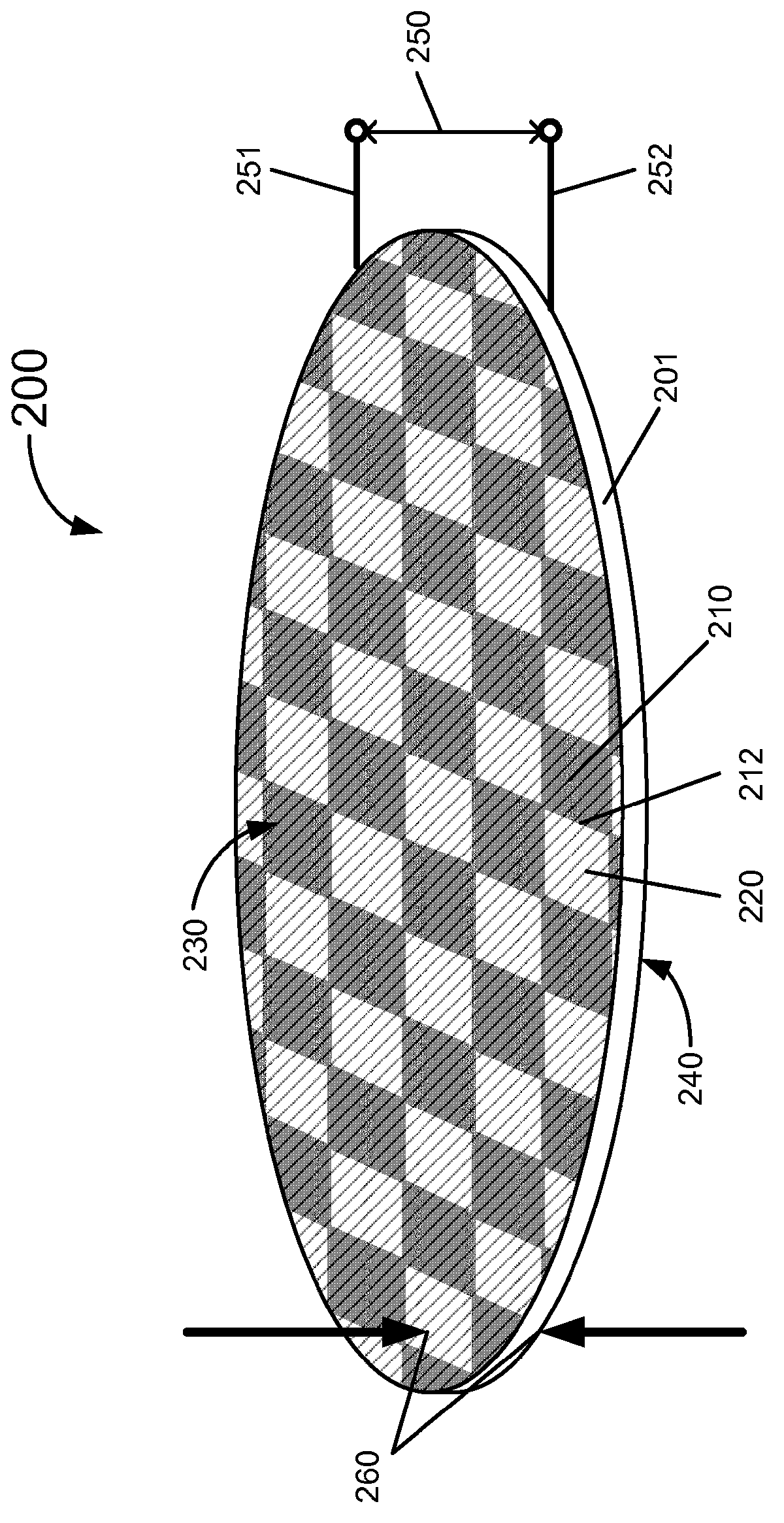

Flexible temperature-pressure sensor, and preparation method and application thereof

ActiveCN110736559AImprove conductivityImprove thermoelectric performanceThermometers using electric/magnetic elementsForce measurementFiberThermal insulation

The invention provides a flexible temperature-pressure sensor, and a preparation method and an application thereof. The flexible temperature-pressure sensor comprises a flexible temperature sensing and pressure sensing three-dimensional fiber material and upper and lower electrodes. Through an impregnation-adsorption method, PEDO: PSS with excellent electrical conductivity and thermoelectricity isattached to a flexible three-dimensional fiber substrate to form conductive and thermoelectric paths, temperature difference automatic power generation on the thickness of the flexible three-dimensional fiber substrate and functions of the temperature-pressure sensor are realized by using the flexibility and thermal insulation of the flexible three-dimensional fiber substrate, and the good electrical conductivity of the PEDO: PSS, so that simultaneous detection and effective resolution of temperature and pressure stimulation are realized. The flexible temperature-pressure sensor provided by the invention has the advantages of good flexibility, high thermoelectric figure of merit, simple preparation process and capability of realizing large-scale production, and can be made into clothes tobe applied to the field of wearable electronic devices.

Owner:WUHAN TEXTILE UNIV

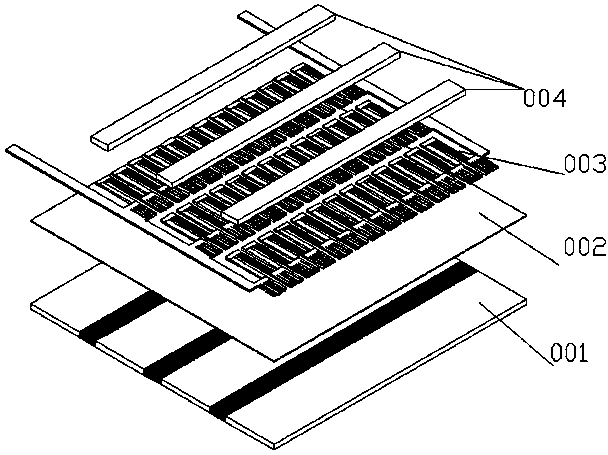

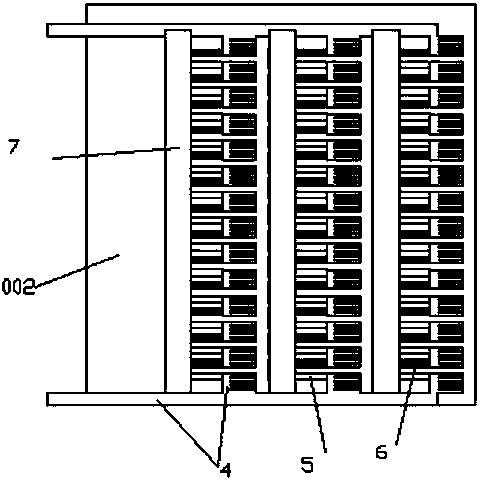

Planar flexible thermoelectric power generation structure

InactiveCN104183691AGood temperature distribution characteristicsImprove thermal conductivityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentEngineeringProtection layer

The invention discloses a planar flexible thermoelectric power generation structure which includes a thermal conduction layer, an insulating layer, a power generation layer and a hot-end protective layer, which are sequentially arrayed and laid from bottom to top. All of the thermal conduction layer, the insulating layer, the power generation layer and the hot-end protective layer adopt flexible materials. A first flexible material and a second flexible material are closely arrayed alternatively so that the thermal conduction layer is formed. The hot-end protective layer is a flexible insulating strip. Both of the heat conduction factors of the first flexible material and the flexible insulating strip are lower than the heat conduction factor of the second flexible material. The structure increases protection of a hot end and heat radiation of a cold end, improves the temperature gradient of a thermoelectric power generator and further improves an output power and an output voltage. The thermal conduction layer provides a temperature gradient needed by the thermoelectric power generator and has a support function; the flexible materials are adopted so that compared with a rigid thermoelectric power generation device, the power generation structure is flexible, light and convenient and capable of better fitting to the plane; and the power generation structure is simple in structure and manufacturing process and capable of realizing mass production, and has an excellent application prospect.

Owner:ZHEJIANG UNIV

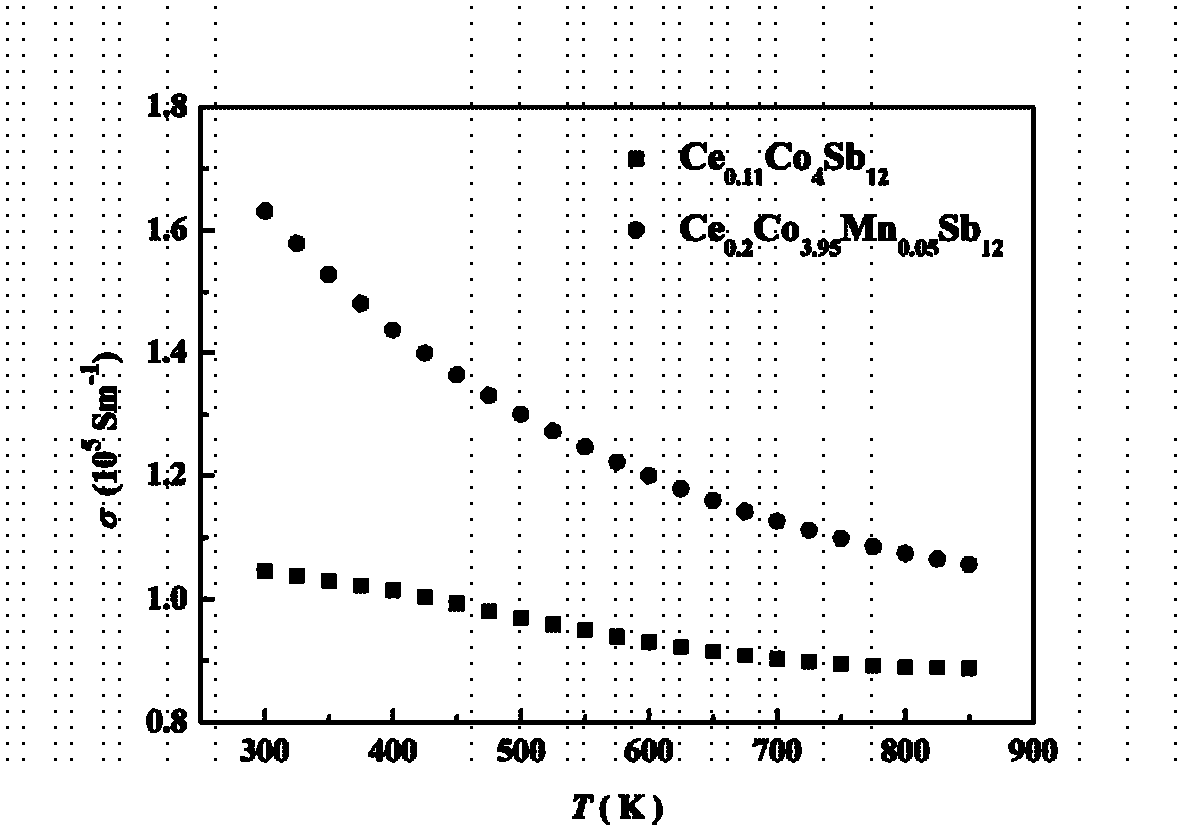

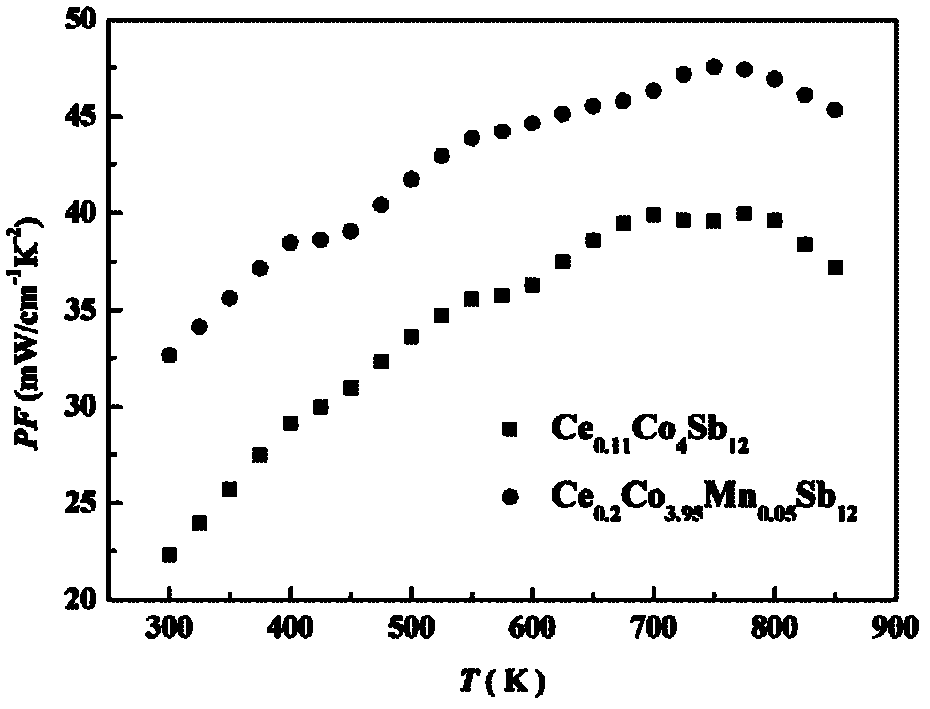

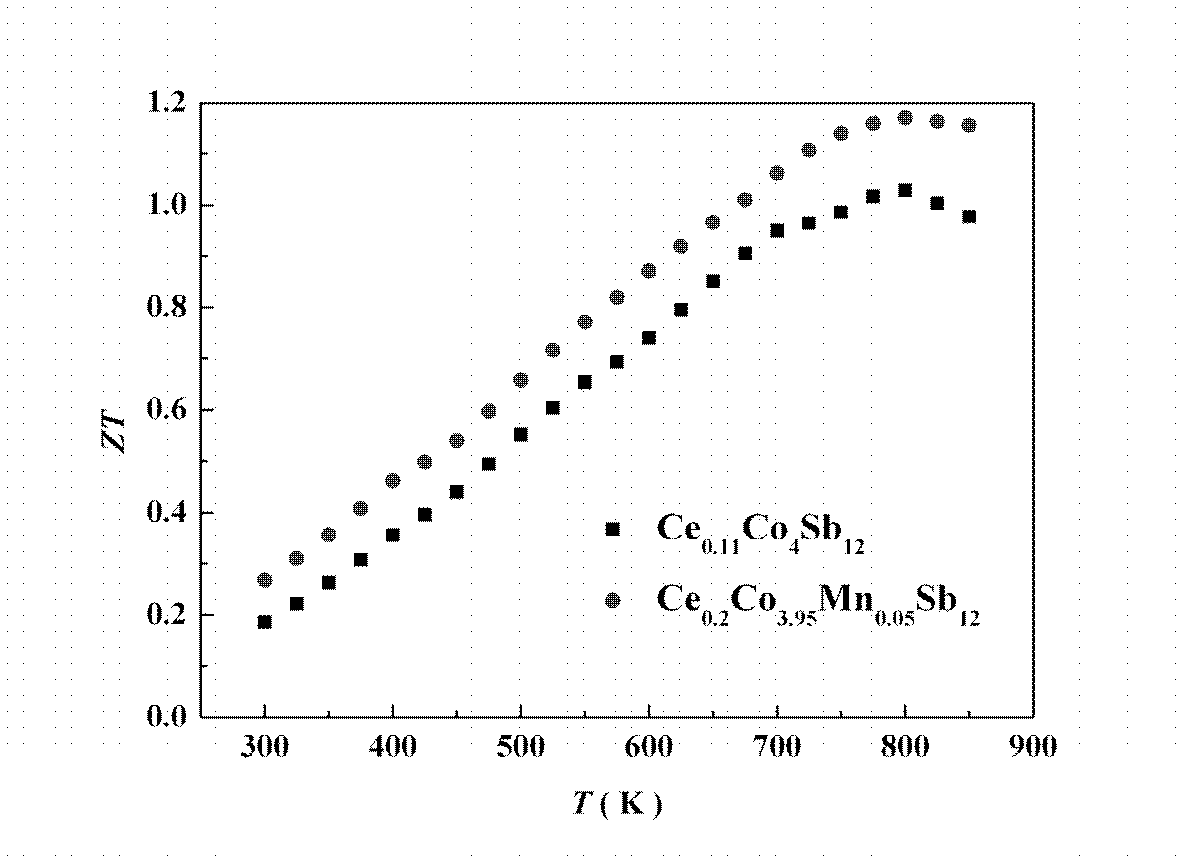

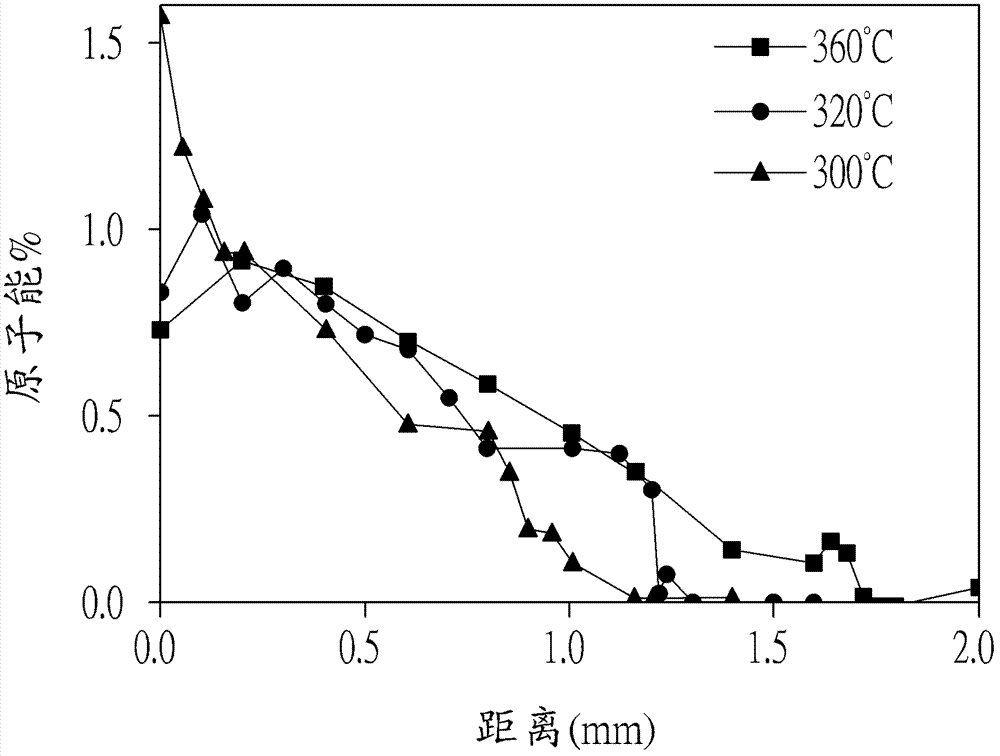

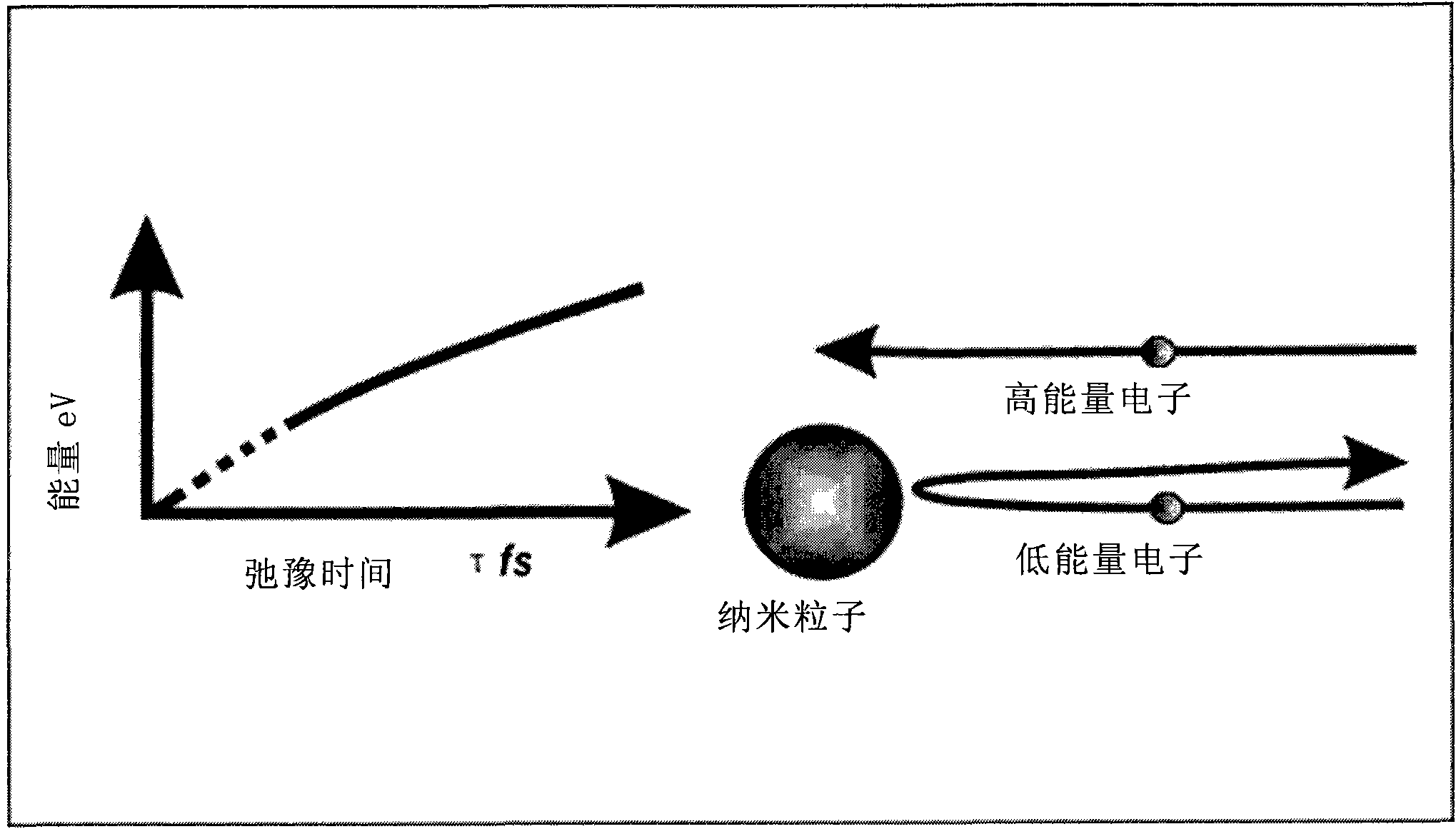

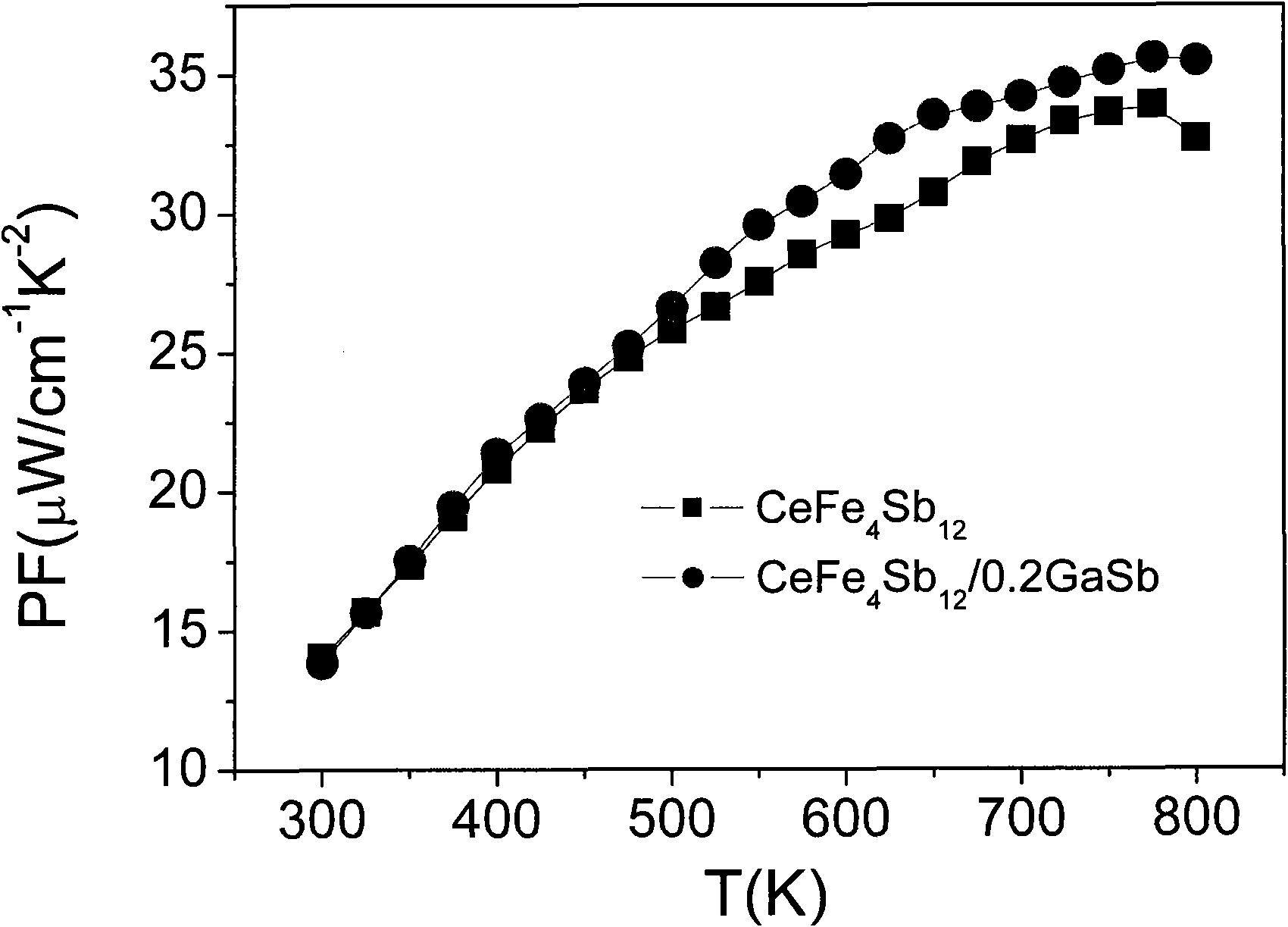

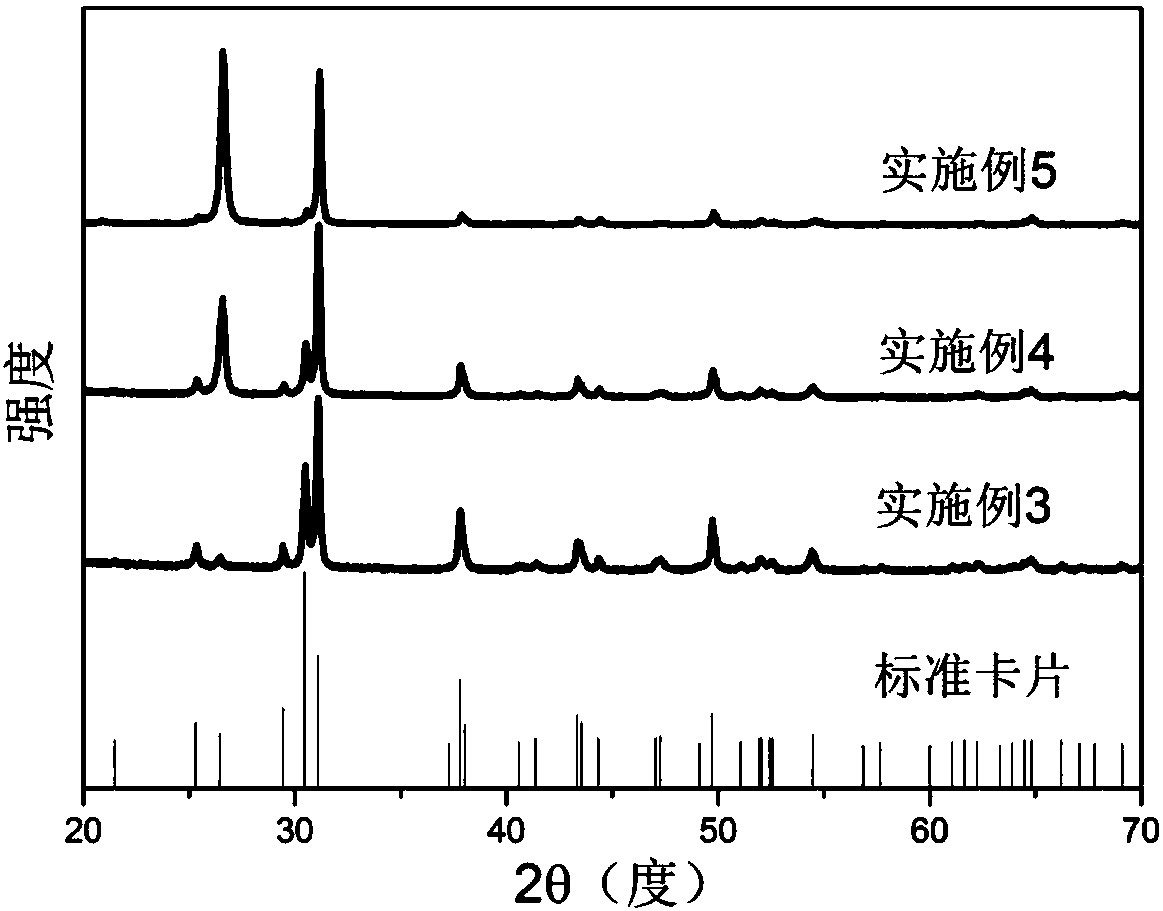

Hole compensation type skutterudite thermoelectric material and preparation method therefore

ActiveCN102881814AIncrease filling volumeHigh conductanceIron compoundsCobalt compoundsSkutteruditeElectron number

The invention relates to a hole compensation type skutterrudite thermoelectric material and a preparation method of the hole compensation type skutterudite thermoelectric material. The hole compensation type skutterudite thermoelectric material is shown in the following description: RyA(4-x)BxSb12 / z NC, wherein x is equal to or greater than 0.01 and equal to or less than 0.5, y is equal to or greater than 0.01 and equal to or less than 1 and z is equal to or greater than 0% and equal to or less than 10%; R is selected from at least one of the following group of elements: Ca, Ba, La, Ce, Pr, Nd and Yb; A is selected from at least one of the following group of elements: Fe, Co and Ni; B is selected from at least one of the following group of transition metal elements: Ti, V, Cr, Mn, Fe, Nb, Mo, Tc and Ru, and electron number of the element B is less than that of the element A; and NC is in phase II, wherein z is mole% in the phase II of the thermoelectric material. The invention also provides the preparation method of the hole compensation type skutterrudite thermoelectric material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Highly efficient thermoelectric material

InactiveCN103094468AHigh thermoelectric figure of meritSolve the problem of point thermal expansion differenceThermoelectric device with peltier/seeback effectThermoelectric device junction materialsMetallurgyAdhesive

A highly efficient thermoelectric material with one end coated in silver adhesive and placed in a high temperature furnace to heat and diffuse the silver adhesive into the homogeneous thermoelectric material, thereby producing an non-uniform thermoelectric material one-side doped thermoelectric material. The non-uniform thermoelectric material one-side doped thermoelectric material is able to achieve a high thermoelectric figure of merit.

Owner:廖建能

Self-repairing MXene/polyurethane thermoelectric composite material and preparation method thereof

InactiveCN110713706ARich sourcesImprove performanceMicroballoon preparationMicrocapsule preparationThermoelectric materialsFiber

The invention relates to a self-repairing MXene / polyurethane thermoelectric composite material and a preparation method thereof. A pretreated loofah sponge fiber skeleton and MXene are hybridized to form a three-dimensional mutual lap joint network structure, the network structure and self-repairing microcapsules are implanted in the polymerization process of polyurethane, and the prepared composite material has a high seebeck coefficient, a high thermoelectric figure of merit and good mechanical properties. The self-repairing microcapsules are used as a functional material, so that automaticresponse to damage and self-repairing of a conductive network can be realized. The composite material can be applied to a conductive composite material, an elastic conductor or a thermoelectric material.

Owner:CHANGZHOU INST OF TECH

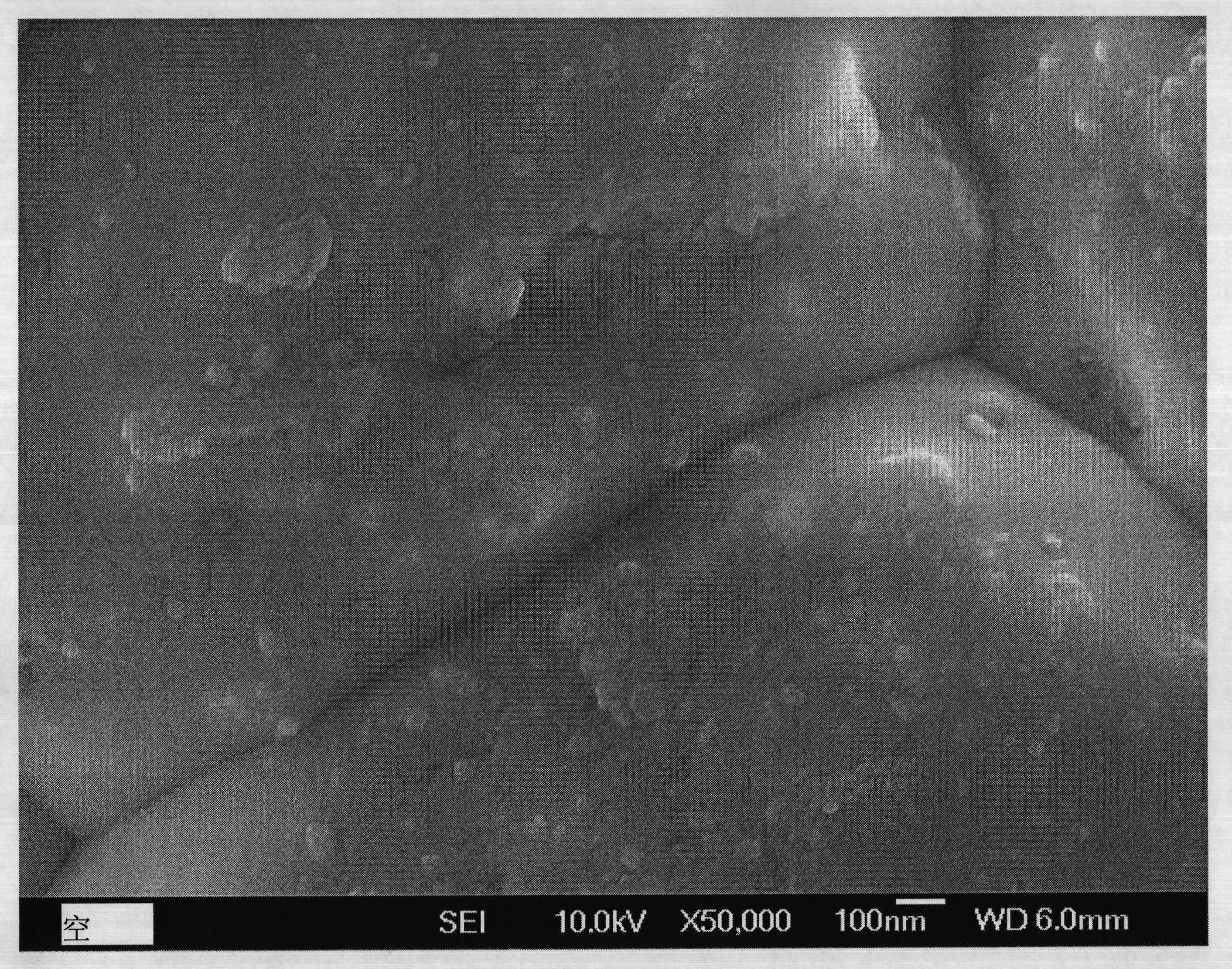

P-type skutterudite material and preparation method thereof

ActiveCN102373348AIncreased maximum theoretical conversion efficiencyHigh thermoelectric figure of meritThermoelectric device manufacture/treatmentThermoelectric device junction materialsSkutteruditeChemistry

The invention relates to a p-type skutterudite material and a preparation method thereof. The invention provides the p-type skutterudite material which has a chemical formula as represented by IyFe4-xMxSb12 / z(phi), wherein, I is one kind or more kinds of filling atoms in a skutterudite phase, the filling amount y of the filling atoms is no less than 0.01 and no more than 1, M is one kind or more kinds of dopant atoms, the dopant amount x of the dopant atoms is no less than 0 and less than 4, phi is one kind or more kinds of second phases, the molar ratio z of phi is no less than 0 and no morethan 0.5, and second phase sediment disperses in the skutterudite phase. The invention also provides the preparation method for the p-type skutterudite material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

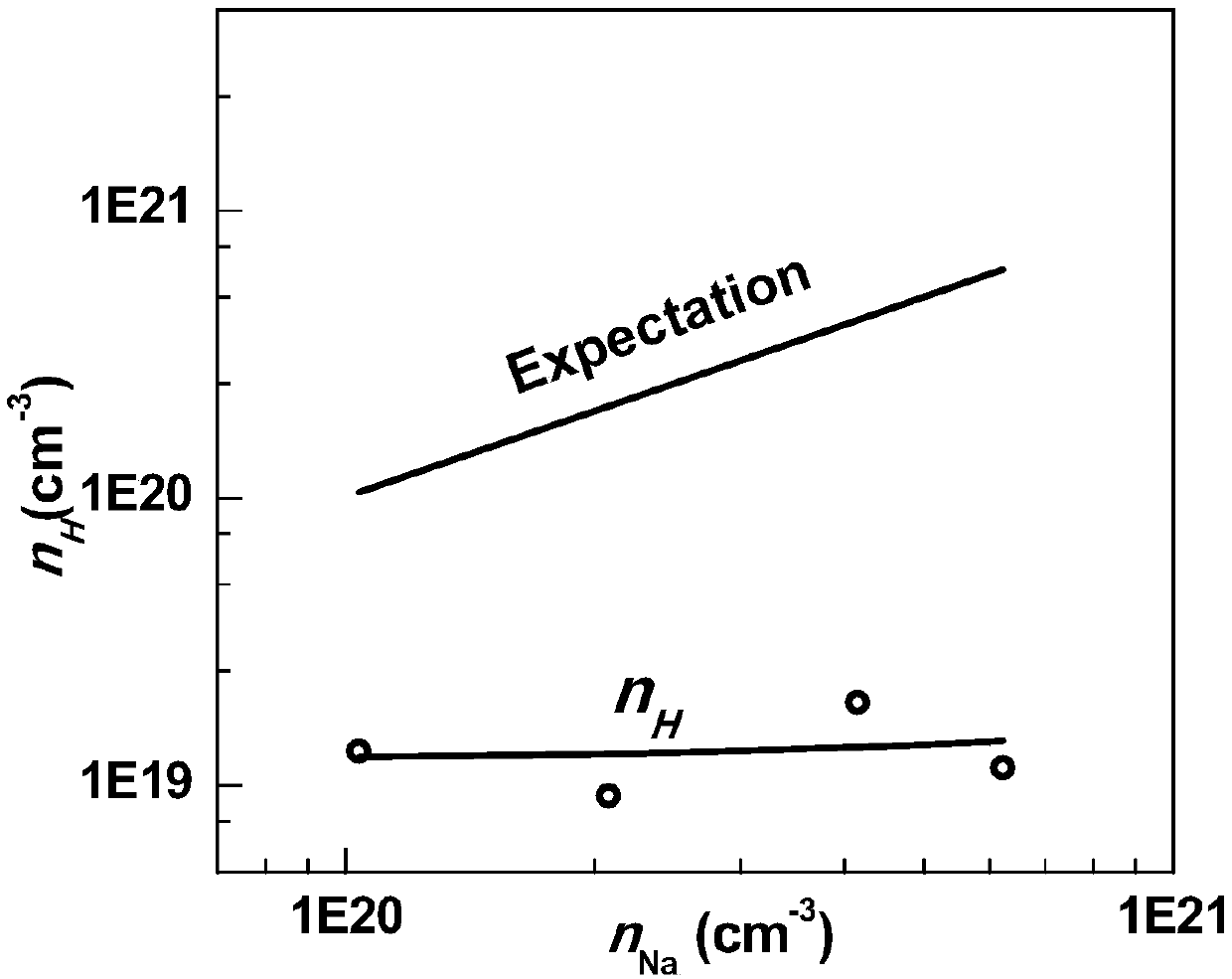

Low-cost environment-friendly SnS-based thermoelectric material and preparation method thereof

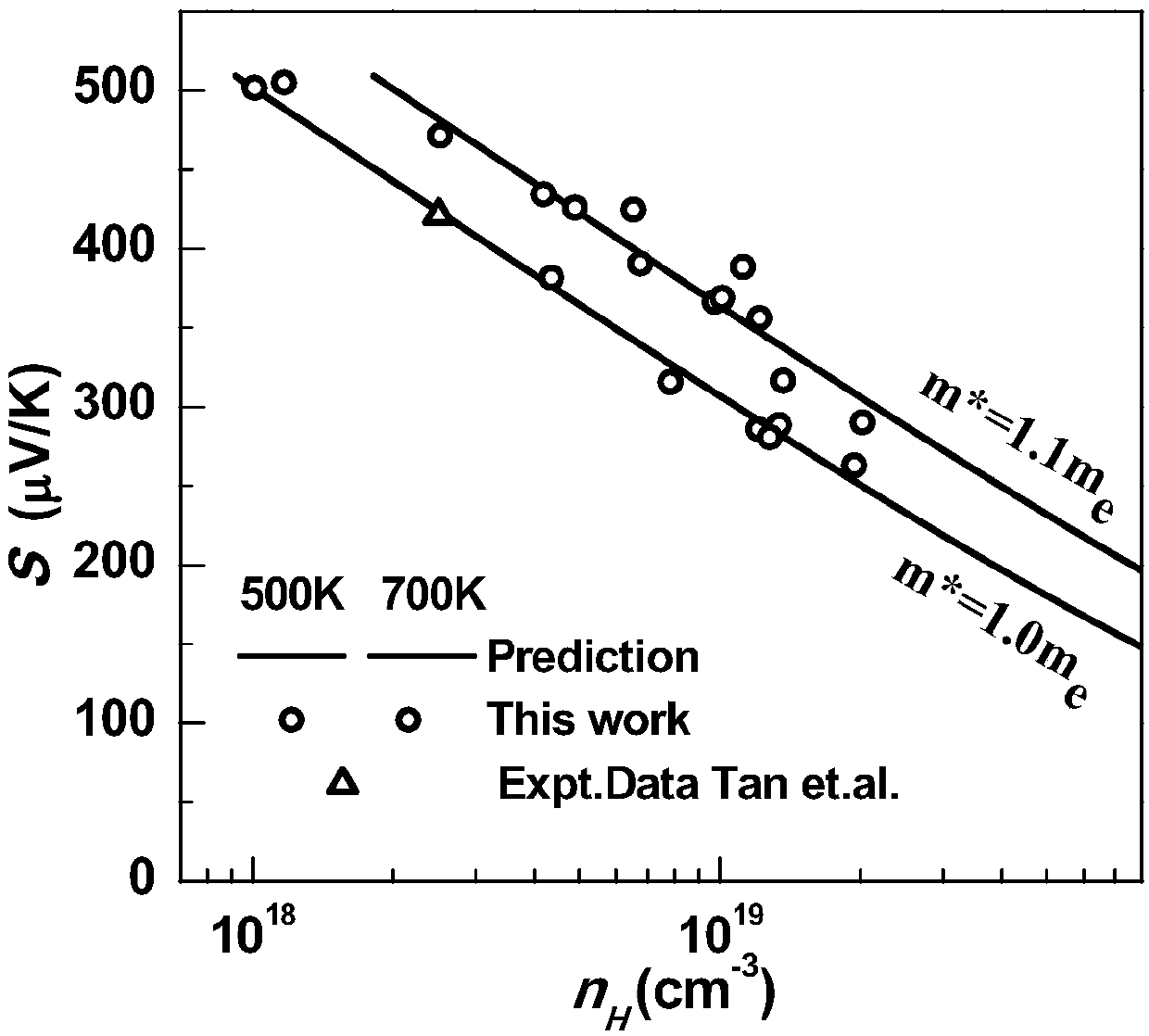

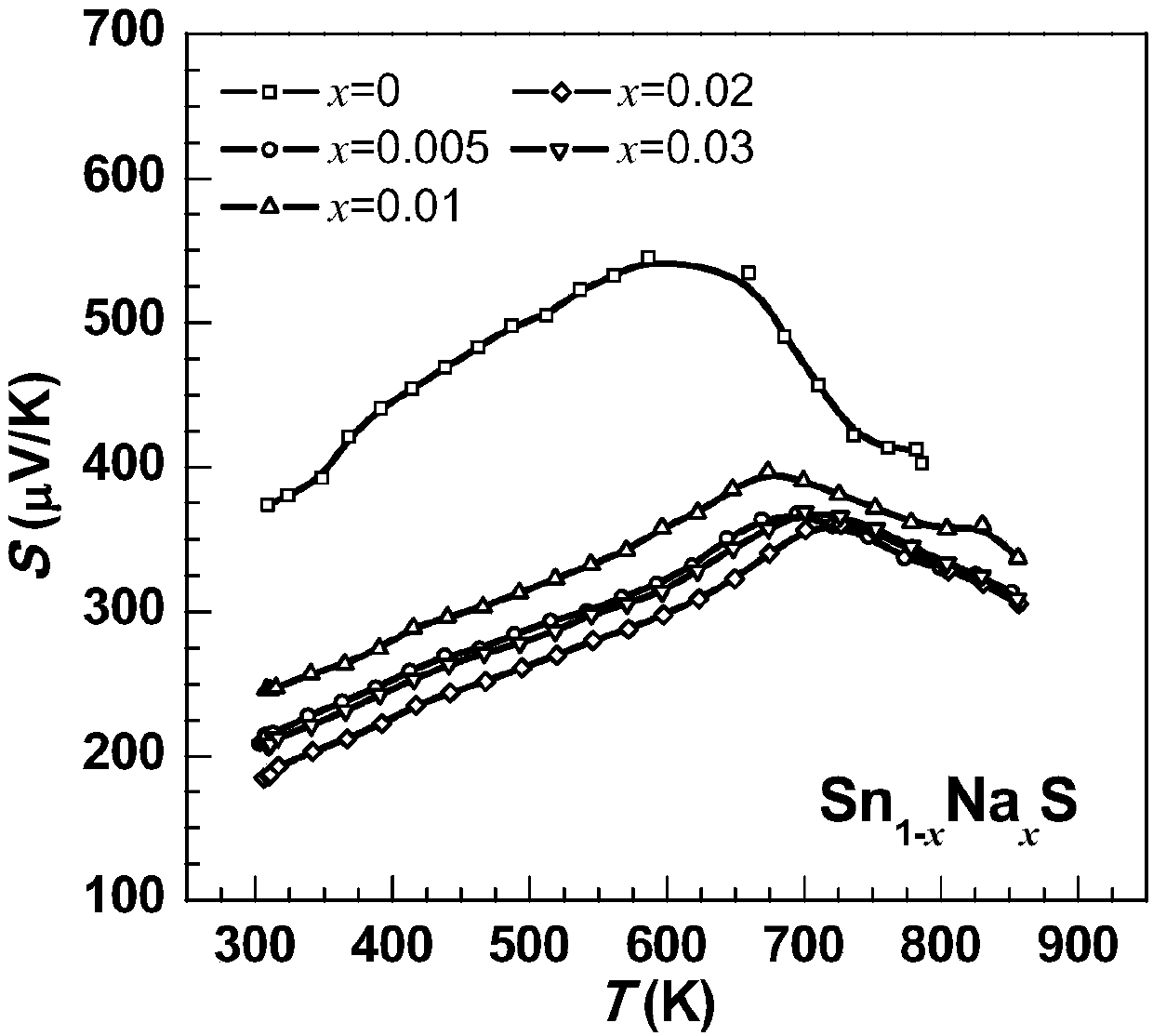

InactiveCN107845724AIncrease concentrationIncrease the carrier concentrationThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsChemical measurement

The invention relates to a low-cost environment-friendly SnS-based thermoelectric material and a preparation method thereof. A chemical formula of the thermoelectric material is Sn<1-x>Na<x>S (x is smaller than or equal to 0.03). The low-cost environment-friendly SnS-based thermoelectric material is prepared by adopting the following method of firstly adopting a high-purity simple substance (greater than 99.99%) as a raw material, dosing according to a stoichiometric ratio and putting a product into a quartz tube for vacuum packaging; and carrying out high-temperature melting, quenching and annealing heat treatment in a pit furnace, grinding the product into powder, carrying out vacuum hot-pressing sintering, slowly cooling and then obtaining a sheet block material, namely a stannic sulfide material of a target component. Compared with the prior art, the low-cost environment-friendly SnS-based thermoelectric material has the advantages that the position of a tin atom is doped through using a low-valence sodium atom, and more holes are introduced into the material, so that the carrier concentration (about 1019cm<-3>) of a p-type SnS thermoelectric semiconductor is effectively improved and the thermoelectric merit figure reaches 0.65 at 850K; and in addition, SnS is a thermoelectric material with large-scale application potential due to relatively low preparation cost.

Owner:TONGJI UNIV

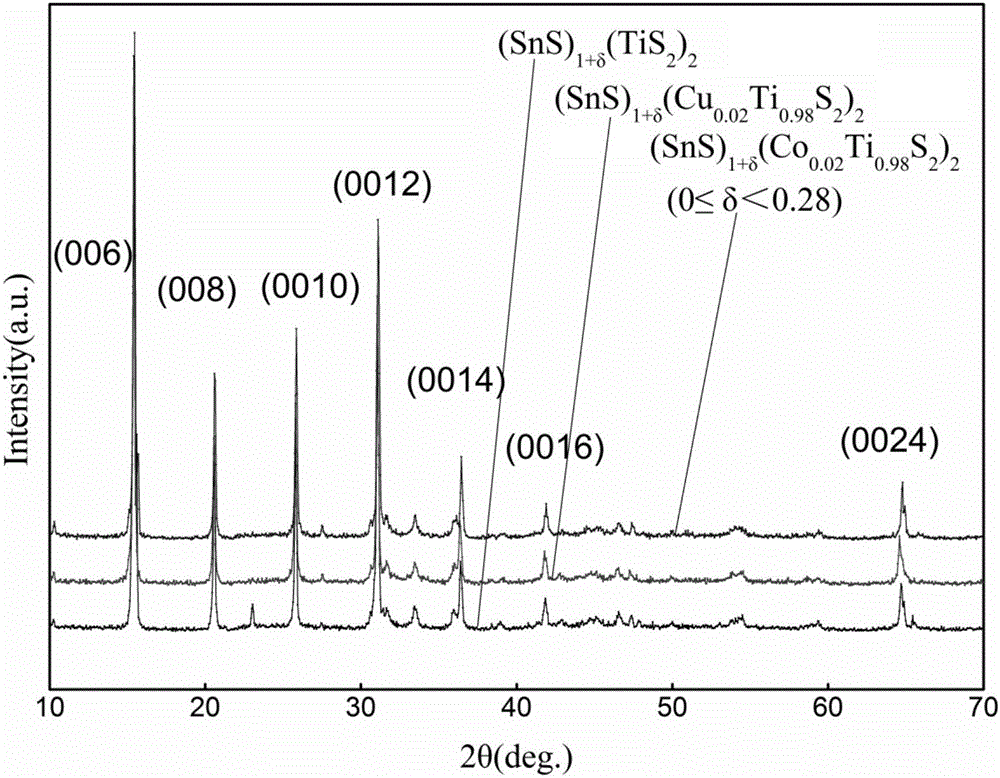

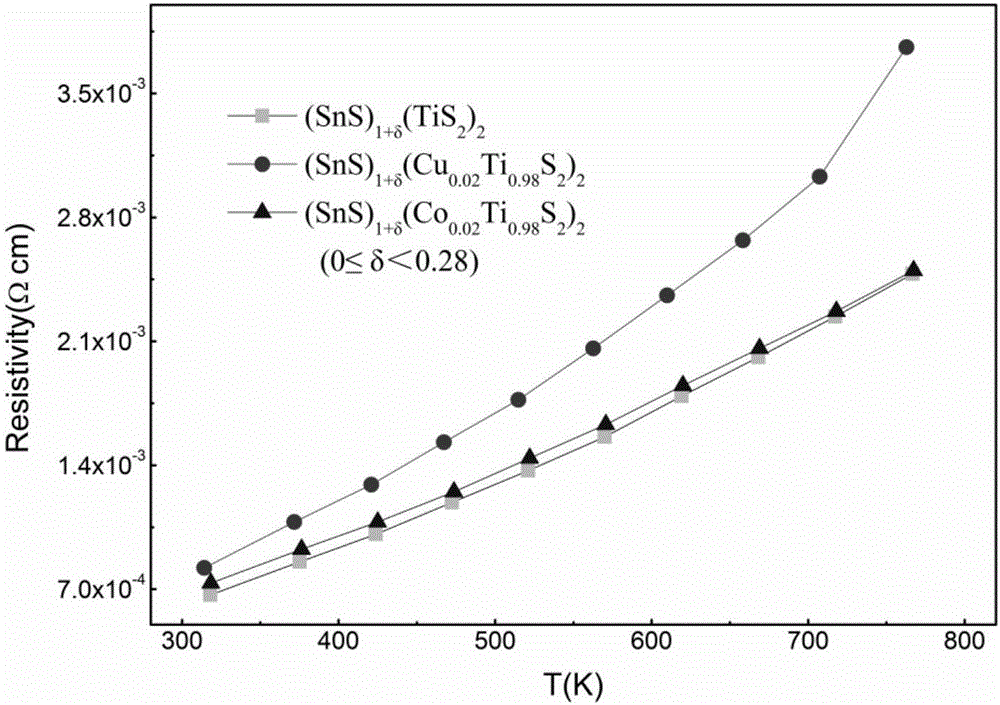

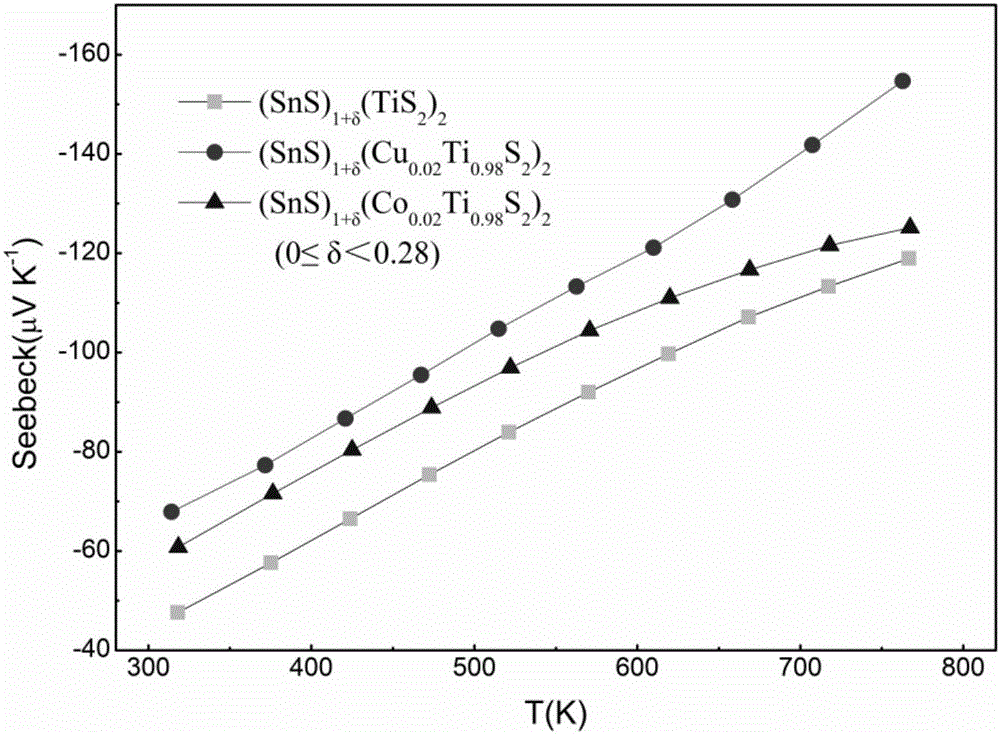

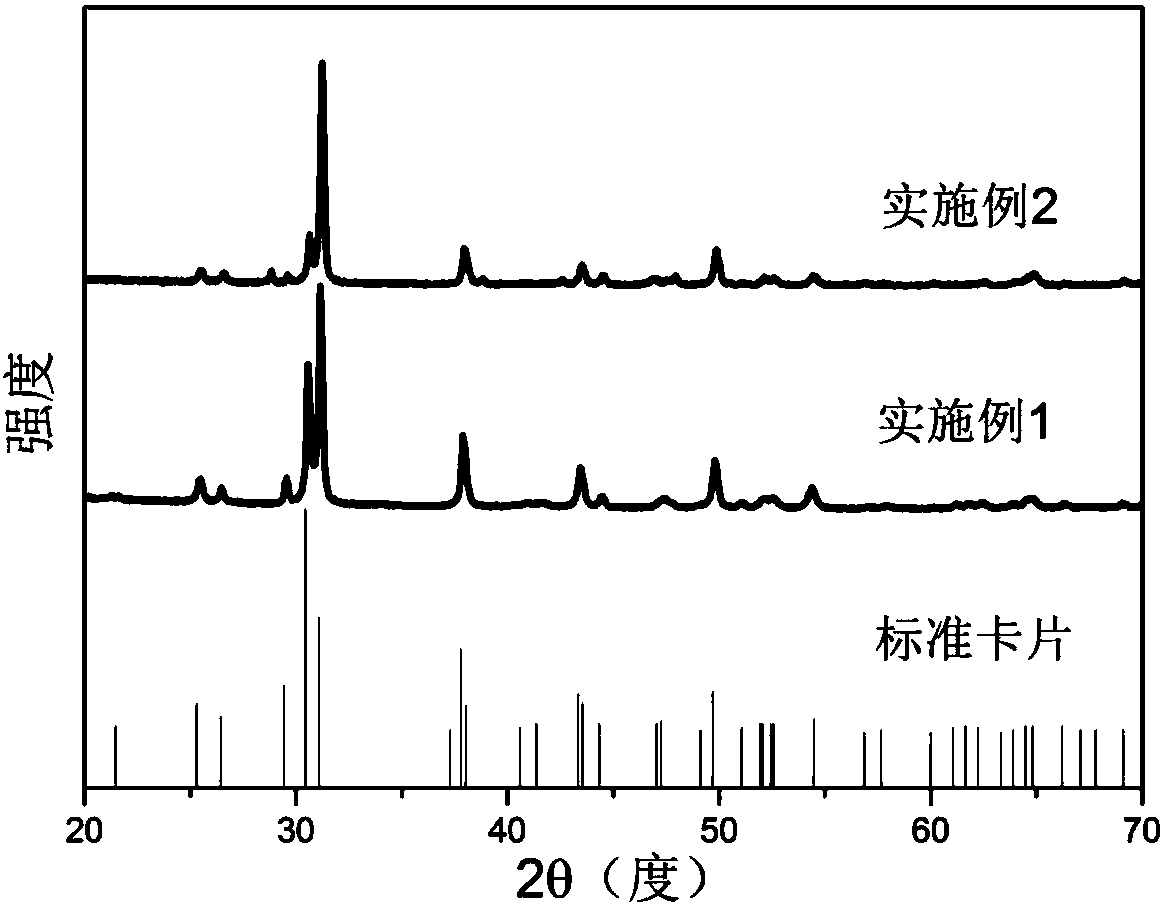

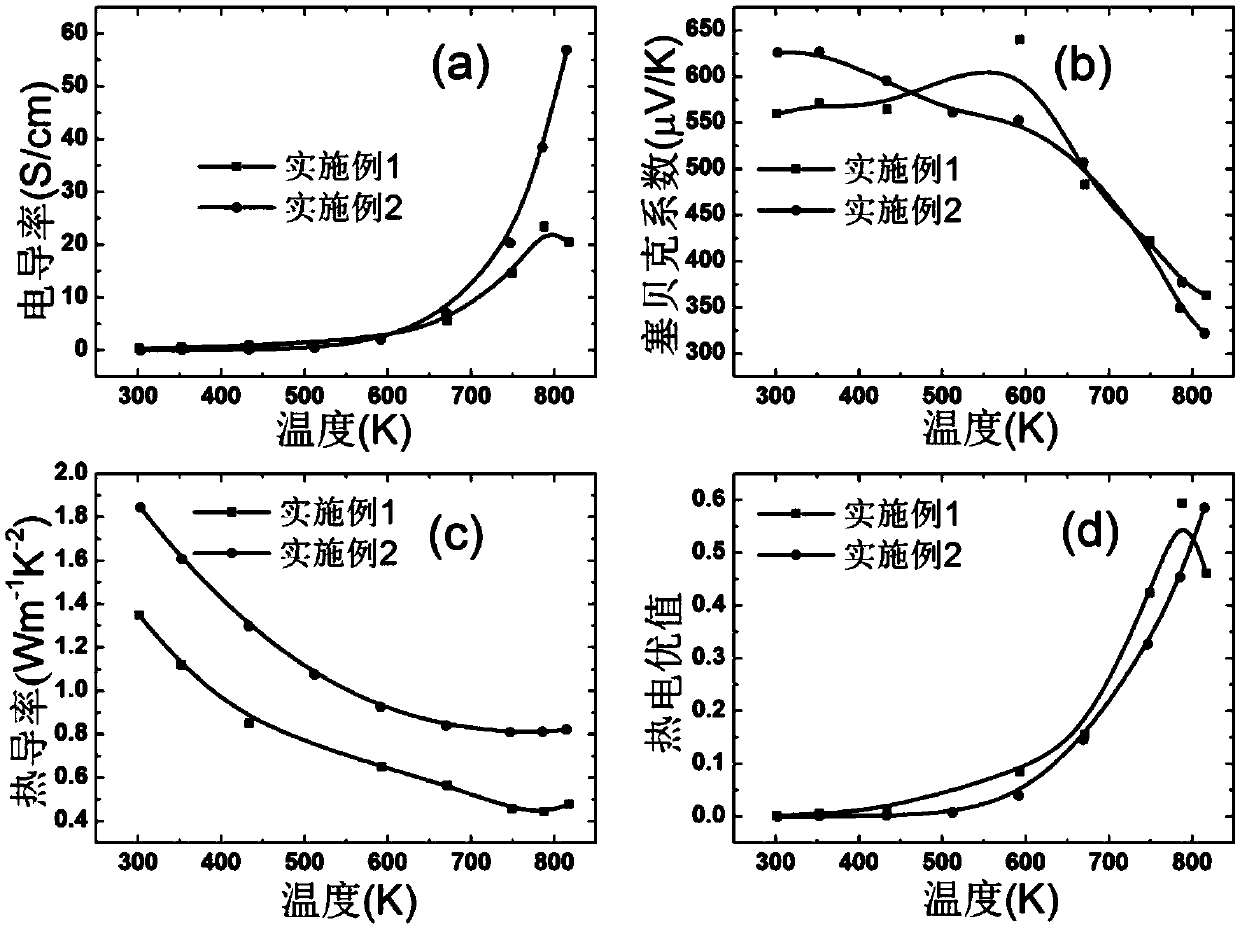

Method for preparing misfit chalcogenide thermoelectric material by solid-phase reaction method

ActiveCN106129241AHigh densityHigh thermoelectric figure of meritThermoelectric device junction materialsSolid state reaction methodChalcogenide

The invention belongs to the field of materials, and relates to a method for preparing a misfit chalcogenide thermoelectric material by a solid-phase reaction method. The method comprises the steps of weighing Sn powder and Cu powder or Co powder, Ti powder and S powder based on a mass ratio of 1 to 0.04 to 1.96 to 5, then grinding and mixing the powder; pressing the powder at the pressure of 3-5MPa into tablets, and putting the tablets into a quartz tube; vacuumizing and sealing the tube and then sintering; and performing steps of grinding, vacuumizing and sintering for two rounds to obtain the misfit chalcogenide. The method for preparing the misfit chalcogenide by the solid-phase reaction method provided by the invention can be used for preparation of the misfit-system chalcogenide thermoelectric material; the process is simple to operate and high in repeatability; the phase-forming degree, the density and the misfit structure of the misfit compound can be controlled by adjusting the technological parameters of temperature rise speed, phase-forming temperature, heat preservation time, sintering times and the like; the method is high in controllability; and the prepared misfit layered compound has the characteristics of high phase-forming degree, low impurities, high density, low thermal conductivity, high thermoelectric figure of merit and the like.

Owner:SICHUAN UNIV

Nano thermal electric material with coaxial cable structure and its making method

InactiveCN101237018ALower heat transfer coefficientImprove thermoelectric conversion efficiencyThermoelectric device manufacture/treatmentThermoelectric device junction materialsPotassium borohydrideCoaxial cable

The invention relates to nano thermoelectric material and comprises a linear inner nano core and an outer sleeve arranged coaxially with the linear inner nano core. Different thermoelectric materials are adopted on the linear inner nano core and the outer sleeve. The method for preparing the structure comprises the steps of: adding raw materials in a reaction vessel, adding distilled water, potassium borohydride and sodium hydroxide and sodium dodecyl benzene sulfonate to prepare the inner nano-core; washing, drying and dispersing the inner nano-core in solvent for surface treatment; putting the inner nano core in a high pressure reaction vessel and then adding raw materials, potassium borohydride, sodium hydroxide and distilled water to prepare an coaxial cable structured nano thermoelectric material. The raw materials are two or more of soluble salt, Tellurium powder and Selenium Powder of Bi, Sb, Zn, Pb, Co, Fe and Sn. Compared with the thermoelectric material with the prior structure and owning to the unique microstructure, the nano thermoelectric material can enhance the phonon transmission, reduce the heat transfer coefficient and improve the thermoelectric figure of merit so as to improve the thermoelectric conversion efficiency.

Owner:HANGZHOU DIANZI UNIV

Preparation method of SnSe-based oriented polycrystalline thermoelectric material

PendingCN110098310AEasy to prepareShorten the growth cycleThermoelectric device manufacture/treatmentThermoelectric device junction materialsIngotBall mill

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

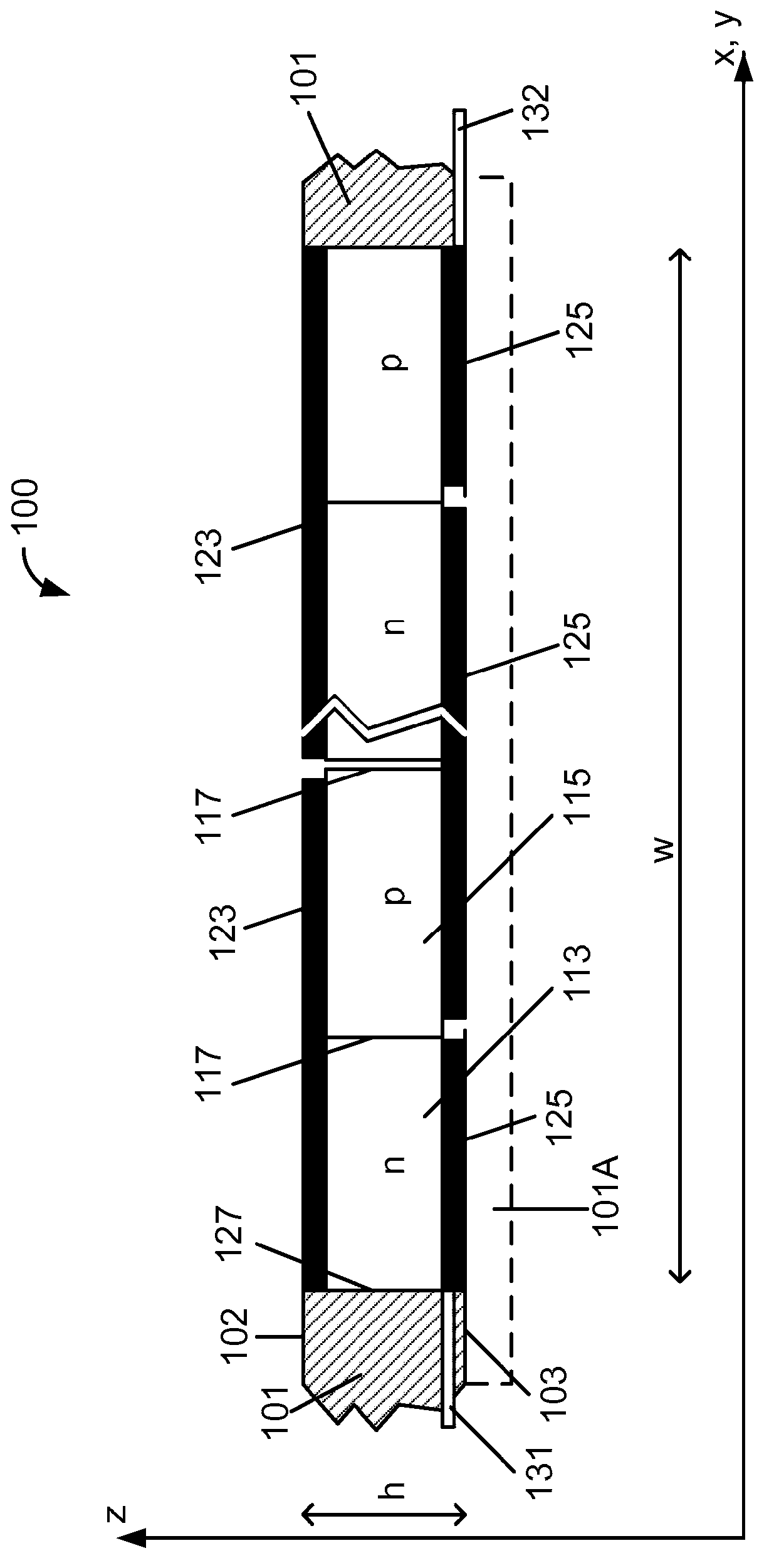

Uniwafer thermoelectric modules

InactiveCN102782855ALow costOptimize layoutThermoelectric device manufacture/treatmentSolid-state devicesThermal isolationHemt circuits

Owner:ALPHABET ENERGY INC

Silver-containing p-type semiconductor

InactiveCN1864278AImprove efficiencyHigh thermoelectric figure of meritThermoelectric device junction materialsTO-18Thermoelectric materials

A thermoelectric material of the general formula Ag 1-X M m M'Q 2+m , wherein M is selected from the group consisting of Pb, Sn, Ca, Sr, Ba, divalent transition metals, and combinations thereof; M' is selected from the group consisting of Bi, Sb, and combinations thereof; Q is selected from the group consisting of Se, Te, S, and combinations thereof; 8 <= m <= 24; and 0.01 <= x <= 0.7. In embodiments of the invention, the compositions exhibit n-type semiconductor properties. In preferred embodiments, x is from 0.1 to 0.3, and m is from 10 to 18. The compositions may be synthesized by adding stoichiometric amounts of starting materials comprising Ag, M, M', and Q to a reaction vessel, heating the starting materials to a temperature and for a period of time sufficient to melt the materials, and cooling the reaction product at a controlled rate of cooling.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

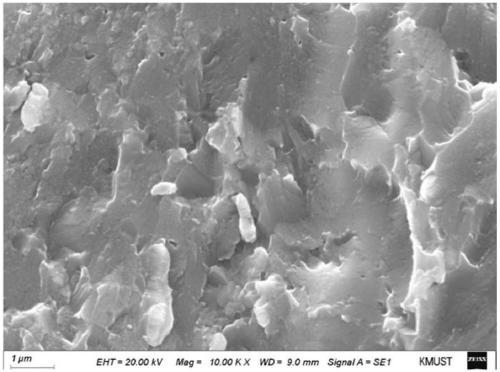

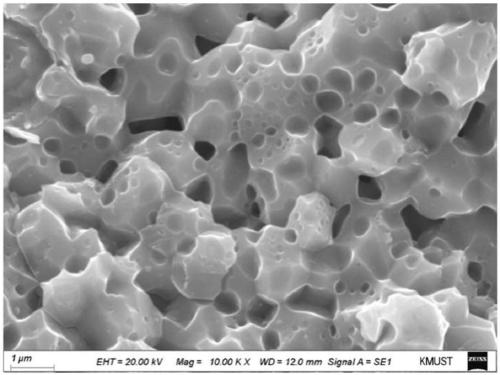

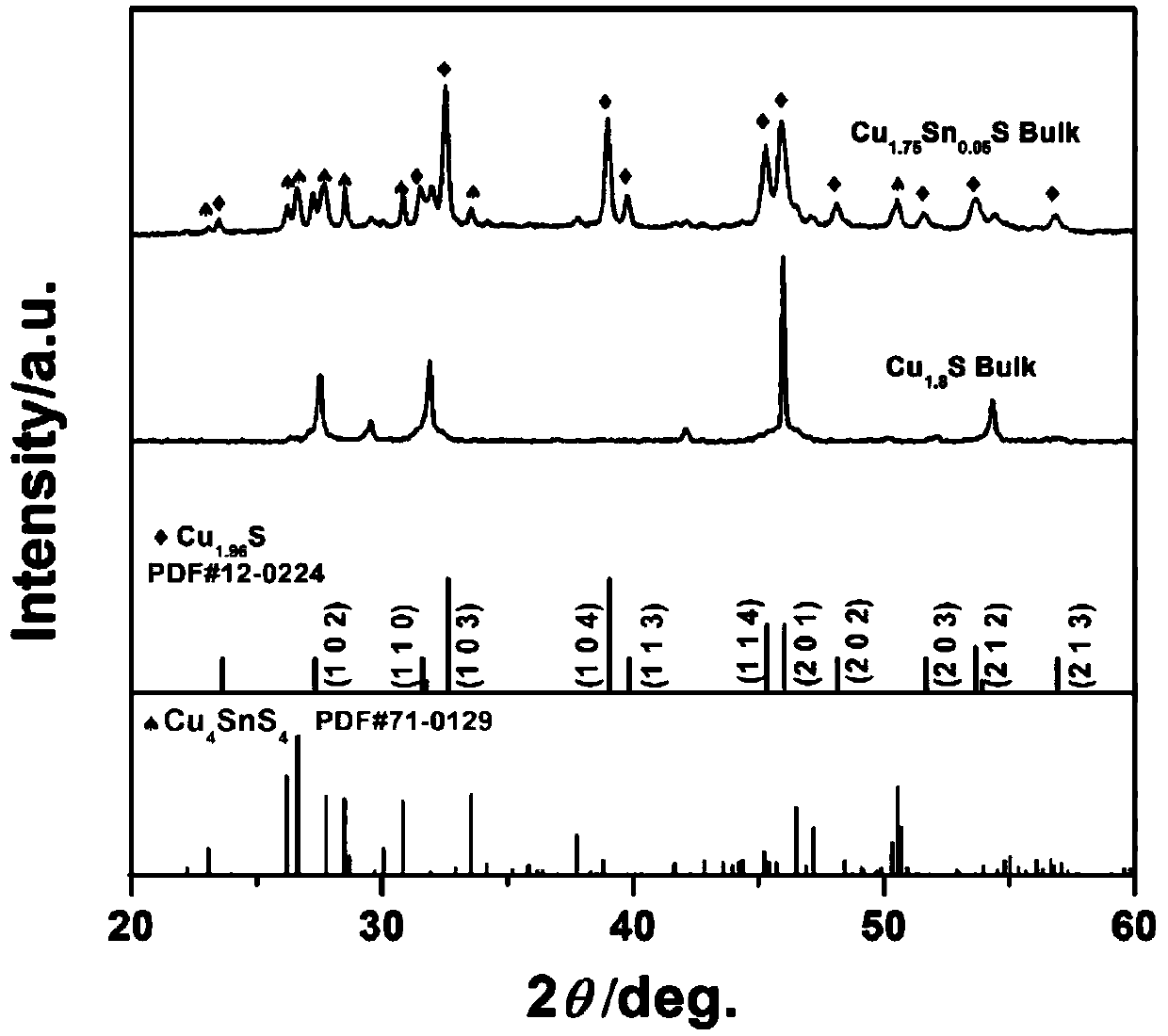

Copper sulfide based thermoelectric composite material and preparation method thereof

ActiveCN109650435AImprove thermoelectric performanceAdequate responseTin compoundsPhosphorus sulfur/selenium/tellurium compoundsThermoelectric materialsAlloy

The invention belongs to the technical field of thermoelectric materials, and discloses a copper sulfide based thermoelectric composite material and a preparation method thereof. The chemical formulaof the copper sulfide based thermoelectric composite material is Cu<1.8-m>M<m>S, and m is 0.05-0.3. The composite material comprises a matrix phase Cu<1.8>S and a second phase Cu<x>M<y>S<z>. The second phase Cu<x>M<y>S<z> is dispersed in the matrix phase Cu<1.8>S in a form of nano precipitates. The preparation method comprises following steps: ball-milling CuM alloy powder and S simple substance powder to obtain Cu<1.8-m>M<m>S powder; and sintering the Cu<1.8-m>M<m>S powder to obtain the copper sulfide based thermoelectric composite material. The problem that the thermoelectric performance of a conventional copper sulfide thermoelectric material is not good is solved.

Owner:KUNMING UNIV OF SCI & TECH

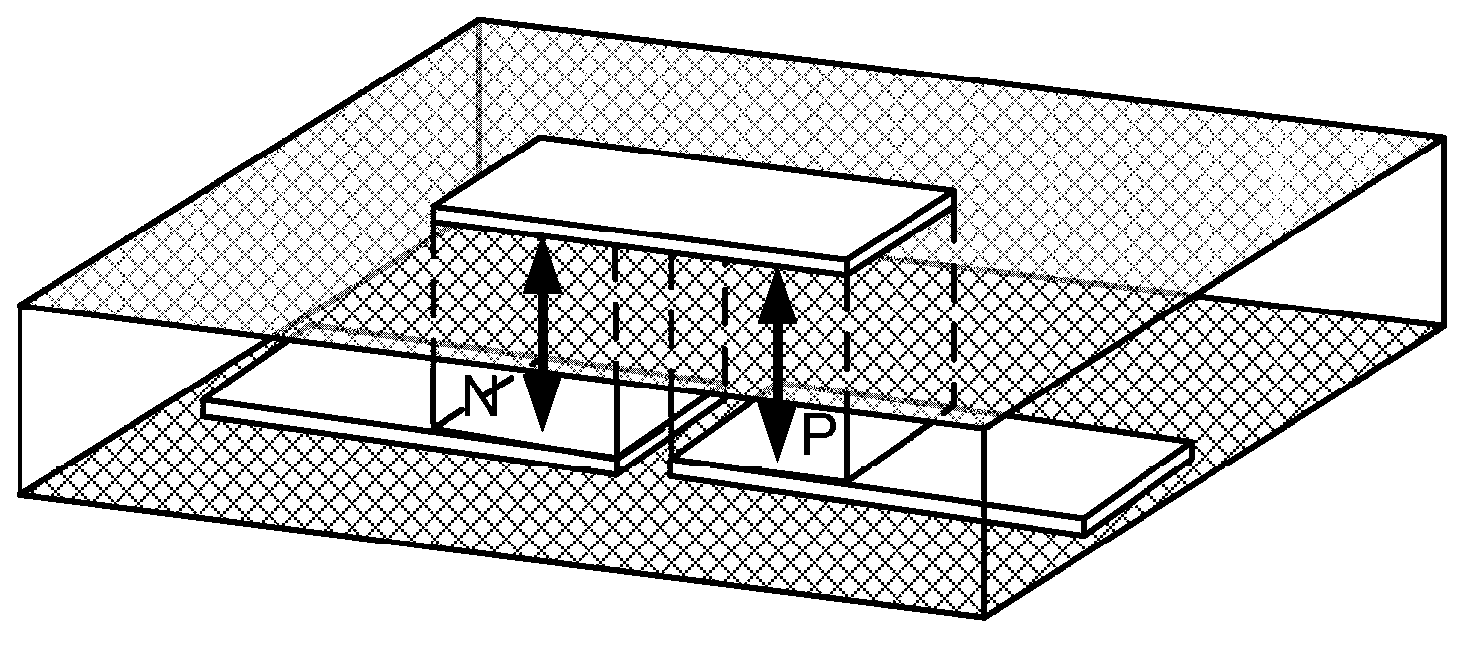

Novel carbon nanotube based organic composite thermoelectric material

InactiveCN104538541AReduce thermoelectric figure of meritEasy transferThermoelectric device junction materialsThermoelectric materialsIsolation layer

A novel carbon nanotube based organic composite thermoelectric material of the invention comprises a flexible organic polymer substrate layer. The flexible organic polymer substrate layer is coated with an n-type conductive layer formed by mixing MWNTs and PVDF. The n-type conductive layer is coated with an insulated isolation layer composed of polymer. The insulated isolation layer is coated with a p-type conductive layer formed by mixing PTh and PVDF. The p-type conductive layer, the n-type conductive layer and the insulated isolation layer are prepared by solution blending so as to ensure uniform dispersive mixing between MWNTs and PVDF and between PTh and PVDF. The p-type conductive layer and the n-type conductive layer are connected with each other only at one end. The novel carbon nanotube based organic composite thermoelectric material of the invention has the advantages of simple processing, easily available raw materials, low cost, free size design, and the like.

Owner:LIAONING NORMAL UNIVERSITY

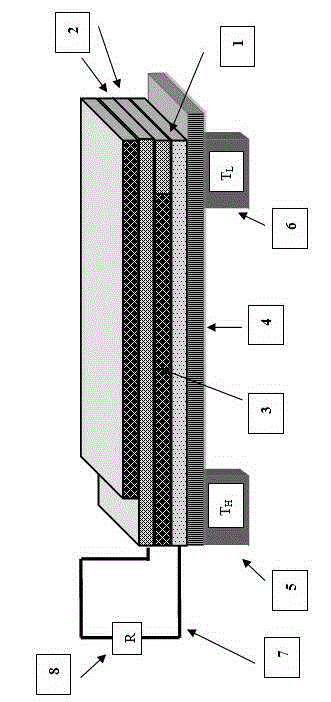

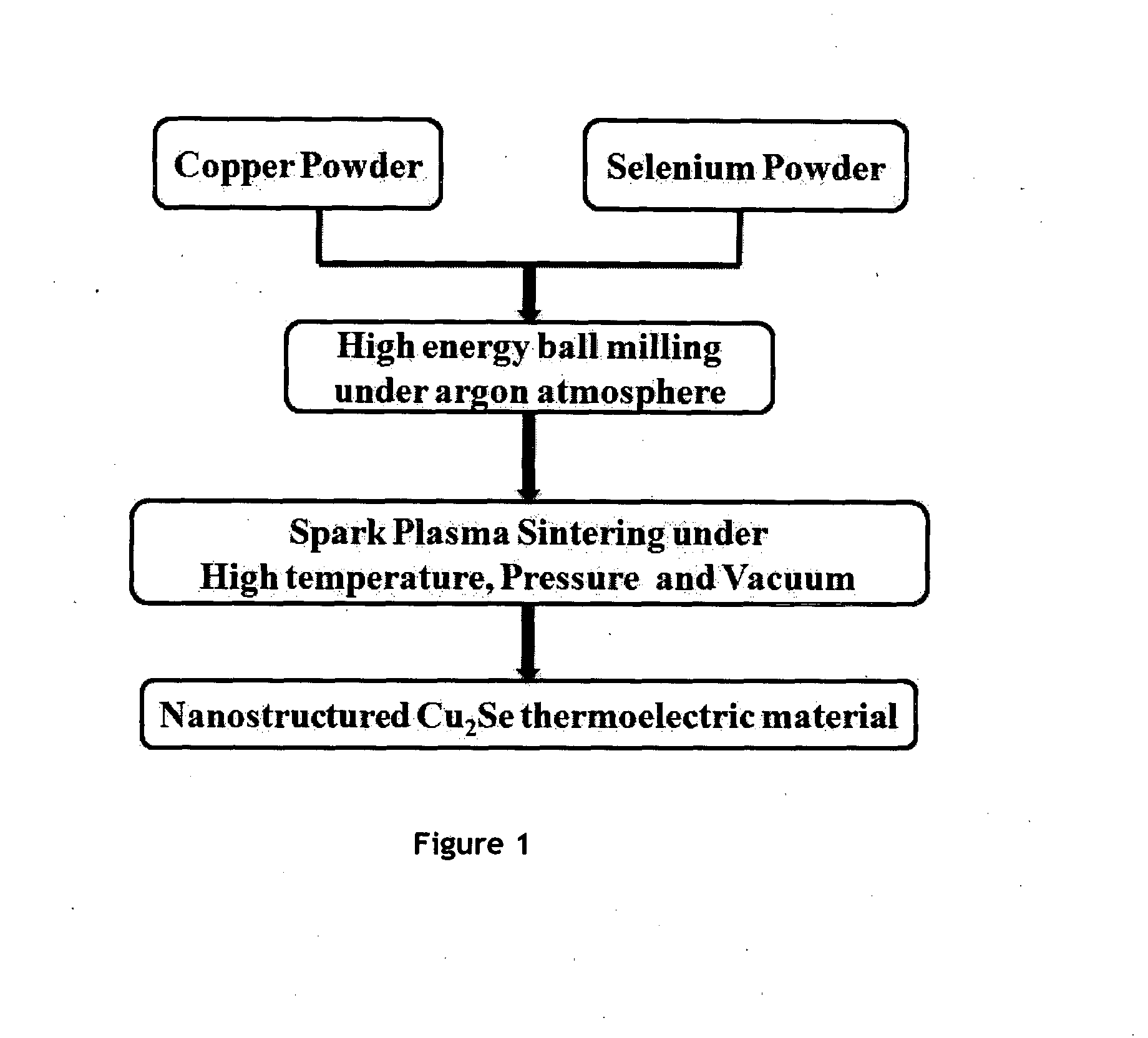

Nanostructured copper-selenide with high thermoelectric figure-of-merit and process for the preparation thereof

InactiveUS20160225972A1Fast heatingEasy to handleMaterial nanotechnologyMetal selenides/telluridesNano structuringHigh energy

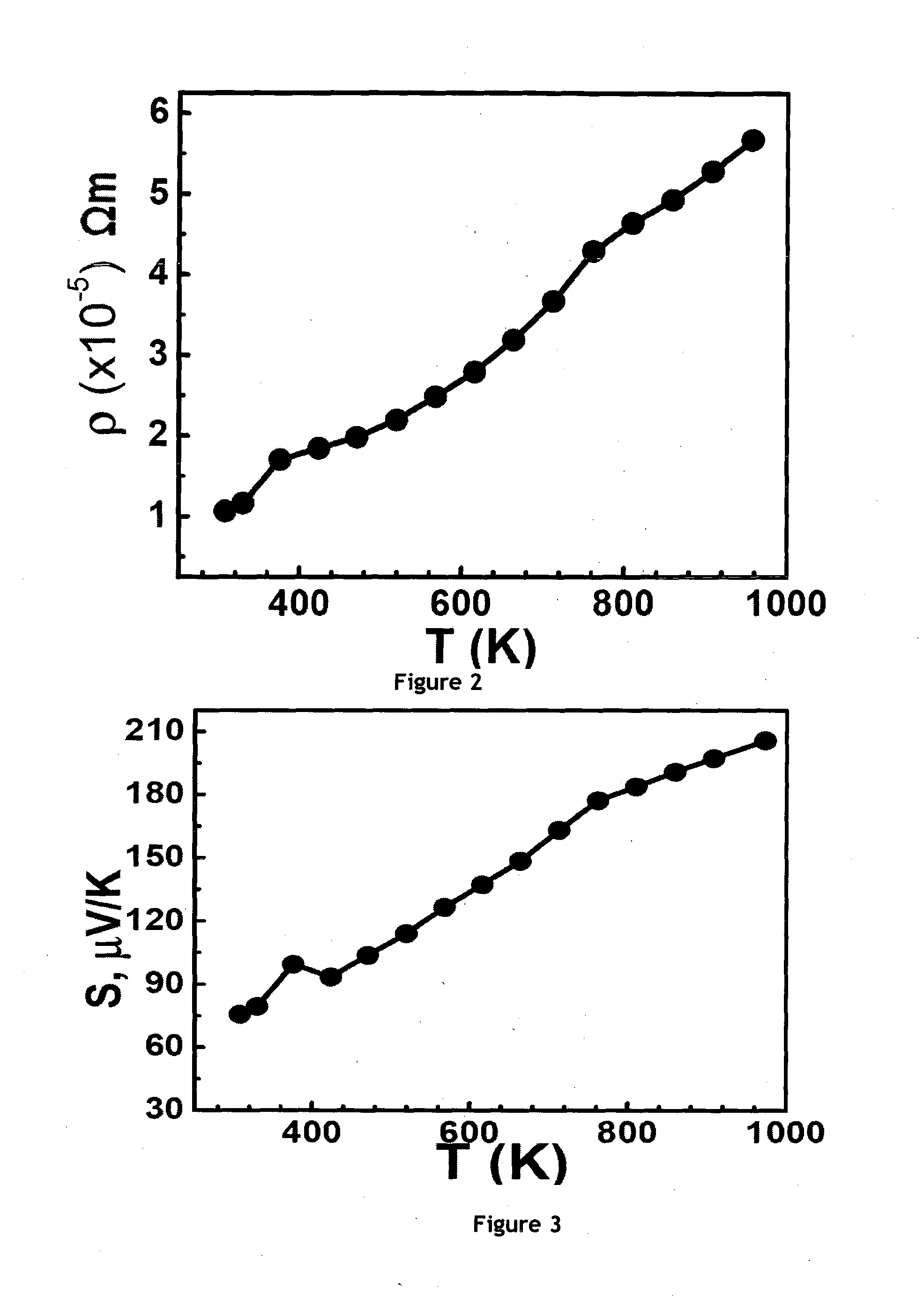

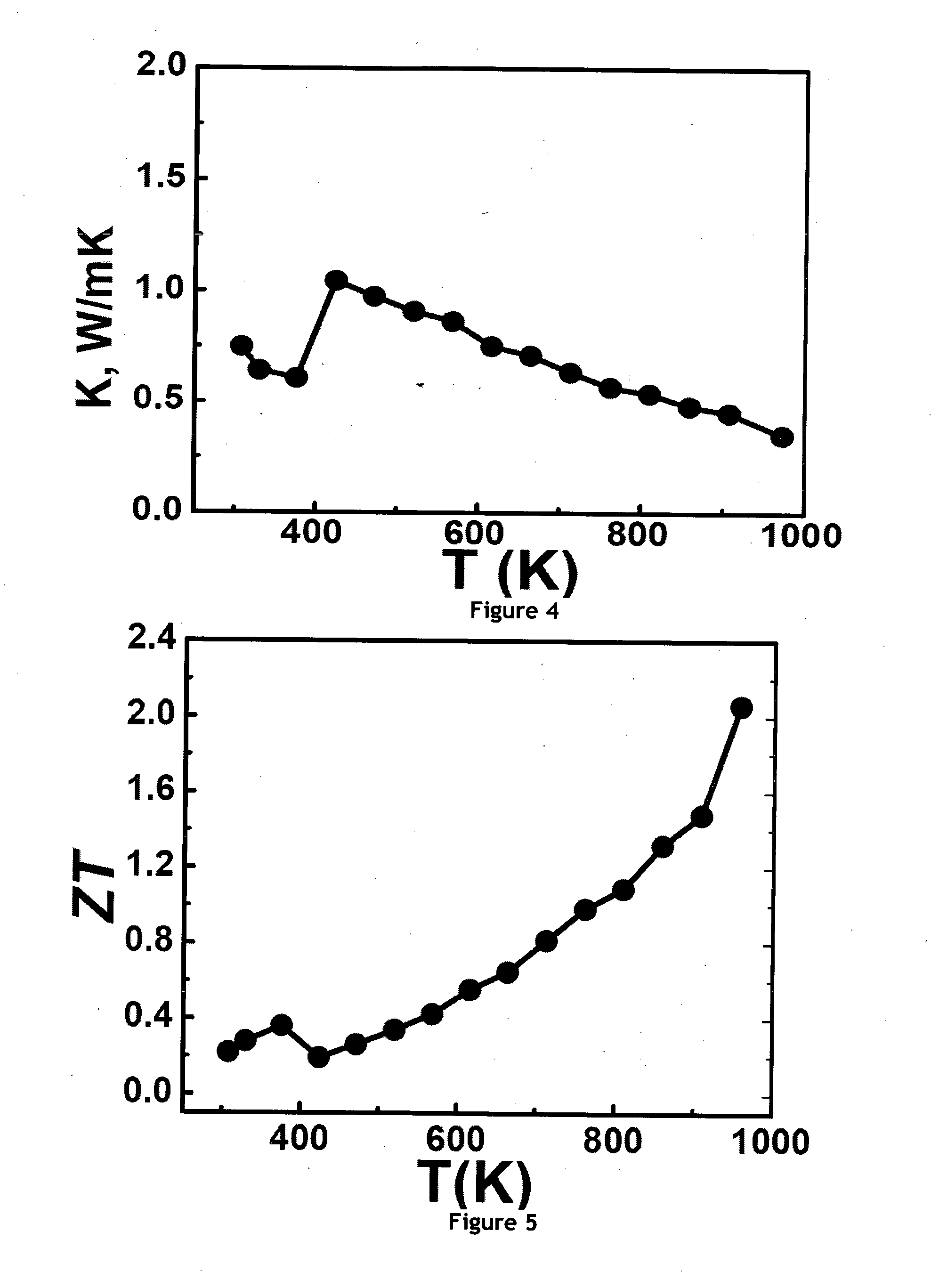

Disclosed is a nanostructured p-type copper-selenide as a cost-effective thermoelectric material with a high thermoelectric figure-of-merit. The nanostructured copper-selenide is a cost-effective p-type thermoelectric material having a high figure-of-merit of 2 at 973 K and is synthesized employing high energy ball milling process followed by reaction sintering under pressure at high heating rates using spark plasma sintering of the resulting nanopowders. The sintered copper-selenide shows a density of 99.9% of theoretical density and retains the nanoscale features introduced during ball milling leading to a thermoelectric figure of merit of 2 at 973 K.

Owner:COUNCIL OF SCI & IND RES

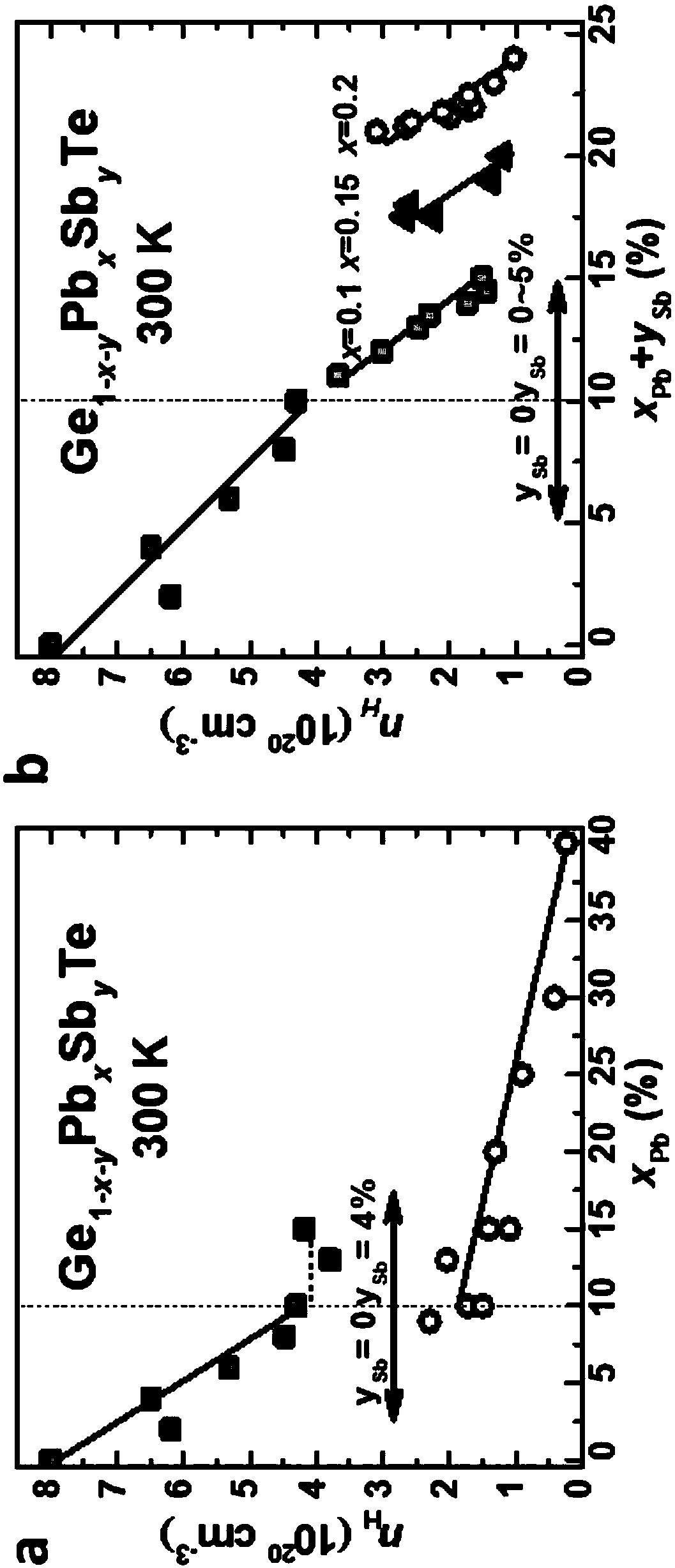

Antimony-doped high-performance GeTe-PbTe solid solution thermoelectric material and preparation method thereof

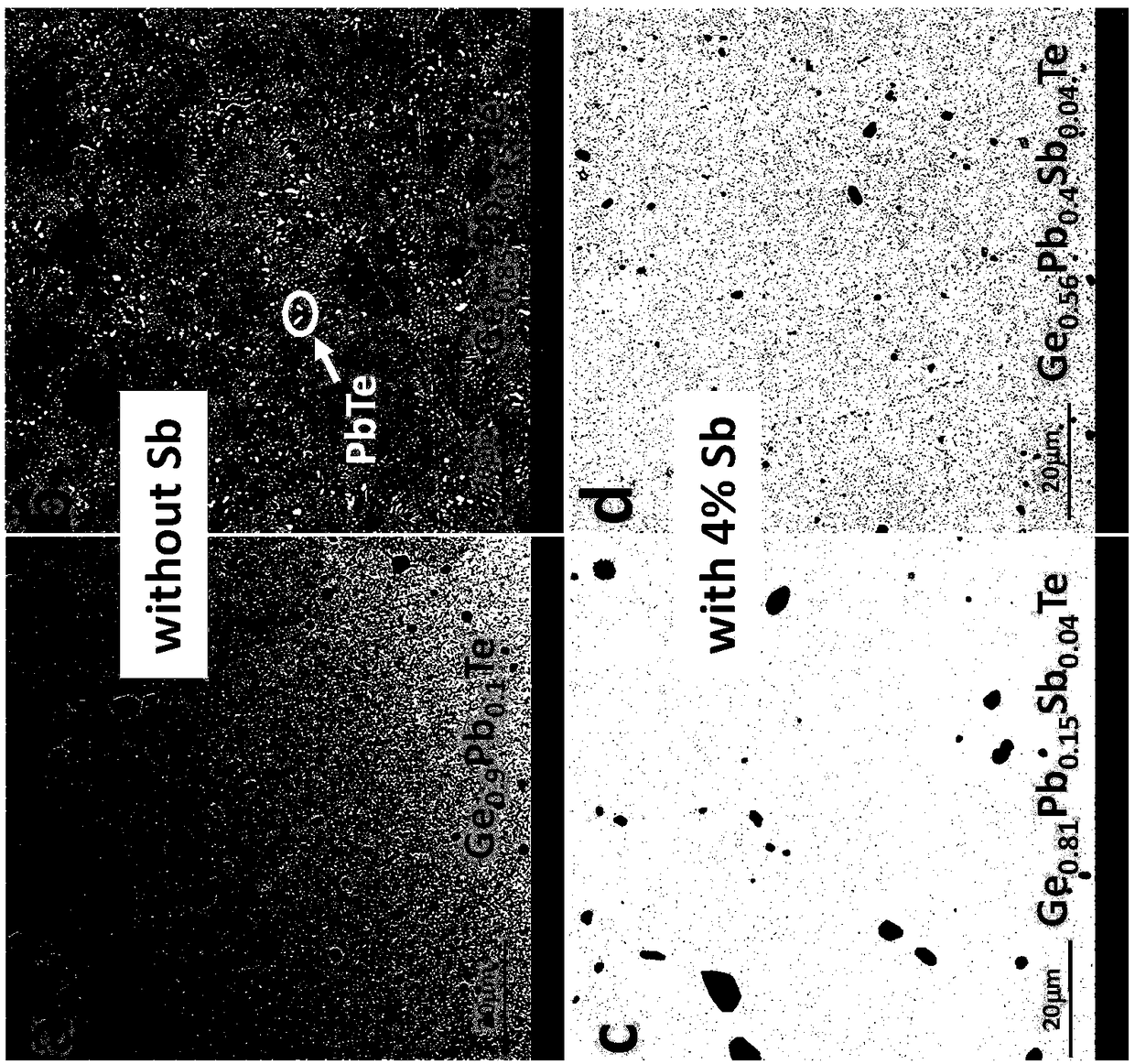

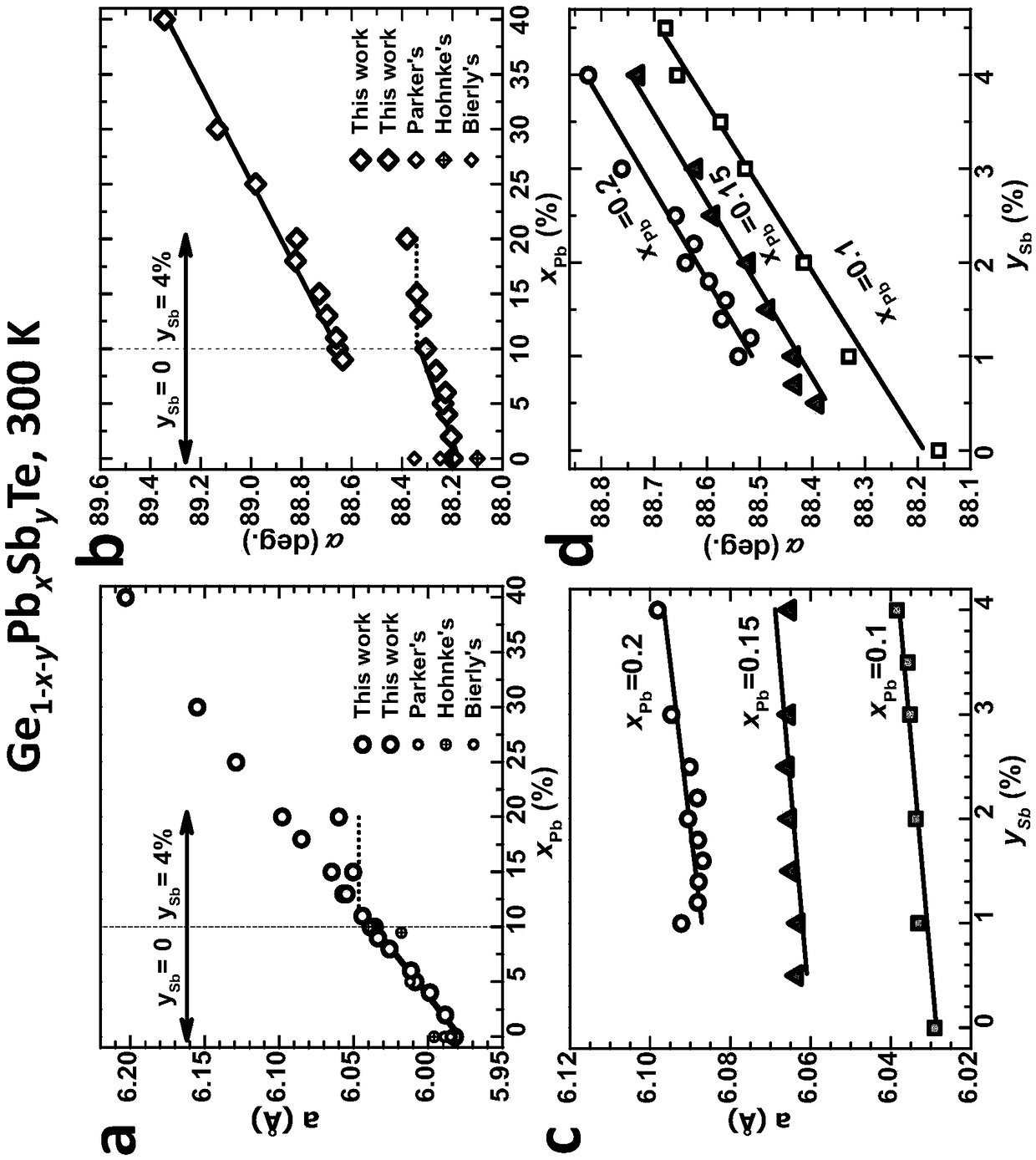

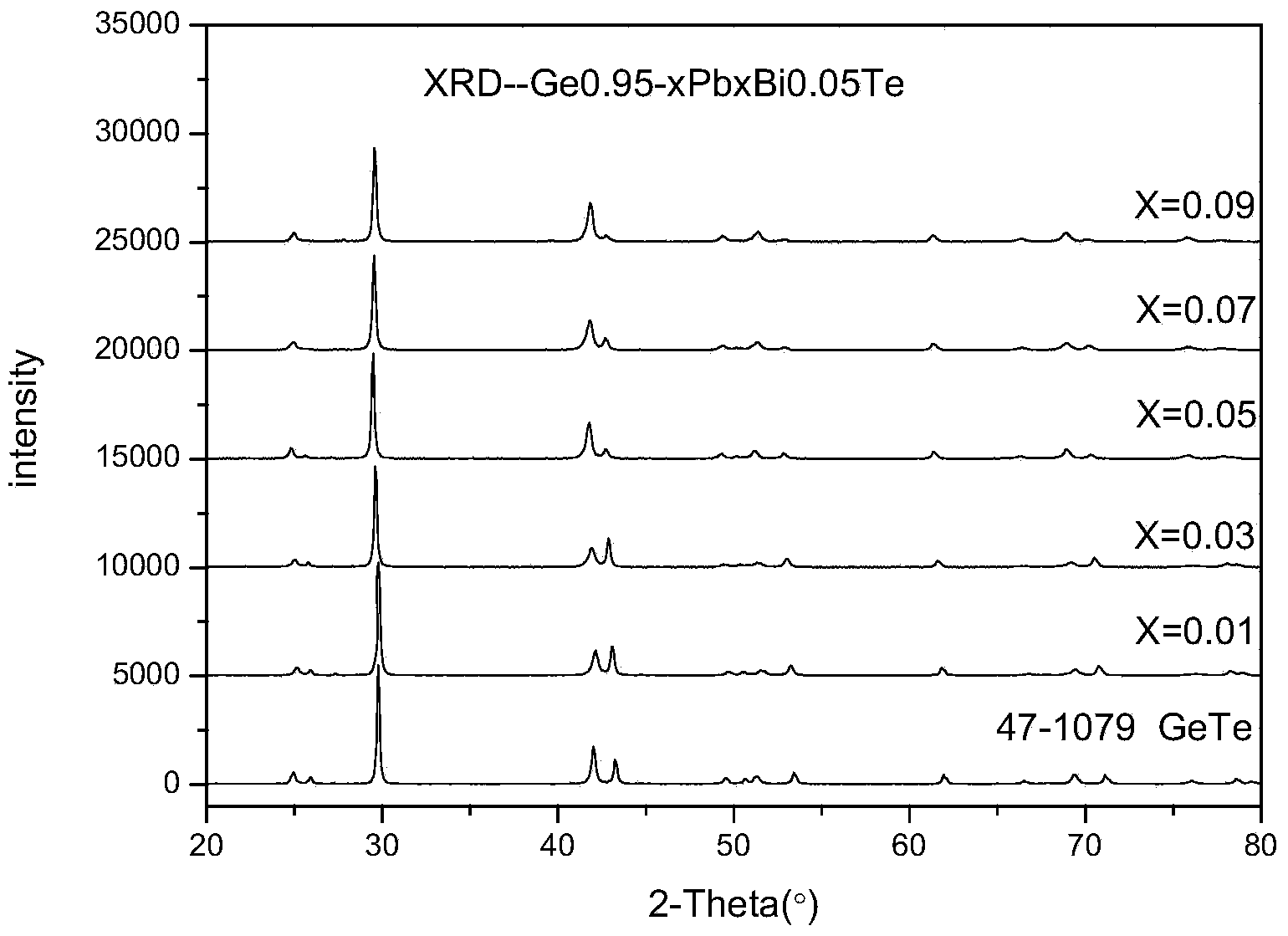

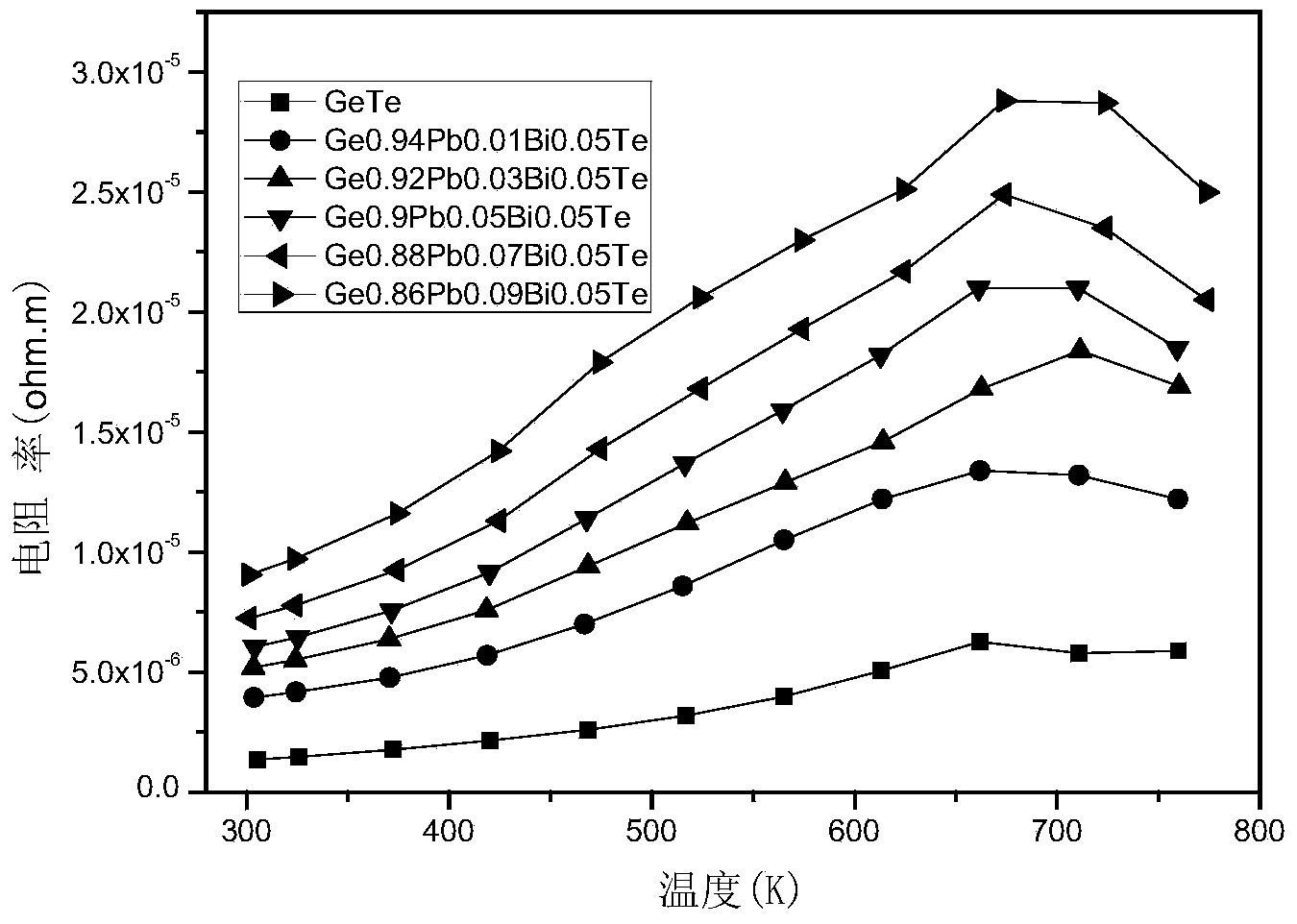

ActiveCN108735887AAchieve high thermoelectric performanceImprove solubilityThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsSolubility

The invention relates to an antimony-doped high-performance GeTe-PbTe solid solution thermoelectric material and a preparation method thereof, wherein the chemical formula is Ge(1-x-y) PbxSbyTe, wherein x is equal to 0-0.4, and y is equal to 0-0.07. The preparation method of the thermoelectric material comprises the following steps: according to the stoichiometric ratio in the above chemical formula, carrying out vacuum package, high-temperature melting and annealing thermal treatment on the single substance elements of Ge, Sb, Pb and Te having high purity (99.99%); grinding into powder; then,carrying out vacuum hot-pressed sintering and fast cooling. Compared with the prior art, the thermoelectrical material prepared by the method in the invention is doped with Sb, so the solubility of PbTe in the GeTe-PbTe solid solution is greatly improved, so that PbTe can obtain high figure of merit in a large solid solution range.

Owner:TONGJI UNIV

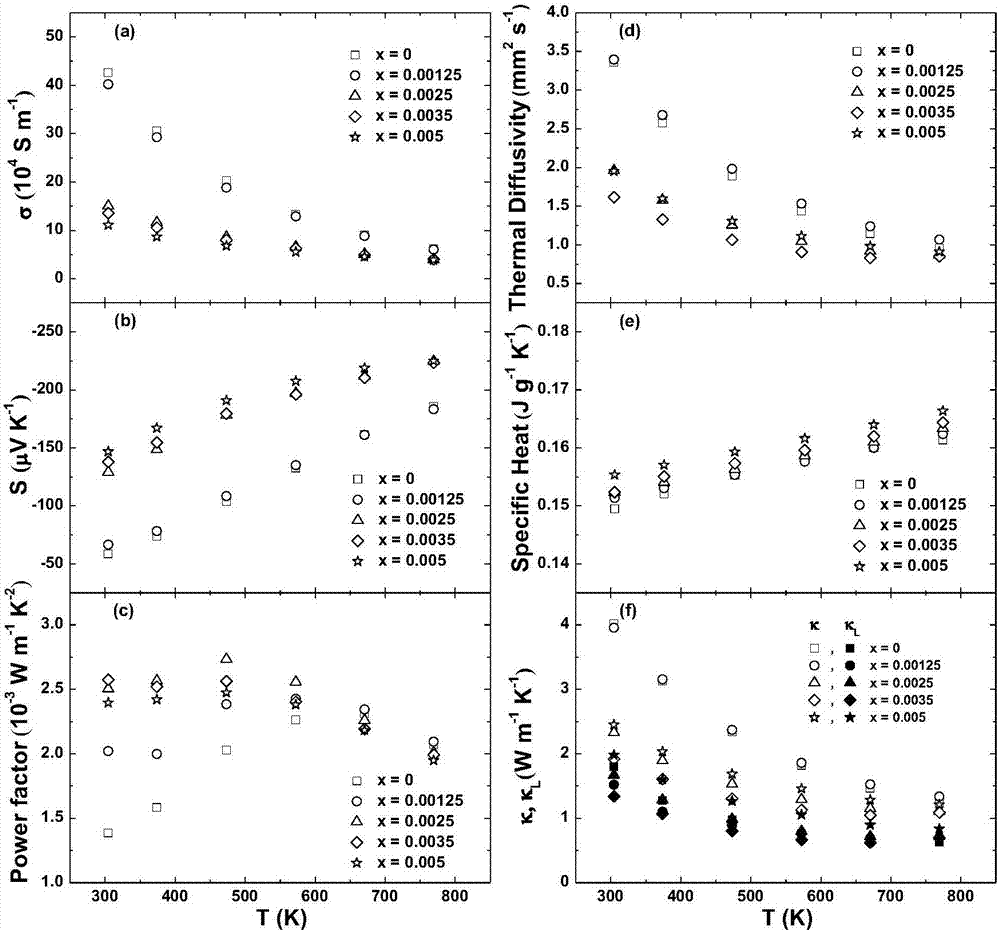

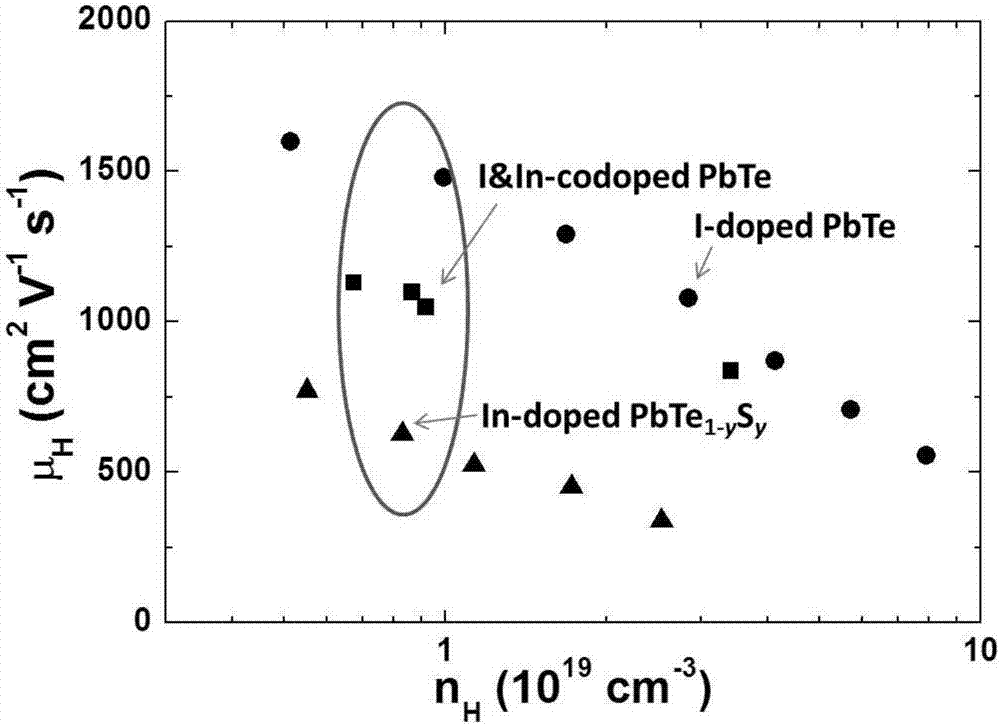

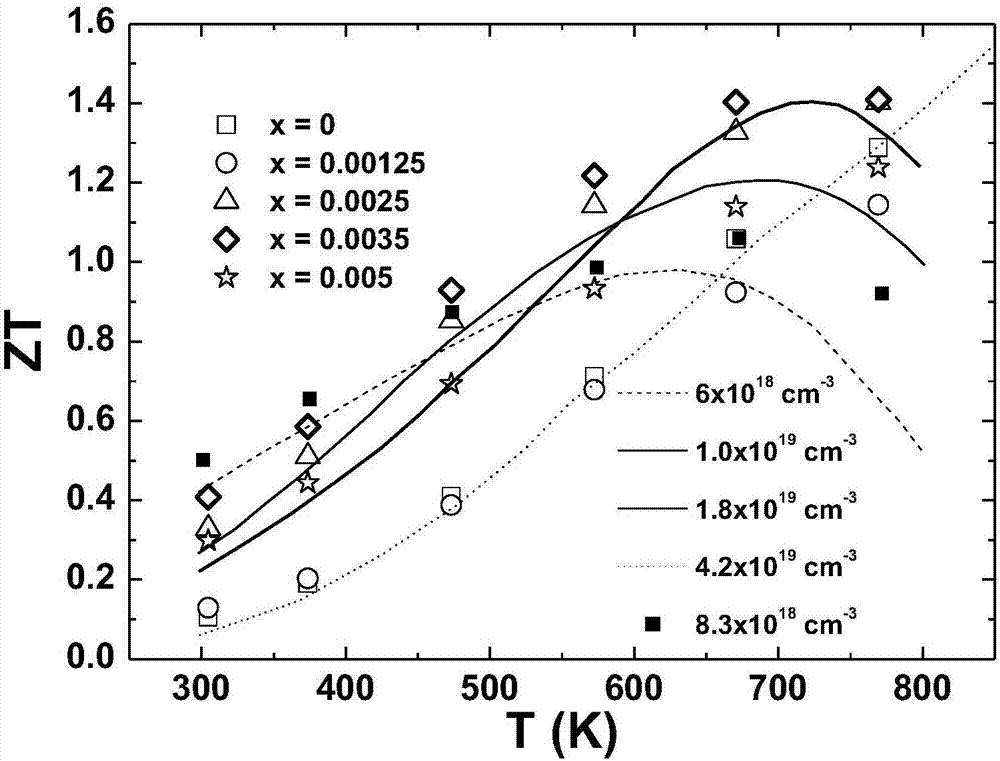

Multi-level doped PbTe-based thermoelectric material and preparation method thereof

ActiveCN106952999AHigh thermoelectric figure of meritHigh thermoelectric efficiencyThermoelectric device manufacture/treatmentThermoelectric device junction materialsDeep levelAmbipolar diffusion

The invention provides a multi-level doped PbTe-based thermoelectric material and a preparation method thereof. A molecular formula of the multi-level doped PbTe-based thermoelectric material is InxPb1-xTe1-yAy, wherein A is Cl, Br, I, Ga or Al; x is greater than 0 and less than or equal to 0.02; and y is greater than 0 and less than or equal to 0.03. According to the technical scheme, simultaneous doping of deep and shallow levels is adopted; carrier concentration at a low temperature is increased by utilizing shallow level doping; carrier concentration at a high temperature is increased by utilizing deep level doping; an ambipolar diffusion temperature is increased; and the thermoelectric material with a high thermoelectric merit figure within a wide temperature range is finally obtained. The thermoelectric efficiency of the material is improved.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

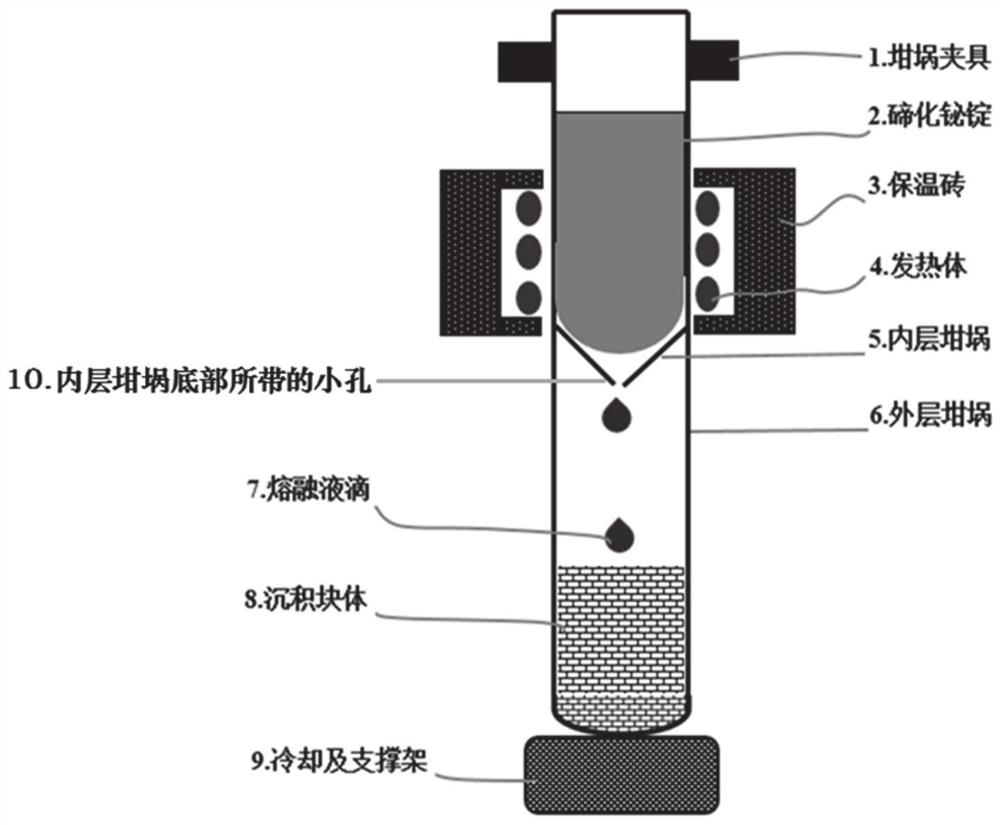

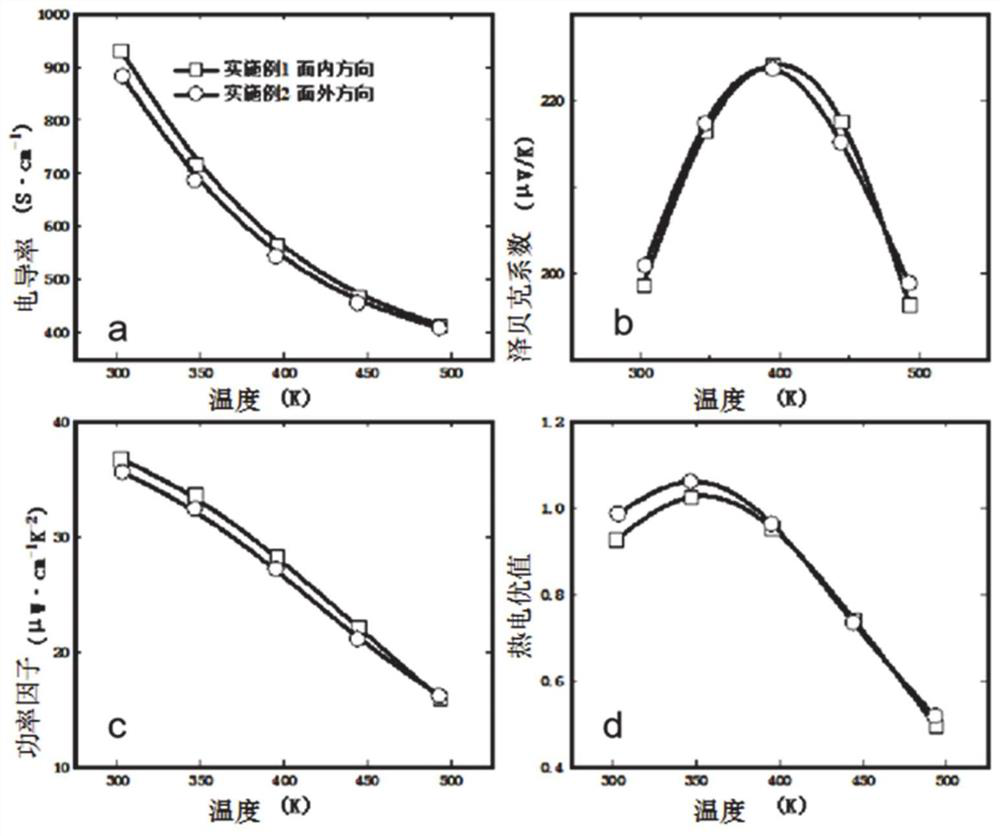

Preparation method of P-type bismuth telluride-based bulk thermoelectric material (Bi1-xSbx)2Te3

The invention discloses a preparation method of a P-type bismuth telluride-based bulk thermoelectric material (Bi1-xSbx)2Te3. The preparation method comprises the following steps: simple substance rawmaterials Bi, Sb and Te powders are weighed according to the chemical formula content of (Bi1-xSbx)2Te3, are added into a quartz tube, and are homogenized for 2h, and the tube is vacuumized and sealed, and is fixed on the vertical lifting frame of a vertical solidification furnace; the quartz tube vertically descends into the heating zone of the vertical solidification furnace with the vertical lifting frame at a rate of 2 cm / h, stops descending after the obtained material in the quartz tube completely passes through the heating zone, and undergoes heat insulation in the heating zone for a certain period of time, then heating is stopped, and the quartz tube undergoes furnace cooling in the vertical solidification furnace to room temperature, and is taken out and crushed to obtain the complete P-type bismuth telluride-based bulk thermoelectric material. The method of the invention has the advantages of high production efficiency, low industrial production cost and high automation degree, and the prepared bismuth telluride product has the advantages of high density, low heat conductivity, high electrical conductivity and high thermoelectric figure of merit.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

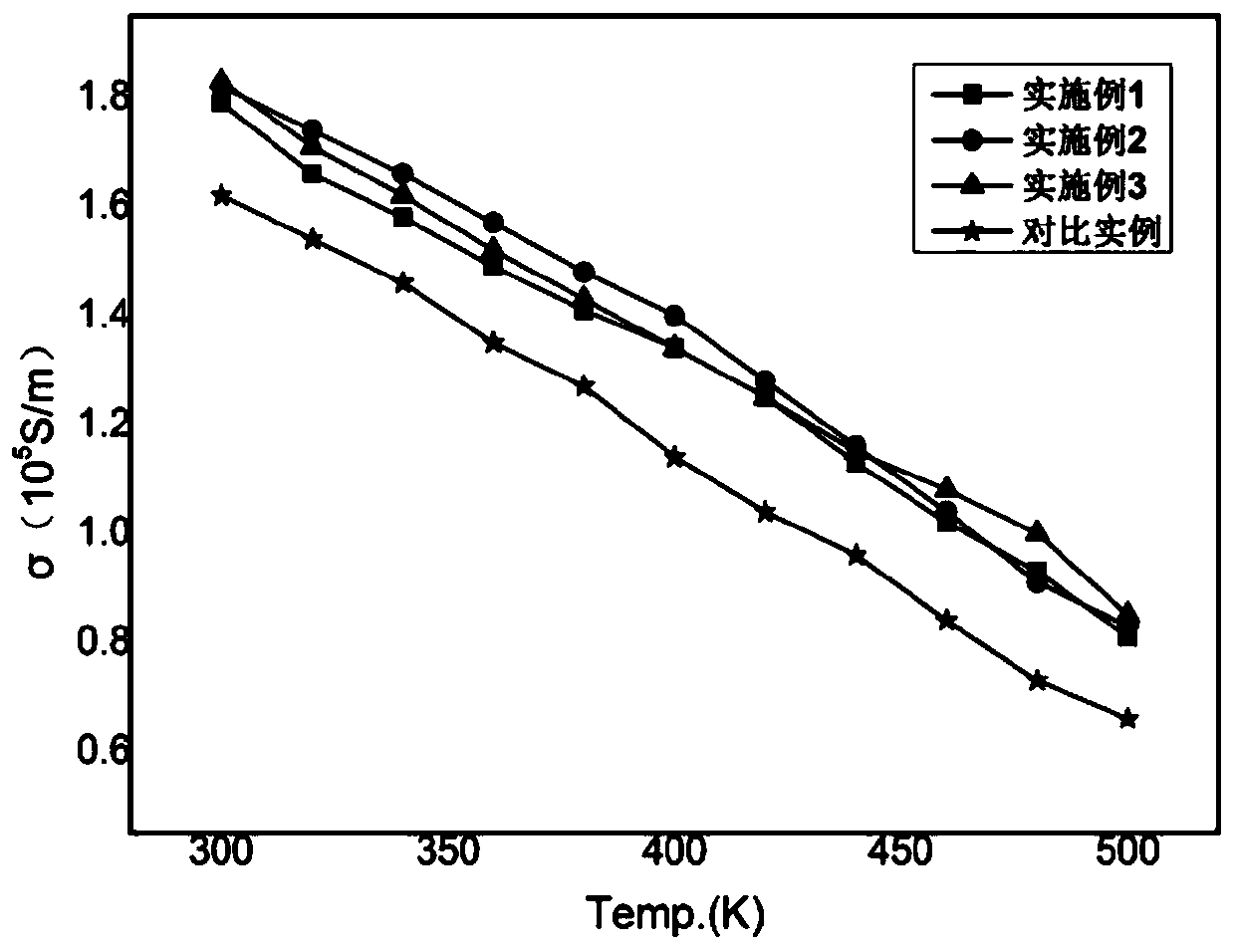

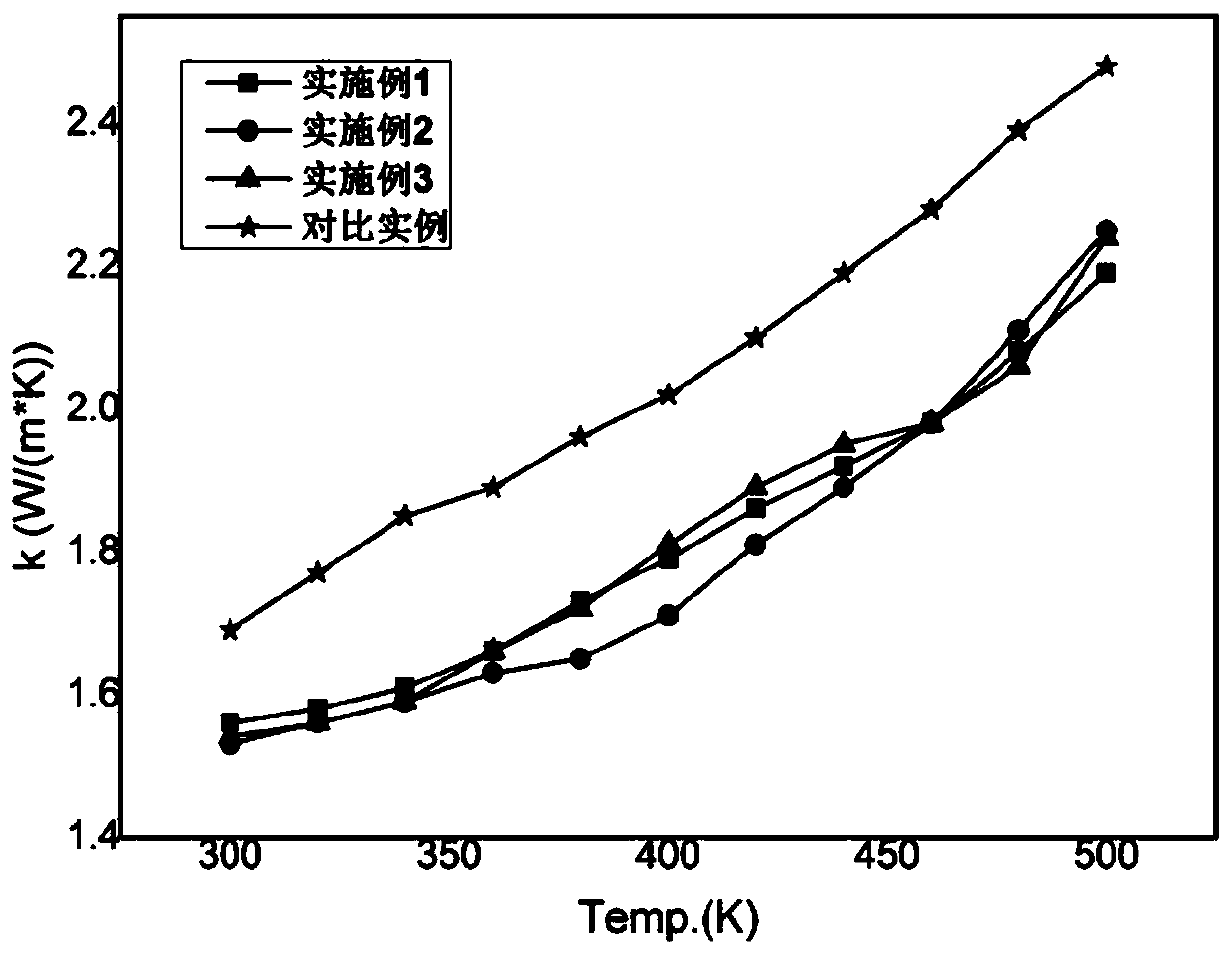

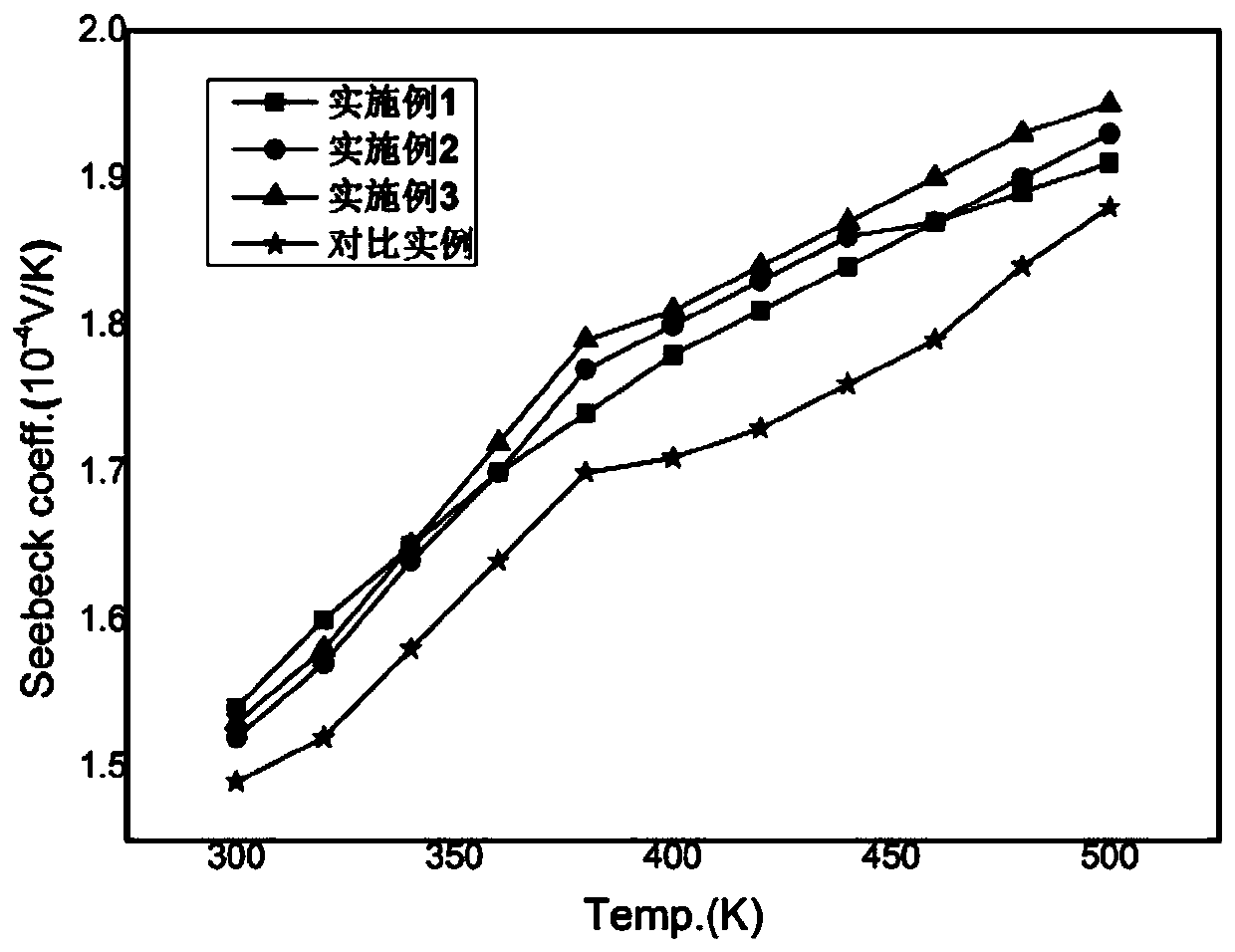

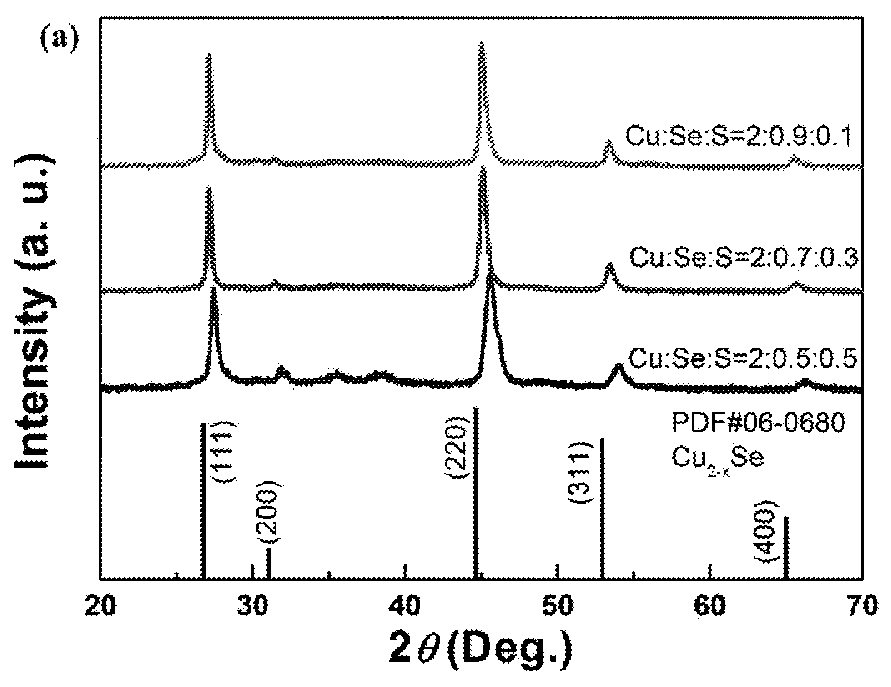

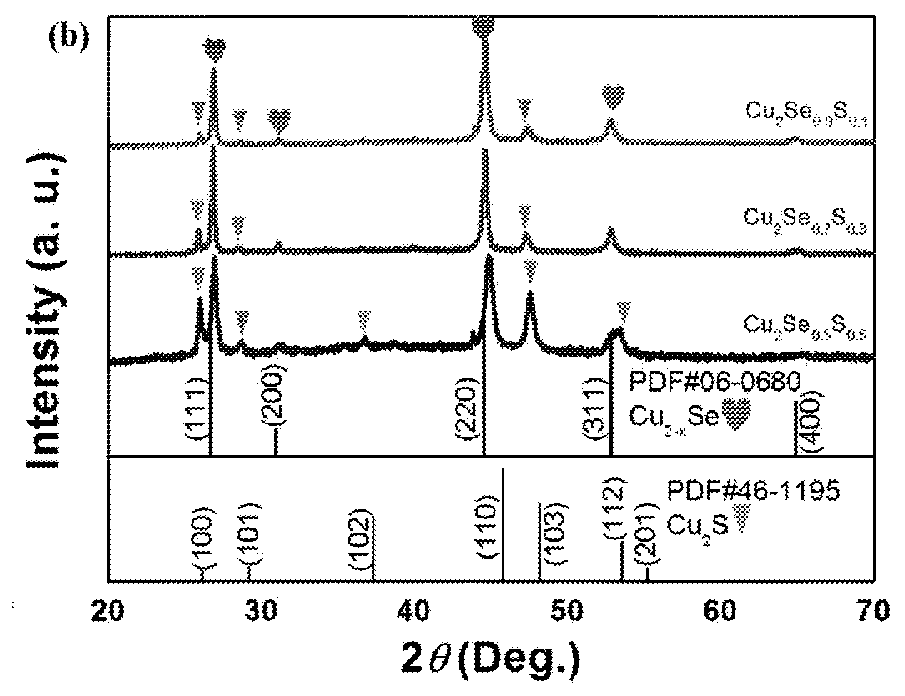

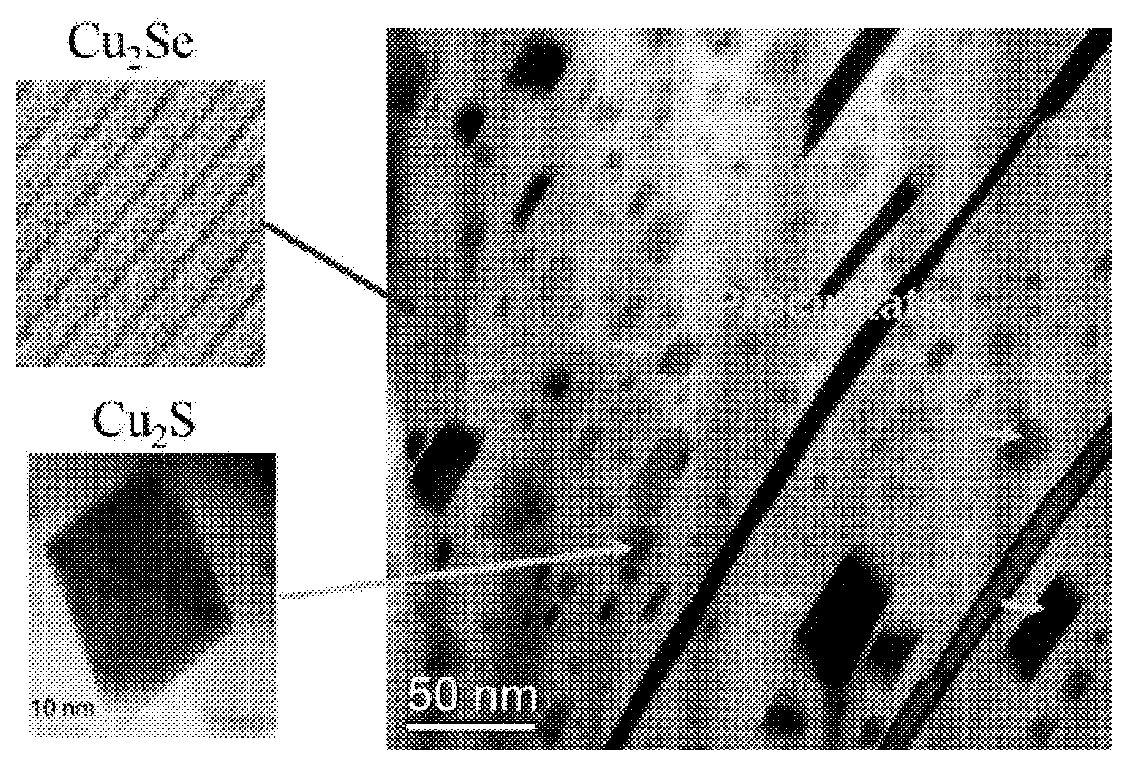

Cu-Se-S system thermoelectric material and preparation method thereof

ActiveCN109713115AHigh thermoelectric figure of meritImprove thermoelectric performancePolycrystalline material growthThermoelectric device manufacture/treatmentThermoelectric materialsS system

The invention relates to the technical field of thermoelectric materials, and specifically discloses a Cu-Se-S system thermoelectric material. The molar ratio of Cu, Se and S in the material is 2:(1-x):x, wherein 0<x<1; and the material is composed of a Cu2Se phase and a Cu2S phase obtained by in-situ phase separation of single-phase Cu-Se-S ternary alloy, wherein the Cu2S phase is dispersed in the Cu2Se phase, the grain size of the Cu2Se phase is 200-500 nm, and the size of the Cu2S phase is 10-50 nm. An alloy material containing both Cu2S and Cu2Se is obtained by employing a technical schemeof the thermoelectric material, and thermoelectric properties of Cu-Se-S system alloy are greatly improved.

Owner:KUNMING UNIV OF SCI & TECH

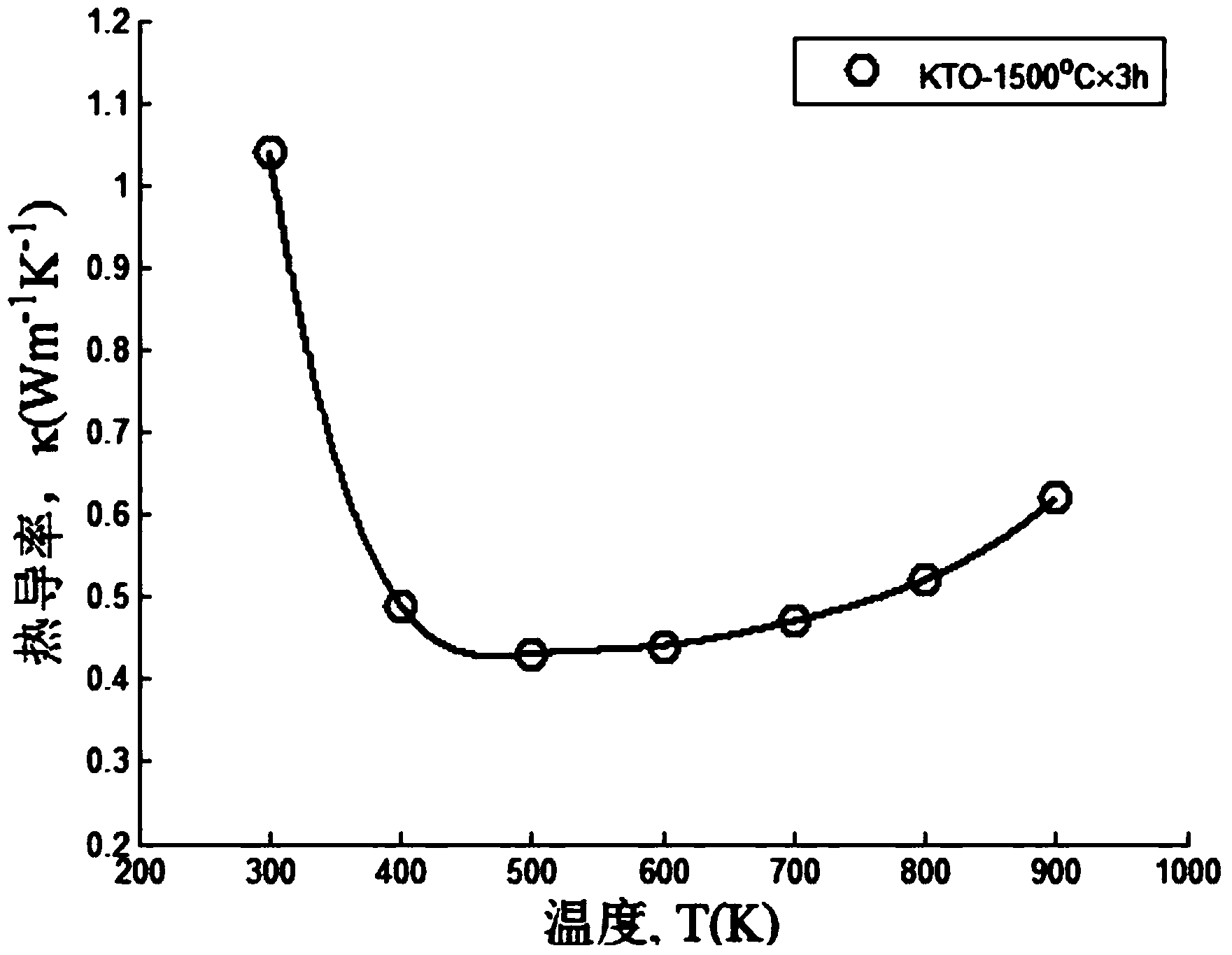

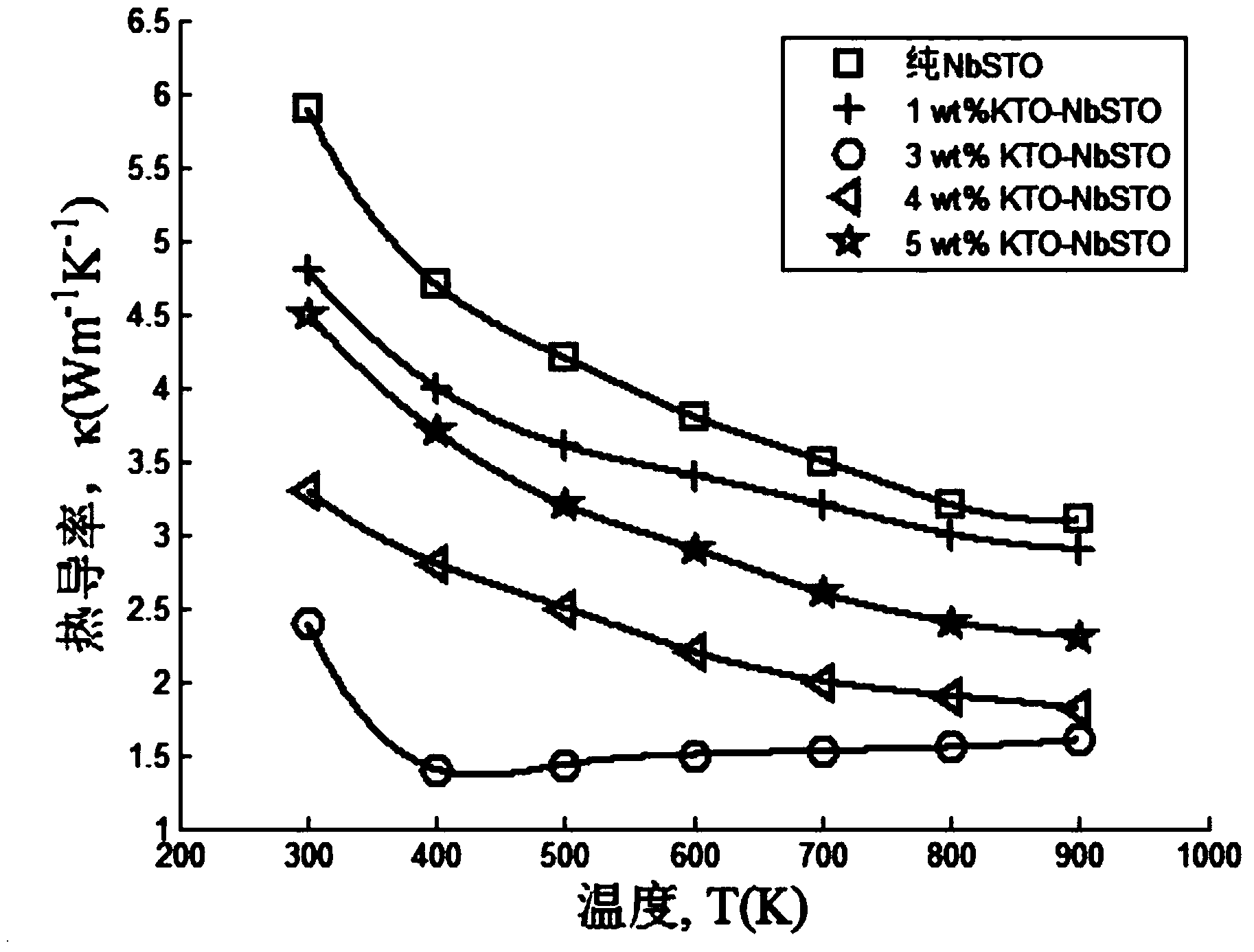

Composite strontium titanate thermoelectric material and preparation method thereof

InactiveCN104230330ALow thermal conductivityHigh thermoelectric figure of meritStrontium titanateCompound a

The invention discloses a composite strontium titanate thermoelectric material. The composite strontium titanate thermoelectric material is prepared from niobium-doped strontium titanate powder and potassium titanate nanowire powder. The invention further discloses a preparation method of the composite strontium titanate thermoelectric material. The preparation method comprises the following steps: uniformly mixing the potassium titanate nanowire powder in a certain ratio into the niobium-doped strontium titanate powder to obtain a mixture; performing 15-25MPa cold isostatic pressing on the mixture to prepare a blank; calcining the blank for 2-4 hours in an argon atmosphere at 1400-1600 DEG C. The nano-composite thermoelectric material is prepared by compounding a nano titanium potassium additive with ultralow thermal conductivity and strontium titanate, and a large number of phonon scattering interfaces are effectively introduced, so that the thermal conductivity of the prepared thermoelectric material is significantly reduced and the electrical conductivity thereof is not significantly reduced, and thus the thermoelectric figure of merit is significantly improved.

Owner:CHENGDU RES INST OF UESTC

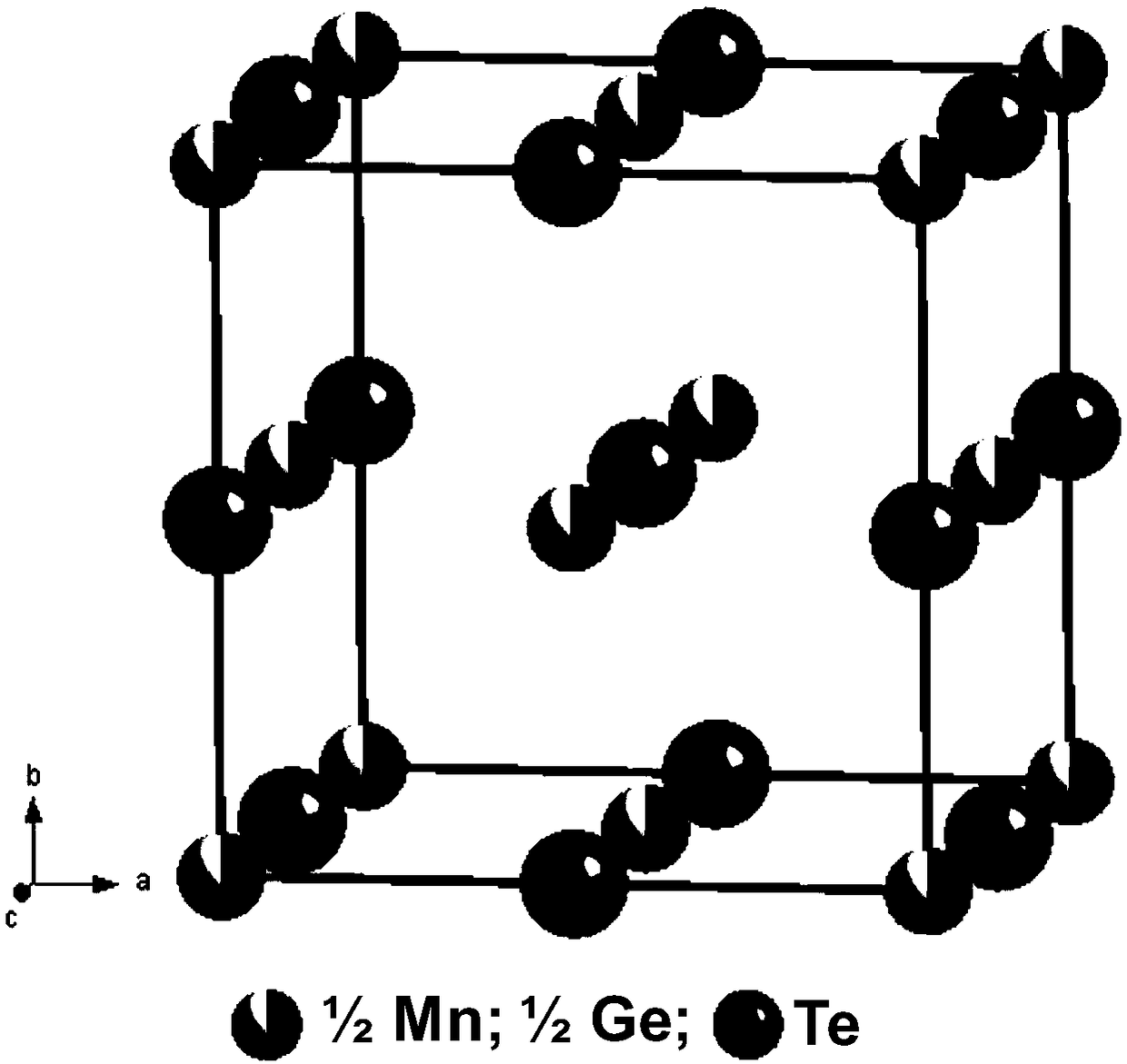

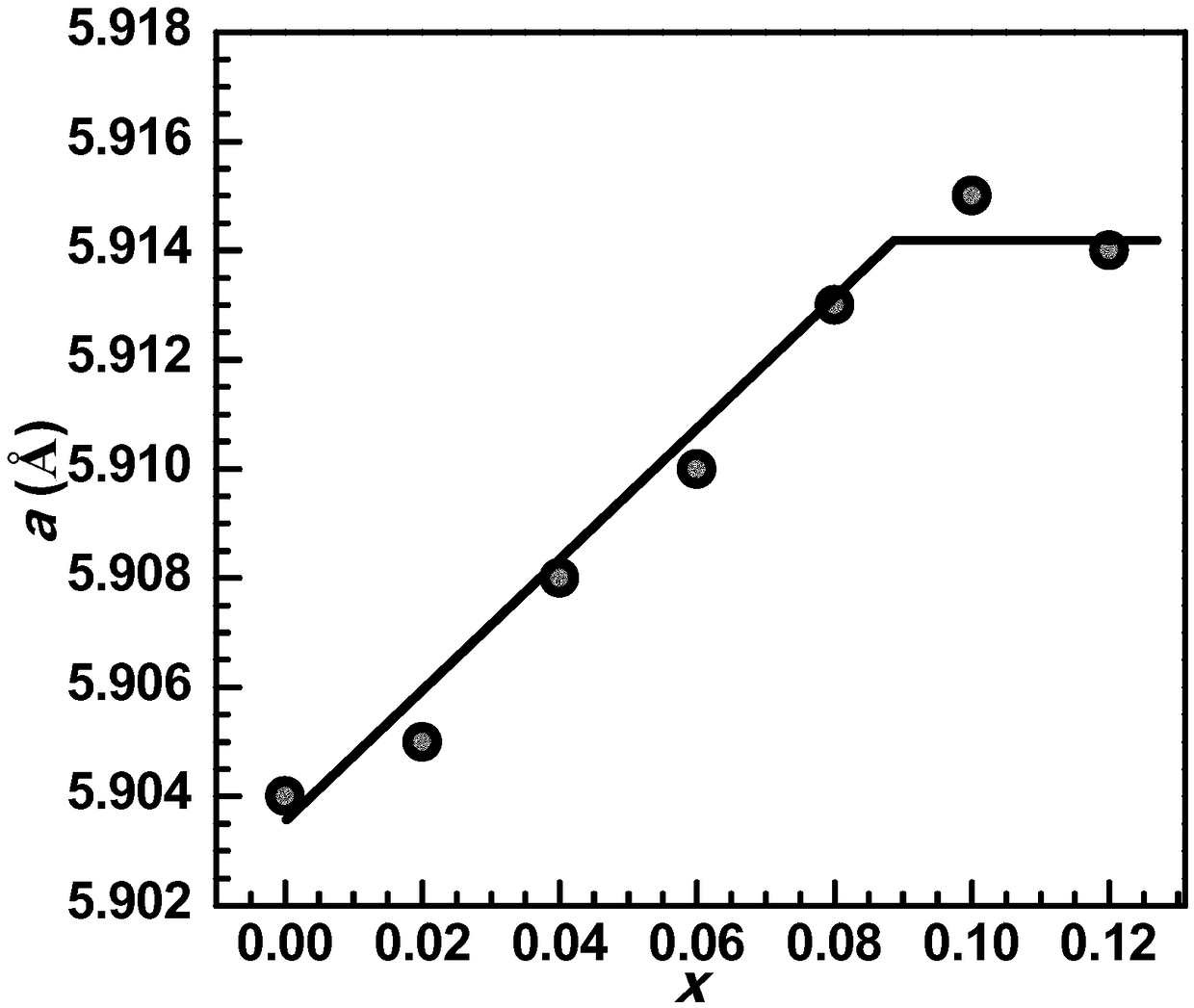

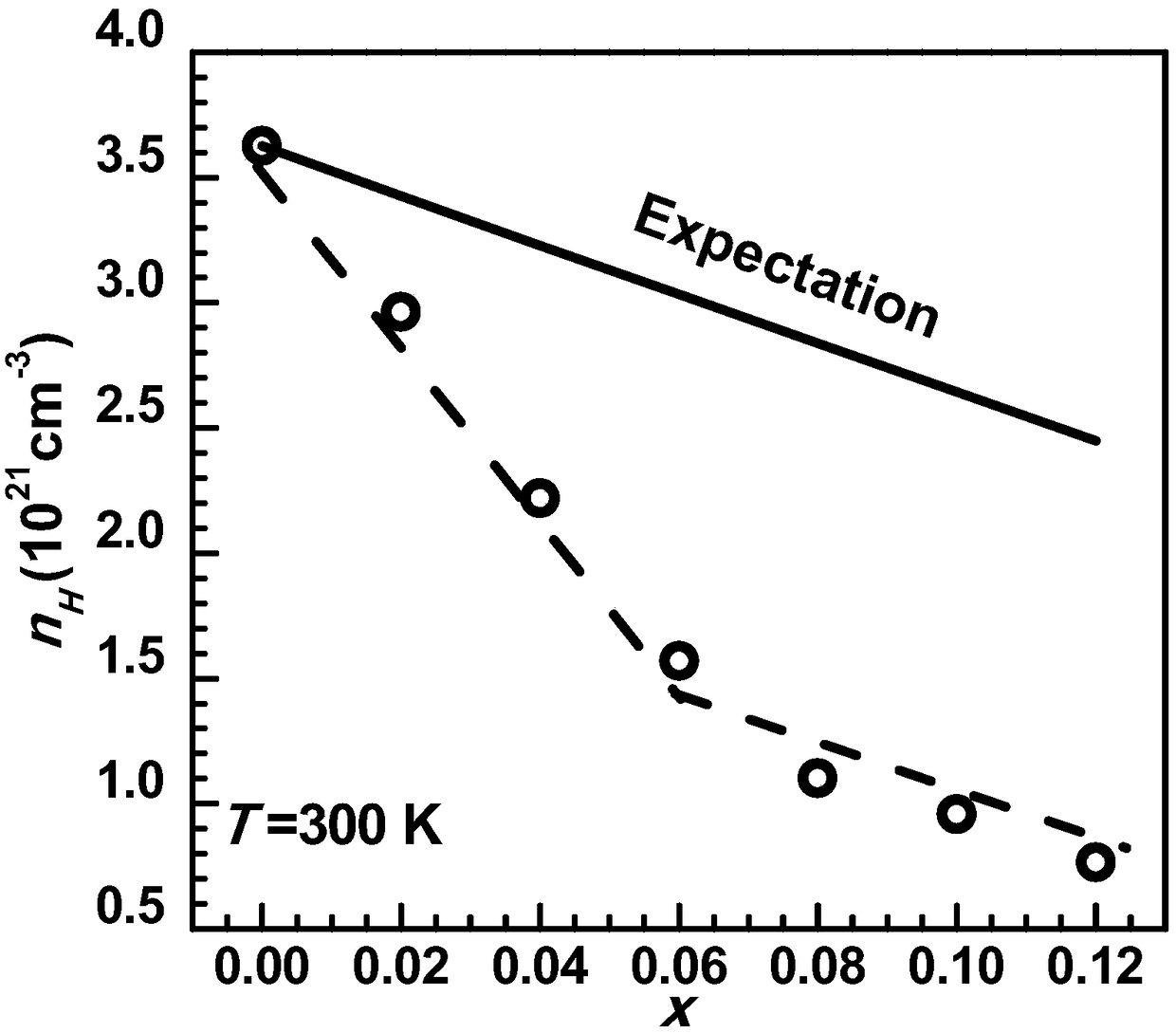

High-performance and low-cost MnGeTe2-based thermoelectric material and preparation method thereof

ActiveCN108807654AReduce concentrationImprove electrical performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsMolten state

The invention relates to a high-performance and low-cost MnGeTe2-based thermoelectric material and a preparation method thereof. The chemical formula of the thermoelectric material is MnGe1-xBixTe2, wherein x< / =0.12. The preparation method includes the steps of firstly: taking single Bi, Ge, Te and Mn according to the stoichiometric ratio, sequentially placing into a quartz tube from high meltingpoint to low melting point, and performing vacuum encapsulation; secondly, heating the quartz tube to allow the raw material to have sufficient reaction in the molten state, and then quenching to obtain a first cast ingot; thirdly, loading the first cast ingot into another quartz tube, heating and annealing, and quenching to obtain a second cast ingot; fourthly, grinding the second cast ingot intopowder, placing into a graphite mould, performing vacuum hot pressing sintering, and cooling to obtain the MnGeTe2-based thermoelectric material. Compared with the prior art, the MnGeTe2-based thermoelectric material is good in thermoelectric performance, mechanical performance, low in cost and high in application potential.

Owner:TONGJI UNIV

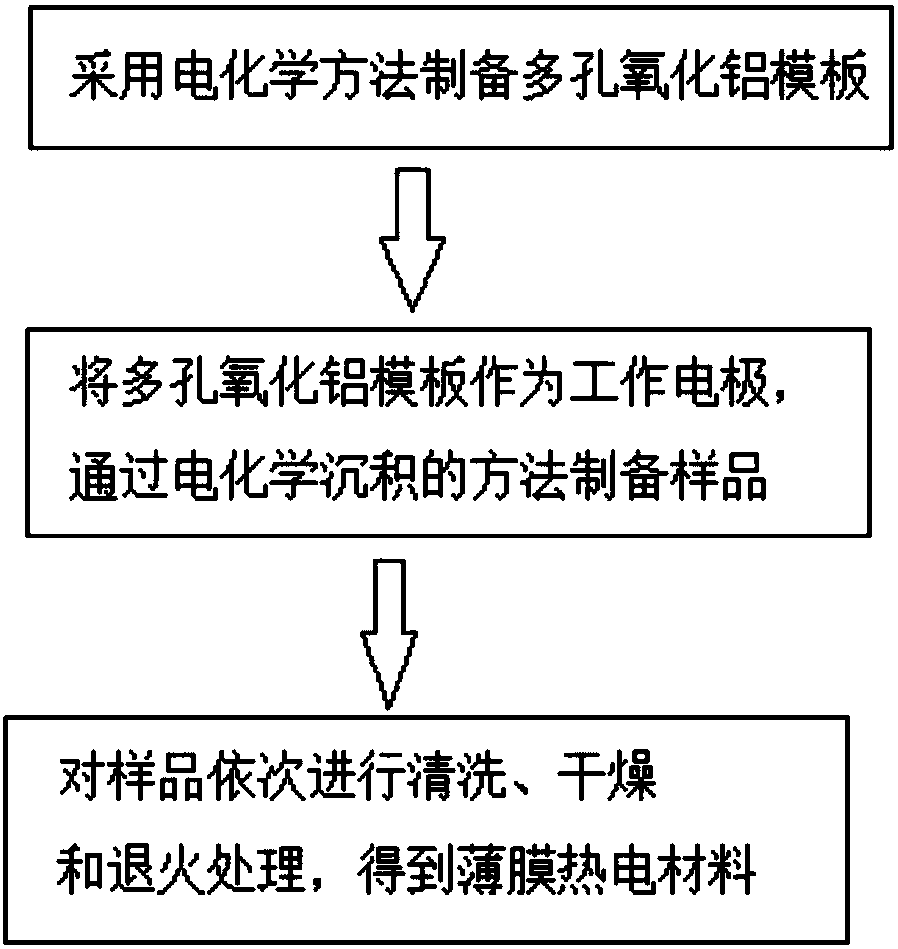

Preparation method of thin-film thermoelectric material

InactiveCN107620100ALow thermal conductivityLow high Seebeck coefficientElectrolytic inorganic material coatingThermoelectric materialsAuxiliary electrode

The invention discloses a preparation method of a thin-film thermoelectric material. The preparation method comprises the following steps: preparing a porous alumina template by adopting an electrochemical method; taking the porous alumina template as a working electrode; putting the working electrode and an auxiliary electrode in an electrolyte, and preparing a sample through an electrochemical deposition method, wherein the electrolyte comprises a precursor, a complexing agent and an additive, and the precursor is a combination of two or three of tellurium dioxide, bismuth nitrate and diantimony trioxide; and subjecting the sample to cleaning, drying and annealing treatment in sequence, so as to obtain the thin-film thermoelectric material. The preparation method disclosed by the invention has the advantages that the thin-film thermoelectric material is low in heat conductivity coefficient, high in electrical conductivity, high in Seebeck coefficient and high in thermoelectric figureof merit.

Owner:滁州玛特智能新材料科技有限公司

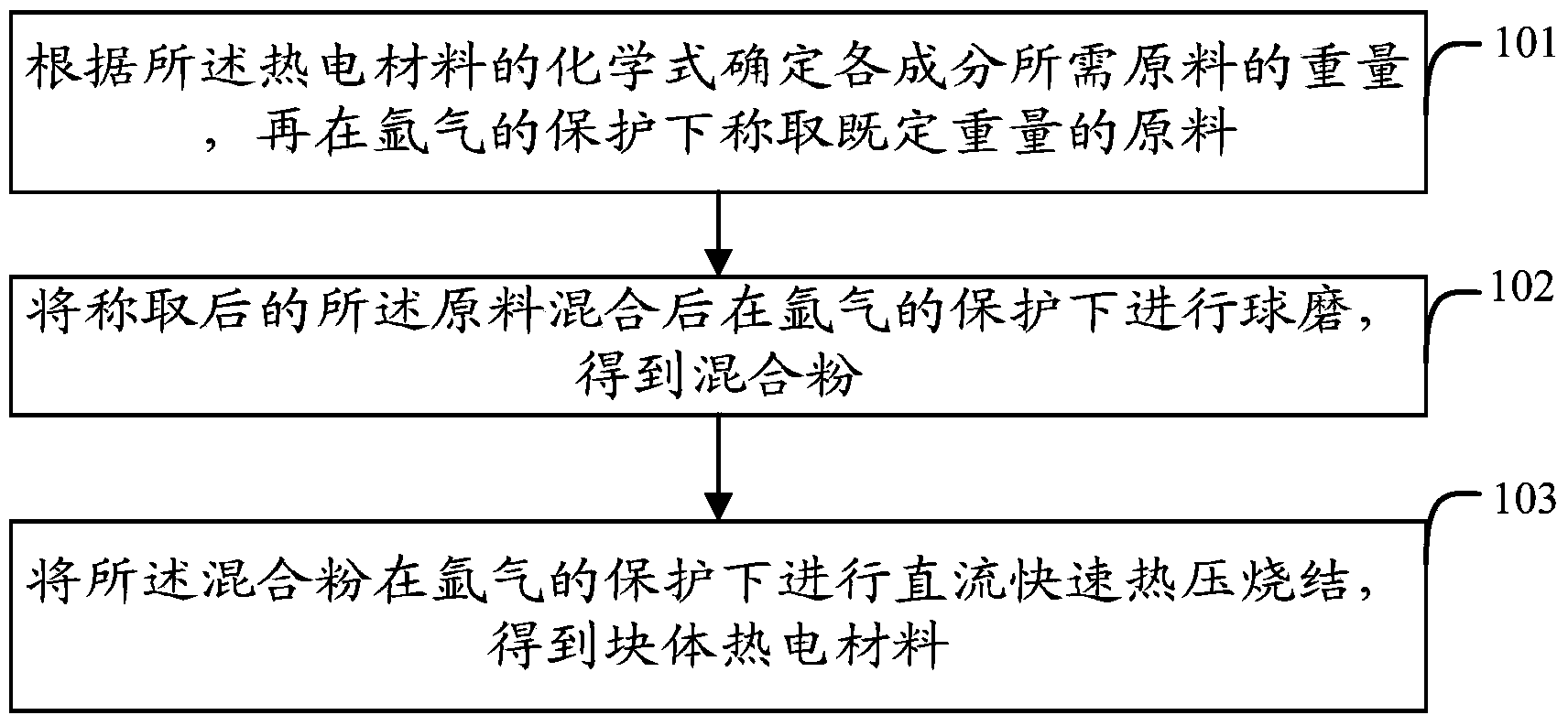

Full-temperature-range high-performance n-type Mg-Sb-based thermoelectric material and preparation method thereof

ActiveCN112038473AHigh thermal conductivityImprove thermal conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsMetallurgy

The invention discloses a full-temperature-range high-performance n-type Mg-Sb-based thermoelectric material and a preparation method thereof, and relates to an n-type thermoelectric material and a preparation method thereof. The full-temperature-range high-performance n-type Mg-Sb-based thermoelectric material aims to solve the problems that an existing n-type Mg3Sb2-based thermoelectric materialcannot simultaneously obtain high performance at room temperature and high temperature and is poor in mechanical property. The chemical general formula of thefull-temperature-range high-performance n-type Mg-Sb-based thermoelectric material is B<x>Mg<3.2-x>Sb<1.99y>Bi<y>Te<0.01>. The preparation method comprises the following steps of: 1, weighing; 2, ball milling; and 3, sintering. The preparation method is used for preparing the full-temperature-range high-performance n-type Mg-Sb-based thermoelectric material.

Owner:HARBIN INST OF TECH

Silver-containing P-type semiconductor

InactiveCN101036240AImprove efficiencyHigh thermoelectric figure of meritThermoelectric device junction materialsPhysical chemistryLanthanide

A thermoelectric composition comprises a material represented by the general formula (AgaX1-a)1+-x (SnbPbl-b)m M'1-yQ2+m wherein X is Na, K, or a combination of Na and K in any proportion; M' is a trivalent element selected from the group consisting of Sb, Bi, lanthanide elements, and combinations thereof; Q is a chalcogenide element selected from the group consisting of S, Te, Se, and combinations thereof; a and b are independently > 0 and =1; x and y are independently > 0 and < 1; and 2 =m =30. The compositions exhibit a figure of merit ZT of up to about 1.4 or higher, and are useful as p-type semiconductors in thermoelectric devices.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

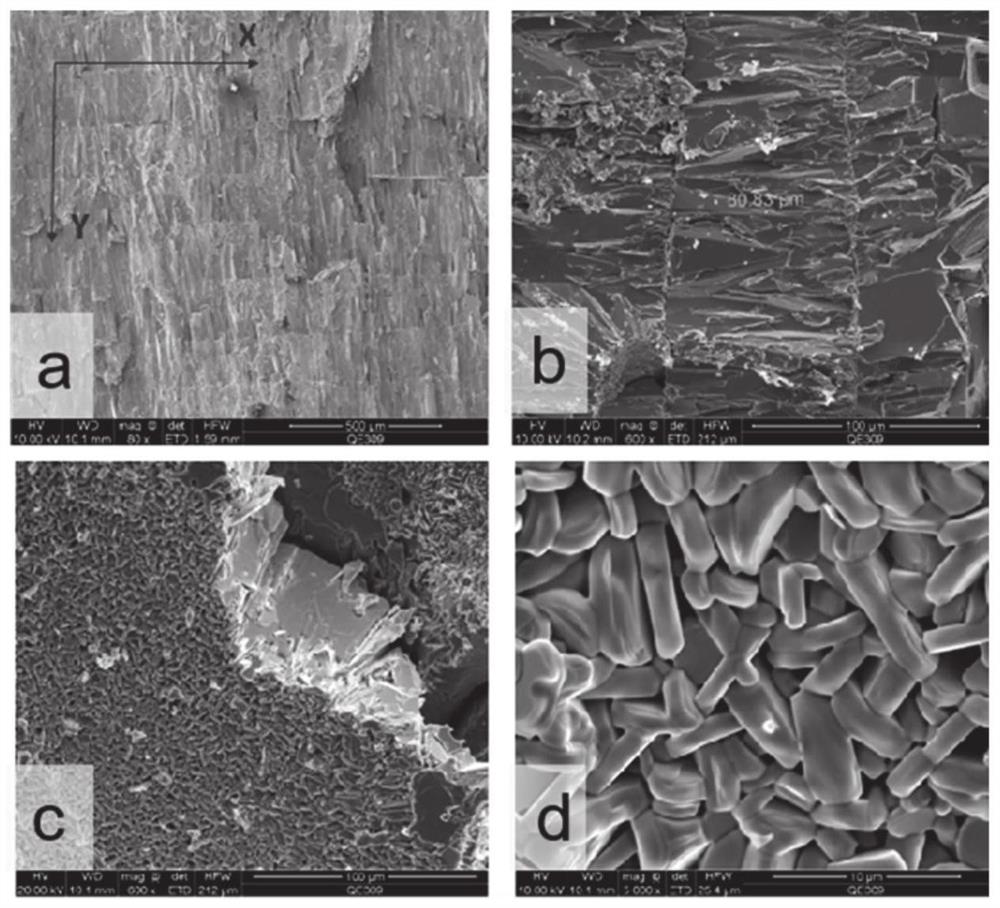

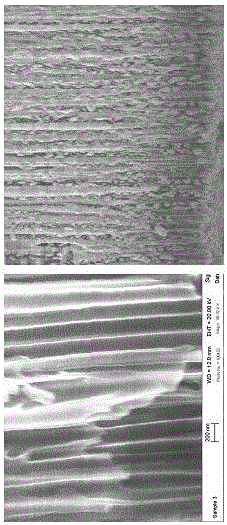

High-strength and high-efficiency bismuth telluride block and preparation method and application thereof

PendingCN113328031AHigh thermoelectric figure of meritImprove uniformityThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideThermal deformation

The invention discloses a high-strength and high-efficiency bismuth telluride block. The bismuth telluride block is in a lamellar shape; the bismuth telluride block is a P-type lamellar bismuth telluride block of Bi0.5Sb1.5Te3+x, and the value range of x is 0-0.05, or, the bismuth telluride block is an N-type lamellar bismuth telluride block of Bi2Te3-ySey, and y ranges from 0 to 0.3. The bismuth telluride block is of a special lamellar structure and has the double characteristics of high orientation degree and grain refinement, and the bismuth telluride block can be directly used for vacuum hot pressing sintering or vacuum thermal deformation sintering without being cut and / or ground into powder. And the bismuth telluride-based thermoelectric material with high thermoelectric figure of merit and high strength can be rapidly prepared.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Hot extrusion forming method of bismuth telluride thermoelectric material

PendingCN114210978AHigh strengthHigh thermoelectric figure of meritThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideIngot

The invention relates to a hot extrusion forming method of a bismuth telluride thermoelectric material. The method comprises the following steps: obtaining elementary substance raw materials of Bi, Te, Sb and Se; crushing the simple substance raw material into blocks with preset diameters; weighing the blocks according to a preset stoichiometric ratio; mixing the blocks, and smelting in a vacuum high-frequency induction smelting furnace in a first protective gas environment to obtain a cast ingot; the cast ingot is subjected to ball milling, and powder is obtained; screening the powder by using an ultrasonic inspection sieve; loading the screened powder into an extrusion die, and carrying out hot extrusion in a second protective gas environment to obtain a bismuth telluride bar; and placing the bismuth telluride bar in a tubular atmosphere furnace, and carrying out heat treatment in a third protective gas environment to obtain the bismuth telluride thermoelectric material. According to the method, powder metallurgy and a hot extrusion process are combined, so that precise forming and performance improvement of the high-brittleness bismuth telluride thermoelectric material are realized, and the problems of low reliability and performance degradation of a thermoelectric refrigerator are solved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

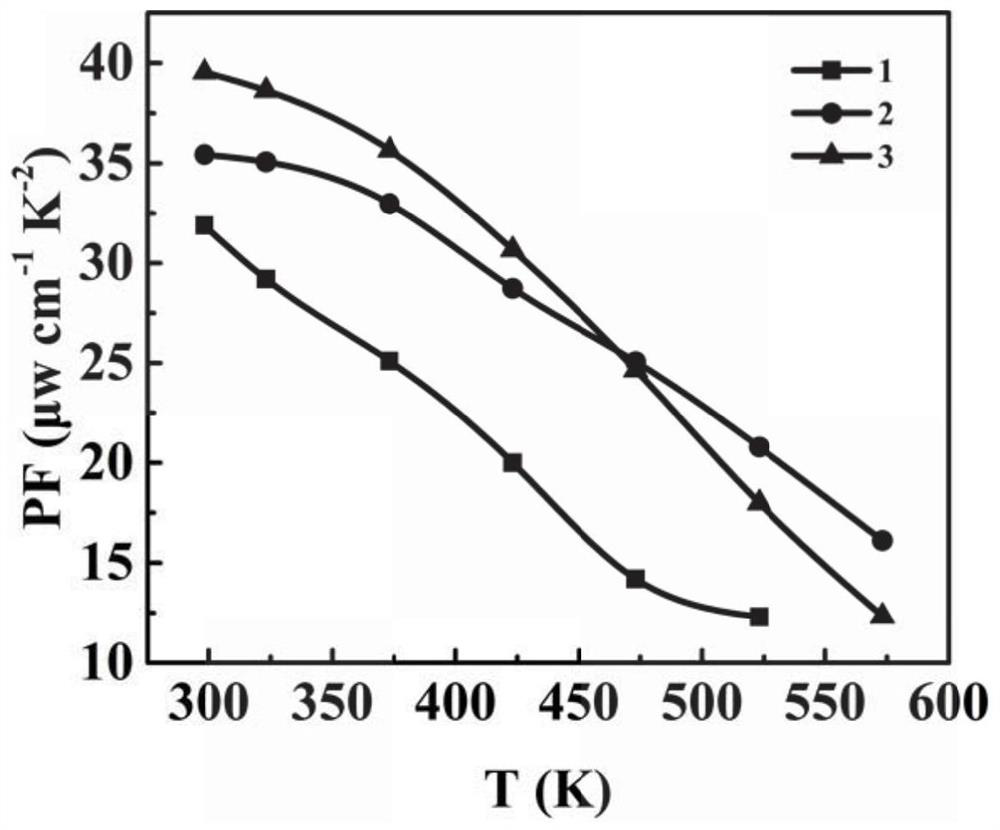

High-performance BiTe-based composite thermoelectric material and preparation method thereof

PendingCN114249304AHigh power factorHigh thermoelectric figure of meritEnergy inputSelenium/tellurium compounds with other elementsElectro conductivityAlloy

The invention discloses a high-performance BiTe-based composite thermoelectric material and a preparation method thereof. The general formula of the material is Bi < x > Sb < 2-x > Te < 3-y > SeyMz, wherein M is an alloy formed by one or more of Bi, Sb, Te and Se and one or more of I, Br, Cu, Ag, Cd, Y and Yb, or an alloy formed by one or more of I, Br, Cu, Ag, Cd, Y and Yb; x, y and z are molar molecule numbers and range from 0 to 1. The Bi2Te3-based thermoelectric material is loaded into a ball milling tank, ball milling is performed for 1-5 h under the condition of the rotating speed of 100-400 rpm, then ball milling is performed for 5-20 h under the condition of 400-800 rpm, alloyed thermoelectric material powder is obtained, the powder is cold-pressed into an alloy block by a cold press under the condition of 100-500 MPa, and then the alloy block is subjected to spark plasma sintering to form a compact block. The Bi2Te3-based thermoelectric composite material disclosed by the invention has the advantages of simple preparation method, high production efficiency, very high conductivity and power factor, low heat conductivity coefficient, good thermoelectric performance and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

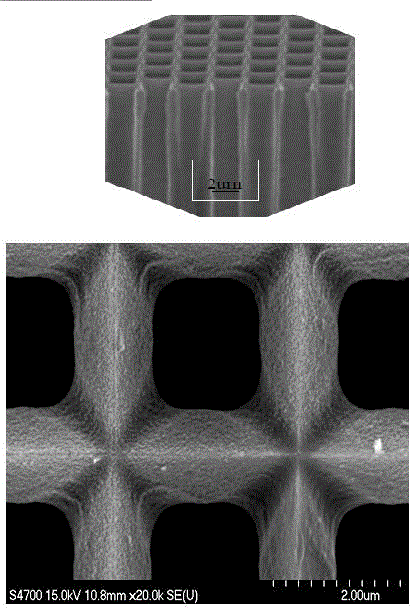

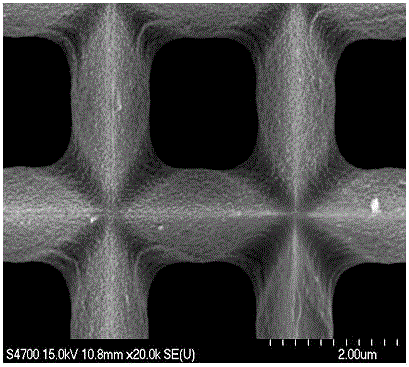

High-temperature quantum well super-lattice thick film thermoelectric material and production method thereof

InactiveCN106784287AImprove performanceHigh thermoelectric figure of meritMaterial nanotechnologyThermoelectric device manufacture/treatmentThermoelectric materialsQuantum well

The invention discloses a production method for a high-temperature quantum well super-lattice thick film thermoelectric material. The production method comprises the following steps: growing a thermoelectric material on a porous silicon, porous aluminium oxide or doped silicon substrate through an atomic layer deposition method, wherein the thermoelectric material can grow from the inner walls of pores and then grow radially layer by layer to the centres of the pores so as to generate a thick film super-lattice thermoelectric material. A base thermoelectric material is SiGe. According to the production method for the high-temperature quantum well super-lattice thick film thermoelectric material, the super-lattice thermoelectric material which is applicable to high-temperature application is synthesized quickly through a chemical method by utilizing an atomic layer deposition method and taking a porous template as a substrate, so that high merit figure and high thermoelectric conversion efficiency are realized. The high-temperature thermoelectric material can be quickly produced on a doped or curved conductive substrate under a non-vacuum condition; the thermoelectric material has set thickness and a quantum well super-lattice structure, and is particularly suitable for high temperature, that is, the using temperature range is 700 to 1,100 DEG C.

Owner:滁州玛特智能新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com