Copper sulfide based thermoelectric composite material and preparation method thereof

A composite material, copper sulfide technology, applied in copper sulfide, chemical instruments and methods, phosphorus compounds of phosphorus sulfur/selenium/tellurium, etc., can solve problems such as poor thermoelectric performance, achieve good thermoelectric performance, optimize Seebeck coefficient, The effect of increasing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

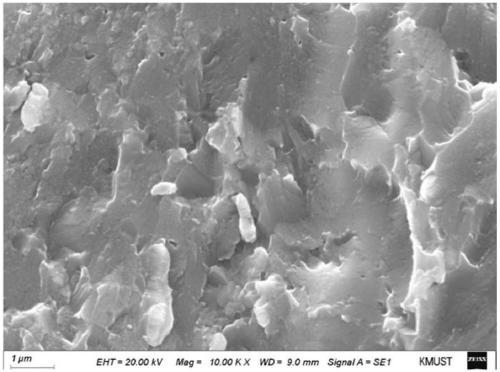

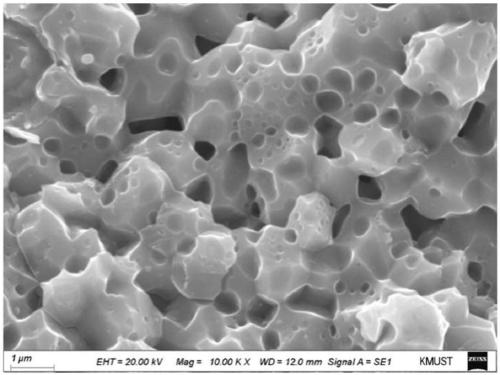

Image

Examples

preparation example Construction

[0058] A preparation method of copper sulfide-based thermoelectric composite material, comprising the following steps:

[0059] Step (1) powder preparation:

[0060] Weigh CuSn with a purity greater than 99.5% 5 3.65g of alloy powder, 1.00g of elemental S powder with a purity greater than 99.9%, and CuSn 5 Put the alloy powder and elemental S powder into the vacuum ball milling tank, and adjust the speed of the vacuum ball milling tank to 300-450rpm. In this embodiment, the speed of the vacuum ball milling tank is 430rpm. 3h, get Cu 1.75 sn 0.05 S powder; protective atmosphere is 5% H 2 +95%N 2 , the spheres in the ball mill tank are stainless steel spheres, and there are two diameters of the spheres, 6mm and 10mm respectively, the total weight of the spheres with the two diameters is equal, CuSn 5 The weight ratio of the total weight of the alloy powder and the S powder to the weight of the sphere is 1:20-50, and the ratio in this embodiment is 1:20.

[0061] Step (2) ...

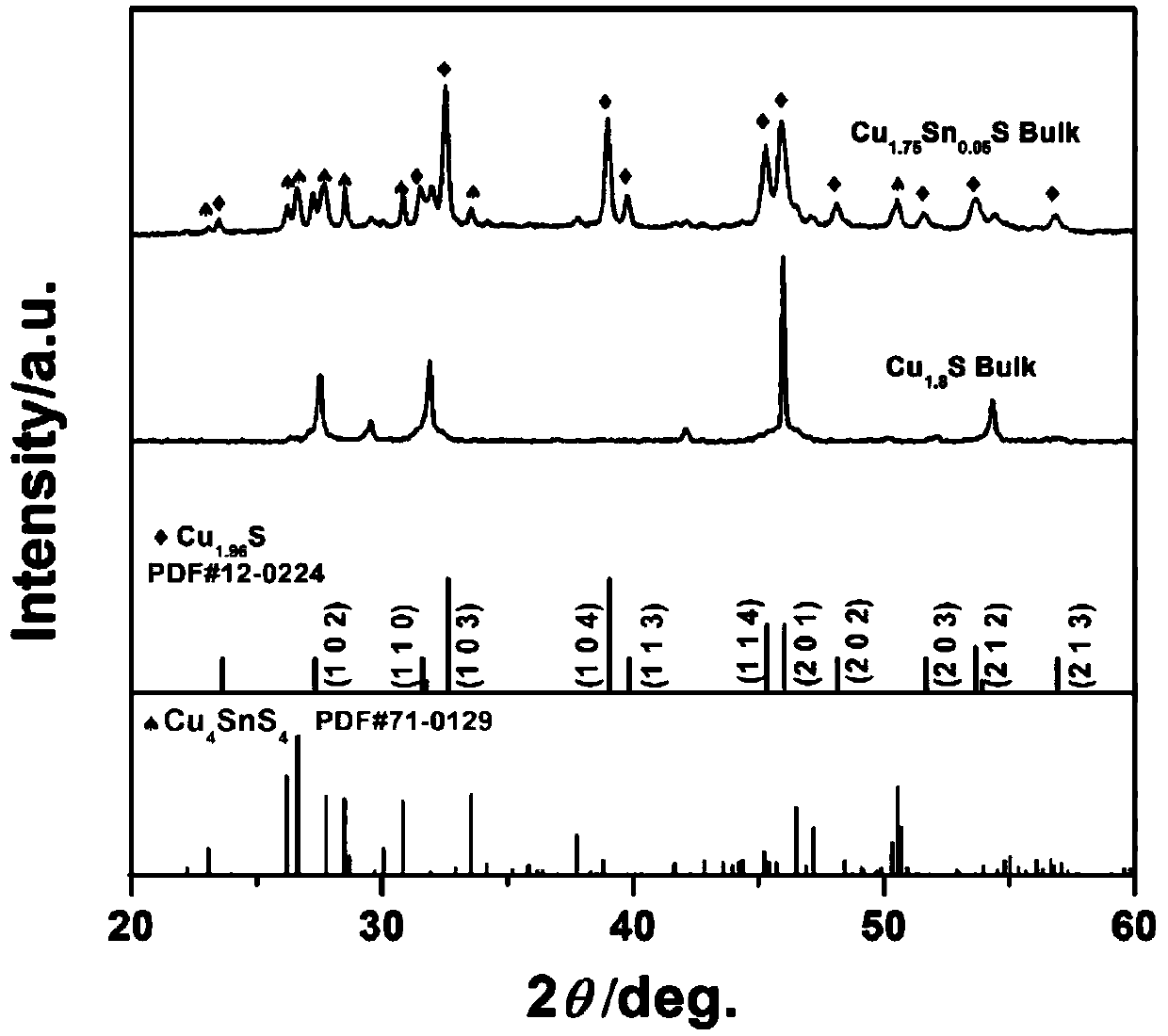

Embodiment 2

[0063] The difference between Examples 2-4 and Example 1 lies in that the parameters shown in Table 1 are different, and the thermoelectric composite material finally formed is different through detection. The thermoelectric composite material that embodiment 2 forms is Cu 1.65 sn 0.15 S, the second phase is Cu 4 SnS 4 , and is an orthogonal structure; the thermoelectric composite material formed in Example 3 is Cu 1.5 mn 0.25 Ni 0.05 S, the second phase is MnS, and has a monoclinic structure, and also includes a CuMnNi phase; the thermoelectric composite material formed in Example 4 is Cu 1.5 P 0.3 S, the second phase is CuP 2 , and a monoclinic structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com