Patents

Literature

400results about How to "Improve the scattering effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

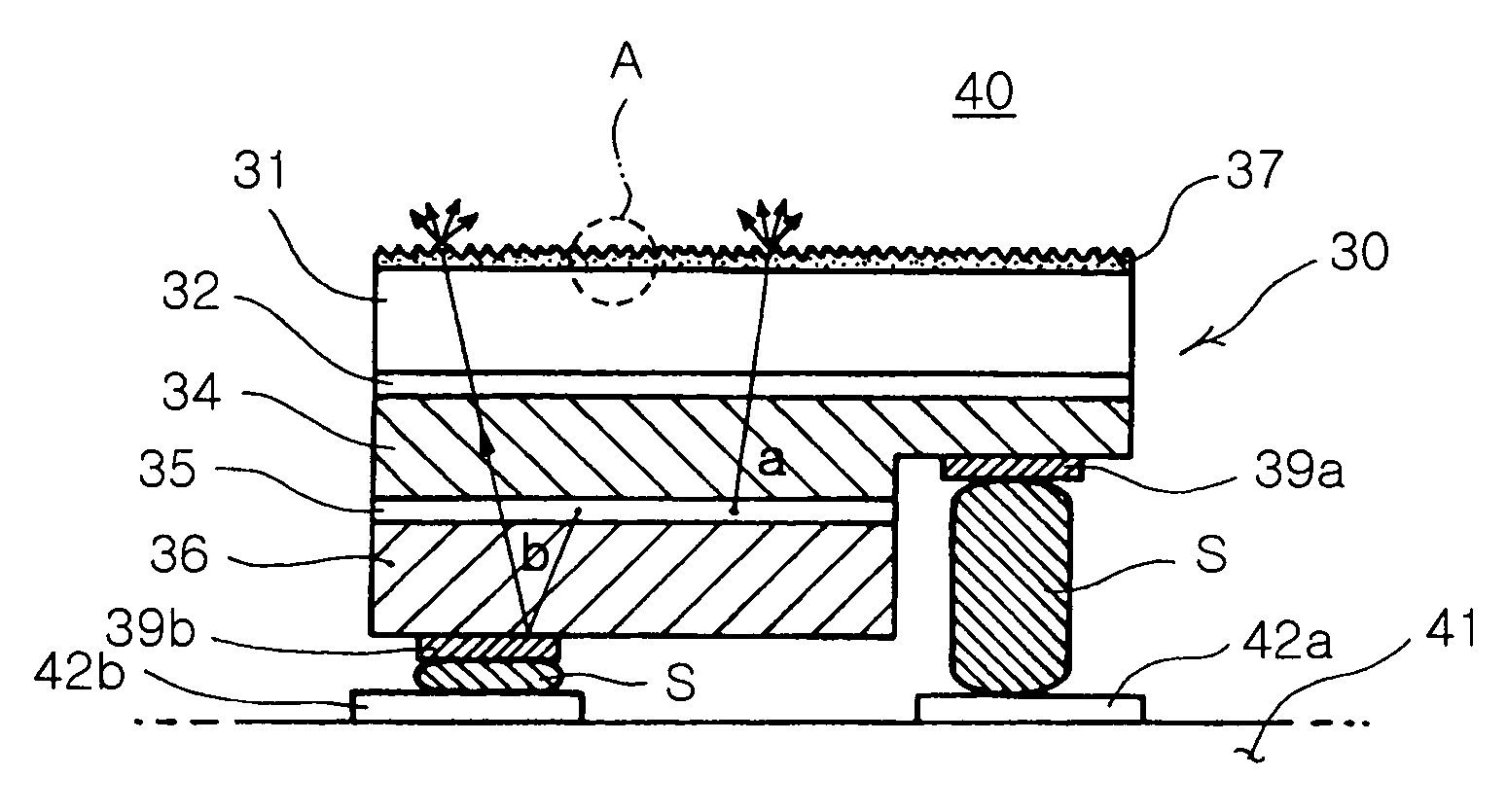

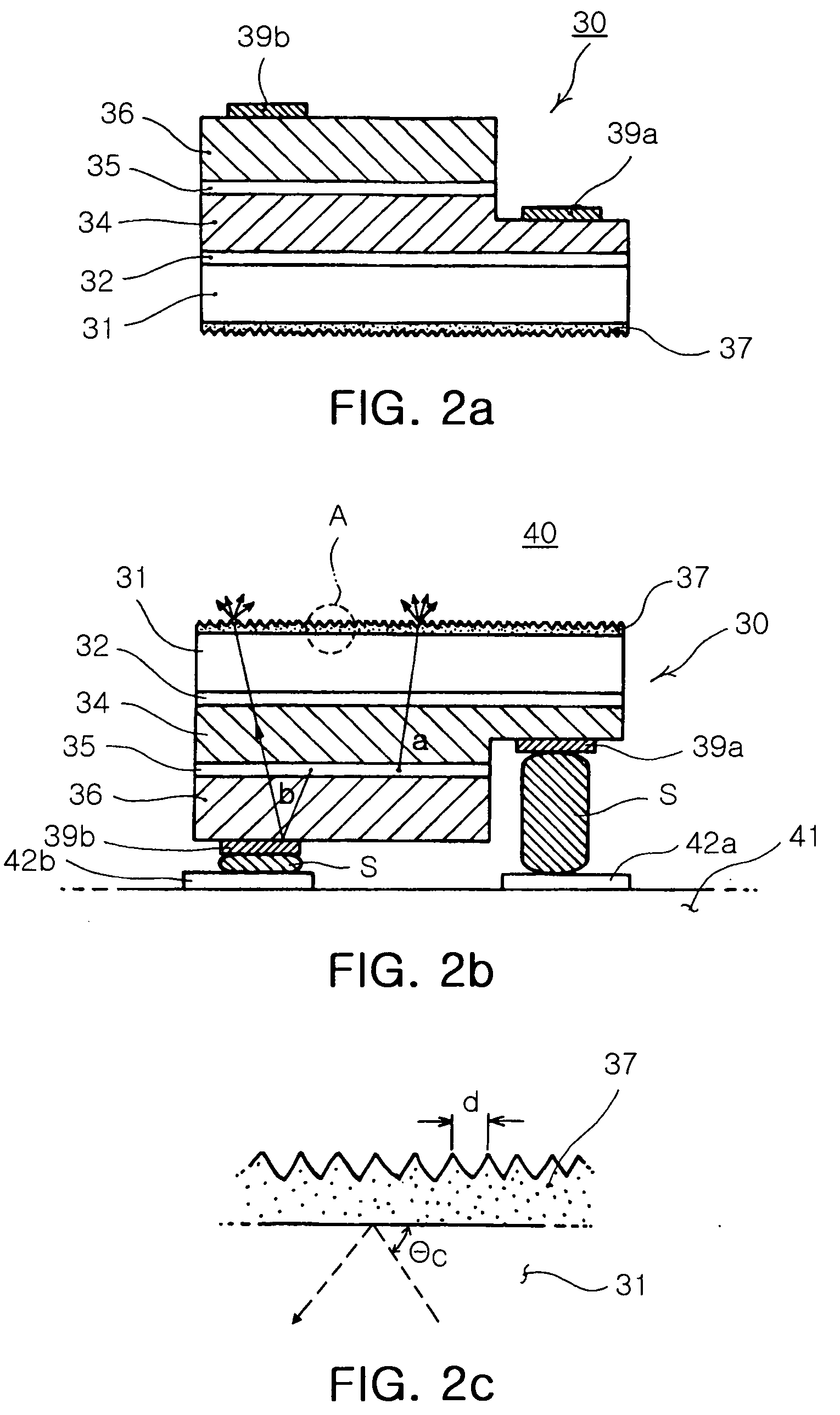

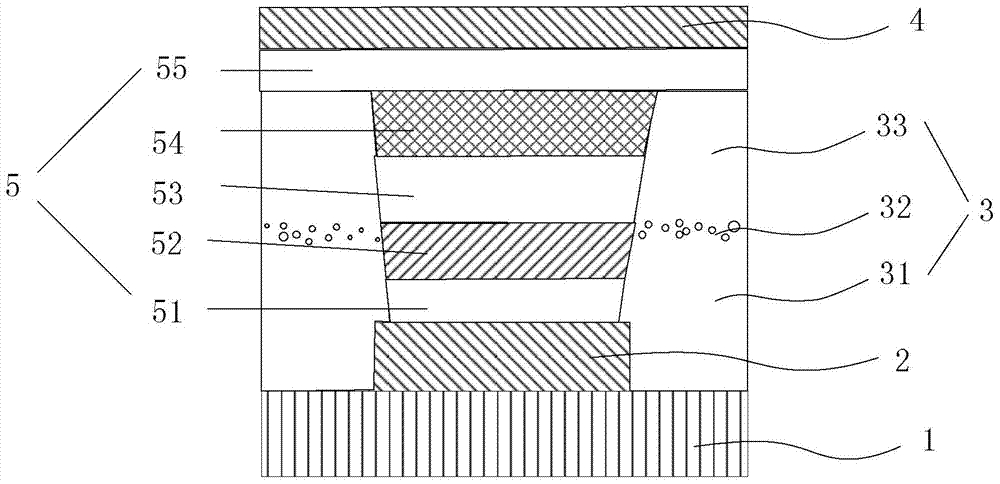

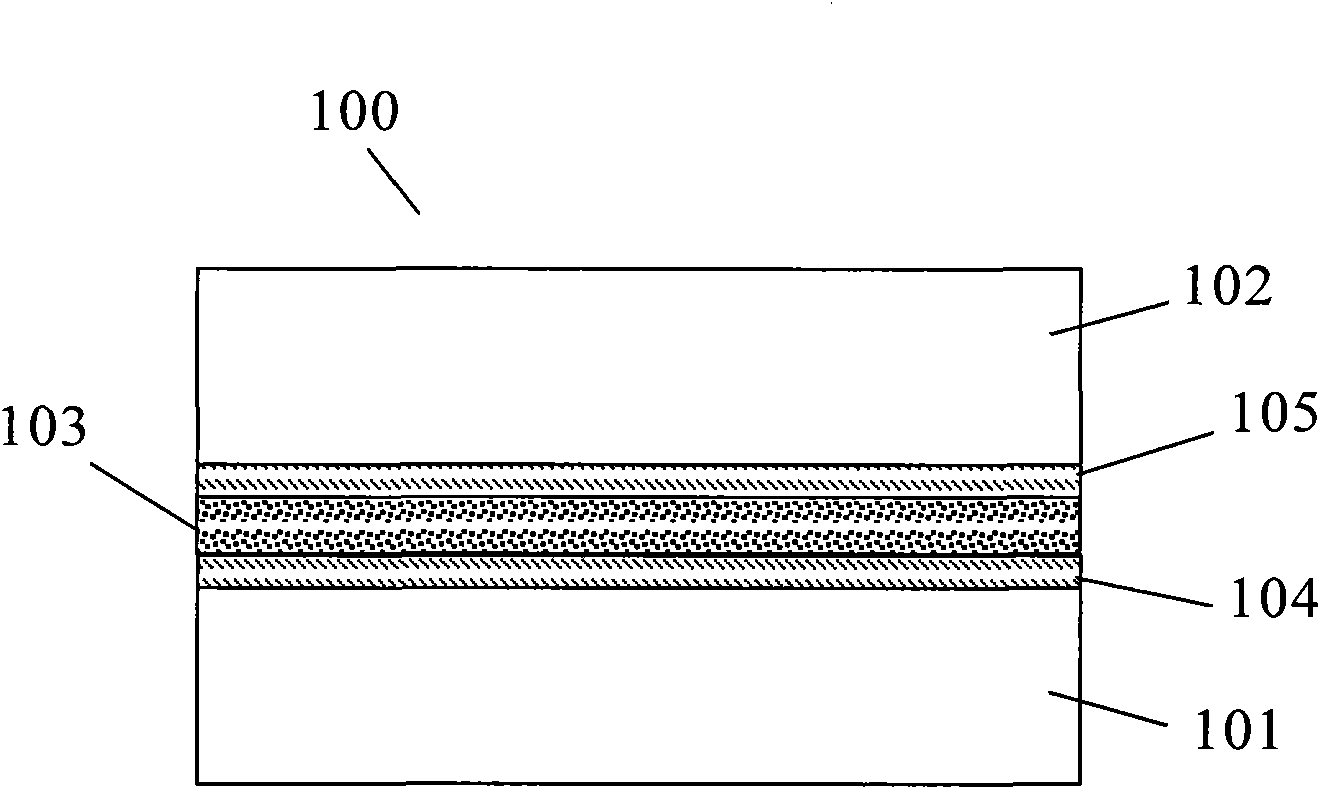

Nitride based semiconductor light emitting device

InactiveUS20060145170A1Light extraction efficiency can be improvedImprove the scattering effectSlide valveValve housingsActive layerLight emitting device

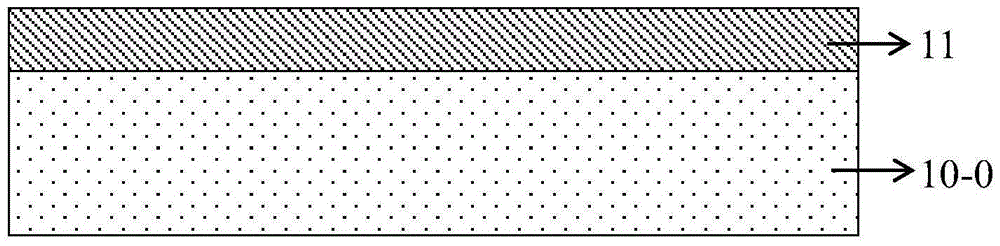

The present invention provides a nitride-based semiconductor light emitting device basically comprising a first conductivity type nitride semiconductor layer, active layer and second conductivity type nitride semiconductor layer, which are sequentially formed on a light-permeable substrate in this order. The light emitting device further comprises an insulating light-scattering layer formed on at least one surface thereof. The insulating light-scattering layer is made of an insulating material having a light permeability of more than 50% and is formed at an outer surface thereof with a roughened pattern for the scattering of light.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

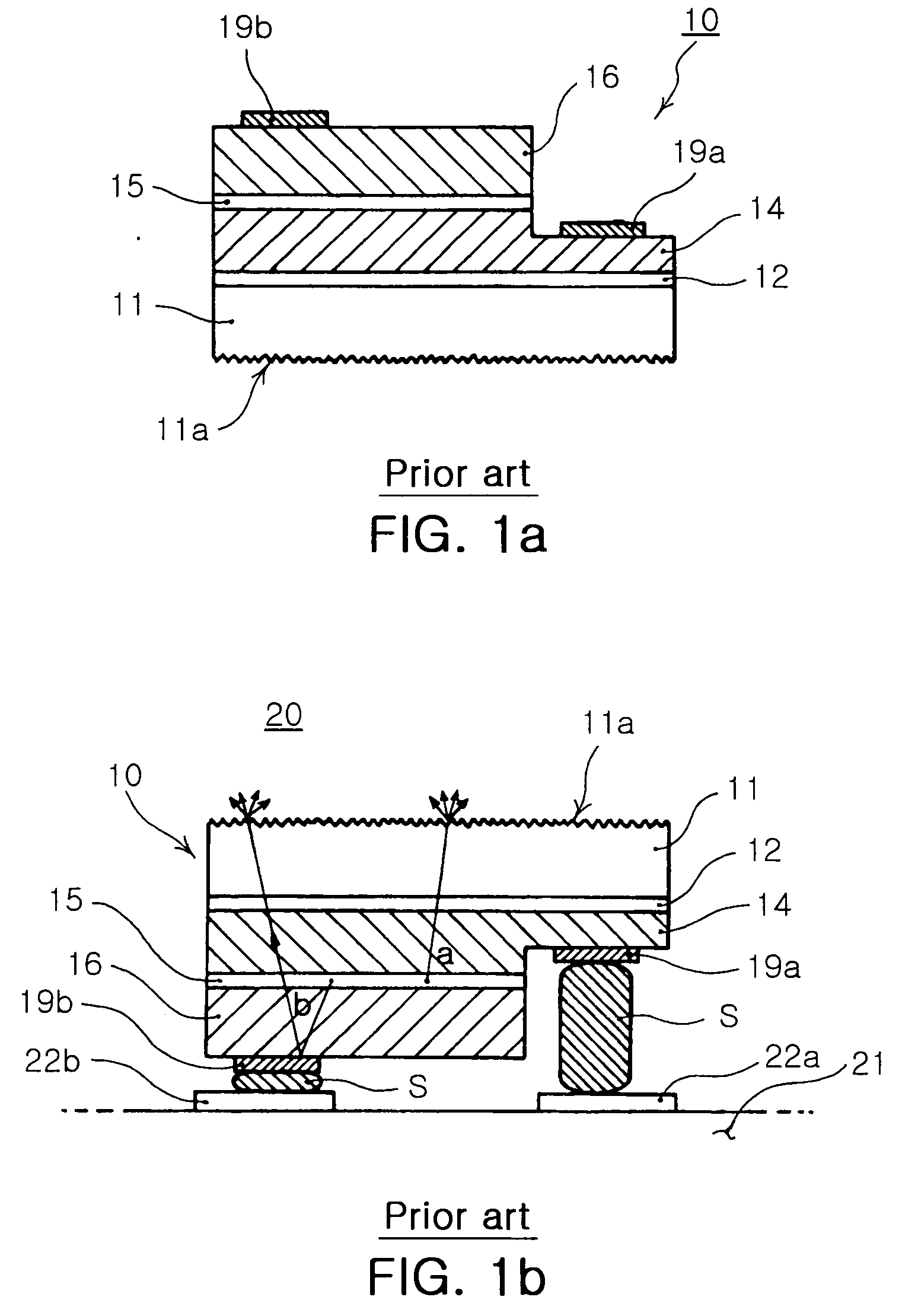

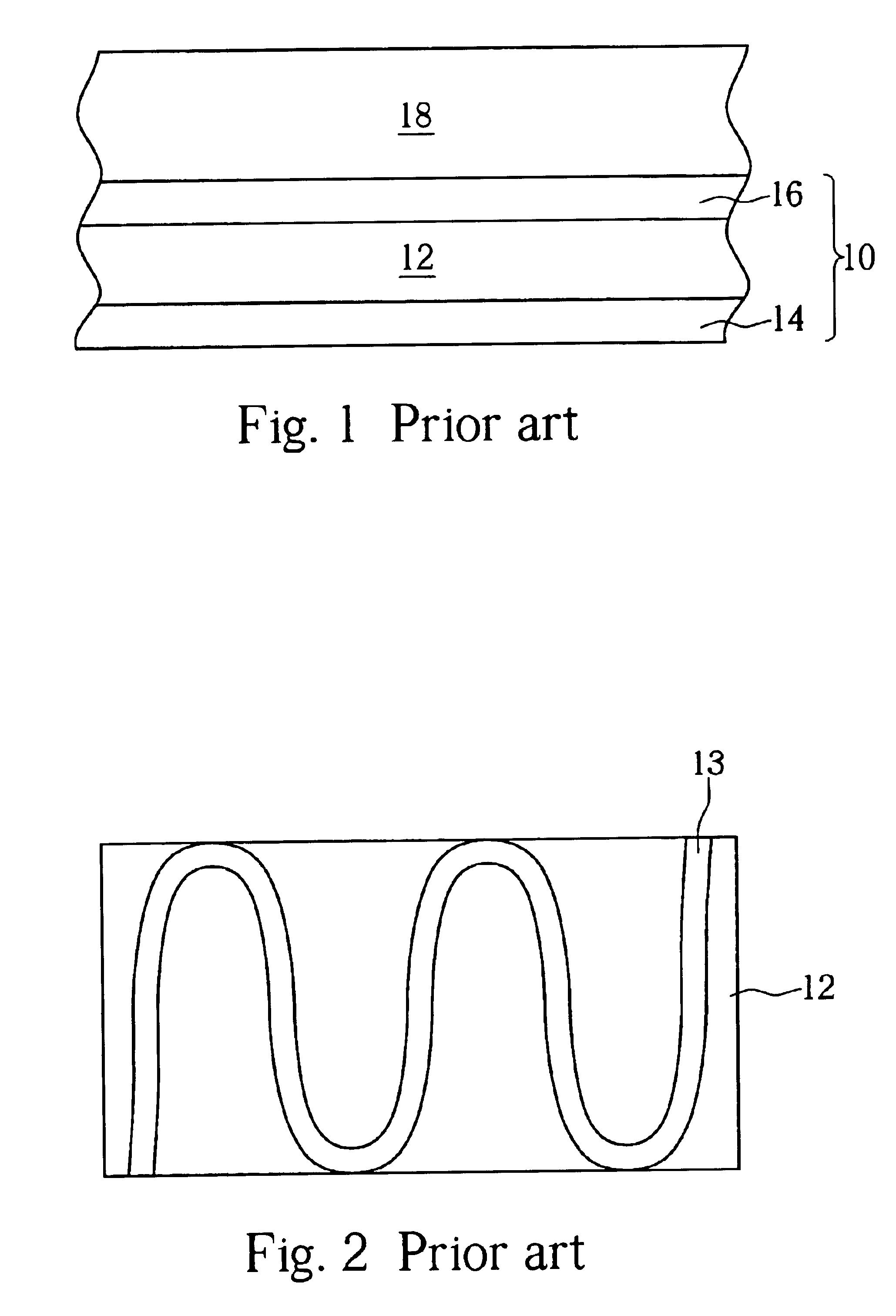

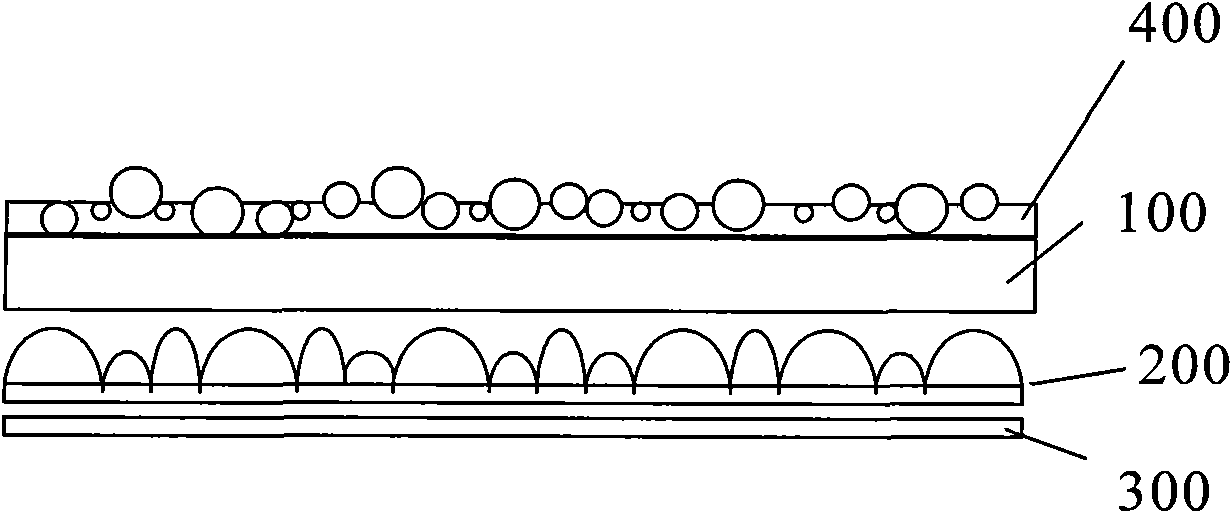

Back light unit including a diffuser with various diffusion effects

InactiveUS6861789B2Improve the scattering effectImprove uniformityStatic indicating devicesIncadescent envelopes/vesselsDiffusionScattering effect

A backlight unit is disposed beneath a display panel. The backlight unit includes an illumination means, which is used to provide a light source, and a diffuser positioned between the illumination means and the display panel, which is used to scatter the light generated by the illumination means. The diffuser, which is composed of liquid crystal particles and polymer, has a plurality of regions. The region thatis closer to the illumination means has greater scattering effect. In addition, the region with the greatest scattering effect has a shape corresponding to the illumination means.

Owner:INNOLUX CORP

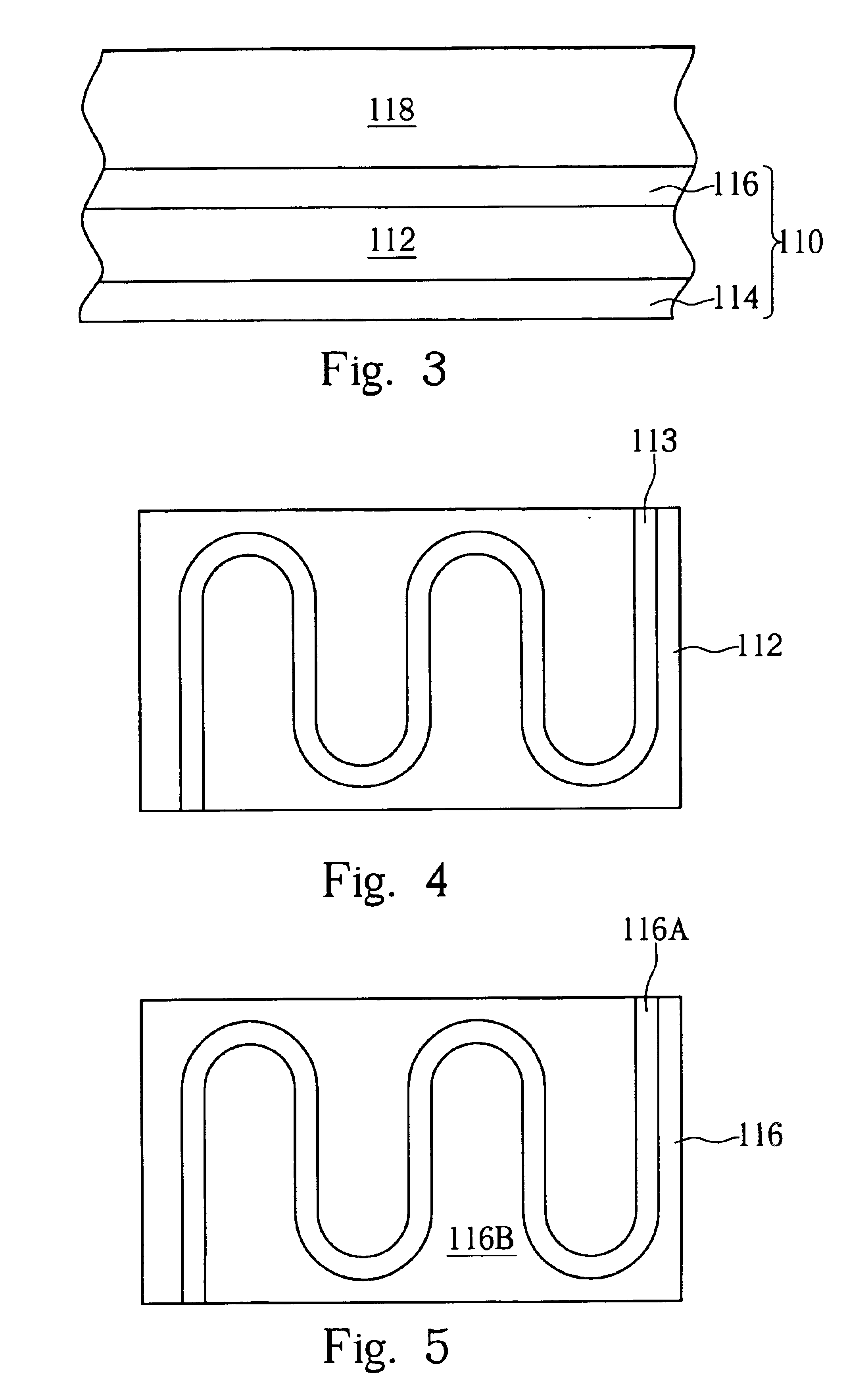

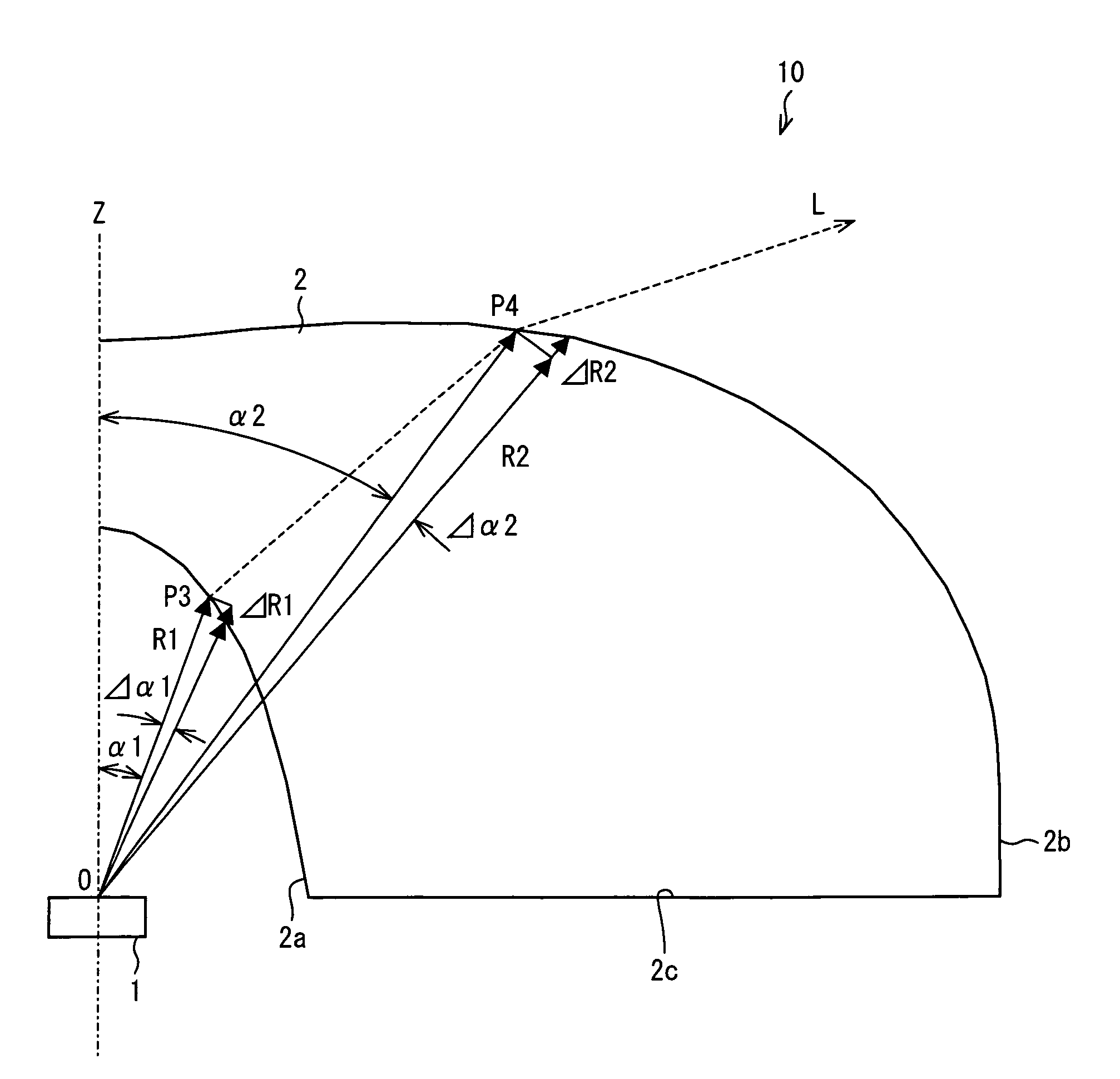

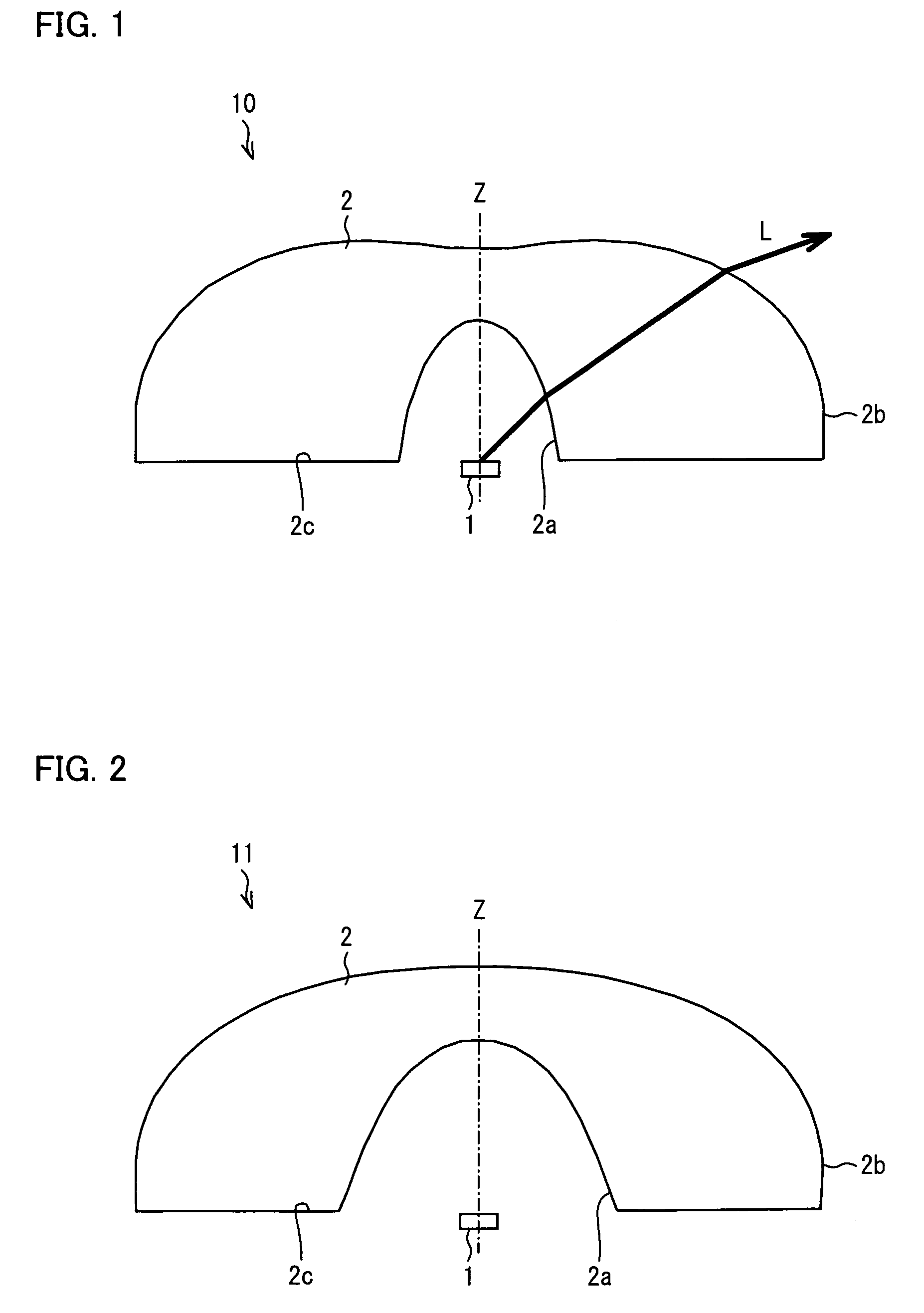

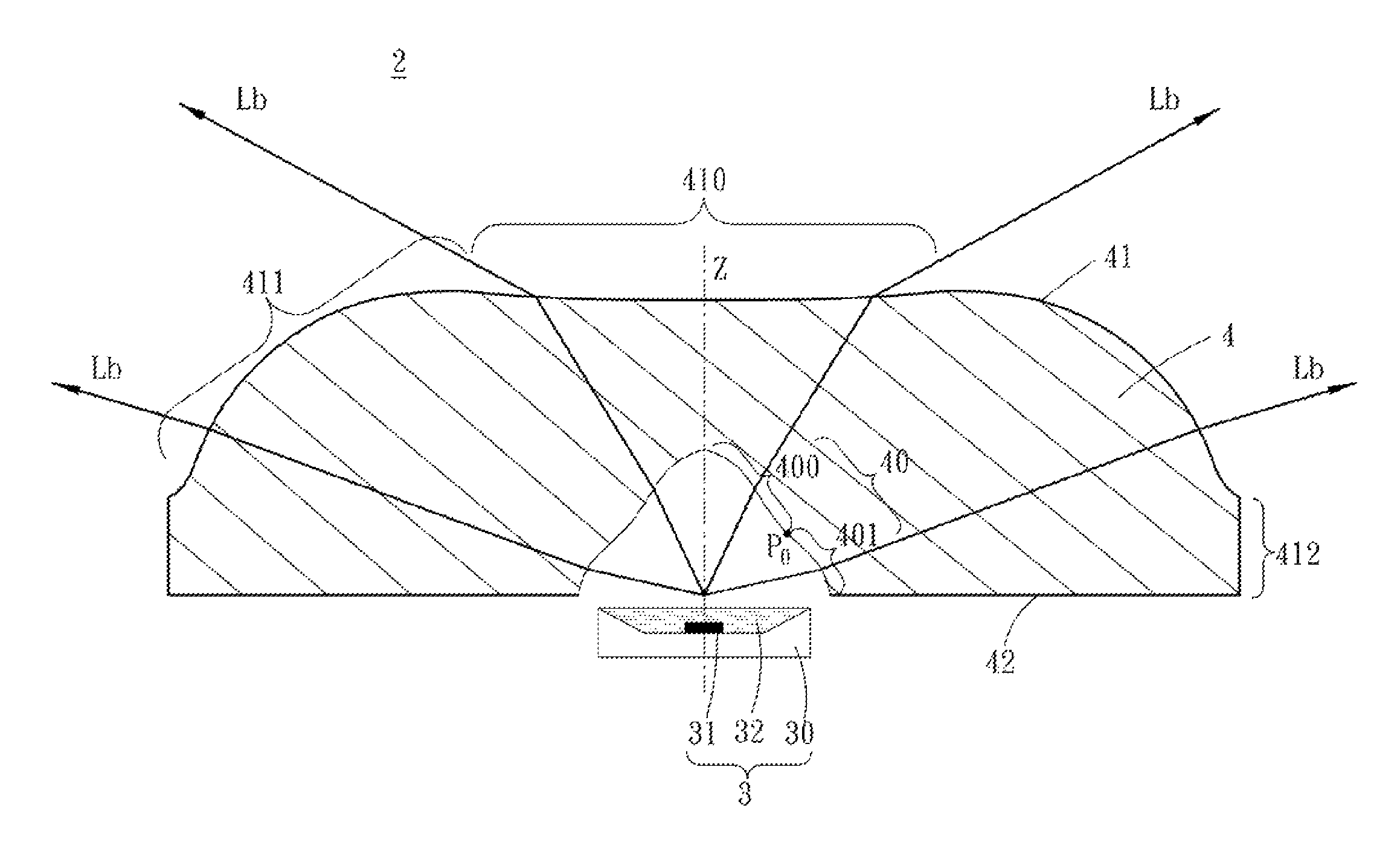

Light emitting device and lighting device having the same

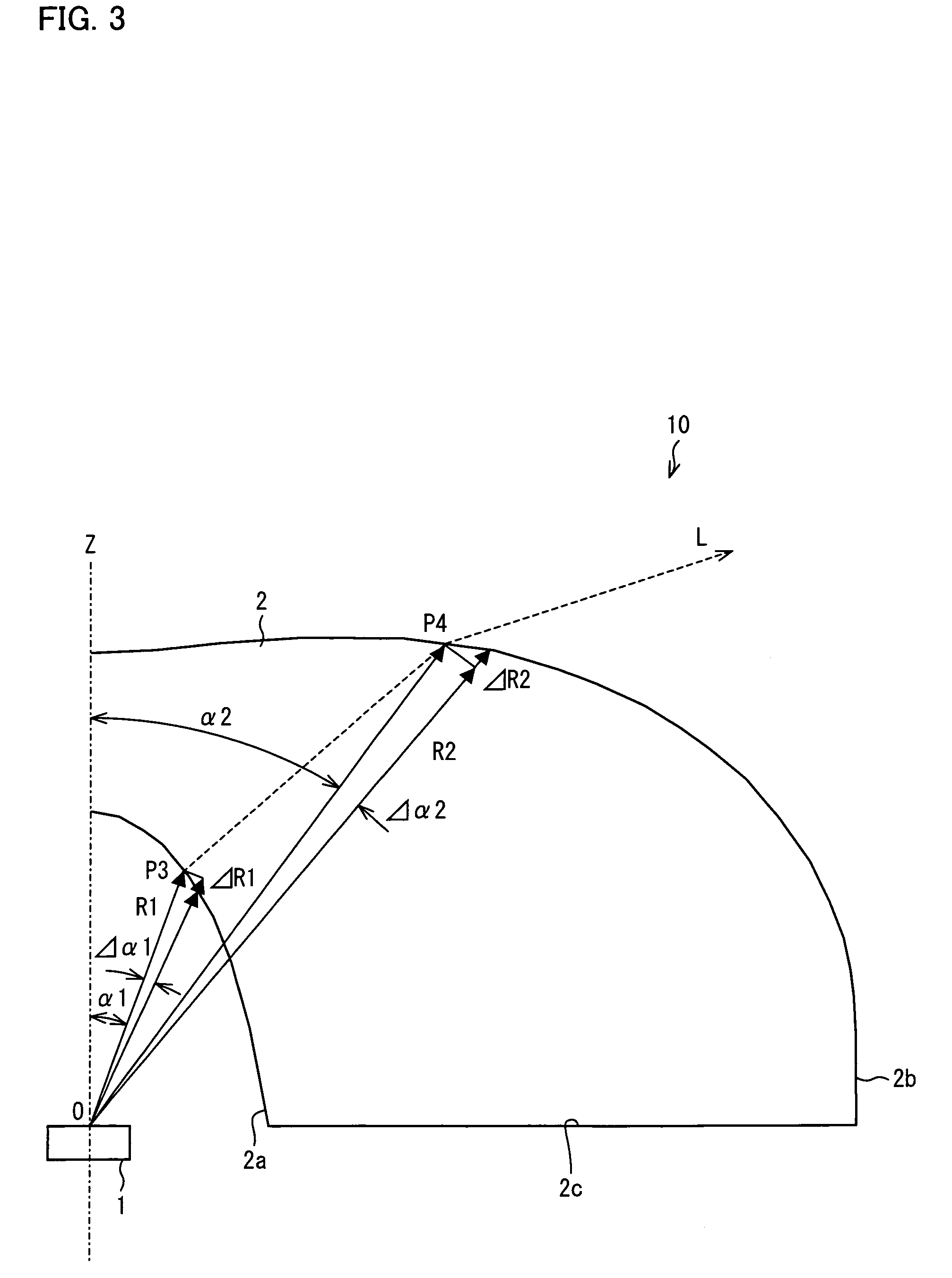

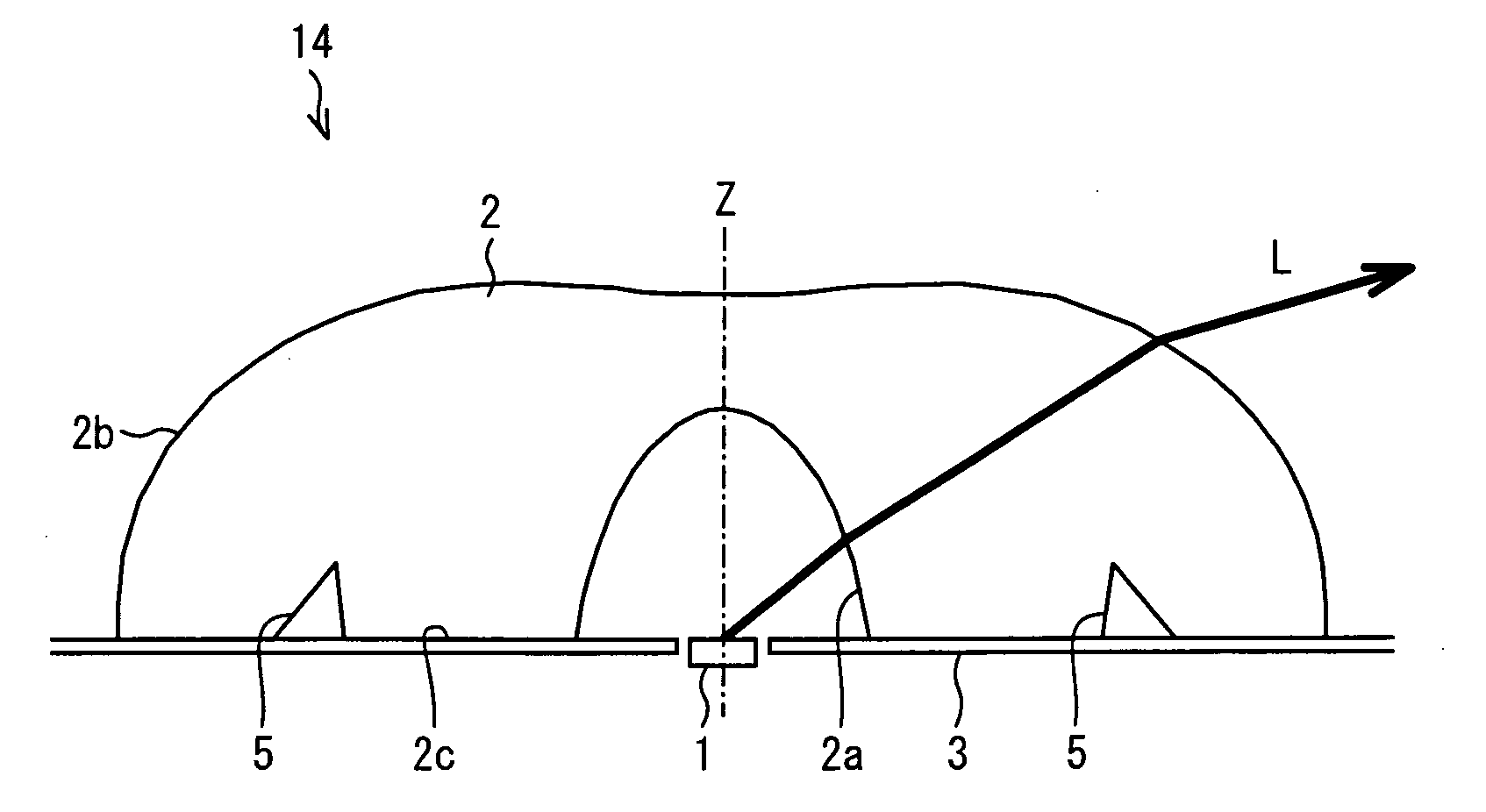

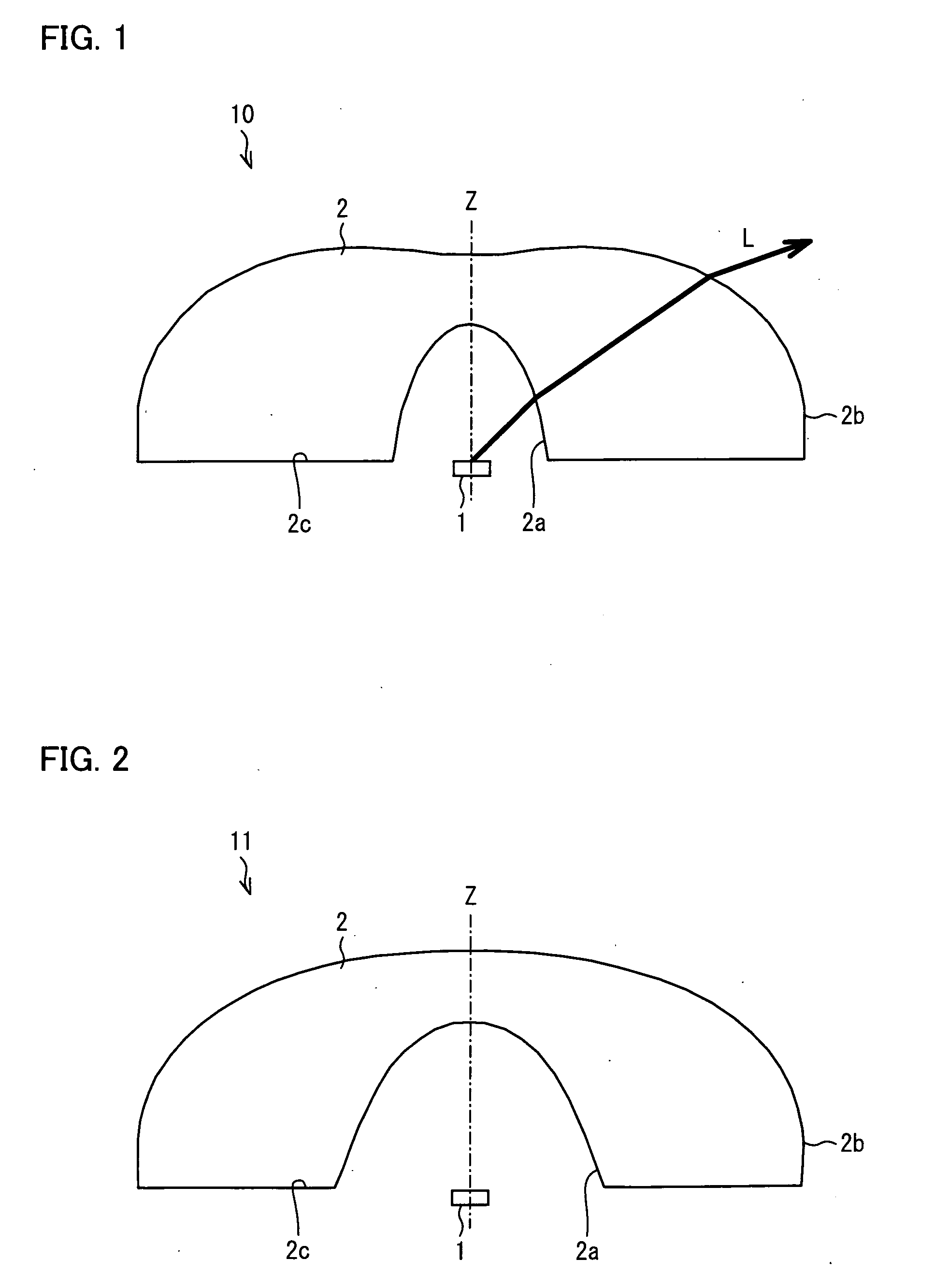

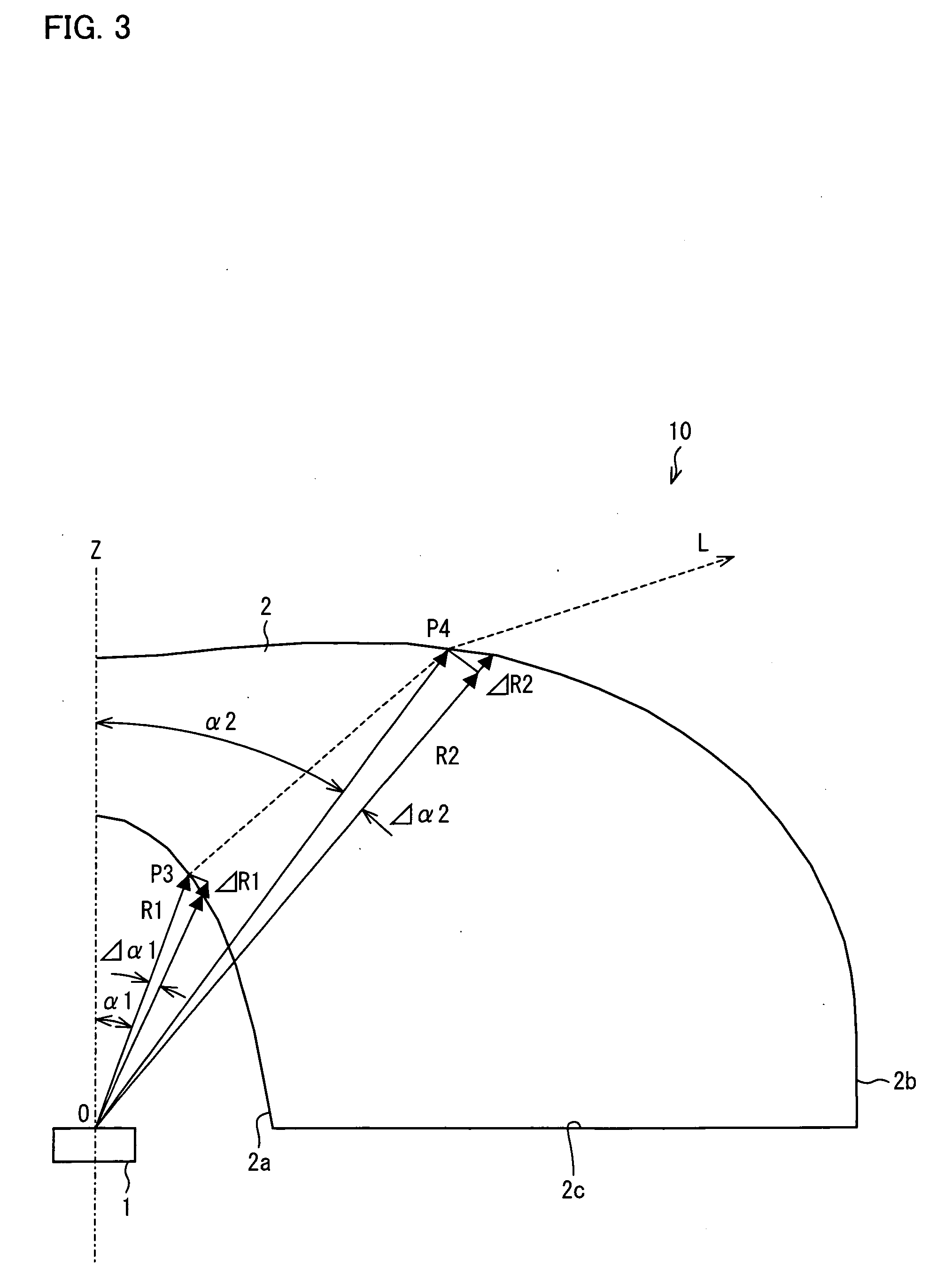

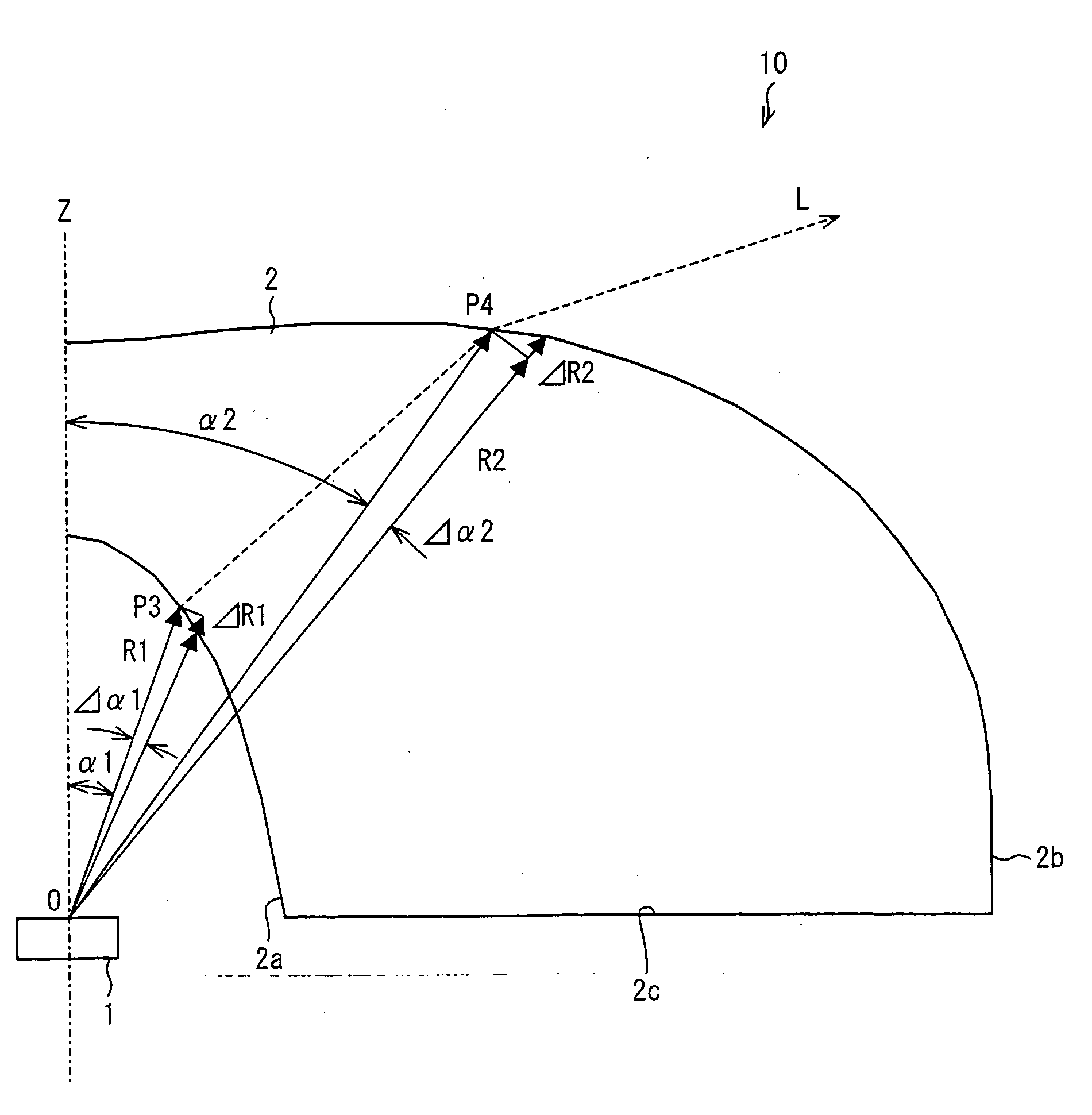

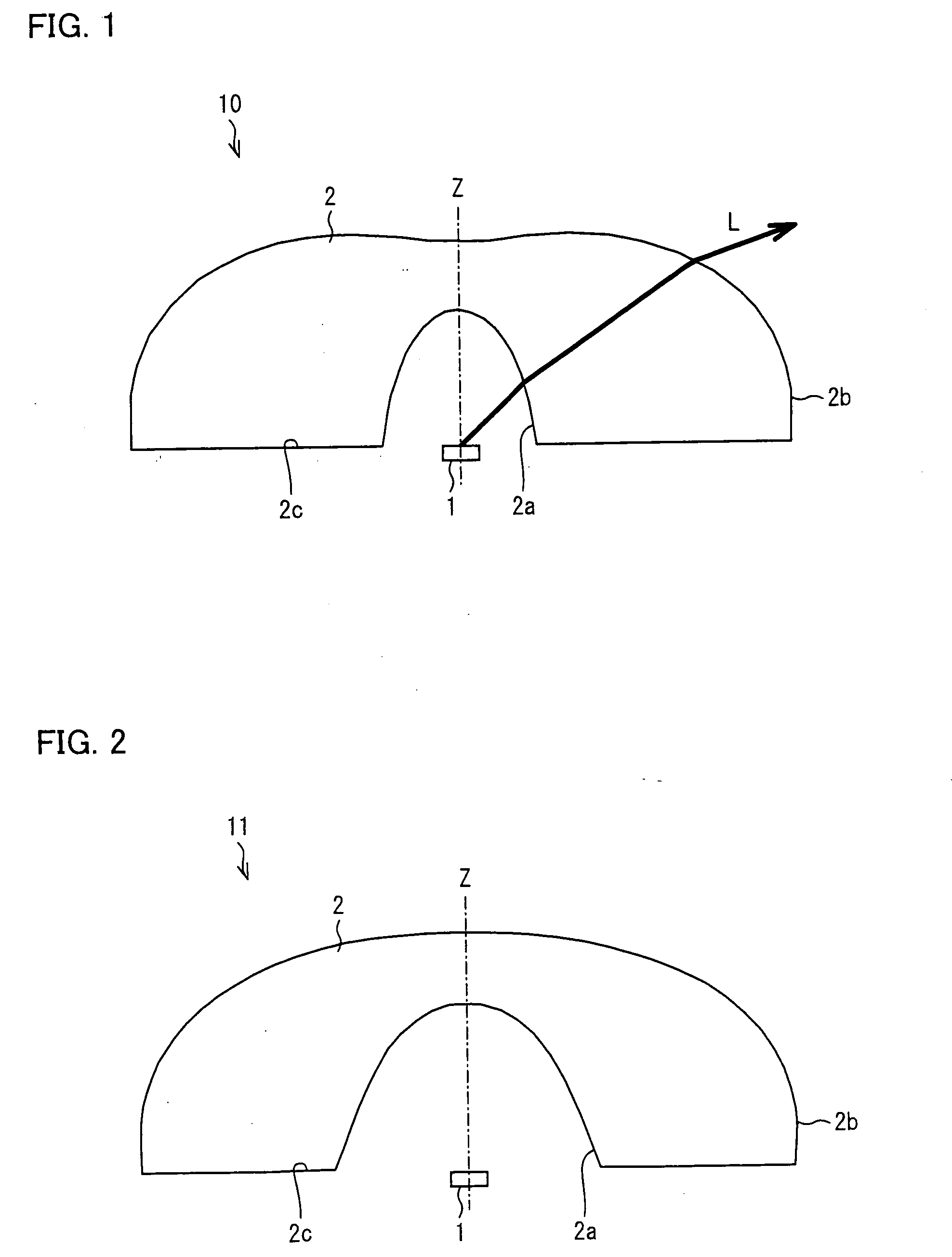

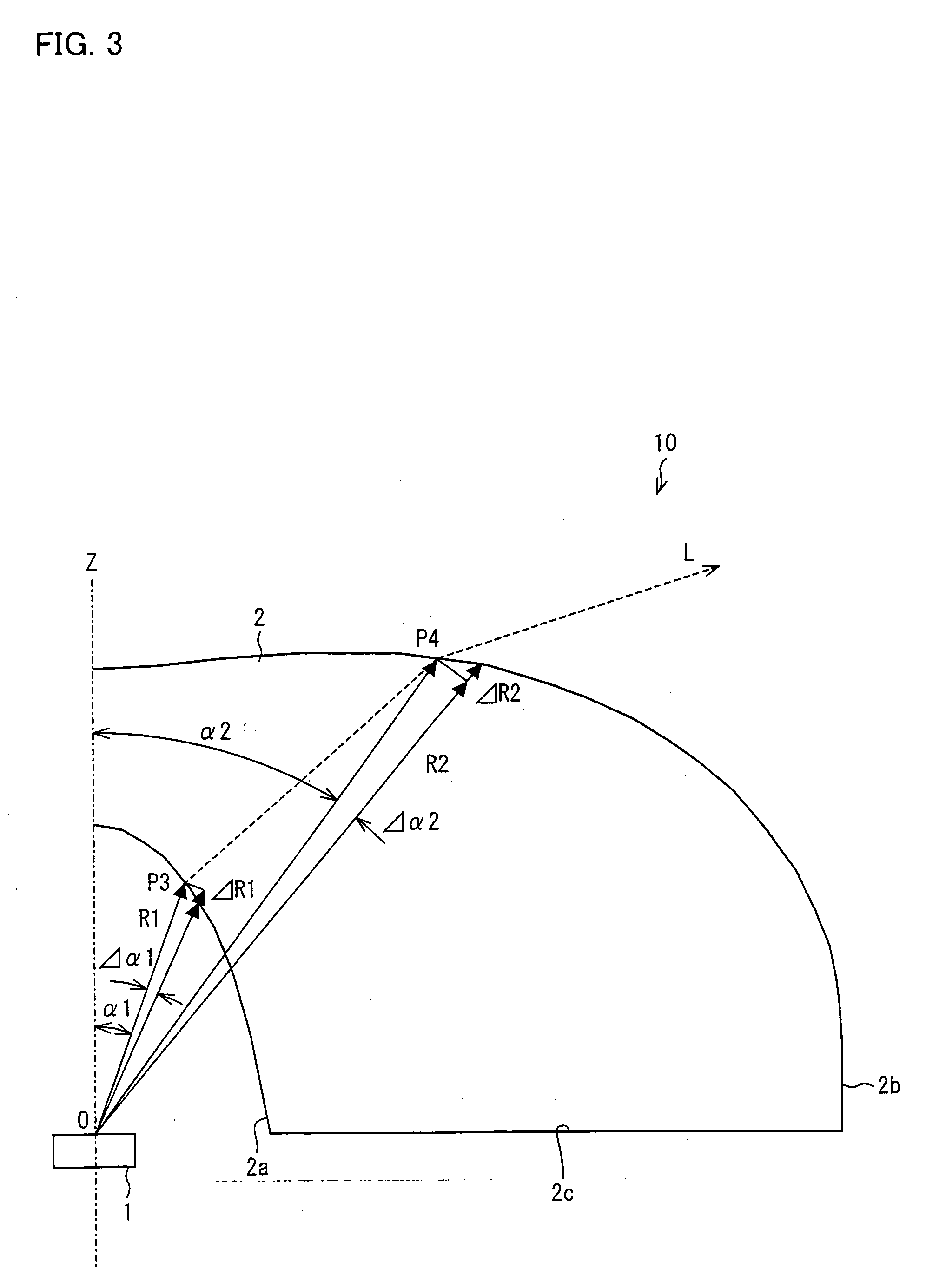

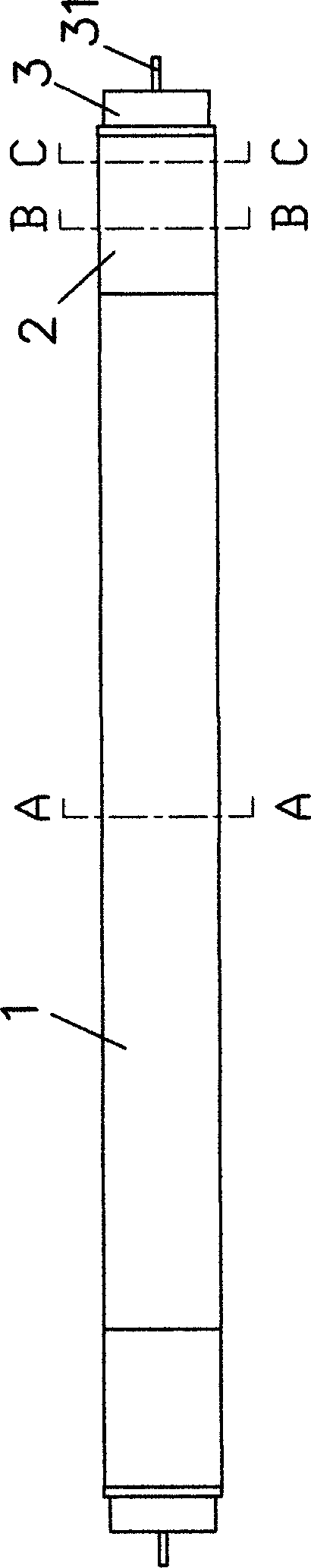

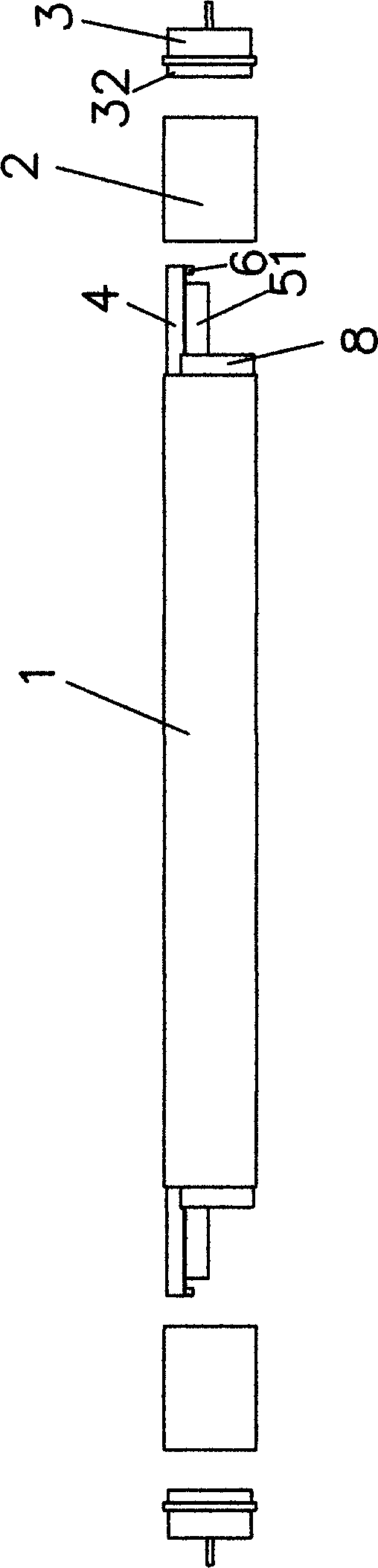

ActiveUS7798679B2Improve the scattering effectMechanical apparatusPoint-like light sourceLiquid-crystal displayLight flux

A light-emitting device (10) is arranged such that (x) R1 monotonically decreasing as α1 increases, at least in a range of α1<π / 3, where an intersection of a light axis Z and an emission surface of a light-emitting element (1) is a reference point; α1 is an angle between the light axis Z and a straight line that passes through the reference point and an arbitrary point on a light-incoming surface (2a), and R1 is a distance between the reference point and the arbitrary point on the light-incoming surface (2a); (y) R2 monotonically increasing as α2 increases, at least in a range of α2<π / 3, where α2 is an angle between the light axis Z and a straight line that passes through the reference point and an arbitrary point on a light-outgoing surface (2b), and R2 is a distance between the reference point and the arbitrary point on the light-outgoing surface (2b); and (z) A2 scatters light without generating uneven brightness on a liquid crystal display panel and has higher scattering ability that is obtained by decreasing a reflectance caused by the Fresnel reflection, where n is a refraction index of a material forming a light flux controlling member (2), and A2=ΔR2 / (R2Δα2), where ΔR2 is an increment of R2 and Δα2 is an increment of α2.

Owner:SHARP KK +1

Light emitting device and lighting device having the same

ActiveUS20090052192A1Improve the scattering effectMechanical apparatusPoint-like light sourceLiquid-crystal displayLight flux

A light-emitting device (10) is arranged such that (x) R1 monotonically decreasing as α1 increases, at least in a range of α1<π / 3, where an intersection of a light axis Z and an emission surface of a light-emitting element (1) is a reference point; α1 is an angle between the light axis Z and a straight line that passes through the reference point and an arbitrary point on a light-incoming surface (2a), and R1 is a distance between the reference point and the arbitrary point on the light-incoming surface (2a); (y) R2 monotonically increasing as α2 increases, at least in a range of α2<π / 3, where α2 is an angle between the light axis Z and a straight line that passes through the reference point and an arbitrary point on a light-outgoing surface (2b), and R2 is a distance between the reference point and the arbitrary point on the light-outgoing surface (2b); and (z) A2 scatters light without generating uneven brightness on a liquid crystal display panel and has higher scattering ability that is obtained by decreasing a reflectance caused by the Fresnel reflection, where n is a refraction index of a material forming a light flux controlling member (2), and A2=ΔR2 / (R2Δα2), where ΔR2 is an increment of R2 and Δα2 is an increment of α2.

Owner:SHARP KK +1

Light emitting device and lighting device having the same

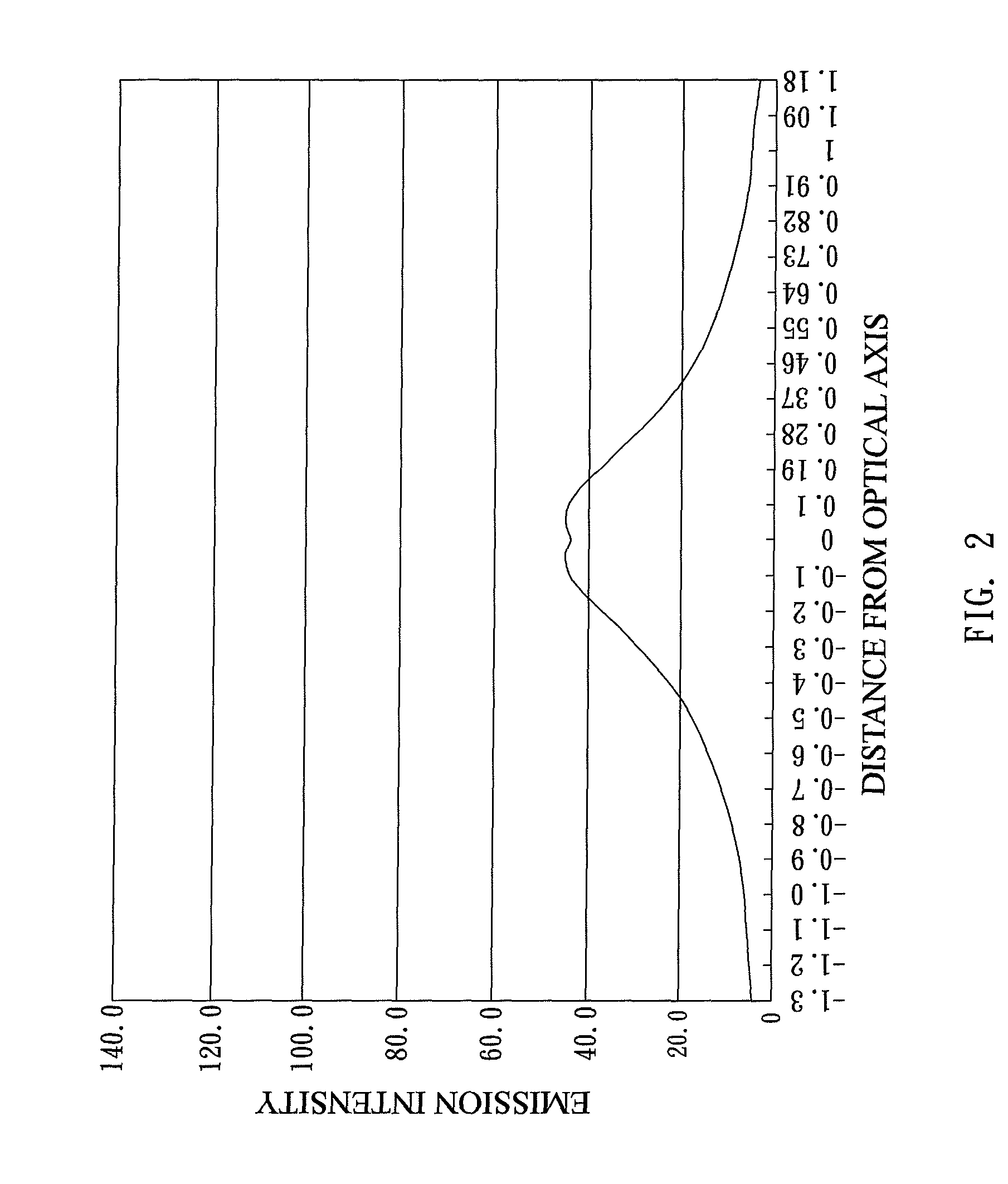

ActiveUS20100135028A1Avoid uneven brightnessImprove the scattering effectPoint-like light sourceDiffusing elementsLiquid-crystal displayOptical axis

A light-emitting device (10) includes: a light-emitting element (1); and a light flux controlling member (2) for controlling light emitted from the light-emitting element (1), the light flux controlling member (2) has (i) a light-incoming surface (2a) which the light emitted from the light-emitting element (1) enters and (ii) a light-outgoing surface (2b), and the following equation (1) is satisfied where r is a length, from a light axis Z of the light-emitting device (10), of a plane that is provided at a certain distance from the light flux controlling member (2) in a direction parallel to the light axis Z so as to be perpendicular to the light axis Z, φ1 is an angle between the light emitted from the light-emitting element (1) and the light axis, P(φ1) is a light distribution property of the light-emitting element (1). This provides a light-emitting device that scatters light without generating uneven brightness on a liquid crystal display panel, reduces a reflectance caused by the Fresnel's reflection, and has an improved scattering ability.

Owner:ENPLAS CORP

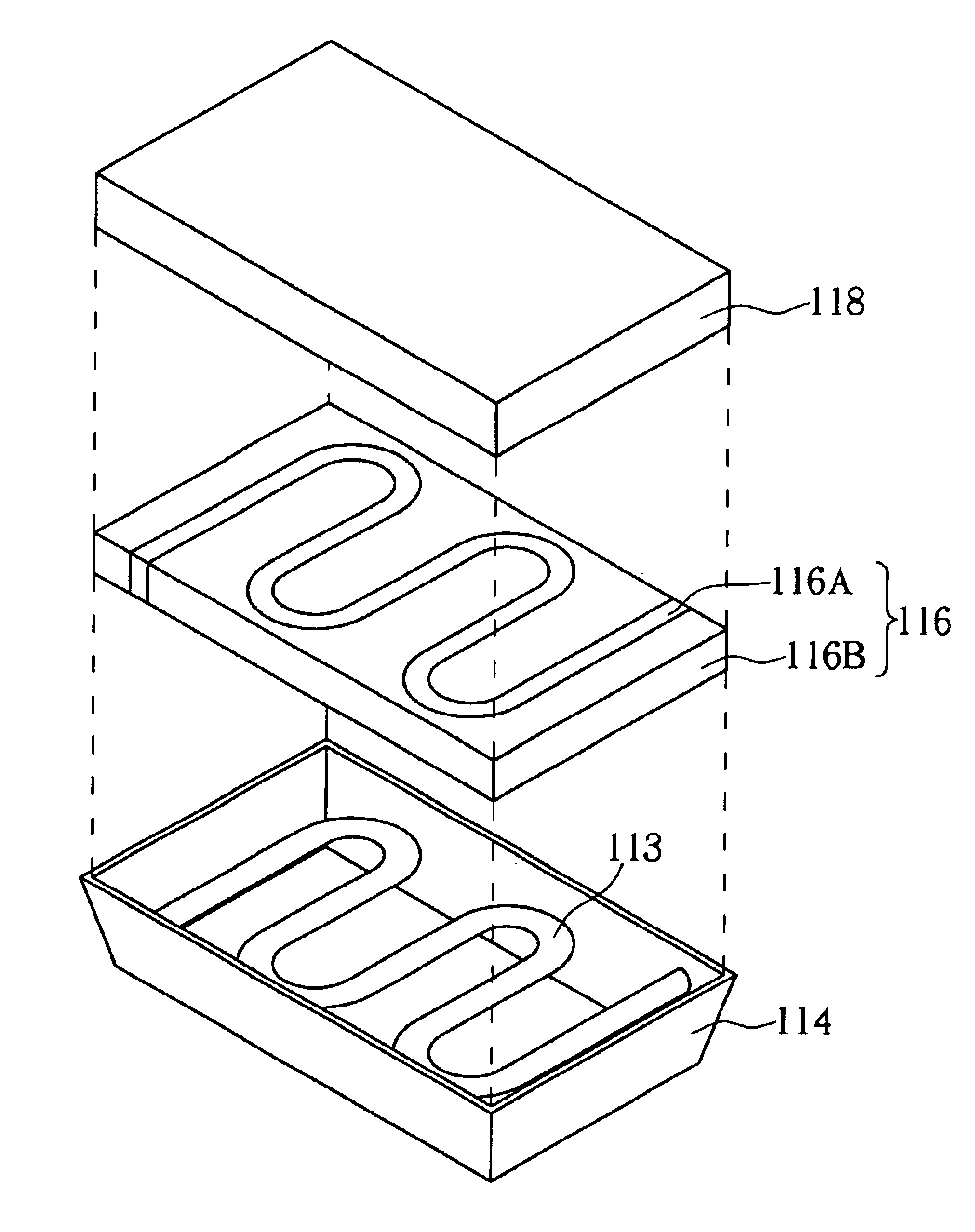

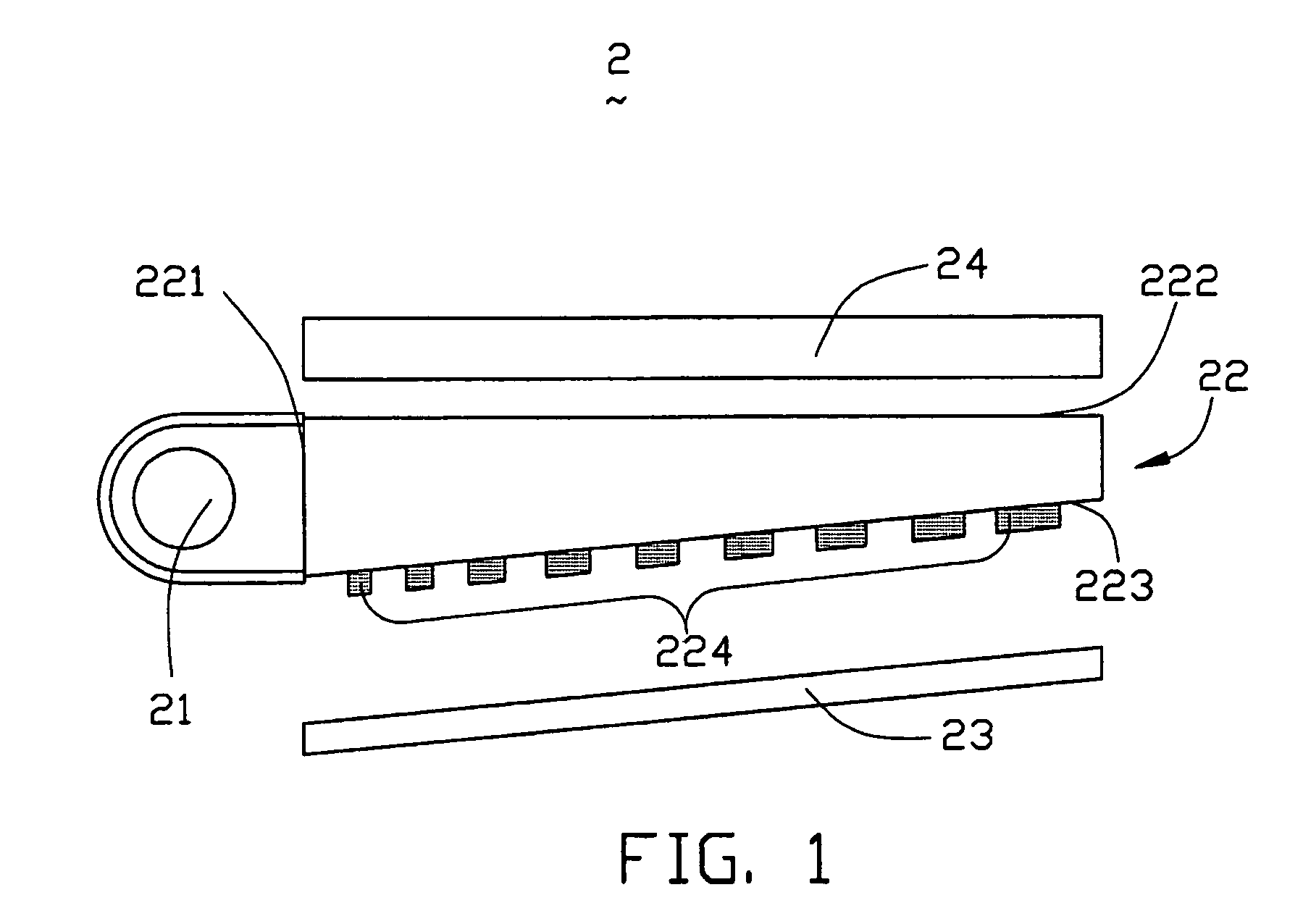

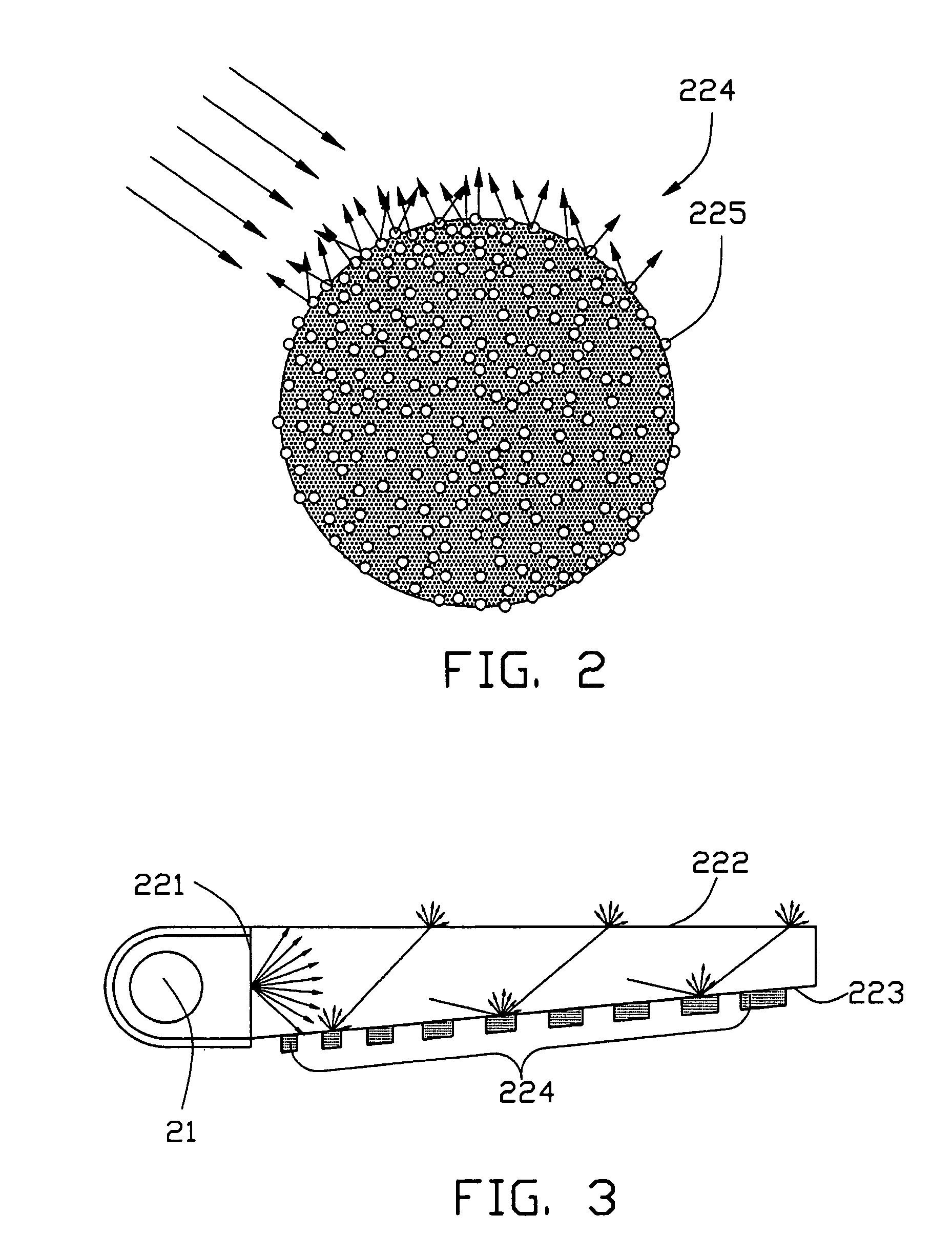

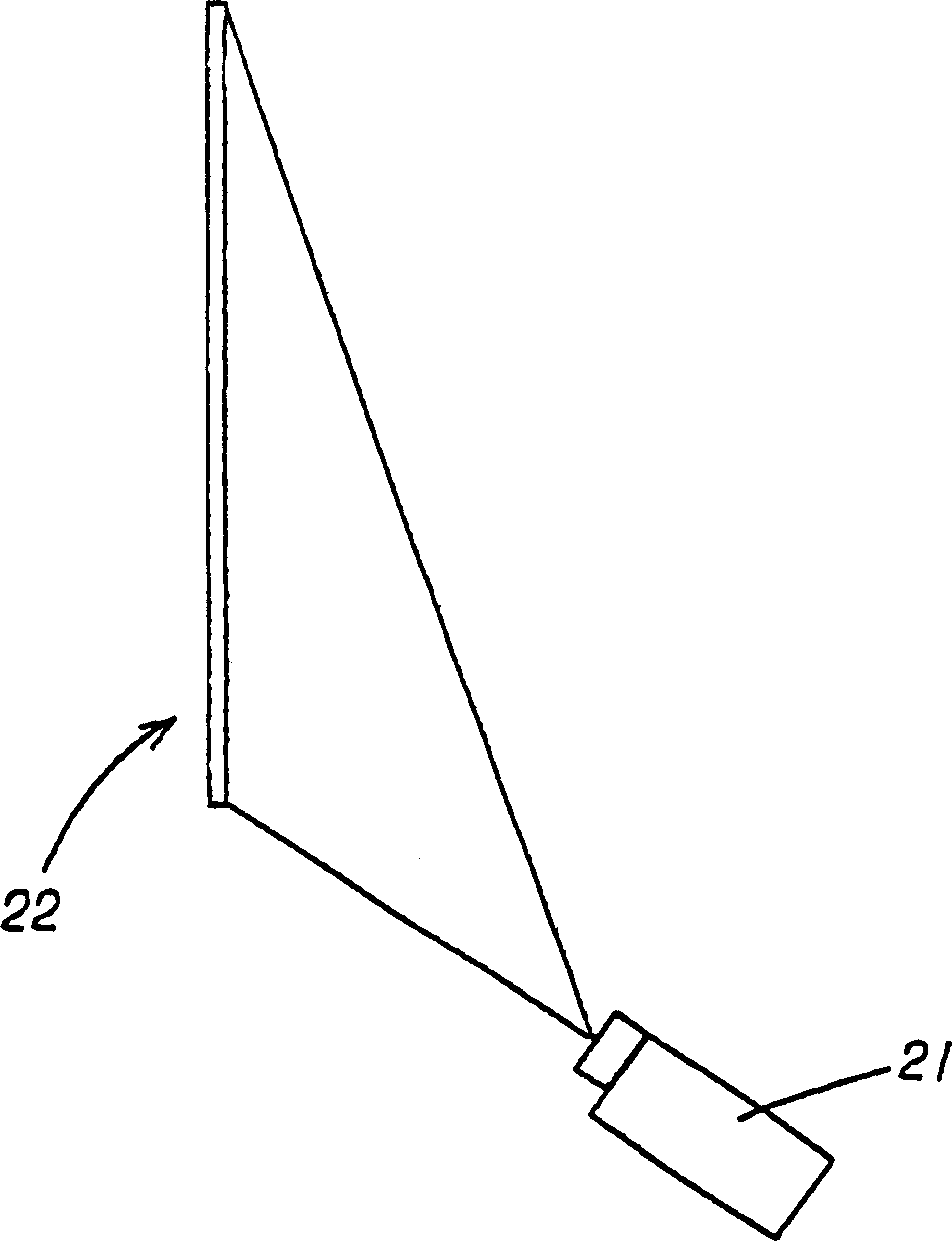

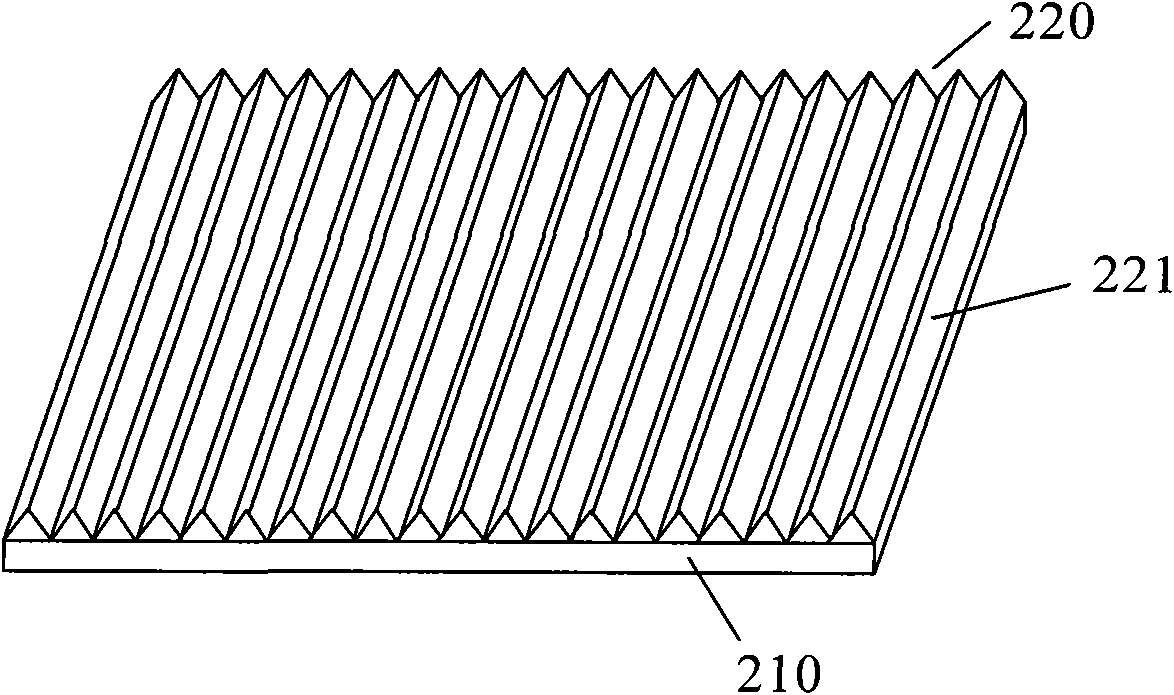

Light guide plate with diffusion dots having scattering particles and surface light source unit incorporating the light guide plate

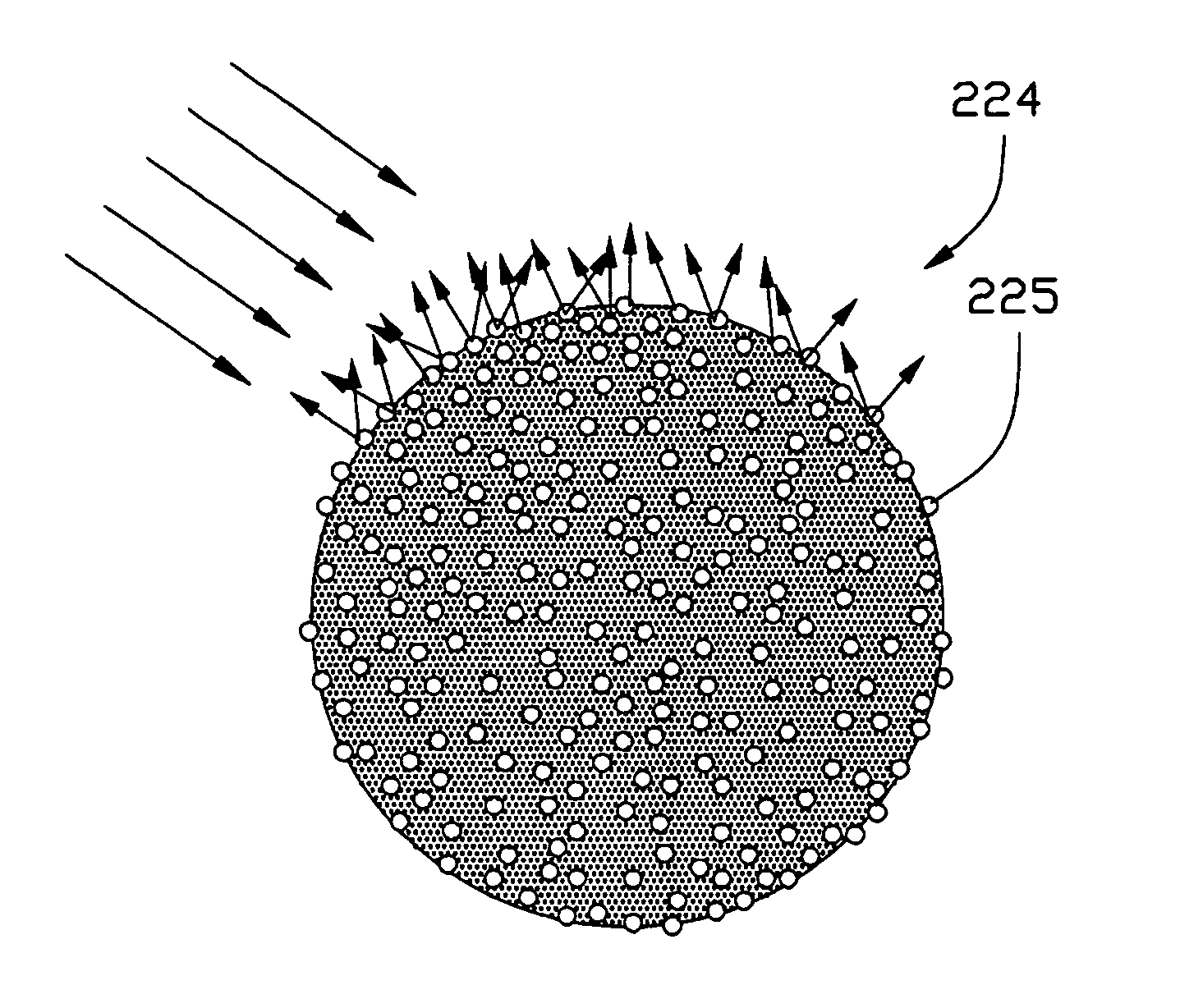

InactiveUS7085460B2Improve reflectivityImprove the scattering effectMechanical apparatusBundled fibre light guideDiffusionLiquid-crystal display

A surface light source unit (2) includes a light source (21), a light guide plate (22), a reflective plate (23) and a diffusing plate (24). The light guide plate includes a light incidence surface (221) adjacent to the light source for receiving light beams, an emission surface (222) for emitting the light beams, a light reflection surface (223) opposite to the emission surface and a plurality of diffusion dots (224) formed on the light reflection surface. The diffusion dots contain a plurality of light scattering particles (225) having substantially global surfaces. The surface light source unit provides high uniform illumination for a liquid crystal display panel.

Owner:HON HAI PRECISION IND CO LTD

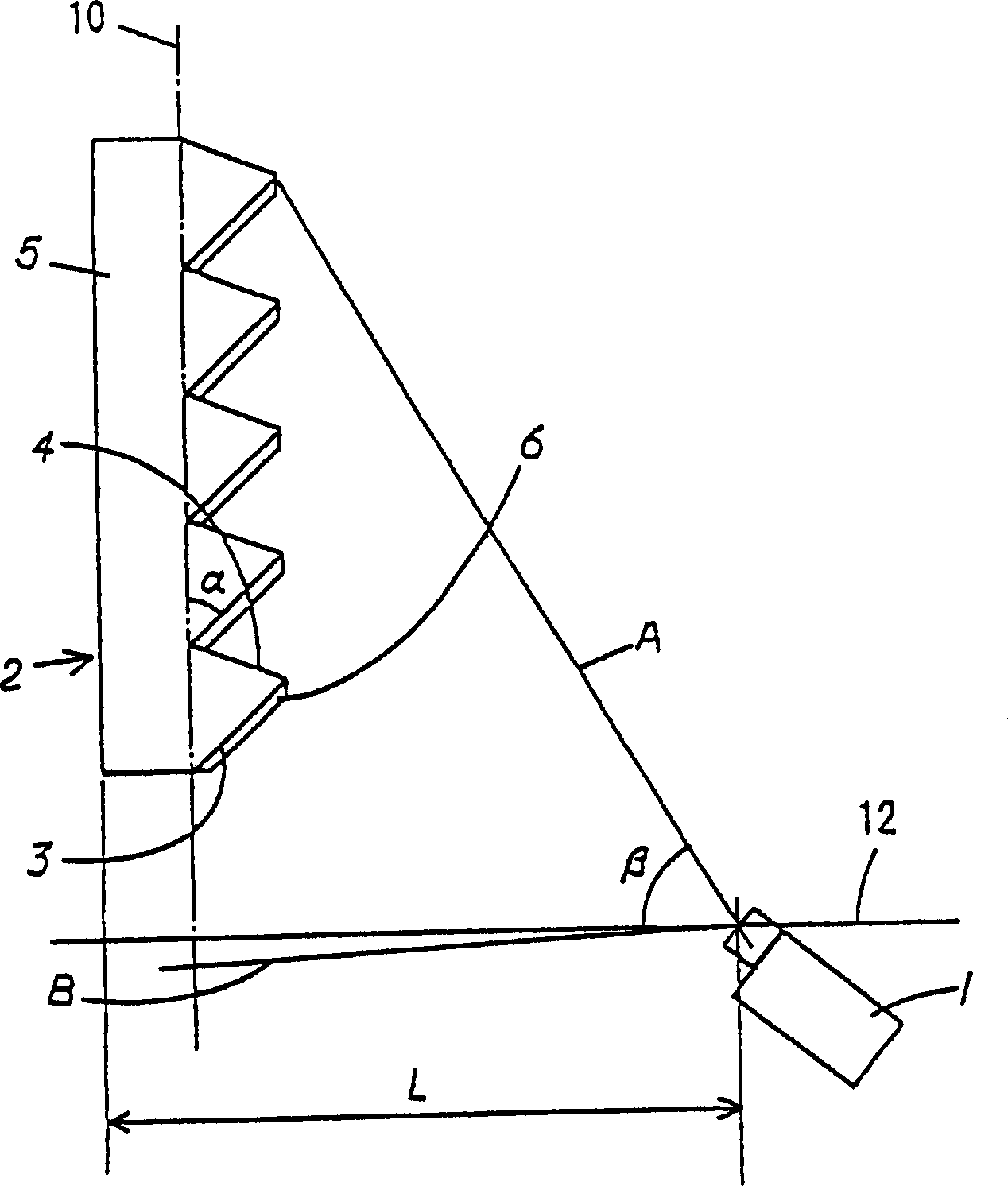

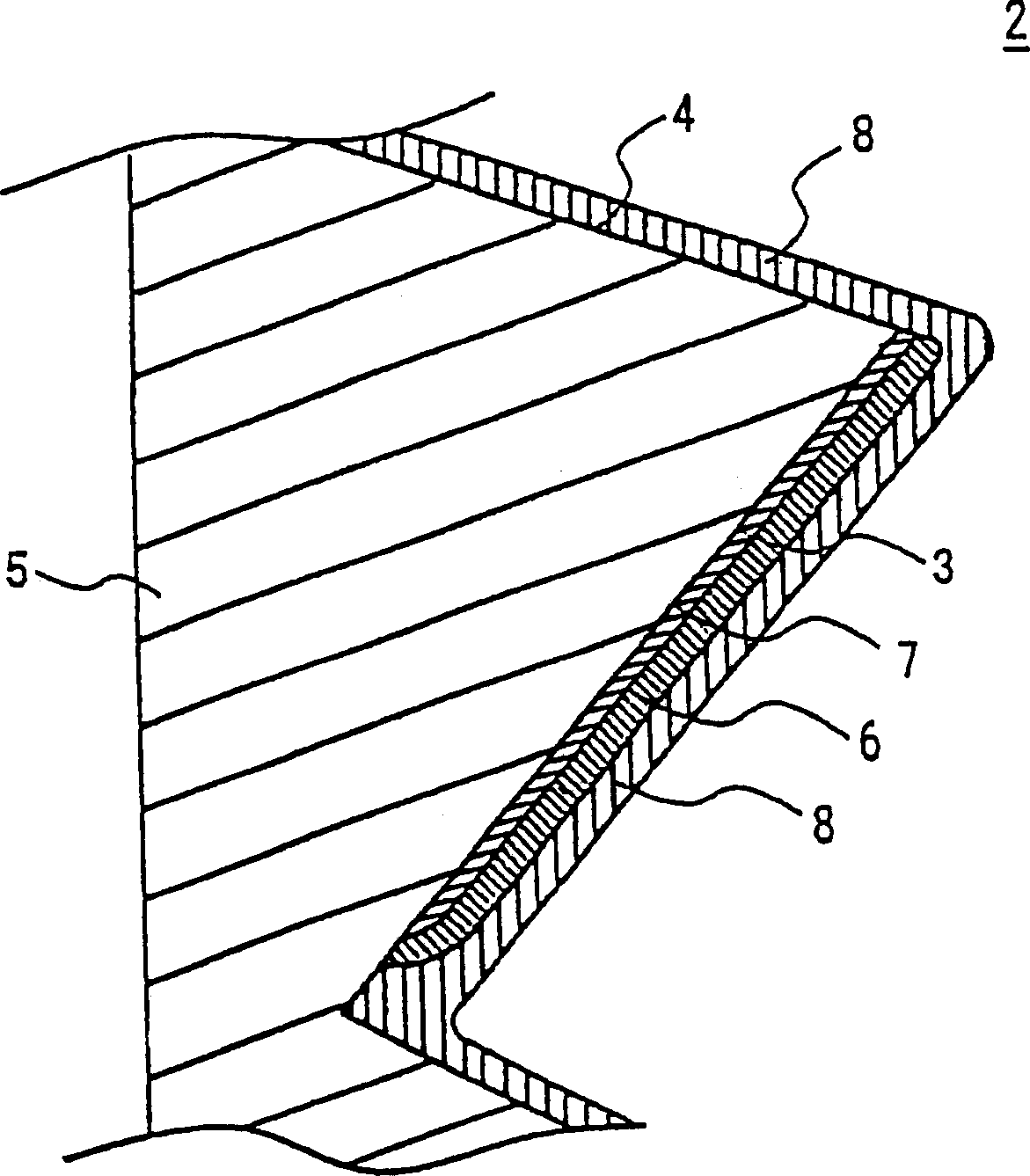

Reflex-type screen

A reflex-type screen for reflecting a light projected obliquely from a projector to a front of the reflex-type screen, including a base material made of material which absorbs light, a white resin layer which is formed on a projector side inclined plane on the base material and reflects light and a transparent diffusing layer which includes transparent binder resin and diffusing agent, and is formed to cover the white resin layer, and the base material includes the projector side inclined plane that is provided at an angle so that light from the projection enters the projector side inclined plane and a non-projector side inclined plane that is provided at an angle so that the light from the projection does not enter the non-projector side inclined plane, and the projector side inclined plane and the non-projector side inclined plane are located alternatively, so that the base material is formed to be saw-toothed shape. The white resin layer reflects the light from the projector to the front of the reflex-type screen, and the non-projector side inclined plane absorbs almost of incident light, and the transparent diffusing layer diffuses light which is reflected by the white resin layer.

Owner:ARISAWA MFG CO LTD

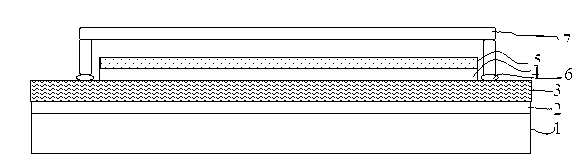

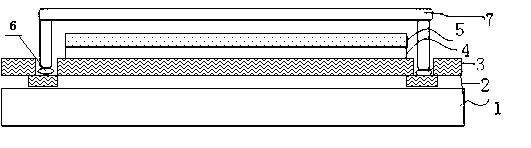

Packaging process of flexible semiconductor film electronic device

ActiveCN103996629AEnhanced scatteringReduce transmittanceSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingThin membraneComposite material

The invention discloses a packaging process of a flexible semiconductor film electronic device. The packaging process comprises a water and oxygen blocking layer preparation working procedure, wherein a water and oxygen blocking layer is formed by one or more water and oxygen blocking units in a stacking mode, each water and oxygen blocking unit comprises an organic blocking layer and an inorganic blocking layer, an uneven morphology structure is arranged on the surface of each organic blocking layer, and each inorganic blocking layer is arranged on the upper surface of the corresponding organic blocking layer. The uneven morphology structure on the surface of an organic film is a regular pattern or an irregular pattern. The uneven morphology structure on the surface of each organic blocking layer is formed in a photoetching mode or physical embossing mode or through particle addition. The uneven morphology structure of the surface of each organic blocking layer is of a rectangular structure or zigzag structure or arc structure. The flexible semiconductor film electronic device is simple in manufacturing process and high in water and oxygen blocking performance, and the device can be kept to be thin while the good water and oxygen isolation performance of the device can be achieved.

Owner:GUANG ZHOU NEW VISION OPTO ELECTRONICS TECH

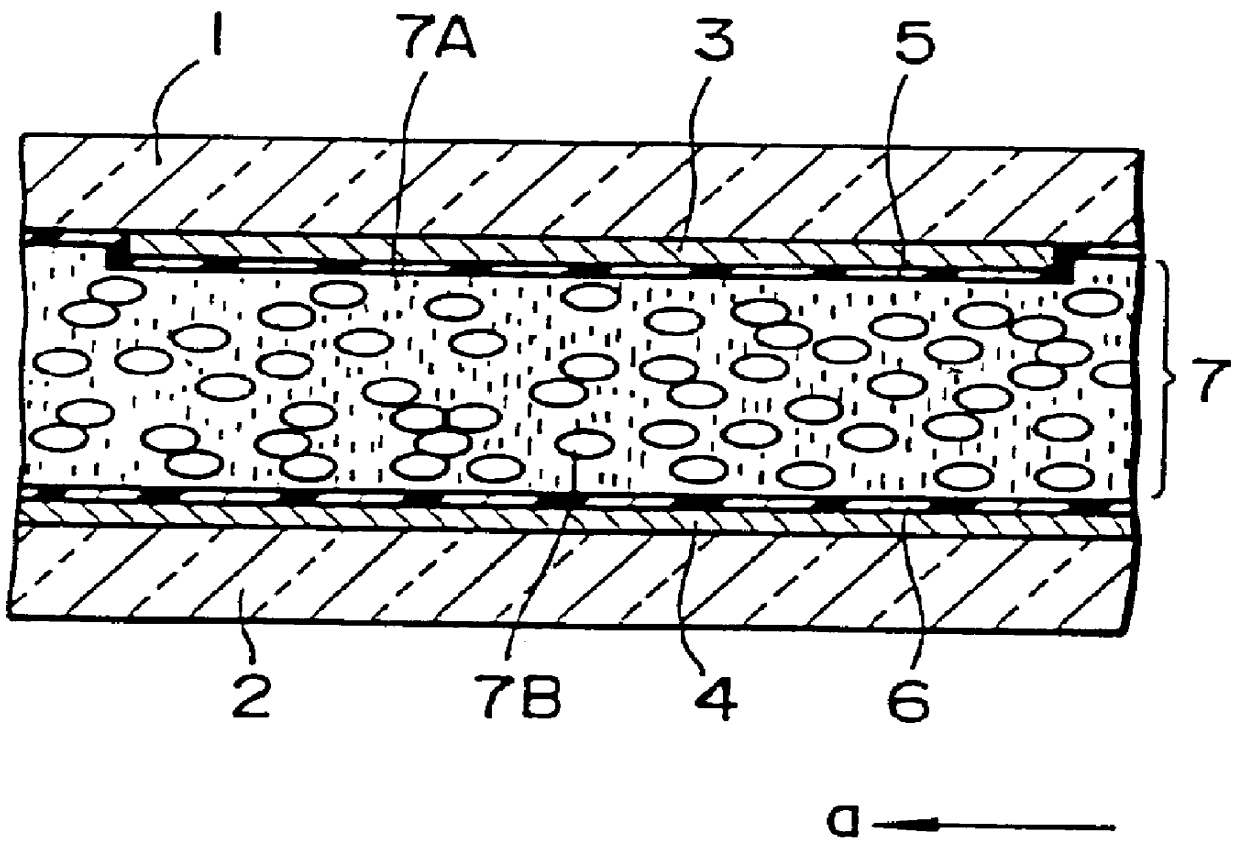

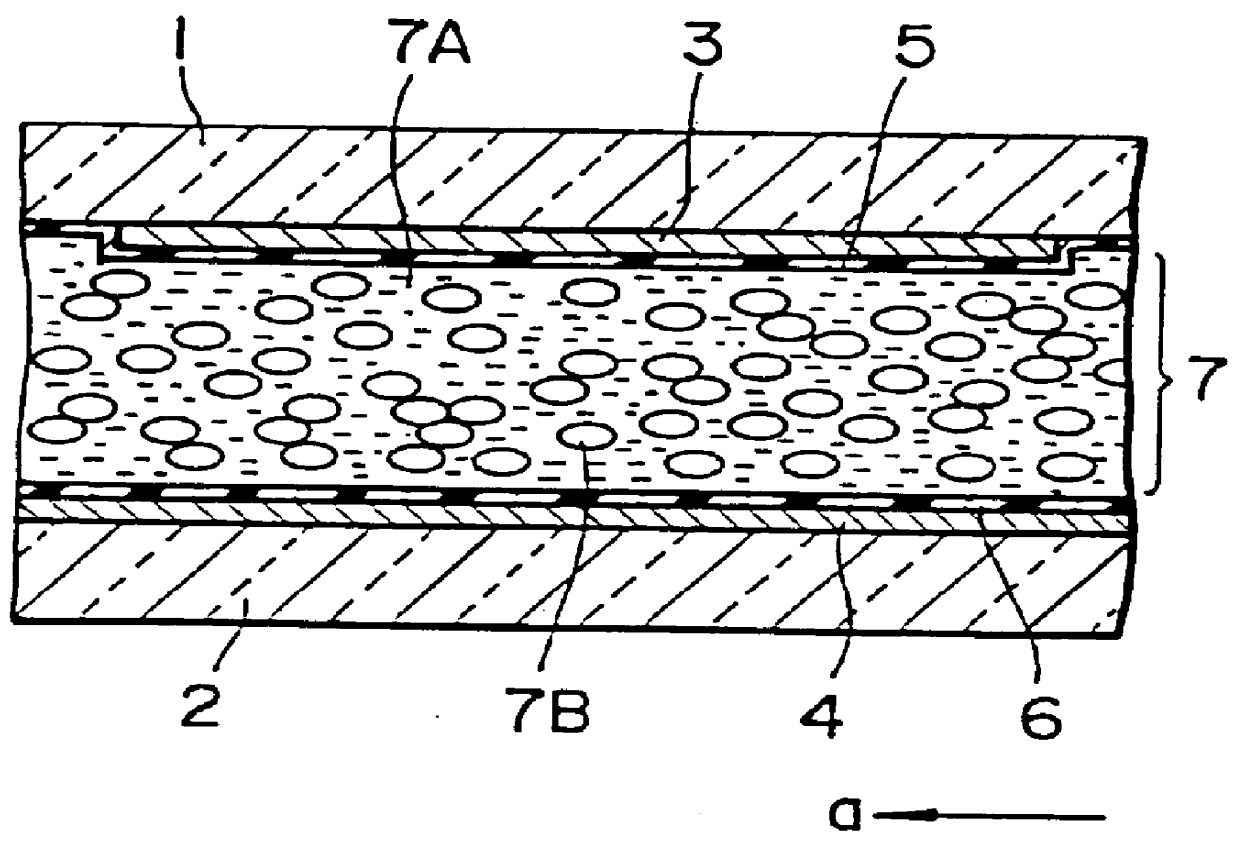

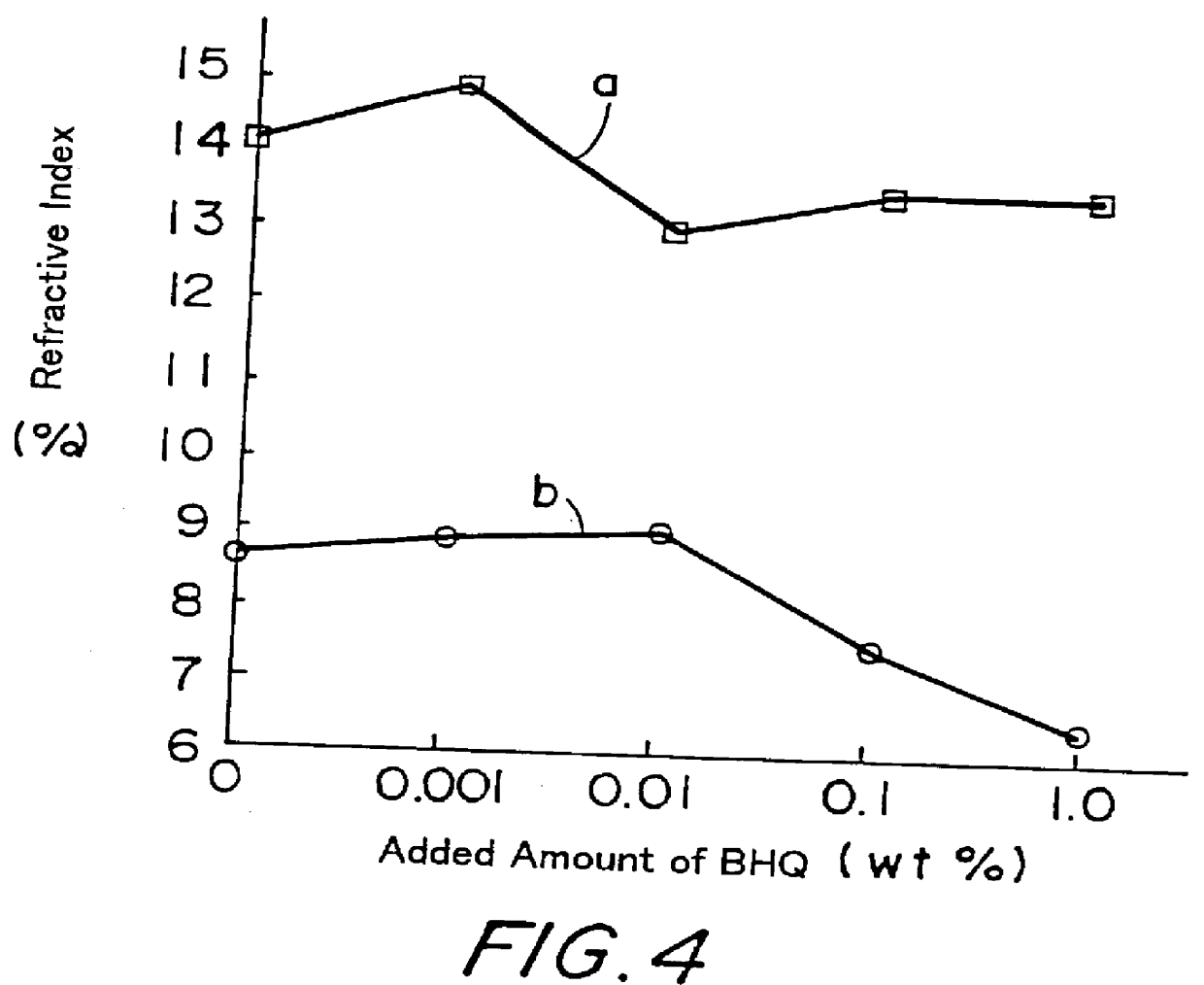

Polymer dispersed liquid crystal electro-optical device and method for manufacturing the same

InactiveUS6046791AImprove the scattering effectSuppresses deterioration of a light-scattering stateLiquid crystal compositionsThin material handlingElectric fieldLiquid crystal

PCT No. PCT / JP96 / 03303 Sec. 371 Date Jul. 9, 1997 Sec. 102(e) Date Jul. 9, 1997 PCT Filed Nov. 11, 1996 PCT Pub. No. WO97 / 17630 PCT Pub. Date May 15, 1997A polymer dispersed liquid crystal electro-optical device comprising a liquid crystal polymer complex layer having a liquid crystal and a polymer, wherein said liquid crystal and said polymer are aligned in the same direction when no electric field is applied, and an electrode structure formed on each side of said liquid crystal polymer complex layer for applying an electric field to said liquid crystal polymer complex layer to align said liquid crystal along the electric field so as to render said liquid crystal polymer complex layer in a light-scattering state. The liquid crystal polymer complex layer is formed by dissolving a liquid crystal and a polymer precursor to form a solution; adding a compound in which at least one hydrogen atom in a benzene ring is substituted by a hydroxy group or a compound having a benzene ring with a hydroxy group as a basic skeleton to said solution; polymerizing said polymer precursor to from a polymer; and phase separating said liquid crystal and said polymer to form a liquid crystal polymer complex layer. The compound improves the initial refractive index, and the refractive index and contrast after energize-aging.

Owner:SEIKO EPSON CORP

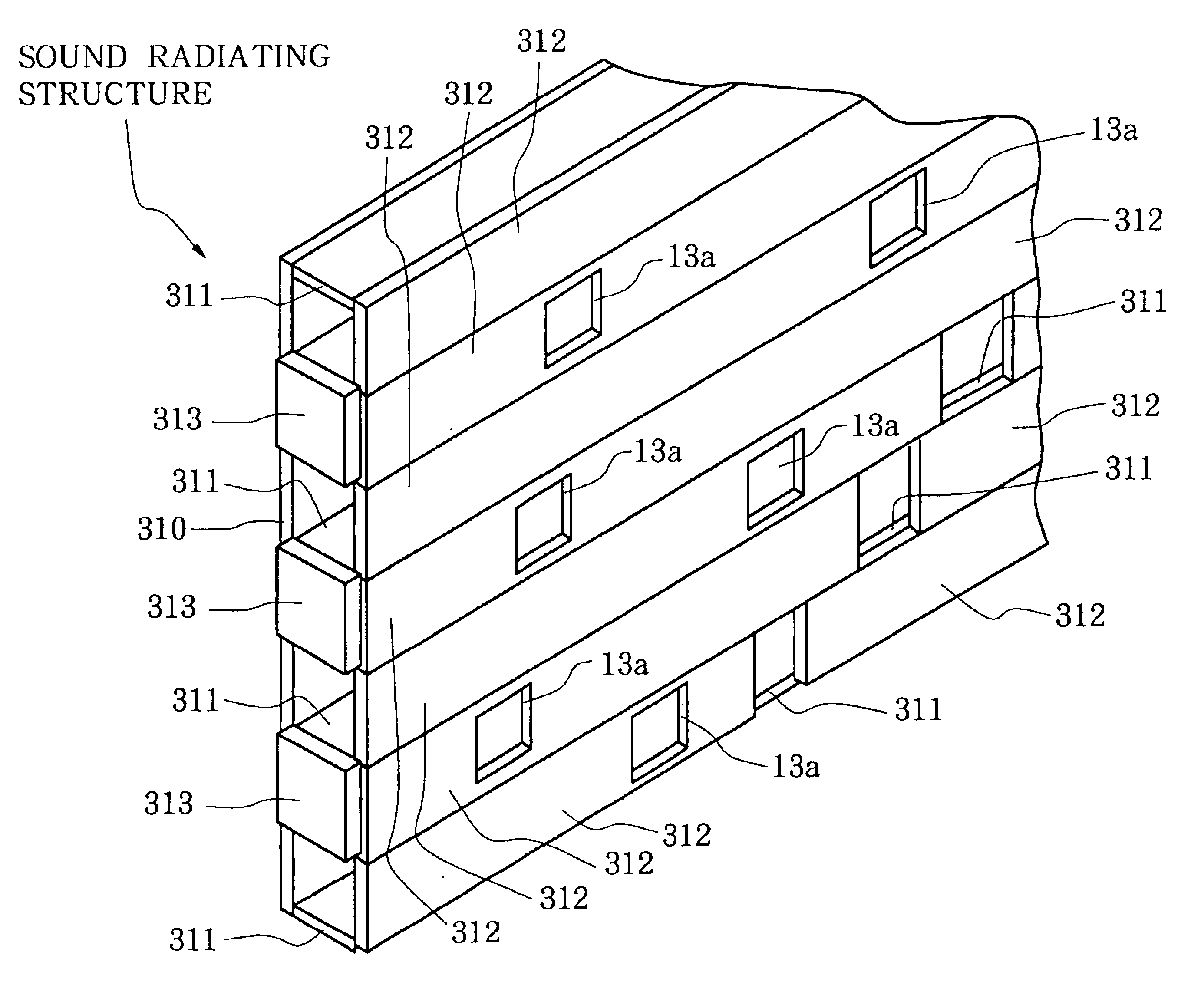

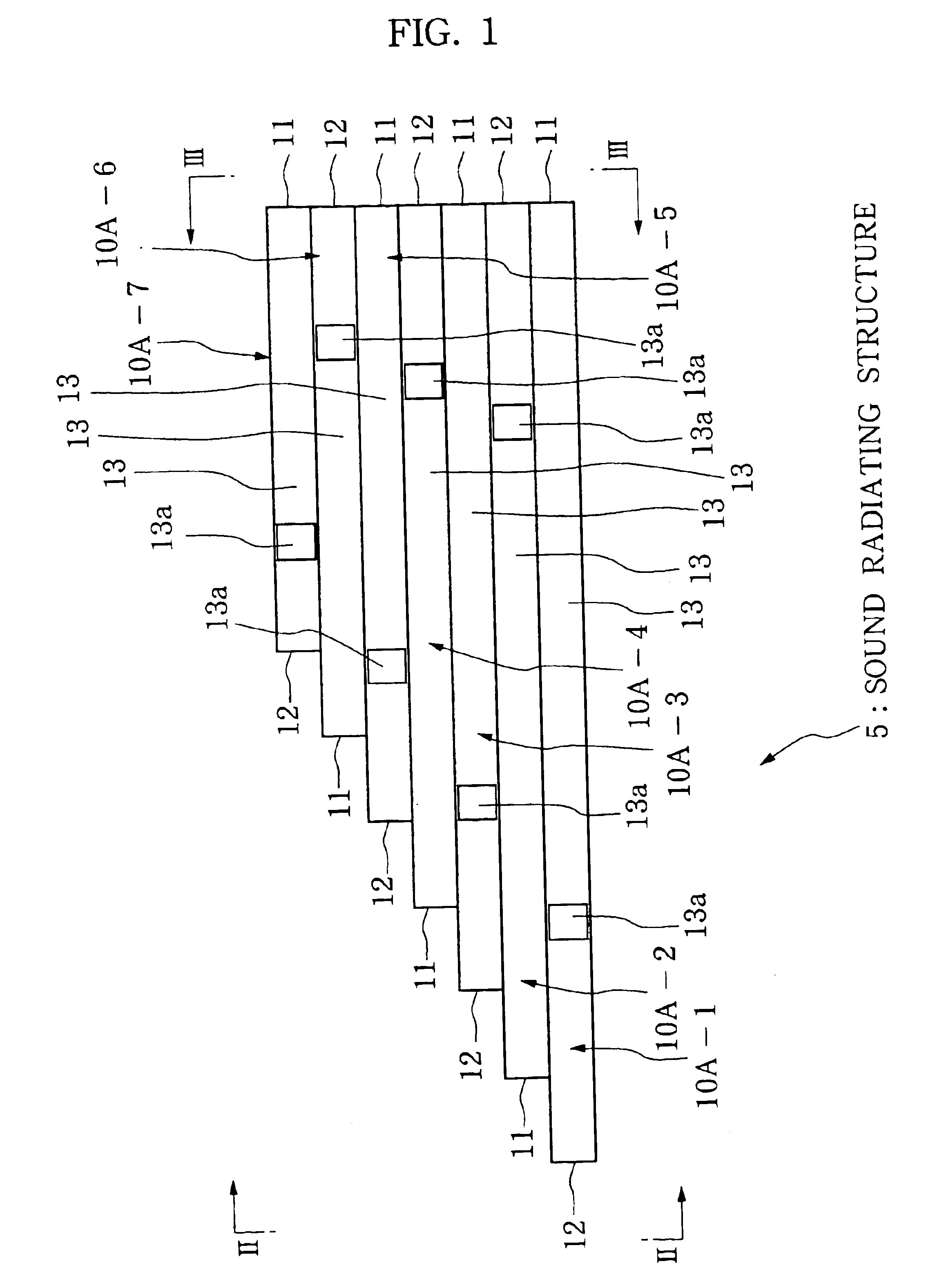

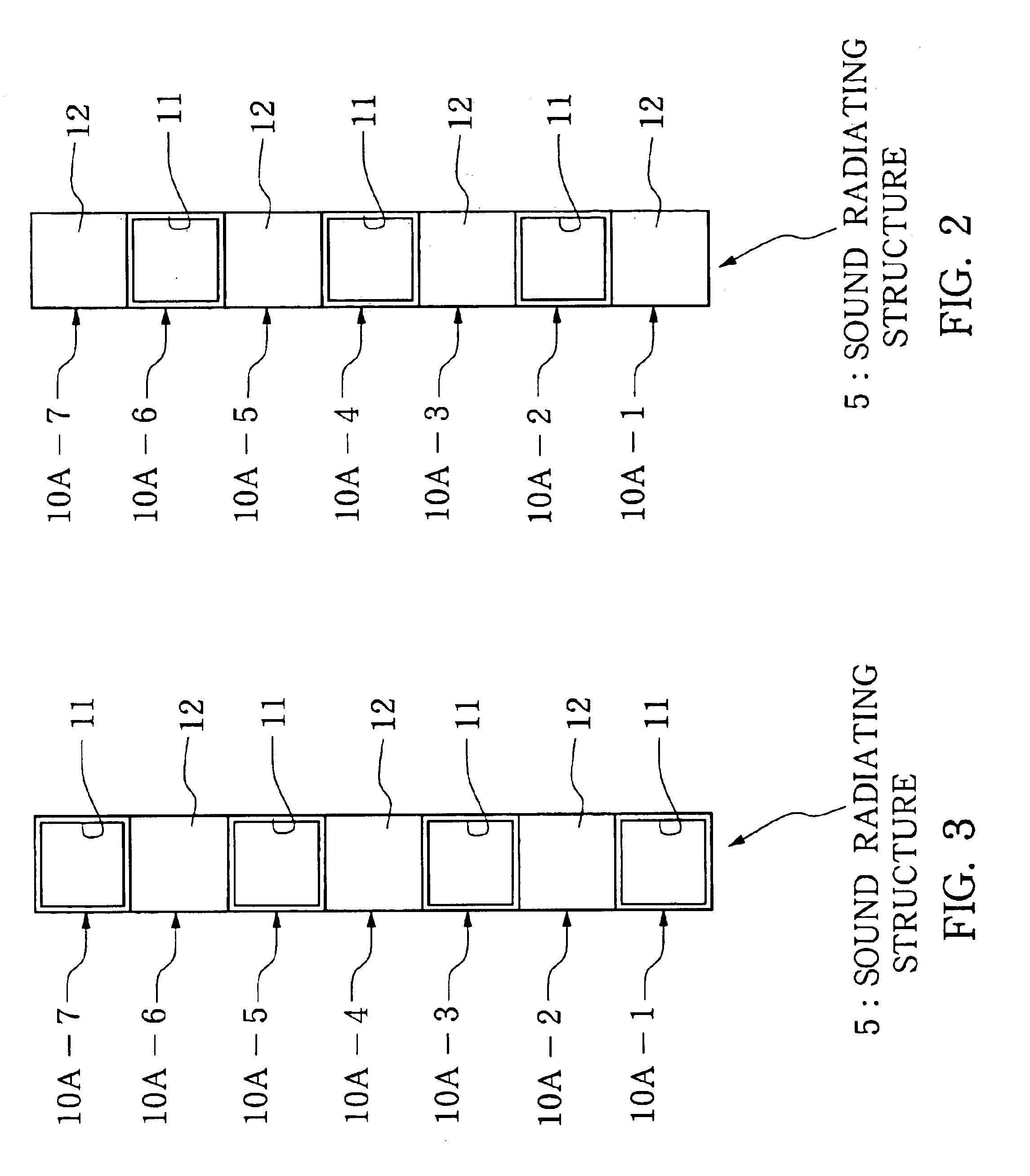

Sound radiating structure, acoustic room and sound scattering method

InactiveUS6892856B2Increase the thickness of the structureImprove the scattering effectCeilingsSound proofingSound wave

Sound radiating structure includes a plurality of pipes each defining an inner cavity along the length of the pipe. Each of the pipes has an end opening at one end and is closed at the other end with a closure. Each of the pipes also has a side opening in its one side portion. When a sound is input to the sound radiating structure, it re-radiates various sound waves through a number of the end and side openings together with reflected sound waves.

Owner:YAMAHA CORP

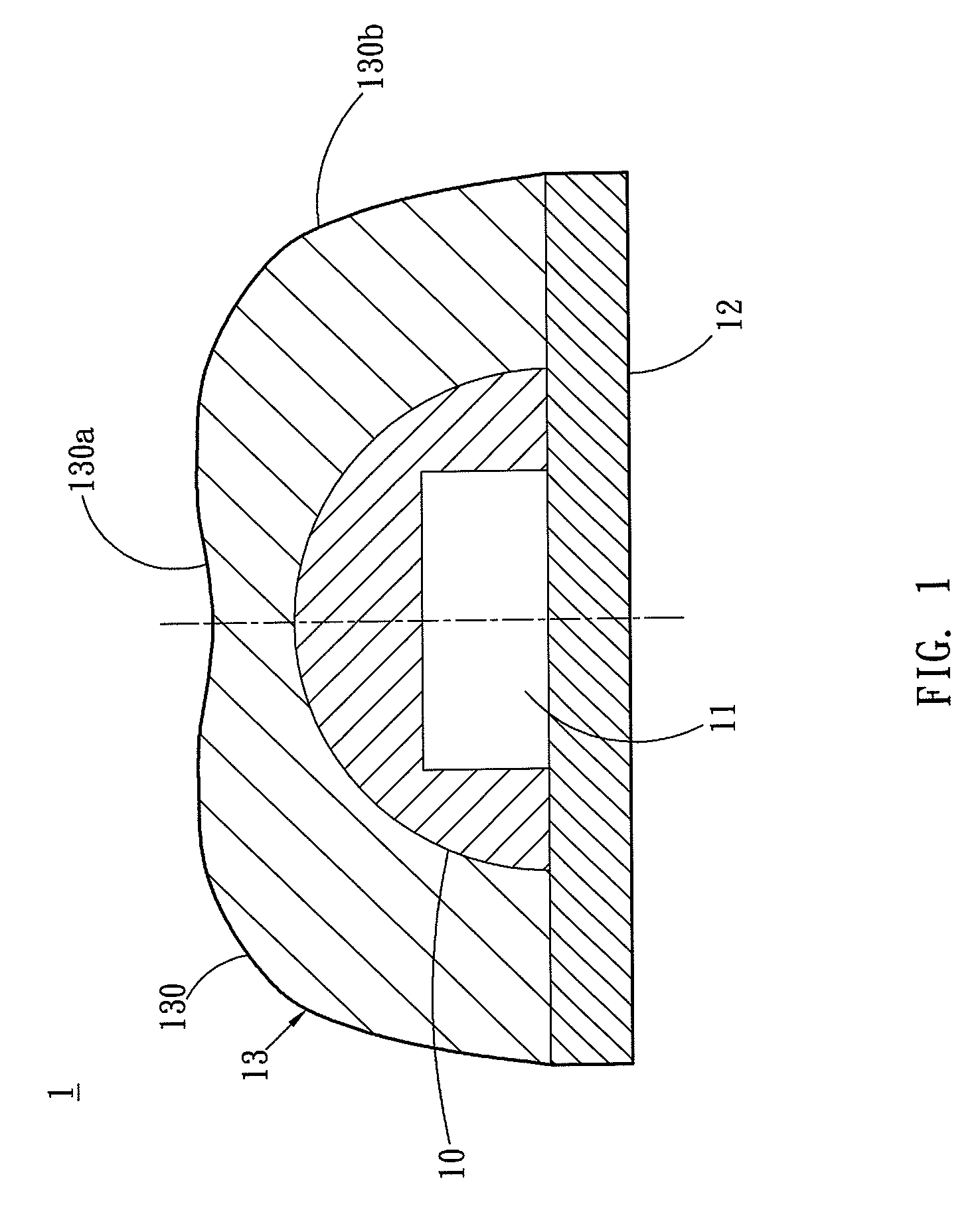

LED lens and light source device using the same

InactiveUS8967833B2Reduce overall chromatic aberrationAccelerate emissionsPoint-like light sourceGlobesOptoelectronicsPhysics

The present invention discloses an LED lens and a light source device using the same. The light source device includes the LED lens and a LED. The LED lens comprises a light incident surface, a light emitting surface, and a bottom surface. The light emitting surface includes a recession portion disposed at the central thereof and a convex portion connected to the recession portion. The light incident surface is a concave surface and comprises a first optically active area and a second optically active area. The first optically active area is disposed at the central of the light incident surface; the second optically active area is connected to the first optically active area and the bottom surface. At the junction between the first optically active area and the second optically active area, it is an optical path inversion point that is disposed satisfying specific condition.

Owner:E PIN OPTICAL IND

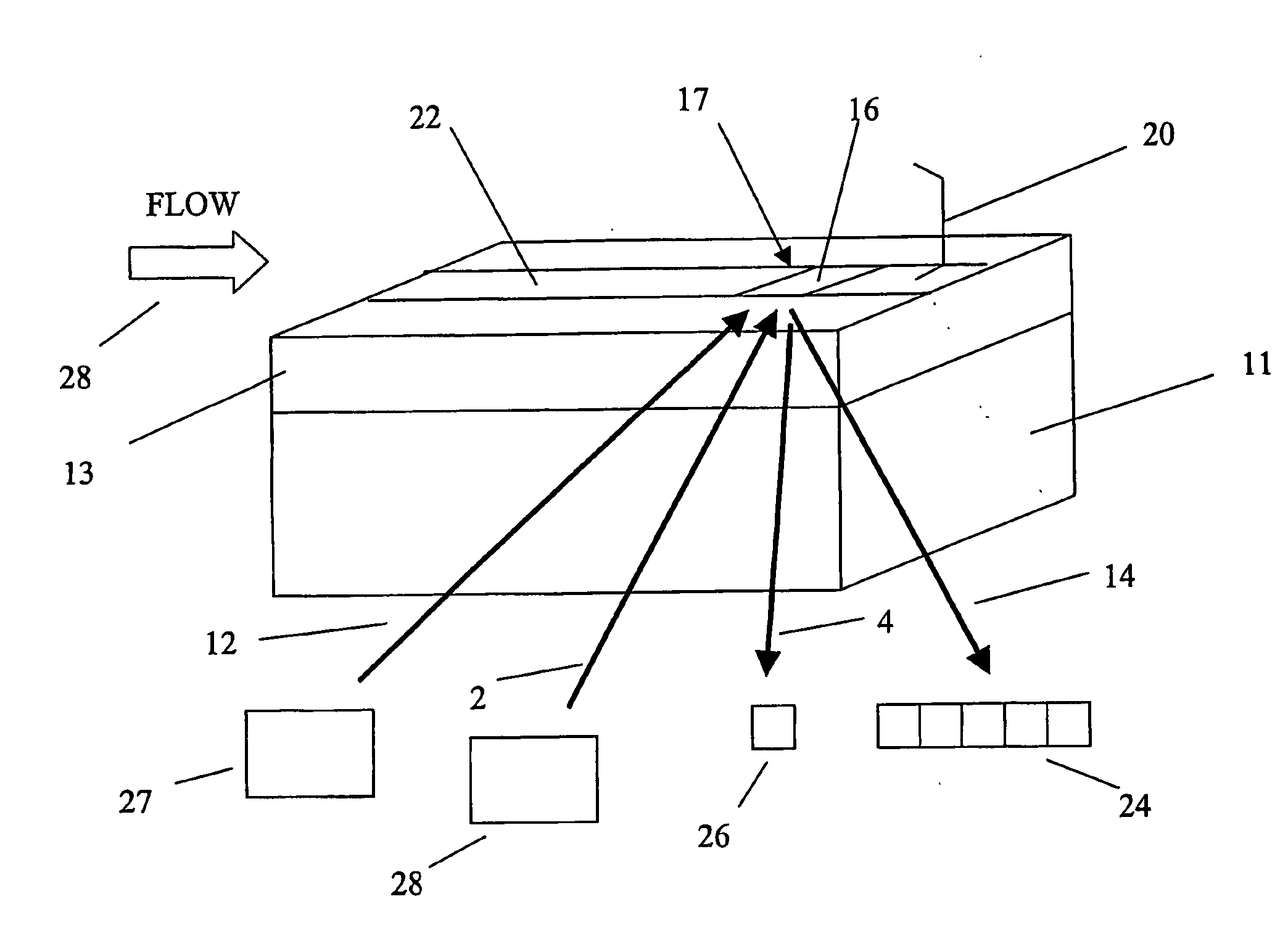

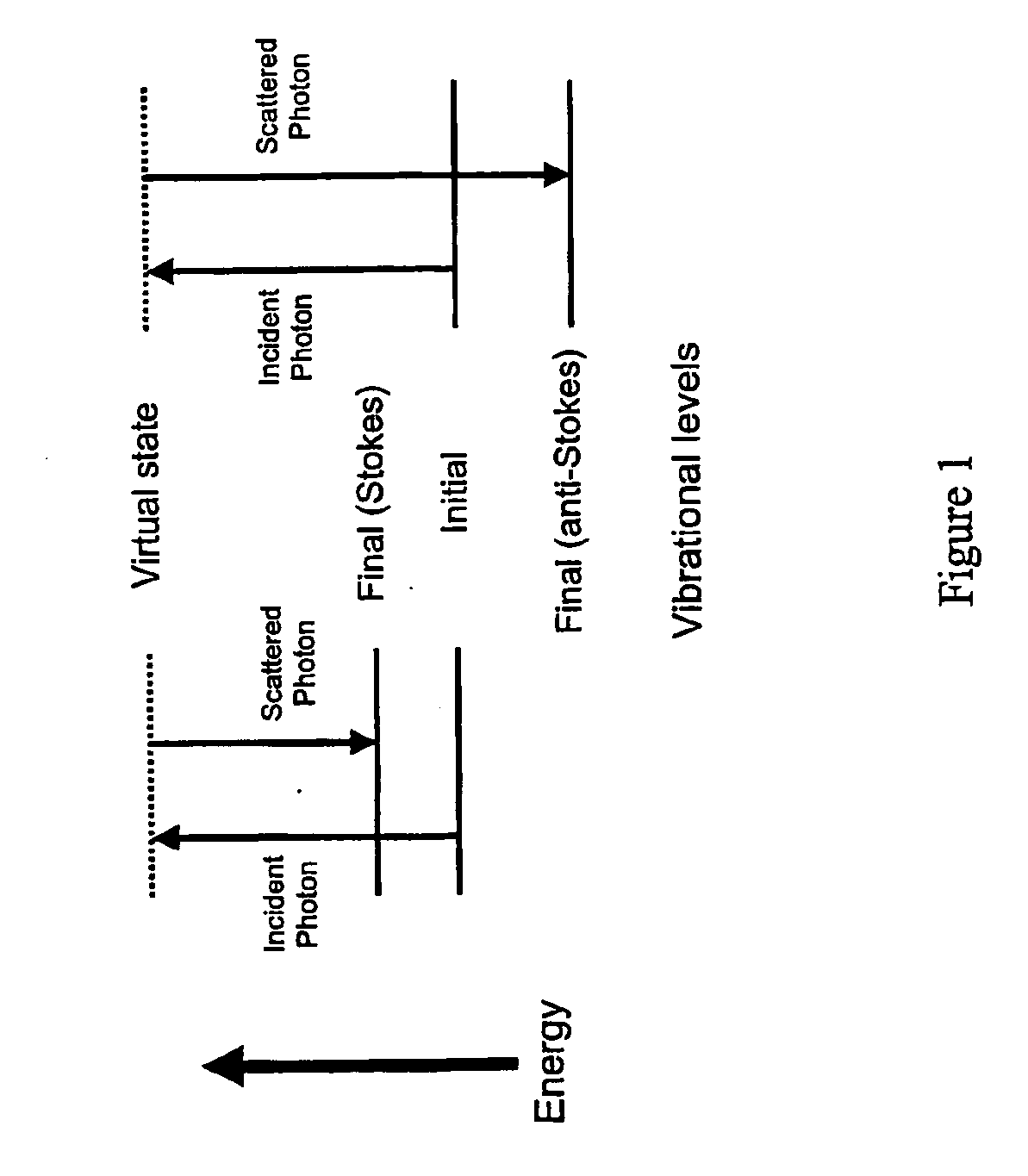

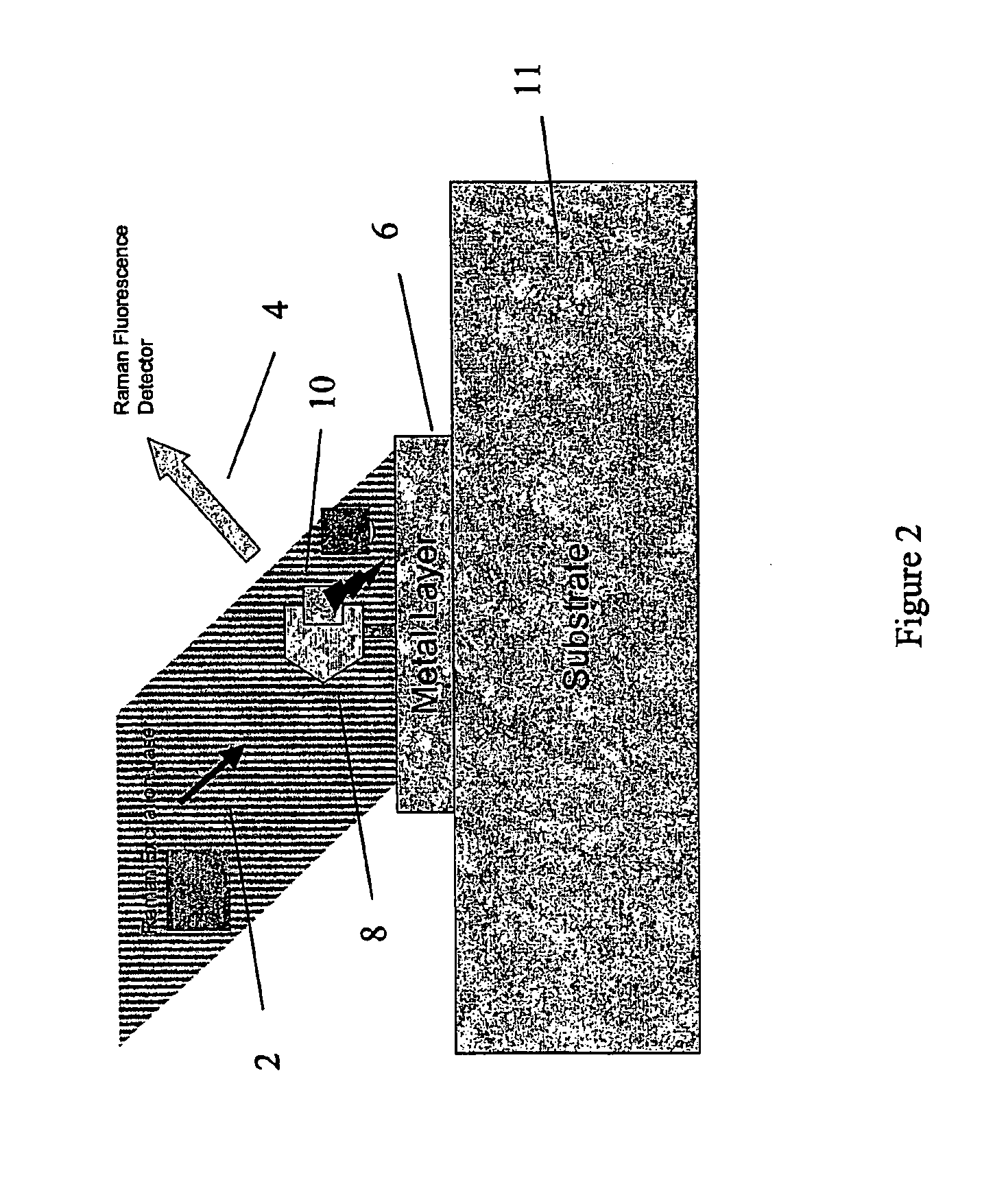

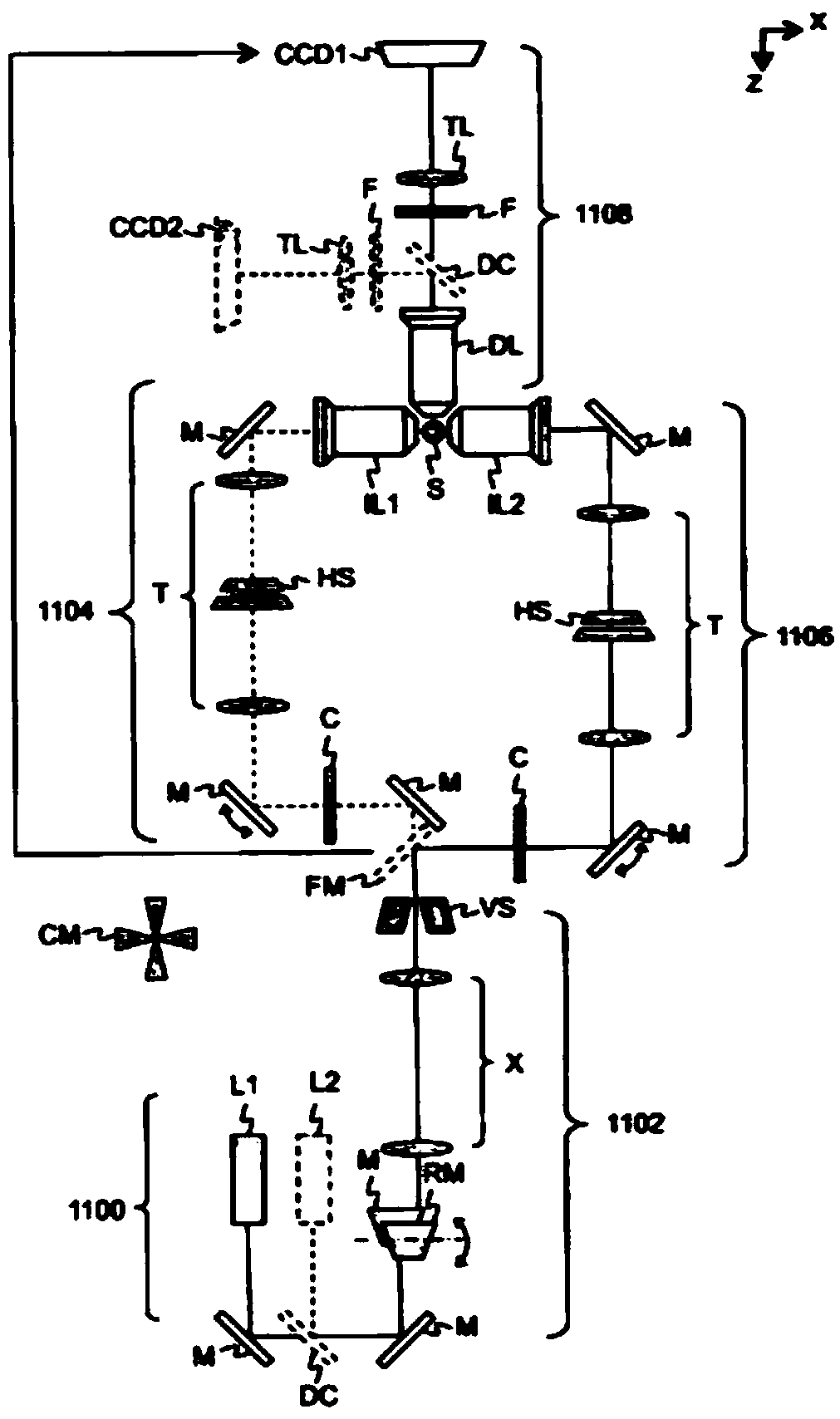

Molecular detector arrangement

InactiveUS20070030481A1Enhances SERS effectImprove the scattering effectRadiation pyrometryScattering properties measurementsAnalyte moleculeMolecular physics

A detector assembly for detecting the presence of analyte molecules, in particular, proteins, uses both Surface Enhanced Raman Scattering (SERS) and Surface Plasmon Resonance (SPR) in synergy. The excitation laser used for SERS provides scattering from a reporter dye to which an analyte molecule is attached in the vicinity of a conducting surface. Simultaneously, a second laser is provided at the critical angle to the conducting surface. The second laser causes a field to be created in the region of the analyte which enhances the Raman scattering effect.

Owner:E2V BIOSENSORS LTD

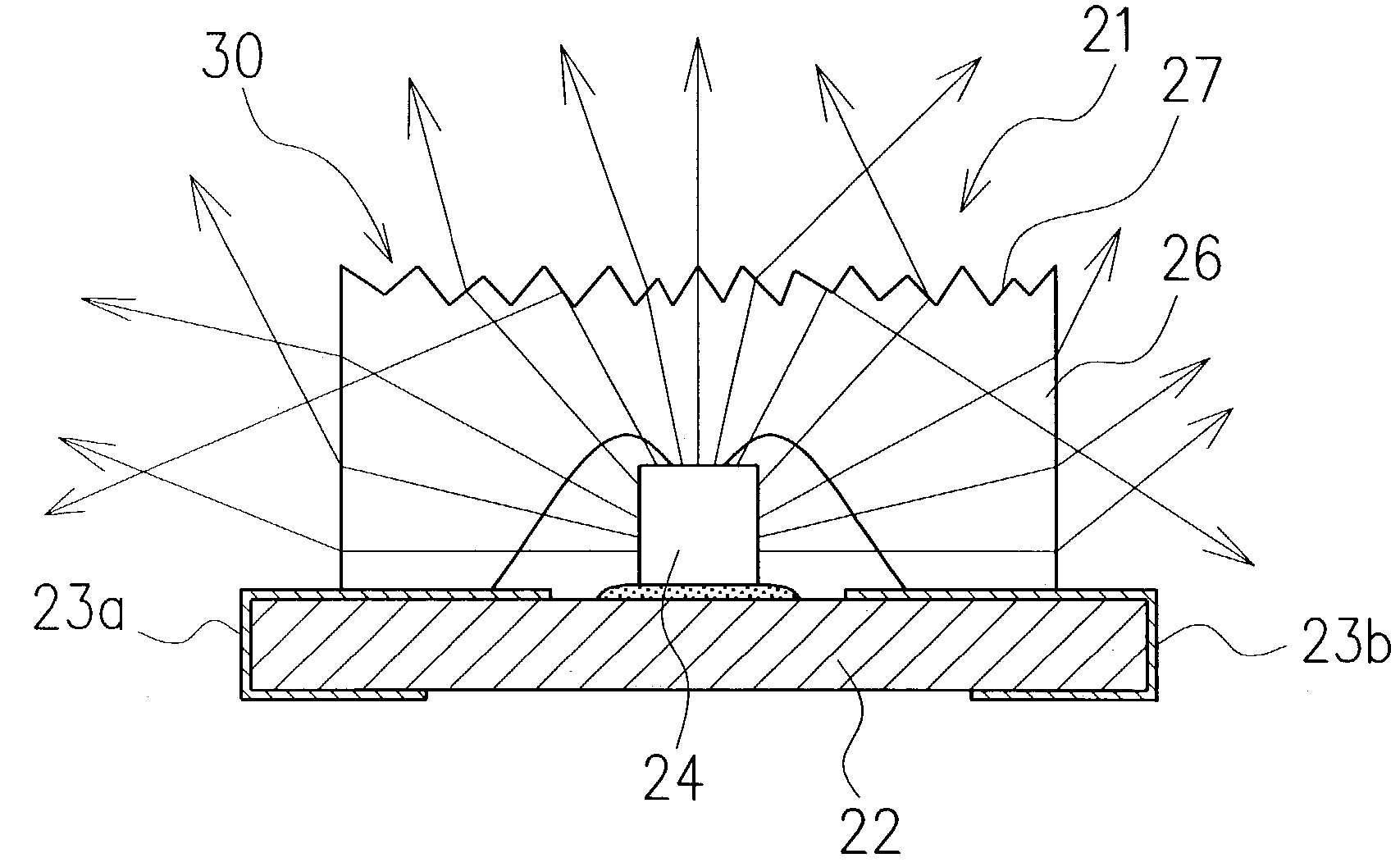

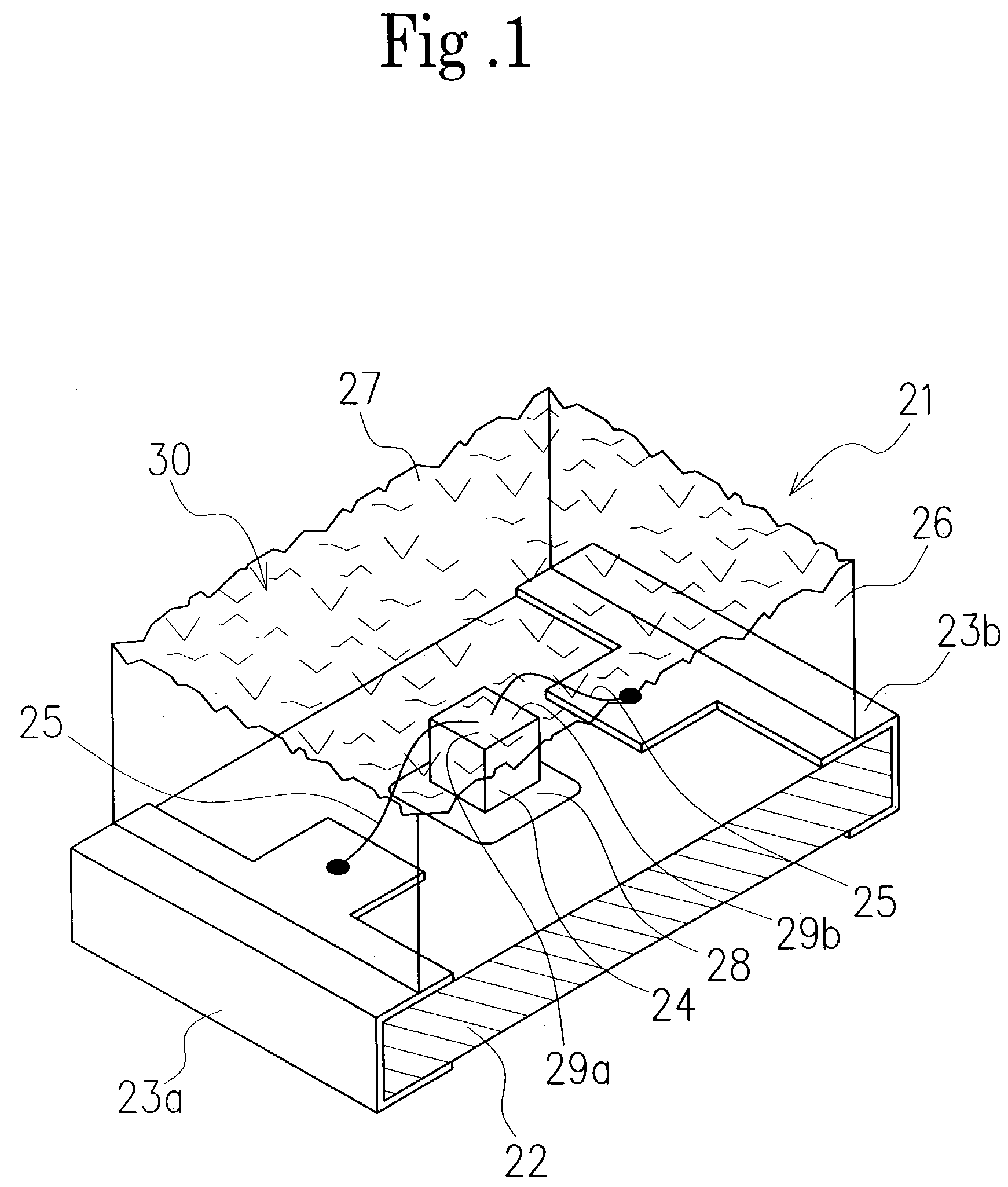

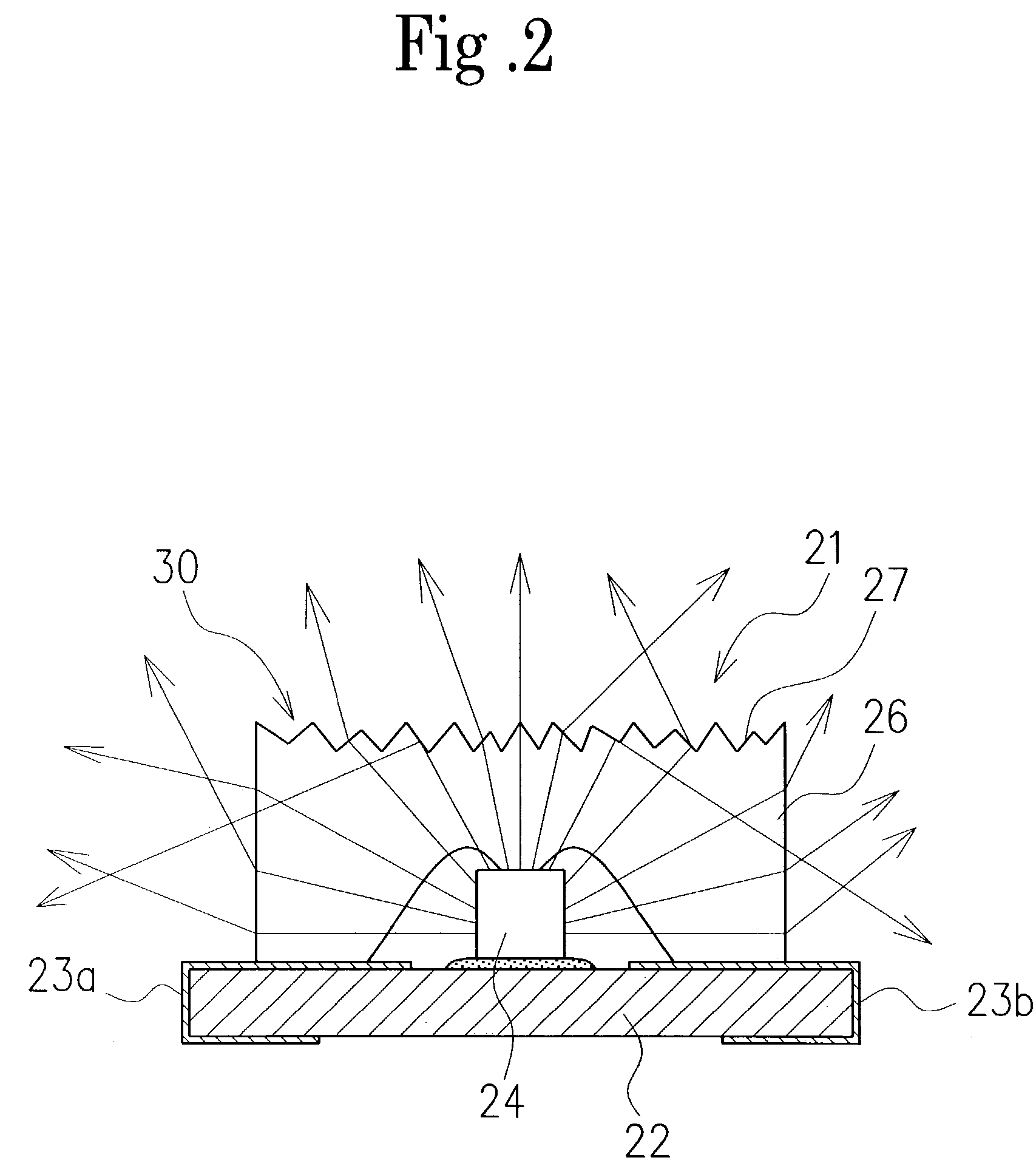

High-intensity light emitting diode with concave and convex shaped light scattering portions formed on a cover

InactiveUS7193365B2Improve lighting effectsExtended scatter rangeIncadescent screens/filtersDischarge tube luminescnet screensHigh intensityHigh intensity light

A light emitting diode, capable of accomplishing enlargement of emitted range of light and equalization of brightness of emitted light has a substrate (22), electrodes (23a, 23b), a light emitting element (24) mounted on the substrate (22) and connected electrically with the electrodes (23a, 23b), a resinous cover (26) for sealing the light emitting element (24) and electrodes (23a, 23b) and an uneven shaped light scattering part (30) provided on the surface of the cover.

Owner:CITIZEN ELECTRONICS CO LTD

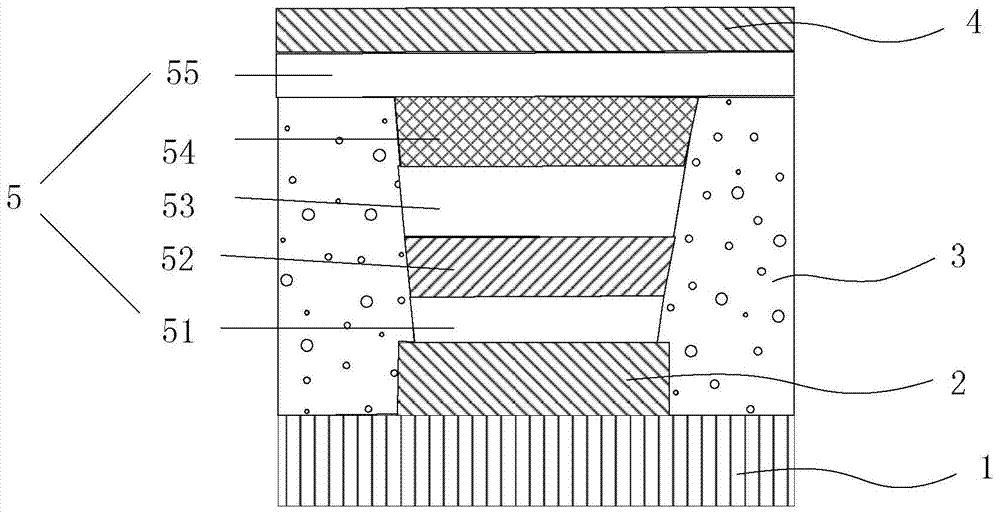

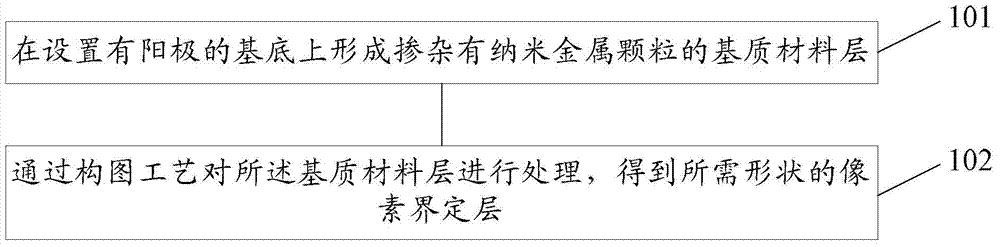

Organic electroluminescence device and manufacturing method thereof

ActiveCN103490018AImprove internal quantum efficiencyIncreased scattering and absorption cross sectionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceMetal particle

The embodiment of the invention relates to the technical field of electroluminescence, and provides an organic electroluminescence device which aims to improve luminous efficiency of the organic electroluminescence device. The organic electroluminescence device comprises a pixel definition layer and a luminescence structure, and nano metal particles are mixed in the pixel definition layer. The manufacturing method can be applied to manufacture processes of the organic electroluminescence device.

Owner:BOE TECH GRP CO LTD

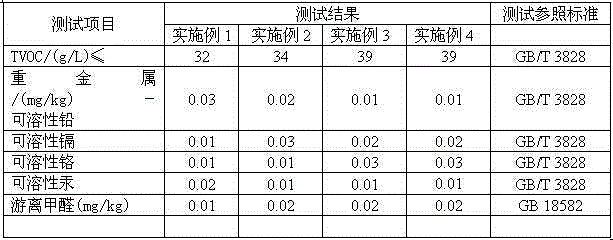

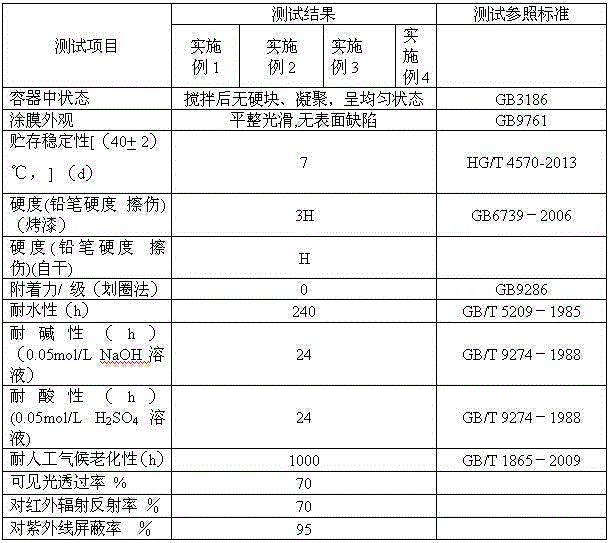

Aqueous colored transparent heat insulation coating, and preparation method and use method thereof

ActiveCN104151970AHigh hydroxyl contentImprove water resistanceReflecting/signal paintsMulticolor effect coatingsTin dioxidePolymer science

The invention discloses an aqueous colored transparent heat insulation coating, and a preparation method and a use method thereof. The aqueous colored transparent heat insulation coating is composed of a water-soluble hydroxy acrylic resin, an aqueous nanometer antimony-doped tin dioxide (ATO) slurry, an aqueous nanometer hydrotalcite slurry, an amino resin, an aqueous color paste, a film forming assistant, deionized water, a dispersant, a wetting agent, a pH adjusting agent, an antifoaming agent, an anti-settling slurry, a thickening agent, an adhesion accelerant and a leveling agent. The preparation method is characterized in that above substances are mixed under specific conditions to obtain the coating. The use method is characterized in that the addition amount of the amino resin is 4-8wt% when the coating is used as a single-component baking varnish; and the addition amount of the amino resin is 0 when the coating is used as a two-component air-dried paint. The coating has the advantages of very good adhesion, high hardness, excellent ageing resistance and good heat insulation effect on the surfaces of glass, plastic films and the like.

Owner:肇庆千江高新材料科技股份公司

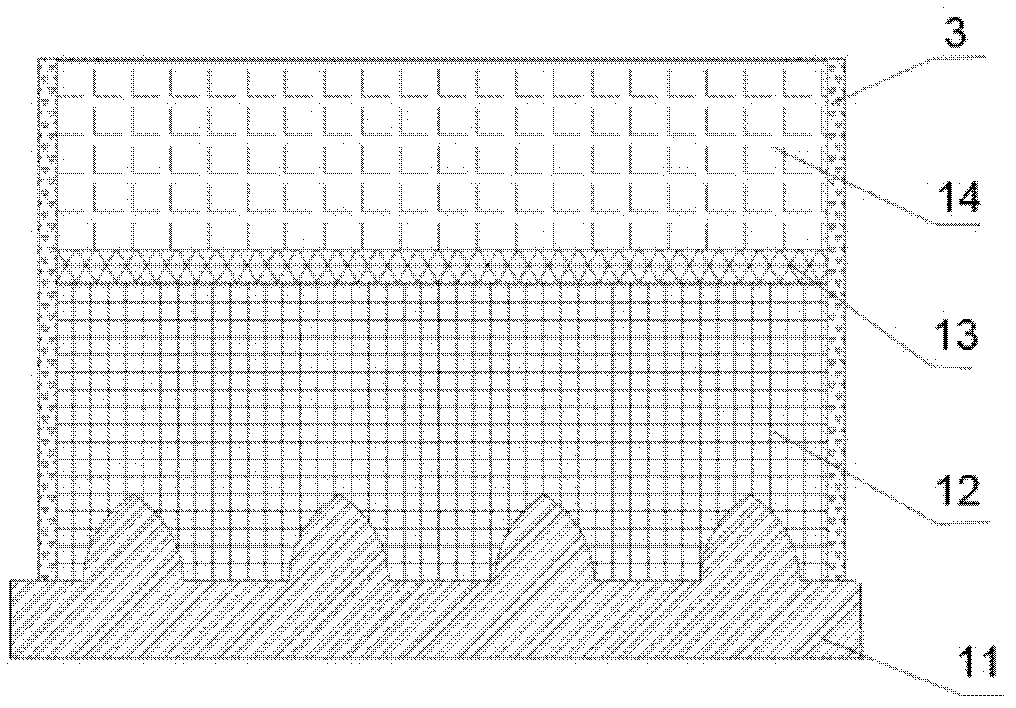

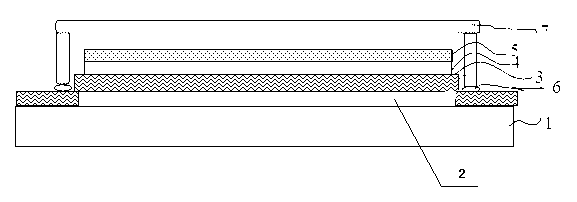

Smectic-state liquid crystal display

ActiveCN101916009AImprove the scattering effectIncrease brightnessPrismsNon-linear opticsHigh contrastLiquid-crystal display

The invention discloses a smectic-state liquid crystal display. The smectic-state liquid crystal display comprises a display layer, wherein the display layer comprises a first base layer and a second base layer; a mixing layer is arranged between the first base layer and the second base layer; the side of the first base layer facing the mixing layer is provided with a first conductive electrode layer; the side of the second base layer facing the mixing layer is provided with a second conductive electrode layer; the back surface of the display layer is provided with a back panel layer; an intensifying layer is arranged between the display layer and the back panel layer and comprises a substrate; and the surface of the substrate facing the display layer and / or the back panel layer is provided with an intensifying member. The display has the advantages of high contrast, good display effect and strong reading and watching comfort.

Owner:HALATION PHOTONICS CORP

UV-resistant polyester fiber of nano titanium nitride

InactiveCN100503910CIncrease reflectionImprove the scattering effectMelt spinning methodsMonocomponent polyesters artificial filamentMasterbatchPolyester

The invention discloses a nano-titanium nitride anti-ultraviolet polyester fiber. The fiber contains nano-titanium nitride with a concentration of 0.5%-2% by weight and has an anti-ultraviolet function. The fiber is made of nano-titanium nitride, other additives and carriers to make a masterbatch, and the masterbatch is added to polyester chips and melt-spun. The addition of nano-titanium nitride makes the polyester fiber have good anti-ultraviolet function; and does not affect its spinnability; the average ultraviolet shielding rate of the spun anti-ultraviolet functional polyester fiber is above 85%; at the same time, it does not affect people's health. Nano-titanium nitride anti-ultraviolet polyester fiber can be widely used in outerwear, sportswear, trousers and other fields.

Owner:DONGHUA UNIV

High-power GaN-based vertical structure LED with light extraction microstructure and preparation method thereof

The invention discloses a high-power GaN-based vertical structure LED with a light extraction microstructure and a preparation method thereof. According to the invention, the LED prepared through the preparation method is provided with a light-emitting surface microstructure transferred through a laser-stripping sapphire pattern substrate and complemented with patterns positioned on the surface of the laser-stripping sapphire pattern substrate; a means which has great high repetitiveness and controls the light-emitting surface microstructure is provided because the morphology of the light-emitting surface microstructure of the laser-stripping sapphire pattern substrate can be controlled through a process means; besides, nanometer-level coarsing is additionally carried out on the local area of a light-emitting surface, therefore the morphology of the light-emitting surface is further optimized; a mirror surface metallic reflection layer is changed into a nanometer-level rough grain metallic diffuse reflection layer during the LED preparation of the traditional process, so that the diffuse reflection and scattering effect is enhanced, the collocation of the reflection layer and the light-emitting surface microstructure is optimized, and the extraction efficiency of light inside the LED is furthest increased. The preparation method disclosed by the invention is simple in process and high in repeatability and can be used for large-scale industrial production.

Owner:EPILIGHT TECH

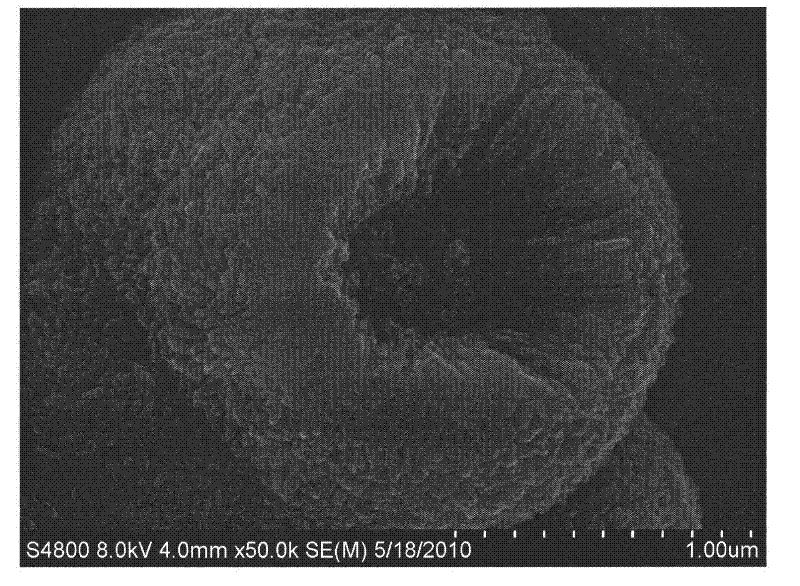

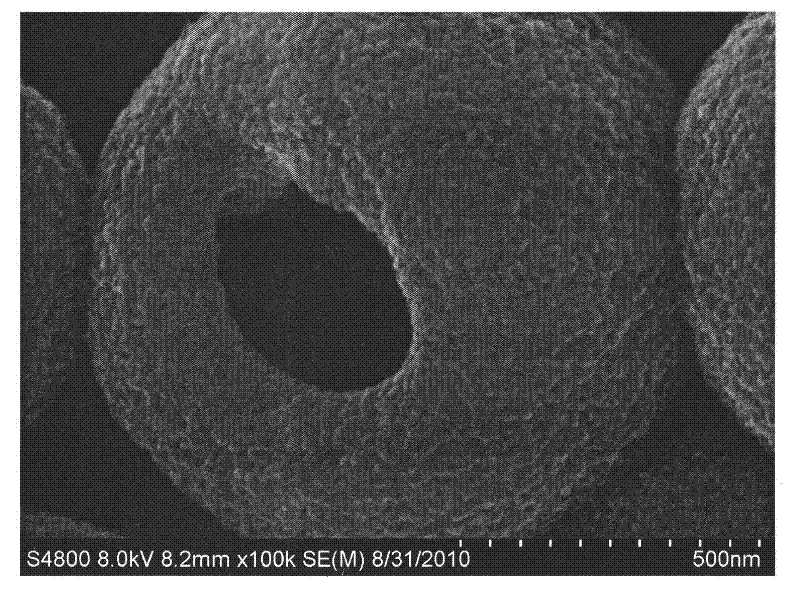

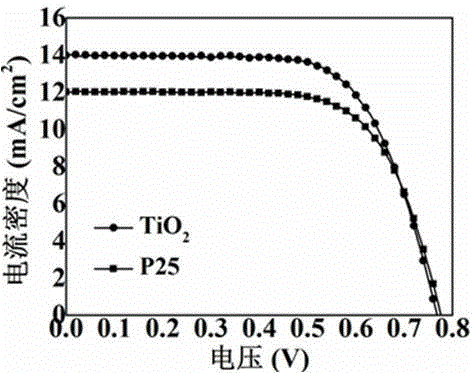

Titanium dioxide light anode, and preparation method and use thereof

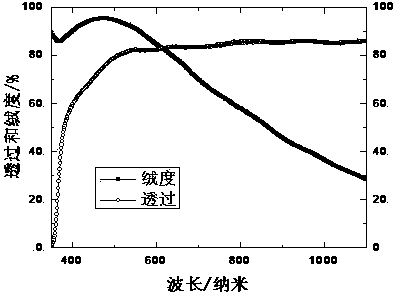

InactiveCN102254697AImprove the scattering effectImprove photoelectric conversion efficiencyLight-sensitive devicesSolid-state devicesMicrosphereLight propagation

The invention discloses a titanium dioxide light anode, comprising a transparent conductive substrate and a coating film coated on the transparent conductive substrate. The coating film contains titanium dioxide nano particles, wherein a titanium dioxide microsphere layer is also coated on the surface of the coating film. The invention further discloses a method for preparing the titanium dioxide light anode and use thereof. Compared with the prior art, the invention has the advantages that by introducing the titanium dioxide light anode with a double-layer structure, the number of light propagation paths in a titanium dioxide film is increased; the rate that light is absorbed by the titanium dioxide film is increased; the photoelectric conversion efficiency of a cell is advantageous for being improved; the preparation of the titanium dioxide microsphere is simple, environment-friendly and cheap and the profile of the titanium dioxide microsphere is novel; the titanium dioxide microsphere is applicable for being used as a scattering layer and coated on a light anode of a dye-sensitized nanocrystalline solar cell; the titanium dioxide light anode with the double-layer structure is formed; the scattering characteristics of the light anode are improved; and the photoelectric conversion efficiency of the cell is improved.

Owner:NINGBO UNIV

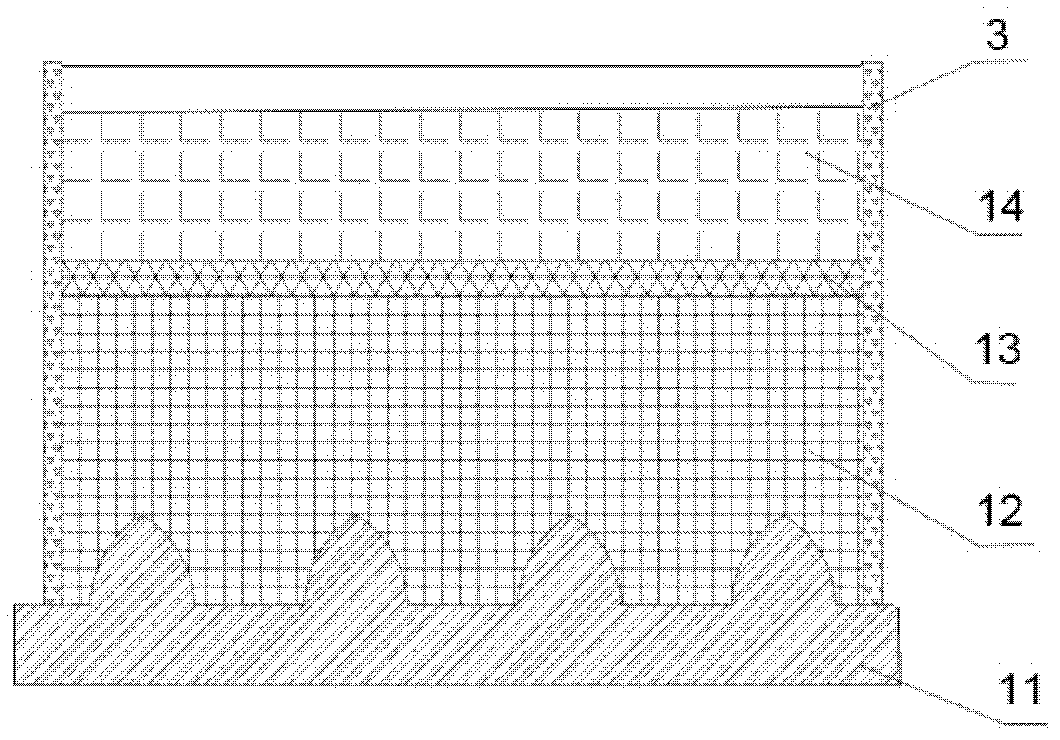

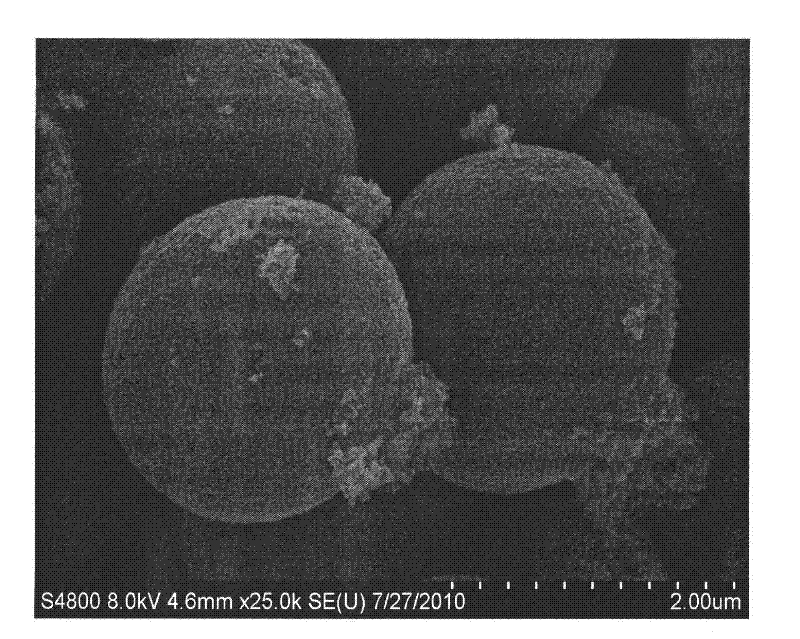

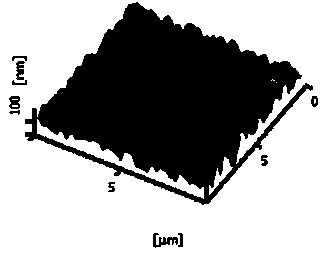

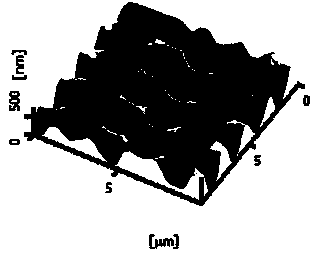

Back reflection electrode with periodic structure and manufacturing method thereof

ActiveCN103474483AIncrease short circuit current densityHigh densityFinal product manufacturePhotovoltaic energy generationSputteringMicrosphere

Provided is a back reflection electrode with a periodic structure. The back reflection electrode with the periodic structure comprises a substrate layer, first layer metal film which plays a role of a template, and second layer metal film which plays a role in decoration, wherein the two layers of metal film are metal Ag film or metal Al film or metal Mo film, and the back reflection electrode with the periodic structure is formed and has the function of broadband-spectrum scattering. A manufacturing method of the back reflection electrode with the periodic structure comprises the steps that PS microspheres are assembled through the water bath method, plasma etching is carried out on the PS microspheres through O2, the template effect of the etched polystyrene microspheres is used for obtaining the back reflection electrode with the periodic structure and the function of broadband-spectrum scattering, and the back reflection electrode with the periodic structure serves as a back reflection electrode of a thin film solar cell. The back reflection electrode with the periodic structure and the manufacturing method of the back reflection electrode with the periodic structure have the advantages that due to the fact that the template effect of the polystyrene microspheres and the mode that magnetron sputtering or evaporation is carried out on the metal film are used, manufacturing of the high-scattering back reflection electrode with the periodic structure is achieved, and when the back reflection electrode with the periodic structure is applied to the thin film solar cell, the short-circuit current density and conversion efficiency of the thin film solar cell are improved.

Owner:NANKAI UNIV

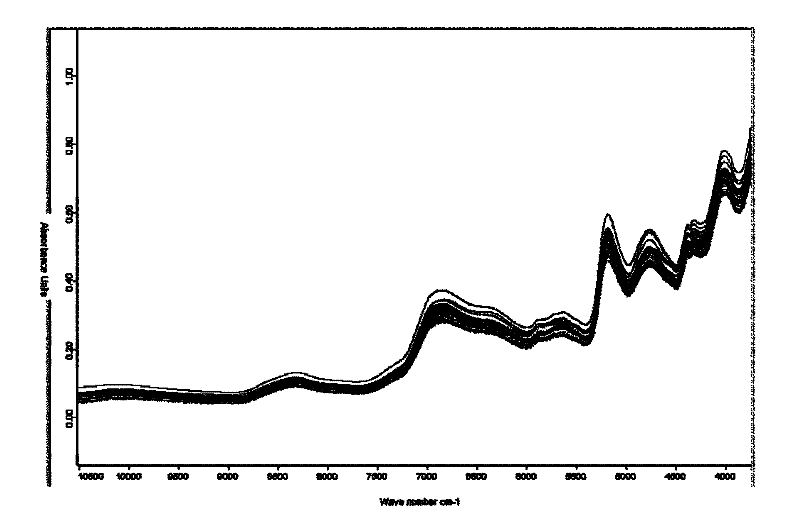

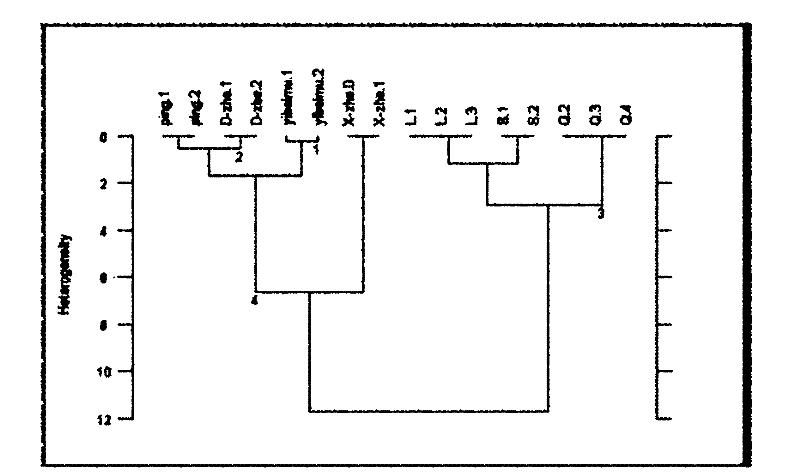

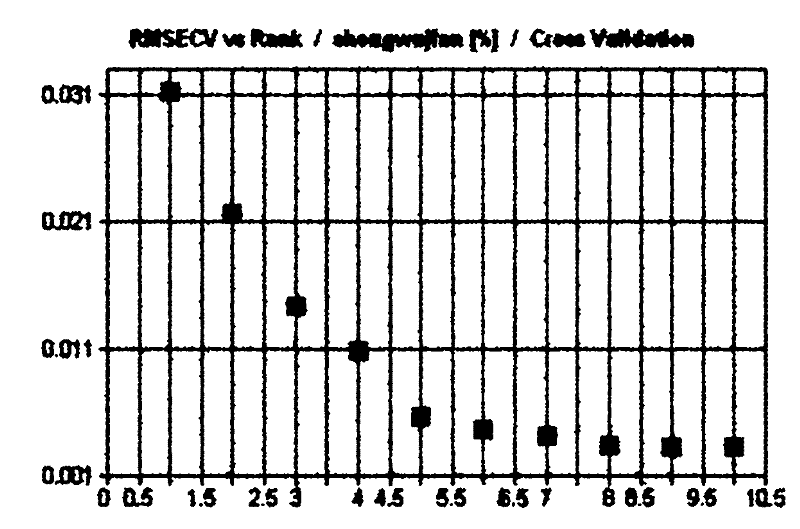

Method for distinguishing variety of fritillaria and detecting total alkaloid content of fritillaria by virtue of near infrared spectrum

InactiveCN102175648ASmall absorption coefficientEasy to collectScattering properties measurementsSample MeasurePrincipal component regression

The invention provides a method for distinguishing variety of fritillaria and detecting total alkaloid content of the fritillaria by virtue of near infrared spectrum. The method provided by the invention comprises the following steps: (1) collecting a fritillaria sample; (2) measuring the near infrared diffuse reflection spectrogram of the fritillaria sample, preprocessing the 4000-5000cm<-1> wave band in the spectrogram, and performing cluster analysis on the pre-processed near infrared spectrogram to build a qualitative model; or preprocessing the 4000-7000cm<-1> wave band in the spectrogram, so as to obtain an absorbance, associating the absorbance with the alkaloid content of the sample measured by virtue of bromothymol blue colorimetry, and building a quantitative correction model for detecting alkaloid by one or more methods of a partial least squares method, a principal component regression method and a multiple linear regression method; (3) collecting the near infrared spectrogram of the sample to be measured, after the corresponding preprocessing is performed, distinguishing the variety of the fritillaria and detecting total alkaloid content of the fritillaria by utilizing the built qualitative model or quantitative correction model. The method provided by the invention has the characteristics of fast speed, no damage, environment friendliness and low cost.

Owner:DALIAN UNIV OF TECH

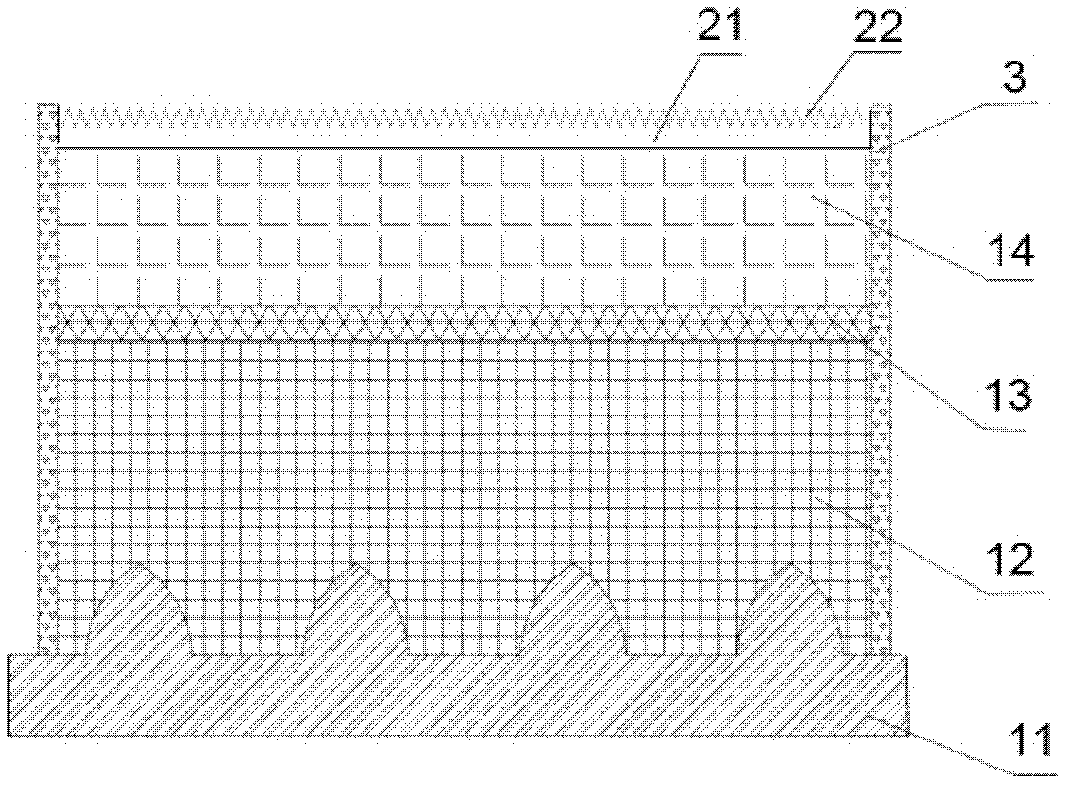

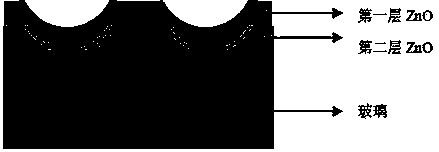

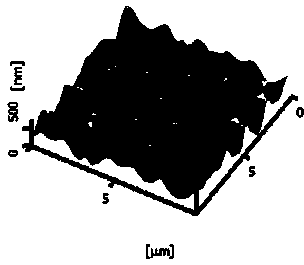

Textured transparent conductive thin film with periodic structure and preparation method thereof

ActiveCN103515484AImprove trapping effectGood scattering effectFinal product manufactureVacuum evaporation coatingMicrosphereThin membrane

Provided is textured transparent conductive thin film with a periodic structure. The textured transparent conductive thin film with the periodic structure comprises a glass substrate layer, first layer ZnO thin film which plays a role in a template, and second layer ZnO thin film which plays a role in modification, wherein a laminated structure is formed by the glass substrate layer, the first layer ZnO thin film and the second layer ZnO thin film in sequence, the thickness of the first layer ZnO thin film is 300-1500nm, the thickness of the second layer ZnO thin film is 400-1000nm, and the textured transparent conductive thin film which has the scattering effect and is of the periodic structure is formed. A preparation method of the textured transparent conductive thin film with the periodic structure comprises the steps of using the water bath method to assemble PS microspheres, using O2 to carry out plasma etching on the PS microspheres, and obtaining the light-trapping ZnO transparent conductive thin film with the periodic structure through the template effect of the PS microspheres. The textured transparent conductive thin film with the periodic structure and the preparation method of the textured transparent conductive thin film with the periodic structure have the advantages that the prepared ZnO transparent conductive thin film has the good light-trapping effect, can serve as a front electrode to be applied to a thin film solar cell, and have a good scattering effect within the range of the wavelength which can be used by cells with the size of 400-1100nm, the optical distance of incident light in silicon-based thin-film cells can be increased, and the use ratio of light can be improved.

Owner:NANKAI UNIV

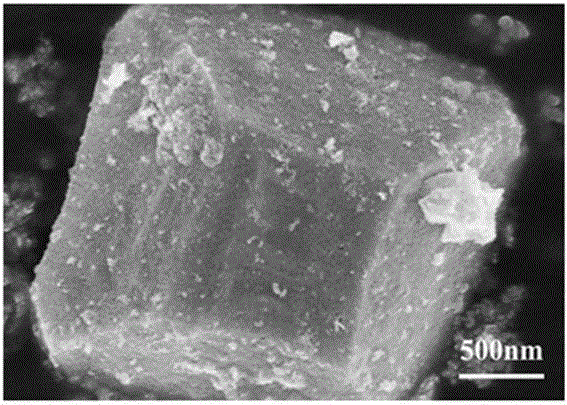

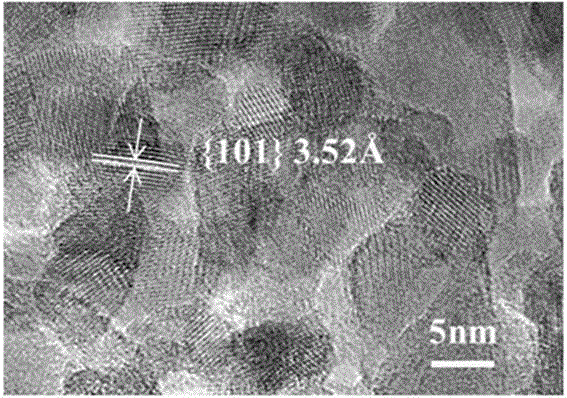

Hierarchical mesoporous TiO2 prepared by taking MOF as precursor and application

InactiveCN105321719ALarge specific surface areaComprehensive adsorptionLight-sensitive devicesPhotovoltaic energy generationN dimethylformamideMetal-organic framework

The invention discloses a hierarchical mesoporous TiO2 prepared by taking an MOF (Metal-Organic Framework) as a precursor and an application. The preparation method comprises the following specific steps: dissolving terephthalic acid into a mixed solution of N, N-dimethylformamide and water; then dripping isopropyl titanate, performing a hydrothermal reaction and obtaining MIL-125 (Ti); and finally, calcining the MIL-125 (Ti) and obtaining the hierarchical mesoporous TiO2. The obtained hierarchical mesoporous TiO2 has a larger specific surface area and a better scattering effect, can increase the light harvesting efficiency and charge collection efficiency, and is suitable to be used as a photo-anode material of a dye-sensitized solar cell.

Owner:FUZHOU UNIV

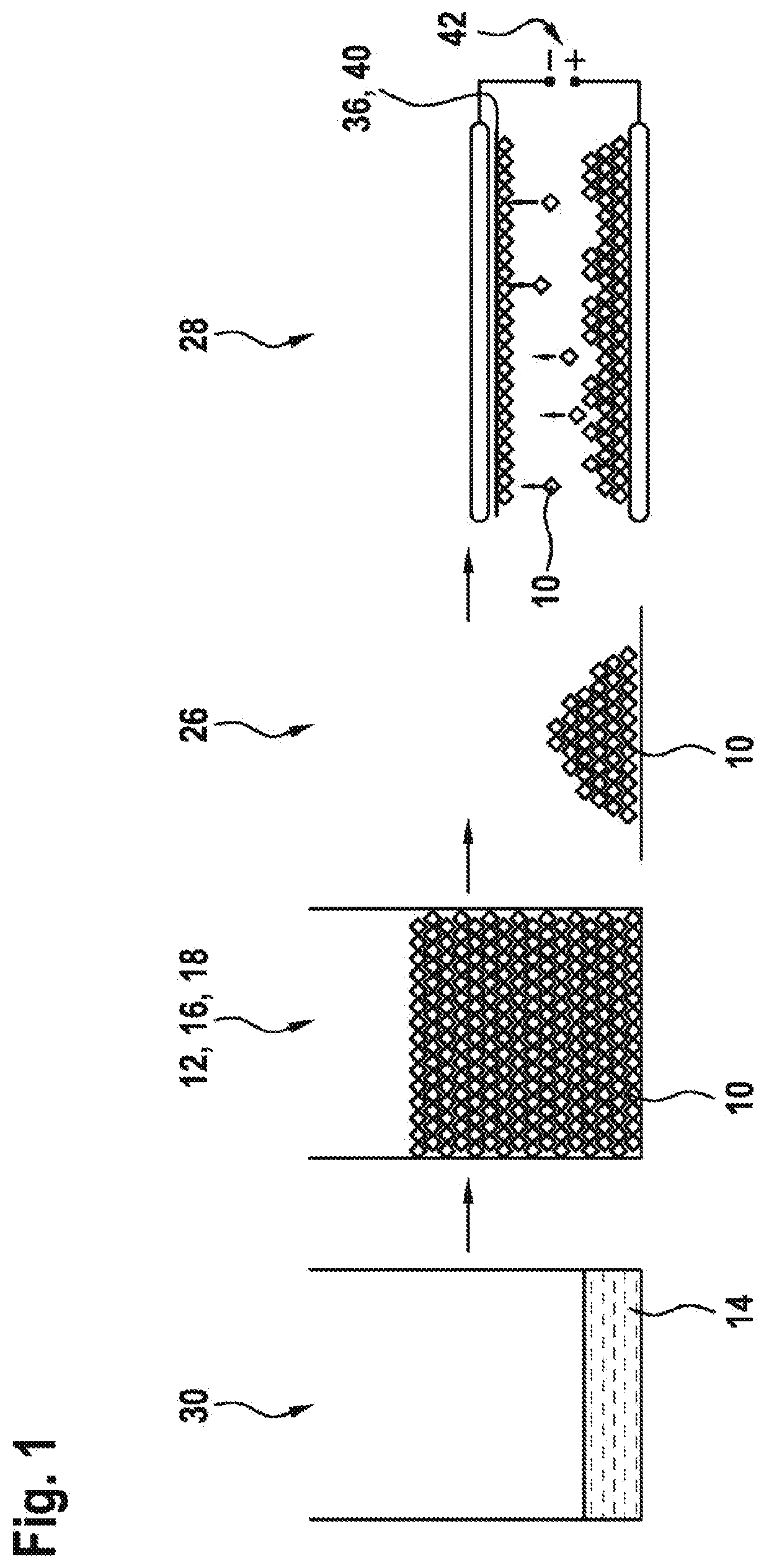

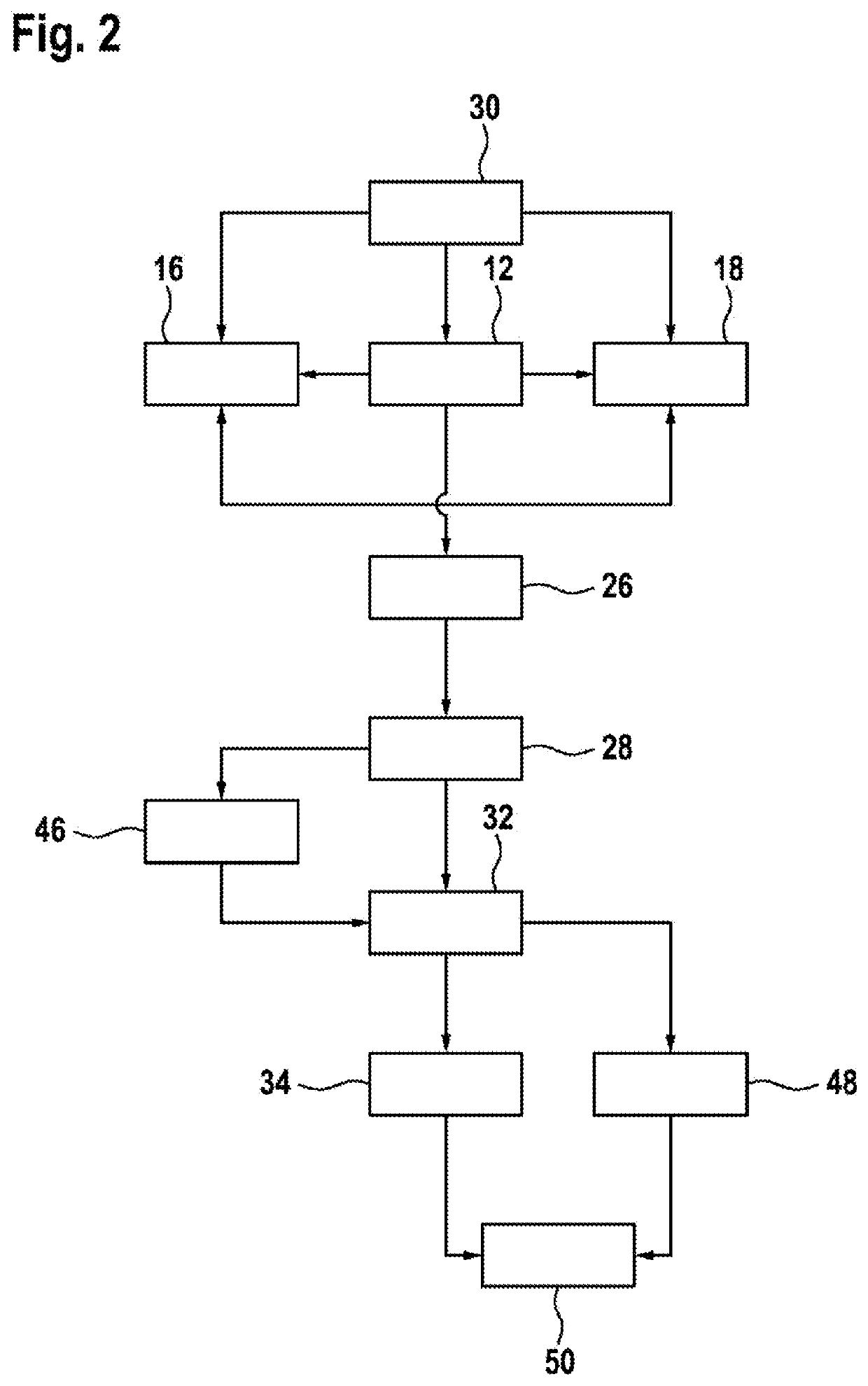

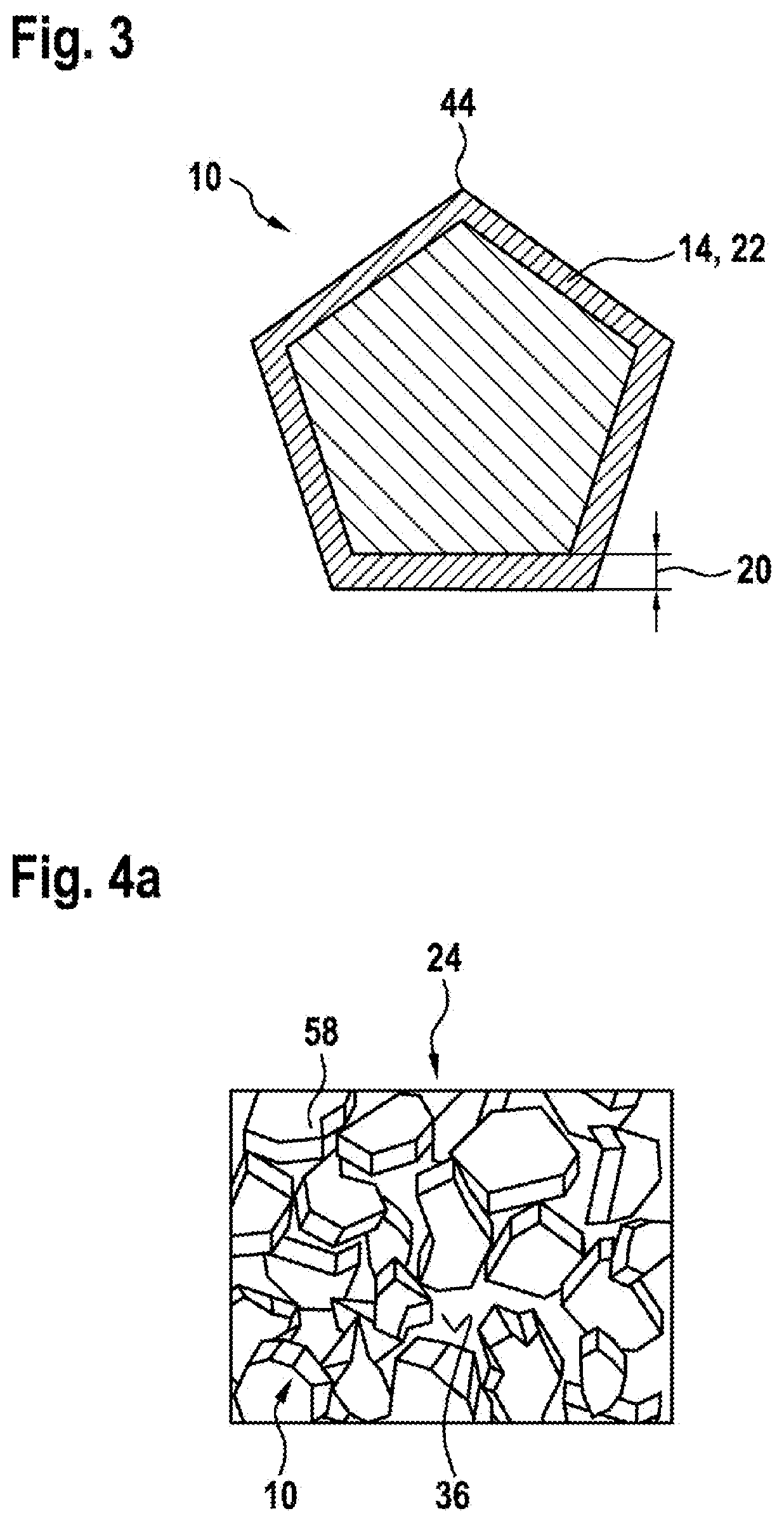

Method for Electrostatically Scattering an Abrasive Grain

ActiveUS20190366511A1Good grainfall behaviorQuality improvementConductive materialAbrasion apparatusConductive materialsOrganic compound

A method for electrostatically scattering an abrasive grain includes applying at least one electro-conductive material to the abrasive grain. The electro-conductive material is in the form of at least one organic compound.

Owner:ROBERT BOSCH GMBH

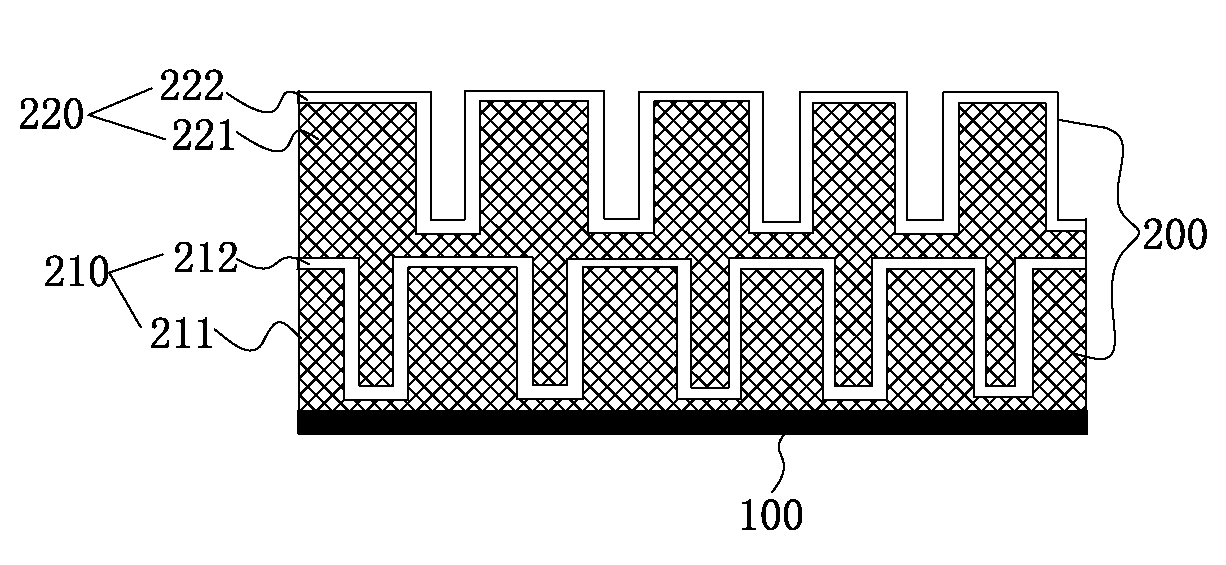

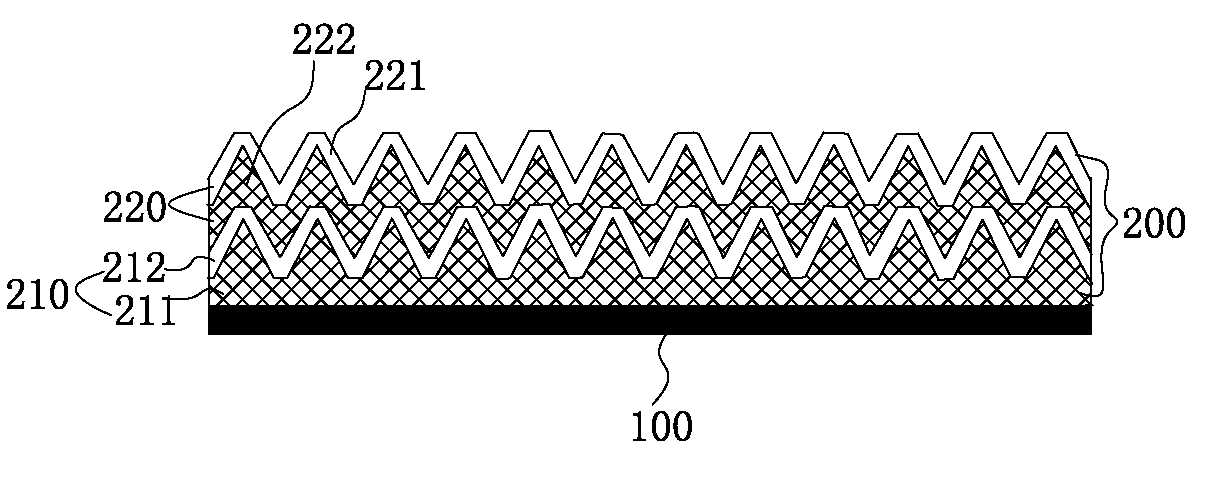

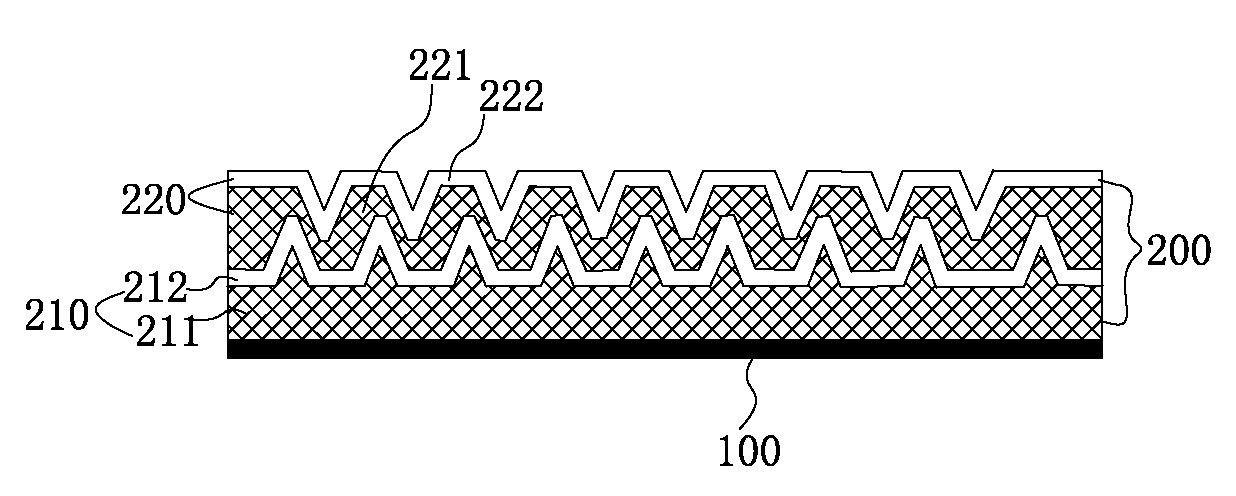

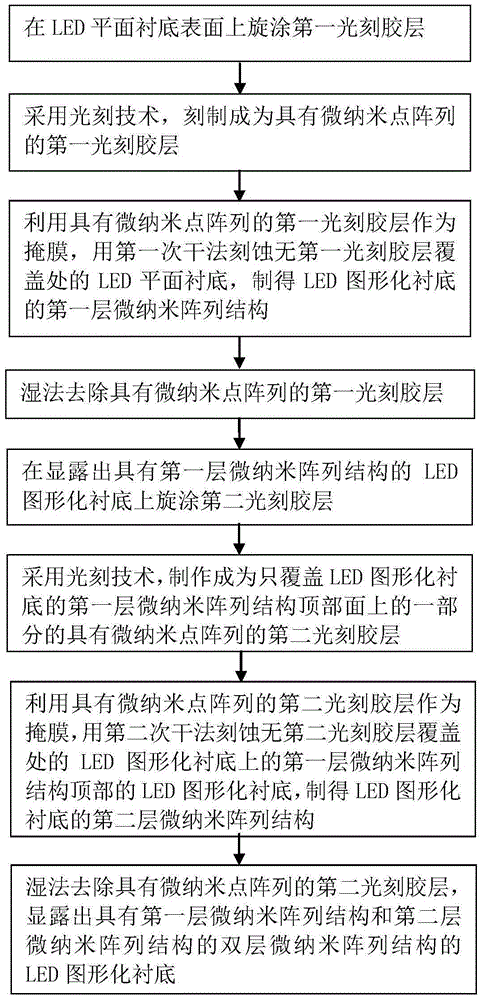

Manufacturing method for LED patterned substrate with double-layer micro-nano array structure

ActiveCN105226144AImprove lattice qualityImprove light extraction efficiencySemiconductor devicesMicro nanoOptoelectronics

The invention discloses a manufacturing method for an LED patterned substrate with a double-layer micro-nano array structure, and relates to a semiconductor device. The manufacturing method comprises the following steps: performing spin-coating to obtain a first photoresist layer; manufacturing a first photoresist layer with a micro-nano spot array; performing primary dry etching; removing the first photoresist layer with the micro-nano spot array by using a wet method; performing spin-coating to obtain a second photoresist layer; manufacturing a second photoresist layer with a micro-nano spot array; performing secondary dry etching; and removing the second photoresist layer with the micro-nano spot array by using the wet method, thus manufacturing the LED patterned substrate with the double-layer micro-nano array structure. According to the method disclosed by the invention, due to the design of the first layer of micro-nano structure, the crystal lattice quality of GaN is improved; due to the design of the second layer of micro-nano structure, the light extraction efficiency of an LED is improved; the defect that the improvement on the crystal lattice quality of GaN and the maximum improvement on the light extraction efficiency of the LED can not be compatible in the prior art is overcome.

Owner:HEBEI UNIV OF TECH

LED energy-saving lamp tube with glass lamp tube

InactiveCN103511892AAvoid flammable safety hazardsNot easy to age and deformPoint-like light sourceLighting support devicesEngineeringScattering effect

The invention relates to an LED energy-saving lamp tube with a glass lamp tube. The LED energy-saving lamp tube comprises the lamp tube, a lamp holder, an LED lamp strip, a lamp strip inserted strip and LED circuit boards, wherein the lamp tube is a circular glass lamp tube, the wall face above the pipe wall of the inner side of the glass lamp tube is in contact connection with the upper portion face of an aluminum profile inserted strip, a lamp strip inserted groove is formed in the lower bottom face of the aluminum profile inserted strip, the LED lamp strip is in inserted connection in the lamp strip inserted groove, the two ends, stretching out of the glass lamp tube, of the aluminum profile inserted strip are respectively in inserted connection with one LED circuit board, the upper wall face of the pipe wall of the inner side of one heat dissipation aluminum tube is in contact connection with the upper portion face of the aluminum profile inserted strip, and the outward side ends of the left sides and the right sides of the two heat dissipation aluminum tubes are in inserted connection with the lamp holder. According to the LED energy-saving lamp tube, the glass lamp tube is adopted, aging and deformation are not easily caused, the light-pervious effect is good and stable, the appearance is attractive, the installation is convenient, the scattering effect is good, and enough space inside the heat dissipation aluminum tubes is provided for containing LED circuit board components.

Owner:梁红燕

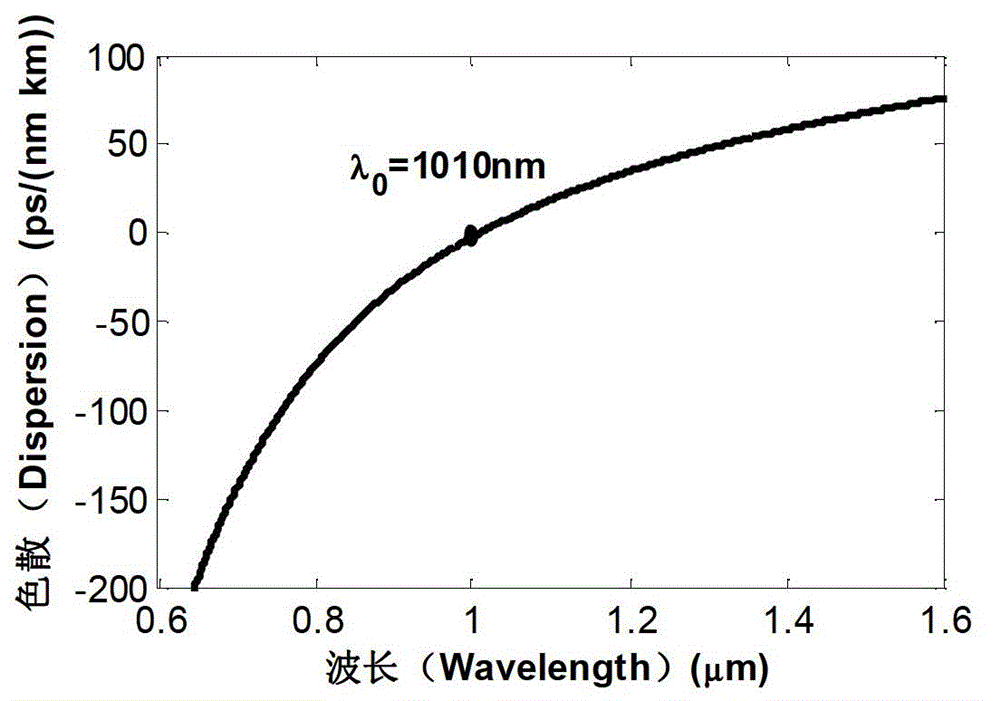

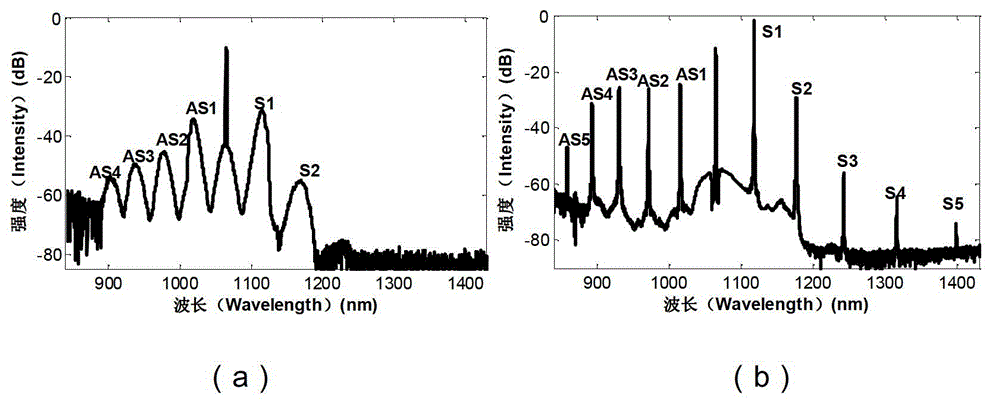

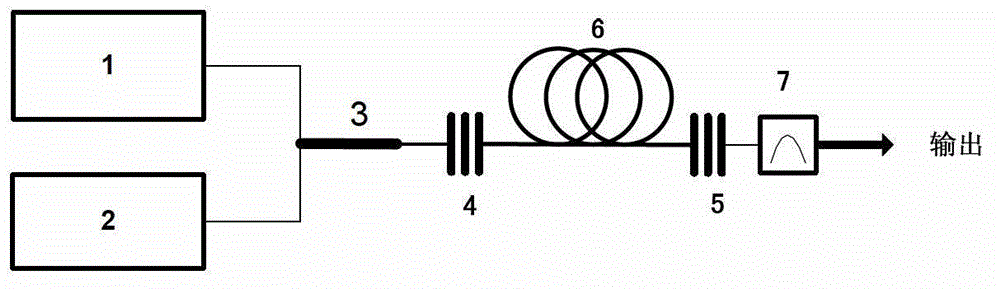

Anti-Strokes Raman fiber laser achieving multi-wavelength output

ActiveCN103151682AImprove the scattering effectVariable wavelengthLaser using scattering effectsActive medium shape and constructionContinuous lightGrating

The invention discloses an anti-Strokes Raman fiber laser achieving multi-wavelength output and aims at providing a laser of which an output wavelength is adjustable and the output wavelength is smaller than a pump wavelength. The fiber laser is composed of a pulse light source, a continuous light source, a wavelength division multiplexer, a high raster, an optical fiber, a low raster and a filter. The central wavelength of the output light of the pulse light source is located at n stage Raman Strokes wavelength of the obtained light wavelength, the output light wavelength of the continuous light source is located at a first stage Raman Strokes wavelength of the output light wavelength of the pulse light source, a zero-dispersion wavelength of the optical fiber is located near the output light wavelength of the pulse light source, the central wavelength of the high raster and the central wavelength of the low raster are equal to the obtained laser wavelength, the input arm working wavelength of the wavelength division multiplexer is respectively equal to the central wavelength of the pulse light source and the central wavelength of the continuous light source, and the central wavelength of the filter is equal to the obtained light wavelength. The anti-Strokes Raman fiber laser is simple in structure, adjustable in the light wavelength and can output a laser shorter than the pump wavelength.

Owner:NAT UNIV OF DEFENSE TECH

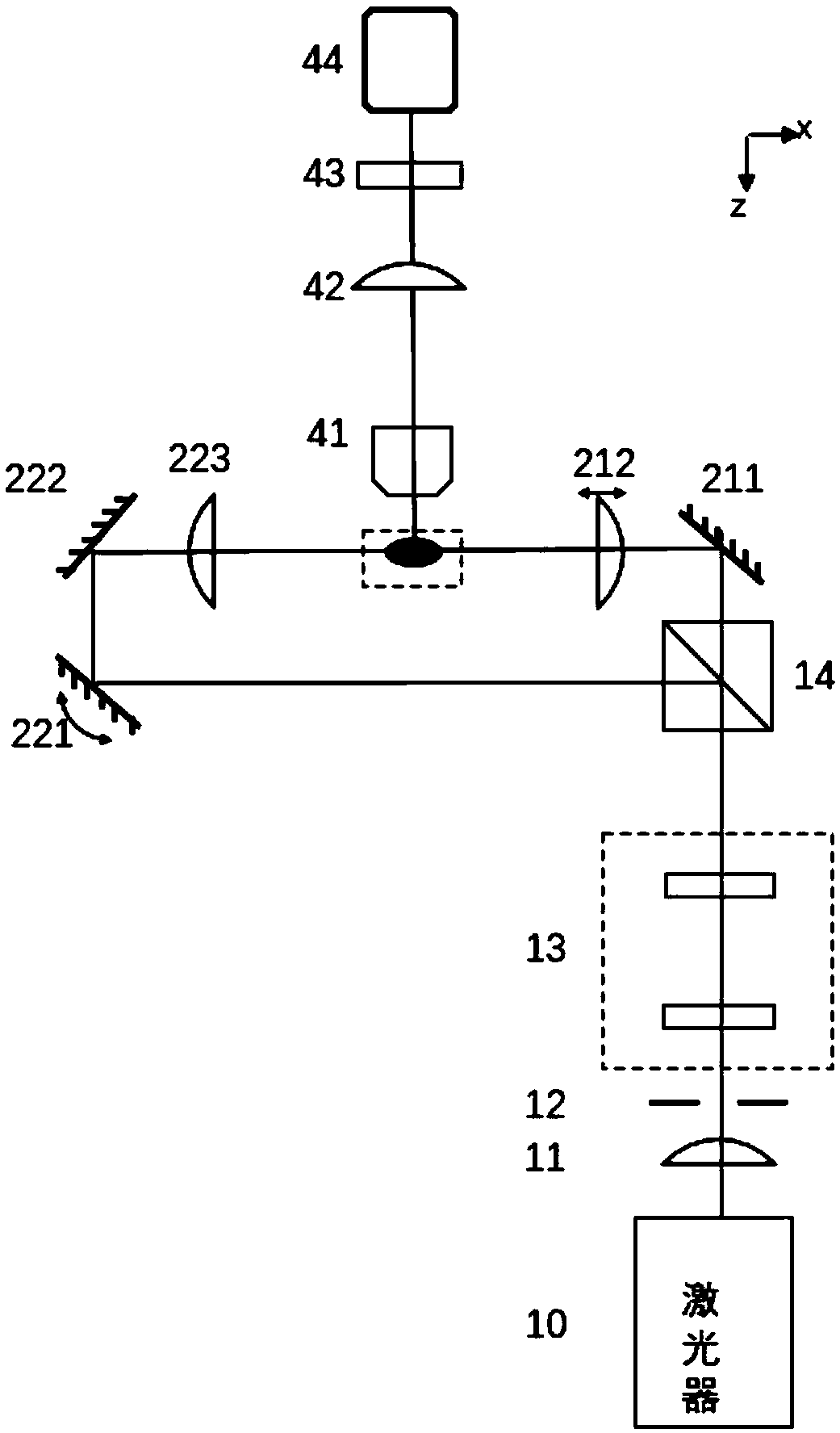

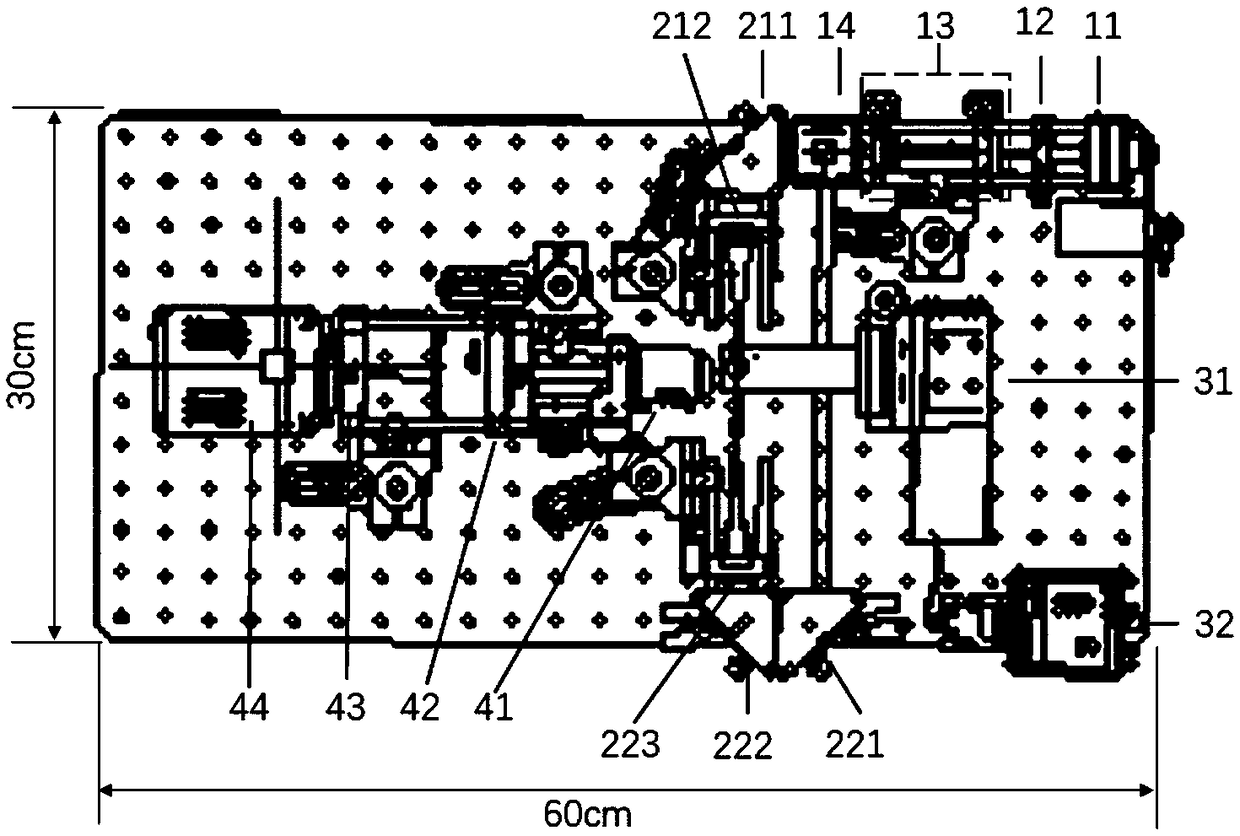

Miniaturized multi-angle three-dimensional super-resolution light sheet fluorescence microscope

The invention discloses a miniaturized multi-angle three-dimensional super-resolution light sheet fluorescence microscope. The microscope comprises a light source module, a light sheet generation module, a sample control module and an image acquisition module; the light source module is used for forming a beam of collimated elliptical light; the light sheet generation module is used for producinga light sheet according to the collimated elliptical light; the sample control module is used for controlling a sample to move to be scanned by the light sheet when the light sheet is irradiated on the sample; and the image acquisition module is used for synchronously acquiring fluorescence light for exciting the sample to form an image sequence. The microscope has relatively high cost performance; relatively few elements are adopted; a hardware device of the microscope is small and exquisite compared with a large-scale Bezier light sheet microscope, a commercial light sheet microscope and thelike; and the microscope is simple in operation and has great practical values.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method for high-refractivity scattering layer and preparation method for organic light-emitting diode (OLED) with high luminous efficiency

ActiveCN102709489AEasy to operateGood flatnessSolid-state devicesSemiconductor/solid-state device manufacturingChemistryPhotoresist

The invention discloses a preparation method for a high-refractivity scattering layer and a preparation method for an organic light-emitting diode (OLED) with high luminous efficiency. The preparation method for the high-refractivity scattering layer comprises the following steps of: S1, preparing grinding dispersion, wherein the grinding dispersion comprises 10 to 60 mass percent of high-refractivity scattering particle, a dispersing agent of which the mass is 1 to 60 percent based on the mass of the high-refractivity scattering particles, 0 to 5 mass percent of anti-settling agent, 0 to 60 mass percent of photoresist and 20 to 89.9 mass percent of organic solvent; S2, filter-pressing the grinding dispersion prepared by the step S1 by using filter paper with filtering hole apertures of 0.8 to 1.2 mu m to obtain a film preparation solution; and S3, photoetching and spinning the film preparation solution prepared by the step S2 to obtain the high-refractivity scattering layer. When the high-refractivity scattering layer is arranged between a substrate and an electrode of the OLED with the high luminous efficiency, the luminous efficiency of the OLED can be greatly improved.

Owner:GUAN YEOLIGHT TECH CO LTD

Manufacturing process of three-layer co-extrusion nano-modified BOPP matt film

InactiveCN105500889AImprove the interface binding forceImprove wear resistanceLamination ancillary operationsSynthetic resin layered productsHigh rateSurface layer

The invention discloses a manufacturing process of a three-layer co-extrusion nano-modified BOPP matt film. The manufacturing process comprises the following steps: after mixing and drying raw materials of a coring layer, an upper surface layer and a lower surface layer, entering respective single screw extruders to carry out melt plastification, and then entering a die head through a filter and a metering pump; flowing out after converging a three-layer polymer melt at the position of the die head, quickly attaching to the surface of a quenching roller under the effect of an air knife attaching device, forming a solid sheet through quick cooling of the quenching roller and a water channel, then carrying out longitudinal and transverse stretching in sequence, and then instantly carrying out air cooling treatment; then subsequently carrying out online thickness measurement, boundary material cutting, static elimination, automatic rolling, aging treatment and slitting. The manufacturing process adopts a three-layer co-extrusion compounding technology, the BOPP matt film with high extinction property, good abrasion resistance and high rate of finished products is prepared by using an improved raw material formula.

Owner:HAINING CHANGKUN PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com