Titanium dioxide light anode, and preparation method and use thereof

A technology of titanium dioxide and photoanode, applied in the field of photoanode, can solve the problems of unfavorable photoelectric conversion efficiency of batteries, low utilization efficiency of sunlight, weak scattering, etc., and achieves the improvement of photoelectric conversion efficiency, photoelectric conversion efficiency, and absorption probability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: The photoelectric conversion performance of a titanium dioxide thin film electrode uniformly mixed and coated with 0.2 g of 1000 nm ring-shaped titanium dioxide microspheres and 5 ml of absolute ethanol.

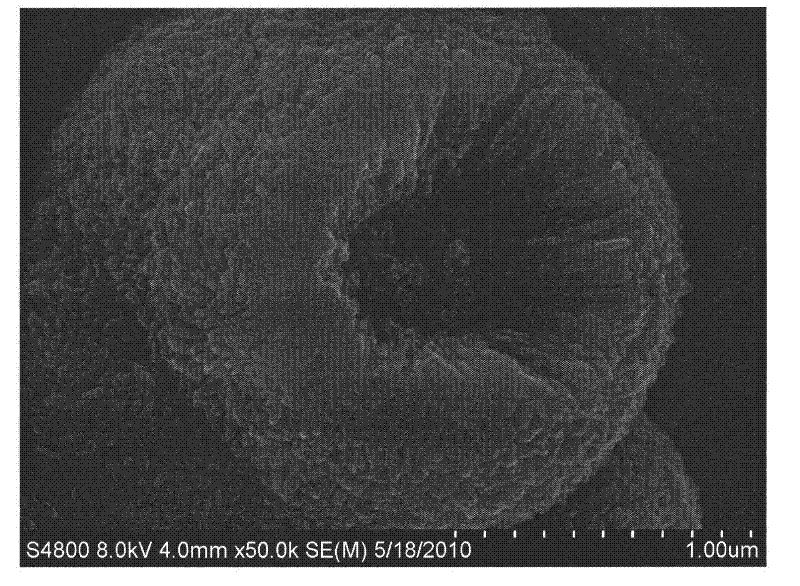

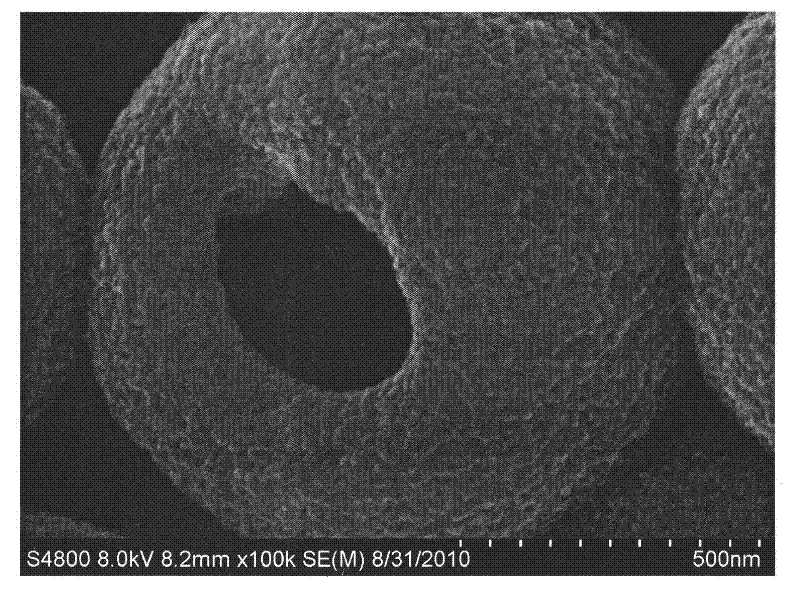

[0033] 1000nm (microsphere diameter) cyclic titanium dioxide microspheres (see figure 2 Shown) is obtained from 0.51ml of tetrabutyl titanate and 0.2ml of hydrofluoric acid, 16h at 180°C solvothermally. Spin centrifugal separation, dry in an oven at 60°C for 3h, then mix with high-power ultrasonic 0.2g and 5ml absolute ethanol, and then stir for 1h and coat the photoanode of titanium dioxide nanoparticles with a thickness of about 12μm. The coated conductive glass is calcined in a muffle furnace at 450° C. for 2 hours to obtain a double-layer structure photoanode for a dye-sensitized nanocrystalline solar cell. Soak the photoanode in a concentration of 5×10 -4 The mol / L ruthenium complex N719 dye (English name: RuL2(NCS)2:2TBA (L=2,2'-bipyridyl-4,4'-dicarboxy...

Embodiment 2

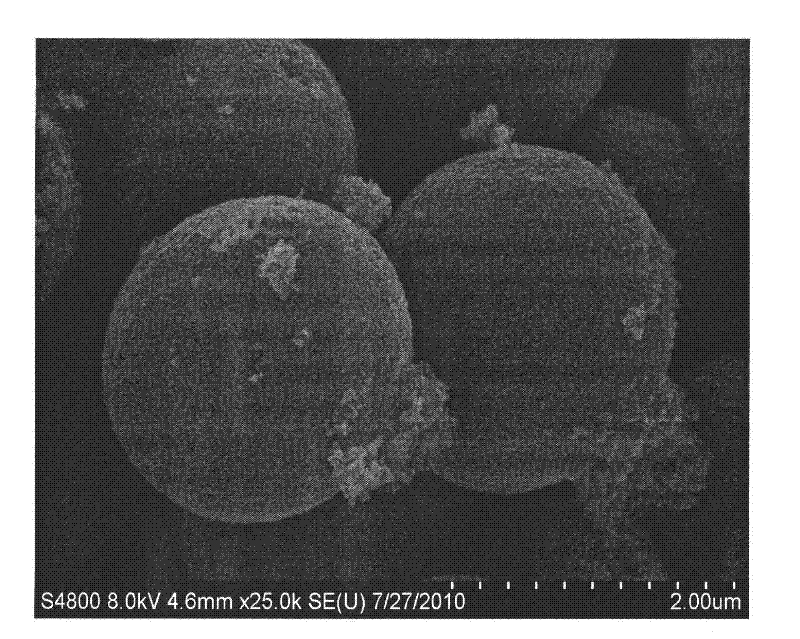

[0034] Example 2: From 0.2g 2000nm spherical titanium dioxide microspheres (see image 3 Shown) and 5ml of absolute ethanol uniformly mixed and coated on the photoelectric conversion performance of the titanium dioxide film electrode.

[0035] 2000nm (microsphere diameter) spherical titanium dioxide microspheres are obtained from 1.02ml of tetrabutyl titanate, 16h, 180℃ solvothermal. Rotate and separate, dry in an oven at 60°C for 3h, then mix with high-power ultrasonic 0.2g and 5ml of absolute ethanol, and after stirring for 1h, apply a film on the photoanode of titanium dioxide nanoparticles with a thickness of approximately 12μm. The coated conductive glass is calcined in a muffle furnace at 450° C. for 2 hours to obtain a double-layer structure photoanode for a dye-sensitized nanocrystalline solar cell. Soak the photoanode in a concentration of 5×10 -4 With the mol / L N719 solution for 24 hours, the photoanode was fully sensitized by the dye. Then the photoanode is connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com