Preparation method for high-refractivity scattering layer and preparation method for organic light-emitting diode (OLED) with high luminous efficiency

A technology of high refractive index and scattering layer, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, electric solid-state devices, etc., can solve the problem of poor surface flatness of the scattering film layer, the lack of scattering effect of the film layer, and particles in the scattering film Unevenness and other problems, to achieve good flatness, improved light extraction efficiency, and uniform film-making solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

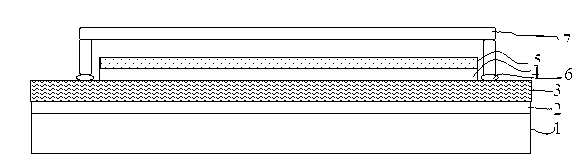

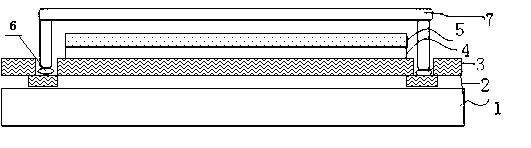

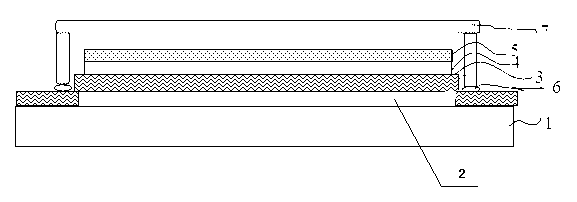

Image

Examples

Embodiment 1

[0046] This embodiment provides a method for preparing a high refractive index scattering layer, comprising the following steps:

[0047] S1, prepare grinding dispersion liquid, described grinding dispersion liquid comprises:

[0048] High refractive index scattering particles, in this embodiment, the high refractive index scattering particles are selected as TiO 2 , its weight selection is 15g, and its mass percentage is 18.6%;

[0049] Dispersant, the dispersant selects byk-163 produced by BYK Chemical Co., Ltd. as a dispersant, its weight is selected as 1.2g, and its mass accounts for 8% of the high refractive index scattering particles;

[0050] Organic solvent, select propylene glycol methyl ether acetate as organic solvent, its weight selection is 60g, and its mass percentage is 78.74%;

[0051]Put the above-prepared solution into the grinding tank, fix the grinding tank and the grinding column, add 90ml of zirconium beads (note: the amount of zirconium beads depends o...

Embodiment 2

[0063] In this example, the following improvements are made on the basis of Example 1. An anti-sedimentation agent is added to the grinding dispersion, and byk-410 produced by BYK Chemical Co., Ltd. is selected, and its weight is selected to be 0.8g, and its mass percentage is 1.03 %;

[0064] And, in this embodiment, the following steps are also included between the step S2 and the step S3: adding photoresist to the film-forming solution prepared in the step S2; in this embodiment Among them, the photoresist is selected to be mixed with the film forming solution, and the mass percentage of the photoresist is 40%.

[0065] In this embodiment, the thickness of the scattering layer is 0.6um. The light extraction efficiency of the OLED device prepared by the preparation method in this example is increased by 100%.

Embodiment 3

[0067] The preparation method of the high refractive index scattering layer provided in this embodiment includes the following steps:

[0068] S1, prepare grinding dispersion liquid, described grinding dispersion liquid comprises:

[0069] High refractive index scattering particles, the mass percentage is: 10%;

[0070] Dispersant, its mass accounts for 36% of the high refractive index scattering particles, that is, its mass percentage is 3.6%;

[0071] Anti-sedimentation agent, its mass percentage is: 5%;

[0072] Photoresist, its mass percentage is: 51.5%;

[0073] Organic solvent, its mass percentage is: 30%;

[0074] S2. Press-filter the grinding dispersion prepared in the step S1 using a filter paper with a filter pore diameter of 0.9um to obtain a film-forming solution;

[0075] S3. The film forming solution prepared in the step S2 is prepared by photolithography and spin coating to obtain a high refractive index scattering layer.

[0076] In this embodiment, the hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com