Hierarchical mesoporous TiO2 prepared by taking MOF as precursor and application

A graded, mesoporous technology, applied in the field of solar cell materials, can solve the problems of harsh experimental conditions, complex synthesis methods, etc., and achieve the effect of simple synthesis process, large specific surface area, and good scattering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A Hierarchical Mesoporous TiO Prepared Using MOF as Precursor 2 , its preparation method comprises the following steps:

[0021] 1) Dissolve 1g of terephthalic acid in a mixed solution of 25mL N,N-dimethylformamide and water ((V N,N-二甲基甲酰胺 :V 水 =5:1), a clear solution was obtained;

[0022] 2) Add 0.5mL isopropyl titanate dropwise to the clear solution obtained in step 1) to obtain a milky white mixture;

[0023] 3) Transfer the milky white mixture obtained in step 2) to a reaction kettle, and conduct a hydrothermal reaction at 120°C for 24 hours to obtain a white precipitate;

[0024] 4) Wash the obtained white precipitate by centrifugation twice with N,N-dimethylformamide and once with methanol to obtain MIL-125(Ti);

[0025] 5) Put the obtained MIL-125(Ti) into a muffle furnace, raise the temperature to 350°C at a rate of 5°C / min, and calcine at a constant temperature for 5h to obtain the graded mesoporous TiO 2 .

Embodiment 2

[0027] A Hierarchical Mesoporous TiO Prepared Using MOF as Precursor 2 , its preparation method comprises the following steps:

[0028] 1) Dissolve 2g of terephthalic acid in a mixed solution of 30mL N,N-dimethylformamide and water ((V N,N-二甲基甲酰胺 :V 水 =8:1), a clear solution was obtained;

[0029] 2) Add 1.0 mL of isopropyl titanate dropwise to the clear solution obtained in step 1) to obtain a milky white mixture;

[0030] 3) Transfer the milky white mixture obtained in step 2) to a reaction kettle, and conduct a hydrothermal reaction at 160°C for 24 hours to obtain a white precipitate;

[0031] 4) Wash the obtained white precipitate by centrifugation twice with N,N-dimethylformamide and once with methanol to obtain MIL-125(Ti);

[0032] 5) Put the obtained MIL-125(Ti) into a muffle furnace, raise the temperature to 400°C at a rate of 5°C / min, and calcine at a constant temperature for 5h to obtain the graded mesoporous TiO 2 .

Embodiment 3

[0034] A Hierarchical Mesoporous TiO Prepared Using MOF as Precursor 2 , its preparation method comprises the following steps:

[0035] 1) Dissolve 3g of terephthalic acid in a mixed solution of 50mL N,N-dimethylformamide and water ((V N,N-二甲基甲酰胺 :V 水 =10:1), a clear solution was obtained;

[0036] 2) Add 1.5mL isopropyl titanate dropwise to the clear solution obtained in step 1) to obtain a milky white mixture;

[0037] 3) Transfer the milky white mixture obtained in step 2) to a reaction kettle, and conduct a hydrothermal reaction at 180°C for 24 hours to obtain a white precipitate;

[0038] 4) Wash the obtained white precipitate by centrifugation twice with N,N-dimethylformamide and once with methanol to obtain MIL-125(Ti);

[0039] 5) Put the obtained MIL-125(Ti) into a muffle furnace, raise the temperature to 450°C at a rate of 5°C / min, and calcine at a constant temperature for 5h to obtain the graded mesoporous TiO 2 .

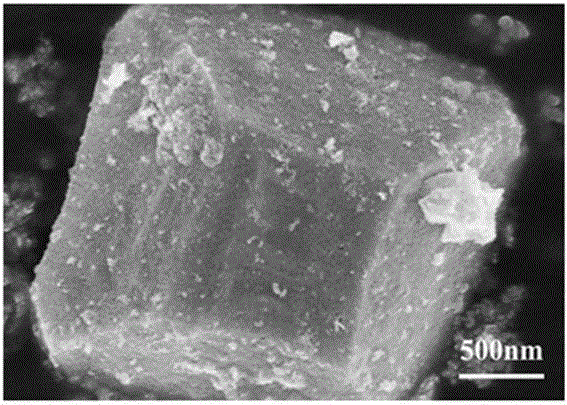

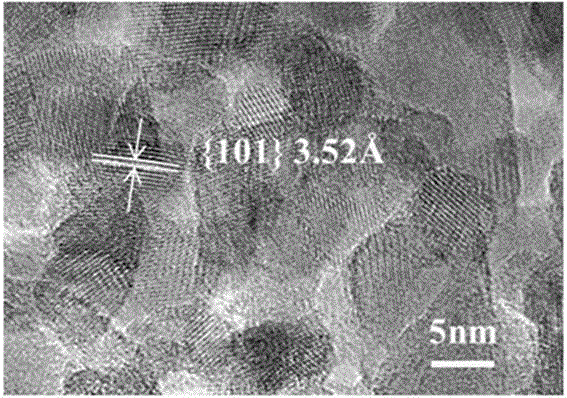

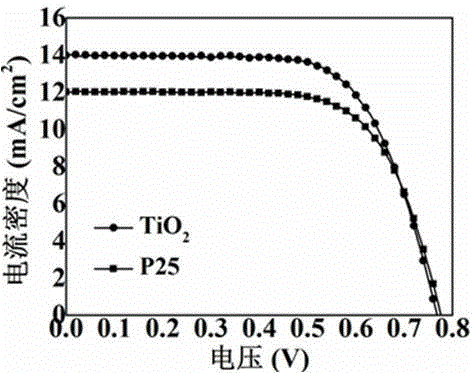

[0040] figure 1 Graded mesoporous TiO prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com