Back reflection electrode with periodic structure and manufacturing method thereof

A periodic structure and back reflection technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low utilization rate of long-wavelength light, poor control of periodicity, and anodic oxidation caused by heat. Achieve good scattering, high scattering, and improved short-circuit current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

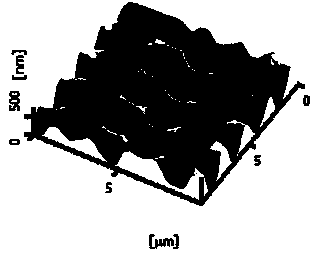

[0023] A periodically structured back reflector, such as figure 1 As shown, it includes the substrate layer, the first layer of Ag thin film that forms a template and the second layer of Ag thin film that plays a role in modification. The substrate layer is hard substrate glass, and the two metal thin films are metal Ag thin films. The thickness of the Ag thin film is 600nm, and the thickness of the second layer of Ag thin film is 300nm, forming a periodic structure back reflective electrode with broad spectrum scattering, and the root mean square roughness of the periodic structure back reflective electrode is 180nm.

[0024] A method for preparing a back reflective electrode with a periodic structure, using a water bath method to assemble polystyrene (PS) microspheres, using O 2 Plasma etching PS microspheres, using the template effect of the etched polystyrene microspheres, to obtain a periodic back reflection electrode with a broad-spectrum scattering effect, the steps are...

Embodiment 2

[0036] A periodically structured back reflector, such as figure 1 As shown, it includes the substrate layer, the first layer of Al thin film that forms a template, and the second layer of Ag thin film that plays a role in modification. The substrate layer is hard substrate glass. The thickness of the thin film is 300nm, which constitutes a periodic structure back reflection electrode with wide spectrum scattering effect, and the root mean square roughness of the periodic structure back reflection electrode is 120nm.

[0037] A method for preparing a back reflective electrode with a periodic structure, using a water bath method to assemble polystyrene (PS) microspheres, using O 2 Plasma etching PS microspheres, using the template effect of the etched polystyrene microspheres, to obtain a periodic back reflection electrode with a broad-spectrum scattering effect, the steps are as follows:

[0038] 1) Soak the glass substrate in H 2 SO 4 with H 2 o 2 Hydrophilic treatment is...

Embodiment 3

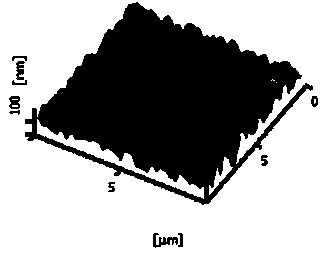

[0046] A periodically structured back reflector, such as figure 1 As shown, it includes the substrate layer, the first layer of Ag thin film that forms a template and the second layer of Ag thin film that plays a role in modification. The substrate layer is hard substrate glass, and the two metal thin films are metal Ag thin films. The thickness of the Ag thin film is 400nm, and the thickness of the second layer of Ag thin film is 300nm, forming a periodic structure back reflective electrode with wide spectrum scattering effect, and the root mean square roughness of the periodic structure back reflective electrode is 85nm.

[0047] A method for preparing a back reflective electrode with a periodic structure, using a water bath method to assemble polystyrene (PS) microspheres, using O 2 Plasma etching PS microspheres, using the template effect of the etched polystyrene microspheres, to obtain a periodic back reflection electrode with a broad-spectrum scattering effect, the step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com