Patents

Literature

165 results about "Back reflector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

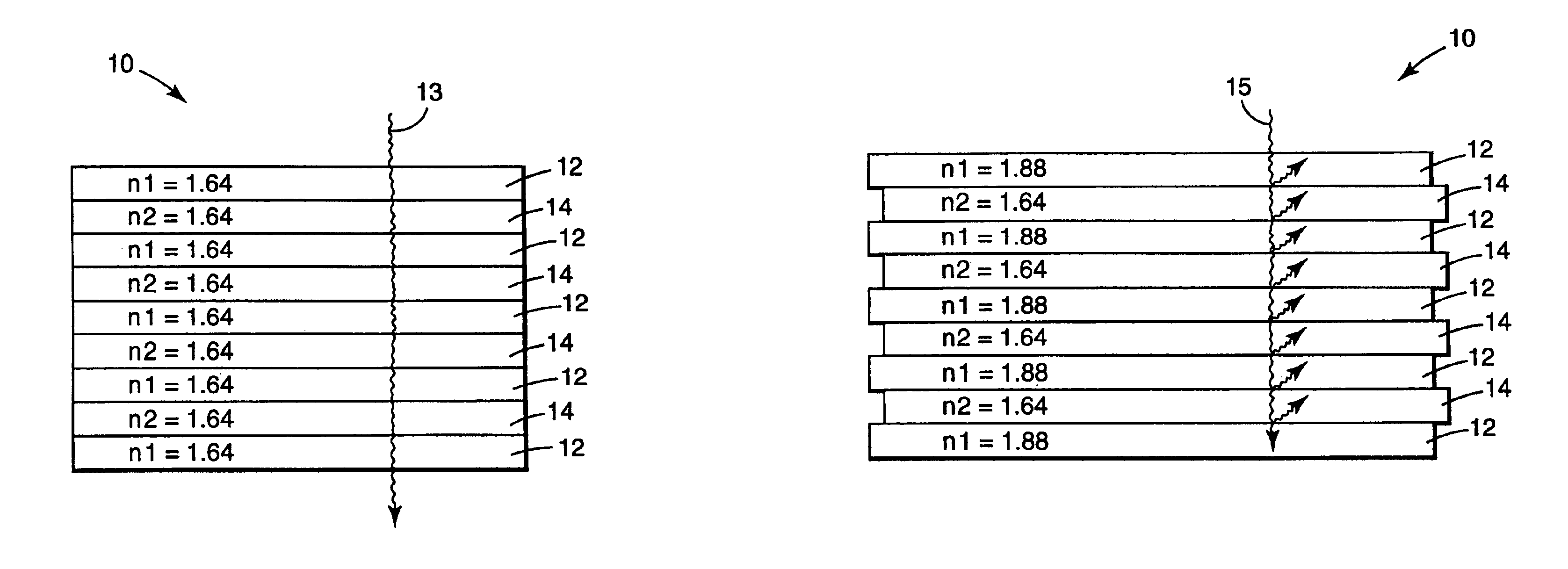

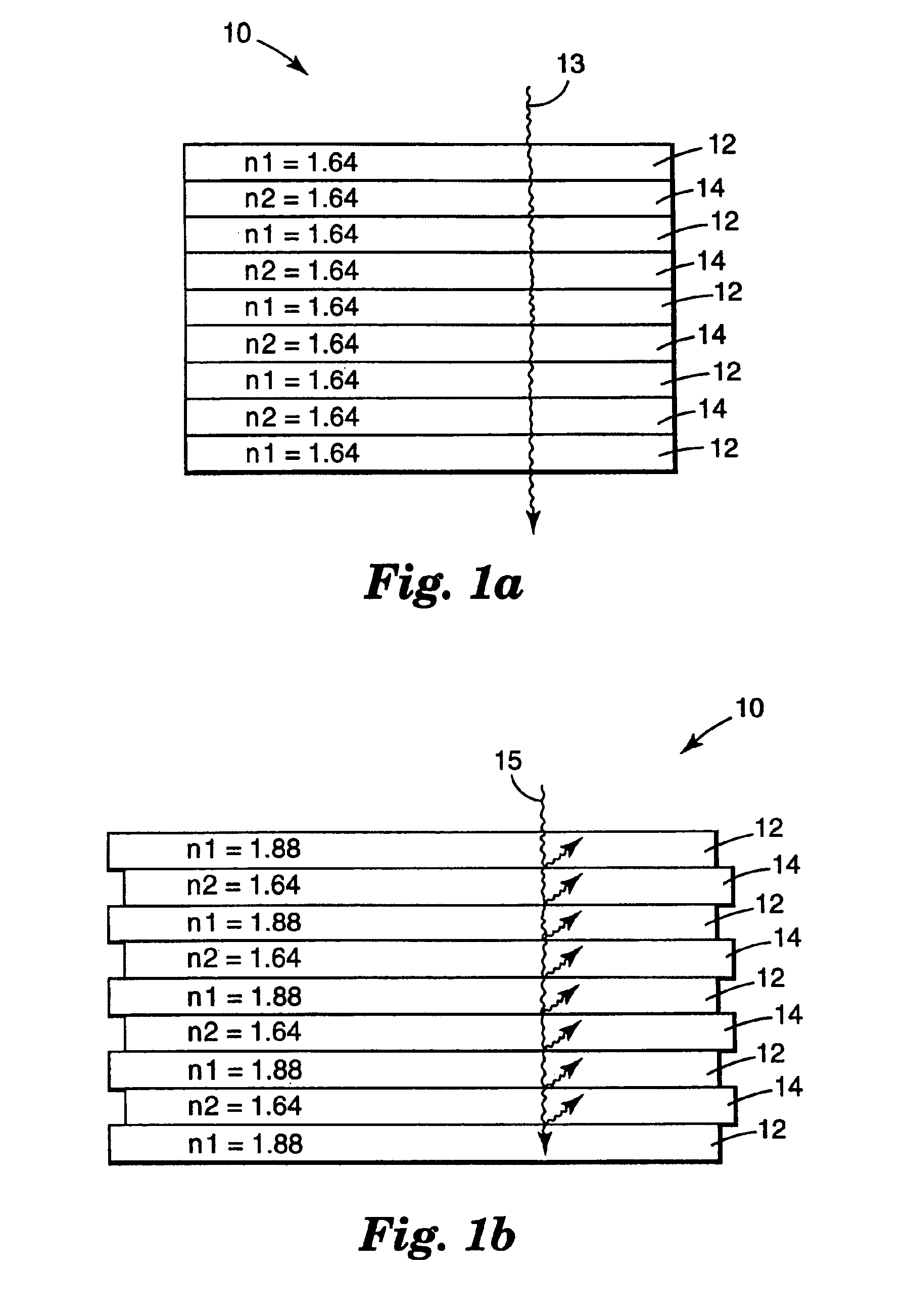

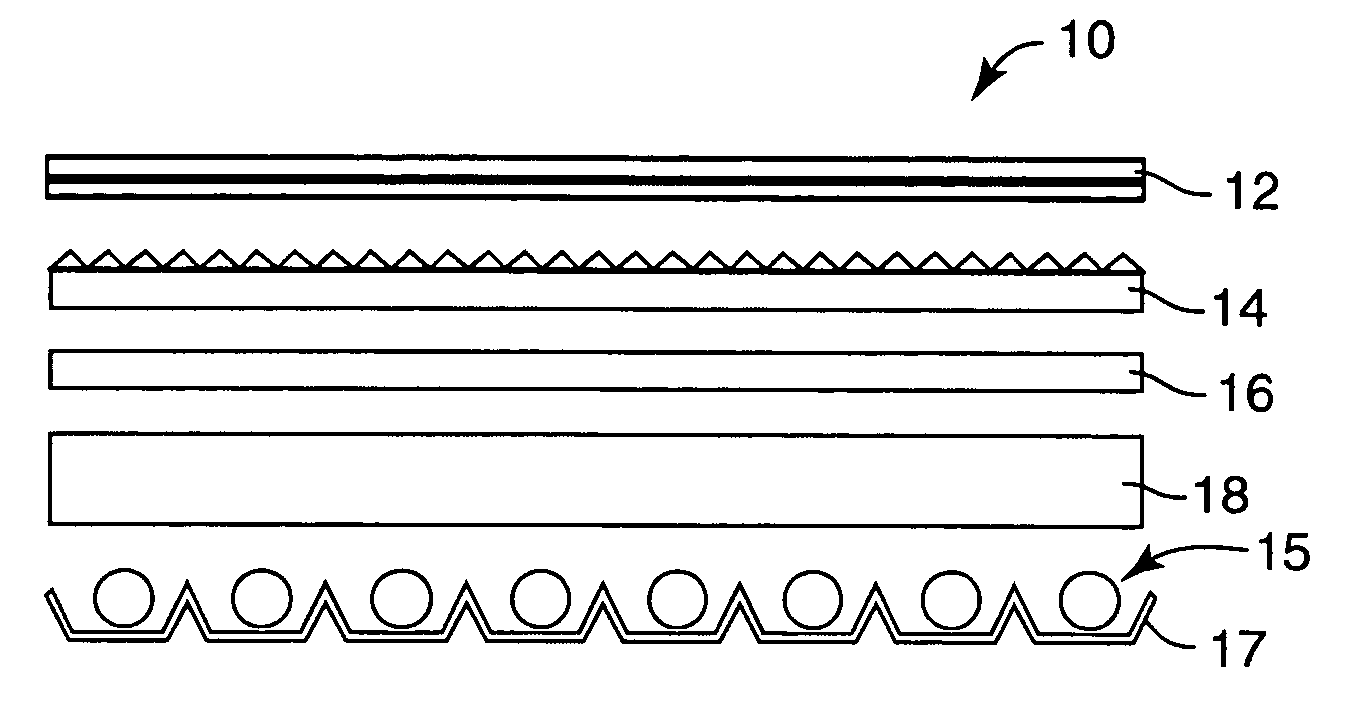

Backlight system with multilayer optical film reflector

InactiveUS6905220B2Efficiently reflecting lightReduce weightMechanical apparatusMeasurement apparatus componentsBack reflectorOptical film

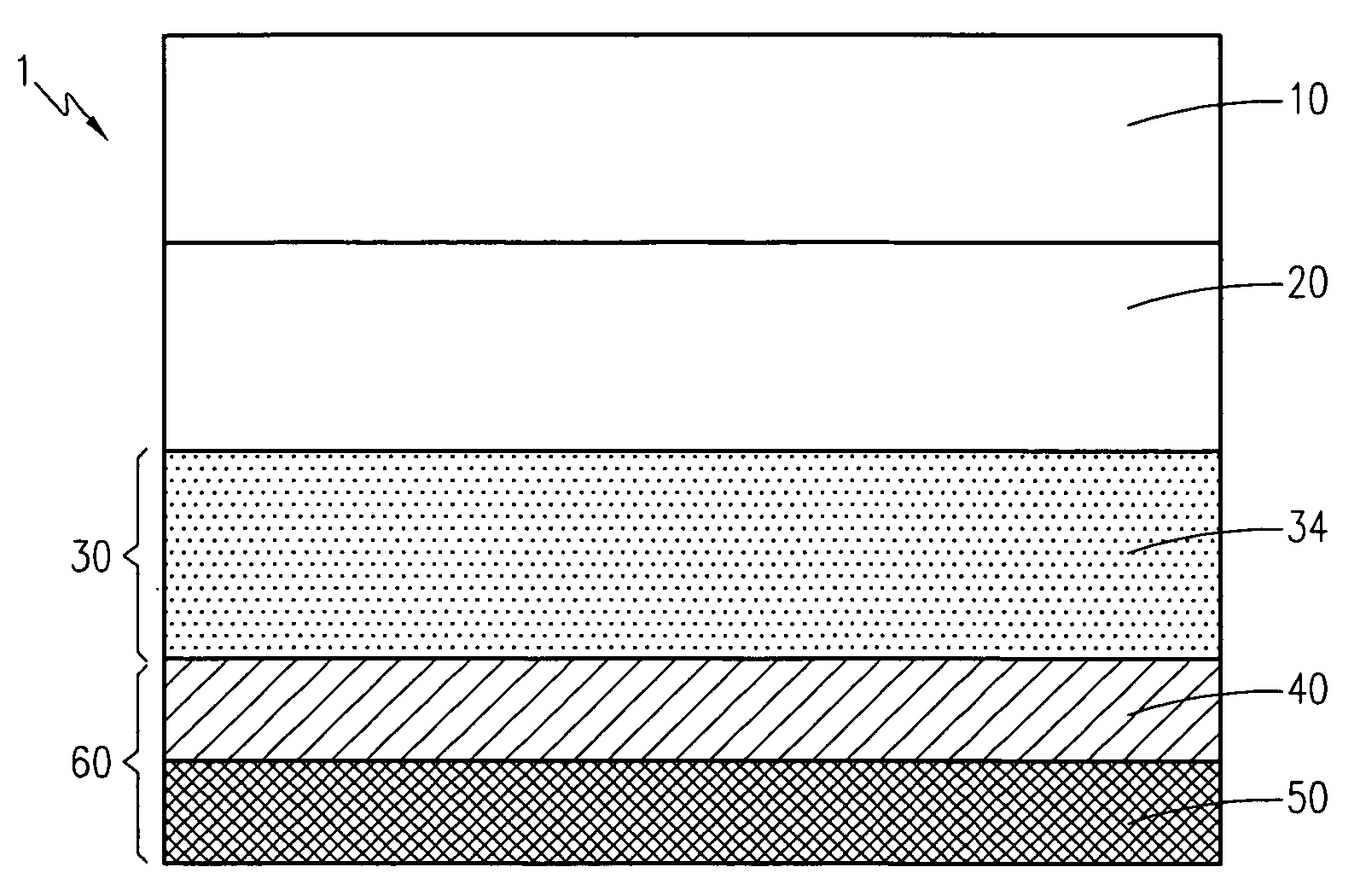

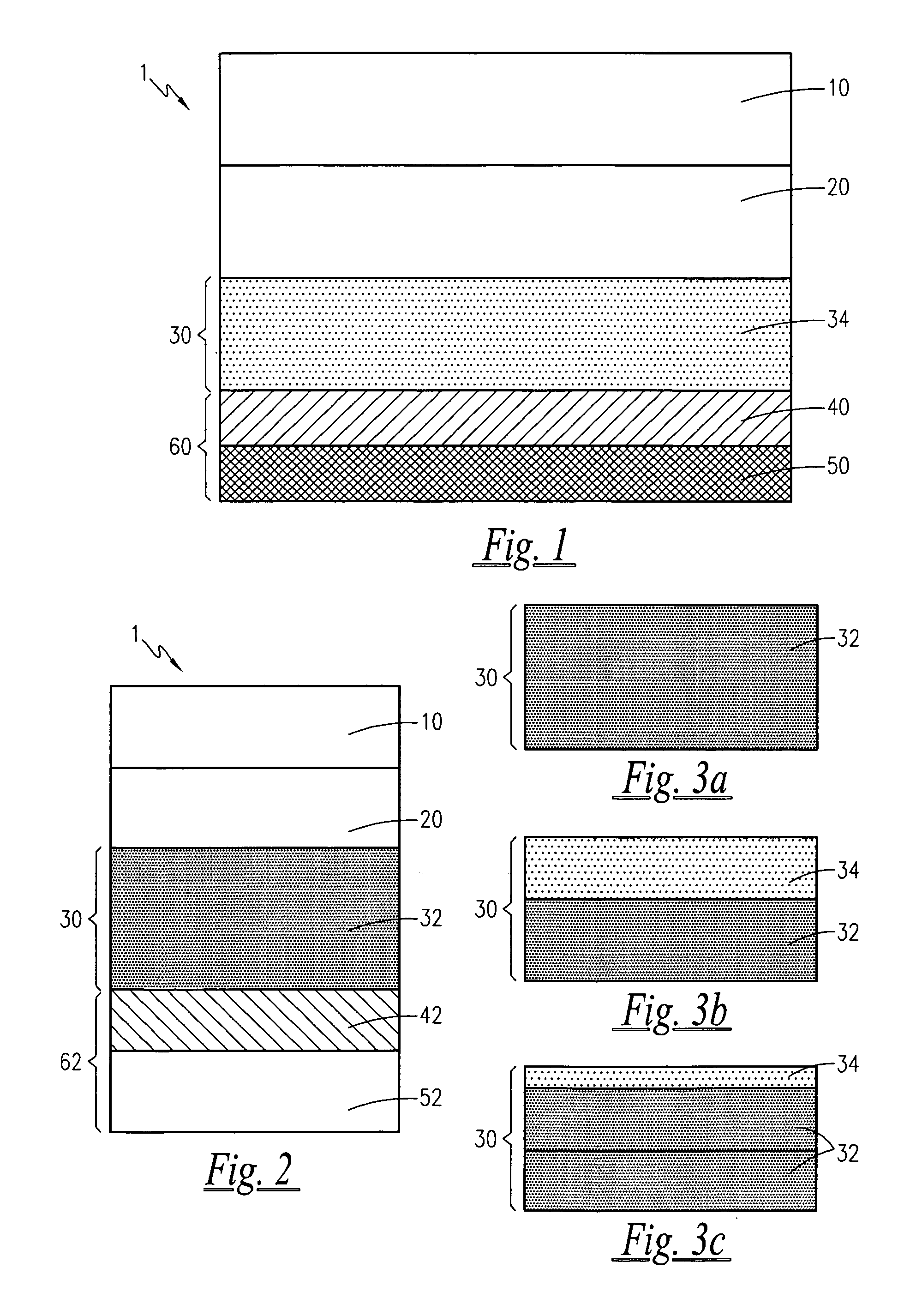

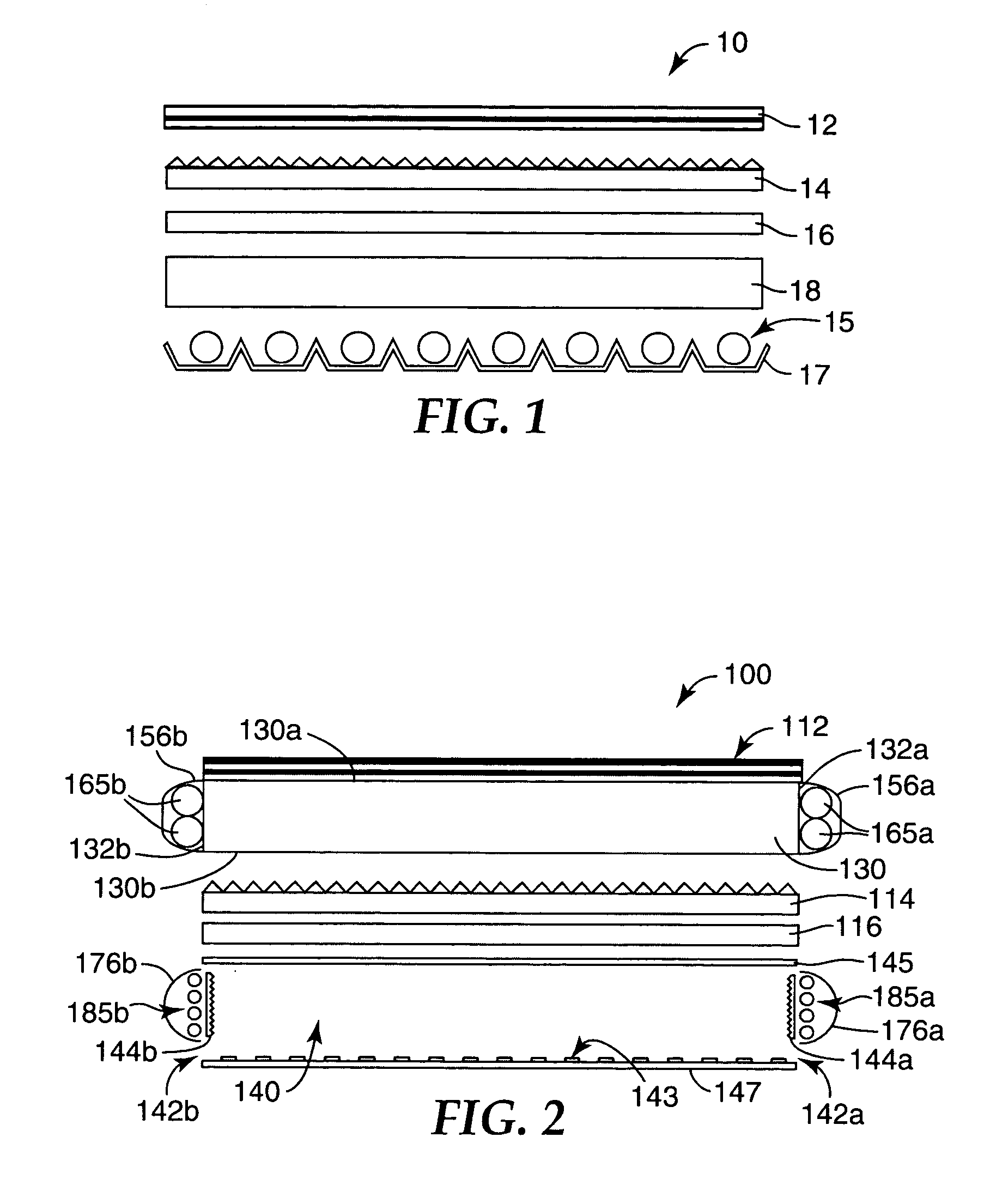

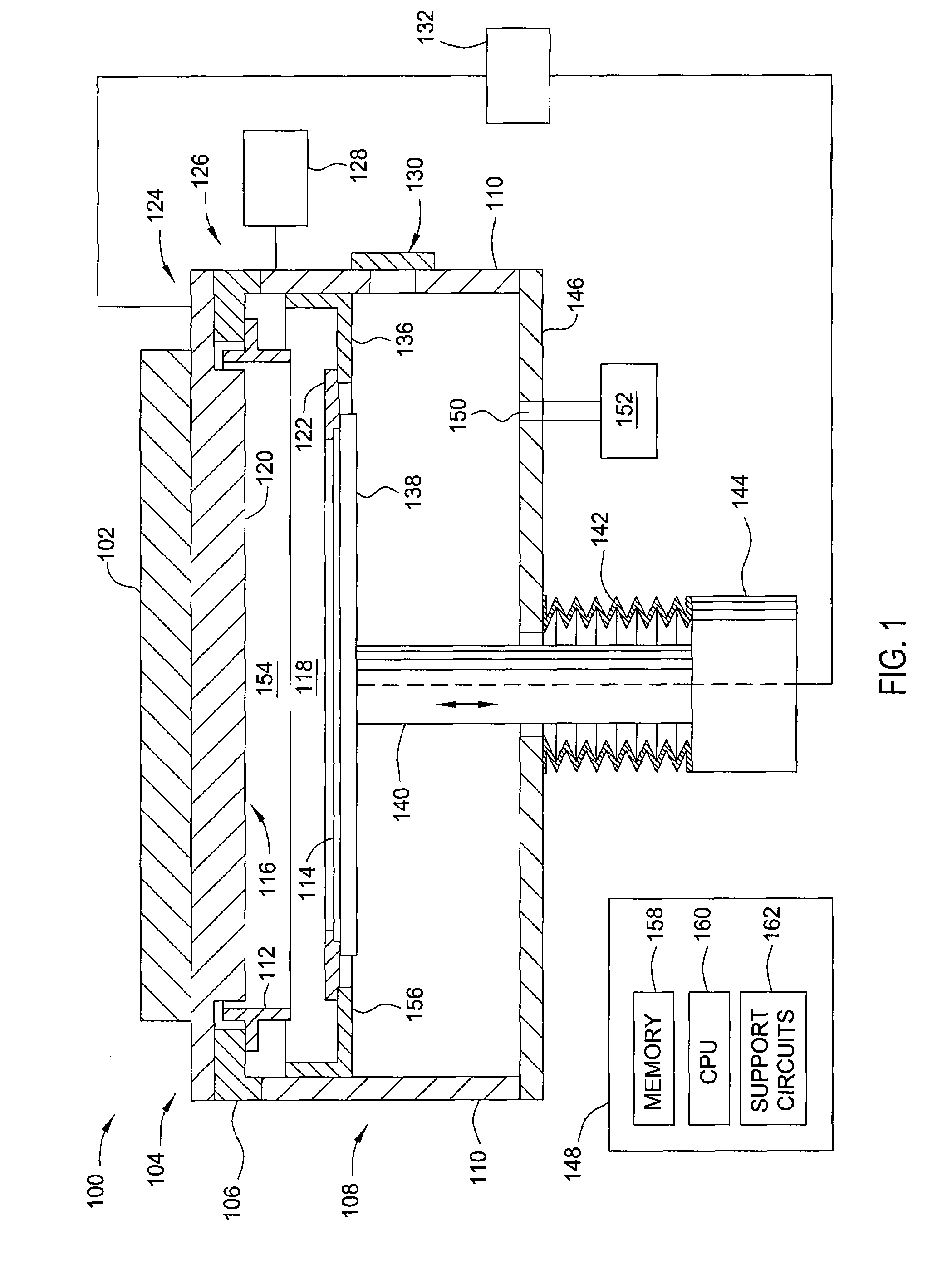

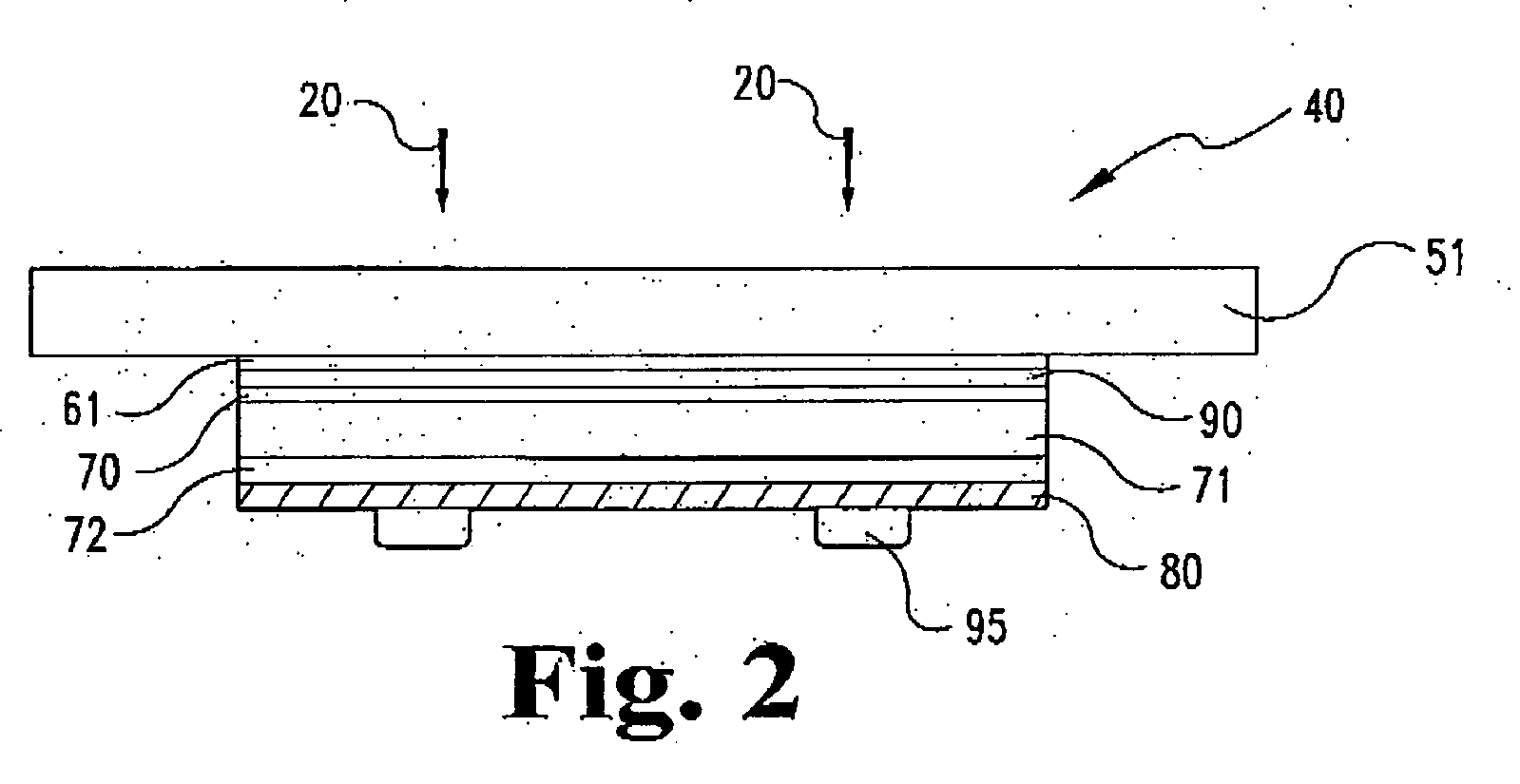

The present invention includes a backlight system incorporating a back reflector and / or a lamp cavity reflector constructed of a multilayer optical film.

Owner:3M INNOVATIVE PROPERTIES CO

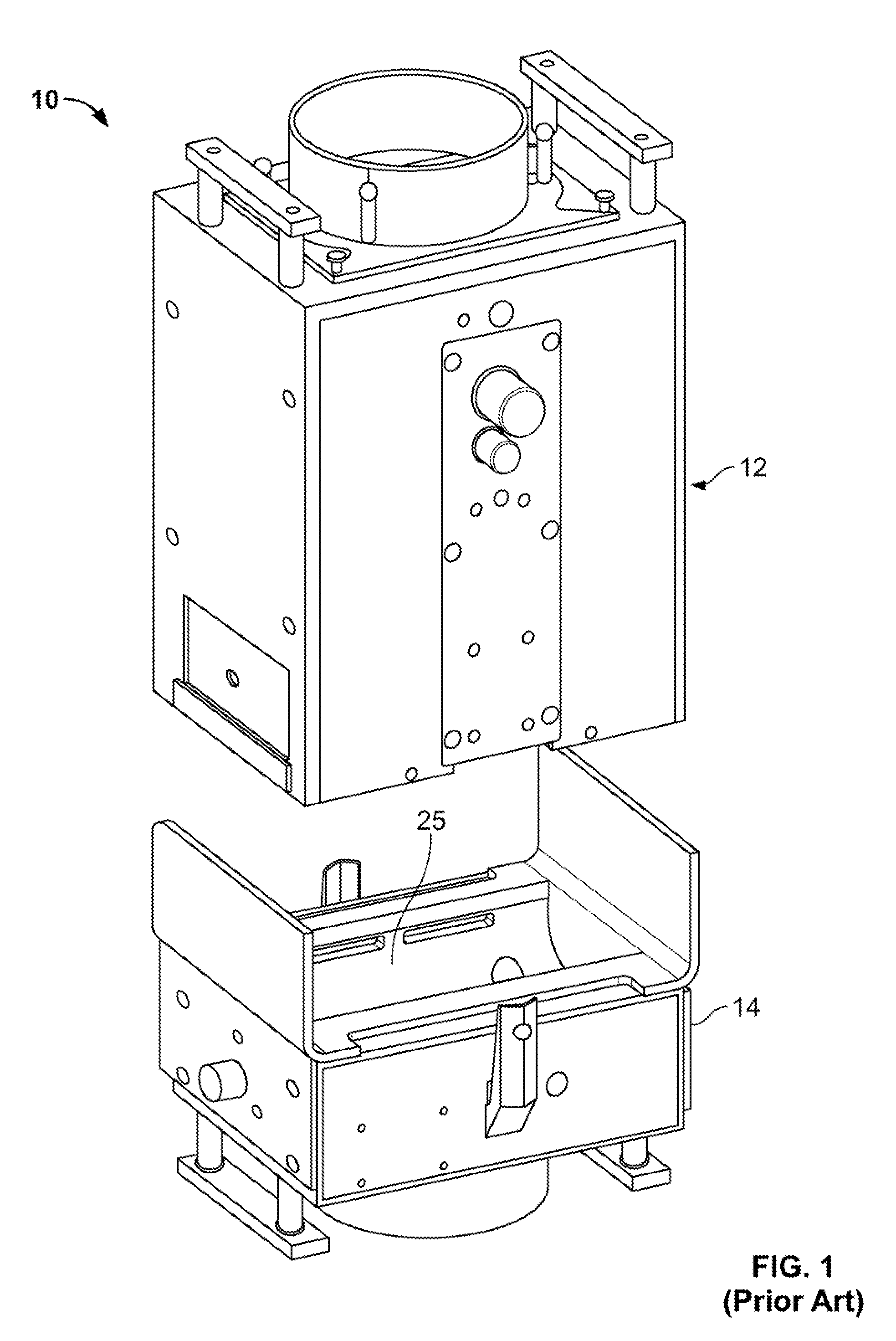

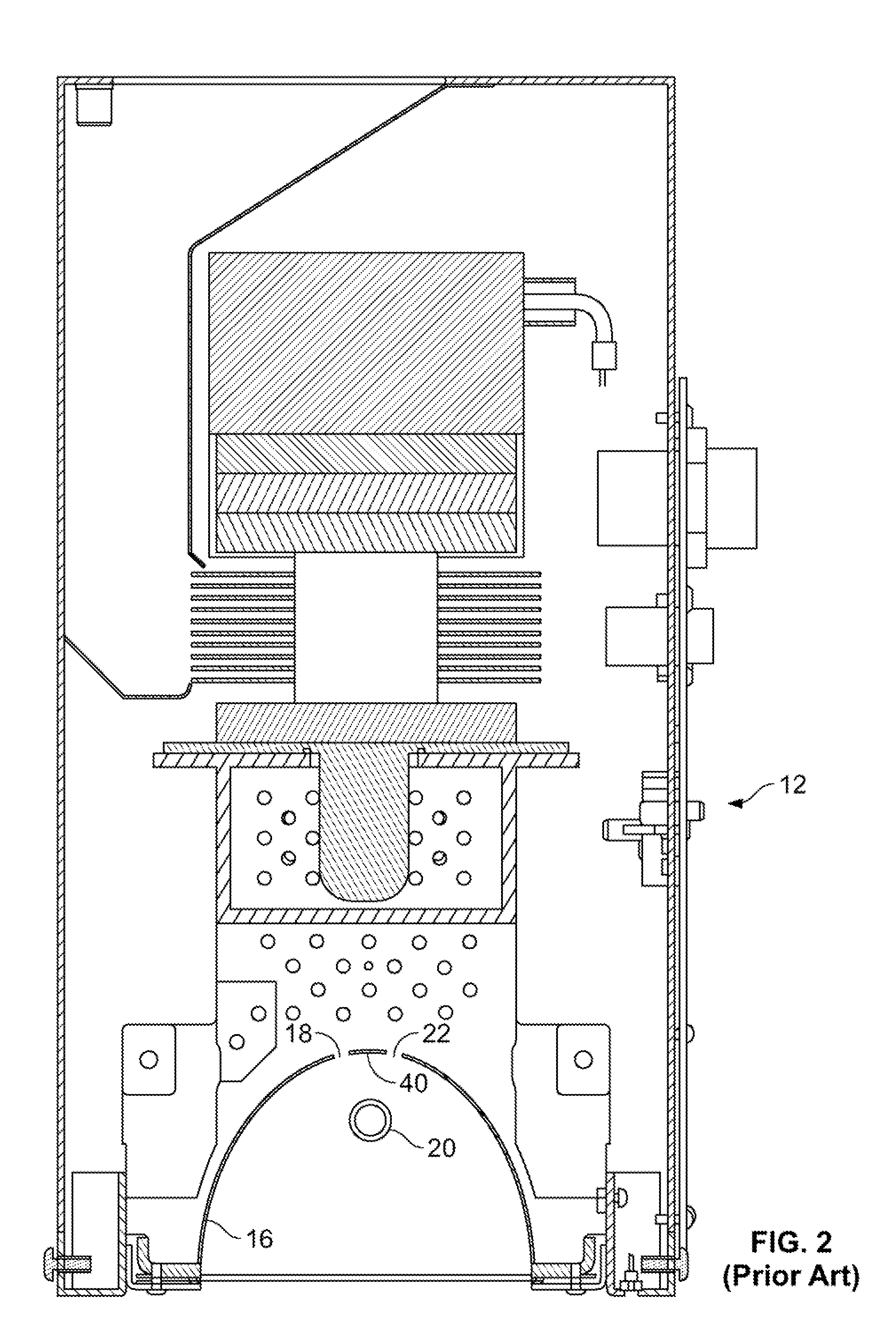

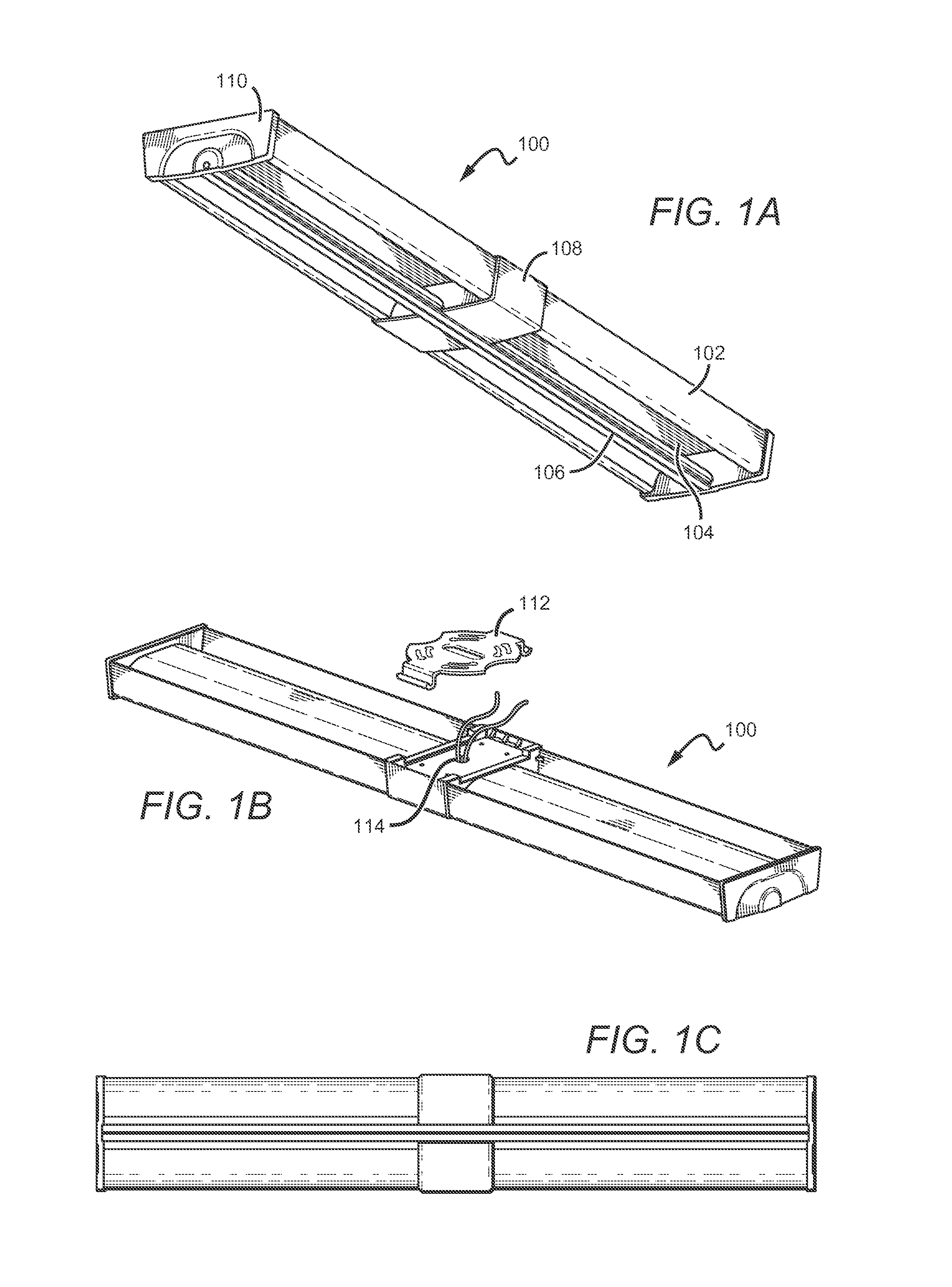

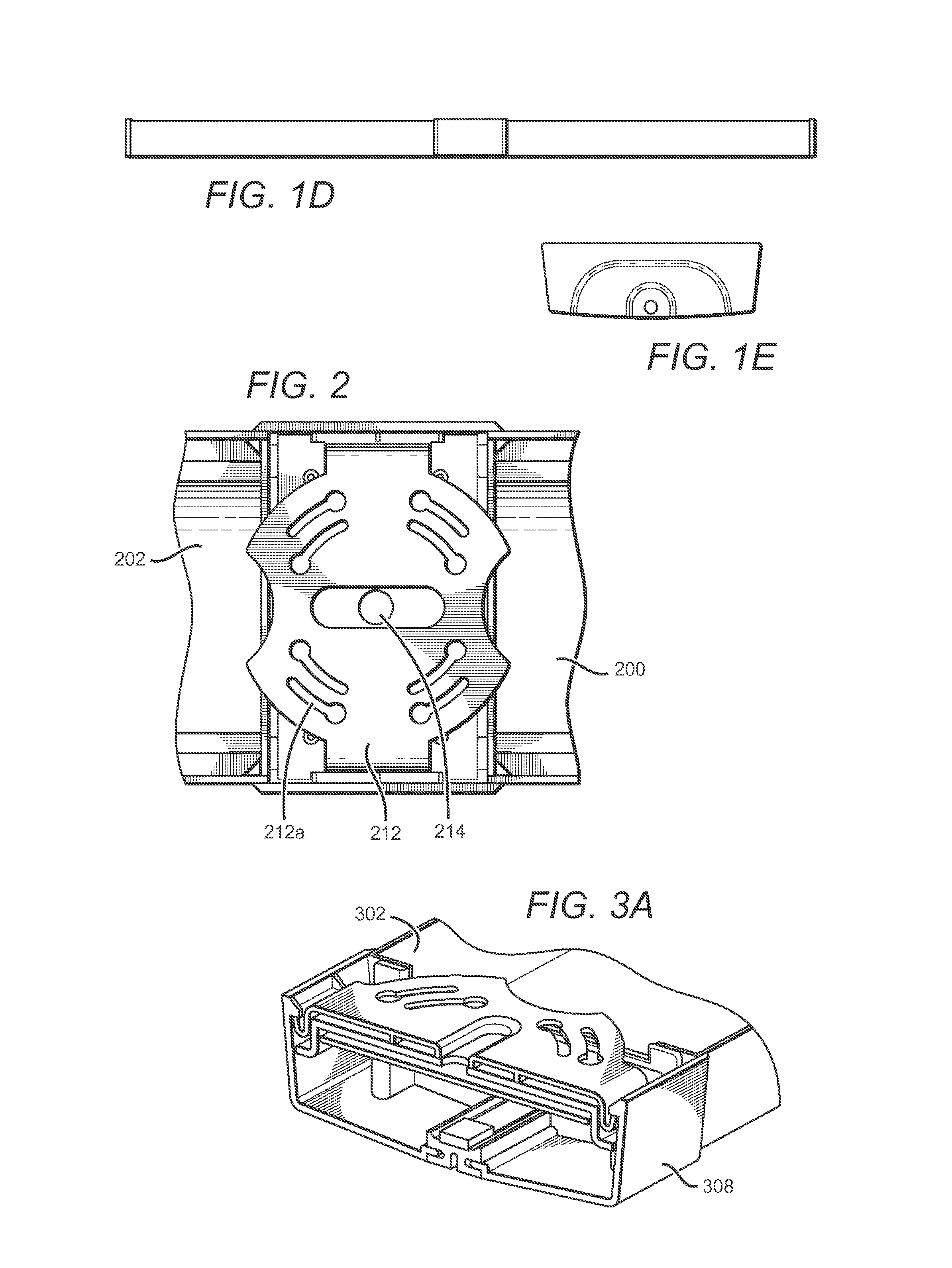

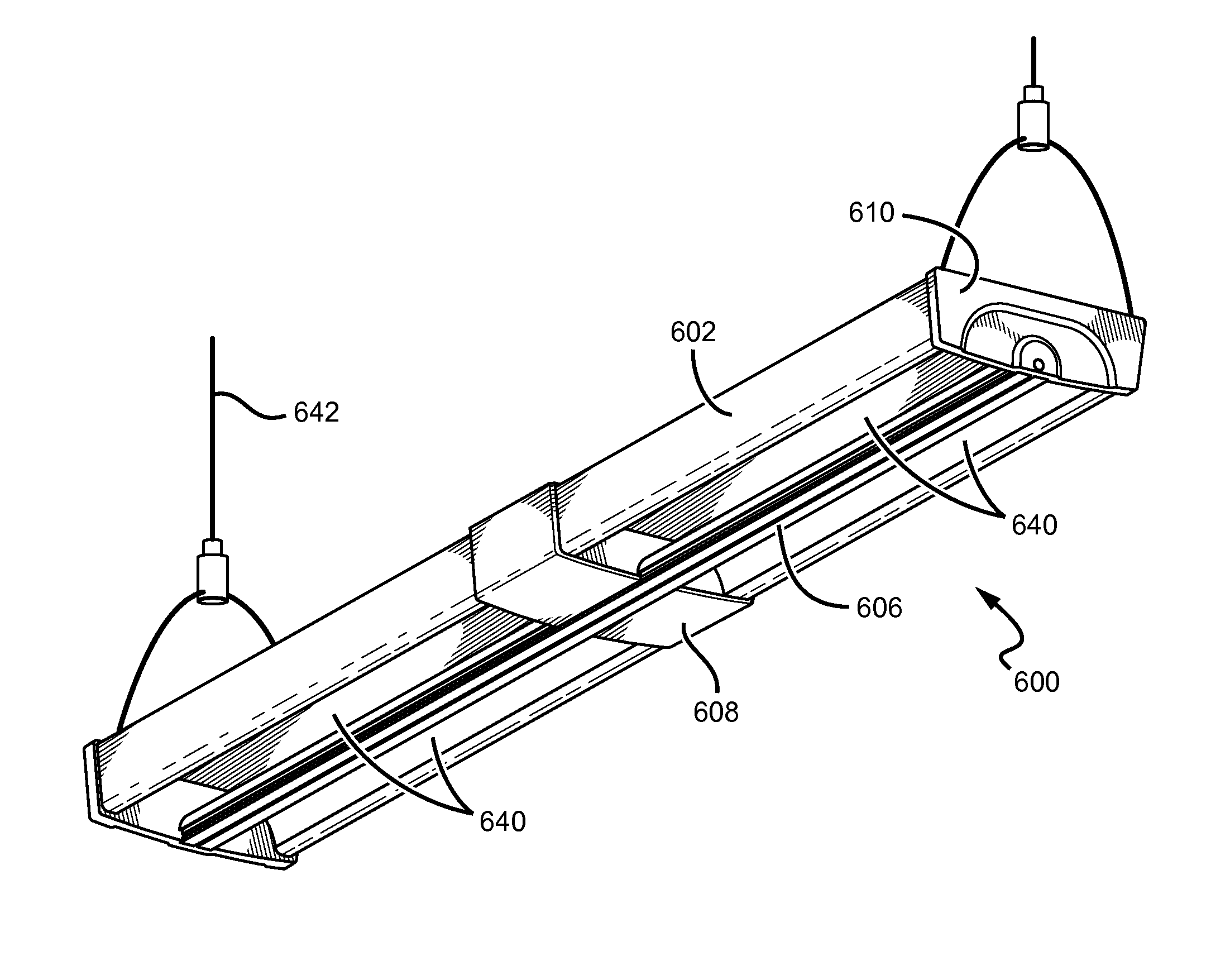

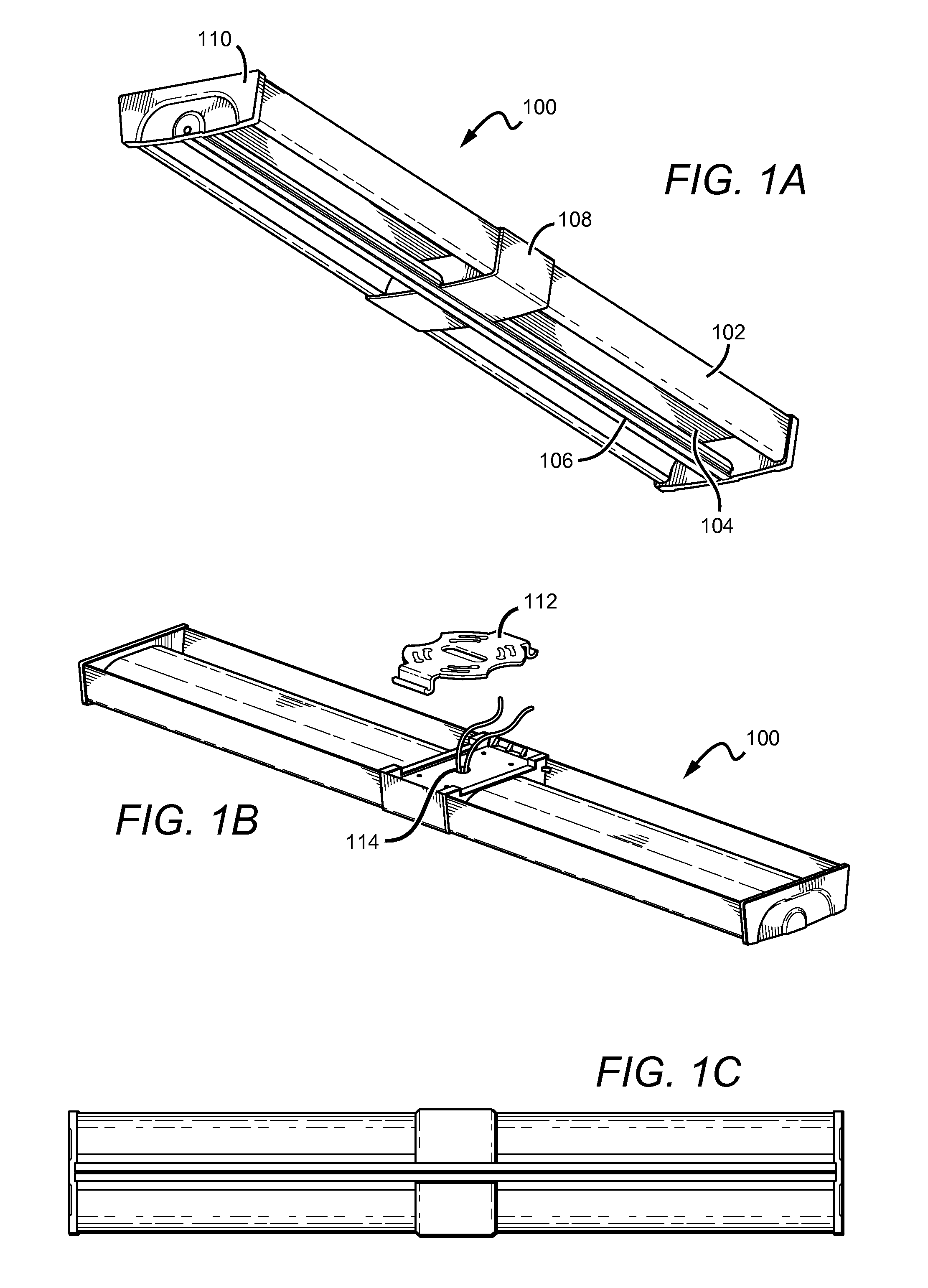

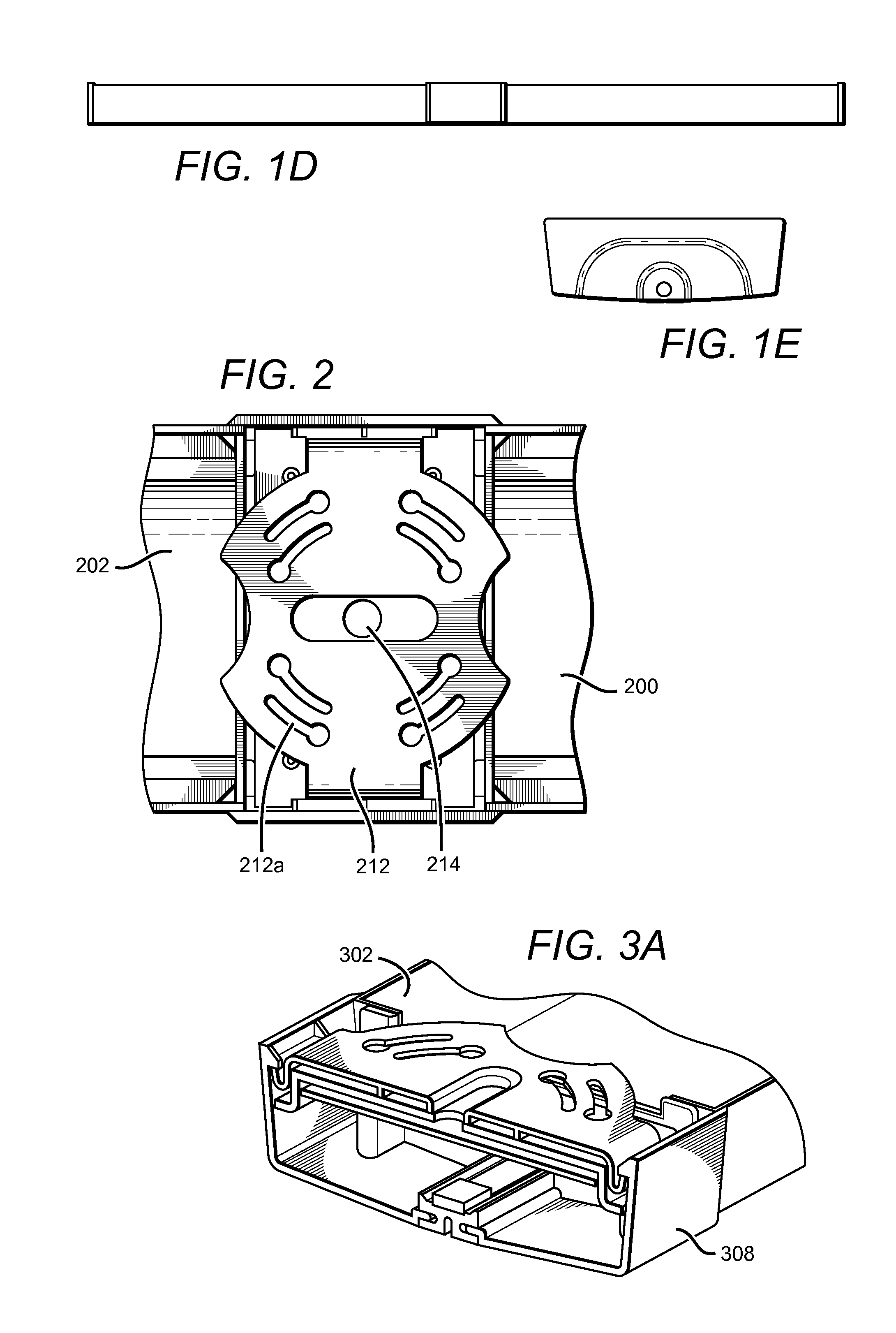

Modular indirect troffer

A modular troffer-style lighting fixture. The fixture is particularly well-suited for use with solid state light sources, such as LEDs. Embodiments comprise a pan structure designed to house one or more modular light engine units within a central opening. Each light engine unit includes a reflective cup that can house several light sources on an interior mount surface. The cup is positioned proximate to a back reflector such that its open end faces a portion of the back reflector. The back reflector is shaped to define an interior chamber where light can be mixed and redirected. At least one elongated leg extends away from the reflective cup toward an edge of said back reflector. The leg(s) are used to mount the reflective cup relative to the back reflector and may also be used as a heat sink and / or an additional mount surface for light sources.

Owner:IDEAL IND LIGHTING LLC

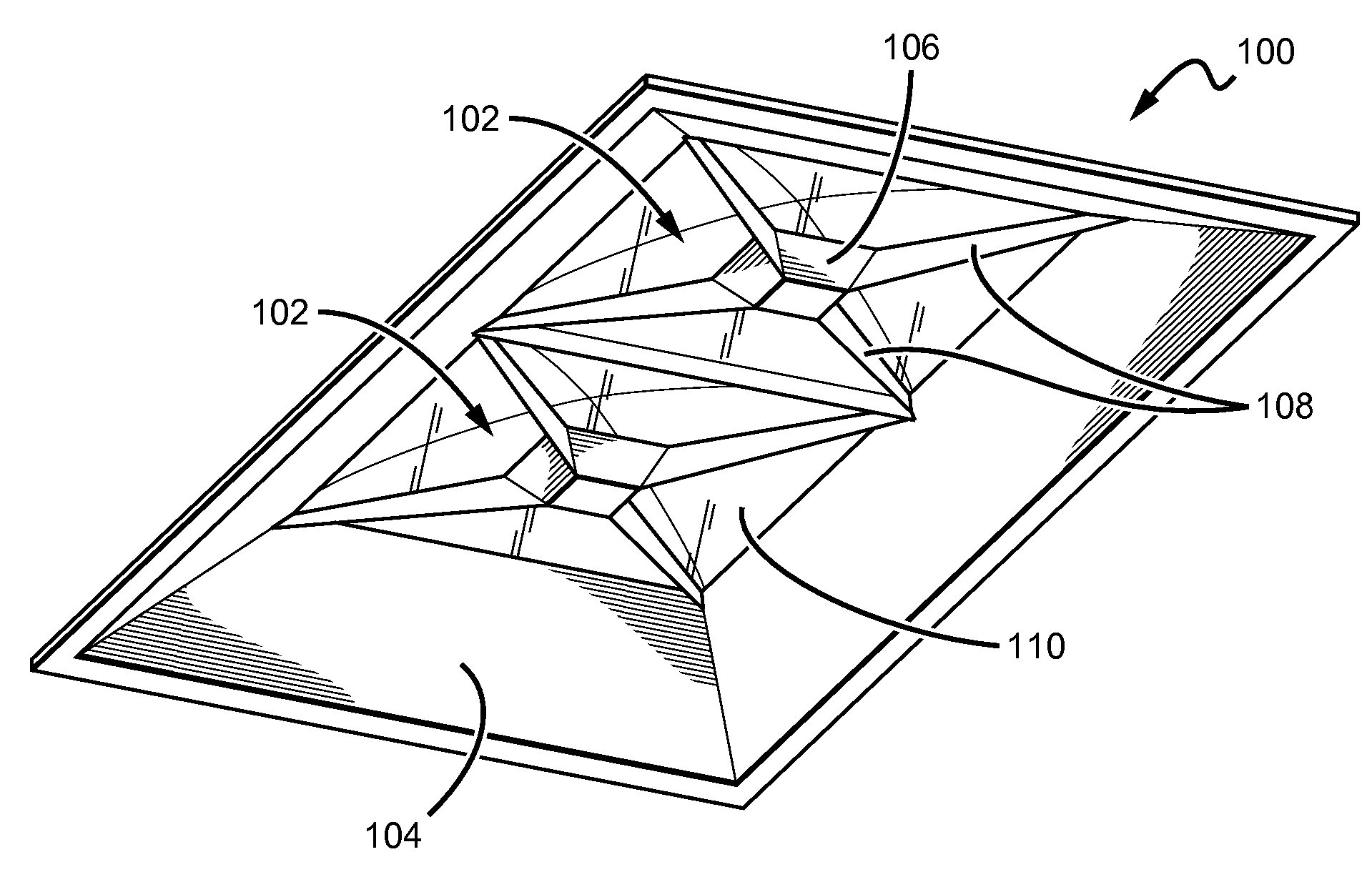

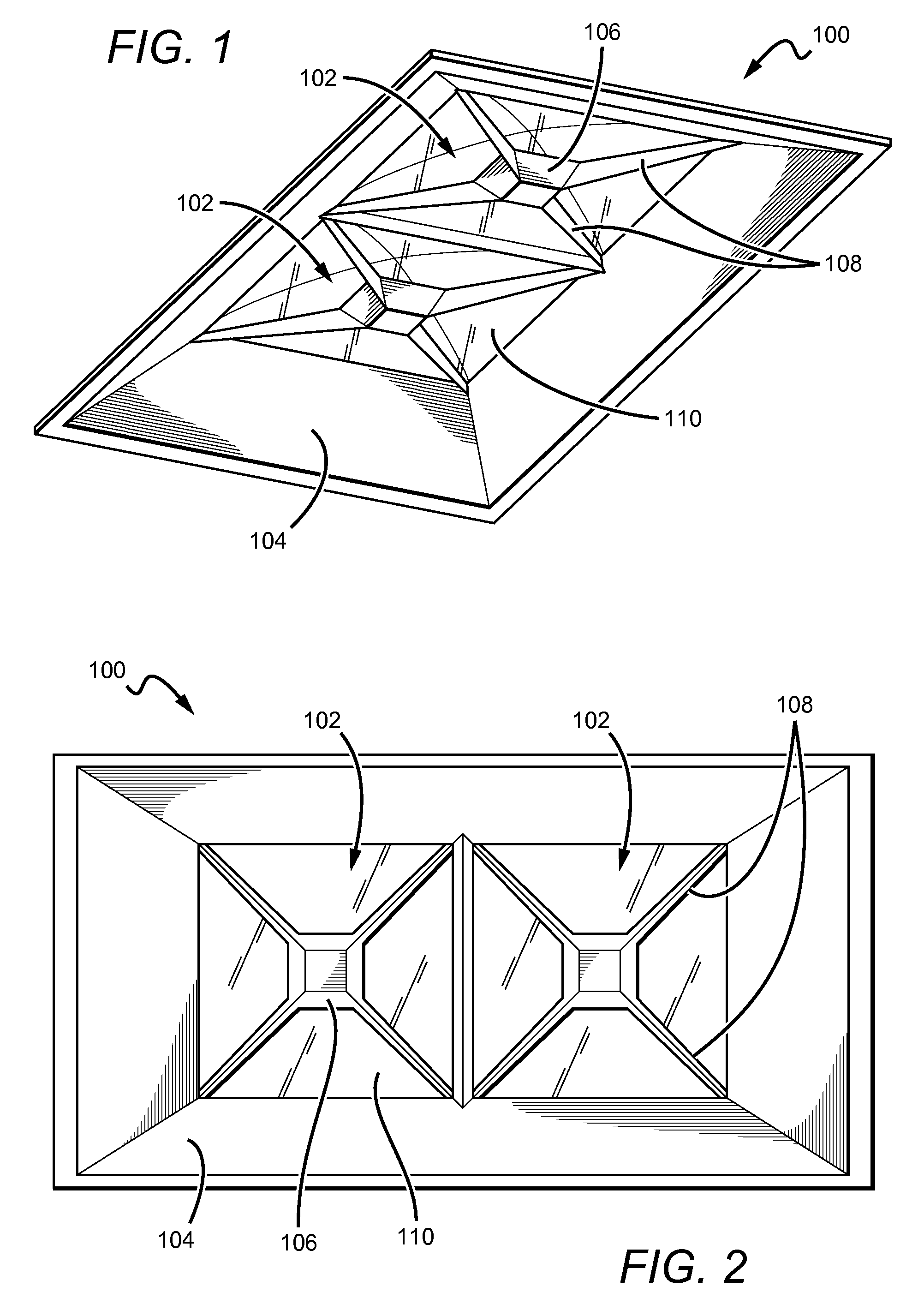

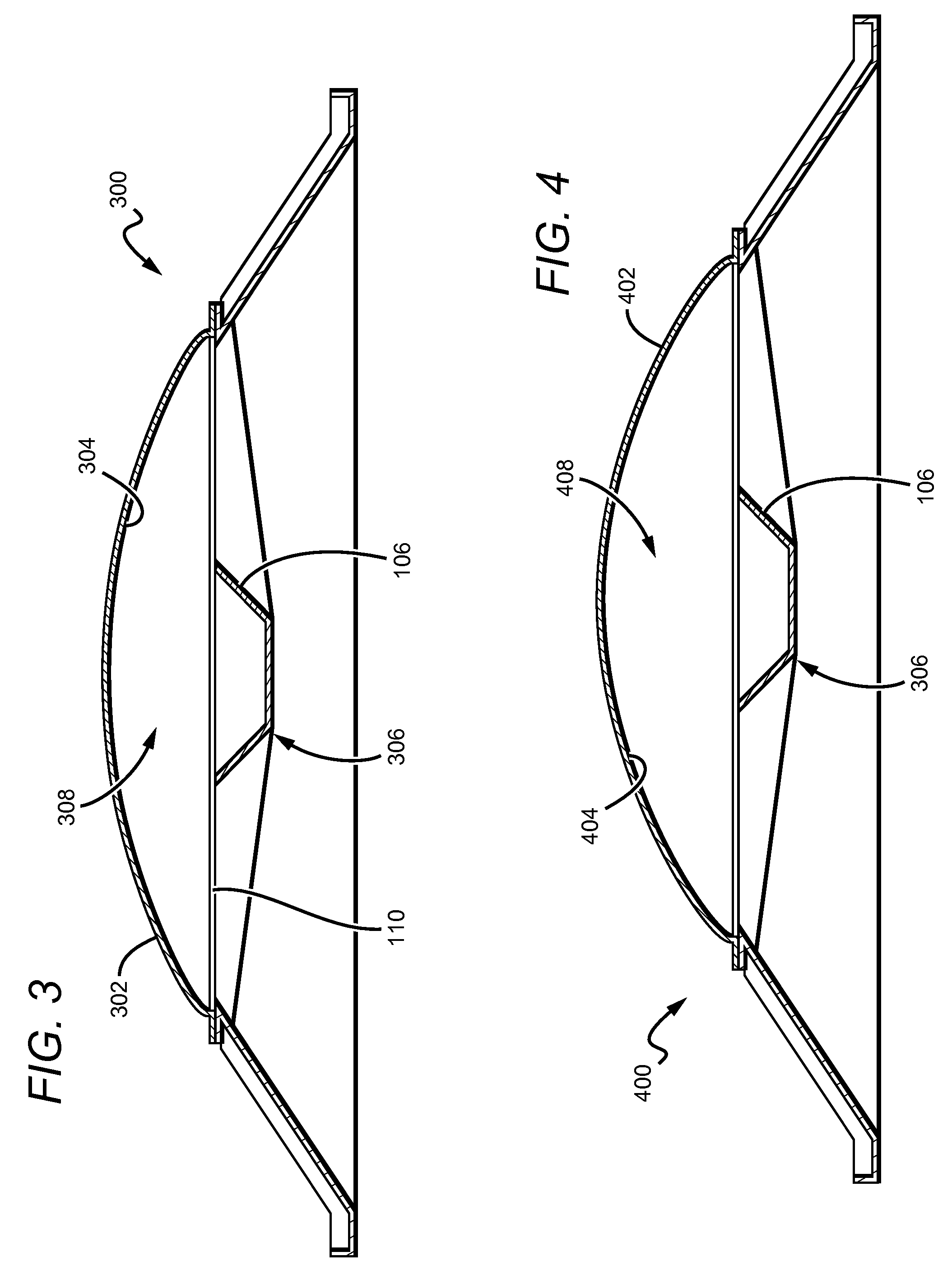

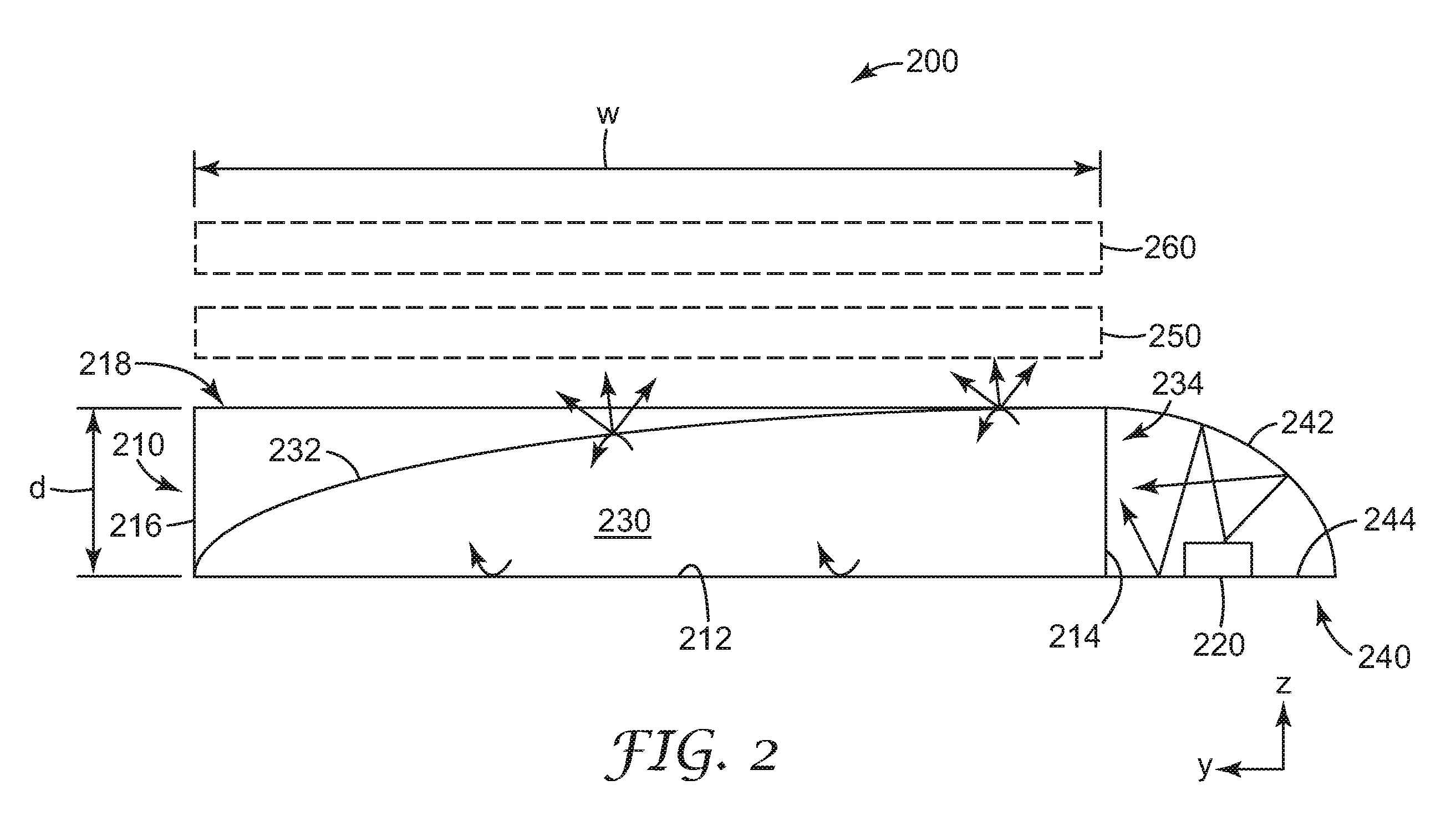

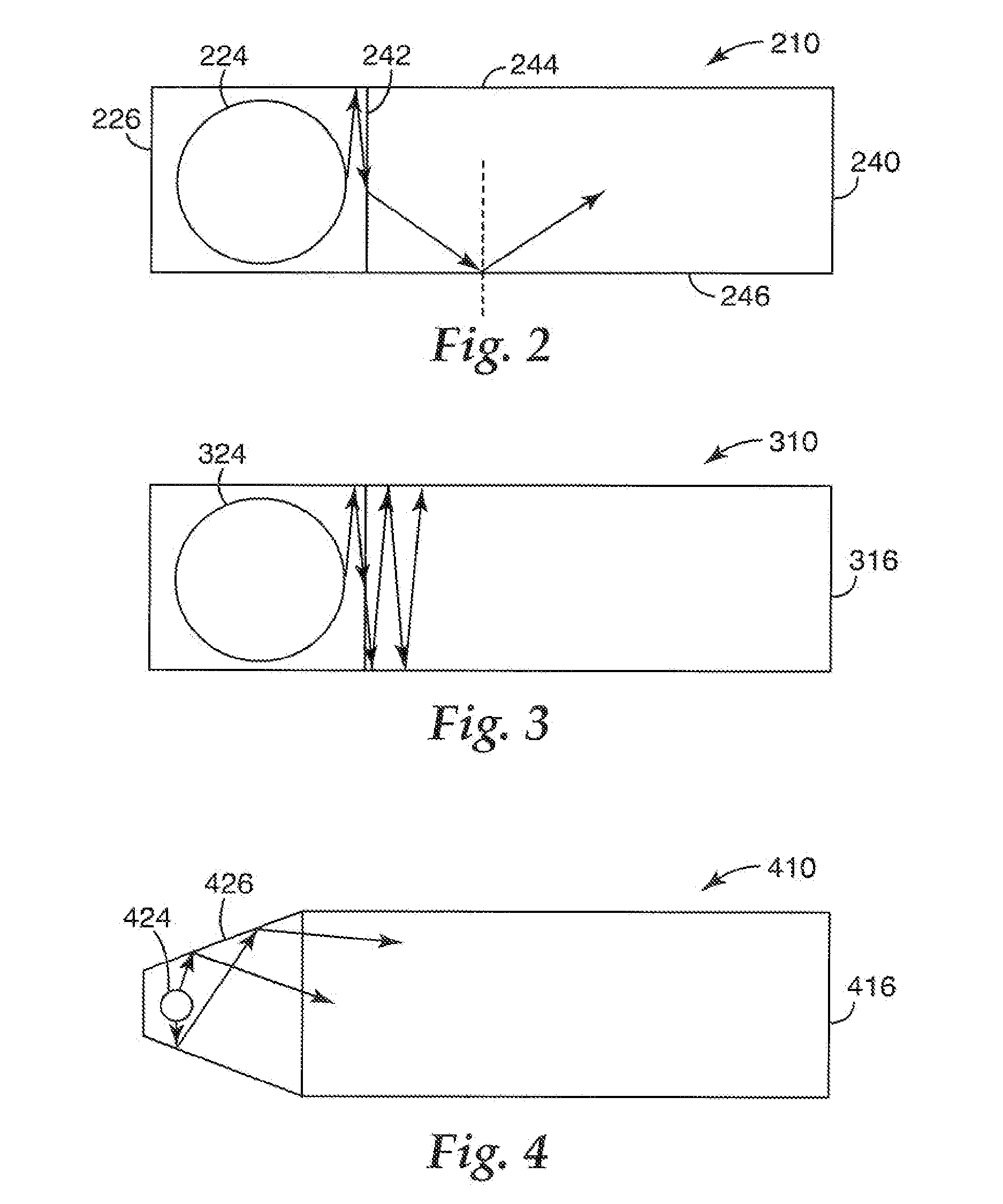

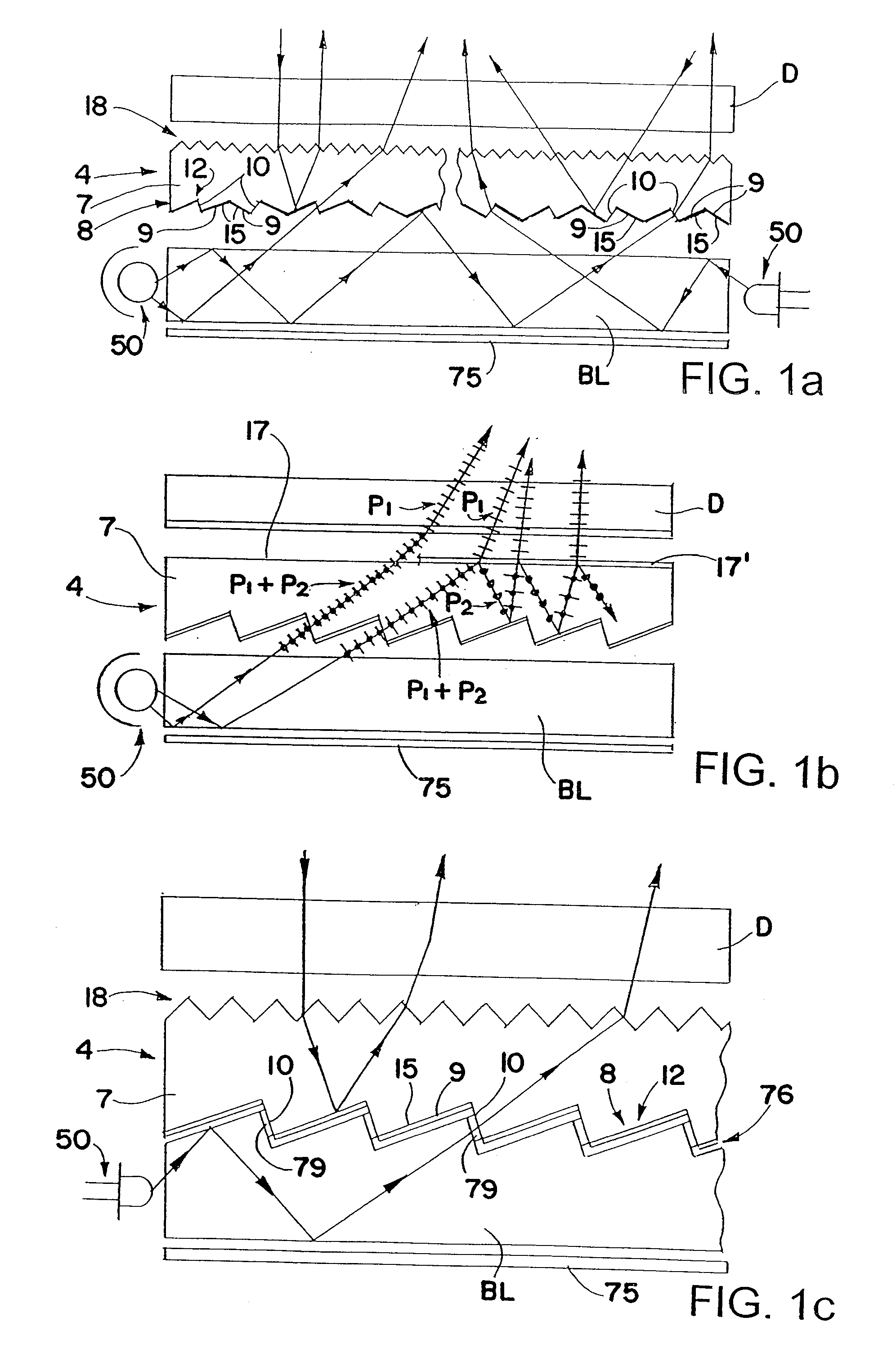

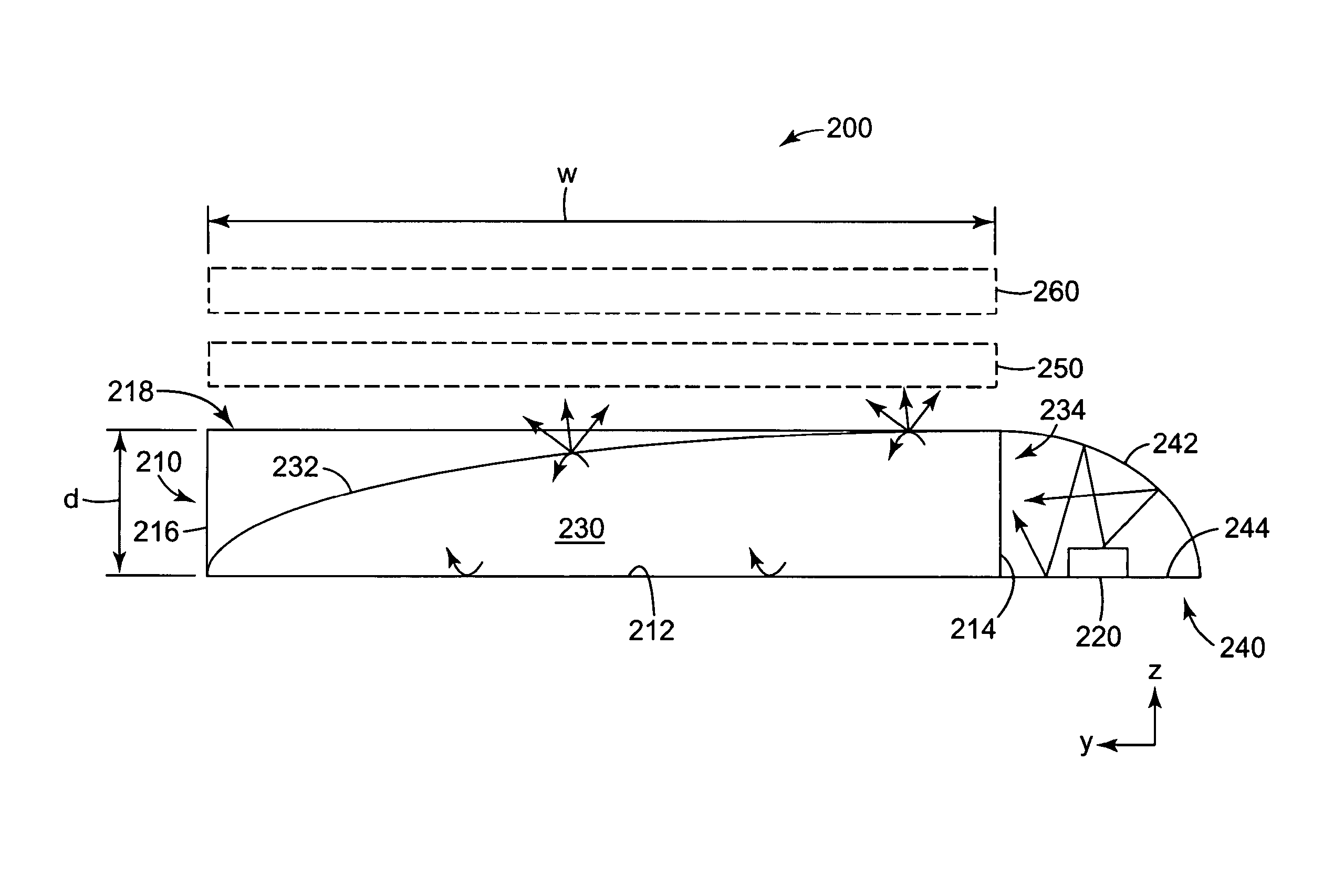

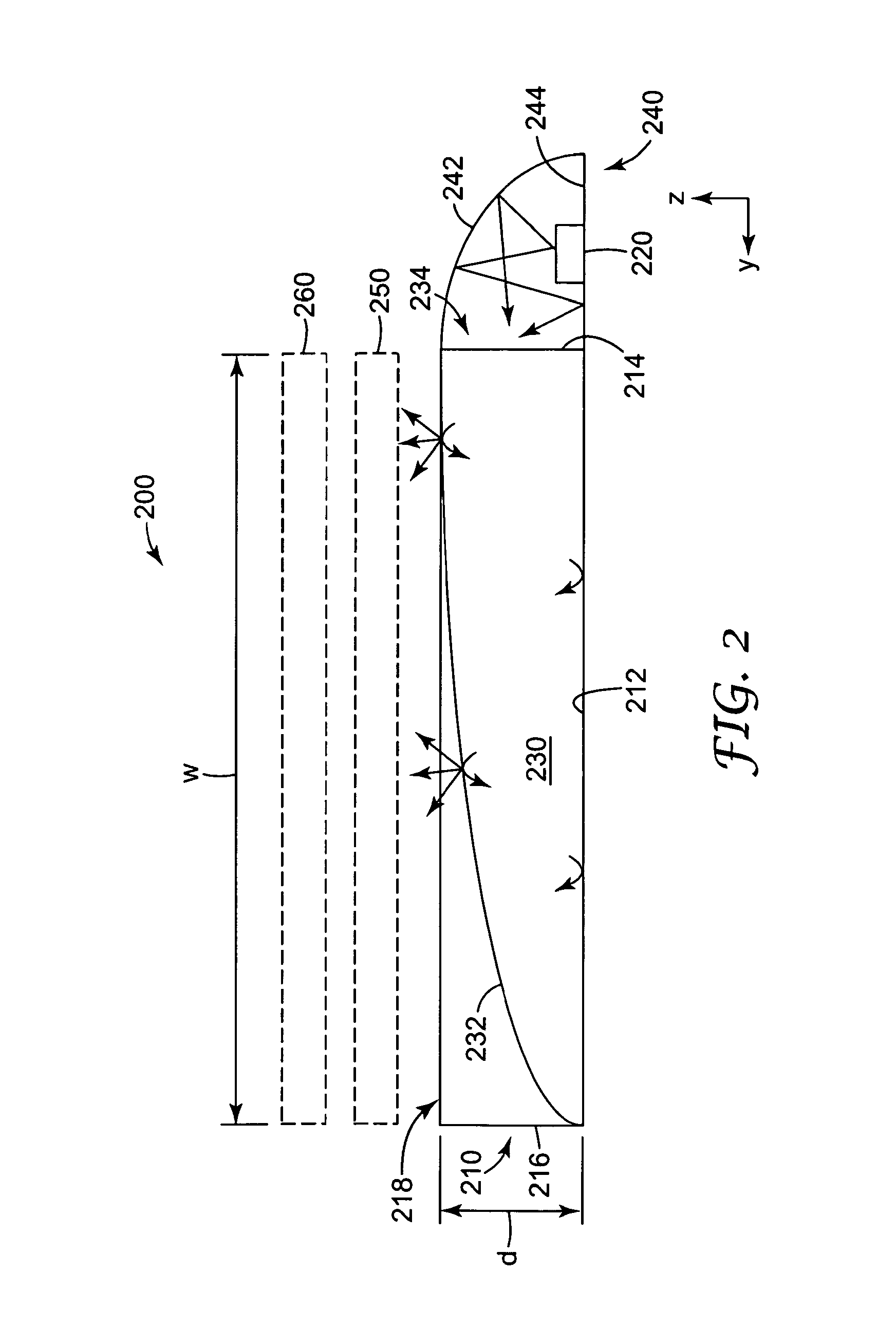

Edge-lit backlight having light recycling cavity with concave transflector

An edge-lit backlight having a light recycling cavity with concave transflector is disclosed. The edge-lit backlight has an output area and includes a back reflector facing the output area of the backlight. The backlight further includes a transflector that partially transmits and partially reflects incident light, the transflector being shaped to form a concave structure facing the back reflector to provide one or more recycling cavities therebetween, where the one or more recycling cavities substantially fill the output area of the backlight. The backlight further includes at least one light source positioned adjacent a first edge of the backlight. The at least one light source is operable to inject light into the one or more recycling cavities through an input surface of the one or more recycling cavities, where the input surface is substantially orthogonal to the output area, and where the at least one concave structure converges with the back reflector in a direction distal from the input surface.

Owner:3M INNOVATIVE PROPERTIES CO

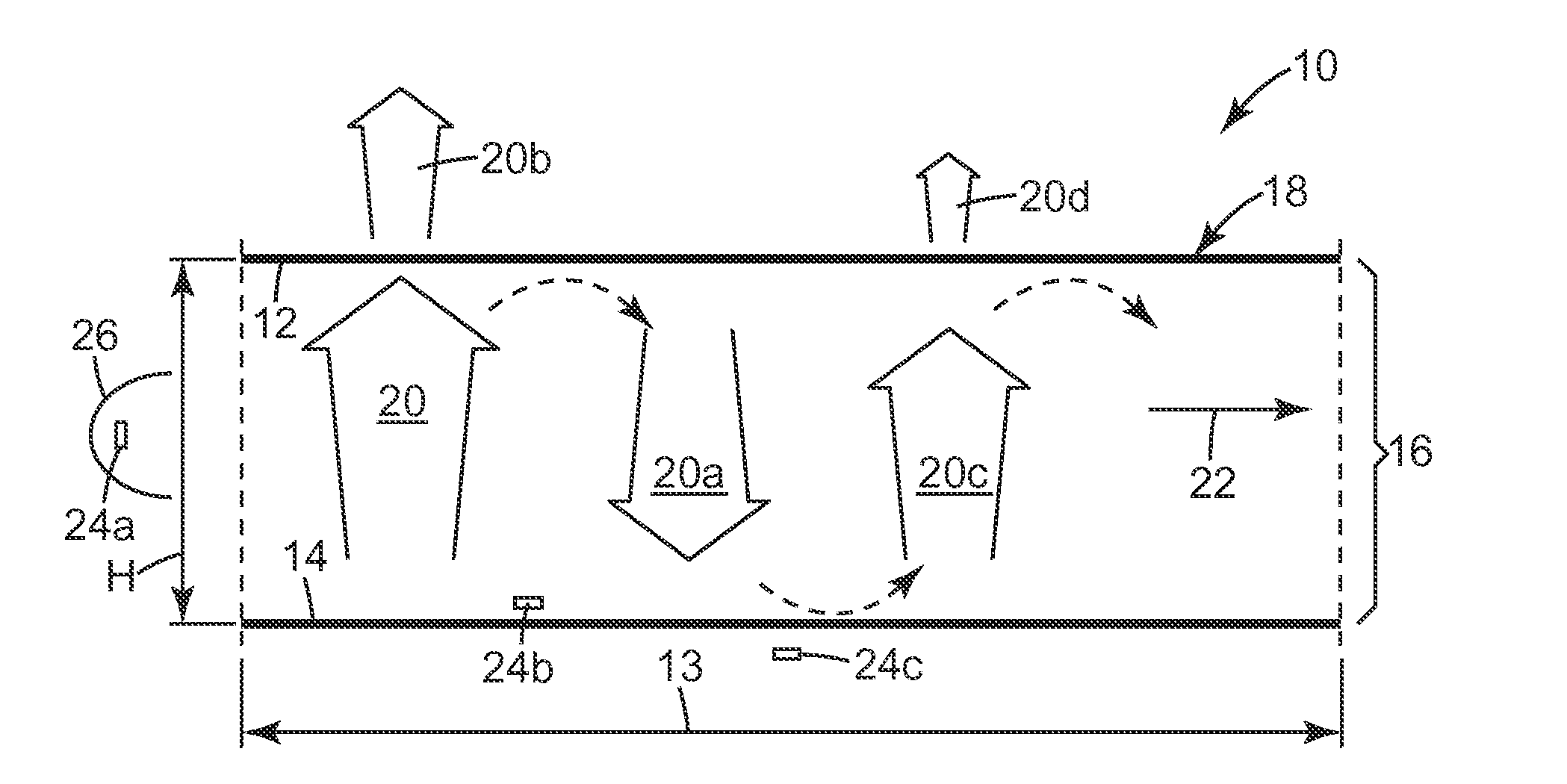

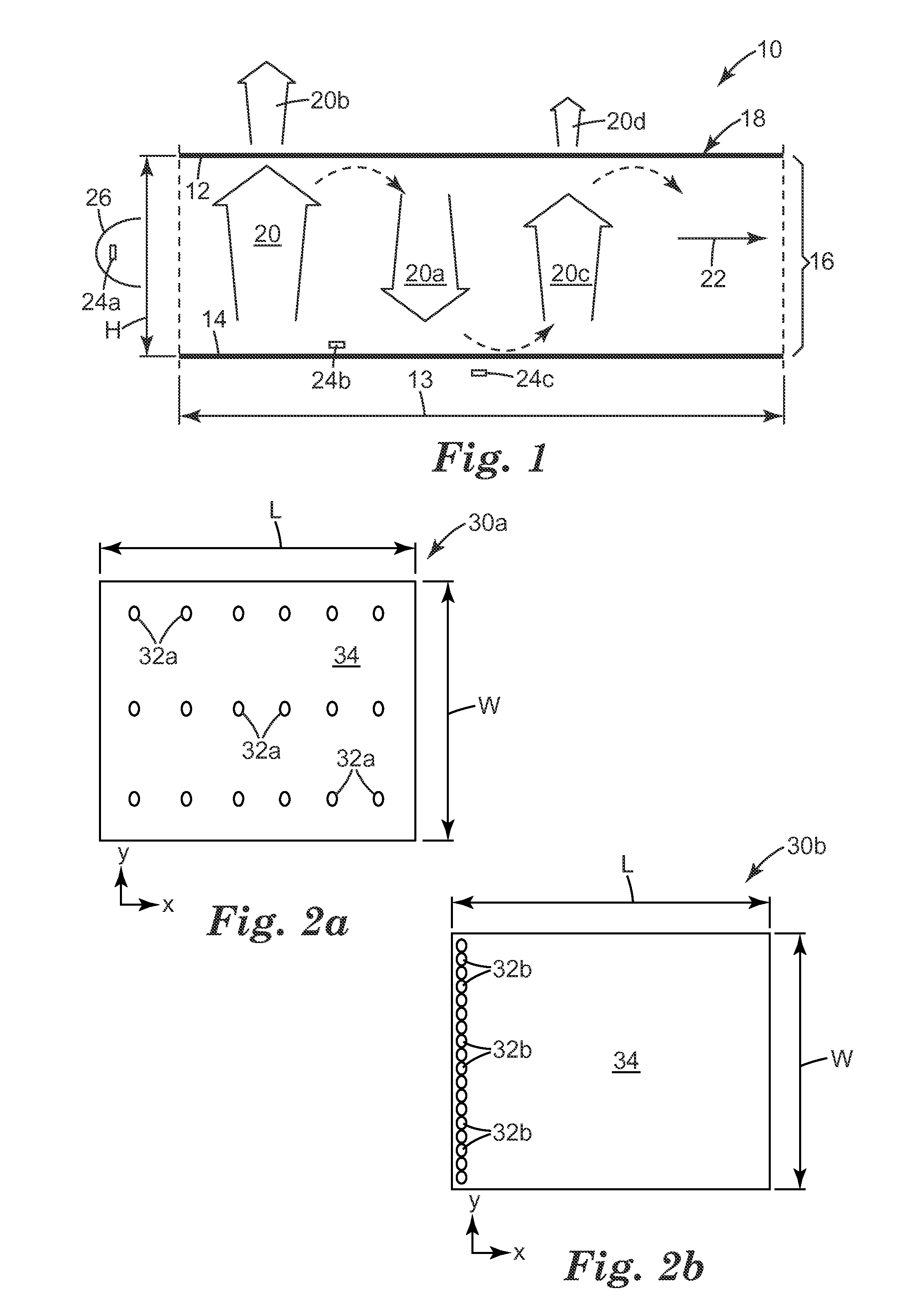

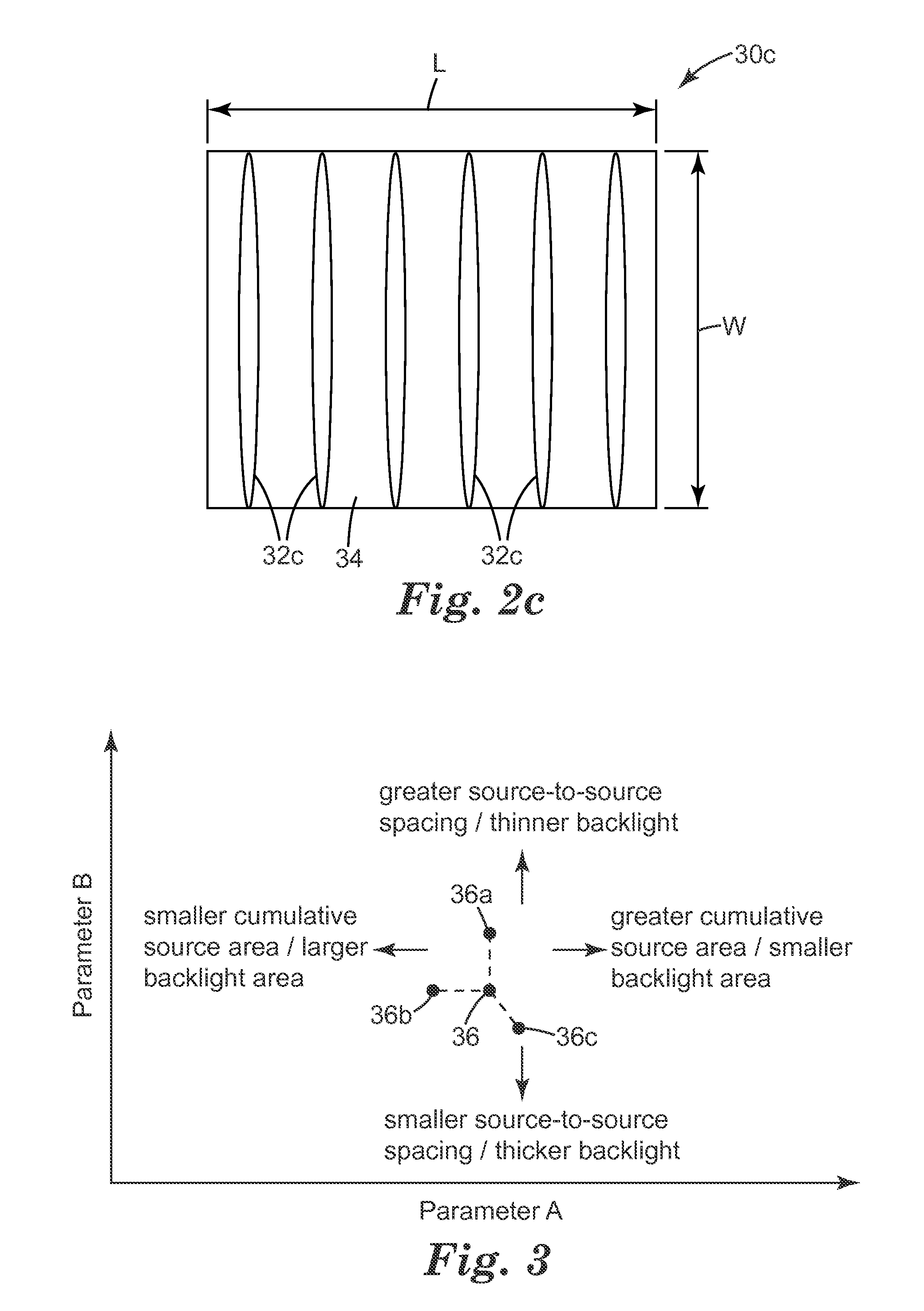

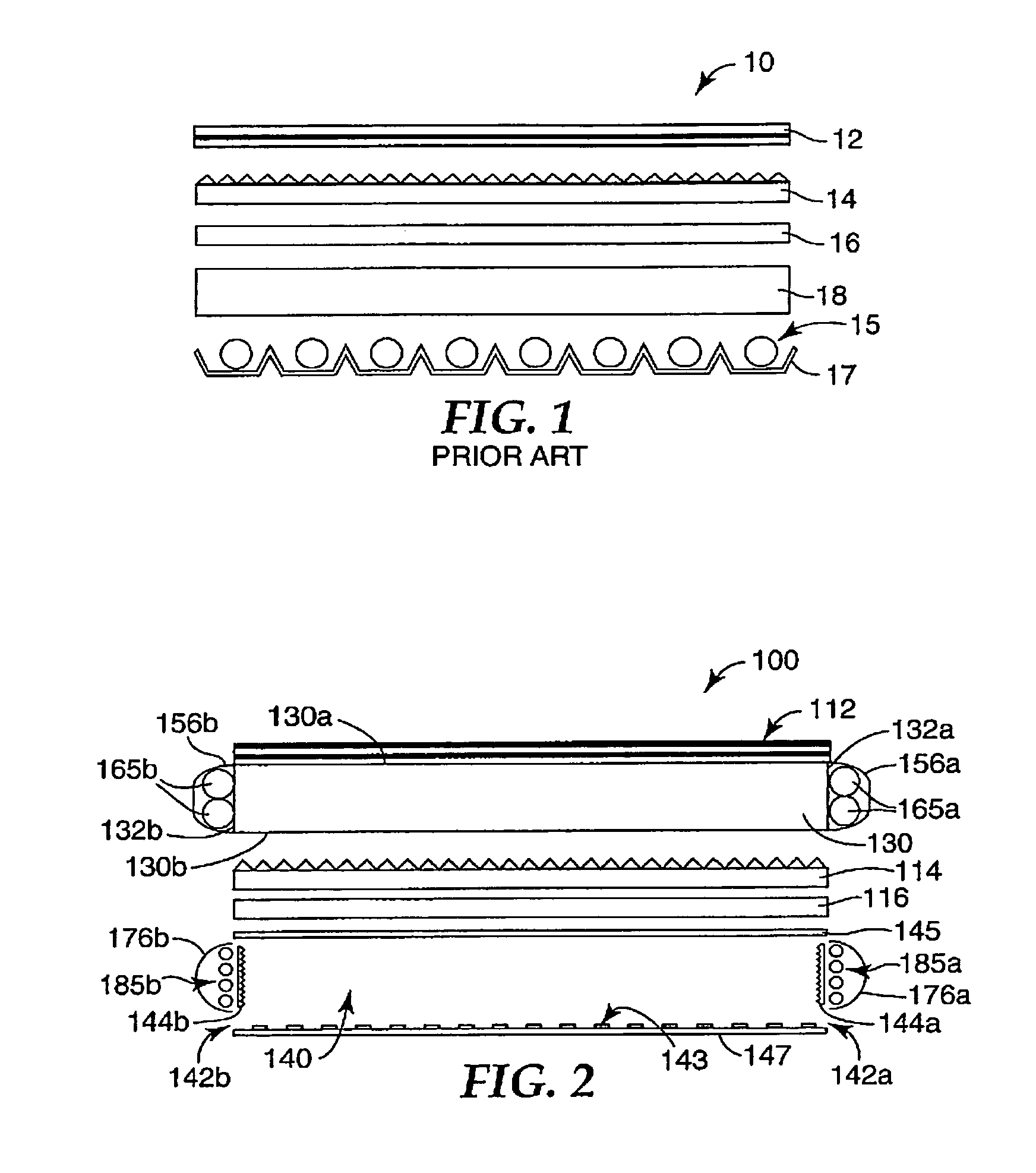

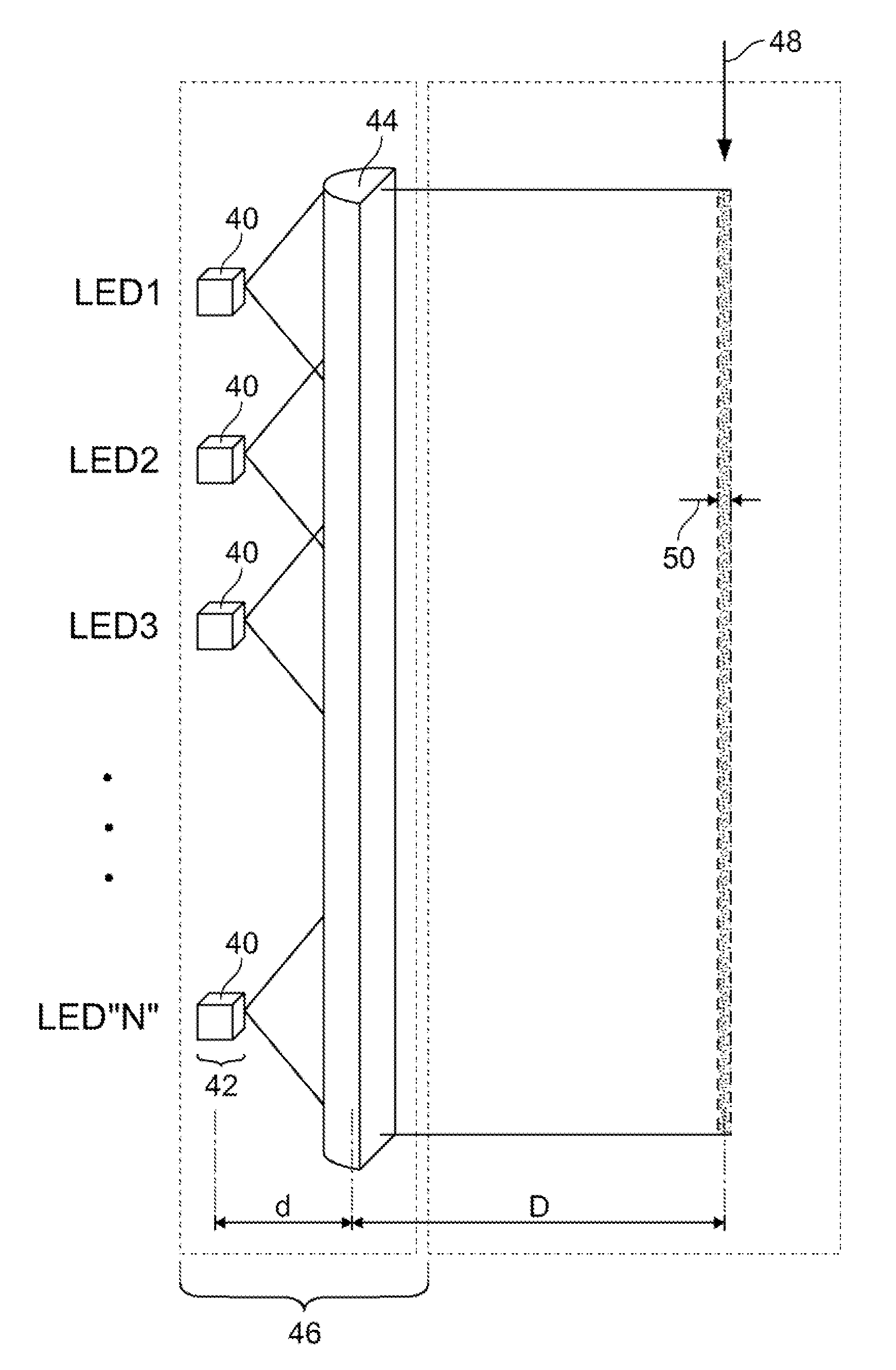

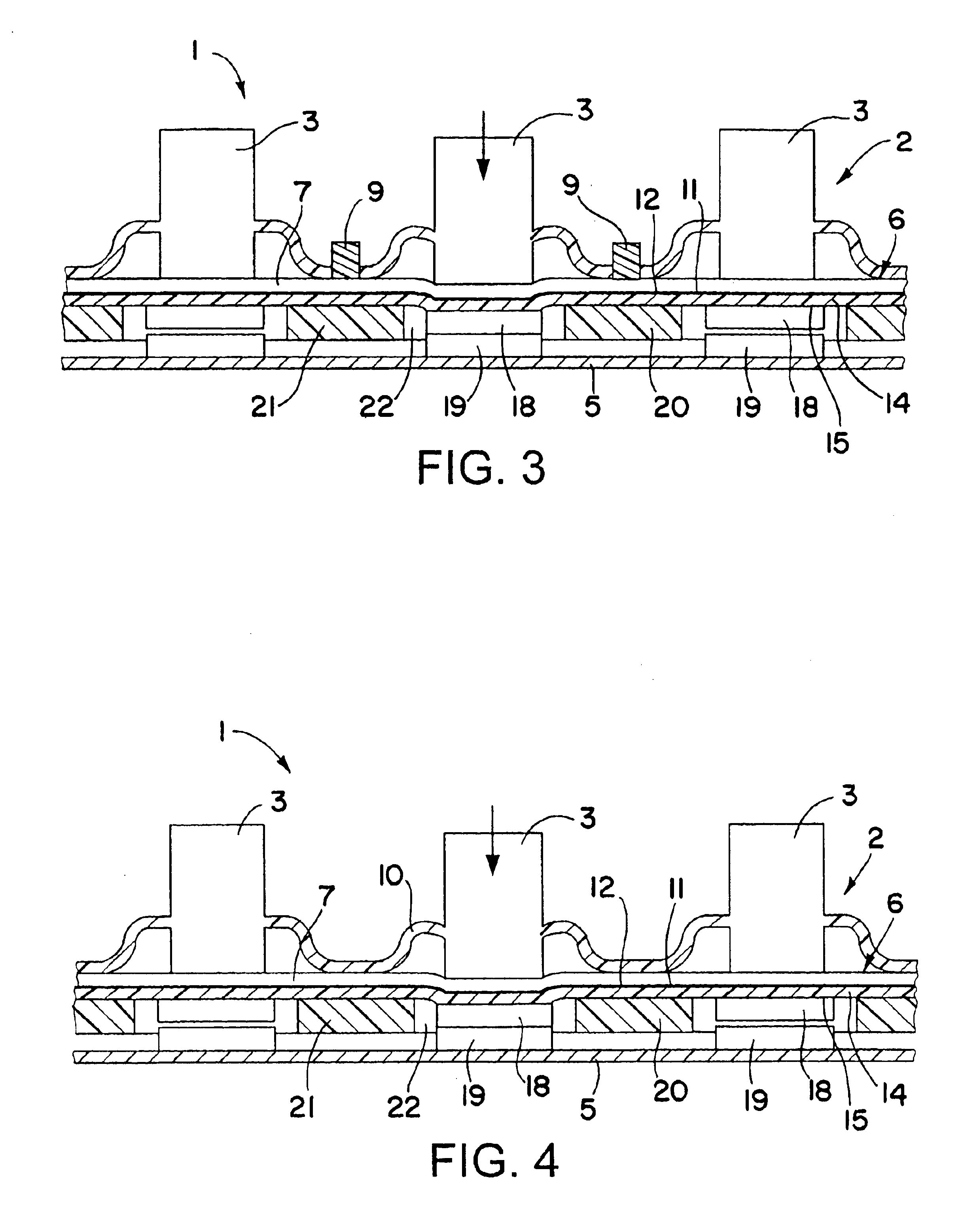

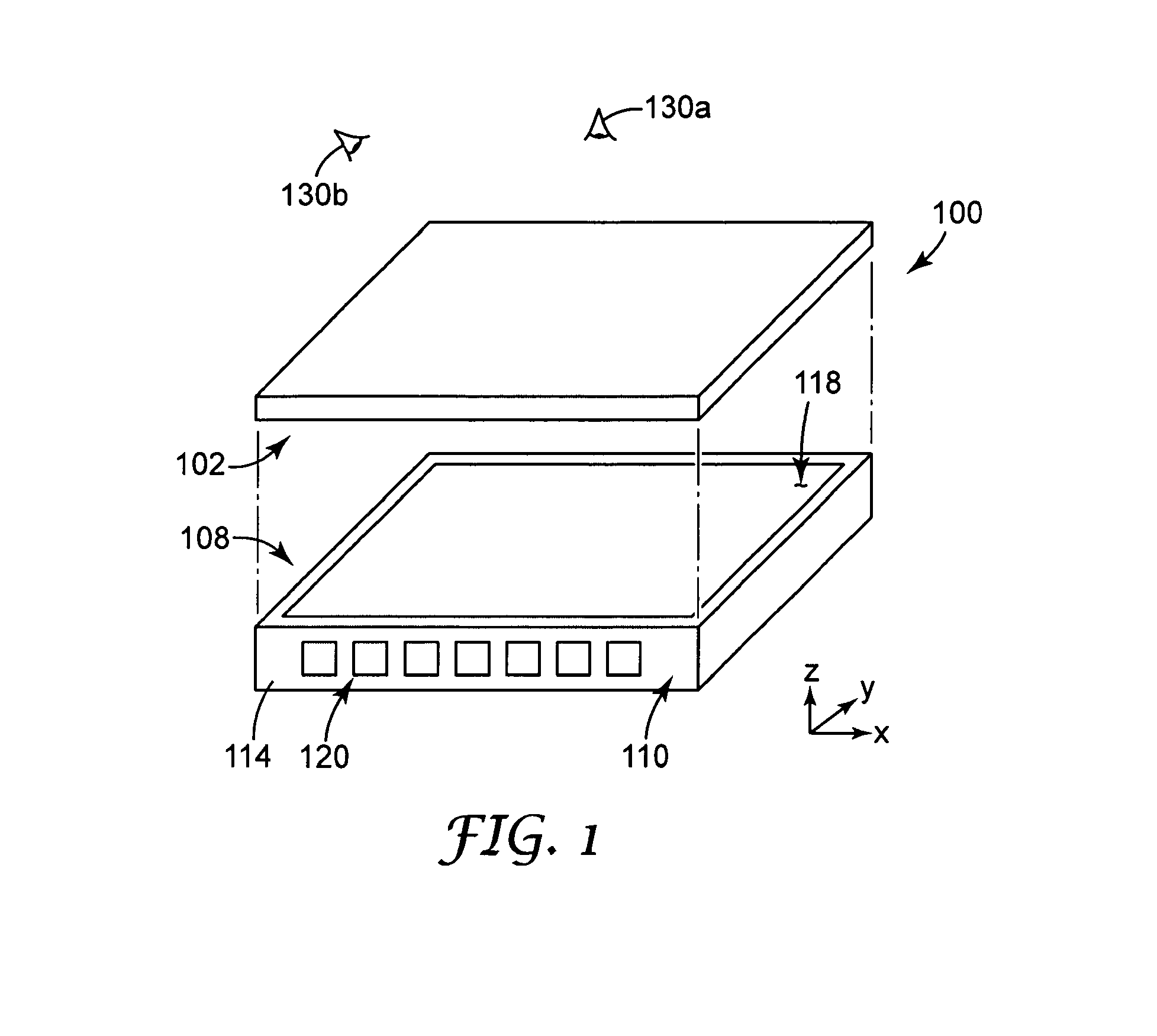

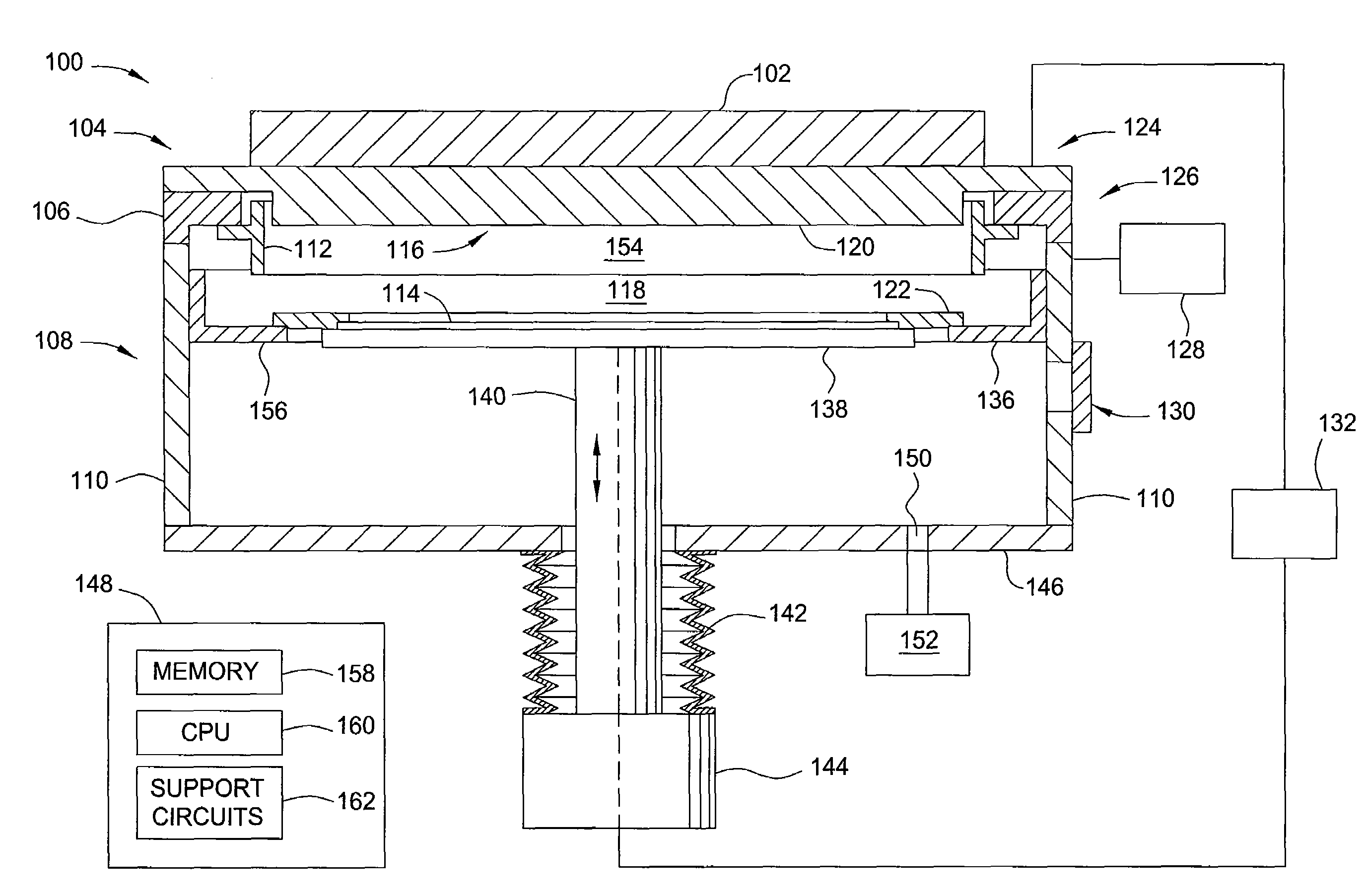

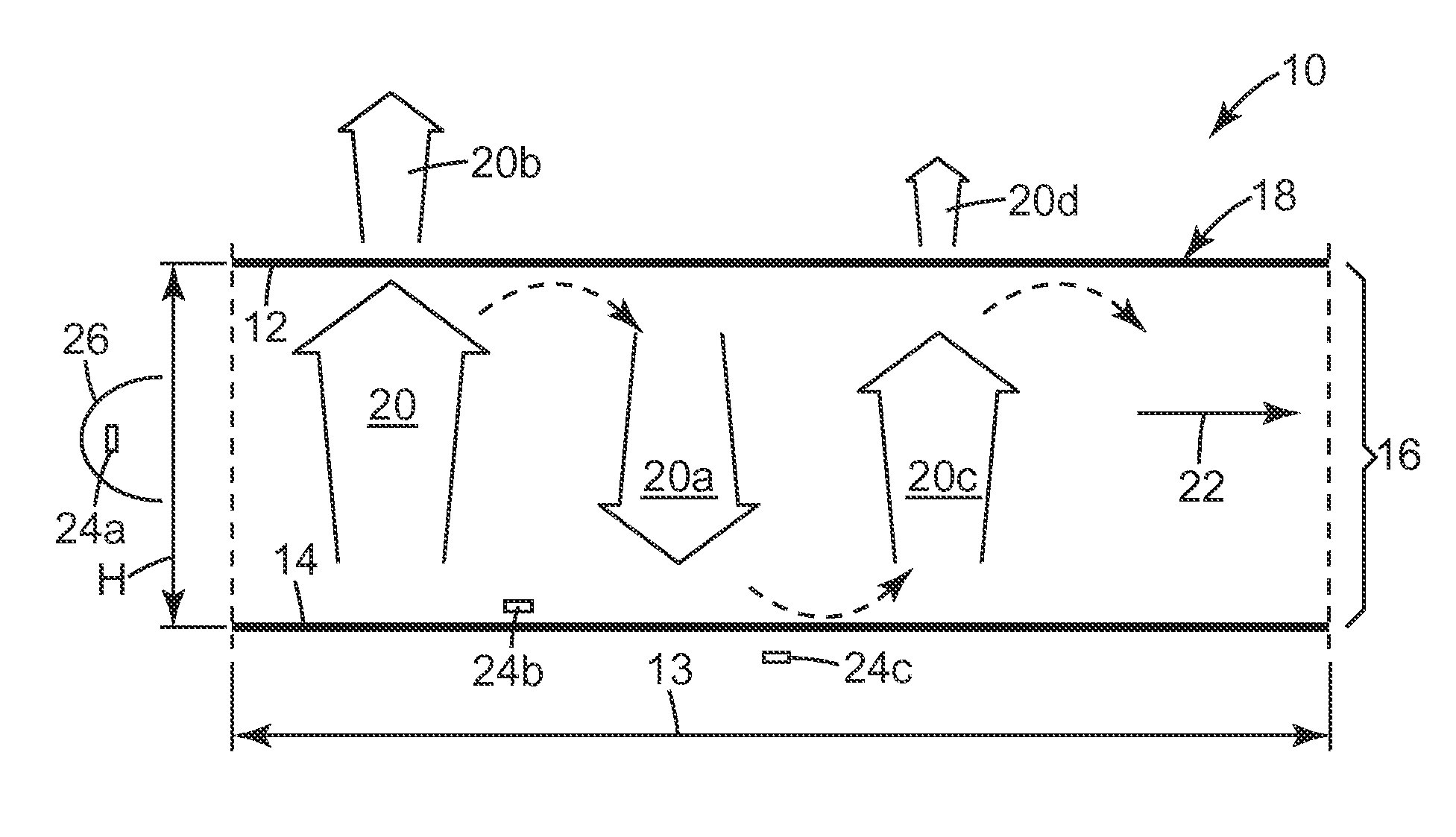

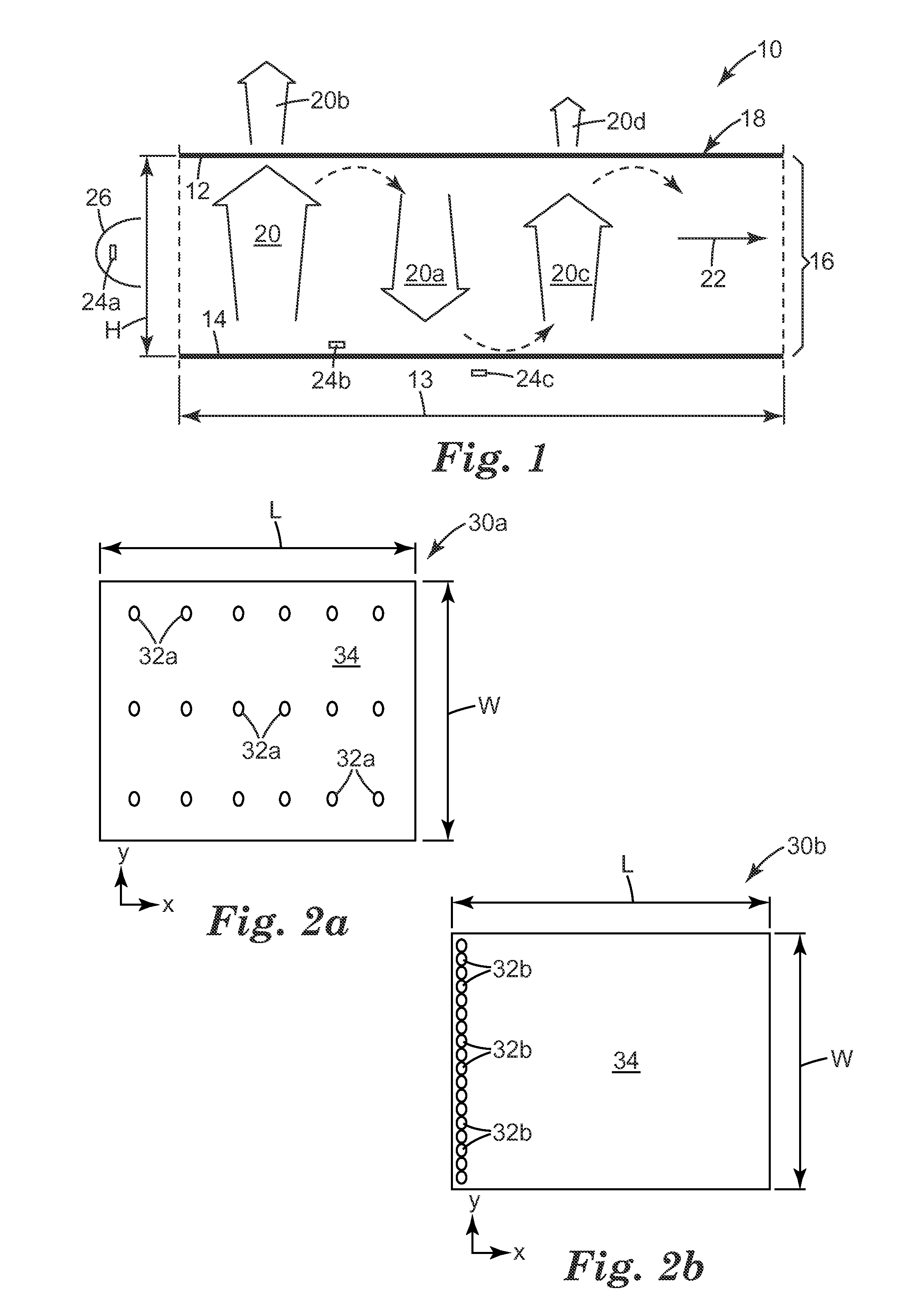

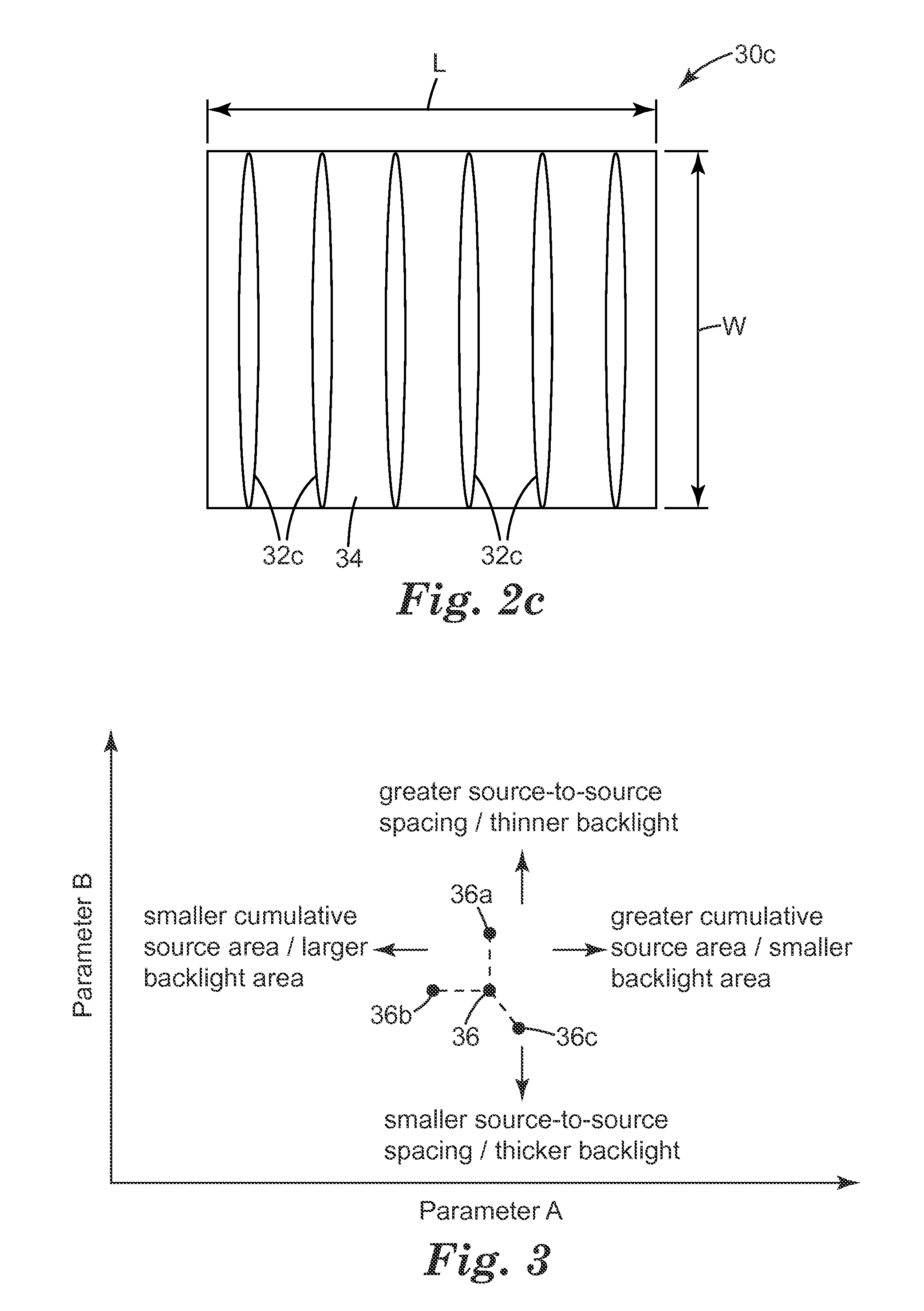

Thin hollow backlights with beneficial design characteristics

InactiveUS20100156953A1Reduce the total massLosses associated with the light sources are kept to minimal levelsCathode-ray tube indicatorsHollow light guidesBack reflectorLight guide

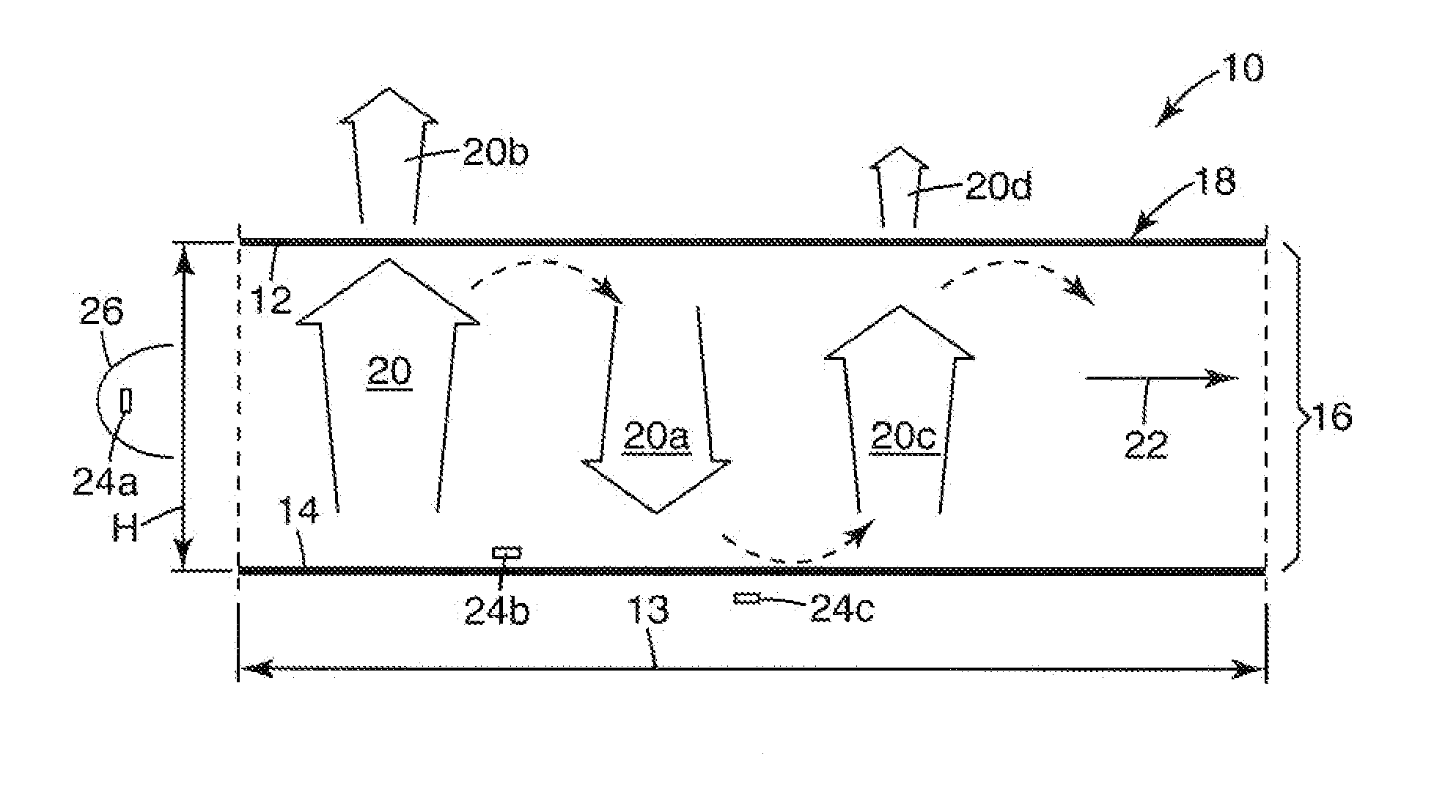

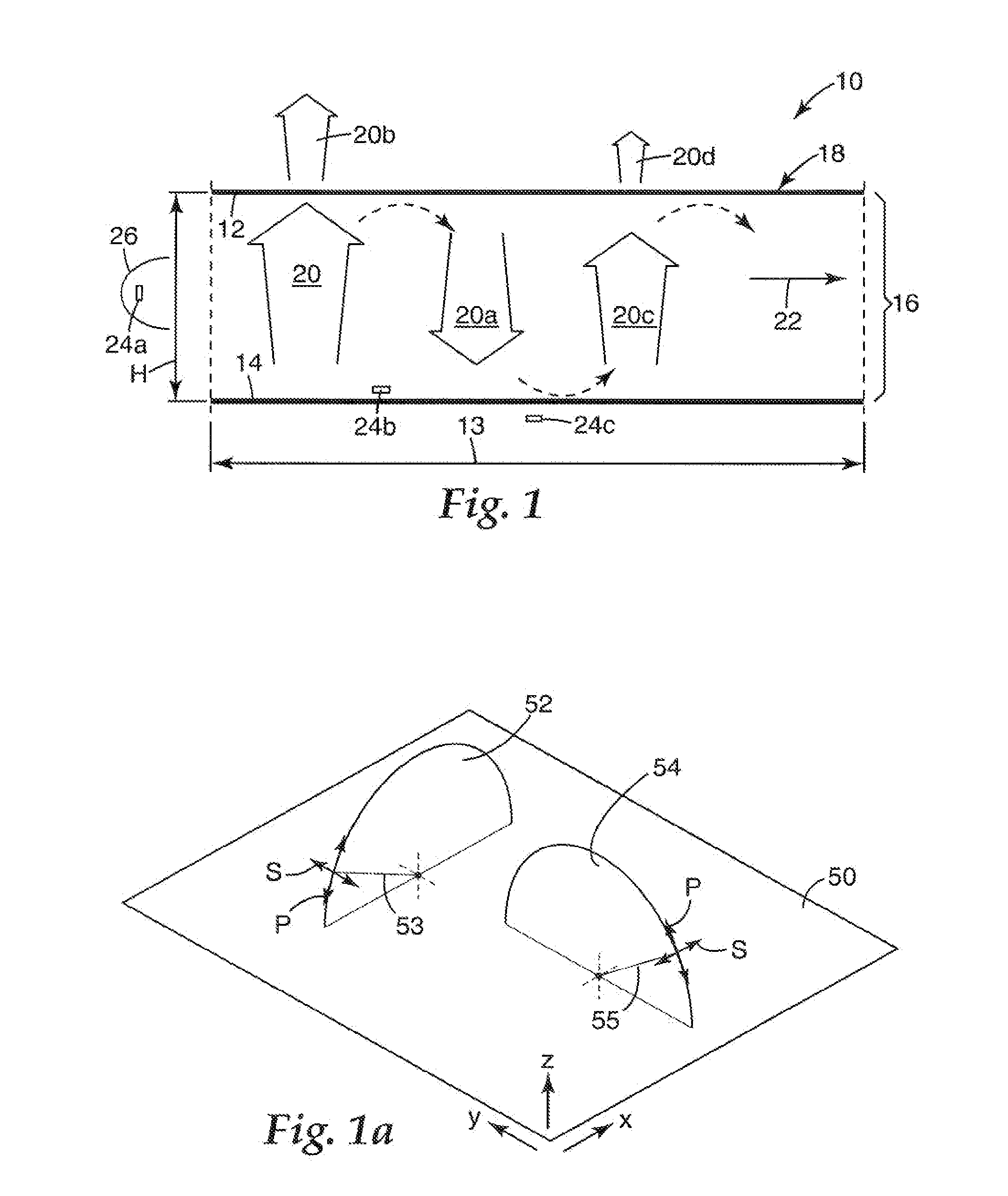

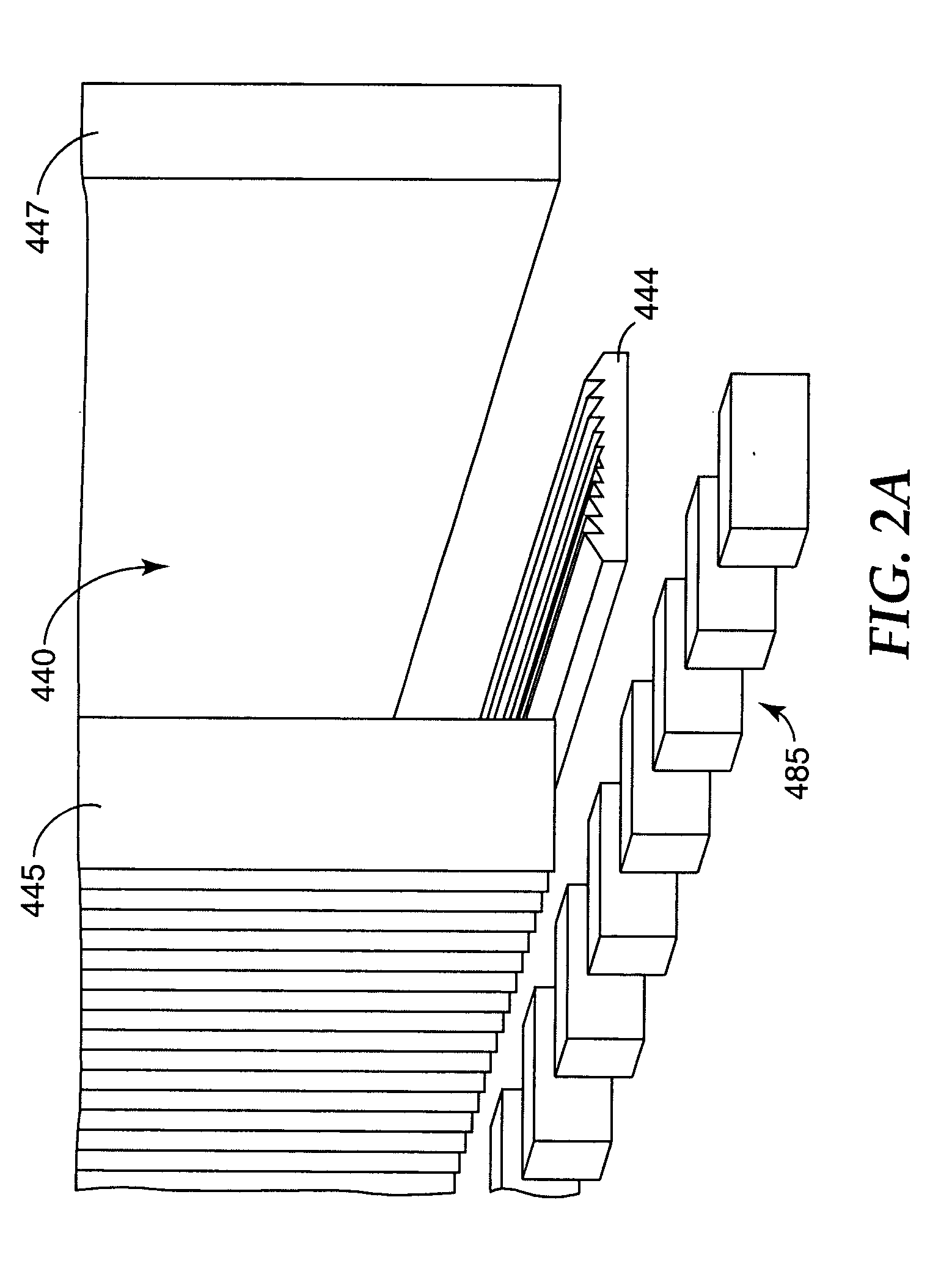

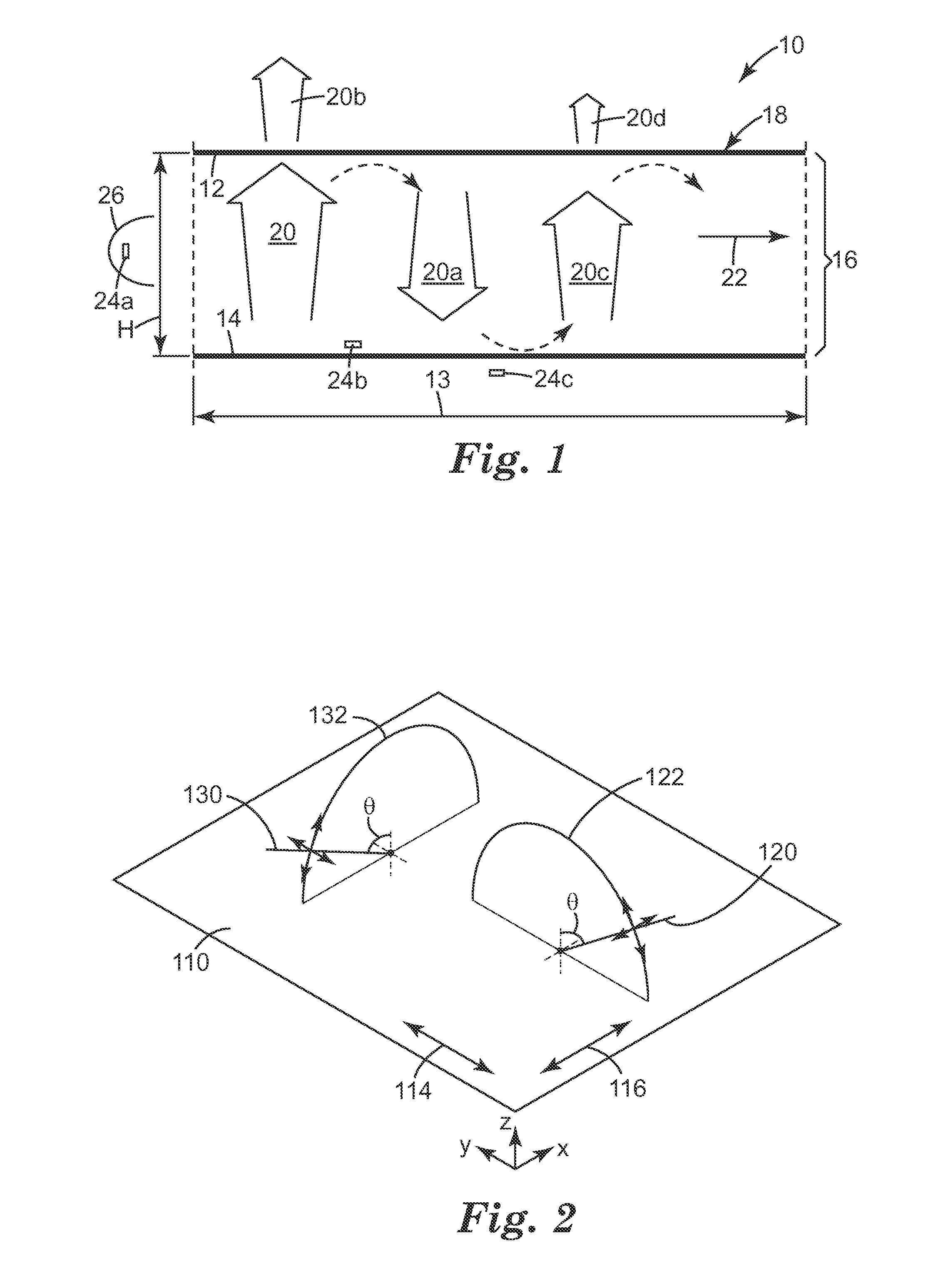

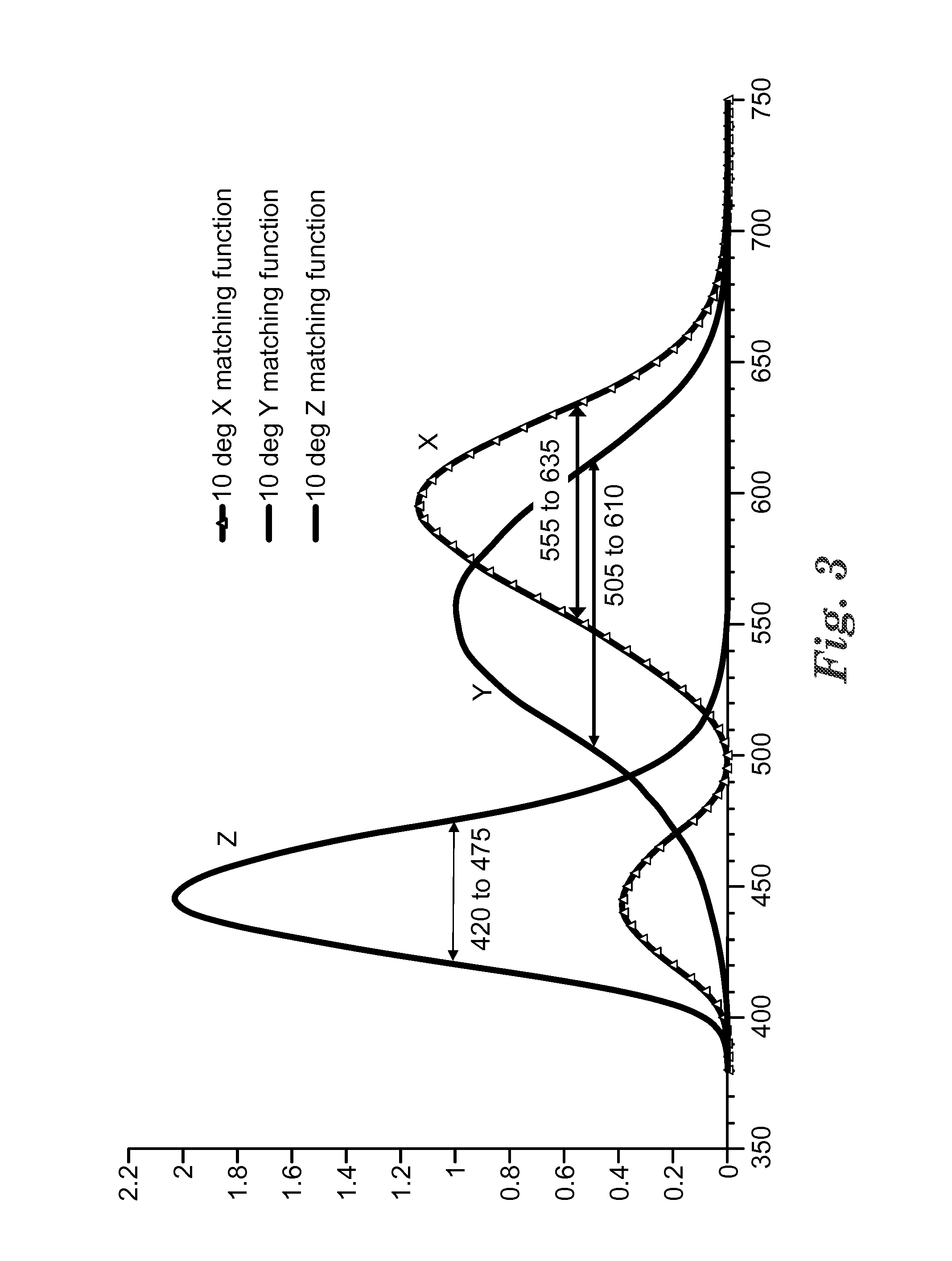

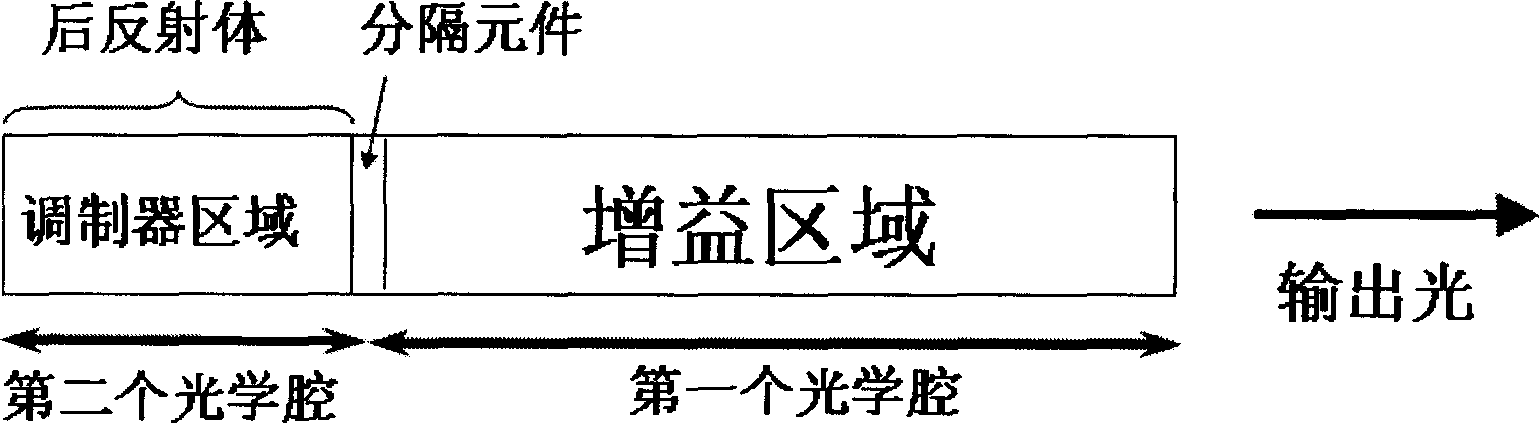

A backlight unit (10) has a hollow cavity (16) instead of employing a light guide. One or more light sources (24a-c), such as LEDs, are arranged to emit light into the cavity, which is formed by a front (12) and a back reflector (14). The backlight is typically of the edge-lit type. The backlight can have a large area, is thin and consists of fewer components than conventional devices. Its design permits light recycling. The unit emits light of a predefined polarisation and can be arranged to have desired horizontal / vertical viewing angle properties. Light is uniformly distributed within the guide and the light output (20b, 2Od) is substantially collimated. Such backlights occupy a specific region in a parameter space defined by two parameters: first, the ratio of the output emission area to the total source emission area should lie in the range 0.0001 to 0.1; and second, the ratio of the SEP to the height of the cavity (H) should be in the range 3 to 10, where the SEP is an average plan view source separation, a special measure of the average spacing of light sources in the plane of the unit. There is also a discussion on the required number of light sources N, their arrangement near the periphery of the cavity, as well as the shape and size of the output emission area. A required minimum brightness uniformity (VESA) value to be maintained, when a subset of Madjacent sources is switched off (where M is at least 0.1 N or M>2 or both), is also disclosed. The backlight can be used for a display or for general lighting purposes.

Owner:3M INNOVATIVE PROPERTIES CO

Back contact and back reflector for thin film silicon solar cells

InactiveUS20050172997A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationDielectricBack reflector

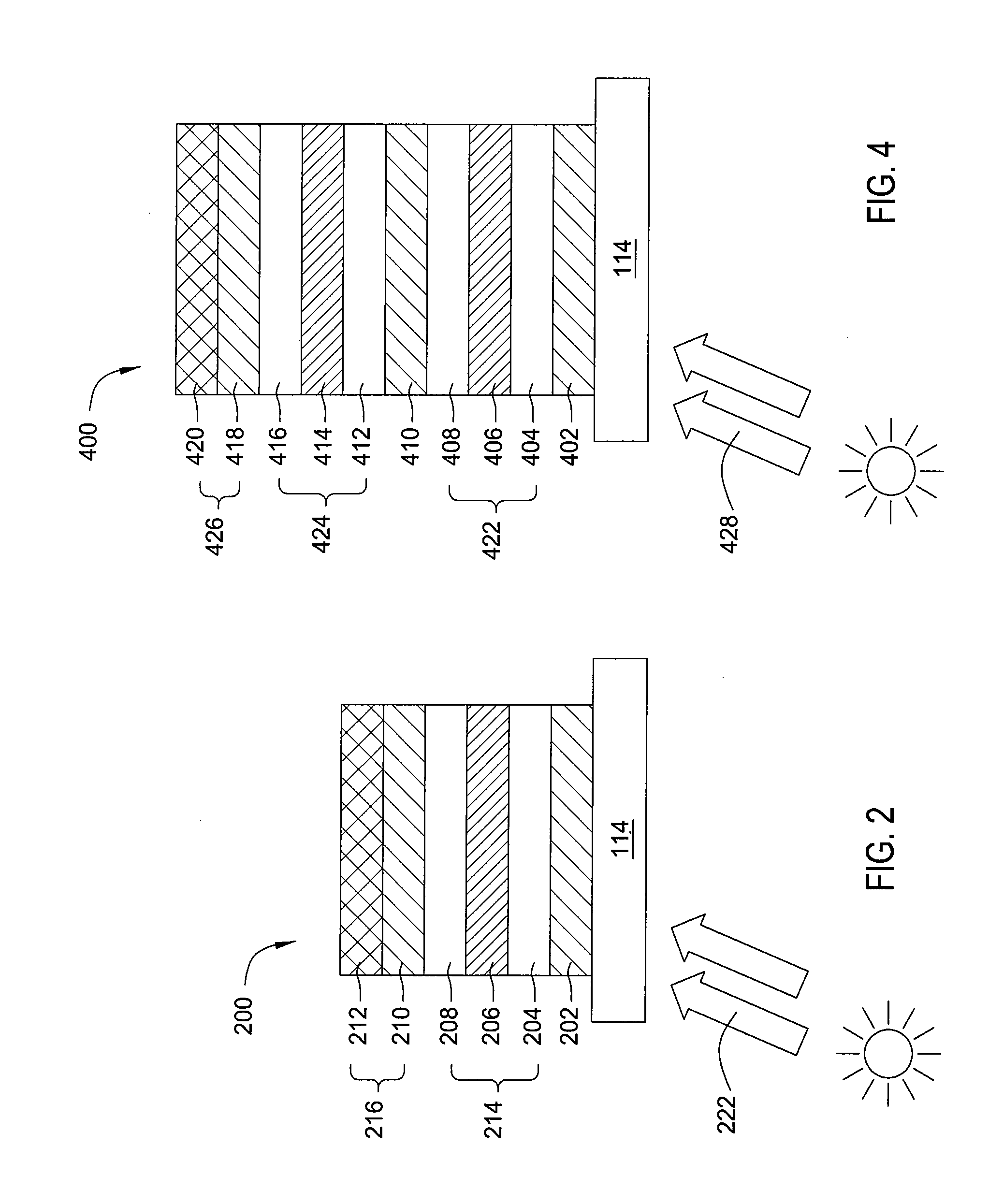

A thin film silicon solar cell for use in photovoltaic cells having a carrier substrate, a front transparent conductive oxide contact, a thin film silicon solar cell layer having at least one layer of hydrogenated microcrystalline silicon or nanocrystalline silicon, and a back contact having a transparent conductive oxide contact layer and a back reflective layer comprising a white pigmented dielectric reflective media.

Owner:UNAXIS BALZERS LTD

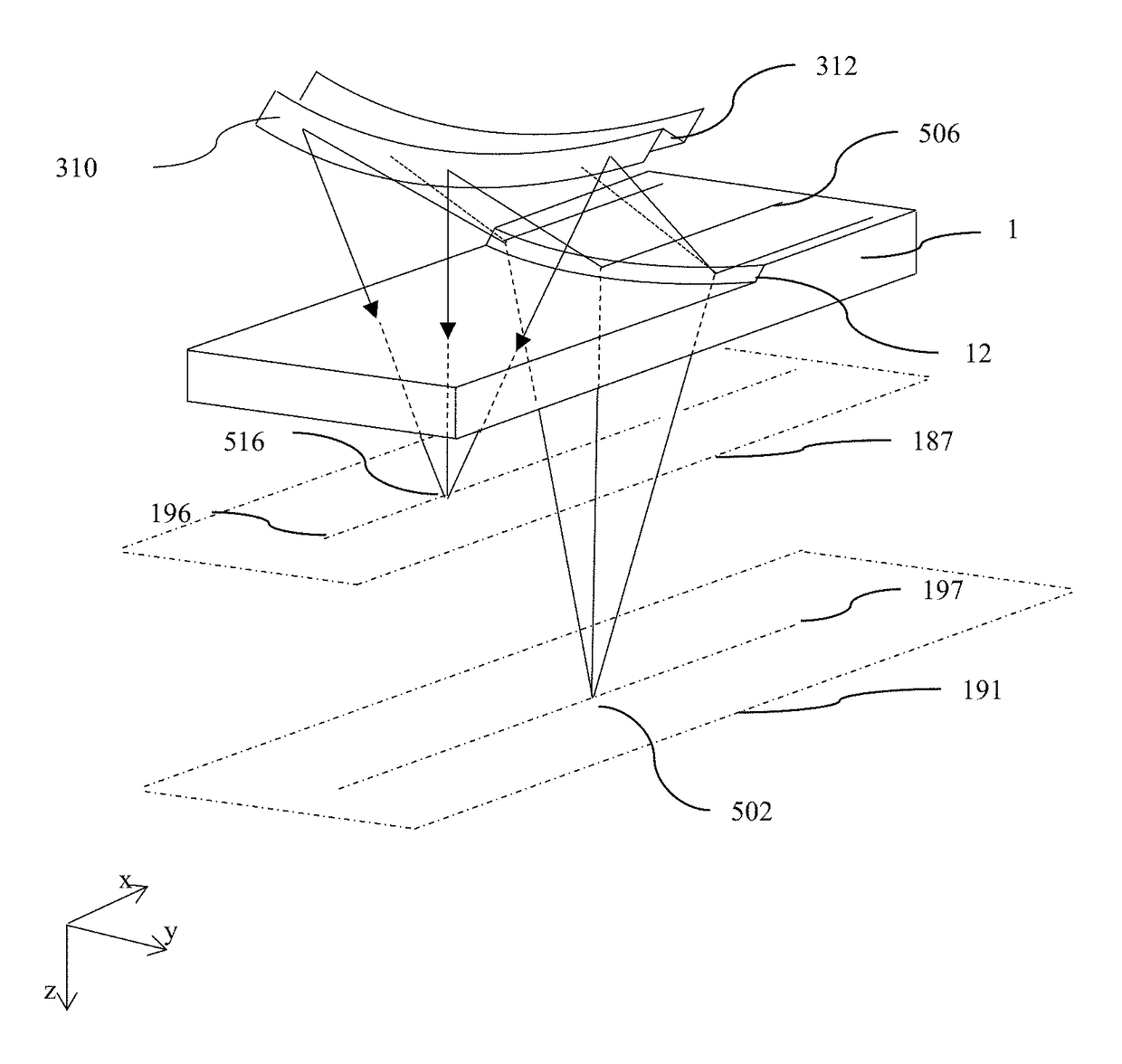

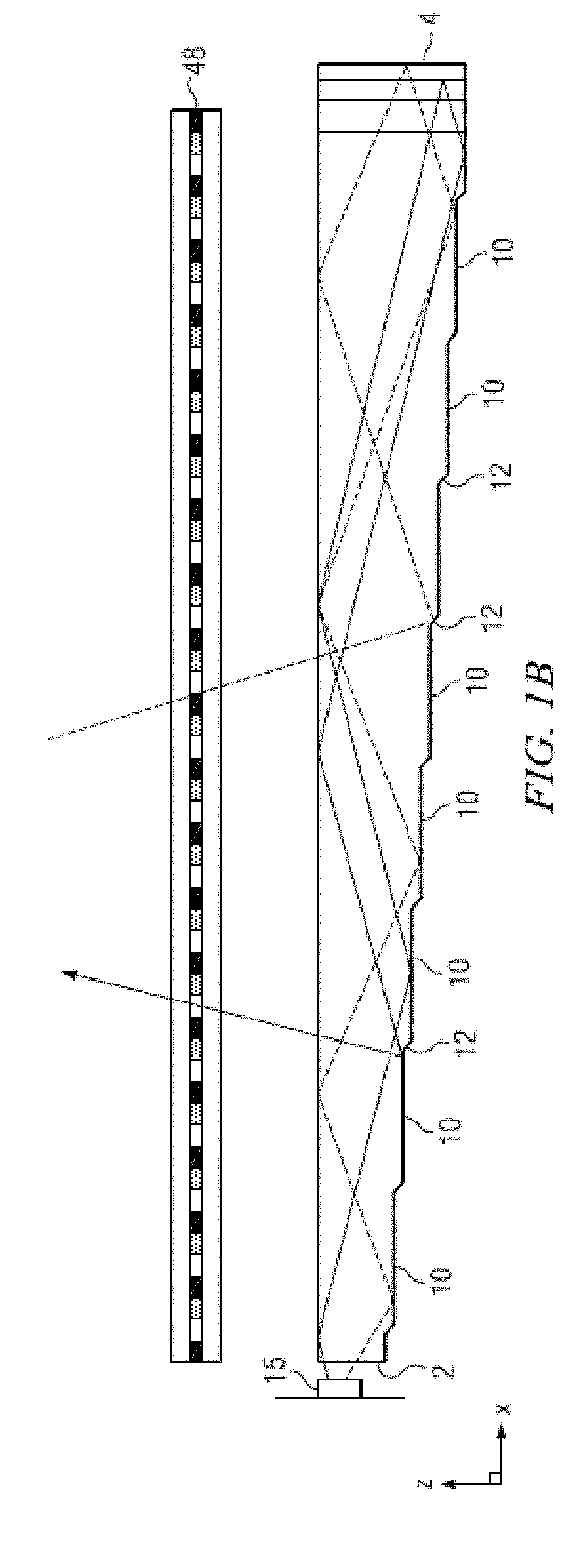

Wide angle imaging directional backlights

ActiveUS20170339398A1Operational savingHigh luminance operationMechanical apparatusStatic indicating devicesWide-angle lensDirect illumination

An imaging directional backlight apparatus including a waveguide, a light source array, for providing large area directed illumination from localized light sources. The waveguide may include a stepped structure, in which the steps may further include extraction features optically hidden to guided light, propagating in a first forward direction. Returning light propagating in a second backward direction may be refracted, diffracted, or reflected by the features to provide discrete illumination beams exiting from the top surface of the waveguide. Viewing windows are formed through imaging individual light sources by waveguide facets and rear reflector images in cooperation. Viewing windows may be provided at first and second different window planes to improve uniformity in a lateral direction. Further, stray light may be reduced by inner and outer portions of reflective facets with different inclinations for the rear reflector.

Owner:REALD SPARK LLC

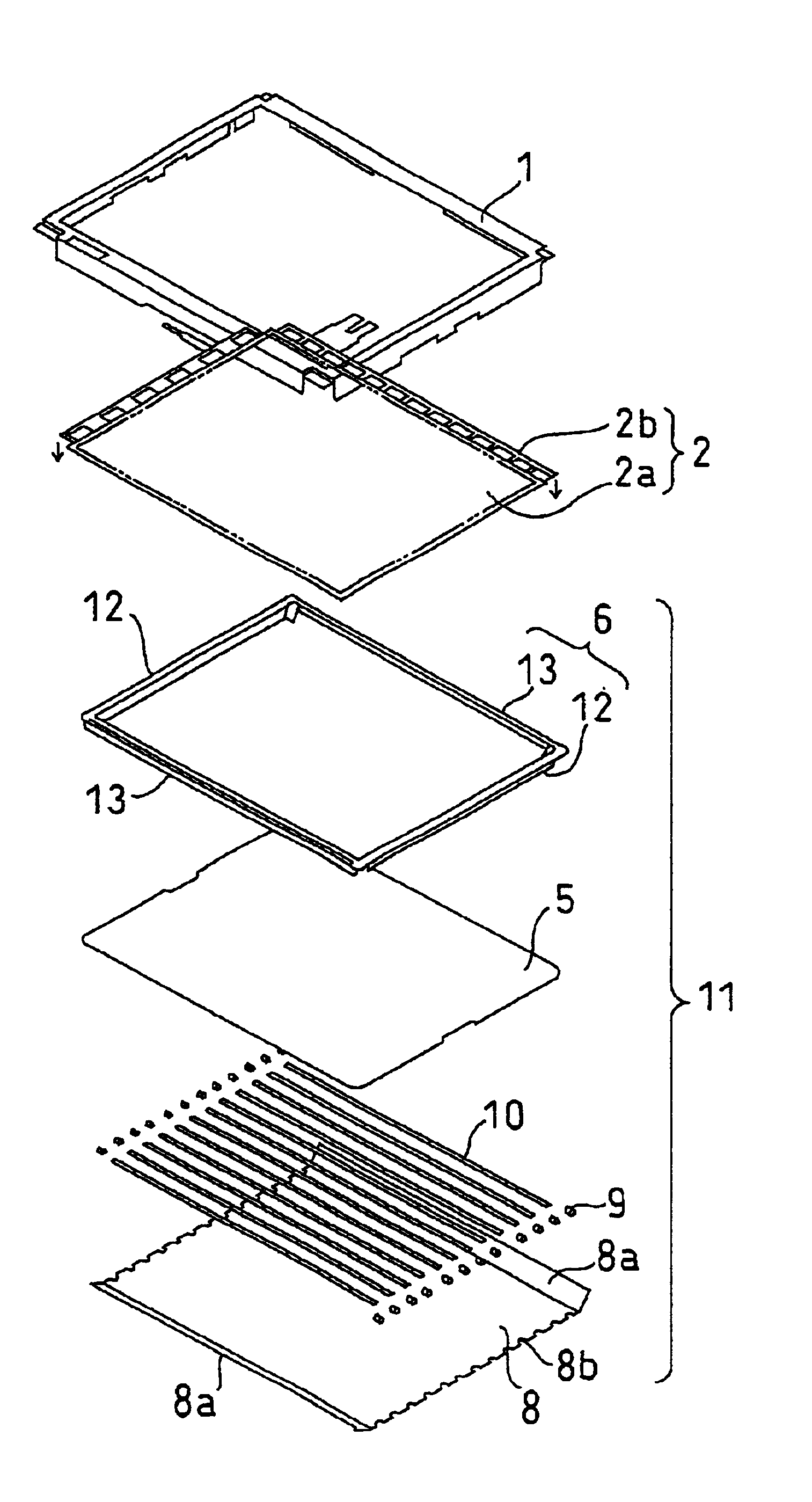

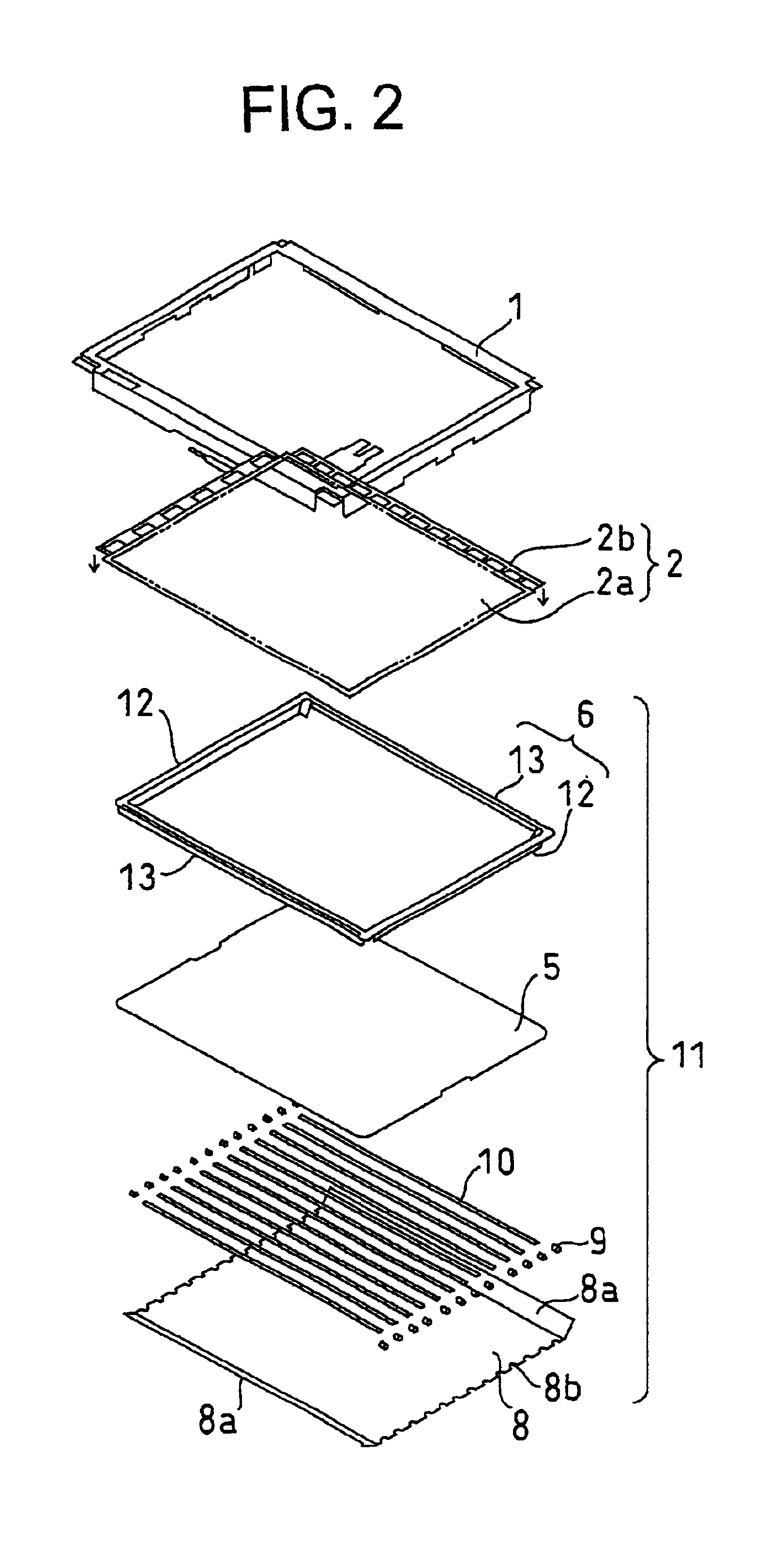

Hybrid lightguide backlight

InactiveUS7223005B2Reduce riskGood for mixing lightMechanical apparatusLight guides for lighting systemsBack reflectorOptoelectronics

Owner:3M INNOVATIVE PROPERTIES CO

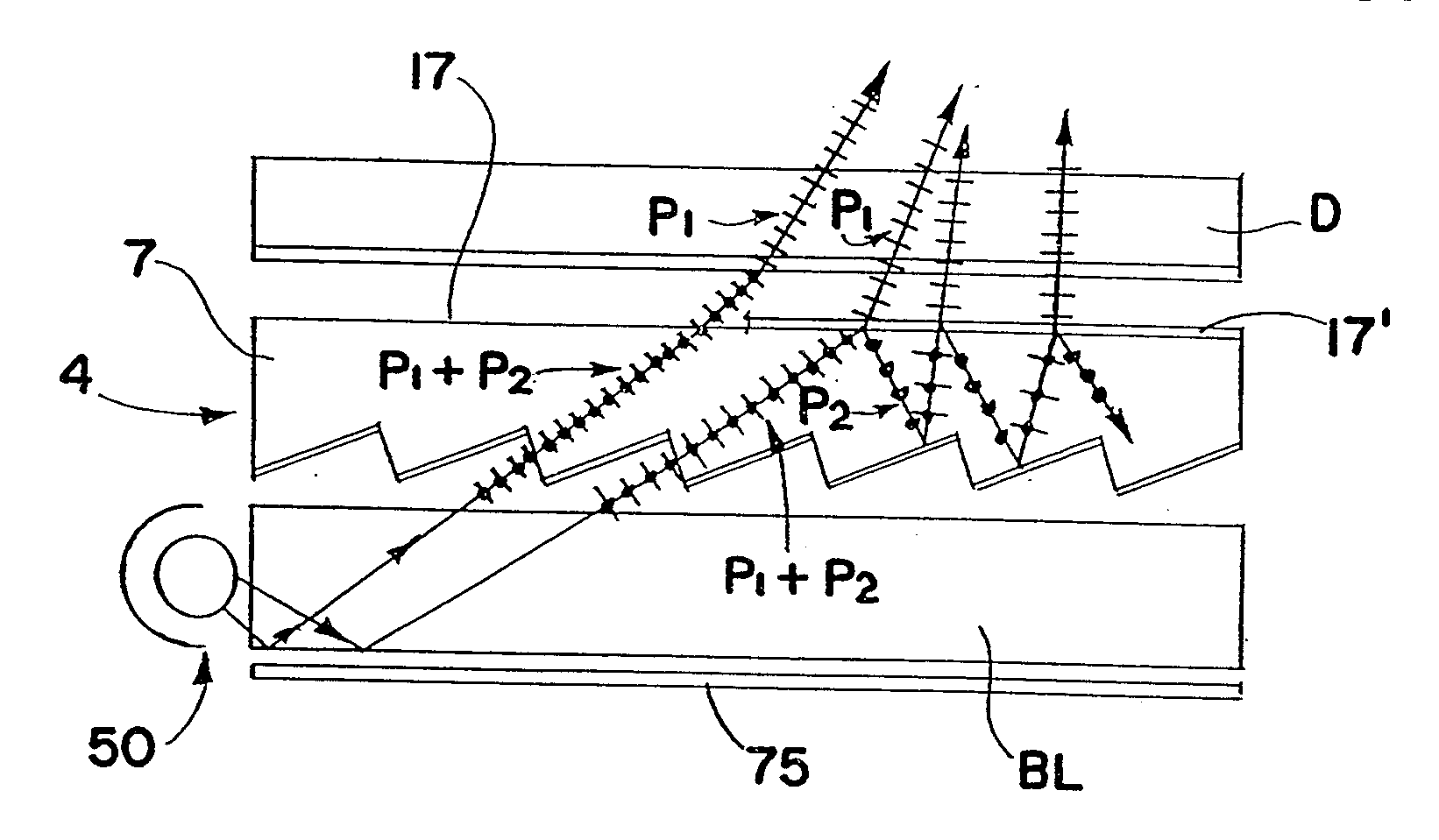

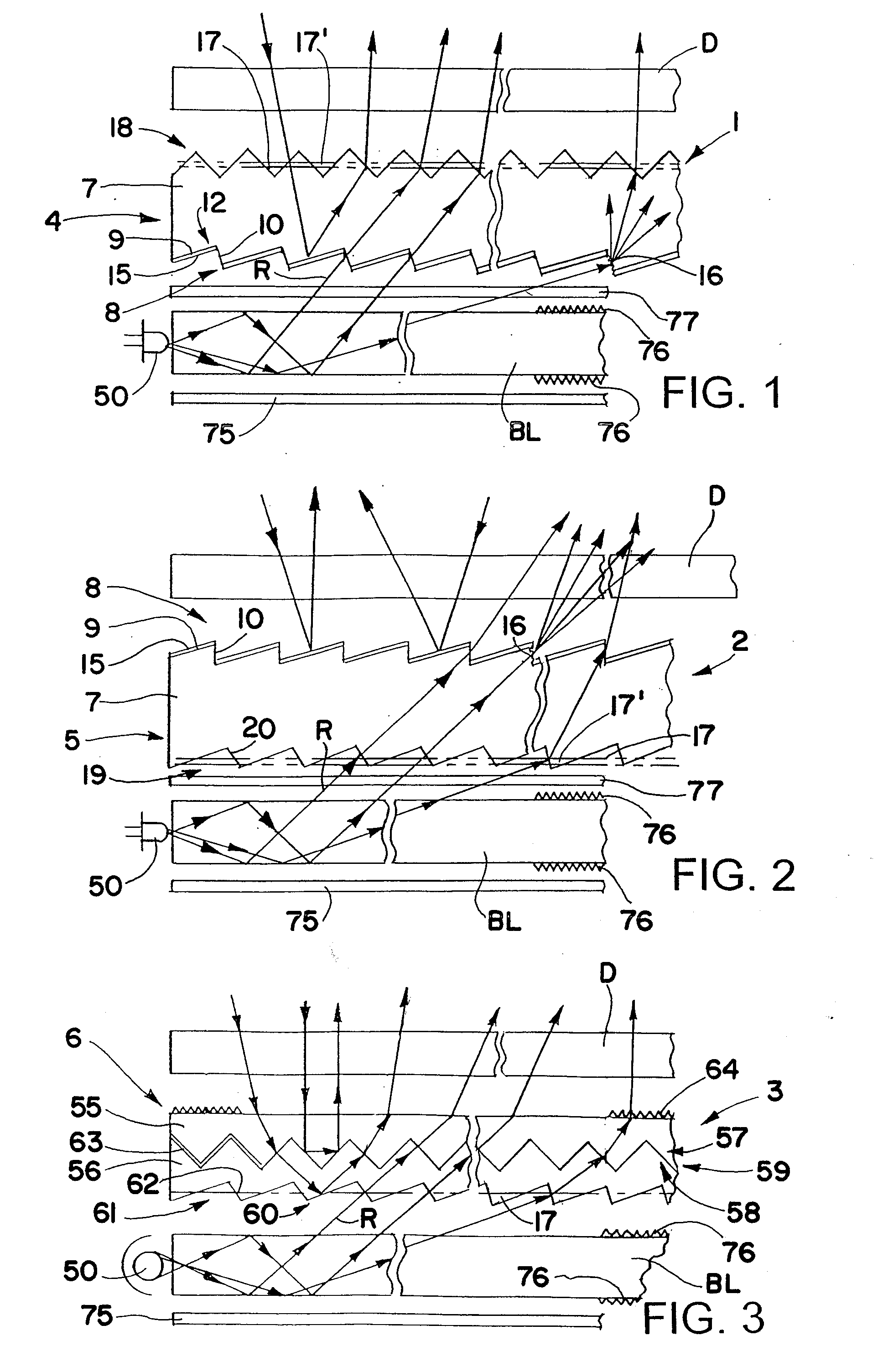

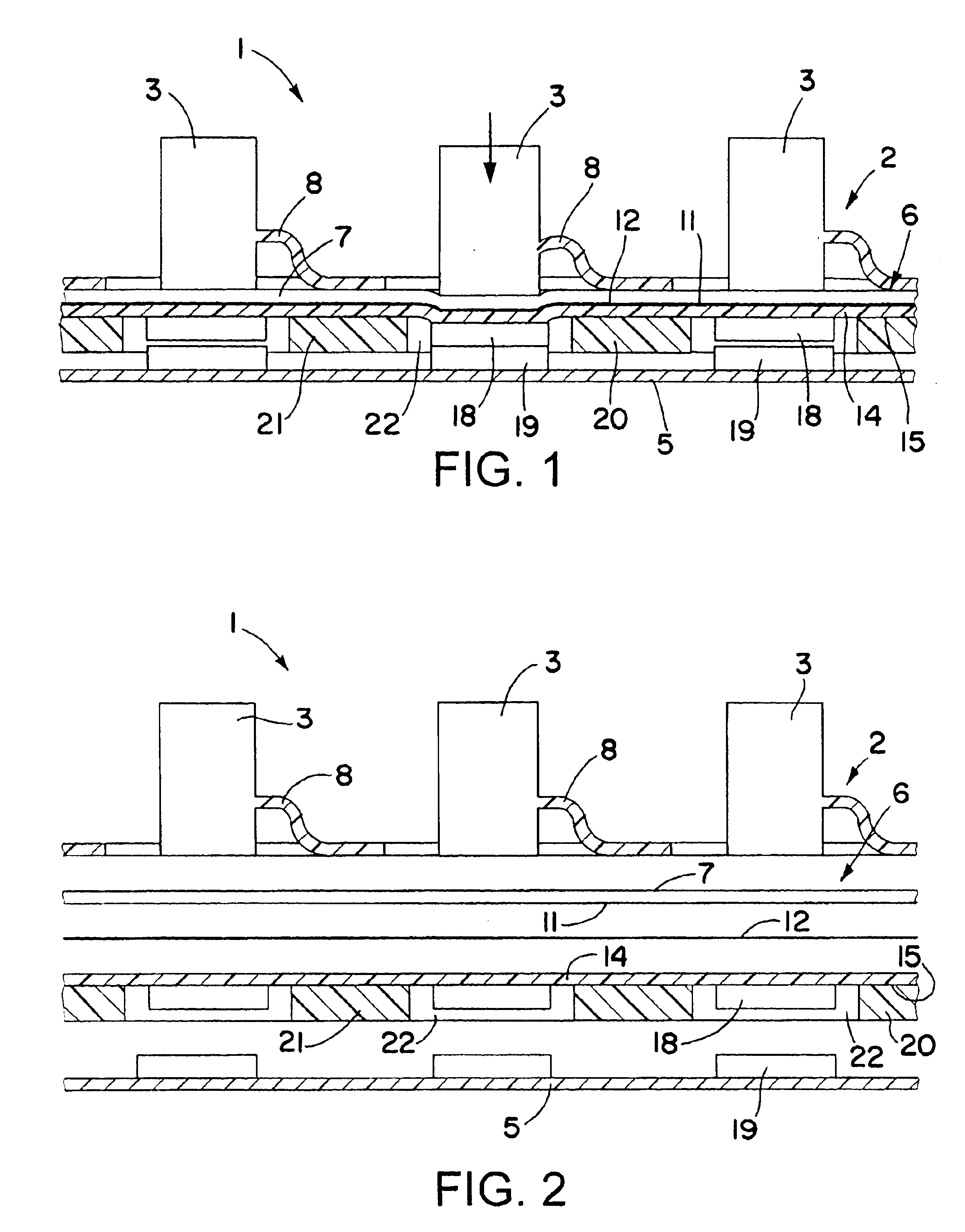

Recycling backlights with semi-specular components

ActiveUS20100238686A1Improve output performanceHollow light guidesIlluminated signsBack reflectorInjection point

A hollow light-recycling backlight has a “semi-specular” component providing a balance of specularly and diffusely reflected light improving the uniformity of the light output. The component may be arranged on the reflectors (1021), (1014) or inside the cavity (1016). This balance is achieved by designing the component's “transport ratio” defined by (F−B) / (F+B), (F and B are the amounts of incident light scattered forwards and backwards respectively by the component in the plane of the cavity) to lie in a certain range. Furthermore, the product of the front and back reflector “hemispherical” reflectivities should also lie in a given range. Alternatively, the “cavity transport value”, a measure of how well the cavity can spread injected light from the injection point to distant points in the cavity should lie in a further range and the “hemispherical” reflectivity of the back reflector should be >0.7.

Owner:3M INNOVATIVE PROPERTIES CO

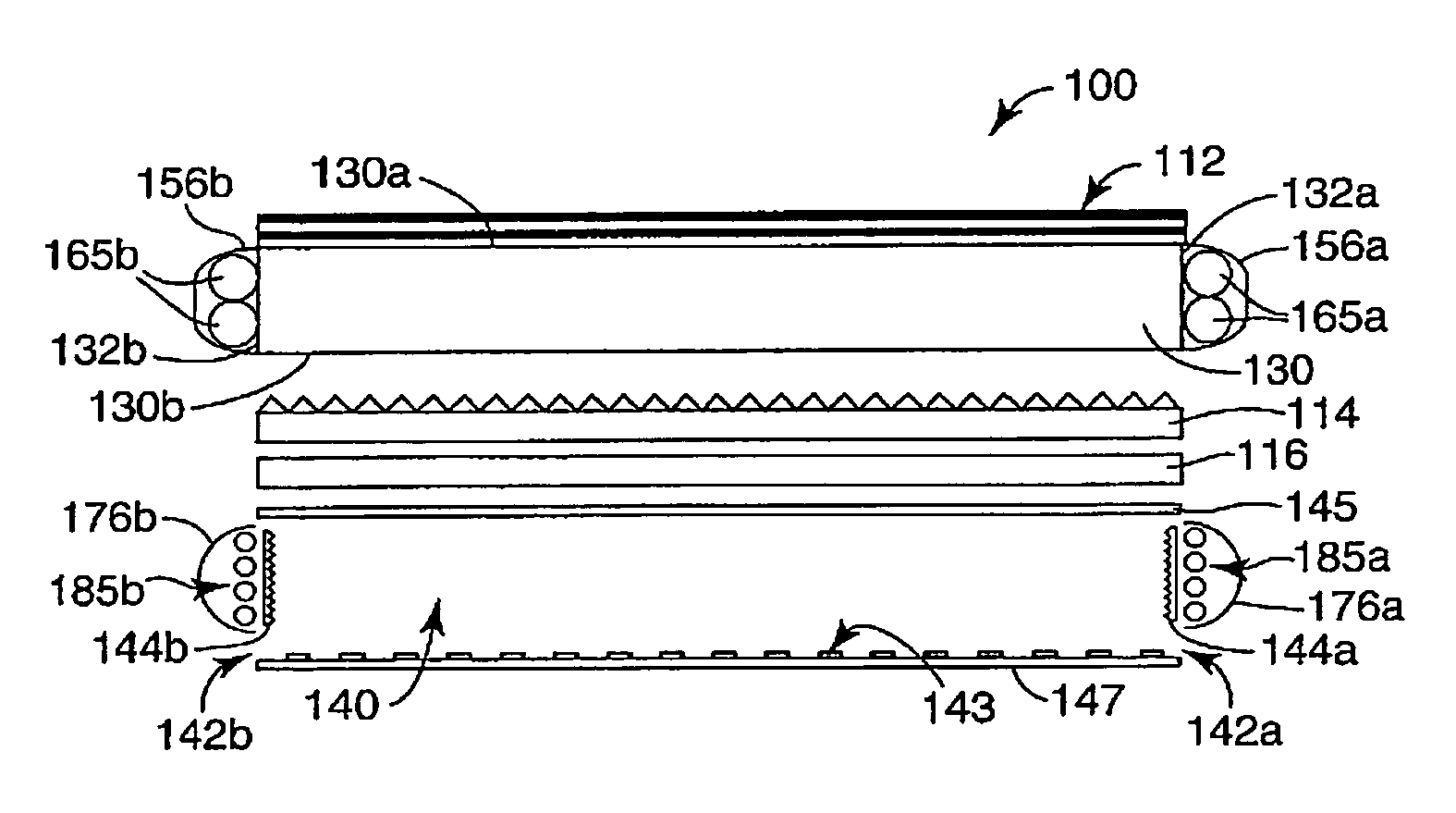

Hybrid lightguide backlight

InactiveUS20050135117A1Reduce riskGood for mixing lightMechanical apparatusLight guides for lighting systemsBack reflectorOptoelectronics

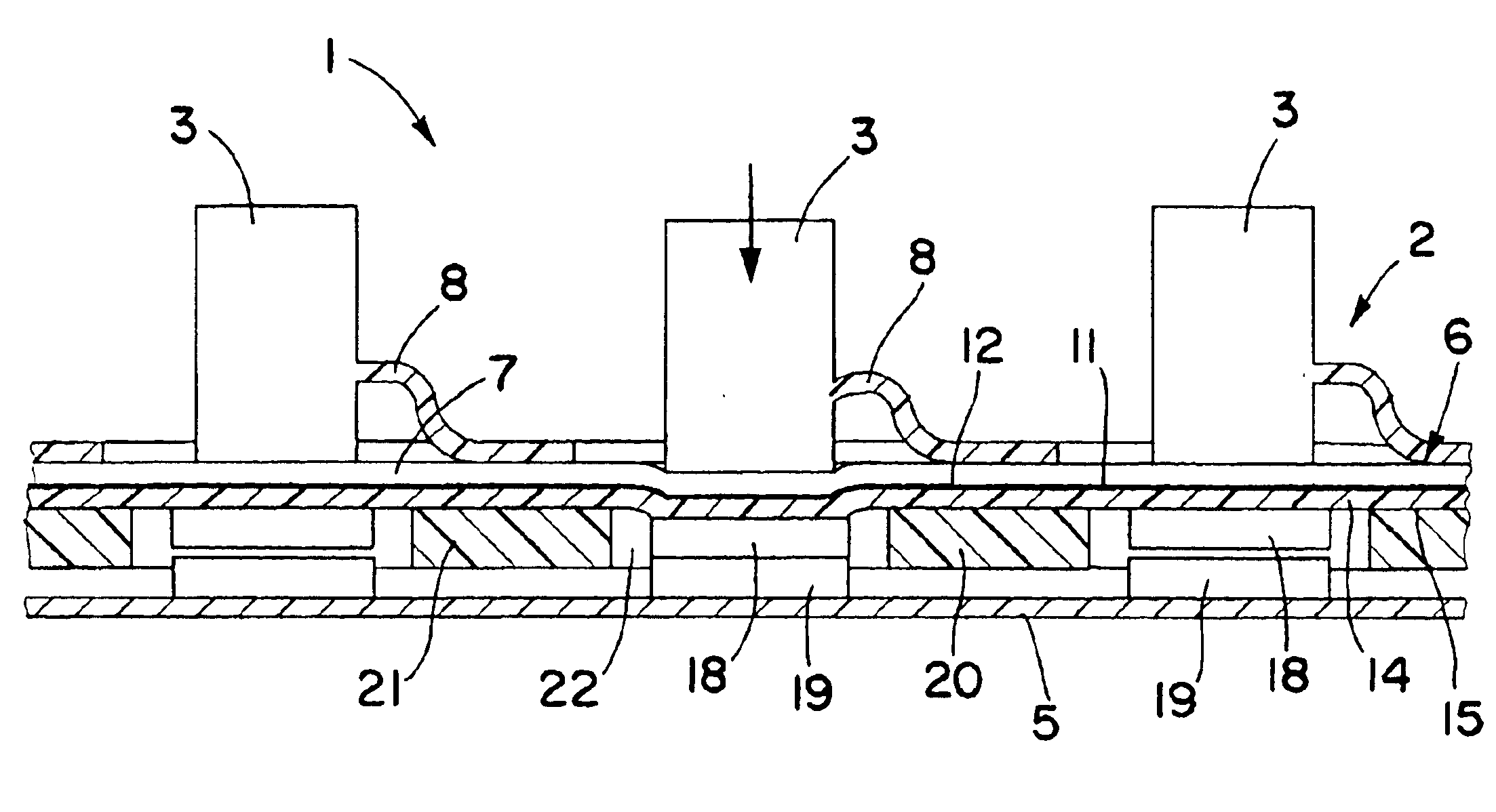

Backlighting systems are disclosed, which include a lightguide with at least one light source optically connected to an edge of the lightguide for supplying light into its interior and a reflective cavity with at least one light source optically connected to the reflective cavity for supplying light into its interior. The reflective cavity may include a first reflector and a second reflector and at least one source may be disposed at an edge of the reflective cavity. Alternatively, the reflective cavity may include a back reflector portion and light sources may be disposed at the back reflector portion.

Owner:3M INNOVATIVE PROPERTIES CO

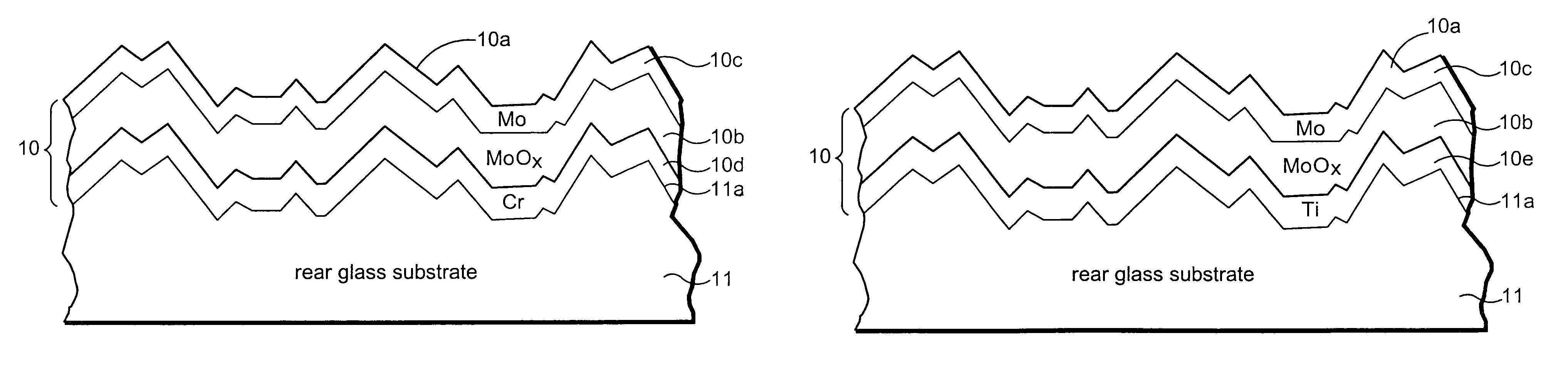

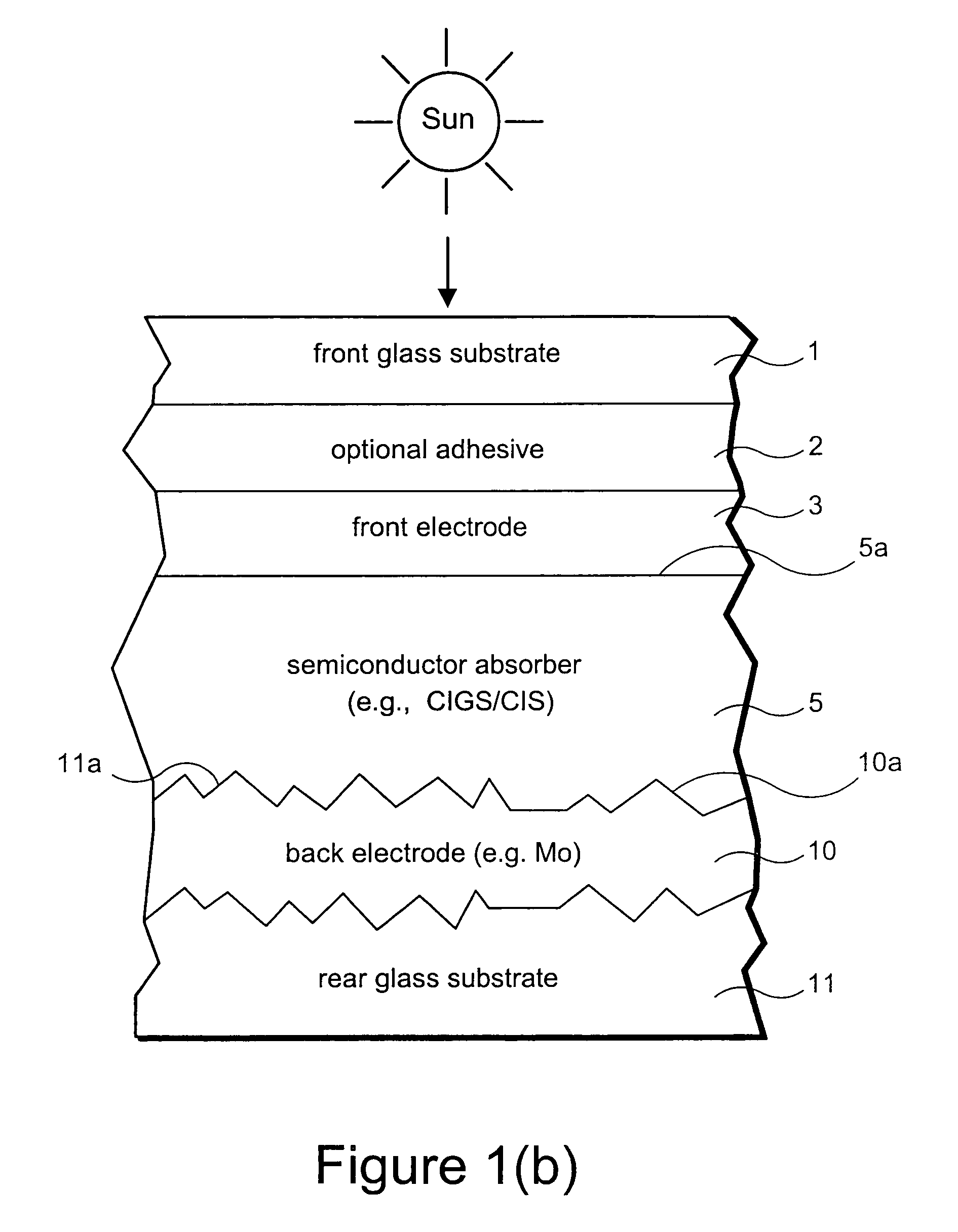

Rear electrode structure for use in photovoltaic device such as CIGS/CIS photovoltaic device and method of making same

InactiveUS7875945B2Relieve pressureImprove the immunityFinal product manufactureSolid-state devicesEngineeringSputter deposition

Owner:GUARDIAN GLASS LLC

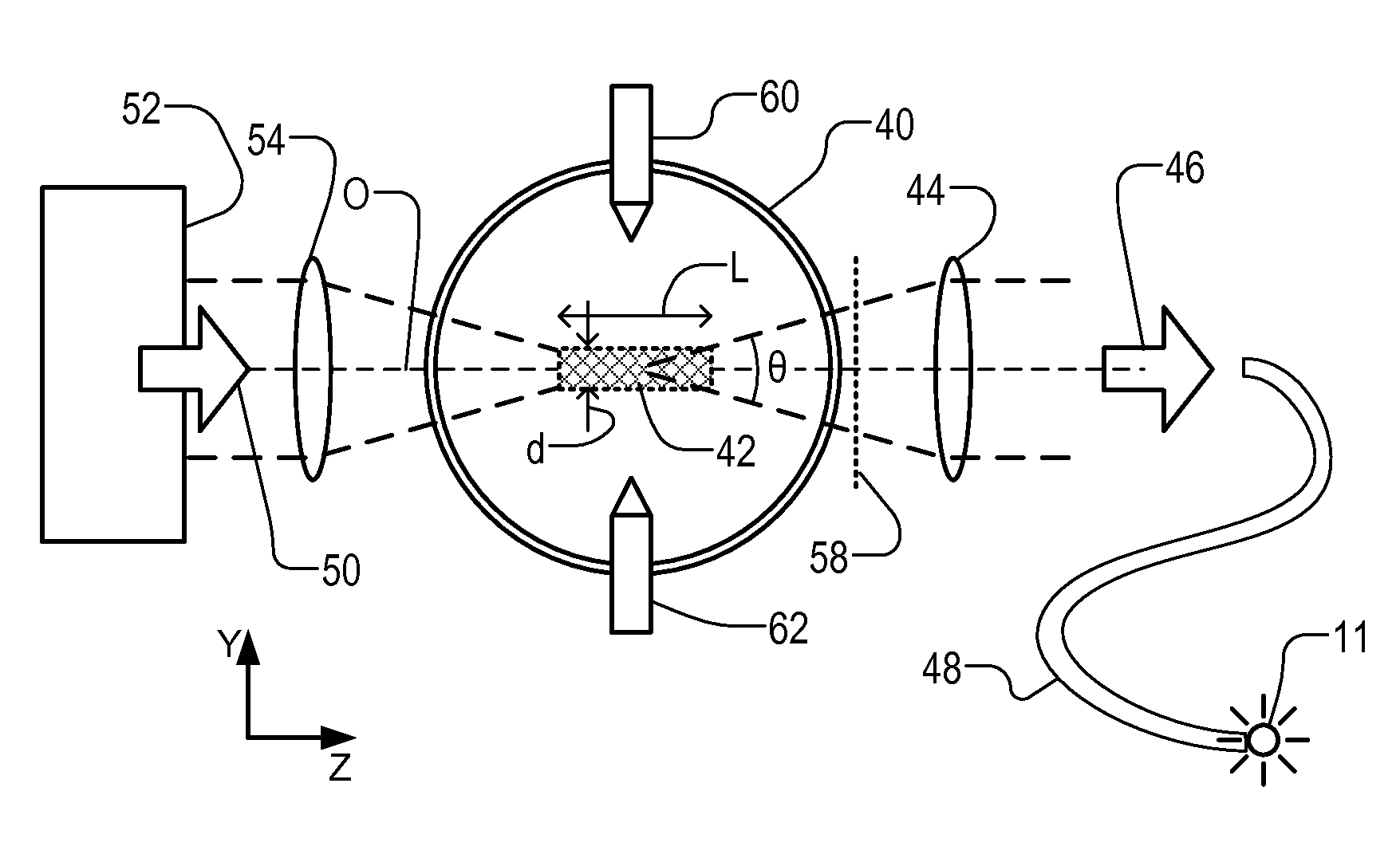

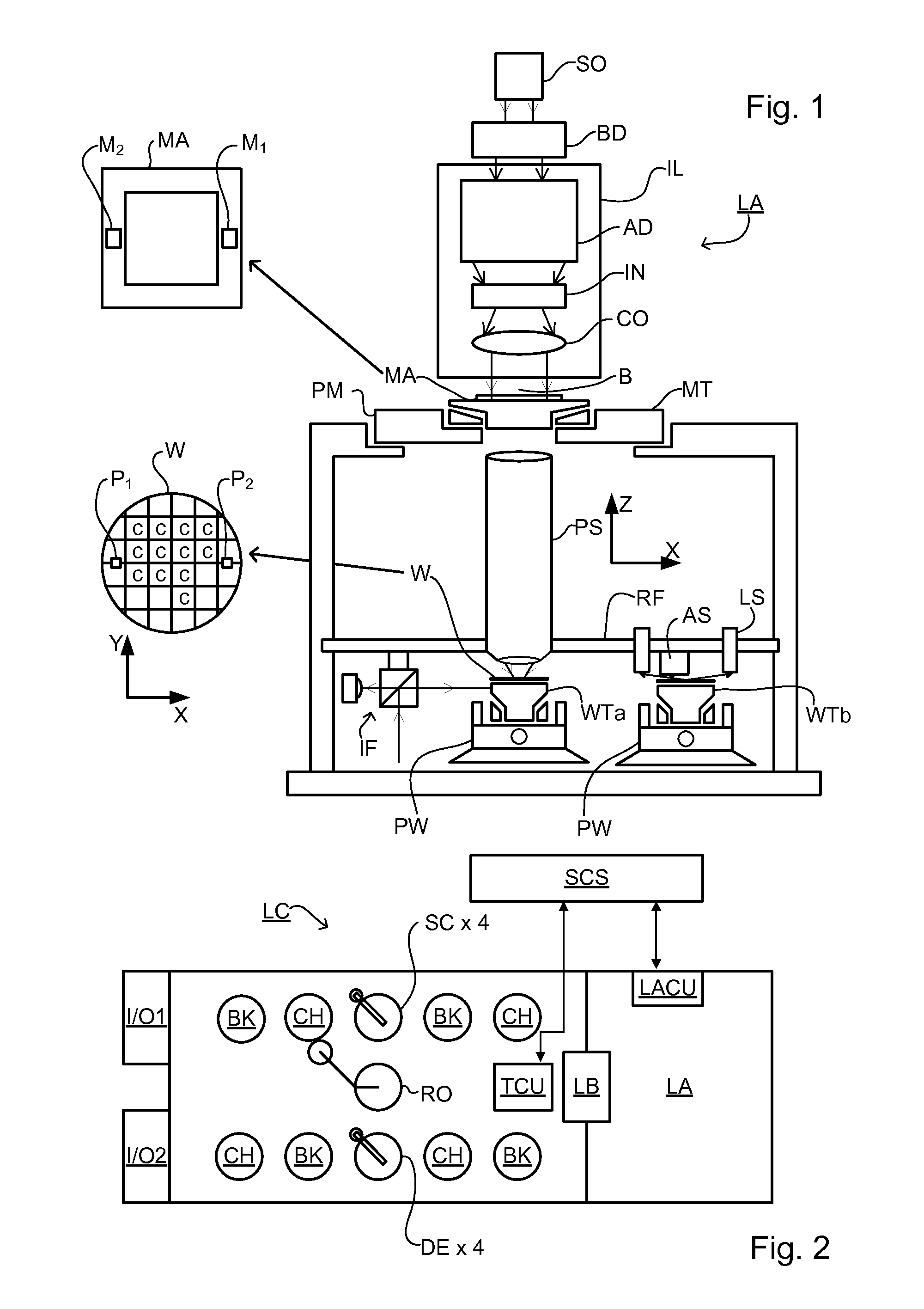

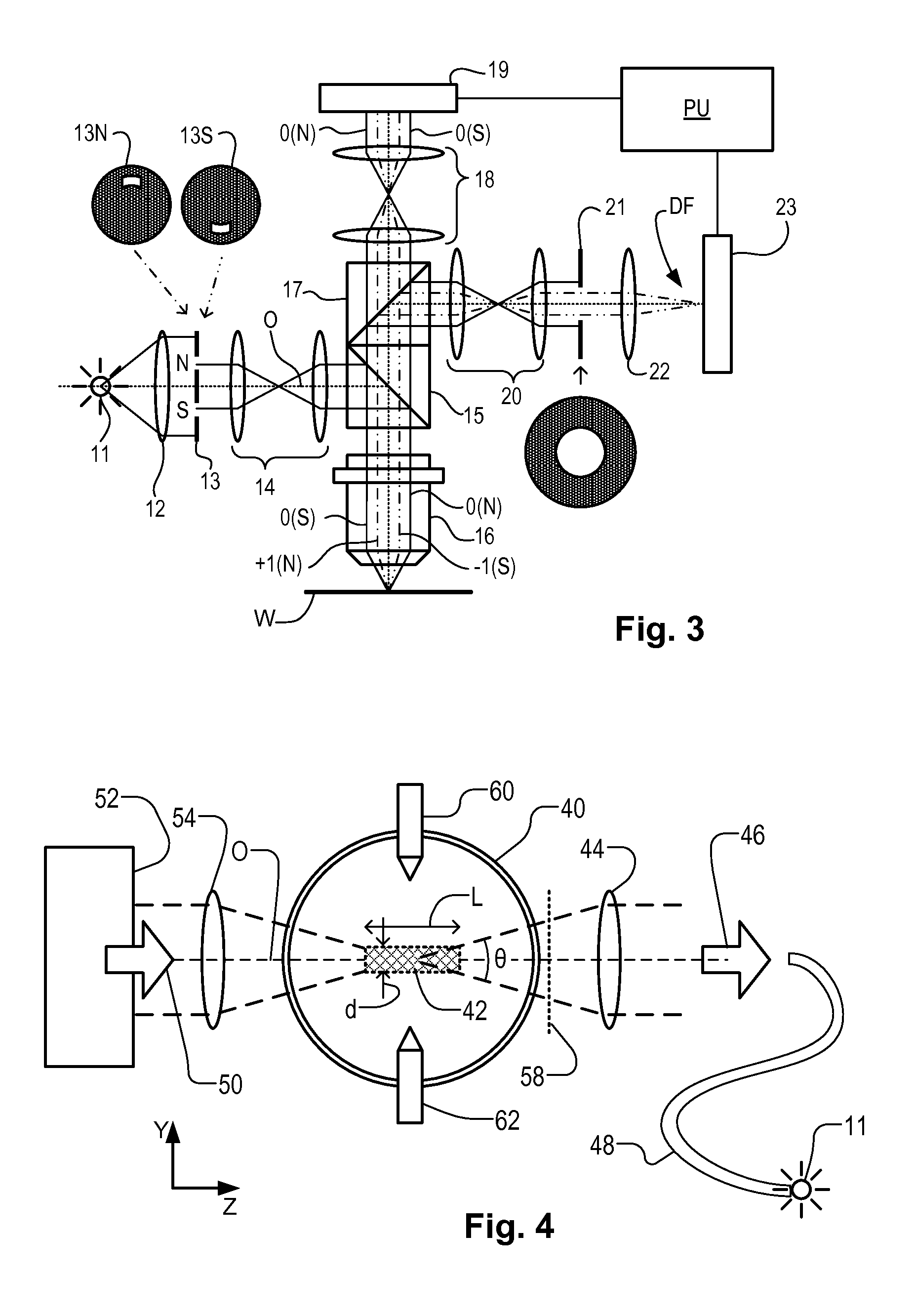

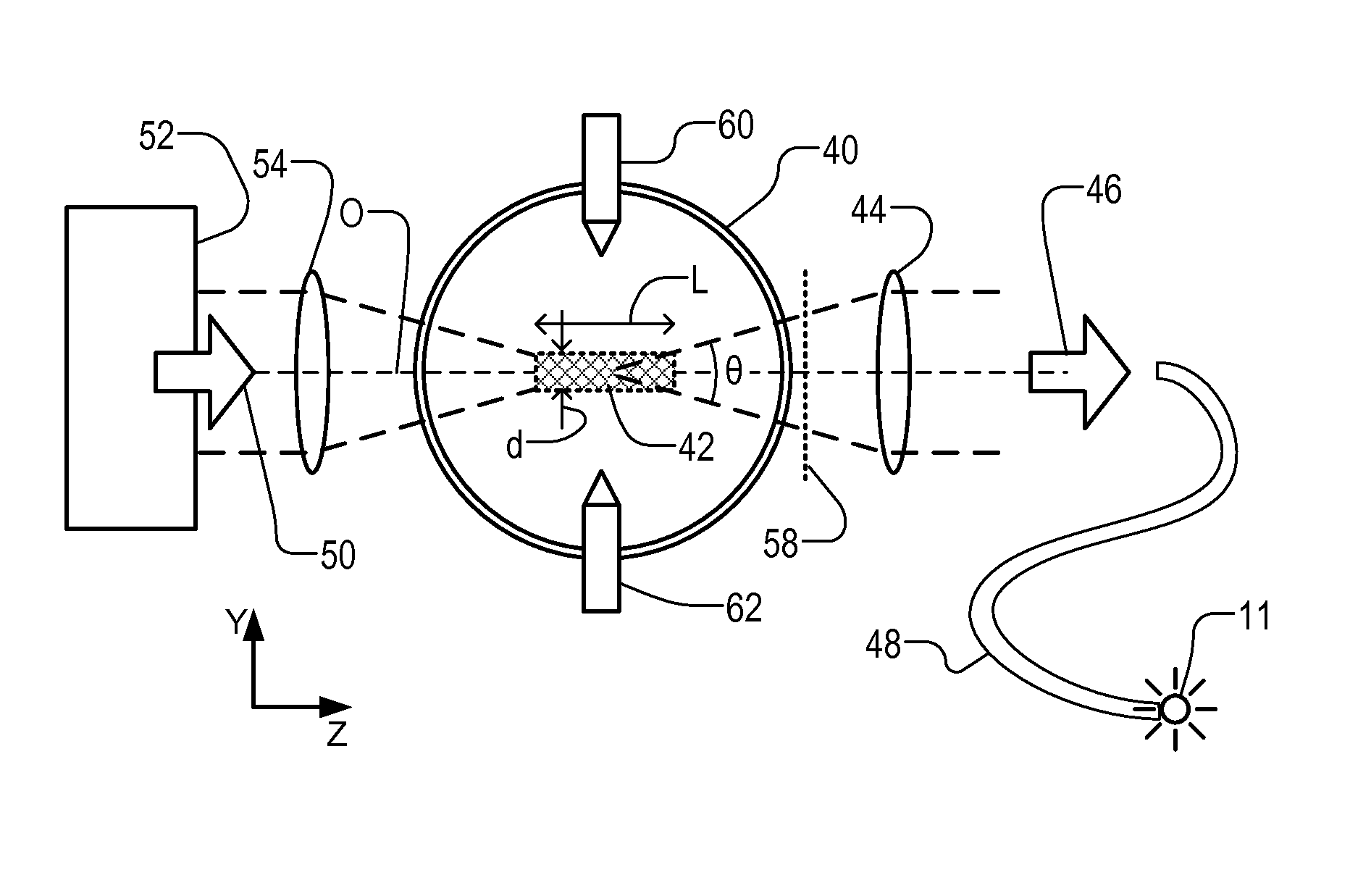

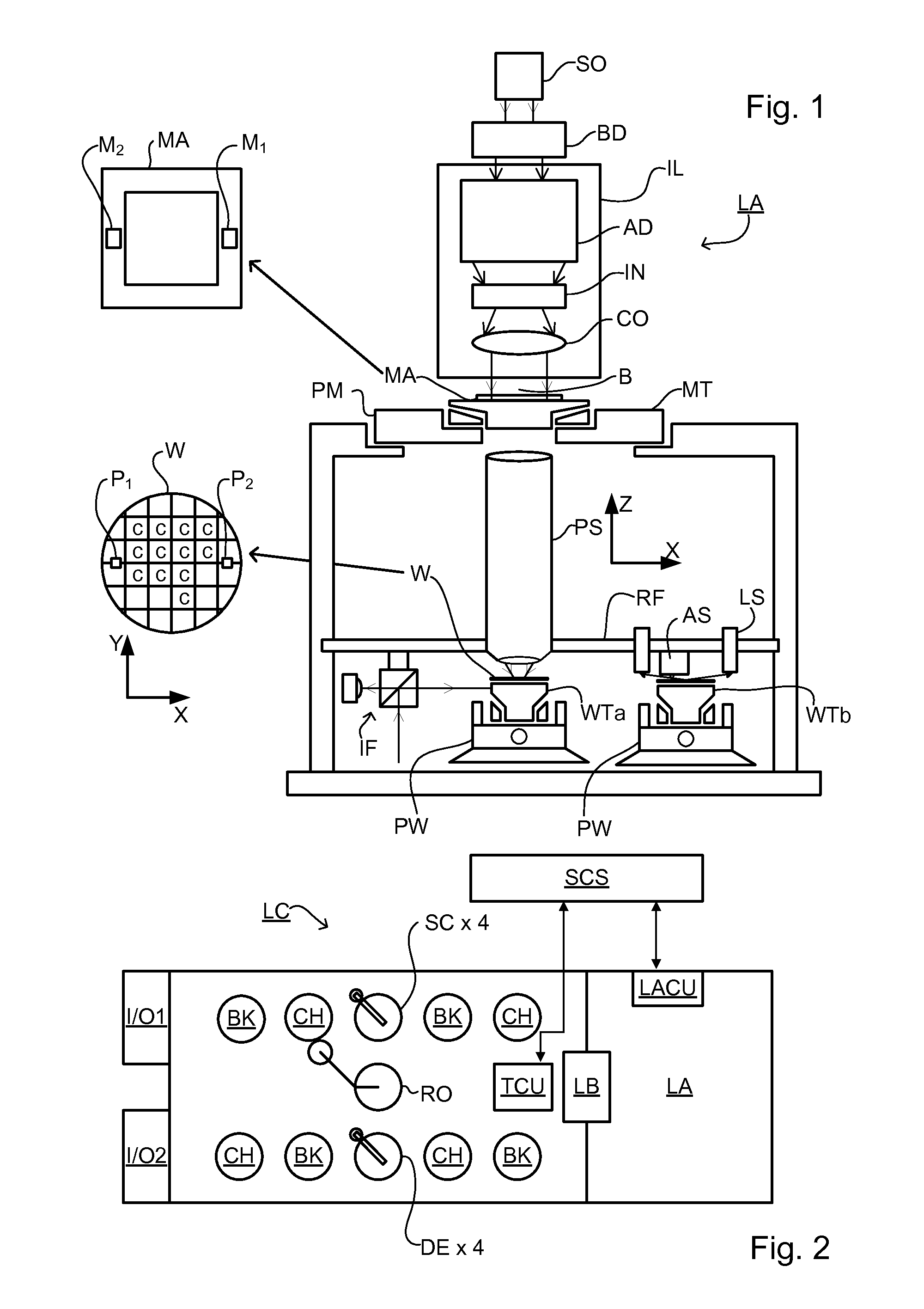

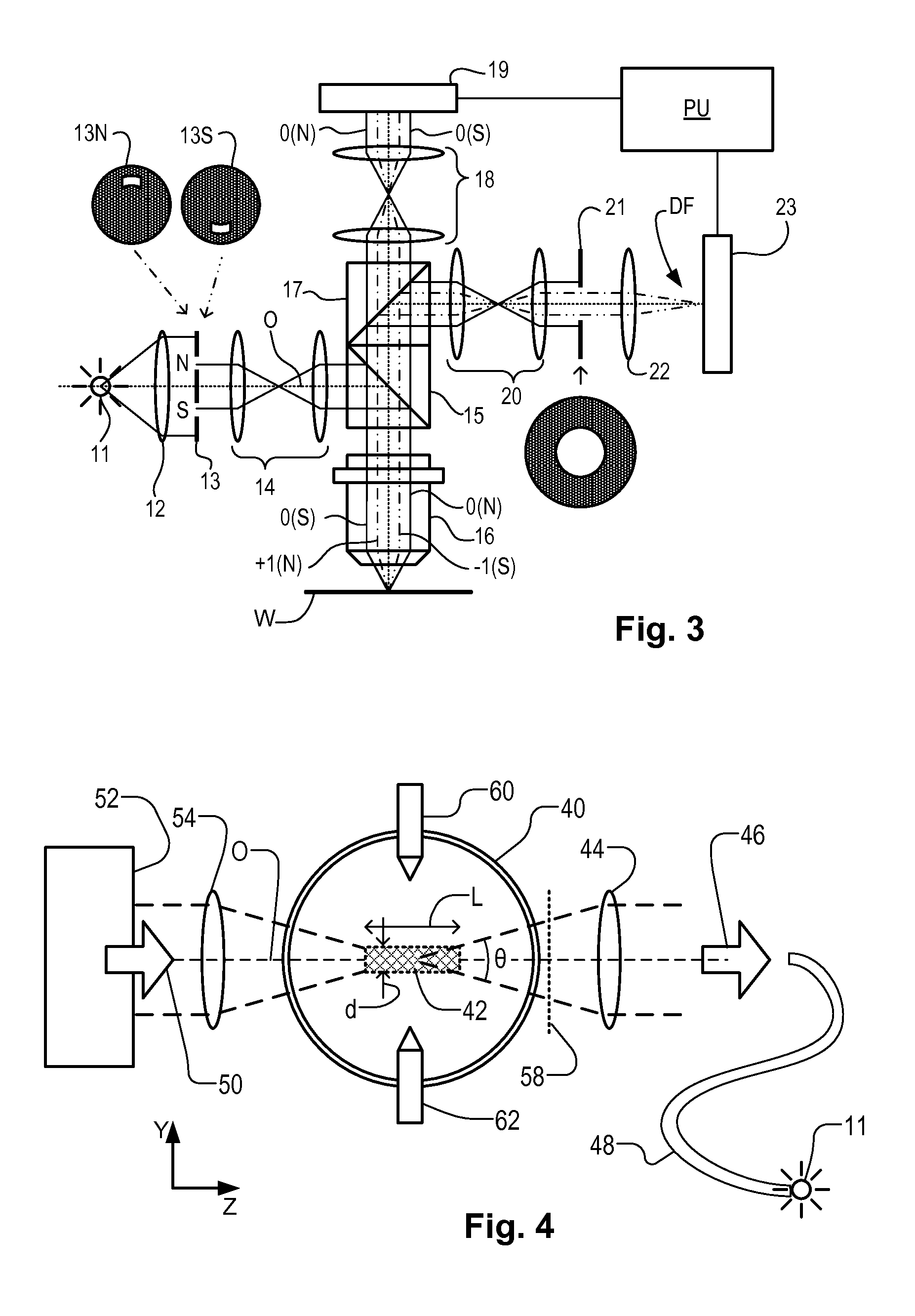

Photon Source, Metrology Apparatus, Lithographic System and Device Manufacturing Method

ActiveUS20130329204A1Increase brightnessElectric discharge tubesMaterial analysis by optical meansBack reflectorMetrology

A laser driven light source comprises laser and focusing optics. These produce a beam of radiation focused on a plasma forming zone within a container containing a gas (e.g., Xe). Collection optics collects photons emitted by a plasma maintained by the laser radiation to form a beam of output radiation. Plasma has an elongate form (L>d) and collecting optics is configured to collect photons emerging in the longitudinal direction from the plasma. The brightness of the plasma is increased compared with sources which collect radiation emerging transversely from the plasma. A metrology apparatus using the light source can achieve greater accuracy and / or throughput as a result of the increased brightness. Back reflectors may be provided. Microwave radiation may be used instead of laser radiation to form the plasma.

Owner:ASML NETHERLANDS BV

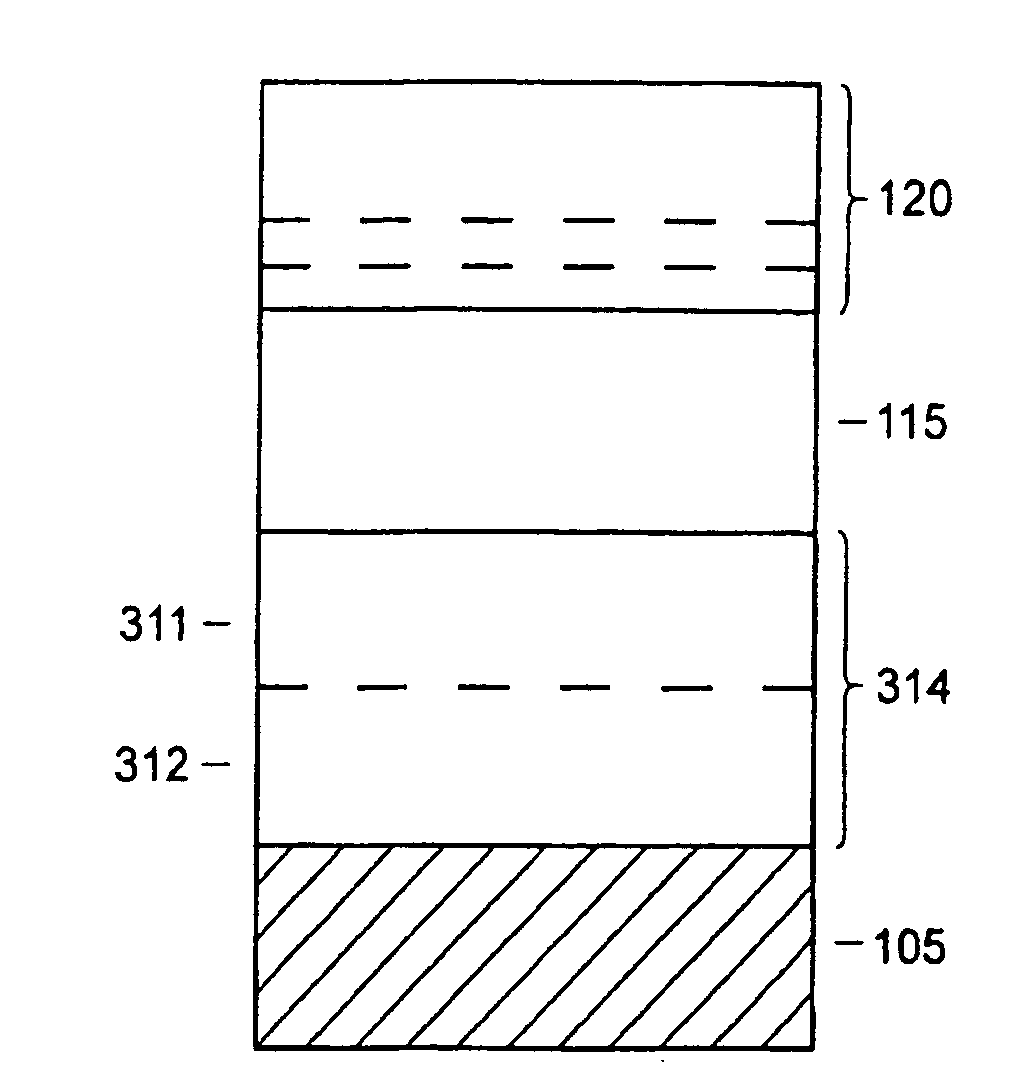

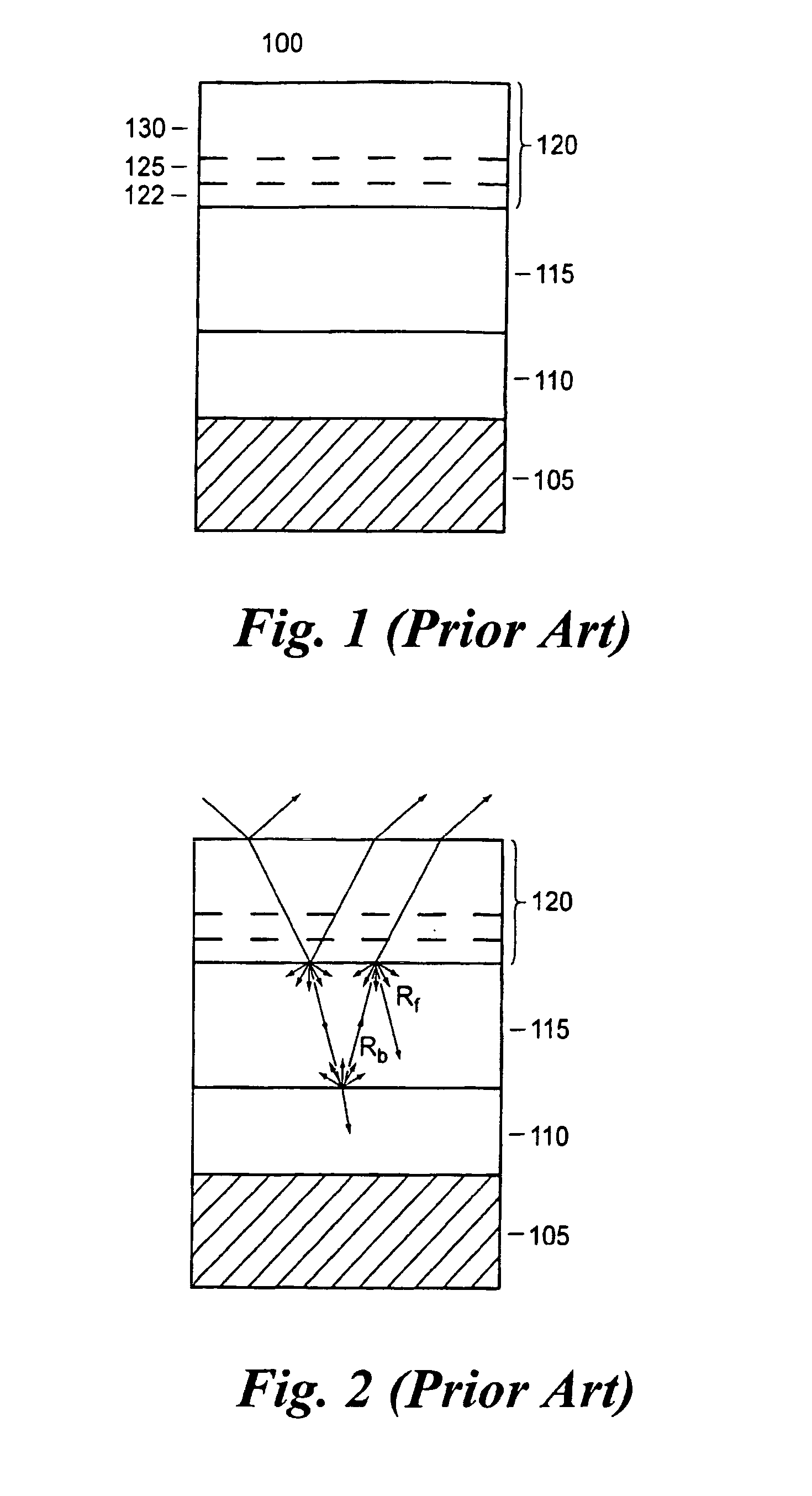

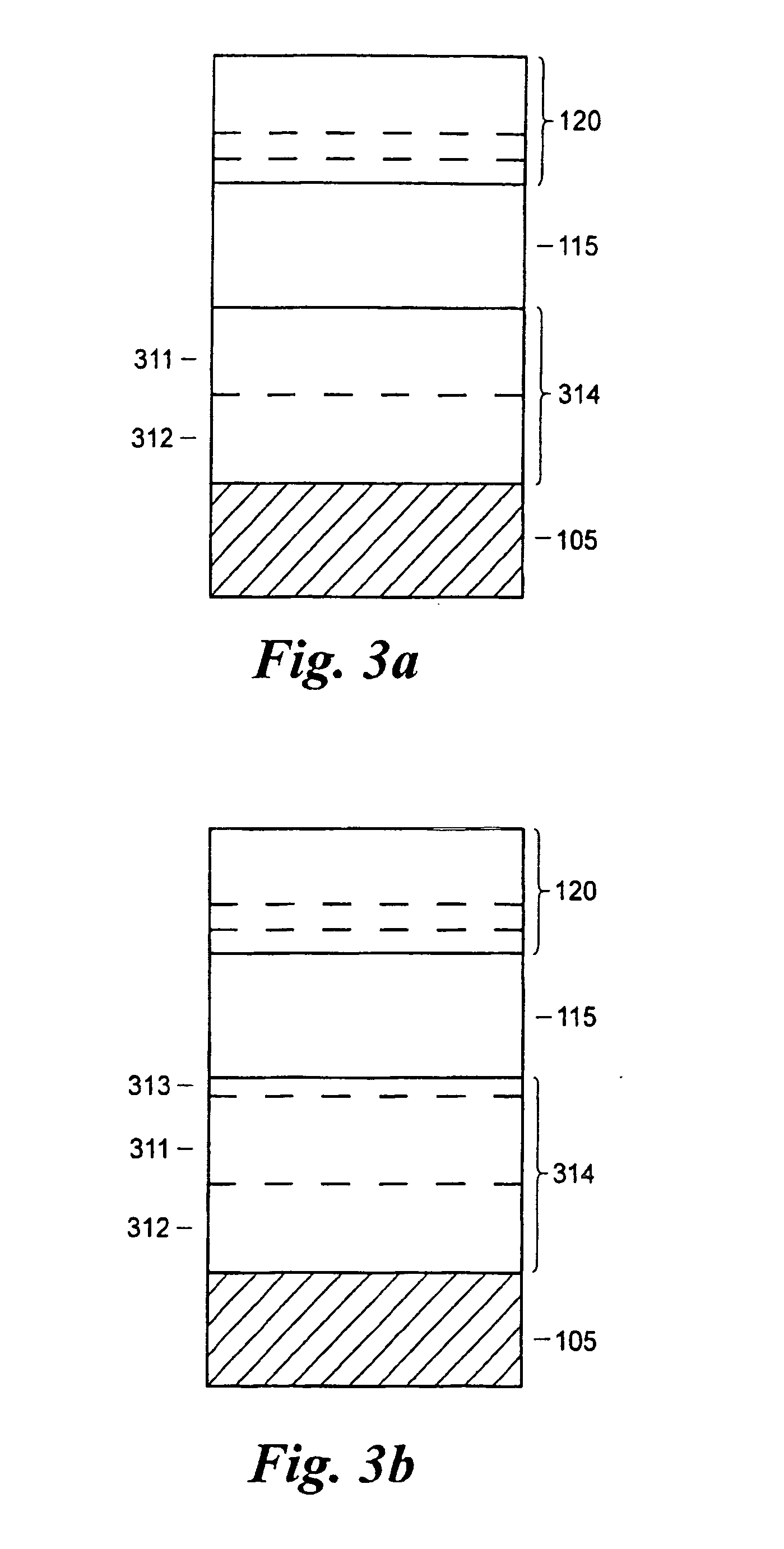

Thin Film Solar Cell and Manufacturing Method

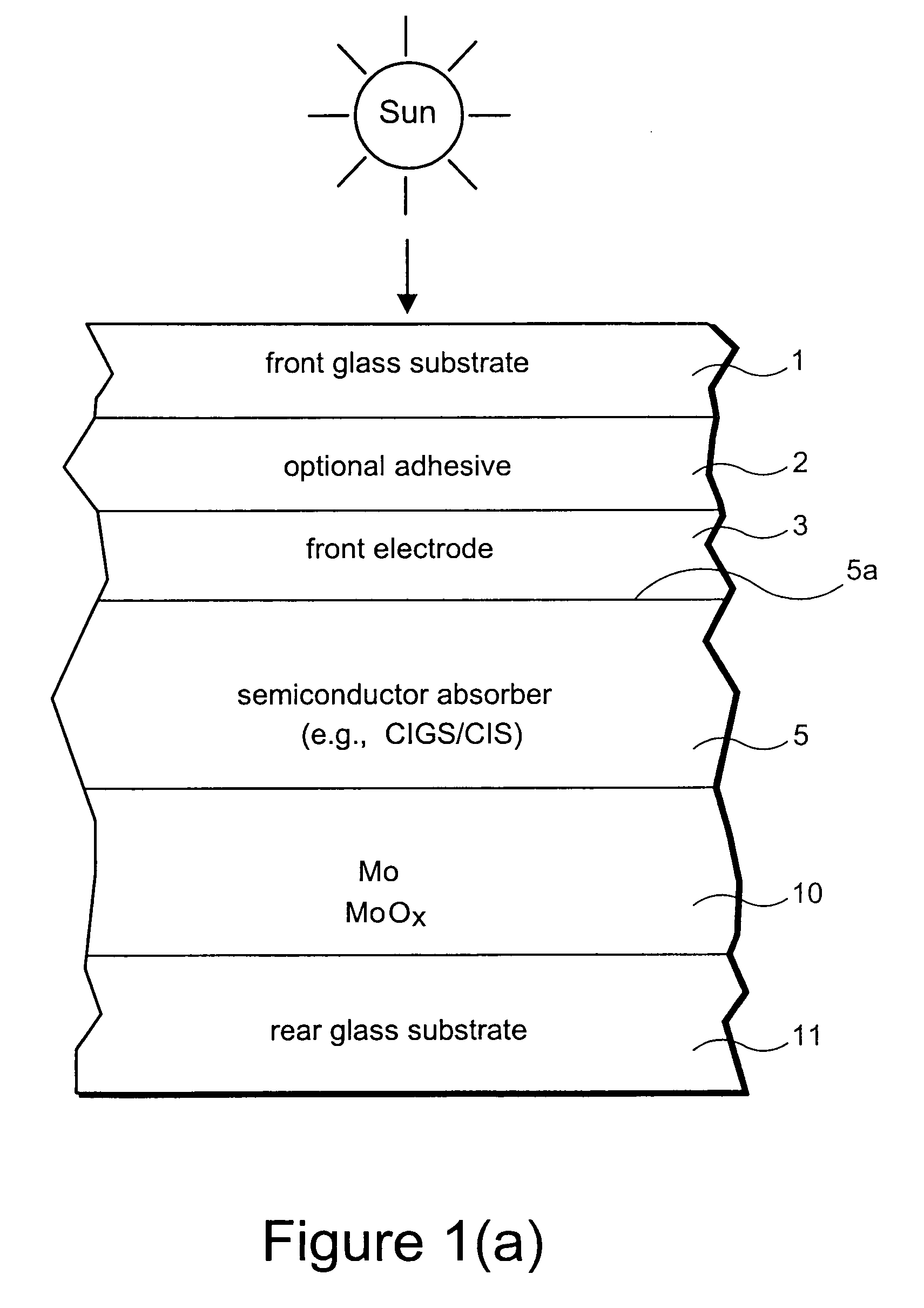

InactiveUS20080251120A1Improve bindingAvoid exposureFinal product manufactureSemiconductor/solid-state device manufacturingBack reflectorIn plane

The present invention relates to a thin film solar cell and a method of manufacturing such cells. In particular the invention relates to the use of a composite back contact (314) in Cu(In,Ga)Se2 (CIGS) based thin film solar cells with thin absorber layers. The composite back contact (314) is provided between the substrate (105) and the absorber (115) and comprises: a back reflector layer (311) that enhance the reflectance at the absorber / composite back contact interface; and at least a contact layer that contact layer (310, 313) that ensures suitable electrical properties of the back contact with respect to the absorber; and / or a conductance layer (312) that ensures low sheet resistance for the in-plane current flow.

Owner:SOLIBRO RES AB

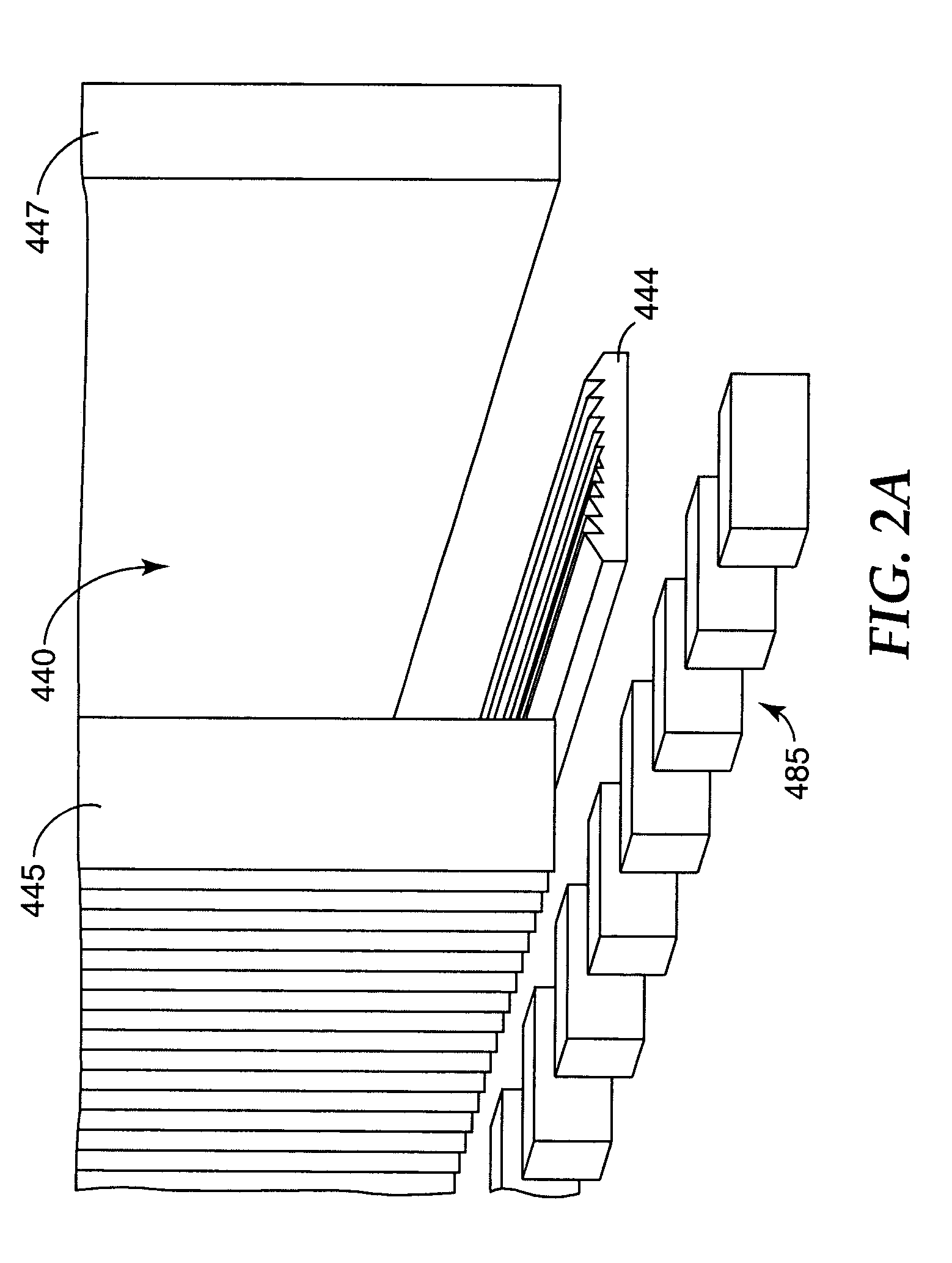

UV LED based lamp for compact UV curing lamp assemblies

InactiveUS20110147356A1Additional componentDrying solid materials with heatMuffle furnacesBack reflectorUV curing

An ultraviolet (UV) LED-based lamp for UV curing lamp assemblies is disclosed. An array of UV emitting LEDs are packaged together and arranged along the length of a cylindrical lens to form a UV LED-based optical component assembly. The UV LED-based optical component assembly may be made to be modular. A UV LED lamp assembly may comprise a plurality of UV LED-based optical component assemblies arranged around a workpiece tube. The workpiece tube may be filled with an inert gas and may be made of quartz or glass. One or more curved back reflectors may be placed opposite the LED UV LED-based optical component assemblies to collect UV light escaping the workpiece tube and refocus the light to the other side of the workpiece. The UV LEDs may be arranged on a single surface or a multi-level tiered platform.

Owner:HERAEUS NOBLELIGHT AMERICA

Transreflectors, transreflector systems and displays and methods of making transreflectors

InactiveUS20090161385A1Improve efficiencyWell-defined shapeMechanical apparatusMirrorsBack reflectorDisplay device

Optical assembly includes a hollow backlight having at least one light input edge and at least one light source positioned adjacent to the at least one light input edge. A back reflector is positioned at or in close proximity to a first side of the hollow backlight for reflecting the light through the hollow backlight and out through a second side of the hollow backlight superimposed on the first side, and a reflective polarizer is positioned at or in close proximity to the second side of the backlight.

Owner:INNOVATIVE DISPLAY TECH

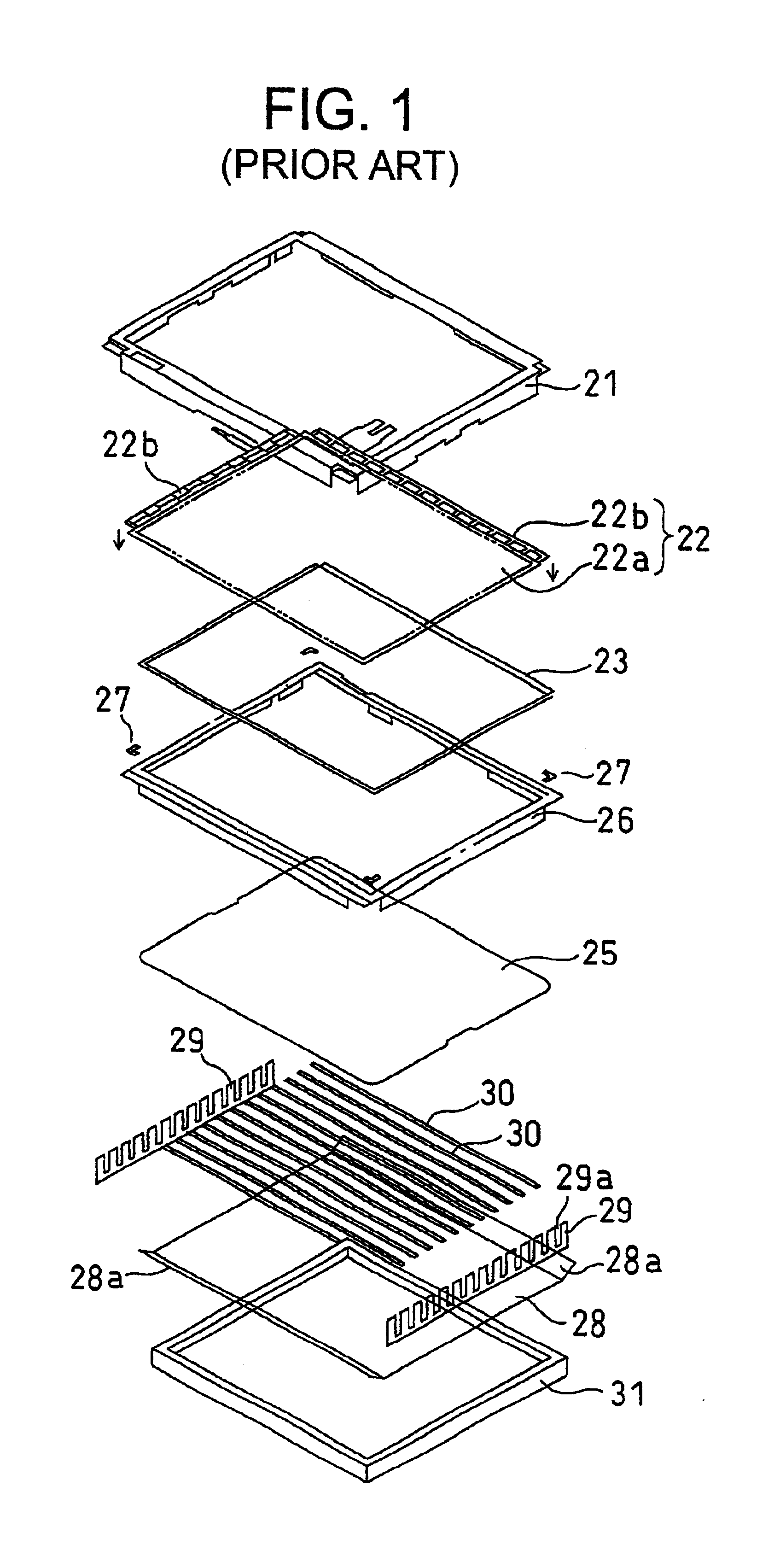

Liquid crystal display device

InactiveUS6867825B2Low costReduce border areaDigital data processing detailsElectrical apparatus contructional detailsBack reflectorLiquid-crystal display

In a liquid crystal display device there are provided a frame, a liquid crystal panel, and a diffuser, the liquid crystal panel and the diffuser being supported by a frame formed of a white resin. The frame is composed of two short-side members and two long-side members. The short-side members are provided with reflectors respectively, and lamp mounting members formed of rubber are fitted with the reflectors to support end portions of lamps. The lamp mounting members are mounted to a back reflector to fix the lamps to the back reflector.

Owner:VISTA PEAK VENTURES LLC

Sandwich acoustic panel

InactiveUS6615950B2Risks of non-homogeneity no longer existMisalignment problemWallsSound proofingElectrical resistance and conductanceBack reflector

Owner:AIRBUS OPERATIONS (SAS)

Integrated switch and backlight assembly

ActiveUS6861600B1Reliable and cost-effective and thinnerReliable and and thinner switchEmergency actuatorsContact surface shape/structureBack reflectorEngineering

Integrated switch and backlight assembly includes a flexible light panel disposed between a circuit board and a keypad for backlighting the keypad. On the back side of the light panel is a back reflector having a plurality of contacts for selectively establishing electrical contact with the circuit board upon actuating selective portions of the keypad to cause corresponding portions of the light panel and back reflector to flex toward the circuit board.

Owner:LUMITEX

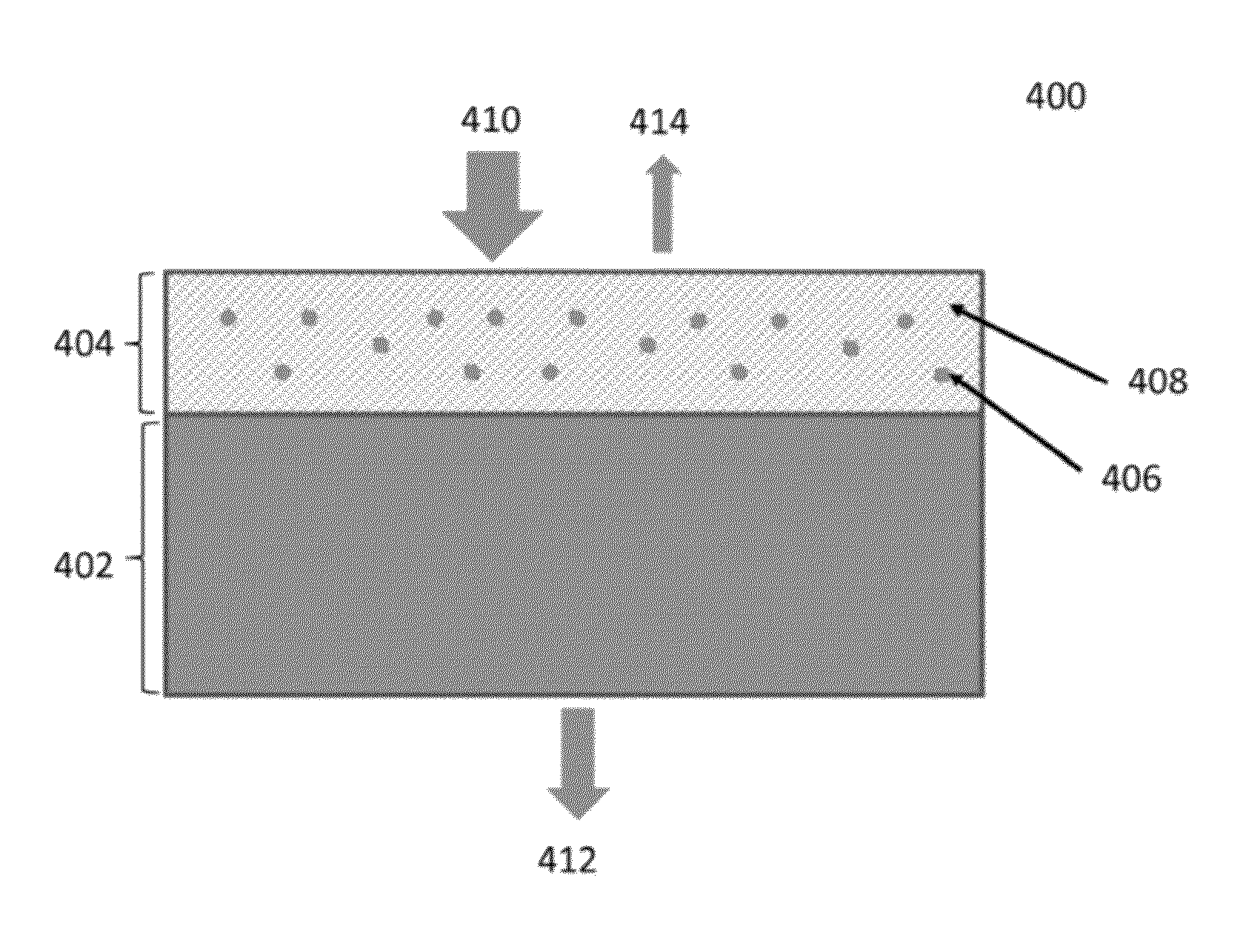

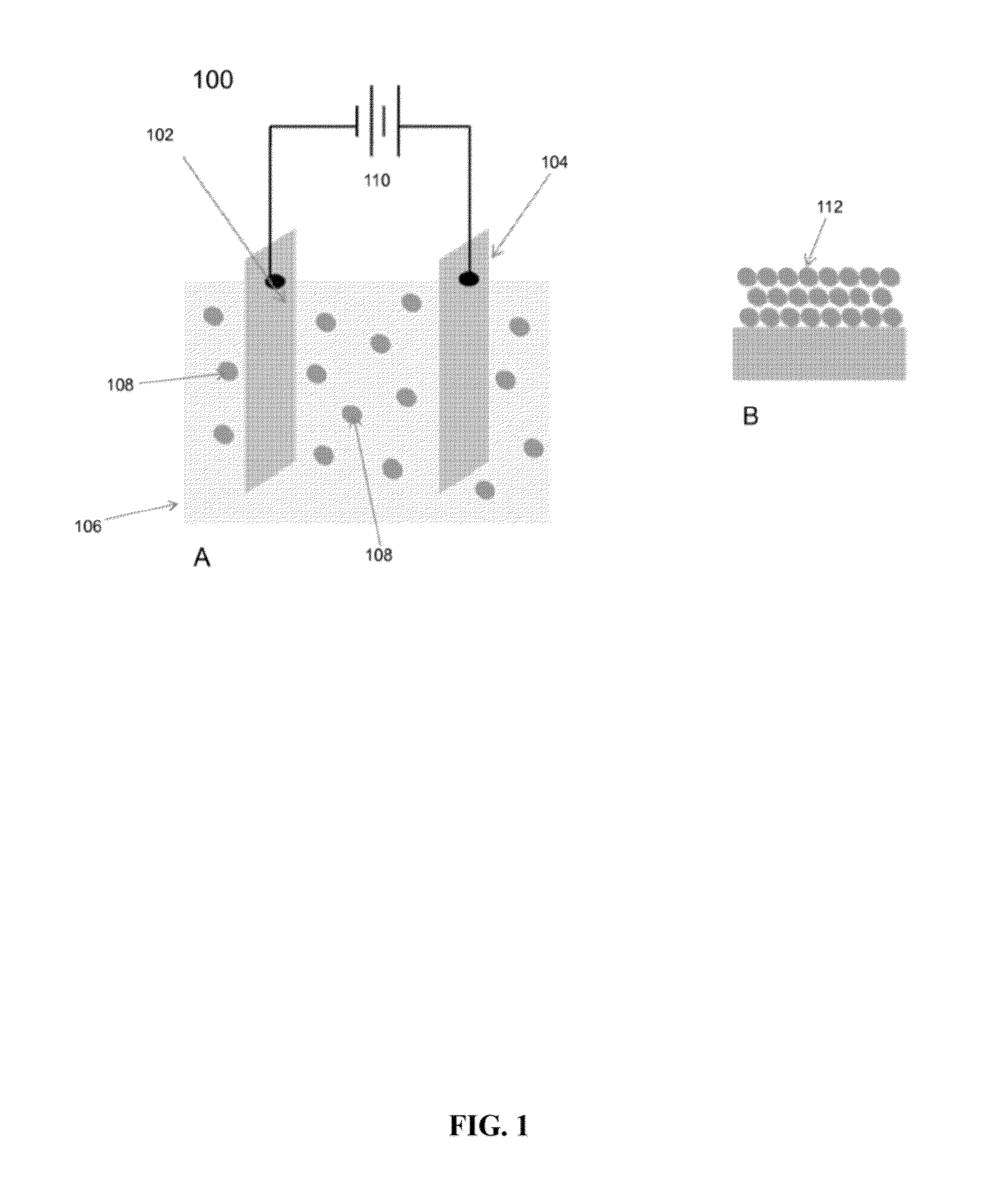

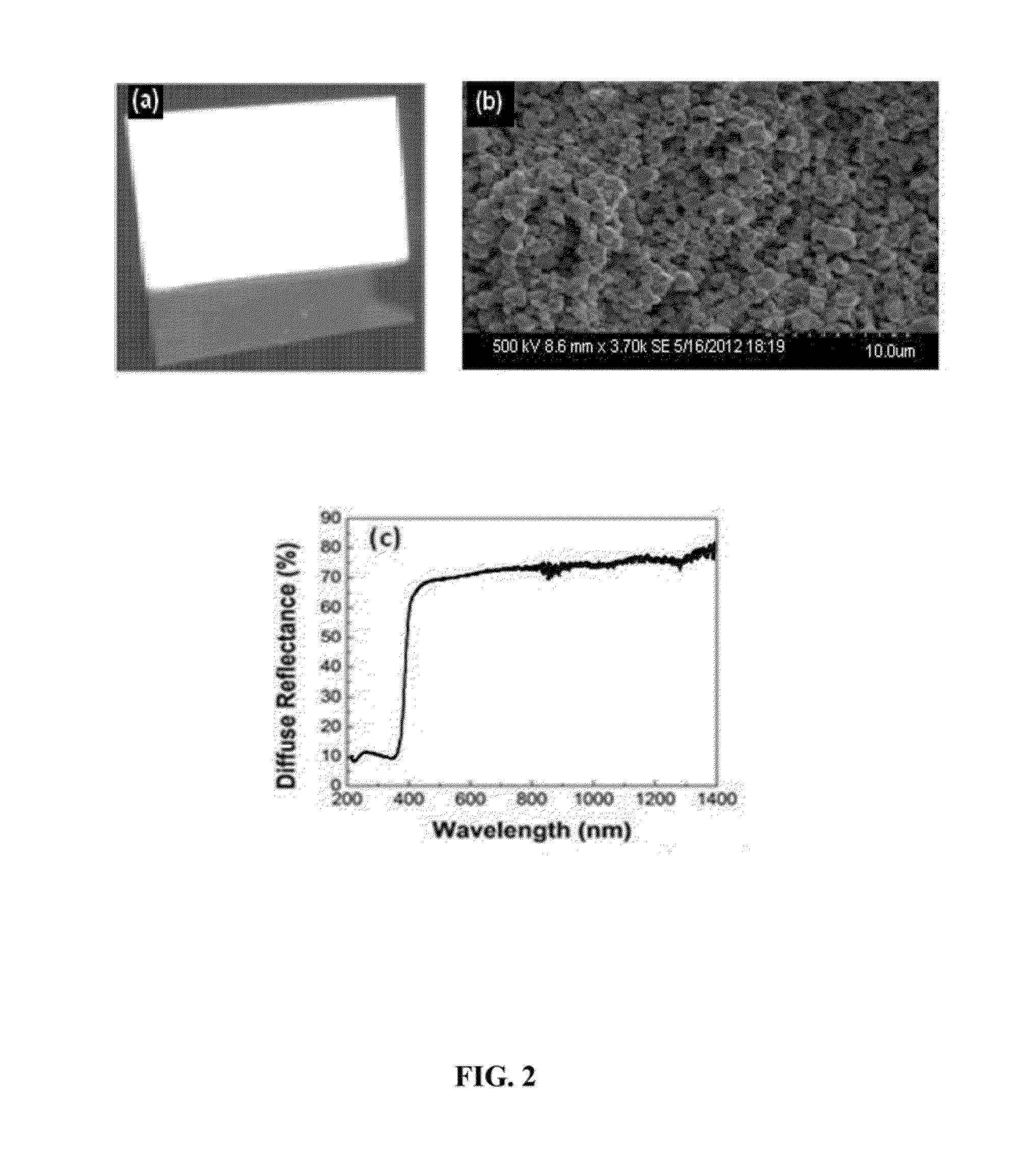

Nanoparticle films for use as solar cell back reflectors and other applications

Disclosed are methods for forming nanoparticle films using electrophoretic deposition. The methods comprise exposing a substrate to a solution, the solution comprising substantially dispersed nanoparticles, an organic solvent, and a polymer characterized by a backbone comprising Si—O groups. The methods further comprise applying an electric field to the solution, whereby a nanoparticle film is deposited on the substrate. Suitable polymers include polysiloxanes, polysilsesquioxanes and polysilicates. Coated glass windows and methods of forming the coated glass windows using the solutions are also disclosed. The methods may be adapted to form nanoparticle films suitable for use as back reflectors in solar cells, where such nanoparticle-based back reflectors exhibit high reflection and light scattering properties, including use of such back reflectors to fabricate solar cells and other photovoltaic-based and light dependent devices such as television screens, computer monitors, portable systems such as mobile phones, handheld games consoles and PDAs.

Owner:THE SOUTH DAKOTA BOARD OF REGENTS

Edge-lit backlight having light recycling cavity with concave transflector

An edge-lit backlight having a light recycling cavity with concave transflector is disclosed. The edge-lit backlight has an output area and includes a back reflector facing the output area of the backlight. The backlight further includes a transflector that partially transmits and partially reflects incident light, the transflector being shaped to form a concave structure facing the back reflector to provide one or more recycling cavities therebetween, where the one or more recycling cavities substantially fill the output area of the backlight. The backlight further includes at least one light source positioned adjacent a first edge of the backlight. The at least one light source is operable to inject light into the one or more recycling cavities through an input surface of the one or more recycling cavities, where the input surface is substantially orthogonal to the output area, and where the at least one concave structure converges with the back reflector in a direction distal from the input surface.

Owner:3M INNOVATIVE PROPERTIES CO

Photon source, metrology apparatus, lithographic system and device manufacturing method

A laser driven light source comprises laser and focusing optics. These produce a beam of radiation focused on a plasma forming zone within a container containing a gas (e.g., Xe). Collection optics collects photons emitted by a plasma maintained by the laser radiation to form a beam of output radiation. Plasma has an elongate form (L>d) and collecting optics is configured to collect photons emerging in the longitudinal direction from the plasma. The brightness of the plasma is increased compared with sources which collect radiation emerging transversely from the plasma. A metrology apparatus using the light source can achieve greater accuracy and / or throughput as a result of the increased brightness. Back reflectors may be provided. Microwave radiation may be used instead of laser radiation to form the plasma.

Owner:ASML NETHERLANDS BV

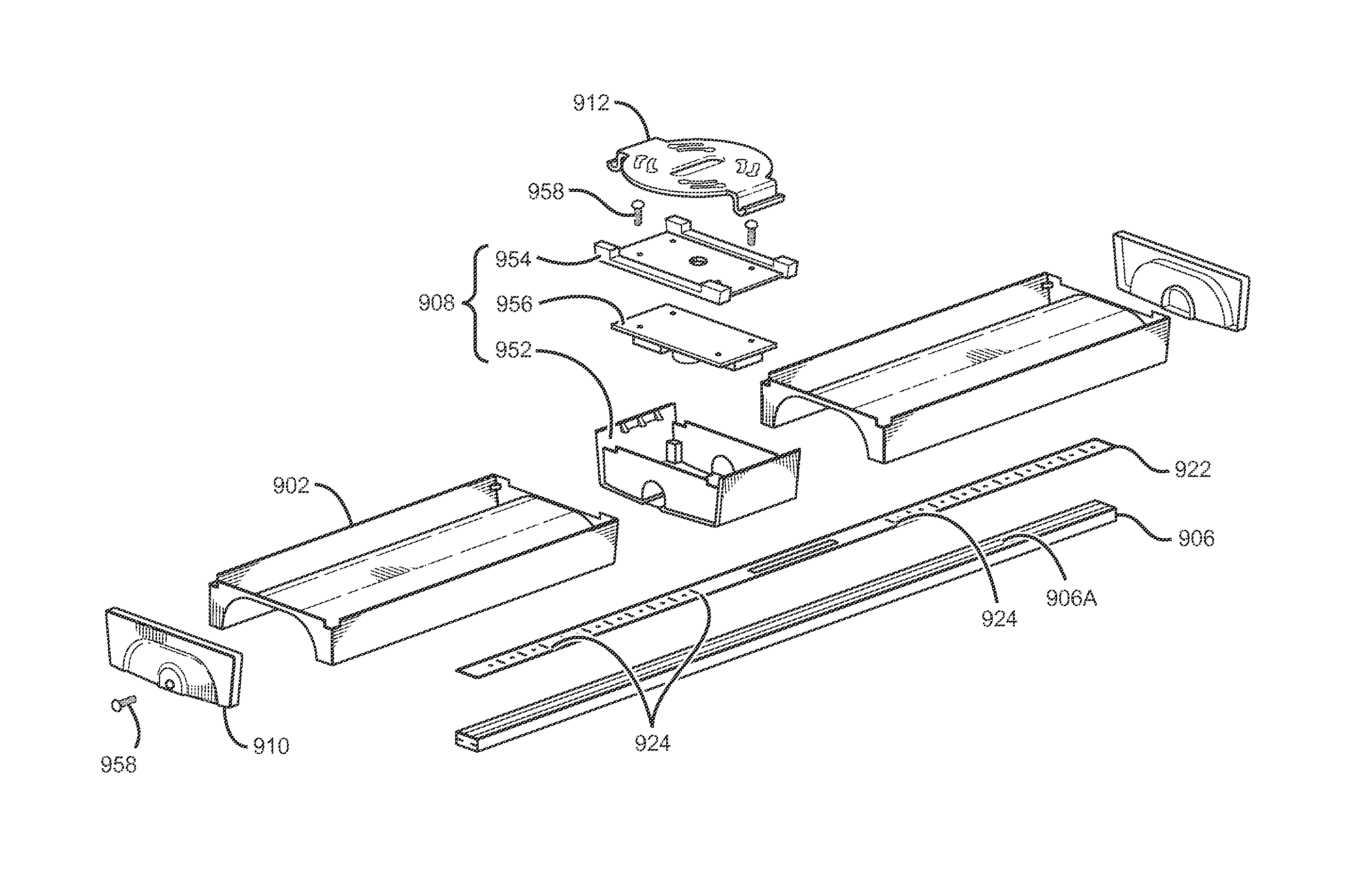

Indirect linear fixture

A light fixture comprising a chamber portion is disclosed. In some embodiments, the fixture comprises a chamber portion shaped to house circuitry required for lighting elements such as light emitting diodes (LEDs) mounted elsewhere in the fixture. In some embodiments, LEDs are mounted facing a back reflector, which in turn reflects light out of a troffer to form an indirect lighting fixture. In some embodiments, light is emitted from one mixing chamber. In some embodiments, light is emitted from two or more mixing chambers. In some embodiments, LEDs are mounted on a heat sink which cooperates with a chamber portion.

Owner:IDEAL IND LIGHTING LLC

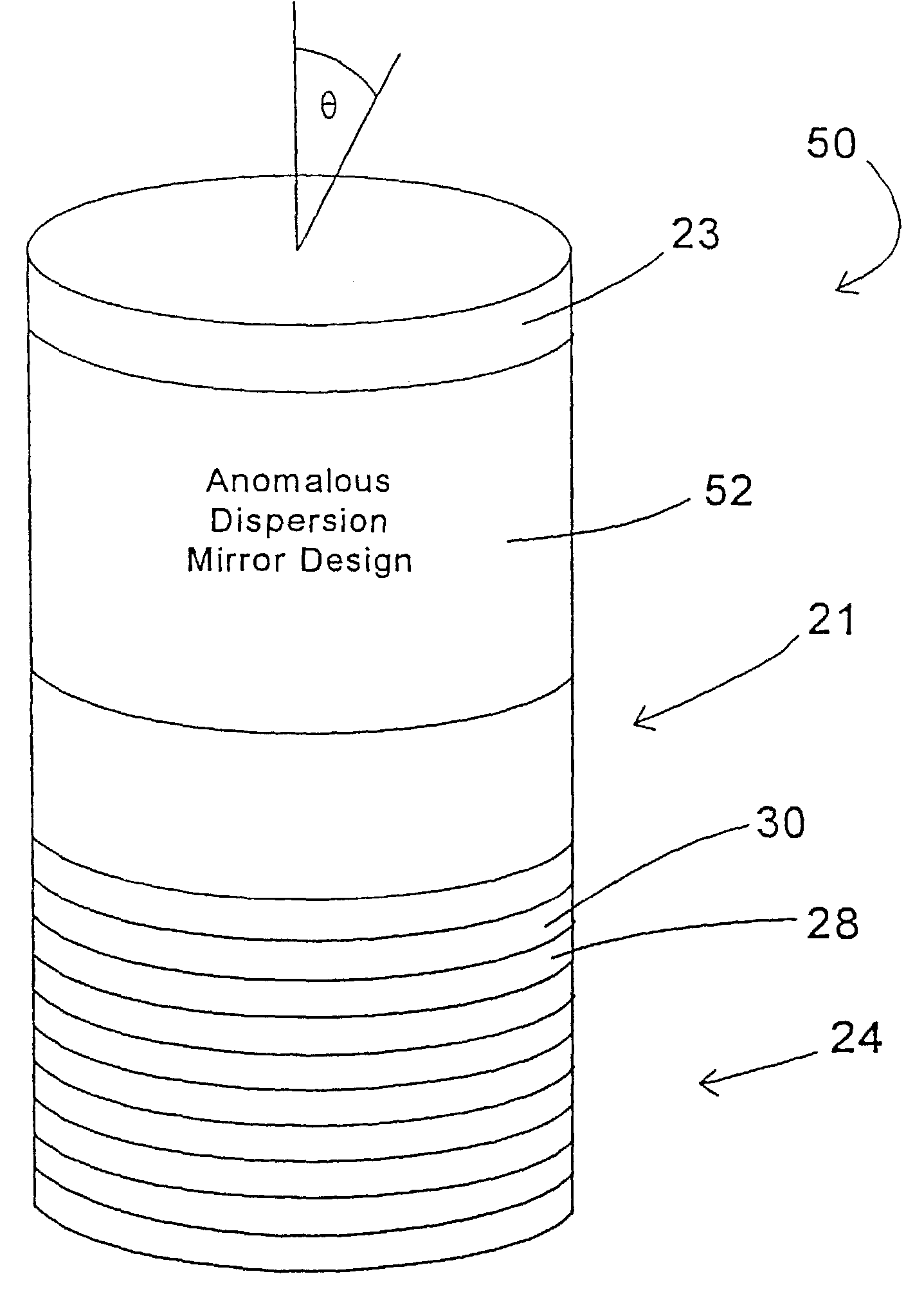

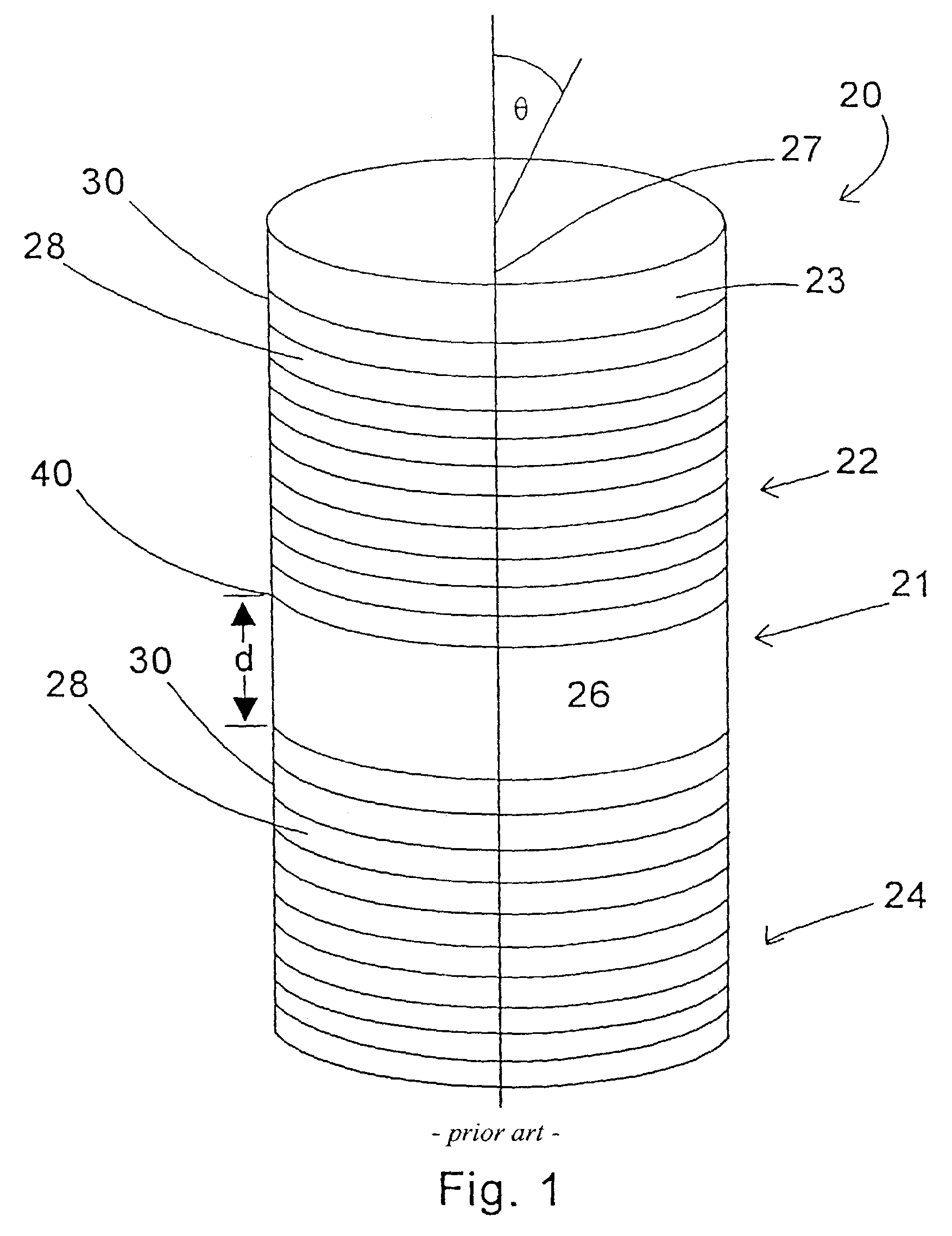

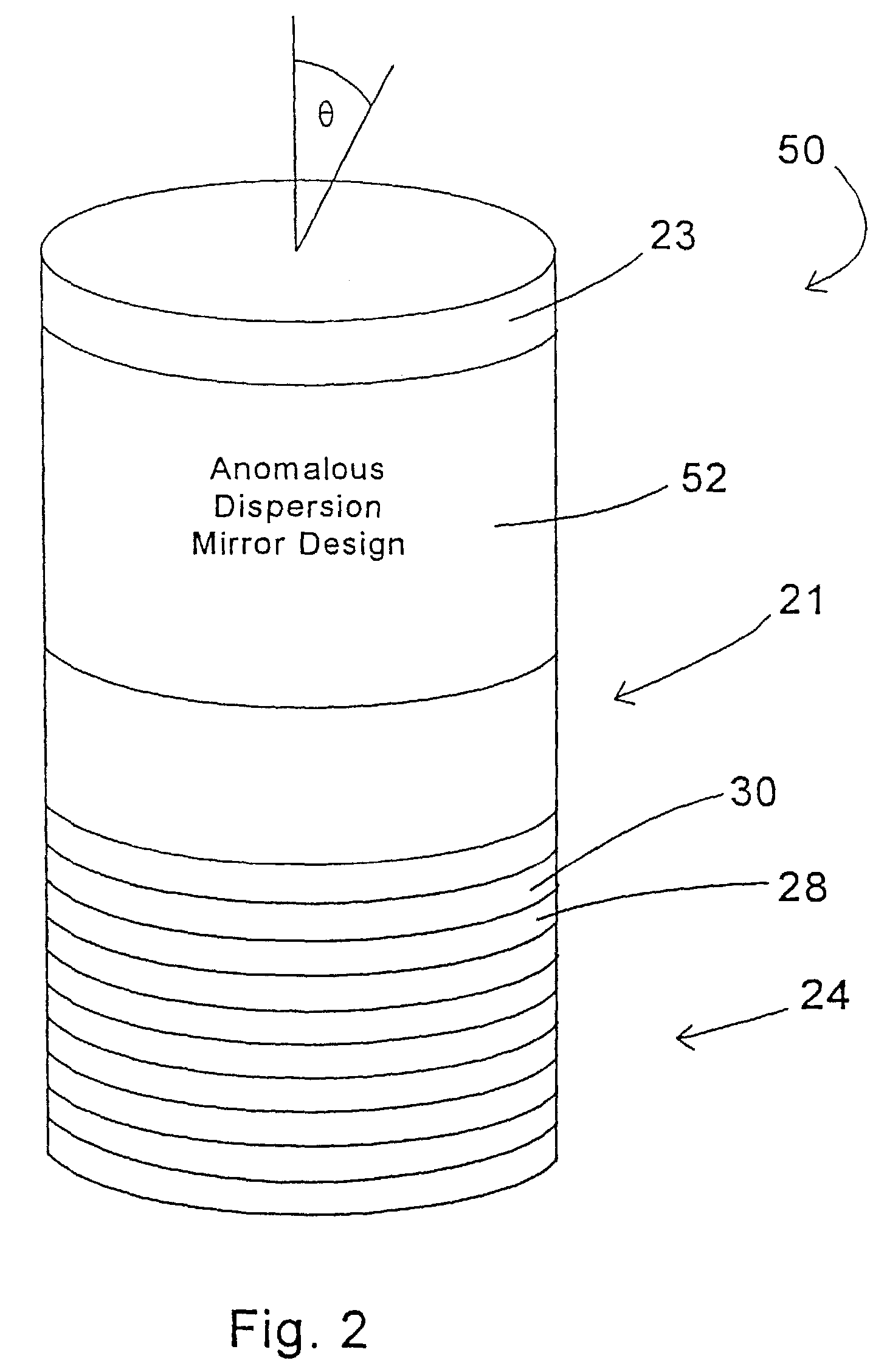

Resonant microcavity display utilizing mirrors exhibiting anomalous phase dispersion

InactiveUS7009211B2Increase the amount of lightLaser detailsSolid-state devicesBack reflectorDisplay device

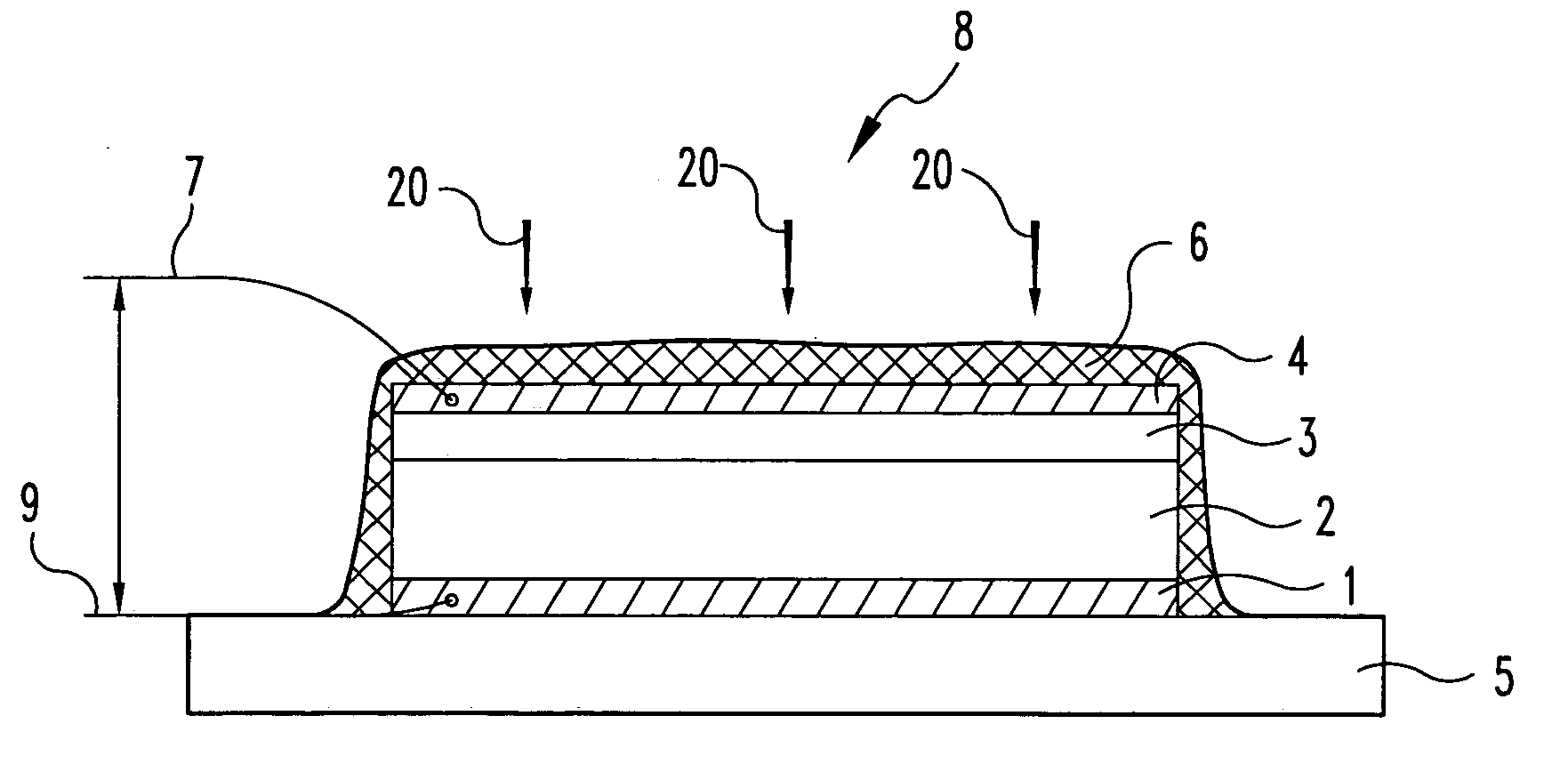

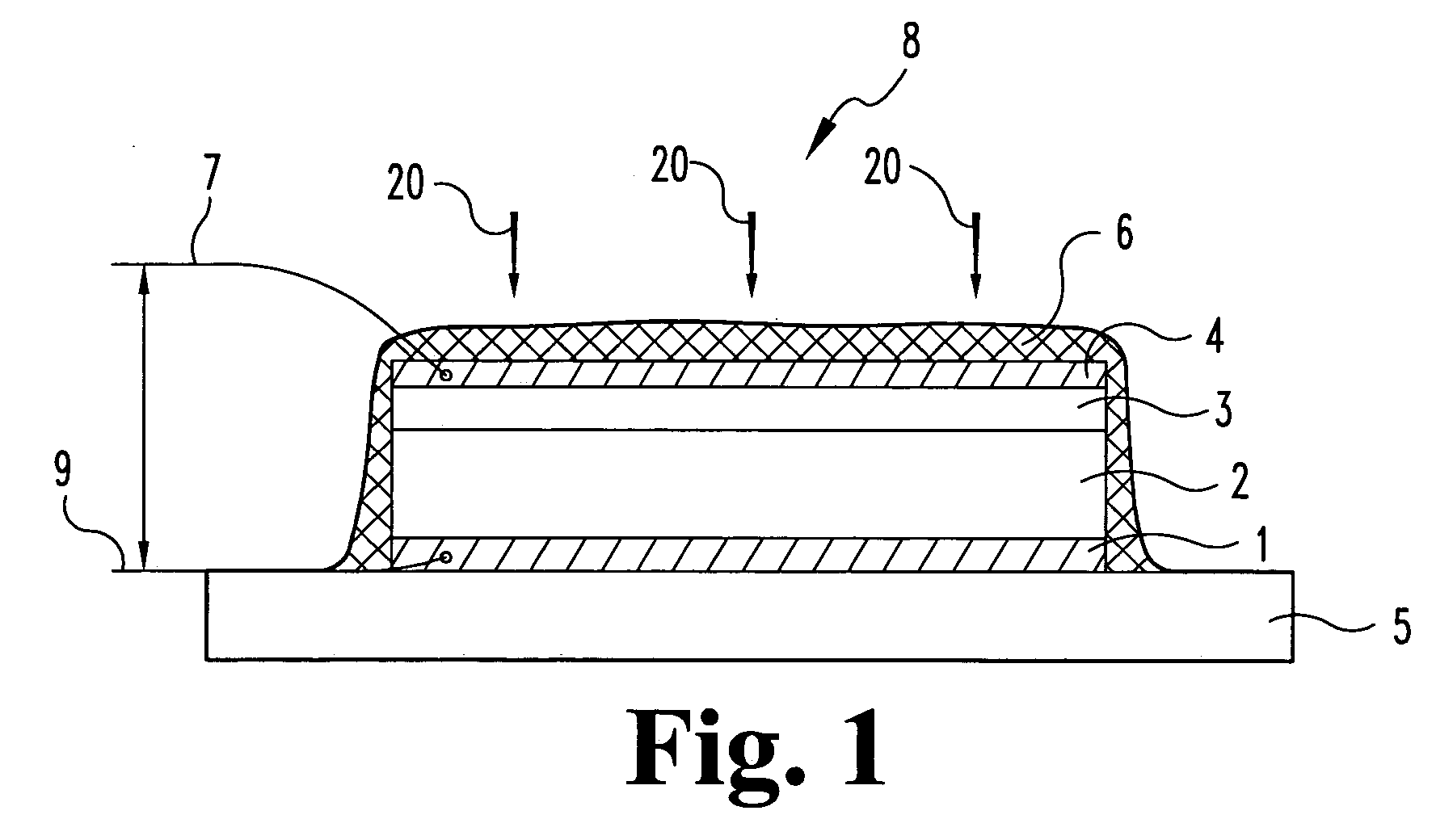

A resonant microcavity display comprises a thin-film resonant microcavity (20, 50, 60) with an active layer (21). The microcavity (20, 50, 60) comprises a front reflector (22, 52), the active region (21) deposited upon the front reflector, and a back reflector (20, 54) deposited upon the active region (21). The display preferentially emits light that propagates along the axis (27) perpendicular to the plane of the display, due to its quantum mechanical properties. The extrinsic efficiency of this device is increased by the use of thin film construction with anomalous phase dispersion.

Owner:QUANTUM VISION

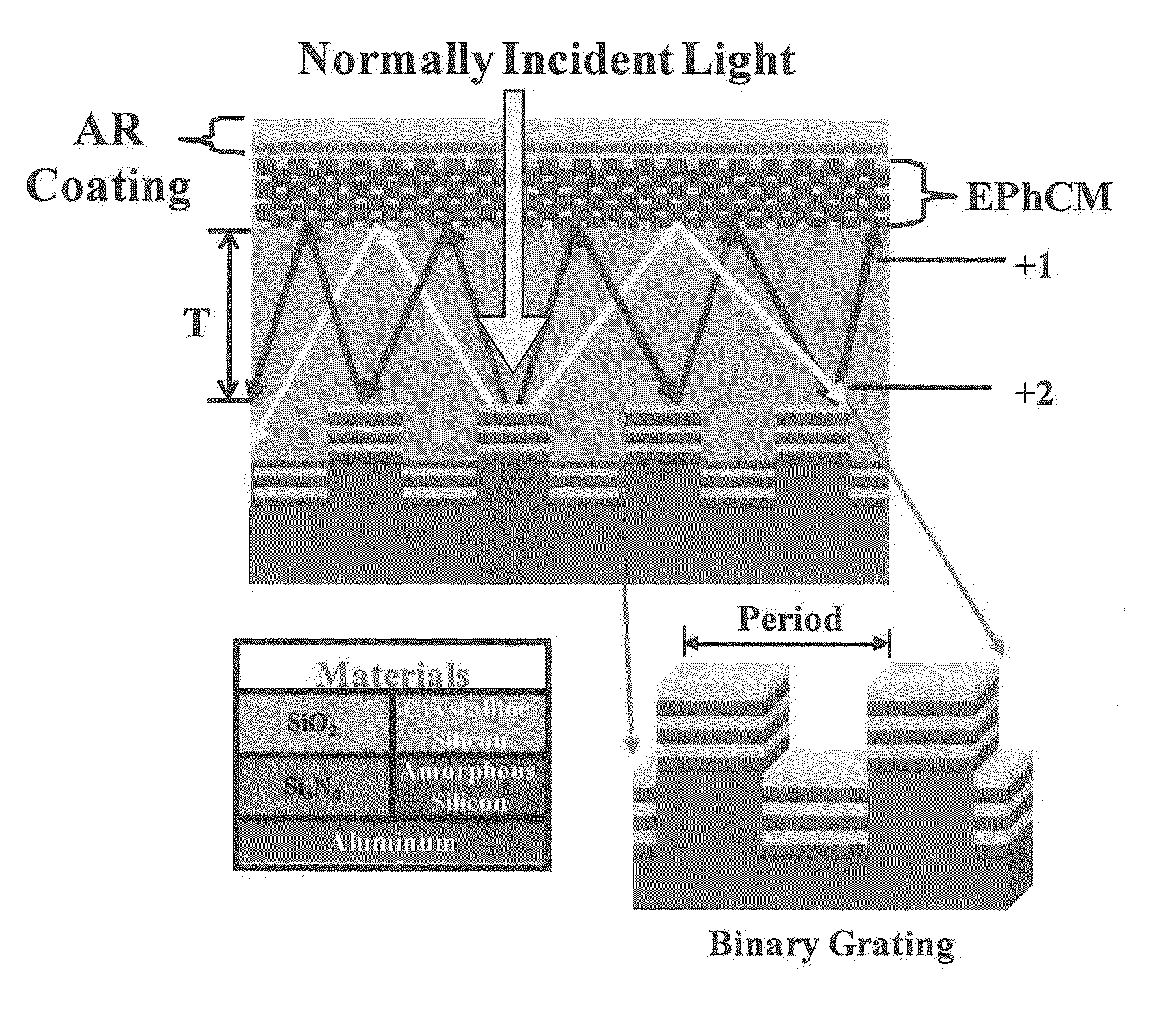

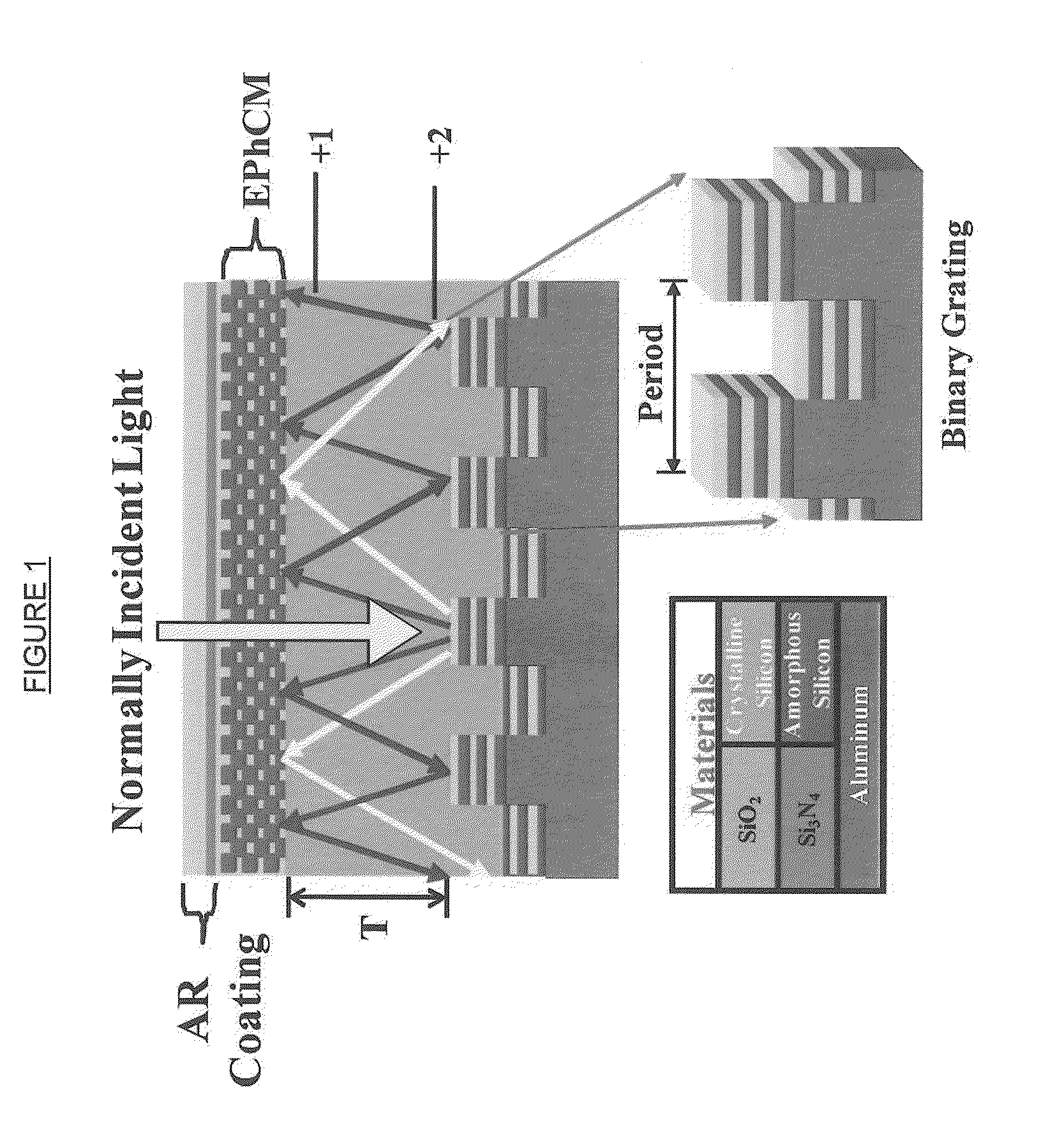

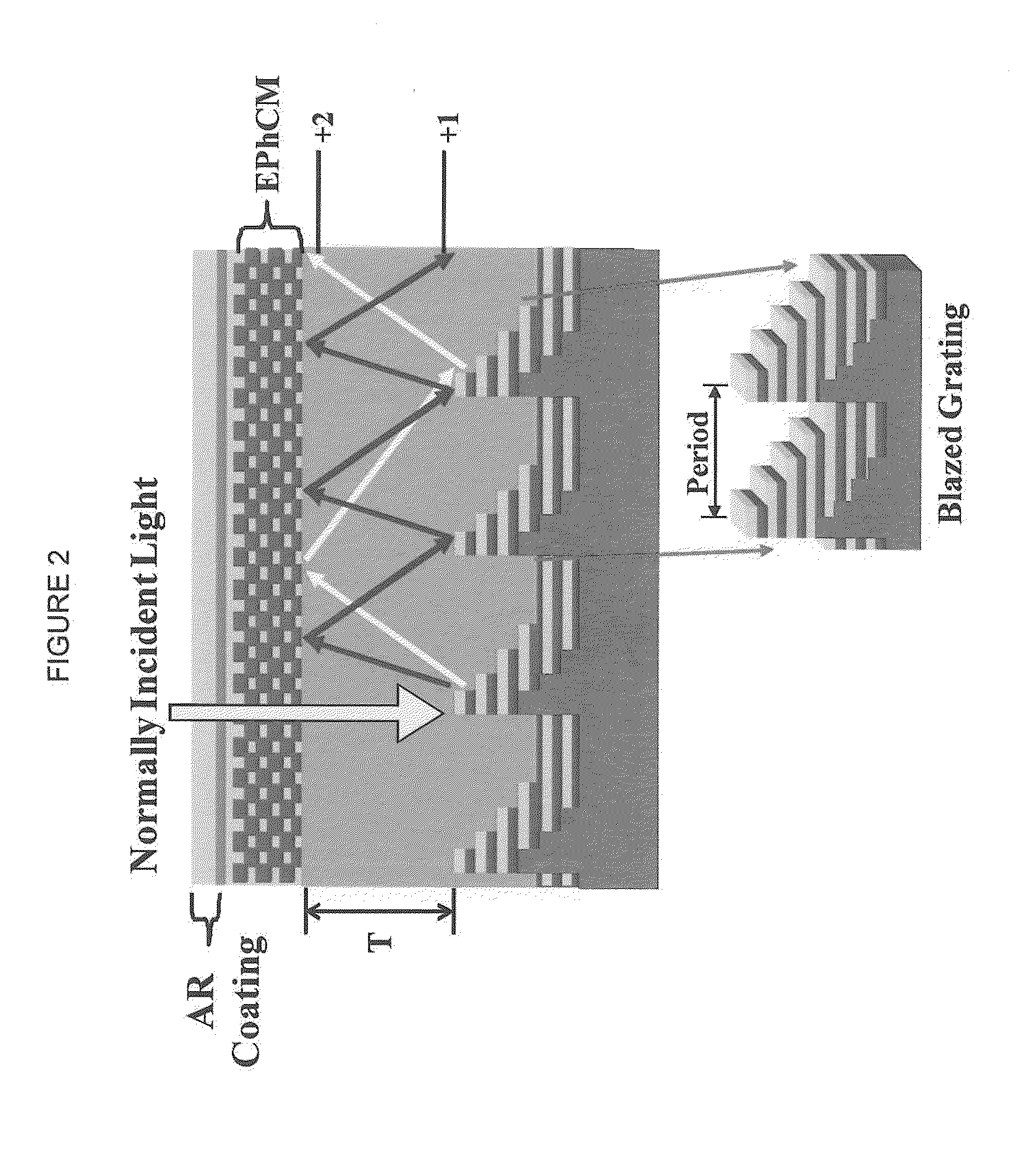

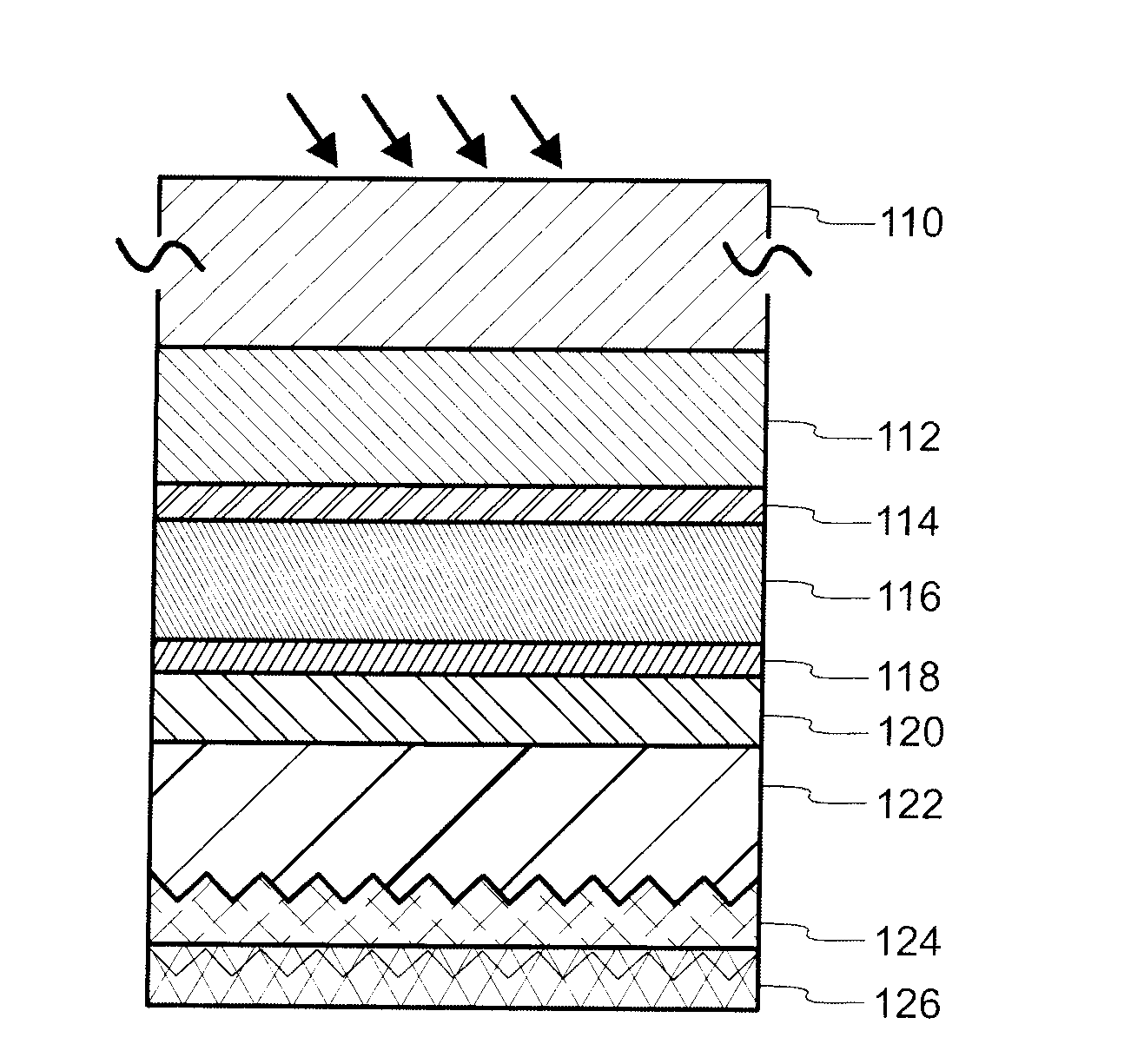

Photonic crystal enhanced light trapping solar cell

This invention relates to a high efficiency solar cell comprising: (a) a top surface of an anti-reflective coating layer; (b) an engineered photonic crystal material layer, (c) an active photovoltaic layer; (d) a photonic crystals with an integrated diffraction grating; (e) a metallic diffraction grating reflective layer, and (f) a metallic back reflector;whereby normally incident light striking the surface of the solar cell passes through the anti-reflective coating and the engineered photonic crystal material layer and is absorbed by active photovoltaic layer thereby generating electrical energy and obliquely incident light is reflected and diffracted by the engineered photonic crystal material layer, the one dimensional photonic crystal layer, the metallic grating reflective layer and the metallic back reflector to the active photovoltaic layer thereby generating electrical energy.

Owner:UNIVERSITY OF DELAWARE

Indirect linear fixture

A light fixture comprising a chamber portion is disclosed. In some embodiments, the fixture comprises a chamber portion shaped to house circuitry required for lighting elements such as light emitting diodes (LEDs) mounted elsewhere in the fixture. In some embodiments, LEDs are mounted facing a back reflector, which in turn reflects light out of a troffer to form an indirect lighting fixture. In some embodiments, light is emitted from one mixing chamber. In some embodiments, light is emitted from two or more mixing chambers. In some embodiments, LEDs are mounted on a heat sink which cooperates with a chamber portion.

Owner:IDEAL IND LIGHTING LLC

Reactive sputter deposition of a transparent conductive film

Methods for sputter depositing a transparent conductive oxide (TCO) layer are provided in the present invention. The transparent conductive oxide layer may be utilized as a back reflector in a photovoltaic device. In one embodiment, the method includes providing a substrate in a processing chamber, forming a first portion of a transparent conductive oxide layer on the substrate by a first sputter deposition step, and forming a second portion of the transparent conductive oxide layer by a second sputter deposition step.

Owner:APPLIED MATERIALS INC

Photo-voltaic cells including solar cells incorporating silver-alloy reflective and/or transparent conductive surfaces

The current invention provides for the manufacture of solar voltaic cells with high sunlight to electricity conversion efficiencies by using improved silver-alloy thin films with a thickness in the range of 30 to 60 as a back reflector / conductor. The back reflector surface may be smooth or roughened depending on the design of the solar voltaic cell and the reflective surface used. Silver-alloy thin film in the thickness range of 3 to 10 nanometers can be used to replace traditional transparent conductor such as indium oxide, indium tin oxide, zinc oxide, tin oxide etc. Elements that can be alloyed with silver to create alloys for use in the invention include, Pd, Cr, Zr, Pt, Au, Cu, Cd, B, In, Zn, Mg, Be, Ni, Ti, Si, Li, Al, Mn, Mo, W, Ga, Ge, Sn, and Sb. These alloys may be present in the silver-alloys in amounts ranging from 0.01 to 10.0 a / o percent. Preferably, elements such as of Cu, In, Zn, Mg, Ni, Ti, Si Al, Mn, Pd, Pt, and Sn are alloyed with silver, these elements are present in the alloy the amounts ranging from 0.05 to 5 a / o percent.

Owner:TARGET TECH

Amorphous silicon photovoltaic cells having improved light trapping and electricity-generating method

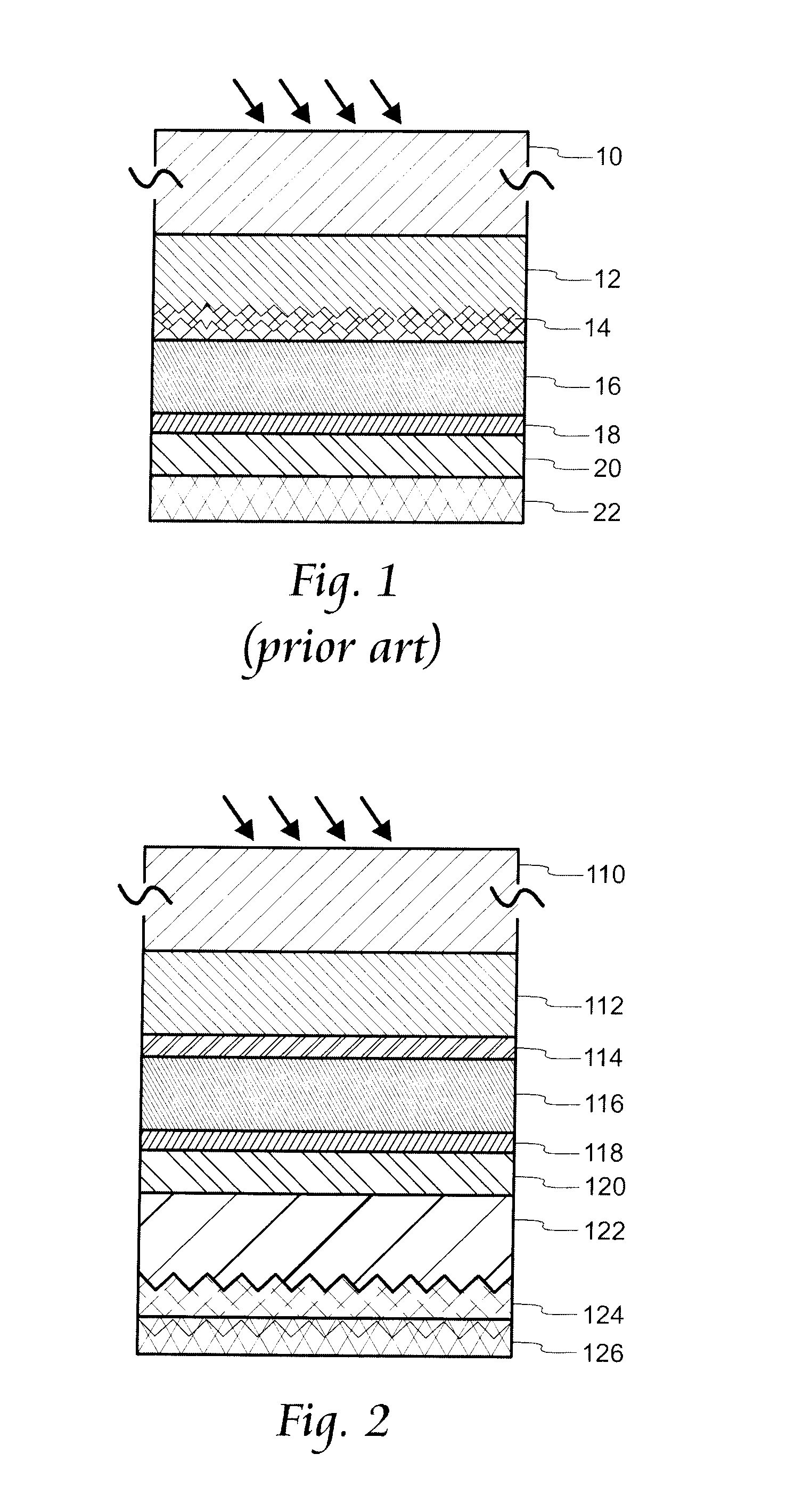

InactiveUS20080264483A1Photovoltaic energy generationSemiconductor devicesBack reflectorElectrical conductor

An amorphous silicon photovoltaic cell exhibiting improved light trapping, and a method for generating electricity from sunlight therewith. The cell comprises a plurality of layers, including a transparent superstrate; a specular, first transparent conductor positioned below the transparent superstrate; at least one p-i-n structure having an active layer positioned below the first transparent conductor; a second transparent conductor positioned below the p-i-n structure; and a layer of transparent material positioned below the second transparent conductor. The layer of transparent material may be textured amorphous silicon having a relatively high dielectric constant. The cell may further include a back coating positioned below the layer of transparent material, and a back reflector positioned below the back coating layer.

Owner:FOREFRONT INNOVATIVE TECH

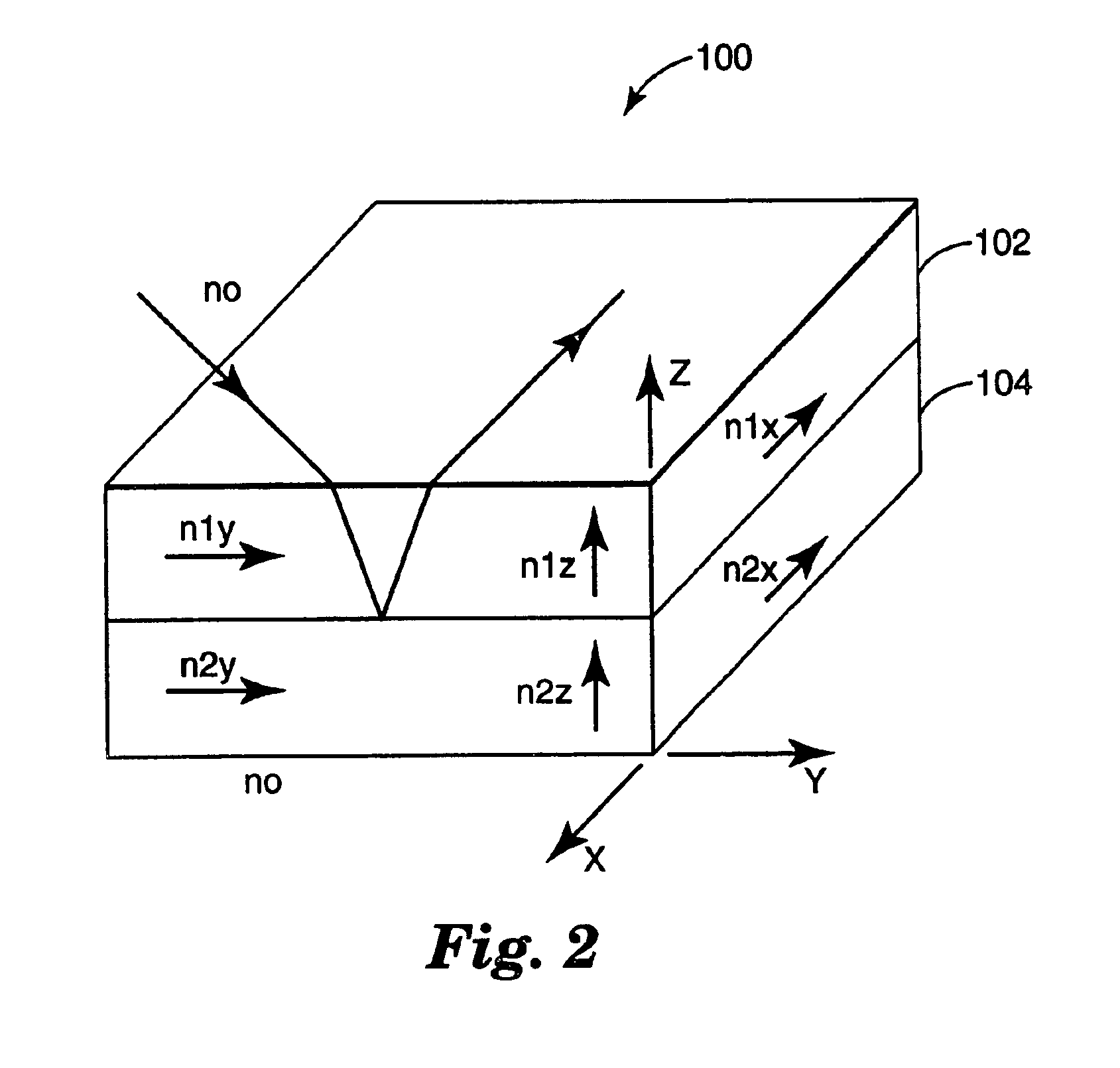

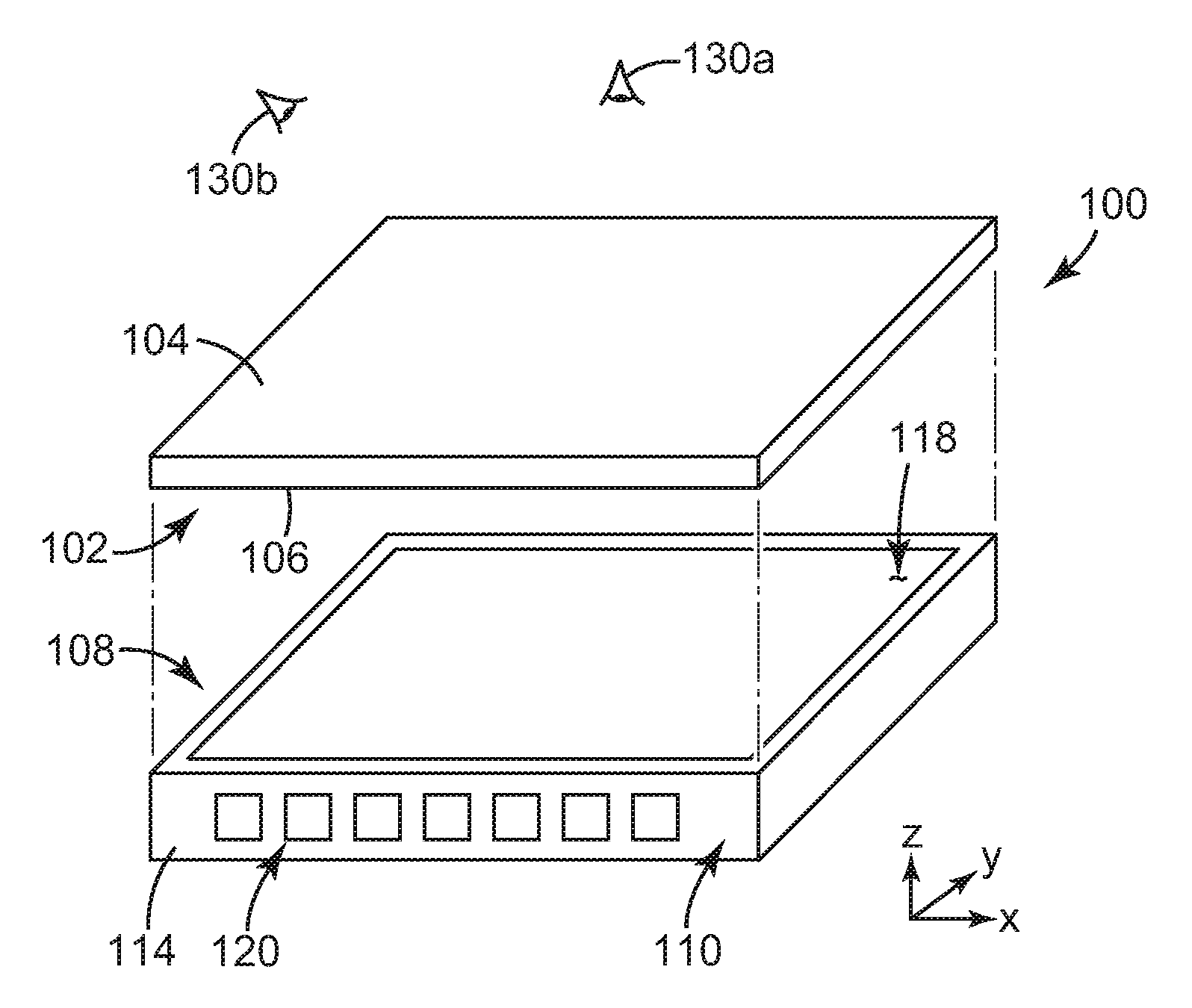

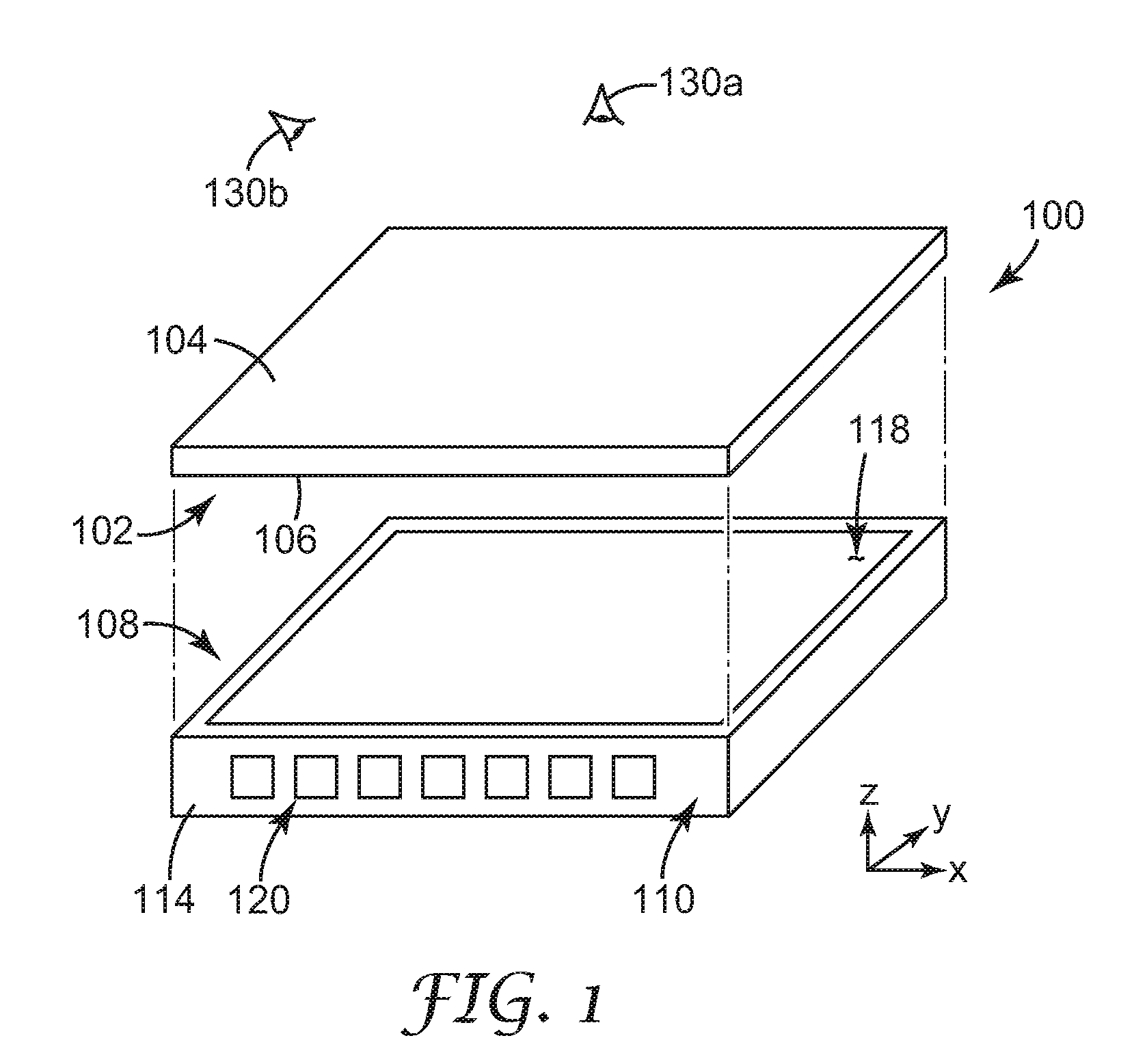

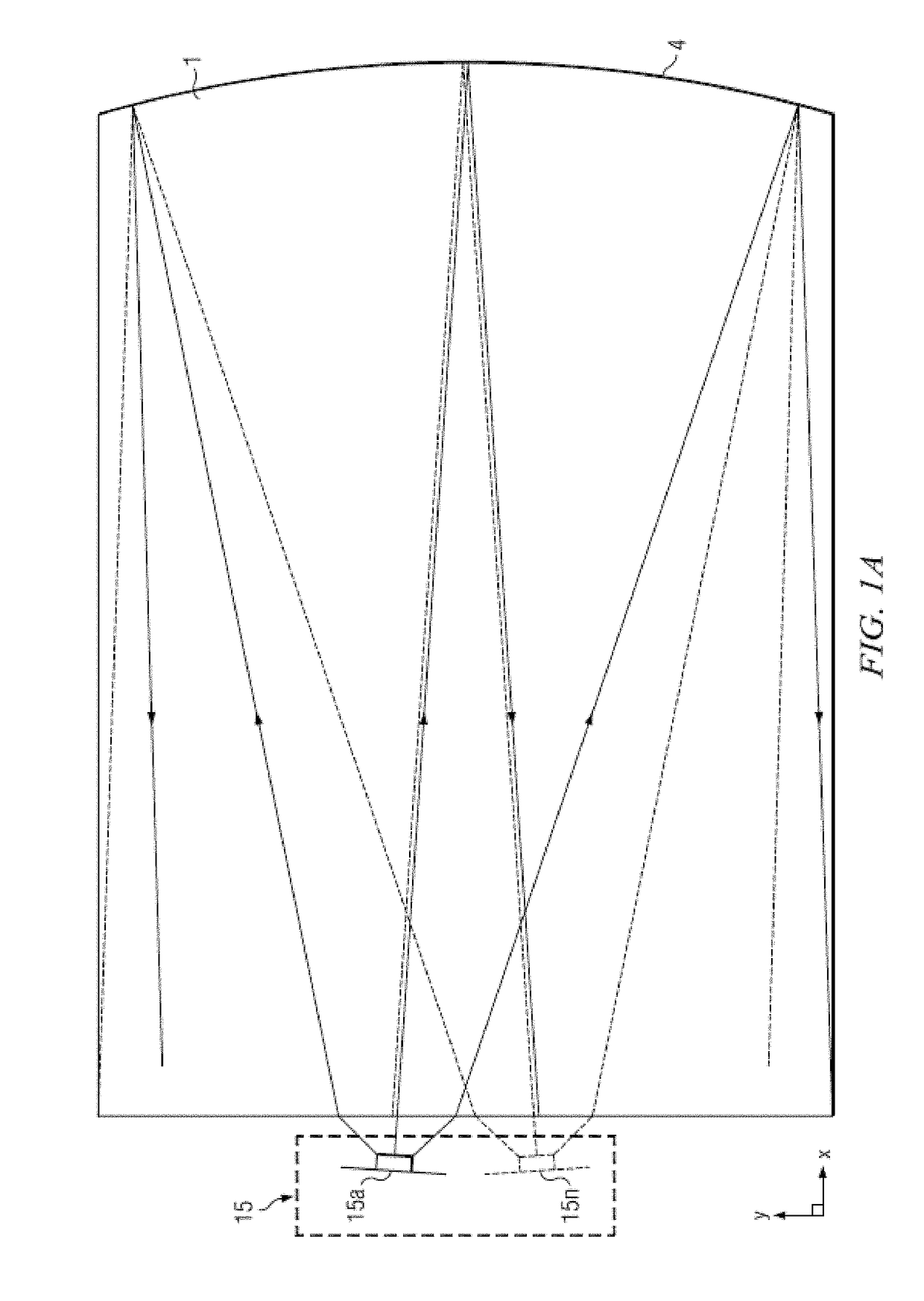

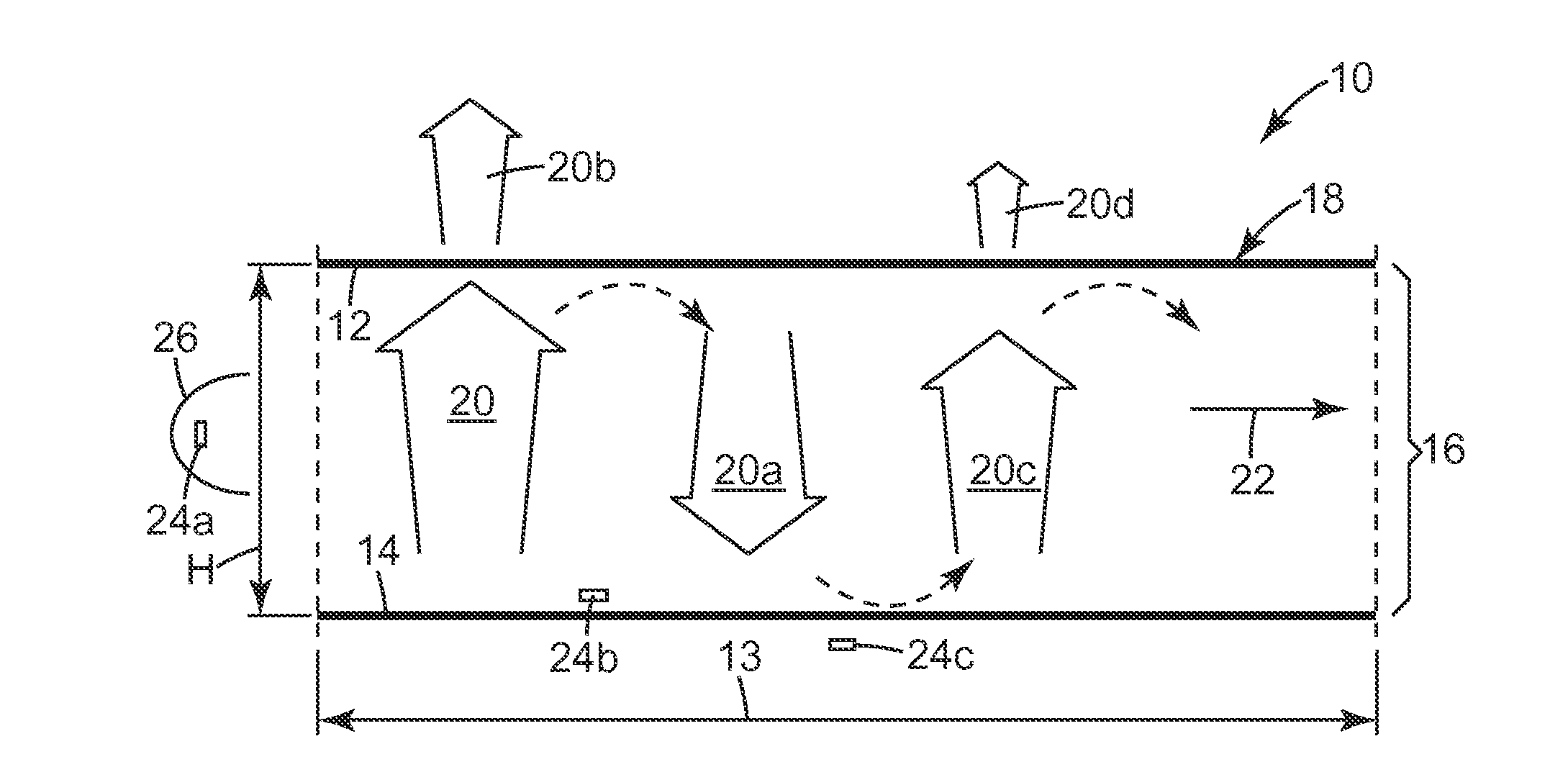

Illumination systems with sloped transmission spectrum front reflector

ActiveUS20140254125A1High hemispherical reflectivityConvenient amountHollow light guidesIlluminated signsBack reflectorOptoelectronics

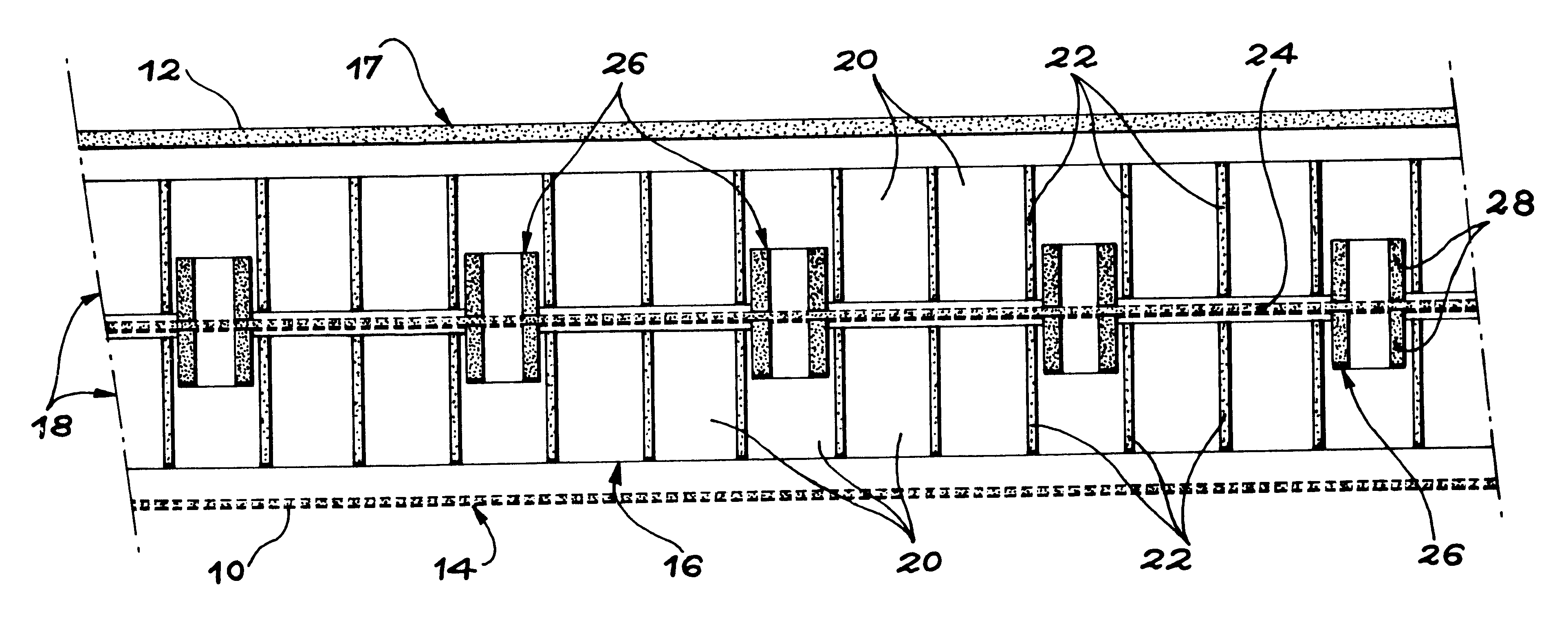

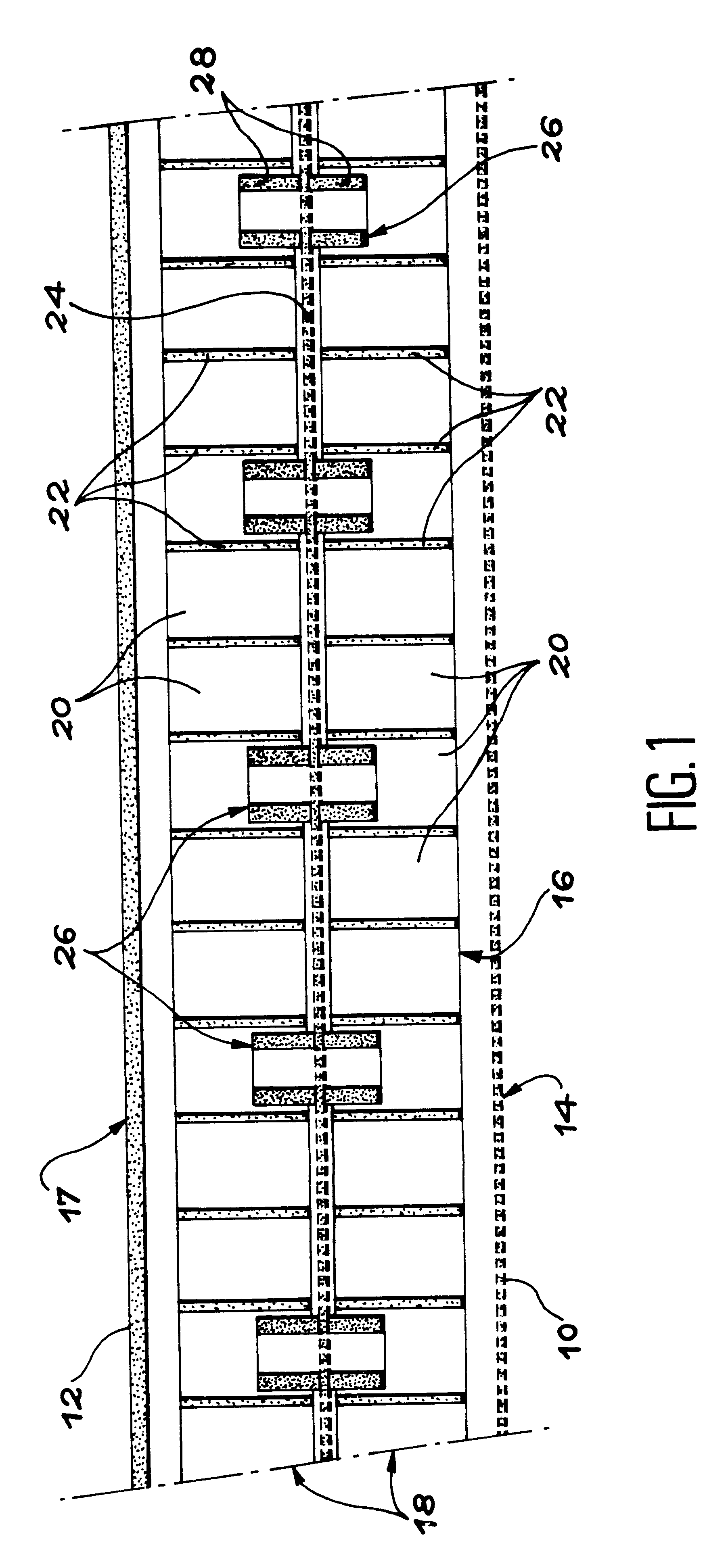

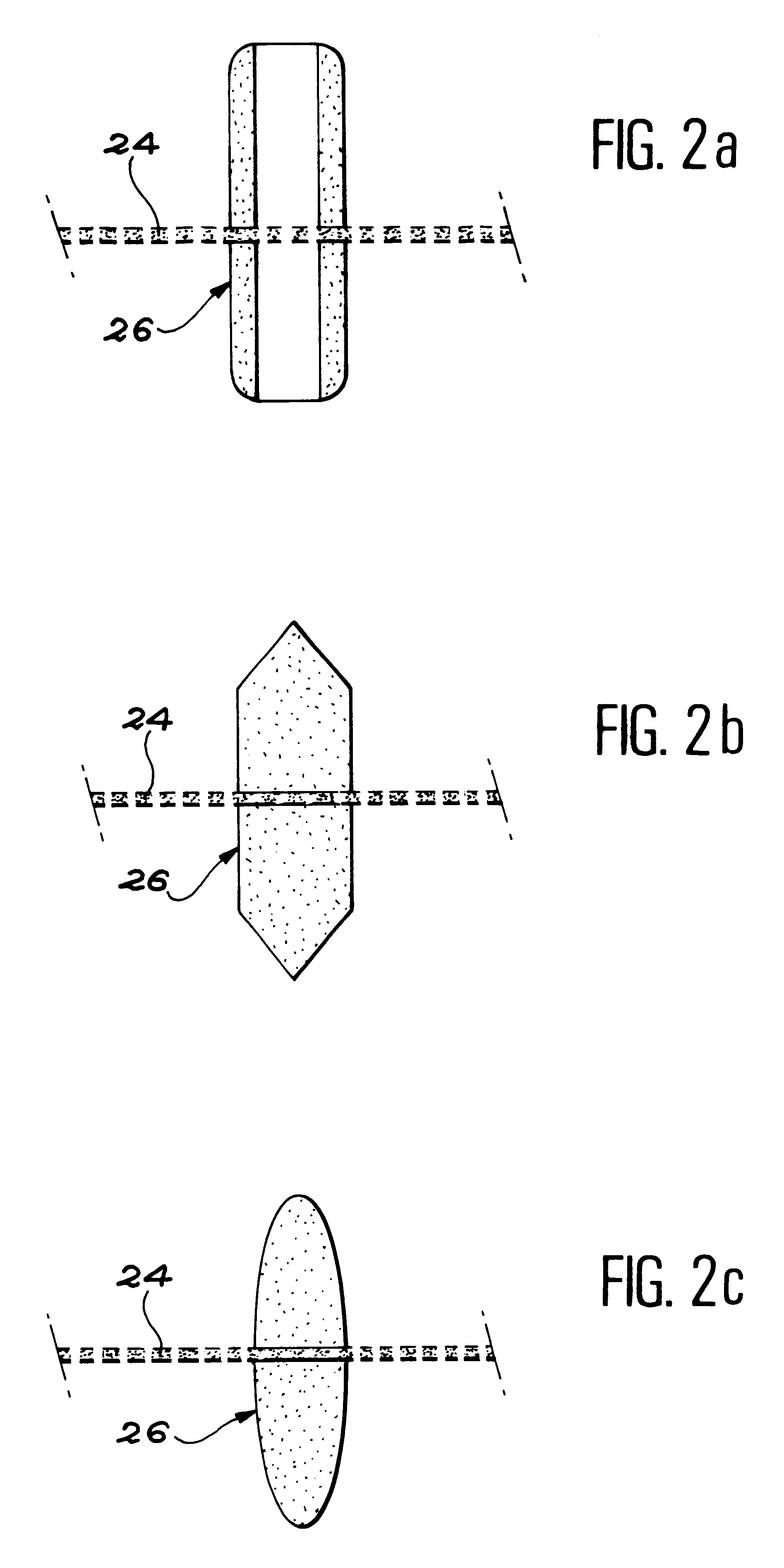

A backlight (10) includes a front and back reflectors (12,14) forming a light recycling cavity (16) and one or more light source members (24a, 24b, 24c) disposed to emit light into the light recycling cavity. The front reflector (12) being partially reflective to provide an output illumination area. The front reflector (12) has a blue sloped transmission spectra, at normal incidence with a range among bin values from 15% to 100%.

Owner:3M INNOVATIVE PROPERTIES CO

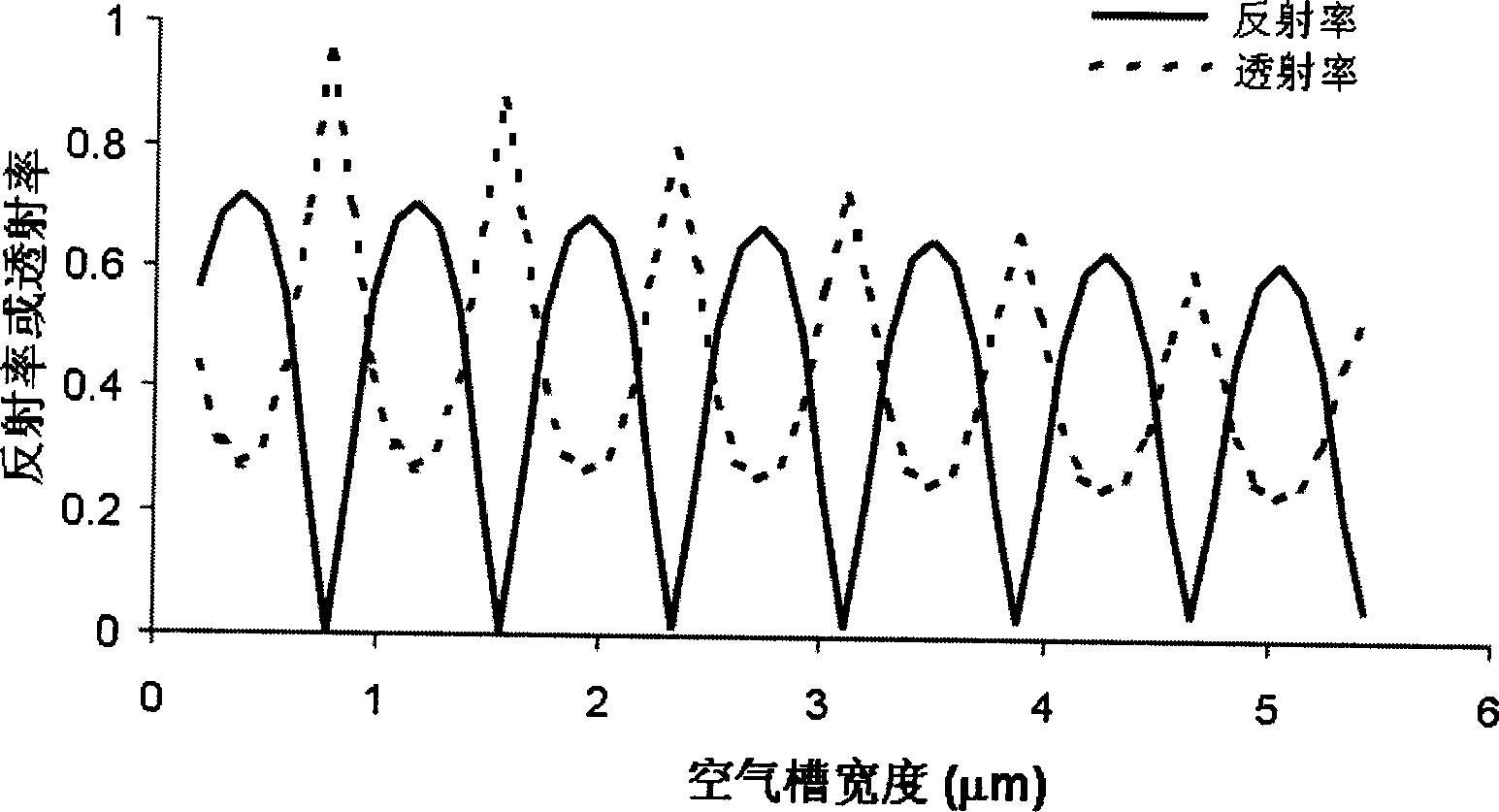

Q-modulation semiconductor laser

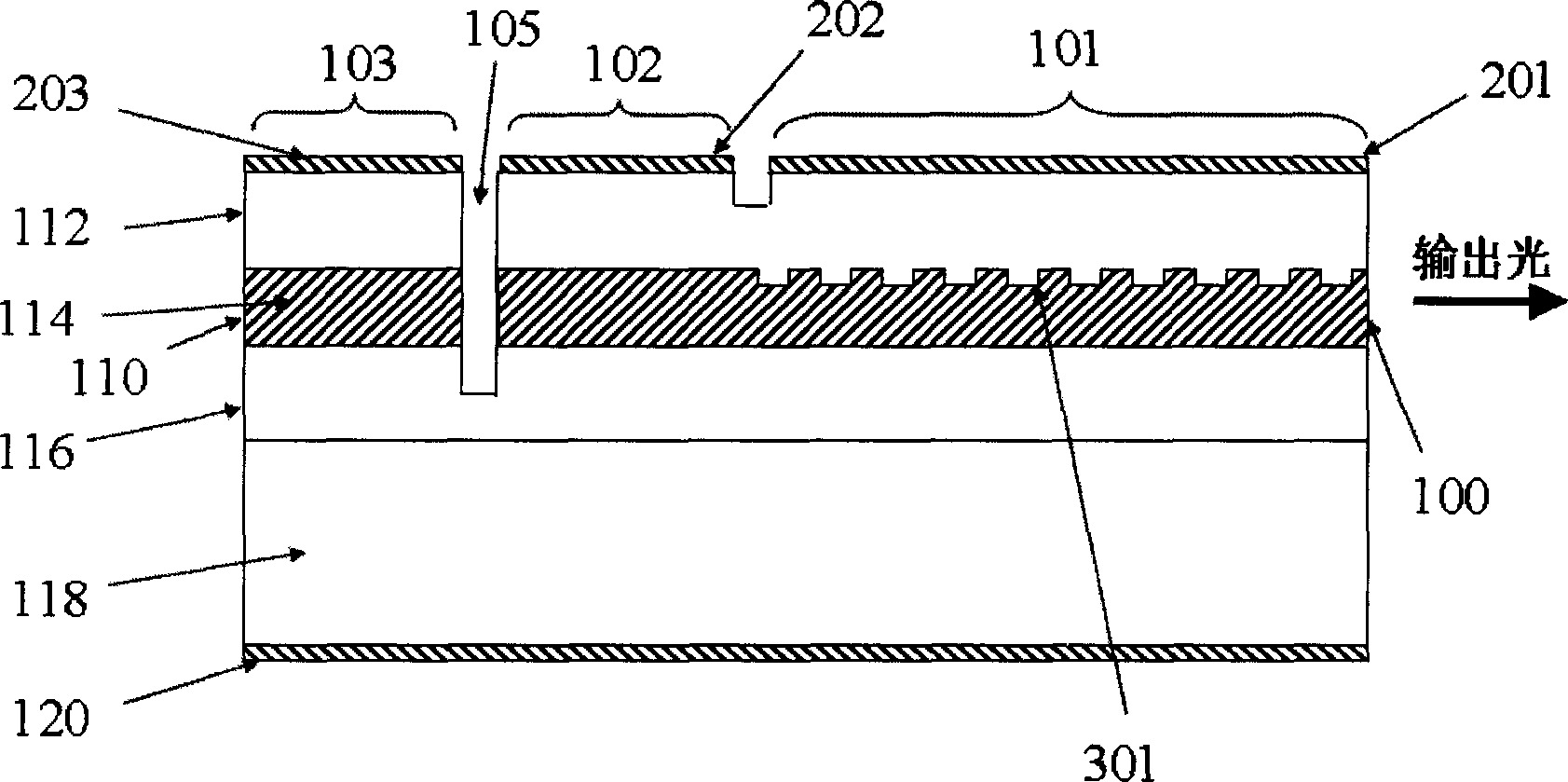

InactiveCN1838492AImprove performanceSmall sizeLaser detailsLaser optical resonator constructionBack reflectorGrating

This invention discloses a Q-modulation semiconductor laser, which includes the first optics cavity and the second cavity, wherein the first optics cavity is a resonator with gain zone, the second optics cavity is a resonator with modulation zone; and the second optics cavity couples with the first optics cavity by the separation element reflected by a section, and the second optics cavity is used as the back reflector of the laser; and the modulation zone's absorption coefficient is modulated by a electrolytic method, which affects the back reflector's reflection rate and laser Q value, which changes the threshold value and output energy of the laser transmitting. The Q-modulation semiconductor laser in this invention has many advantages such as high integration, high speed, high delustring ratio, lower wavelength chirp.

Owner:何建军

Thin hollow backlights with beneficial design characteristics

InactiveUS8523419B2Reduce the total massLosses associated with the light sources are kept to minimal levelsCathode-ray tube indicatorsHollow light guidesBack reflectorOptoelectronics

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com