Patents

Literature

43 results about "Thin film silicon solar cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Back contact and back reflector for thin film silicon solar cells

InactiveUS20050172997A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationDielectricBack reflector

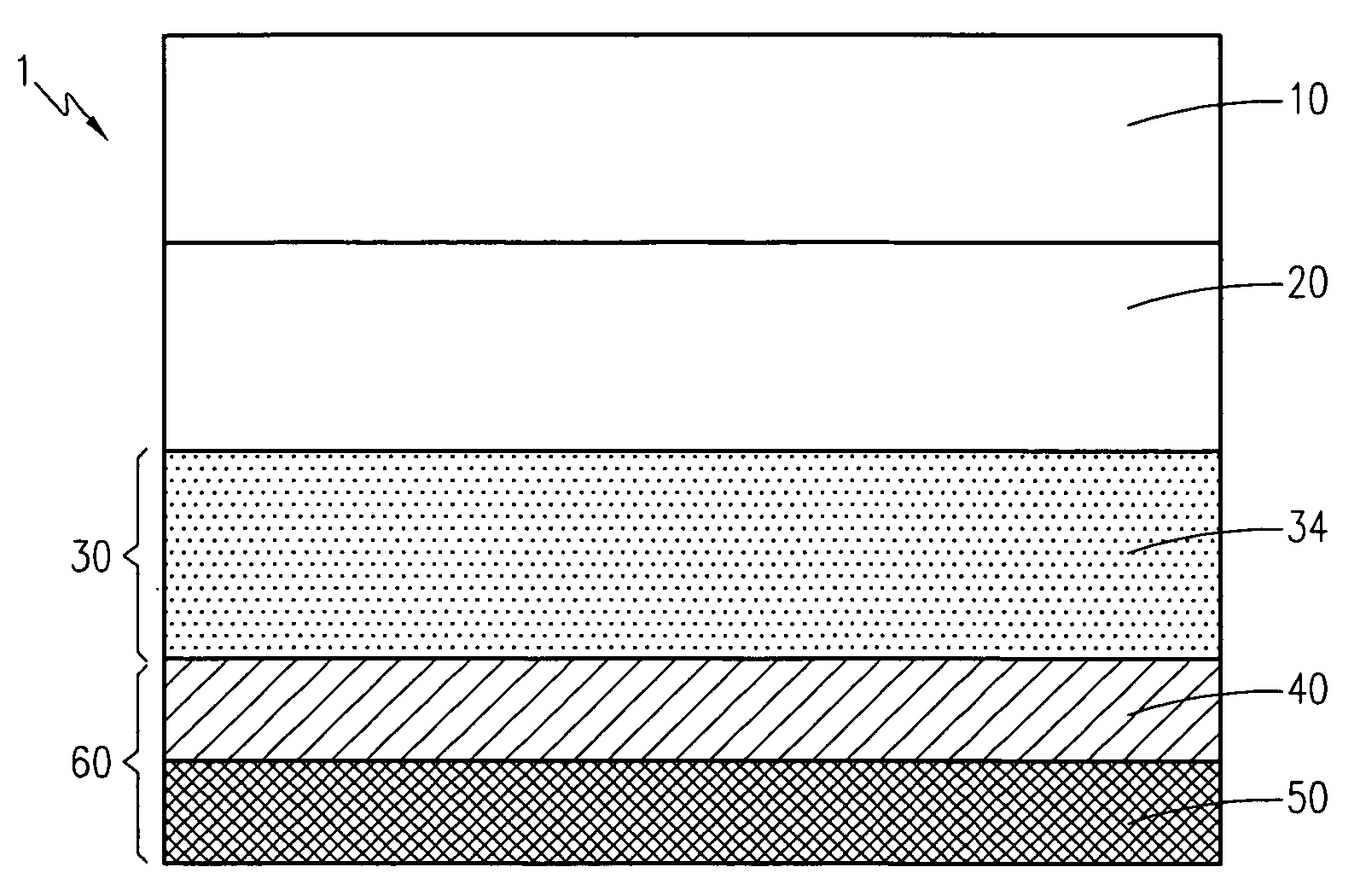

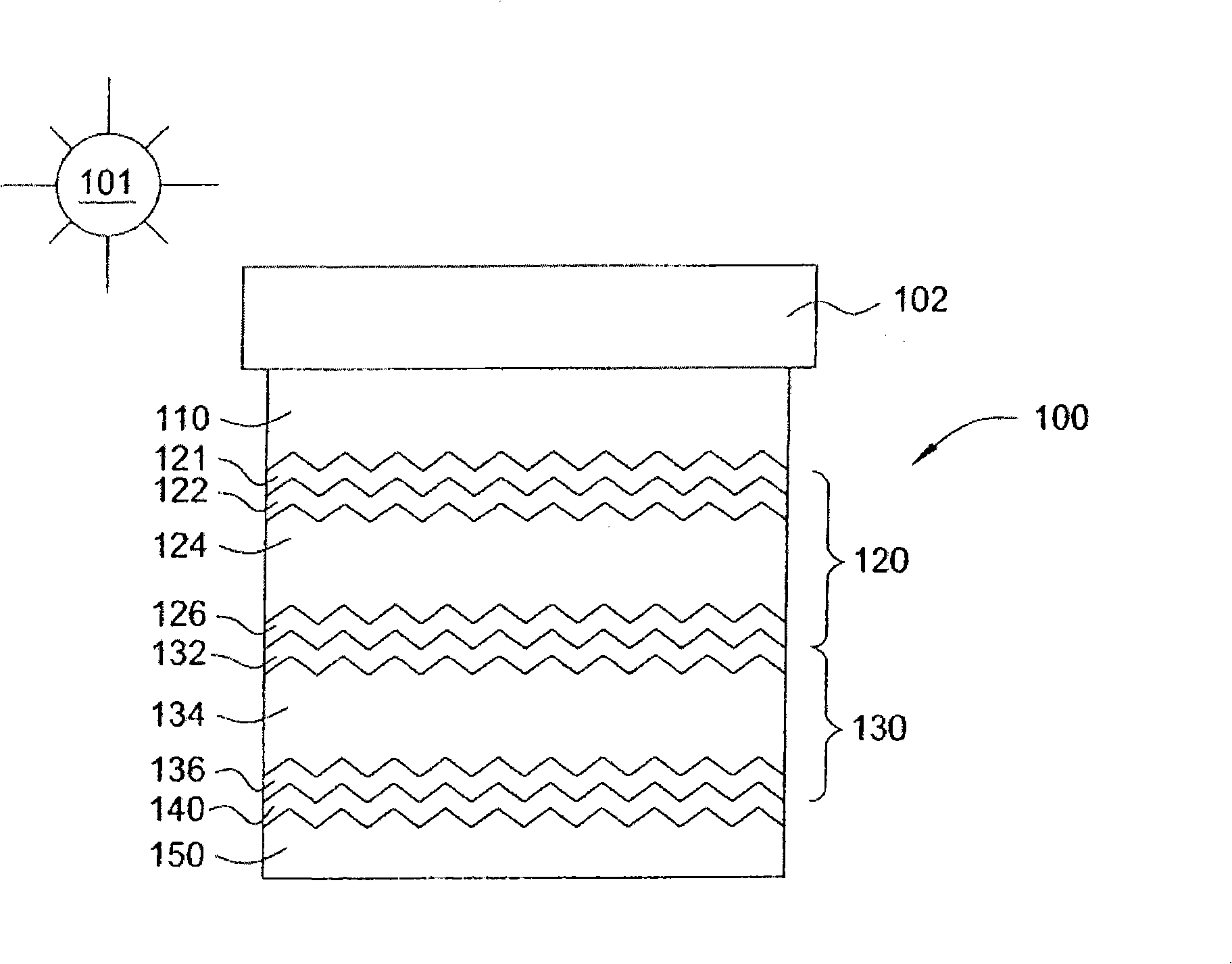

A thin film silicon solar cell for use in photovoltaic cells having a carrier substrate, a front transparent conductive oxide contact, a thin film silicon solar cell layer having at least one layer of hydrogenated microcrystalline silicon or nanocrystalline silicon, and a back contact having a transparent conductive oxide contact layer and a back reflective layer comprising a white pigmented dielectric reflective media.

Owner:UNAXIS BALZERS LTD

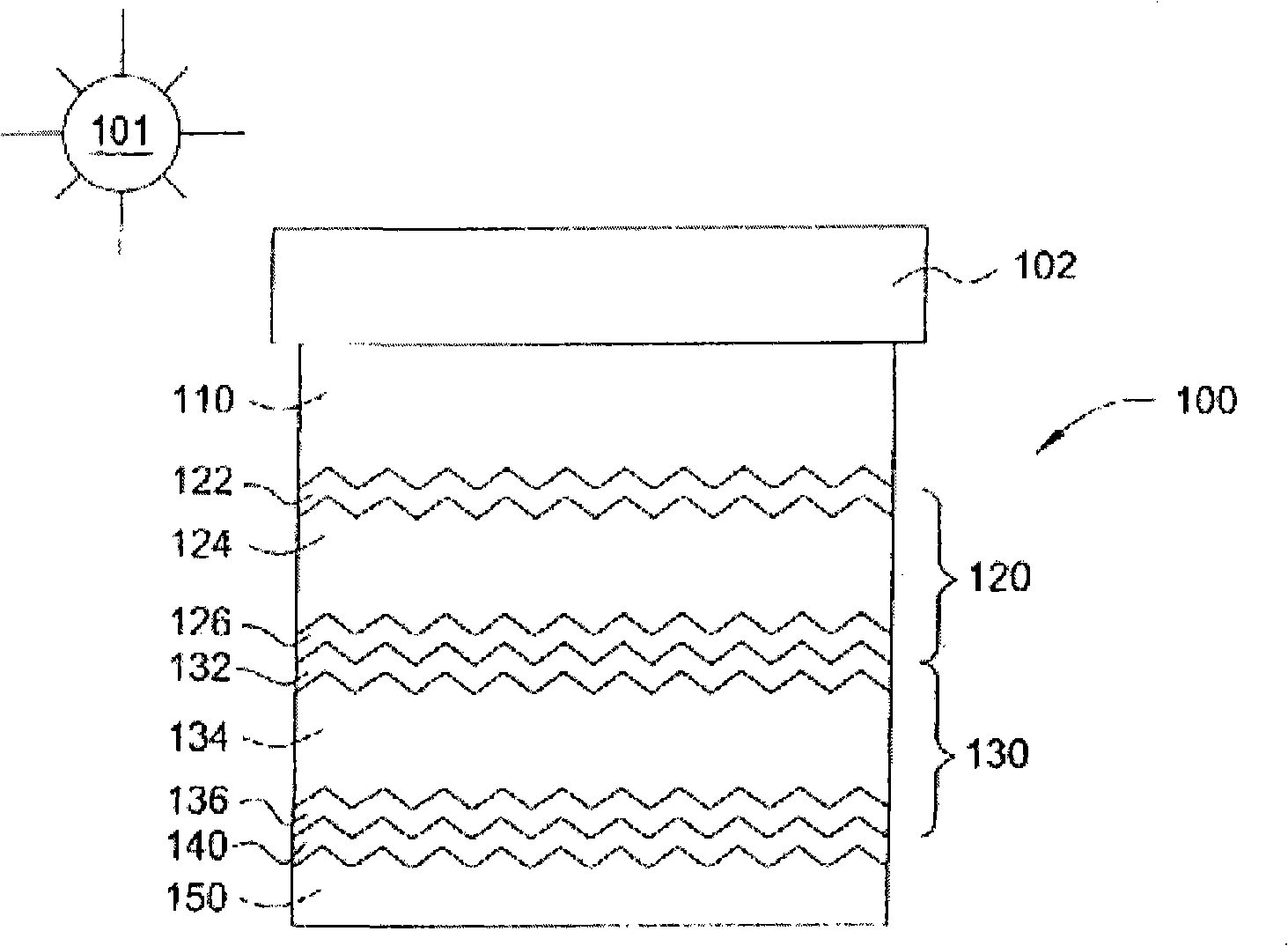

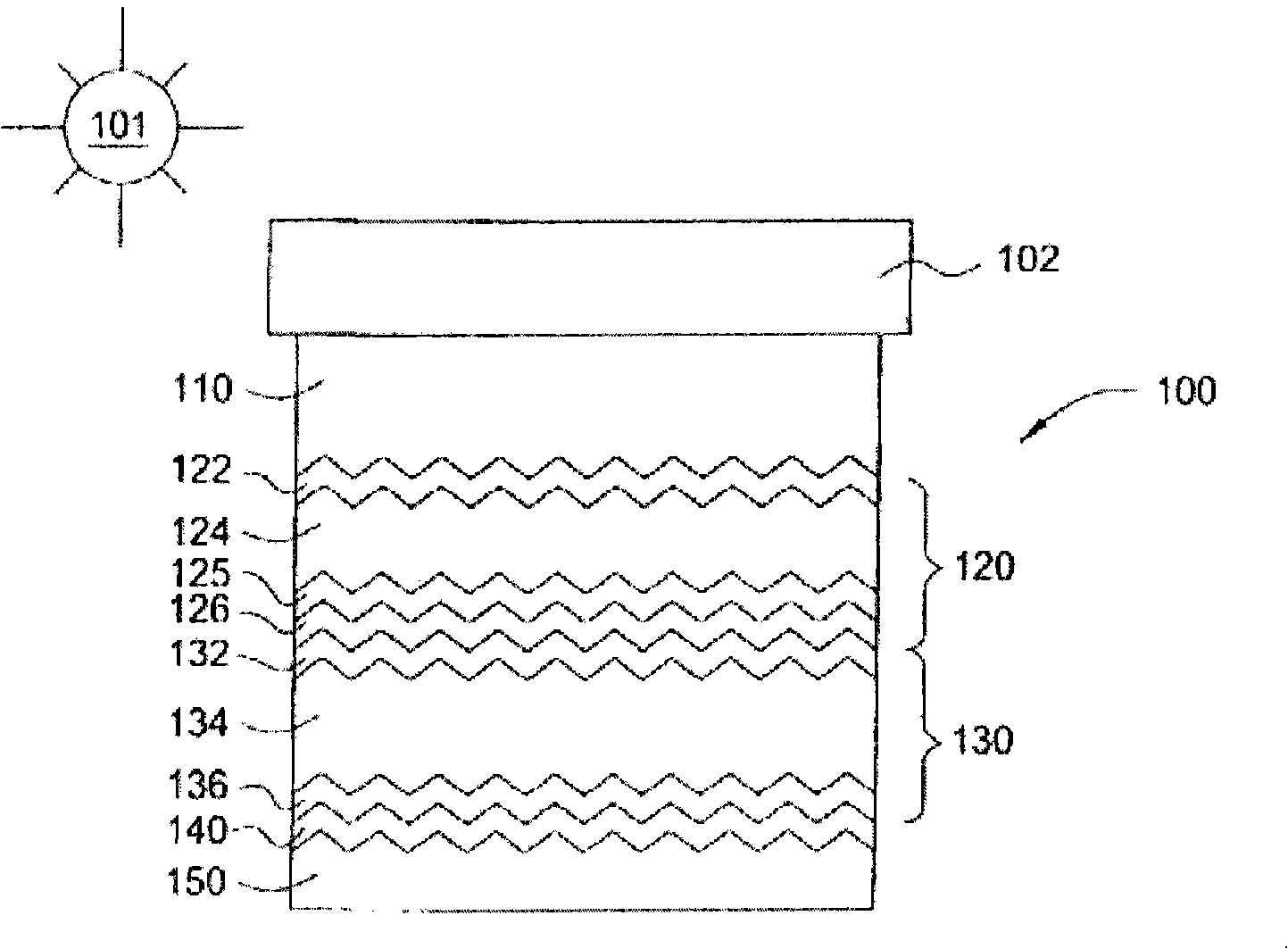

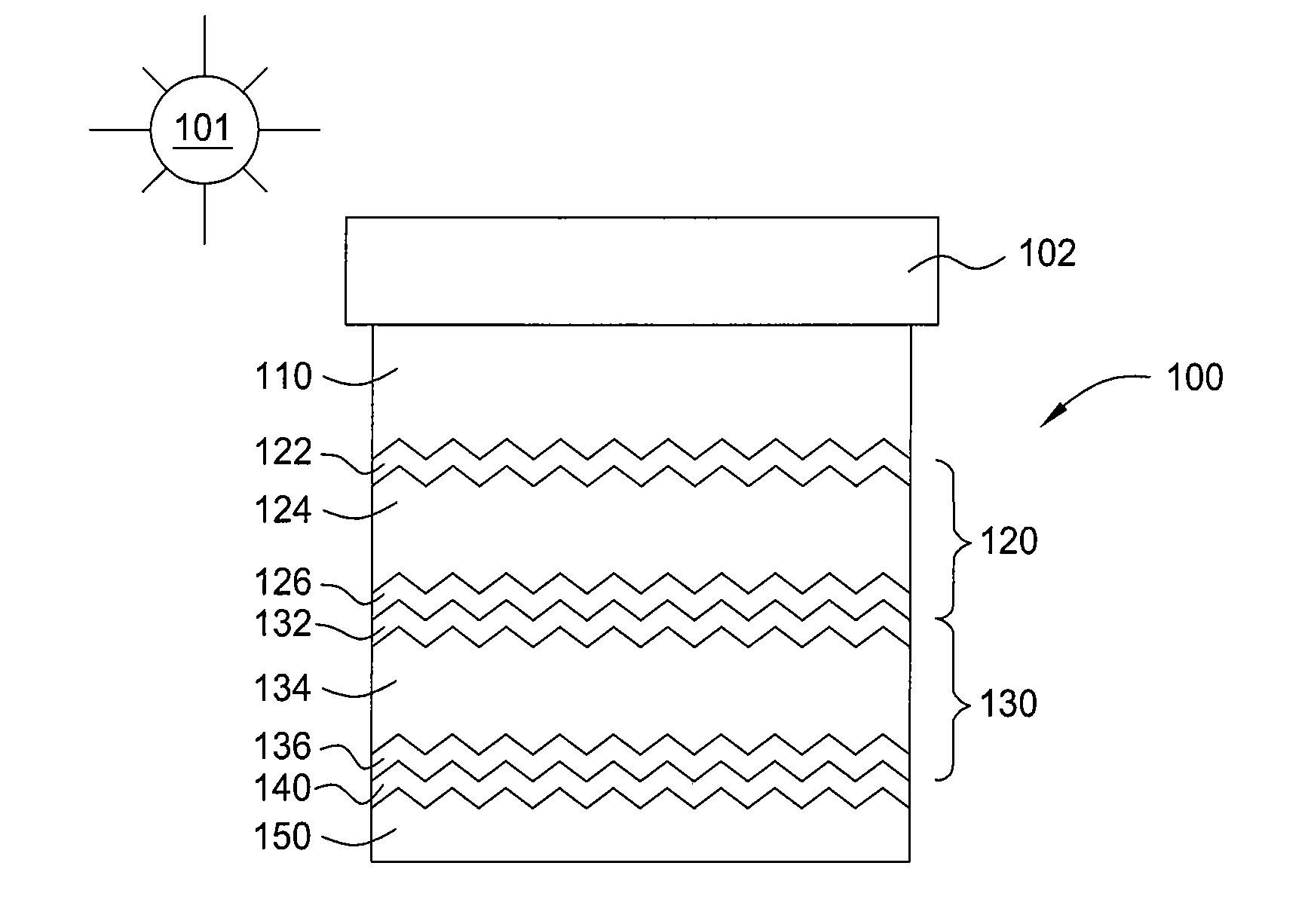

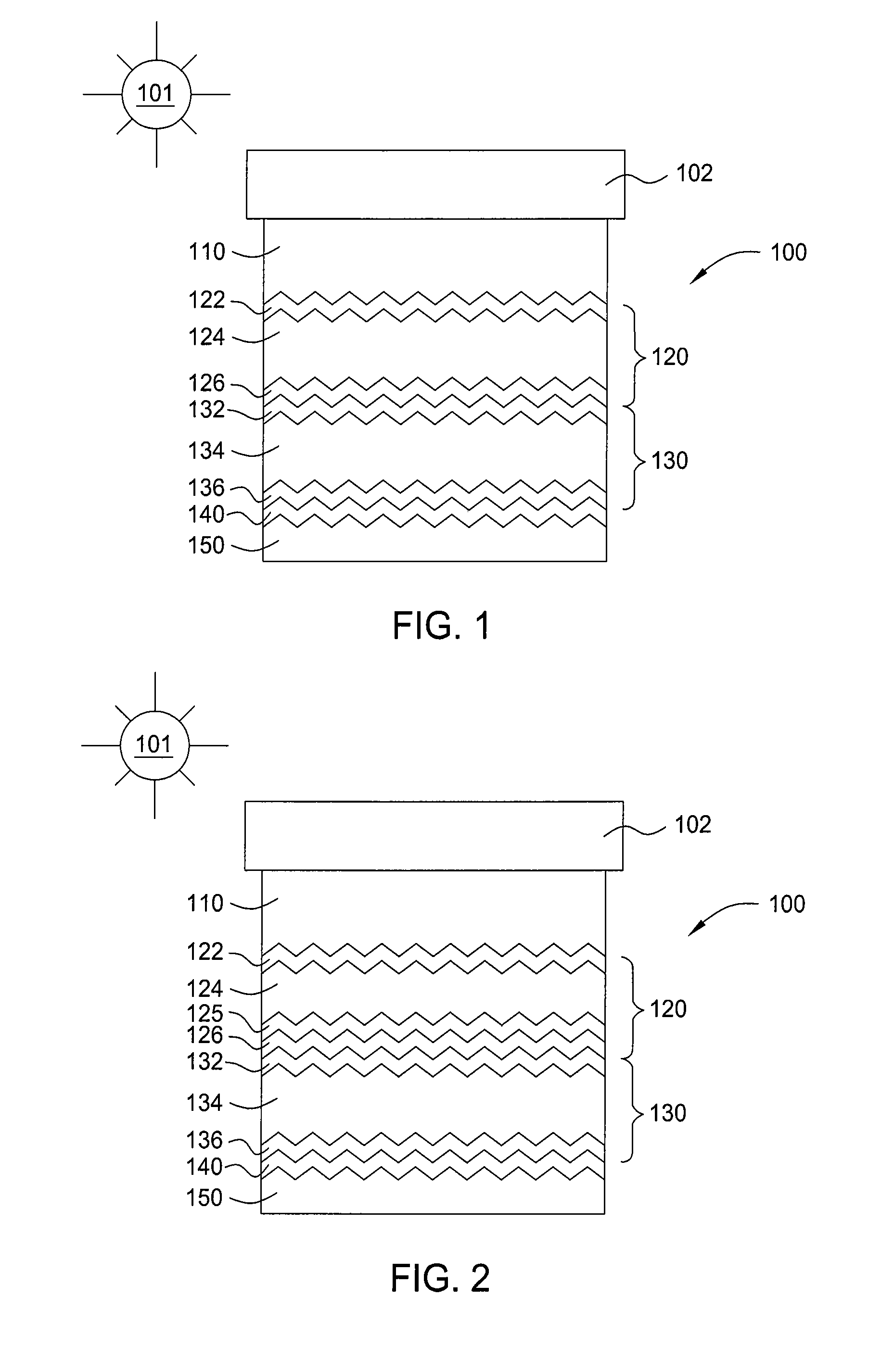

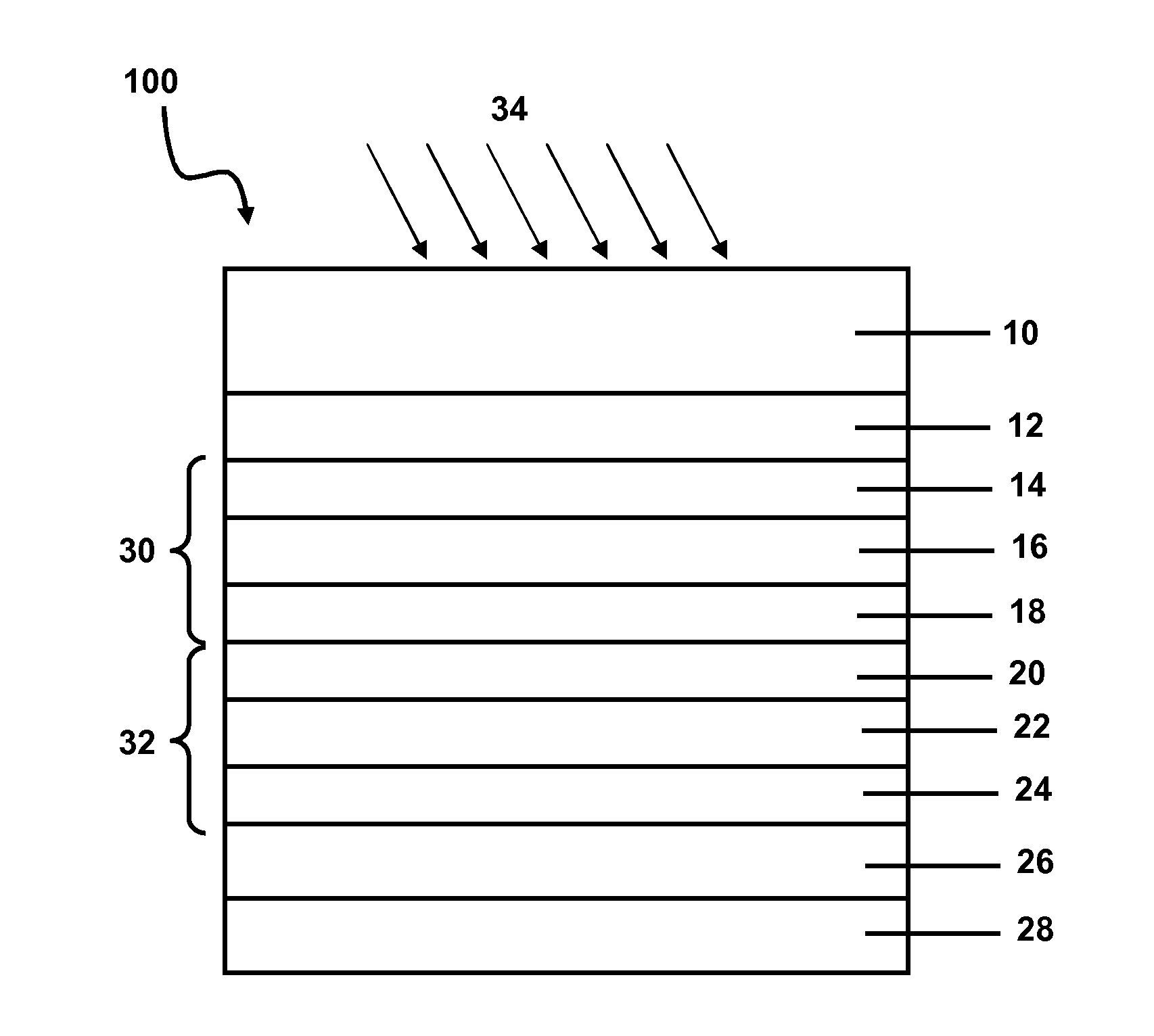

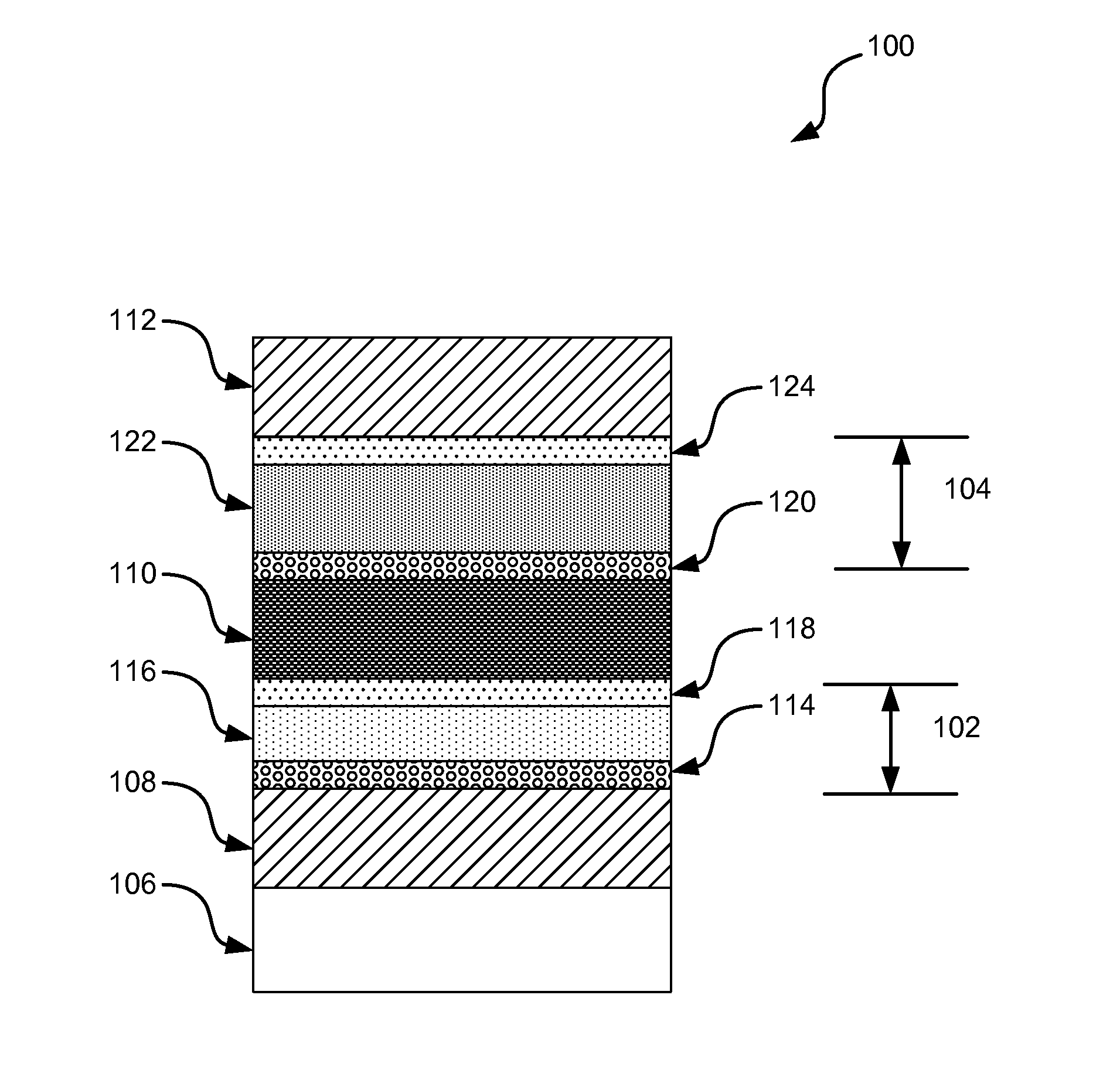

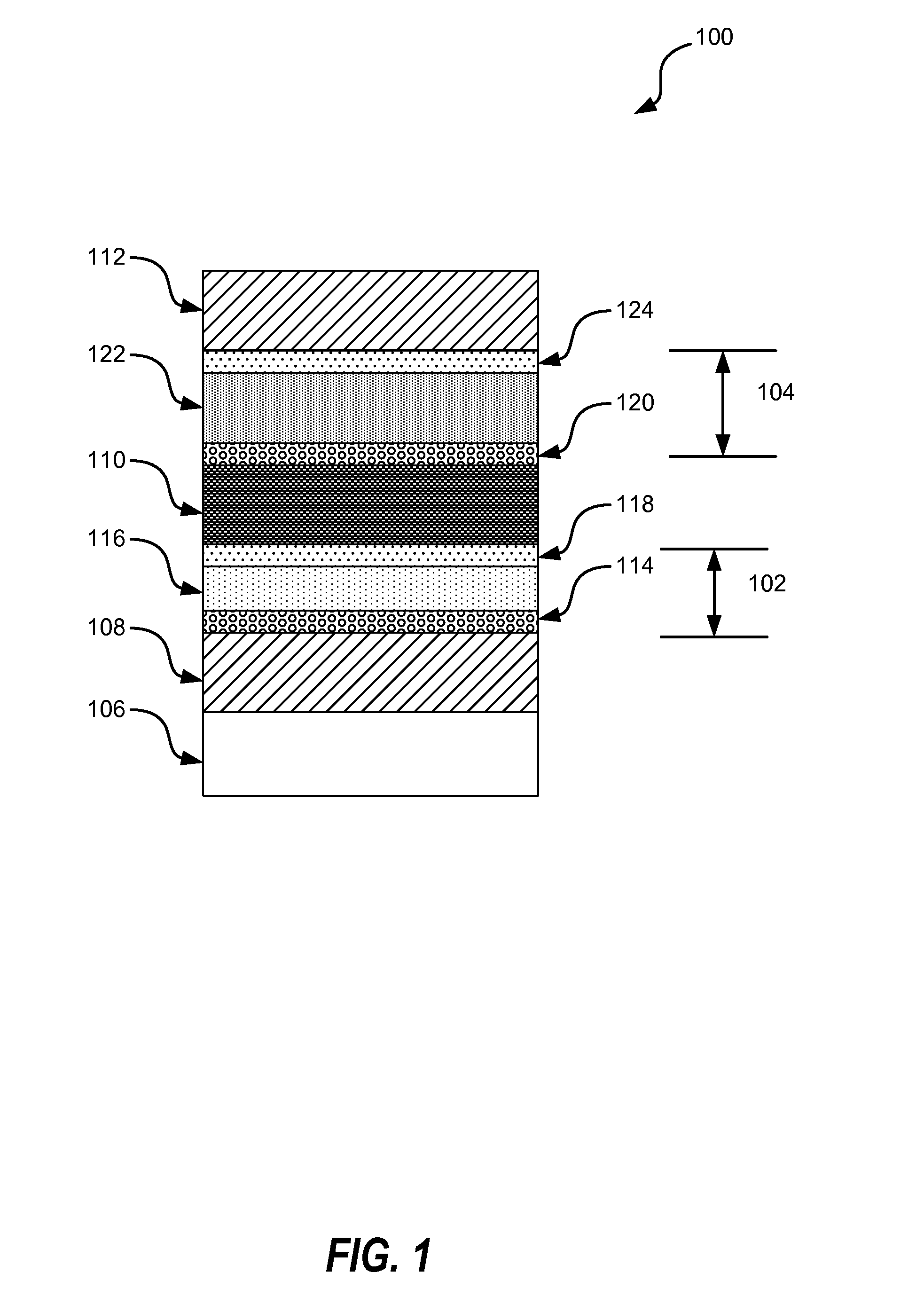

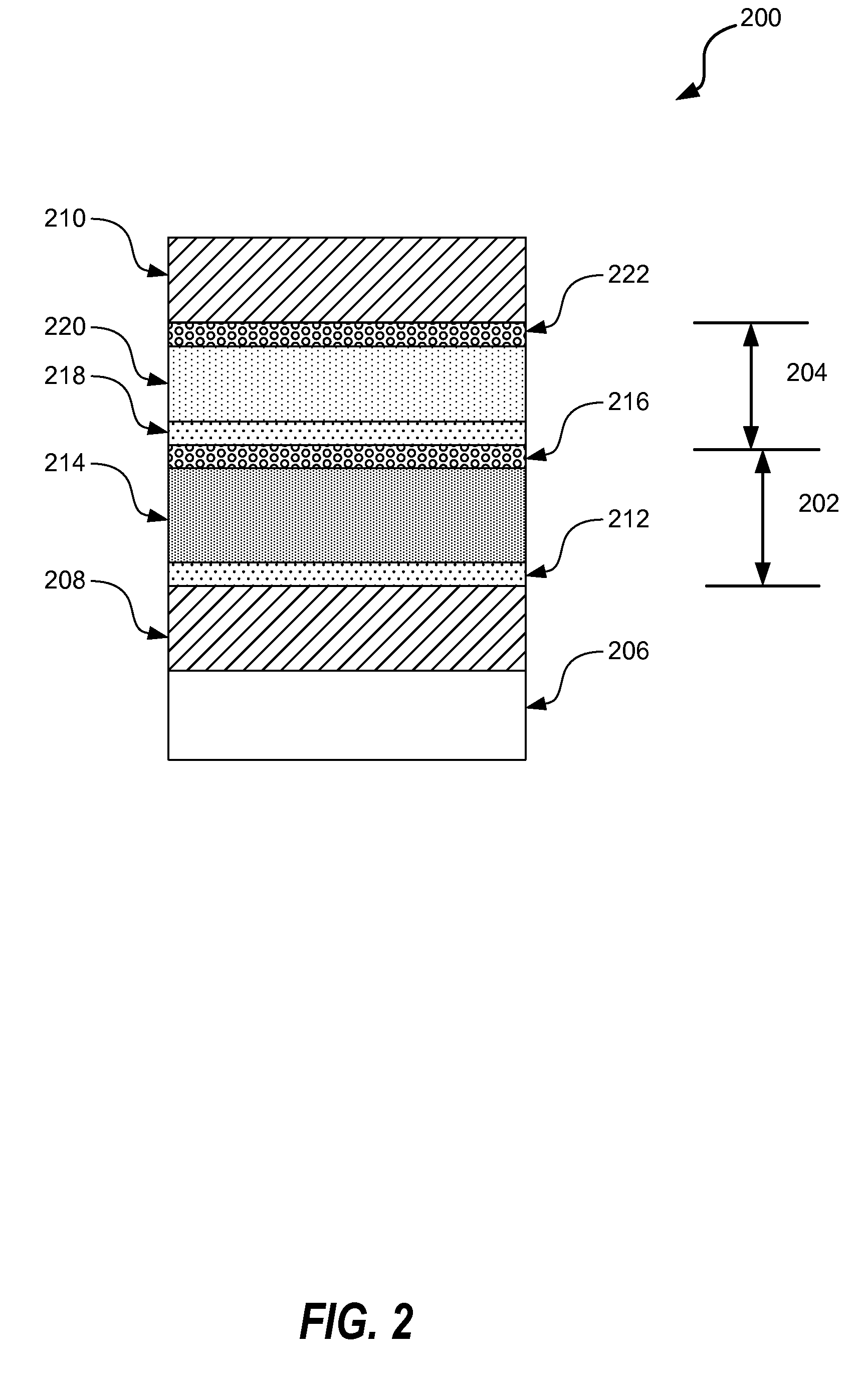

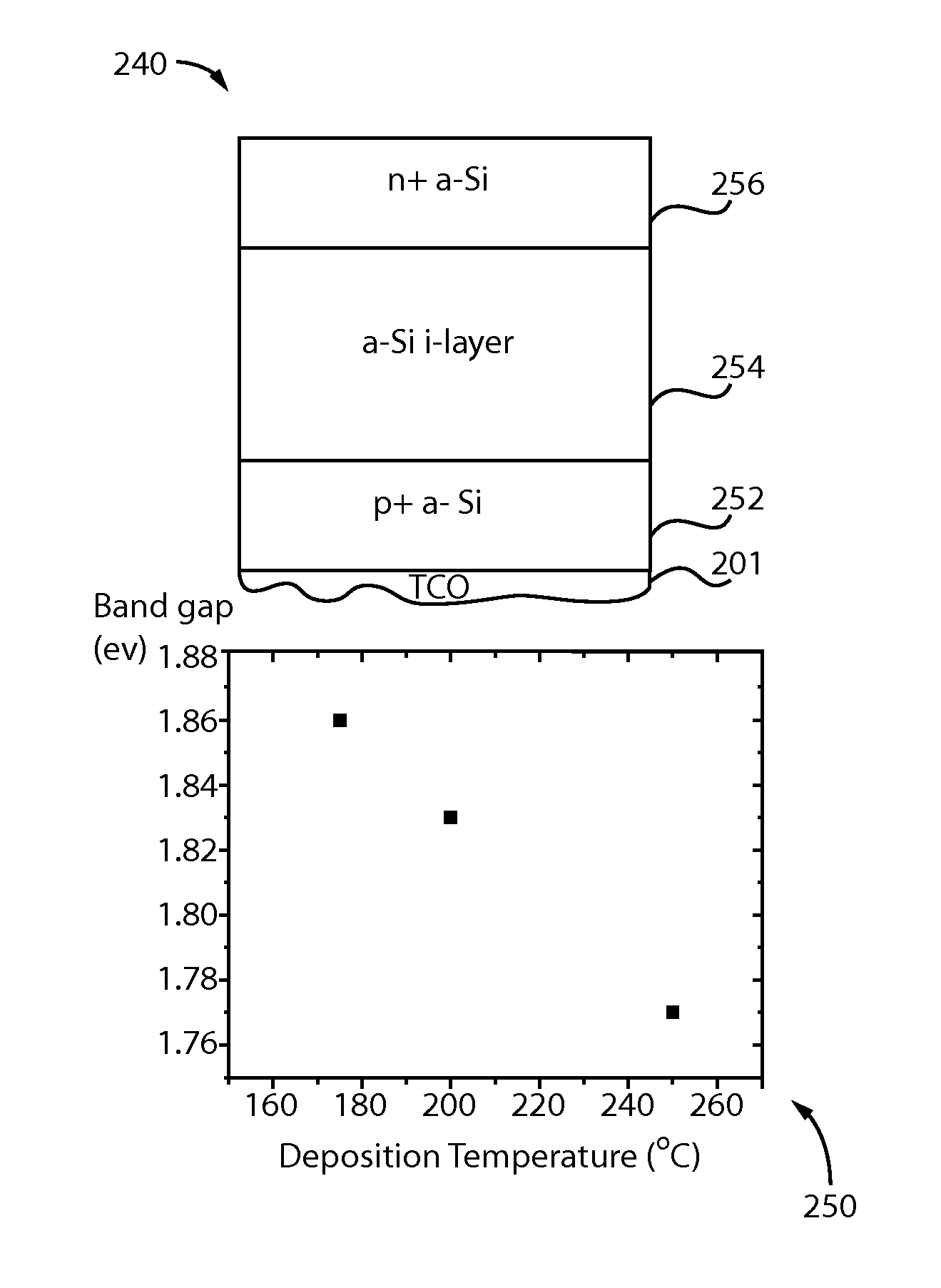

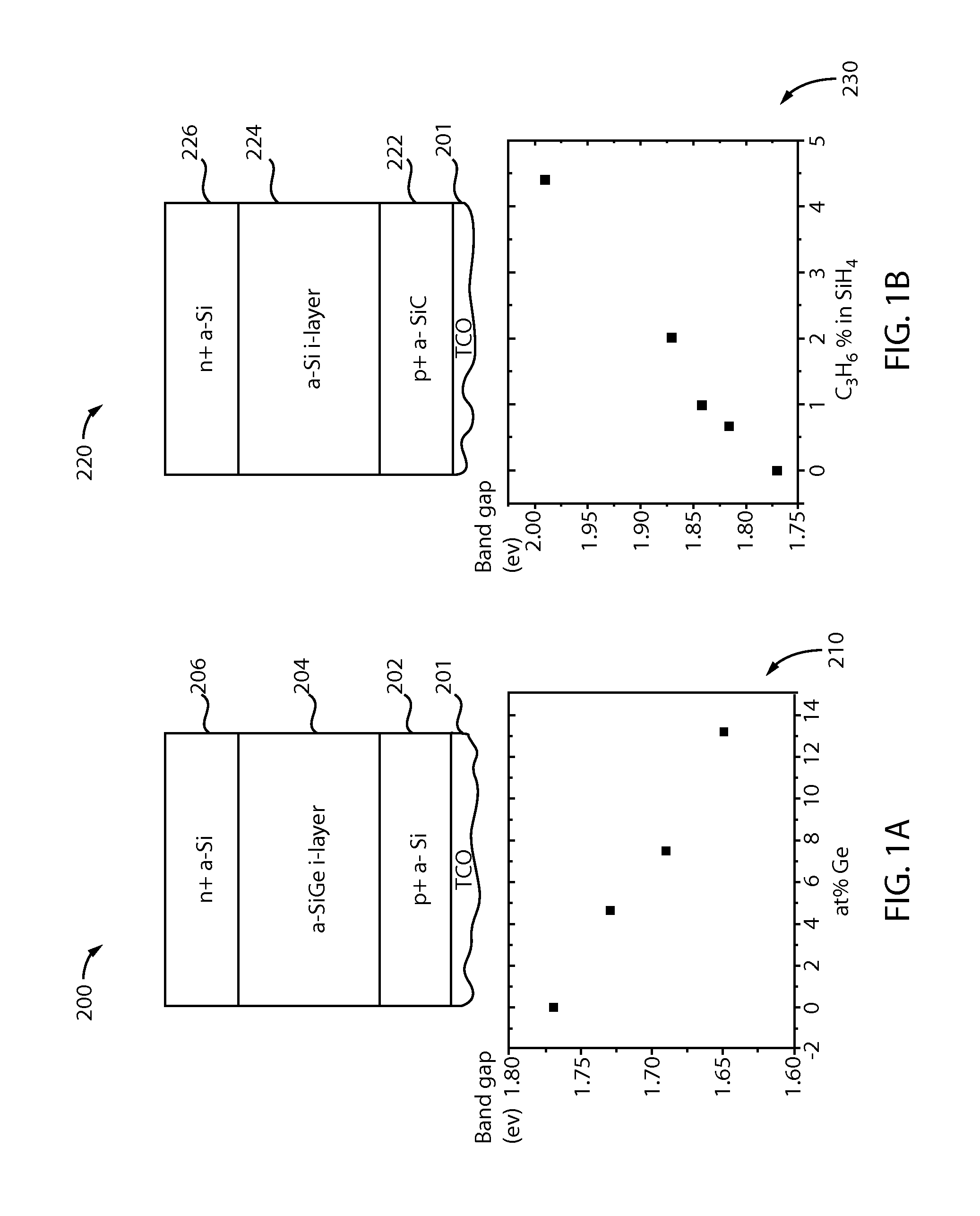

Multi-junction solar cells and methods and apparatuses for forming the same

InactiveUS20090020154A1Uniformly formedFinal product manufactureSemiconductor/solid-state device manufacturingAmorphous siliconSilicon solar cell

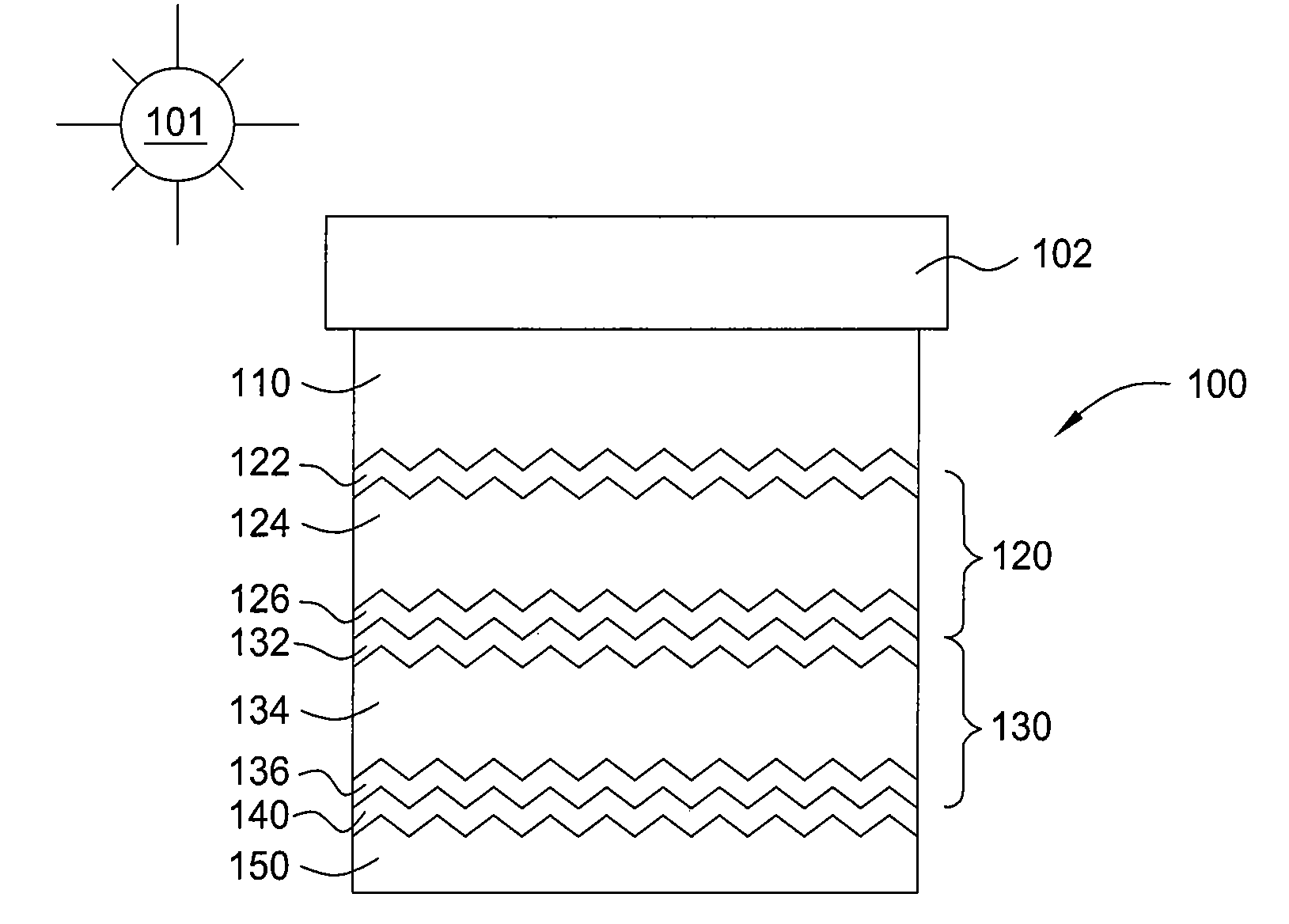

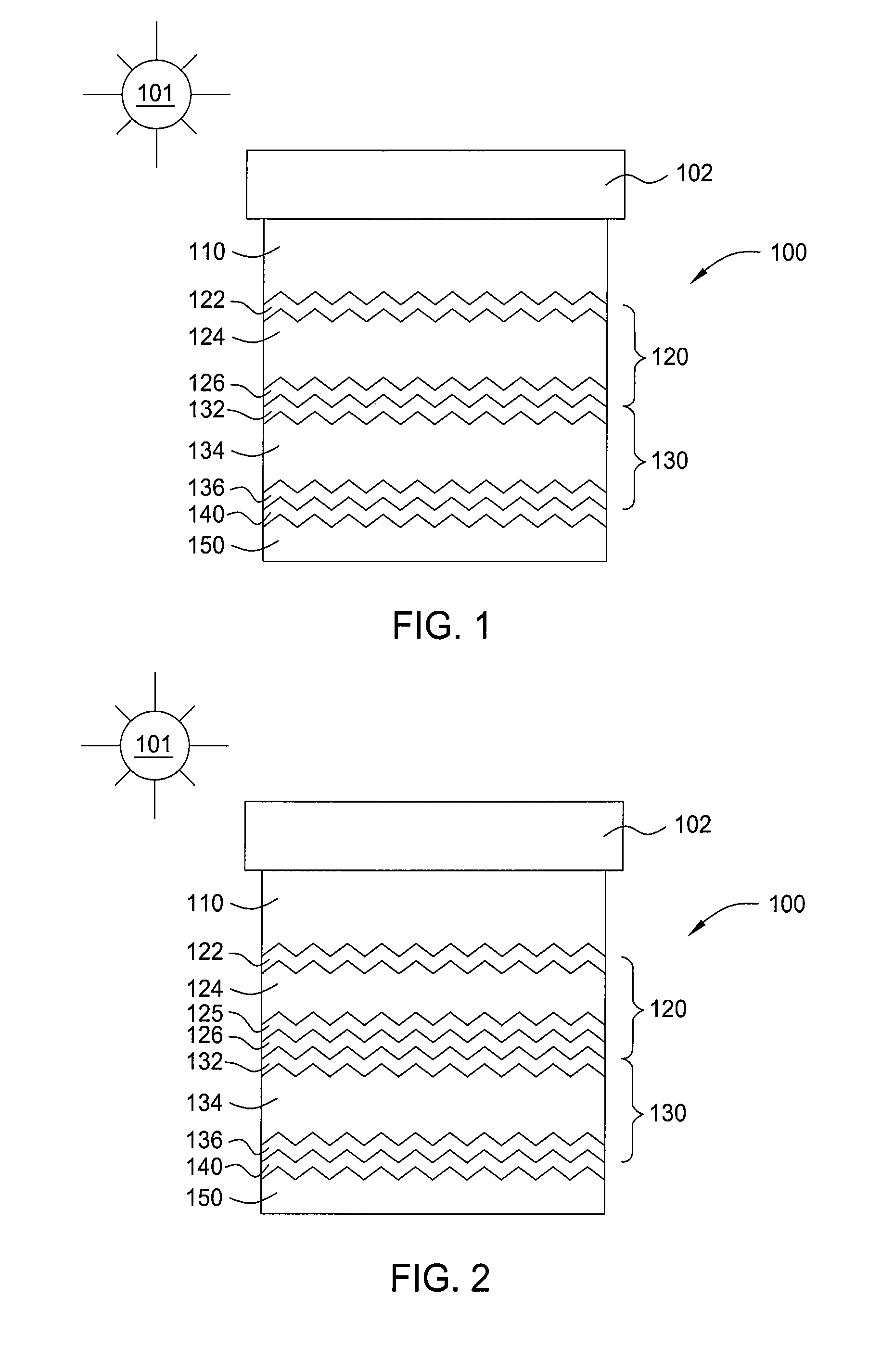

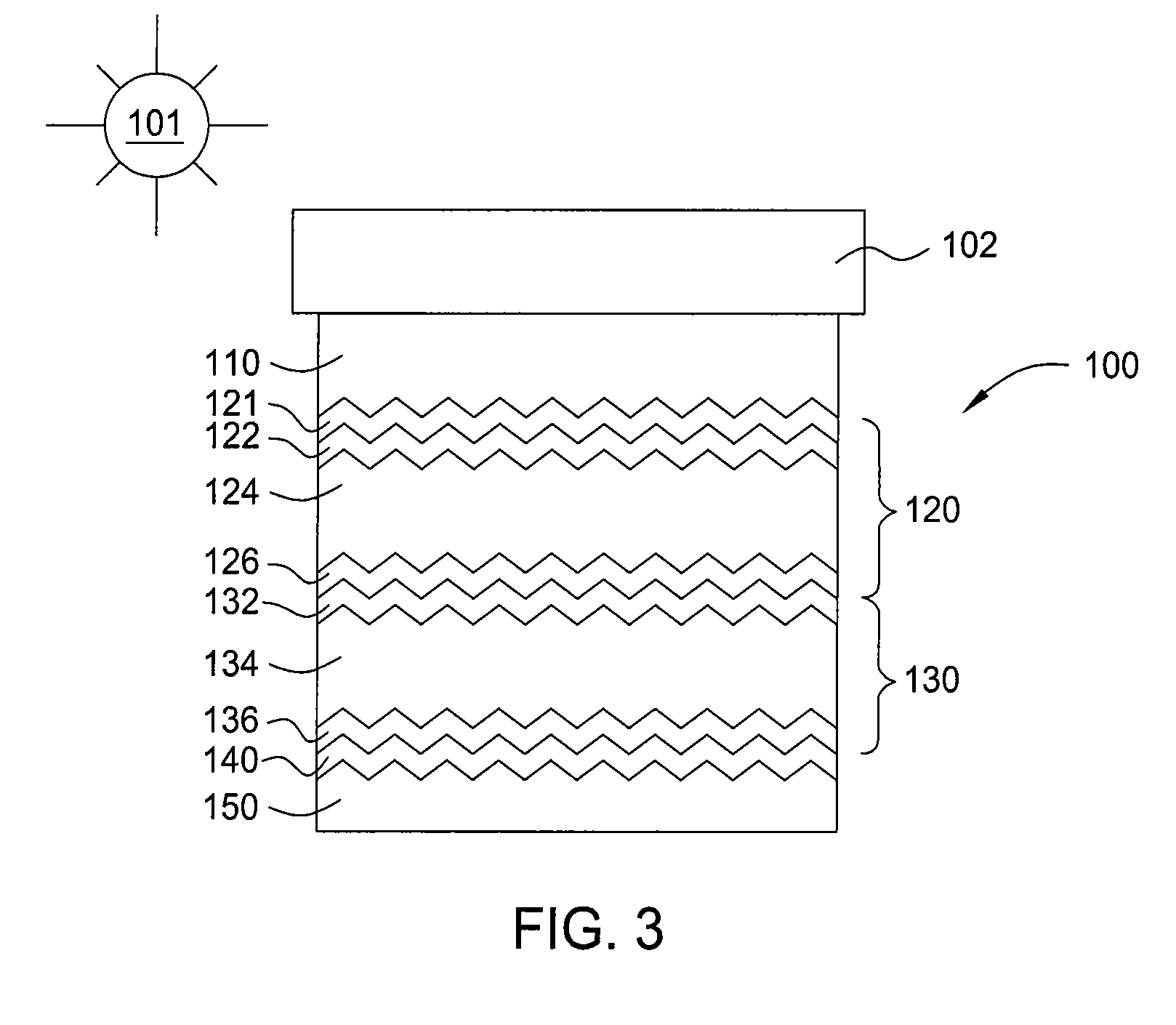

Embodiments of the present invention generally relate to solar cells and methods and apparatuses for forming the same. More particularly, embodiments of the present invention relate to thin film multi-junction solar cells and methods and apparatuses for forming the same. Embodiments of the present invention also include an improved thin film silicon solar cell, and methods and apparatus for forming the same, where one or more of the layers in the solar cell comprises at least one amorphous silicon layer that has improved electrical characteristics and mechanical properties, and is capable of being deposited at rates many times faster than conventional amorphous silicon deposition processes.

Owner:APPLIED MATERIALS INC

Thin Film Silicon Solar Cell Device With Amorphous Window Layer

InactiveUS20100132774A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationMicrocrystalline siliconSilicon cell

Owner:APPLIED MATERIALS INC

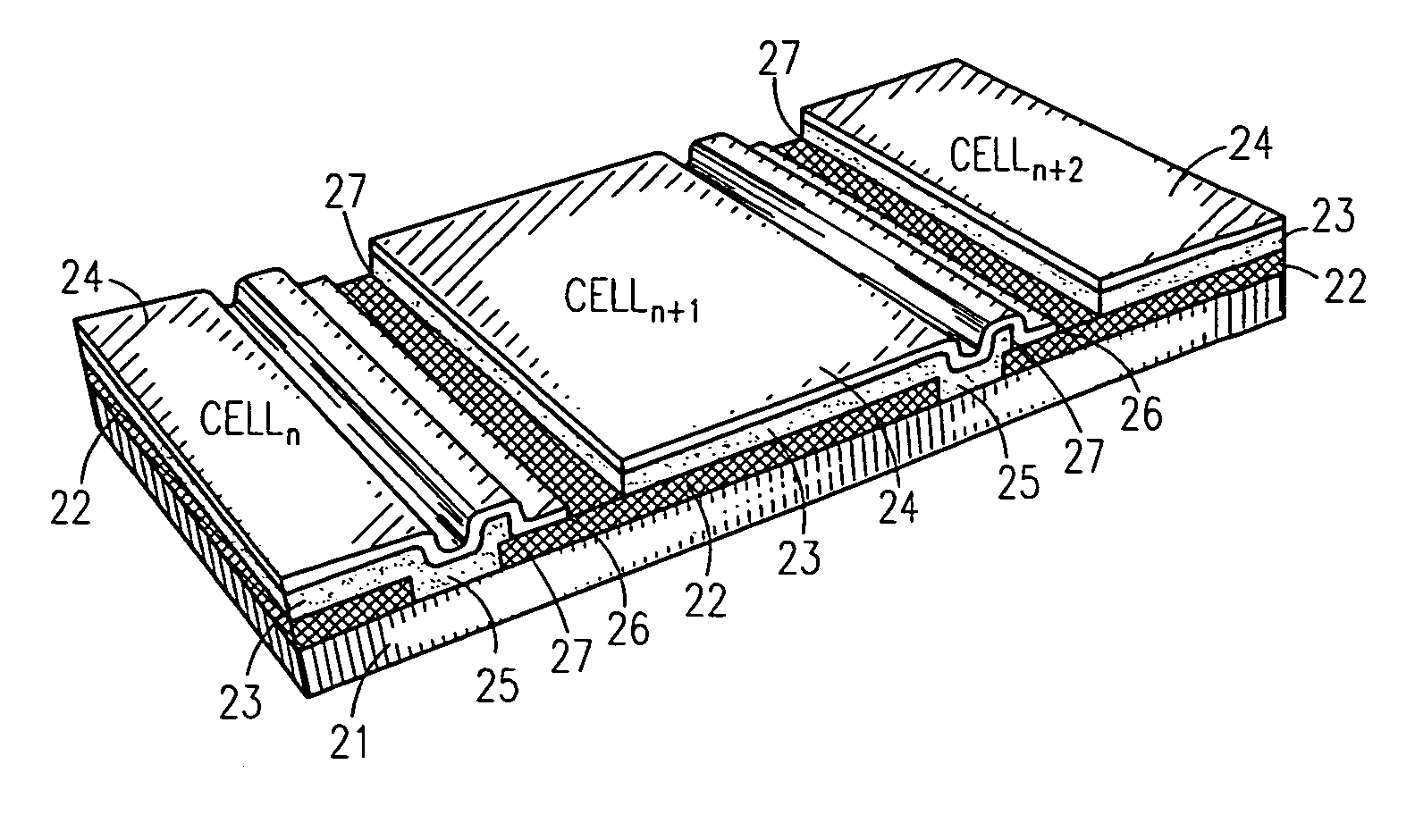

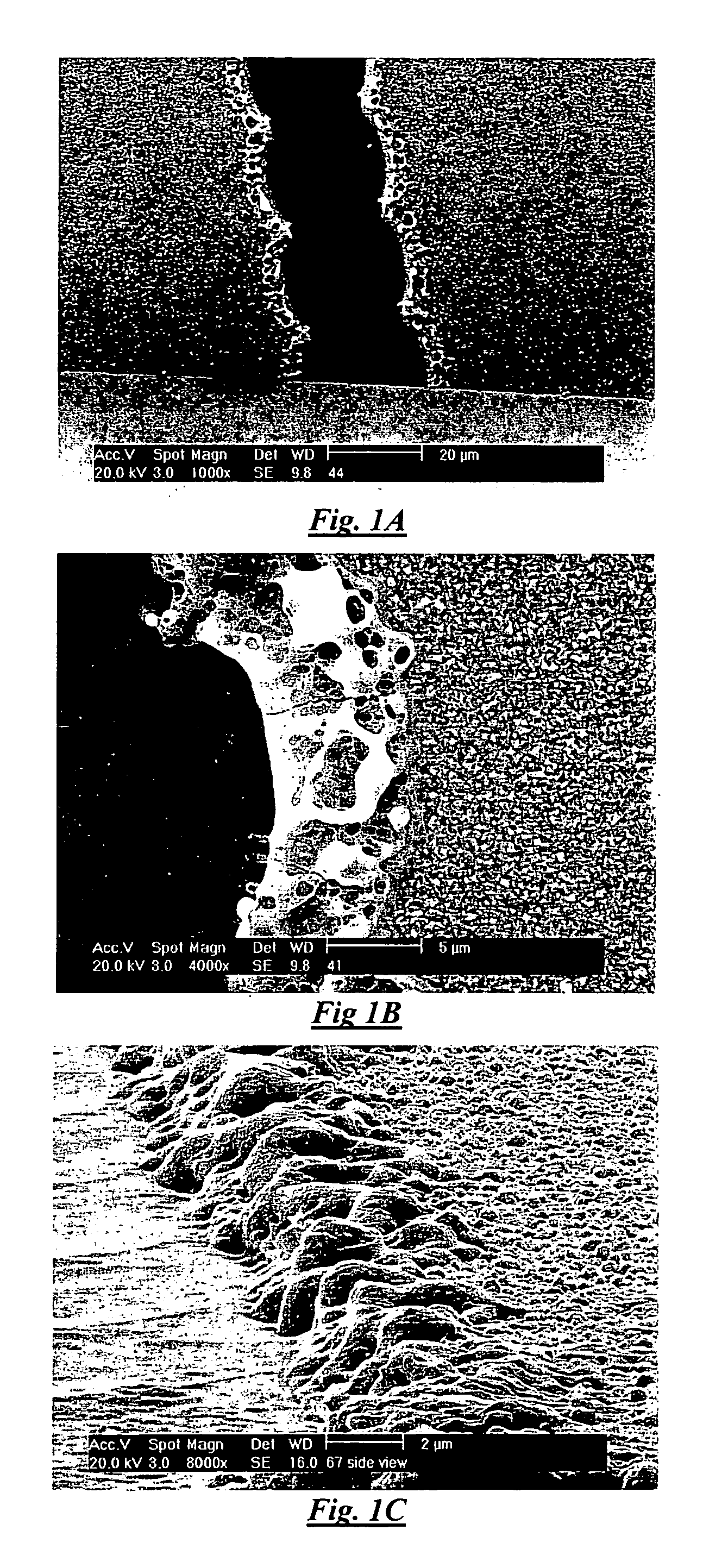

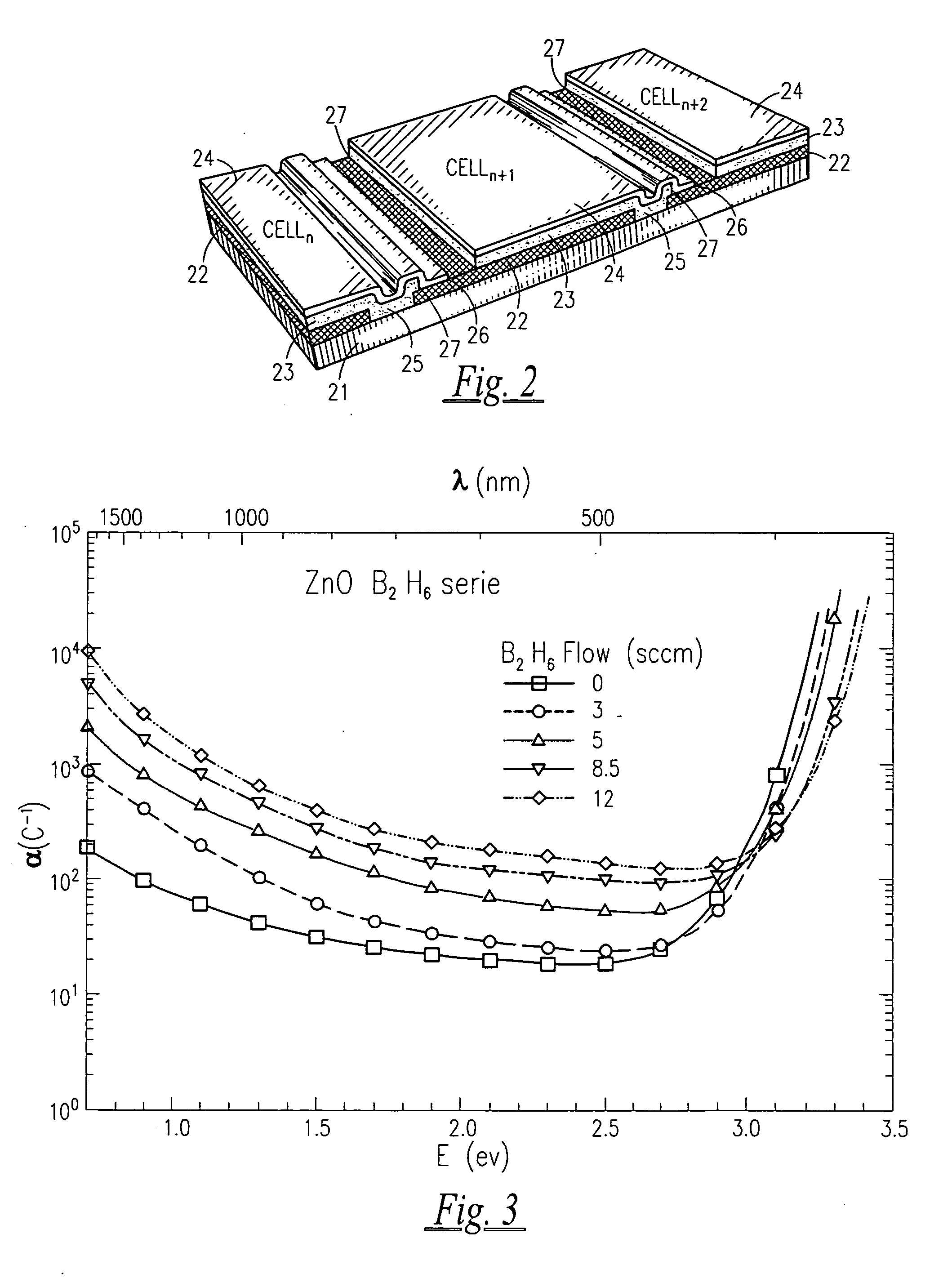

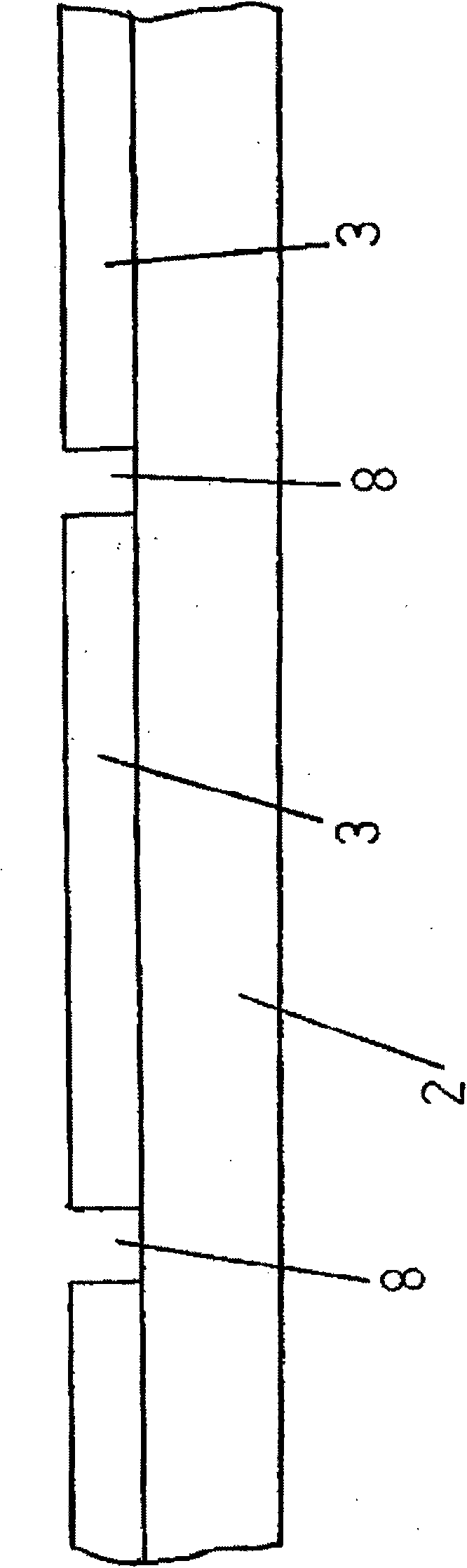

Laser structuring for manufacture of thin film silicon solar cells

InactiveUS20050272175A1Semiconductor/solid-state device manufacturingDiodeSilicon solar cellThin film silicon solar cell

A method of manufacturing thin-film, series connected silicon solar cells having a ZnO TCO layer, for example, using an ultraviolet scribing laser to scribe said ZnO TCO layer to form relatively smooth walls through said TCO layer.

Owner:OERLIKON TRADING AG TRUEBBACH

Silicon thin-film solar cell and manufacturing method therefor

ActiveCN101179087APrevent leakageGood weather resistanceSemiconductor/solid-state device manufacturingDiodeCell layerMoisture resistance

The invention relates a thin film silicon solar cell and the manufacturing method thereof; the thin film silicon solar cell is widely applied to the energy-saving electronic products such as the lawn lambs, the yard lambs, etc. The thin film silicon solar cell consists of the large-scale integrated tandem type cell units, uses a transparent conducting basal-plate as the substrate, and comprises a front electrode layer, a thin film cell layer, a back electrode layer and a back layer which are sequentially superposed; the elementary cell consisting of the tandem type cell units is provided with an insulation groove etched by the laser around the cell, and a screen-printed back paint layer within the groove having the performances of insulation, welding resistance, moisture resistance, and acid and alkali resistance. The thin film silicon solar cell provided by the invention can not only prevent the short circuit and the leakage current around the cell, but also prevent the moisture in the air from entering the cell with causing the deliquescence.

Owner:李毅

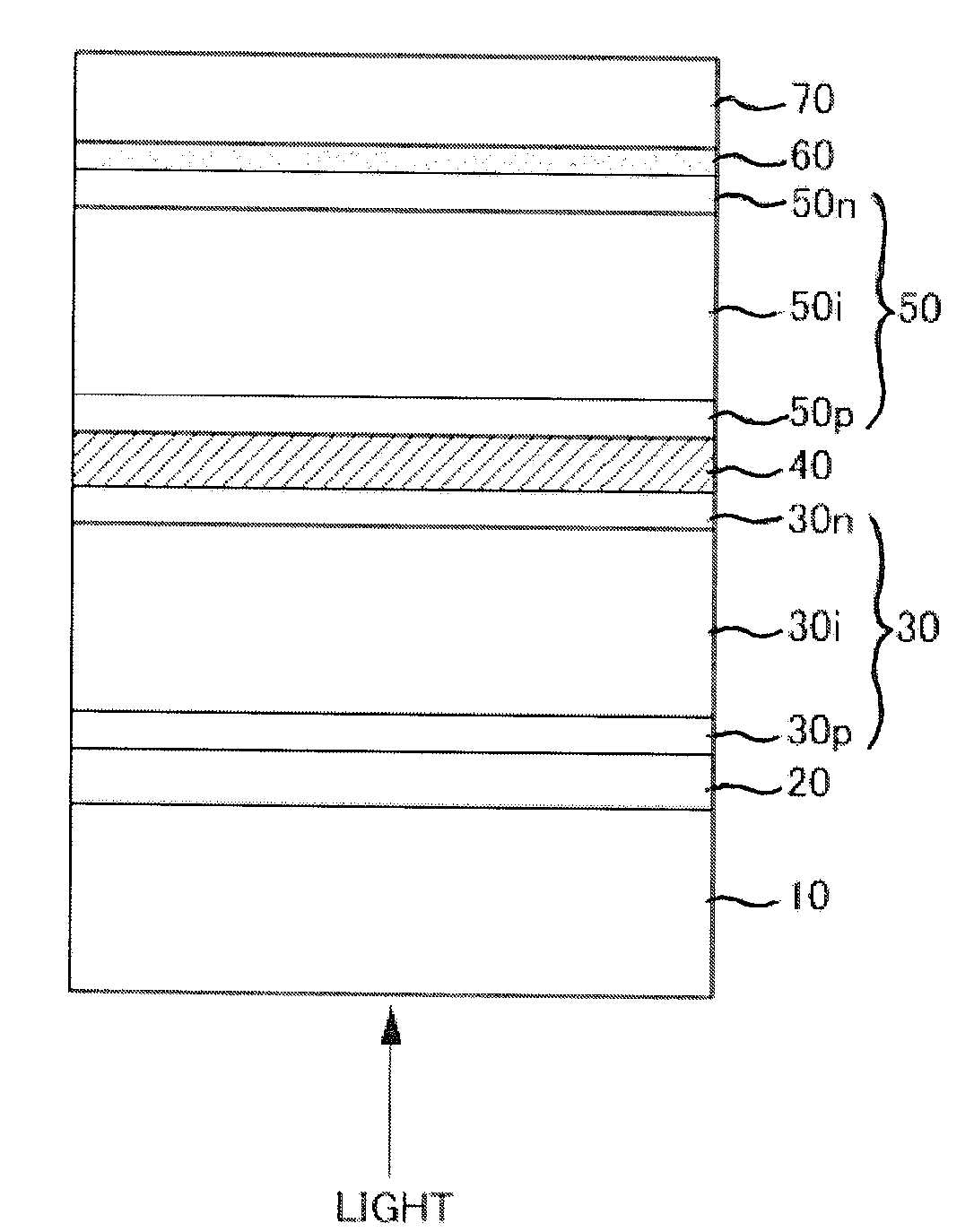

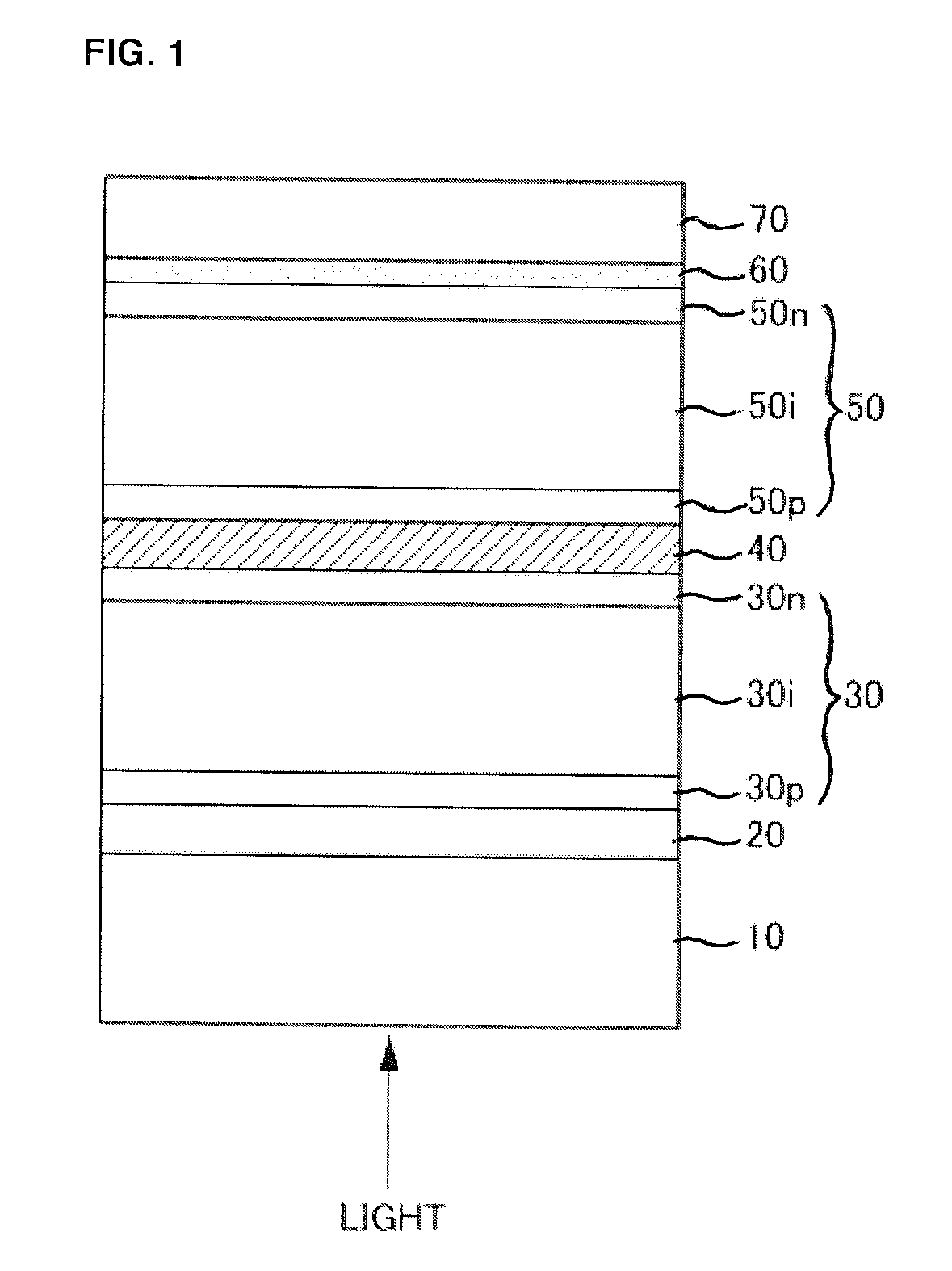

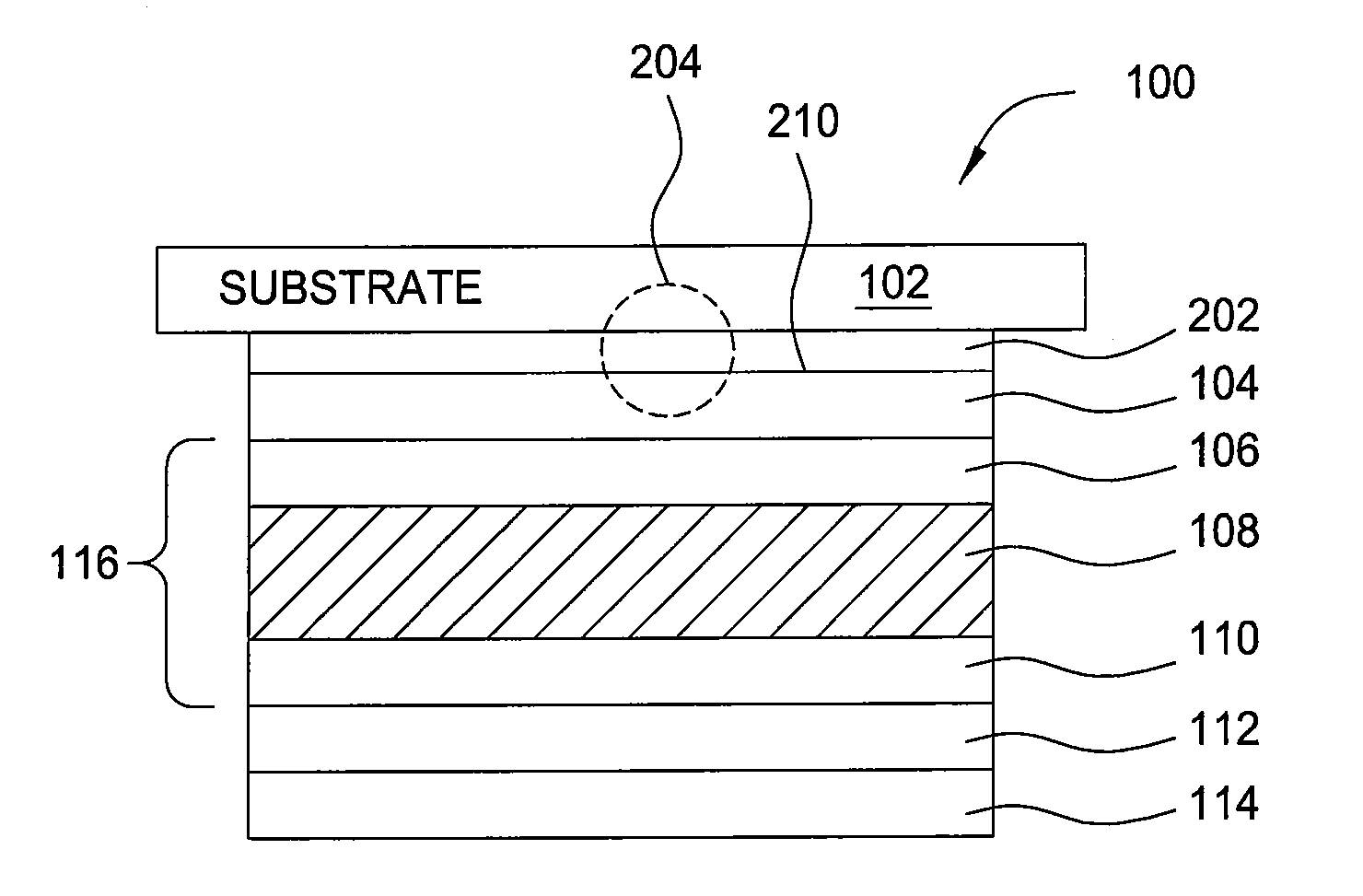

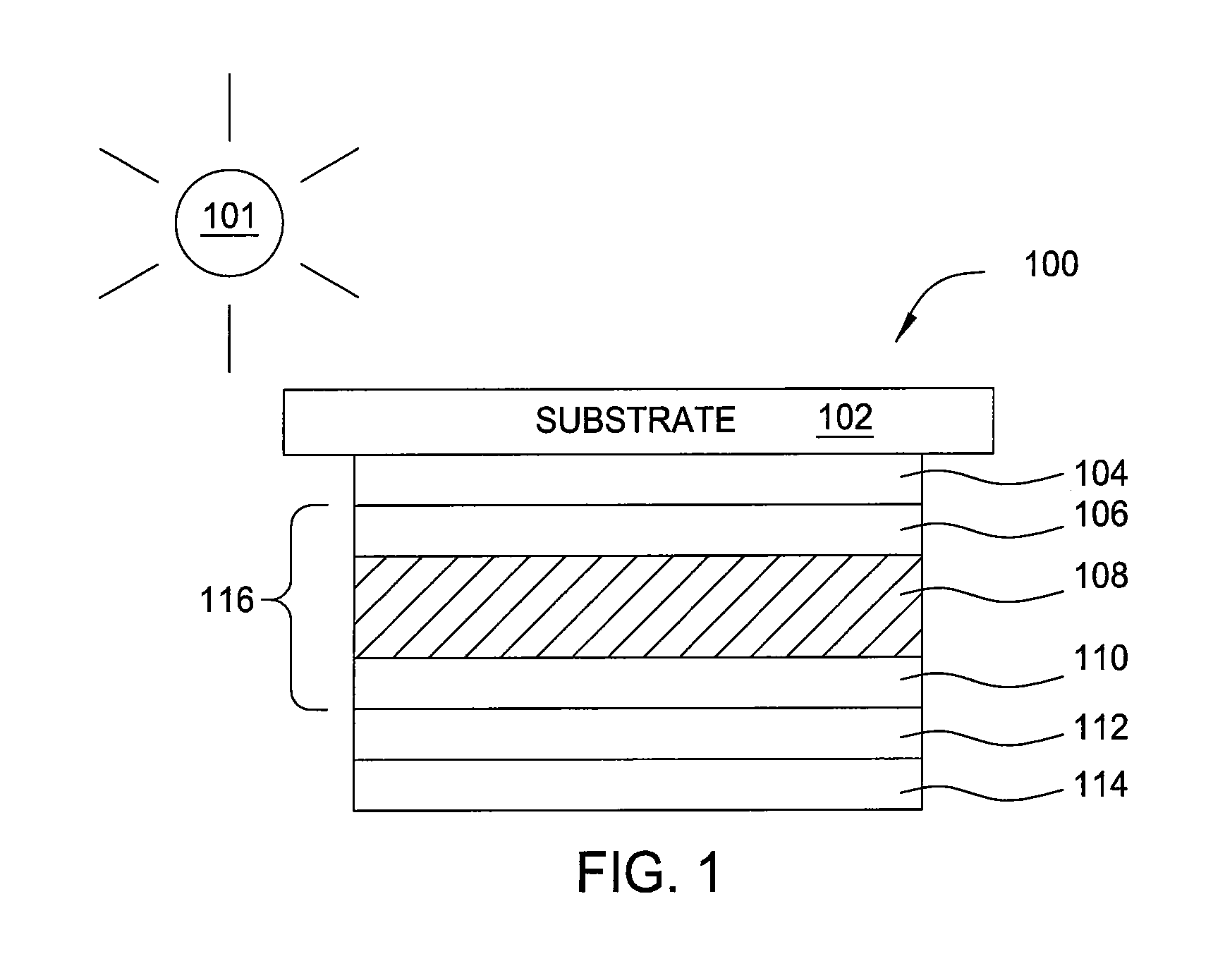

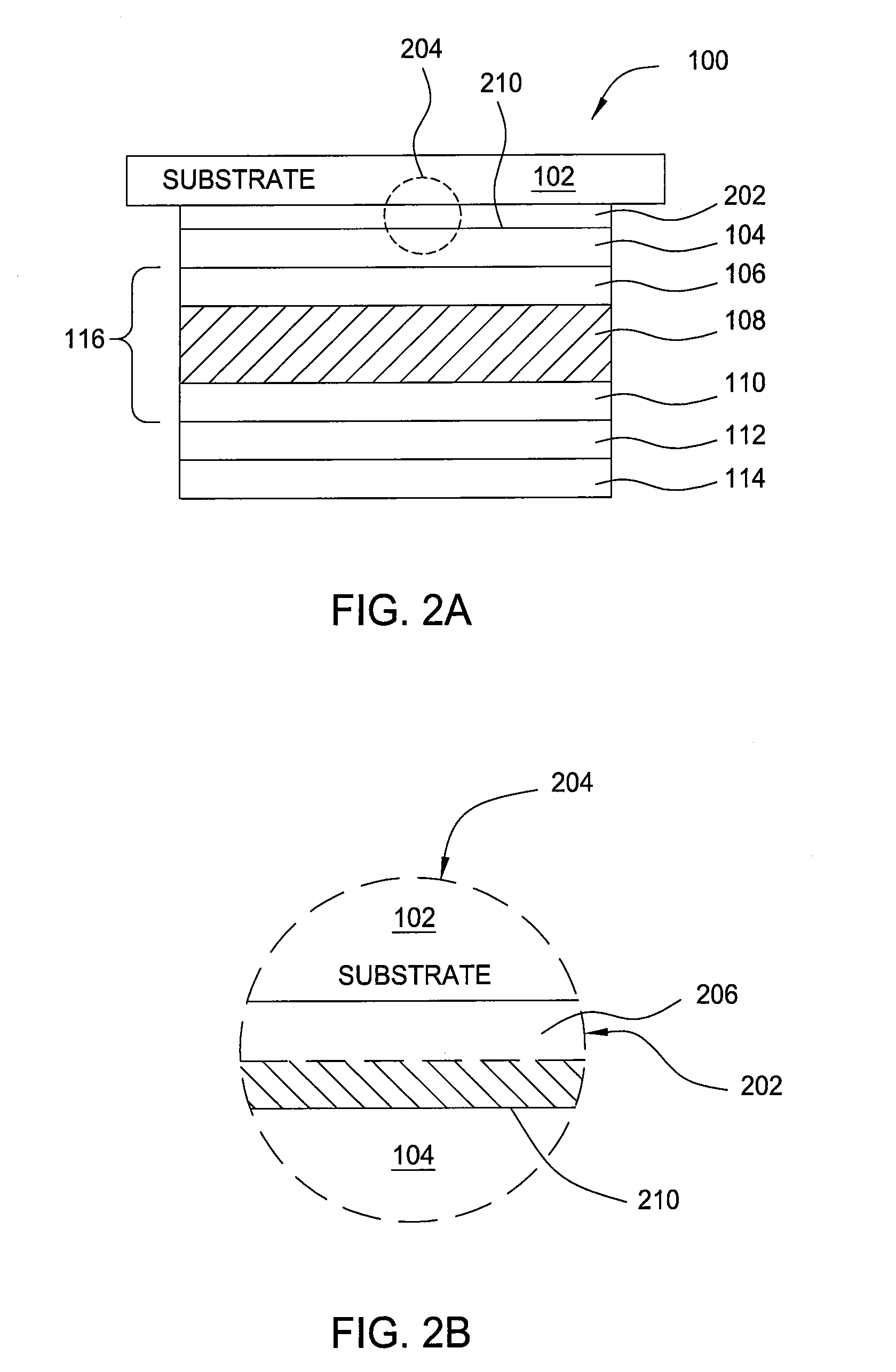

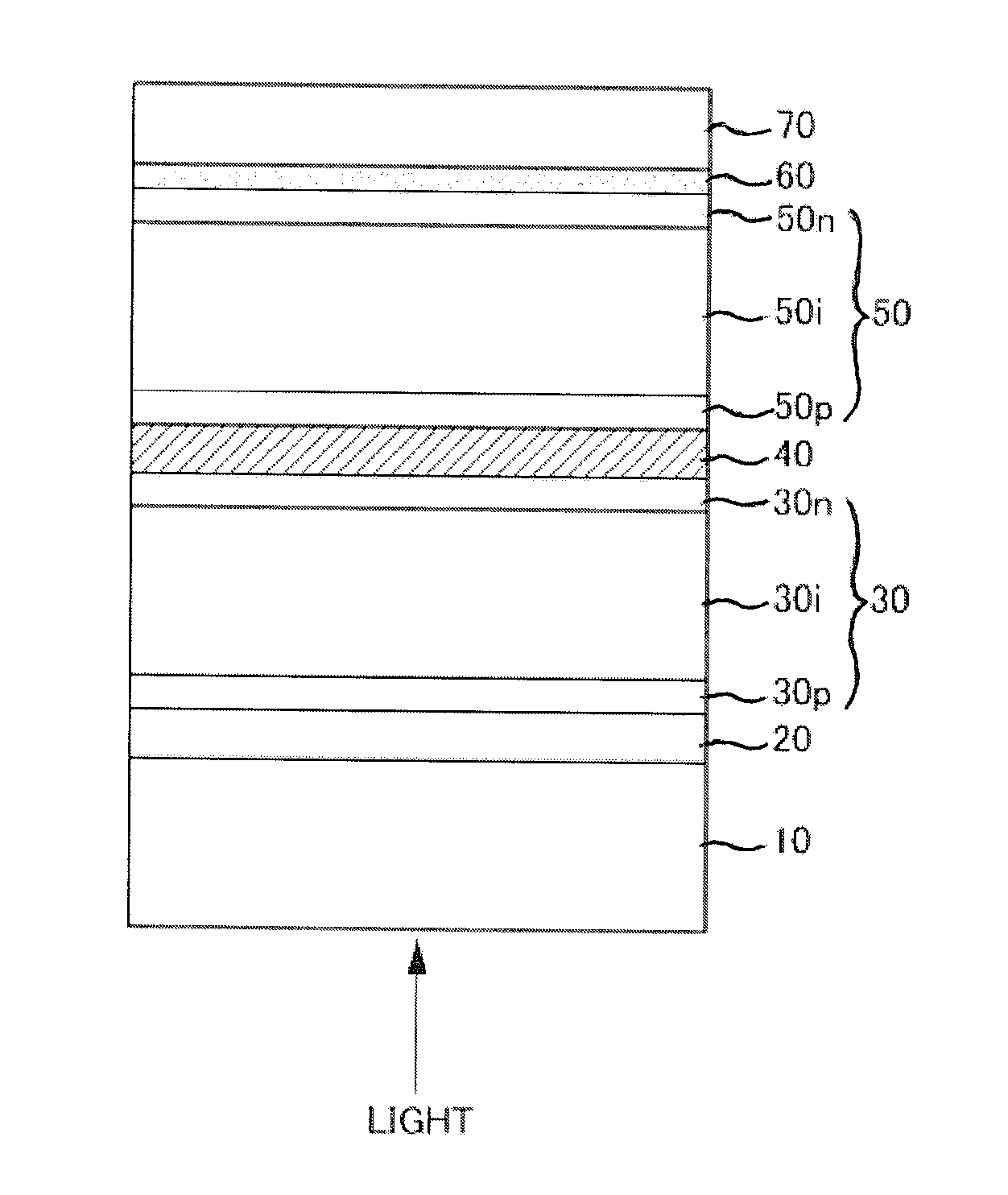

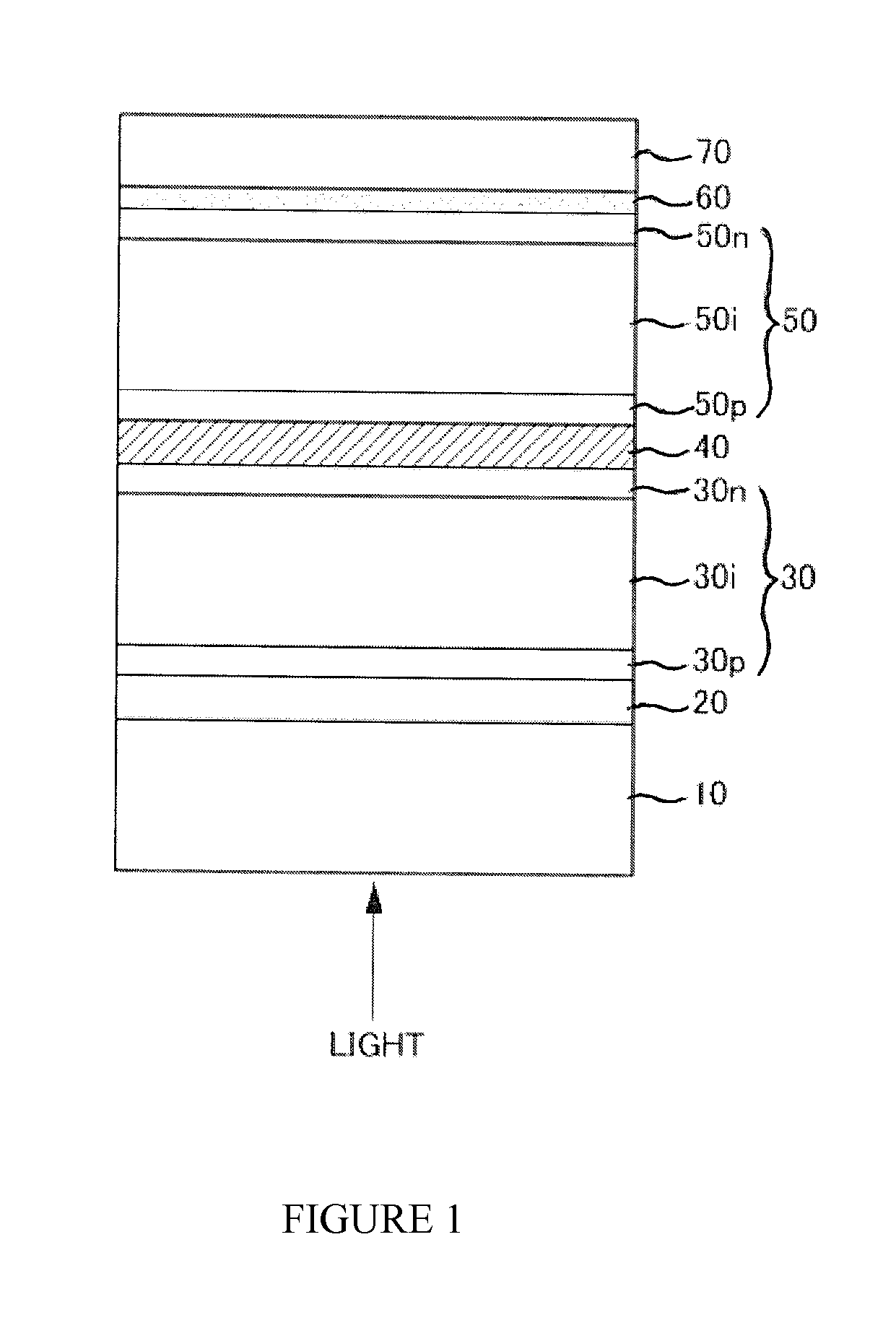

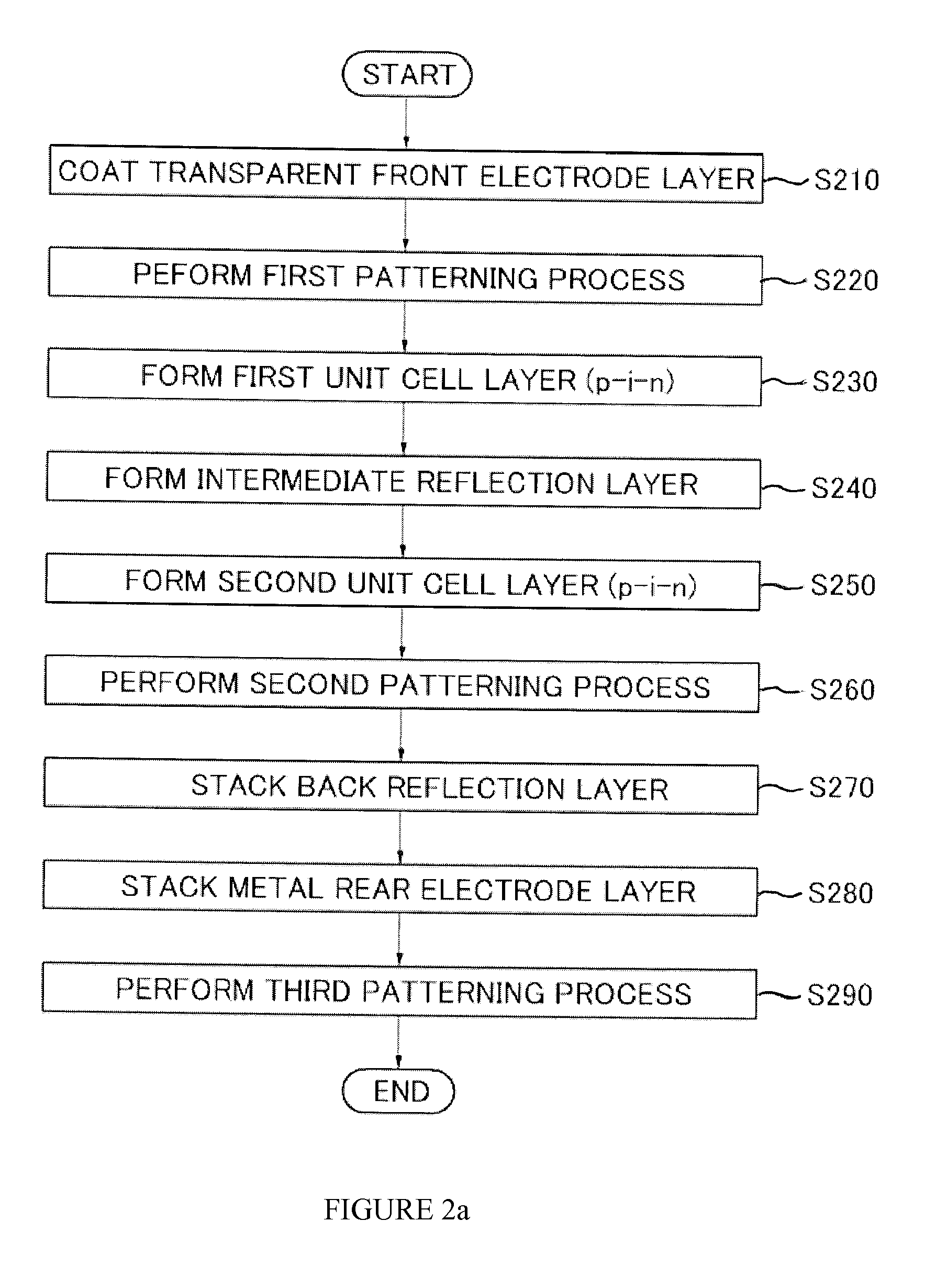

Tandem thin-film silicon solar cell and method for manufacturing the same

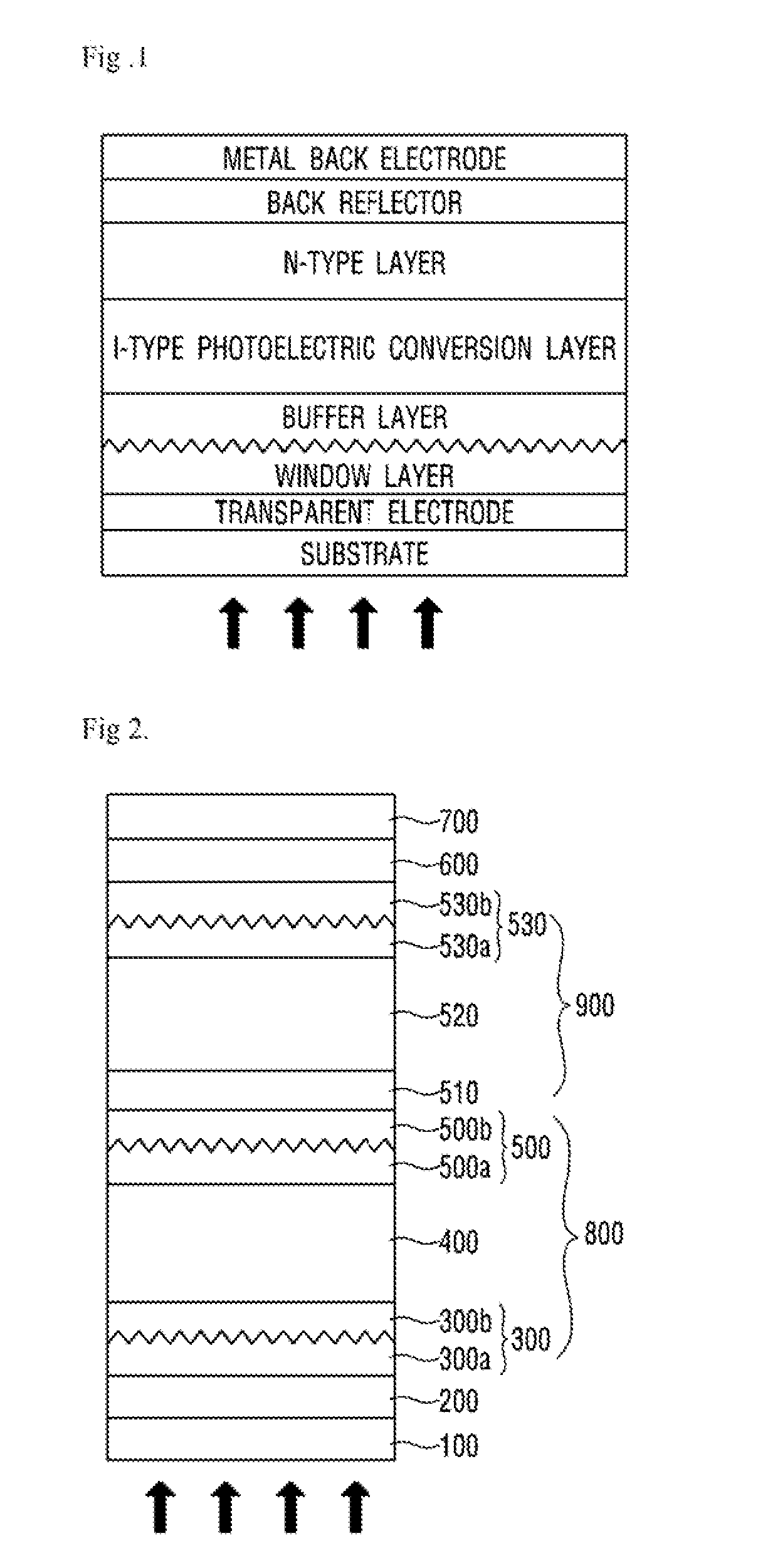

InactiveUS20090293936A1Increase oxygen concentrationFinal product manufacturePV power plantsSilicon solar cellOxygen

A tandem thin-film silicon solar cell comprises a transparent substrate, a first unit cell positioned on the transparent substrate, the first unit cell comprising a p-type window layer, an i-type absorber layer and an n-type layer, an intermediate reflection layer positioned on the first unit cell, the intermediate reflection layer including a hydrogenated n-type microcrystalline silicon oxide of which the oxygen concentration is profiled to be gradually increased and a second unit cell positioned on the intermediate reflection layer, the second unit cell comprising a p-type window layer, an i-type absorber layer and an n-type layer.

Owner:INTELLECTUAL DISCOVERY CO LTD

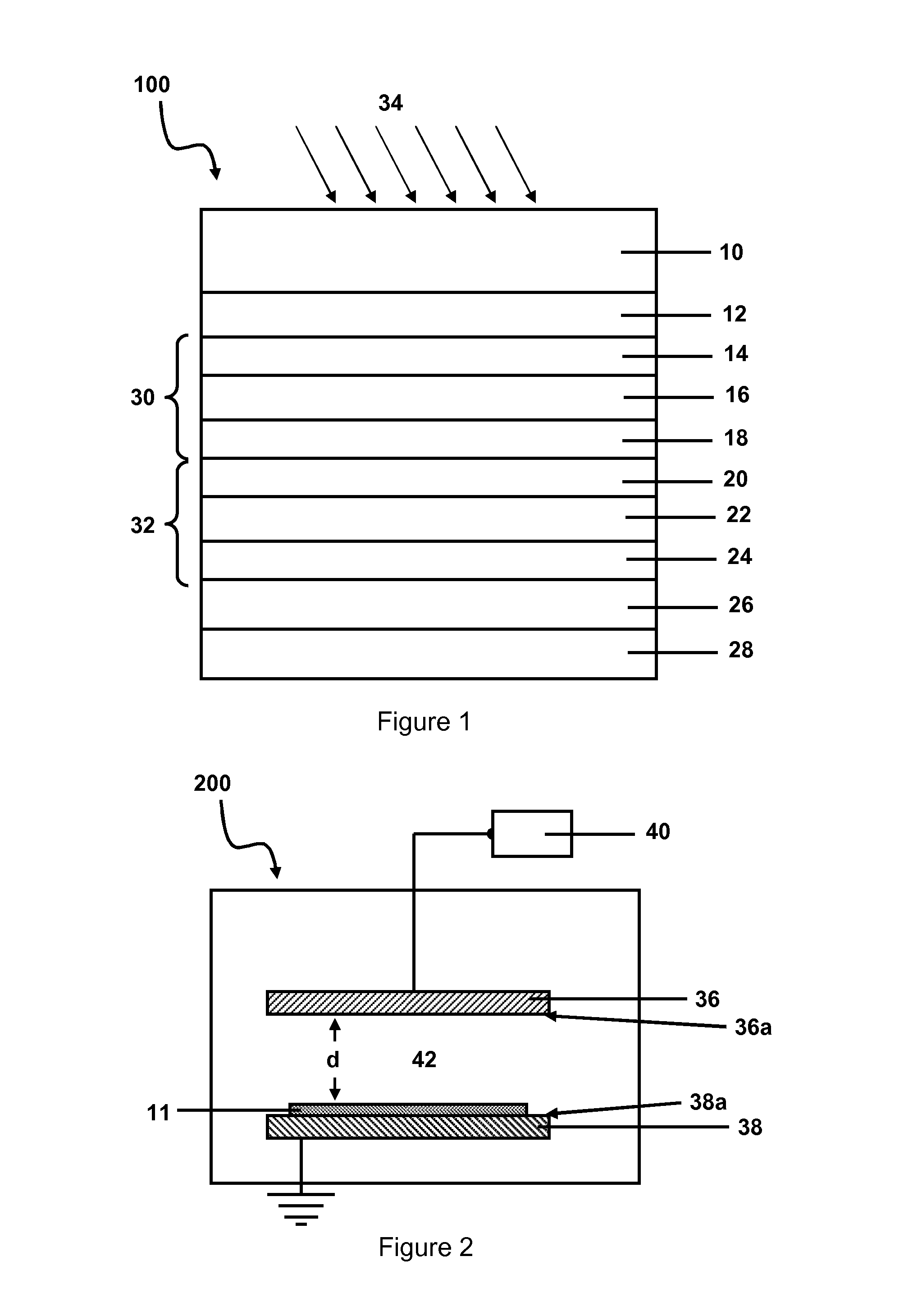

Barrier layer disposed between a substrate and a transparent conductive oxide layer for thin film silicon solar cells

InactiveUS20110088762A1Final product manufactureSemiconductor/solid-state device manufacturingConductive oxideThin film silicon solar cell

A method and apparatus for forming solar cells is provided. In one embodiment, a photovoltaic device includes a barrier layer disposed on a substrate, a TCO layer disposed on the barrier layer, and a p-i-n junction cell formed on the TCO layer. In another embodiment, a method for forming a photovoltaic device includes providing a substrate having a surface, forming a barrier layer on the surface of the substrate, forming a TCO layer on a top surface of the barrier layer, and forming a p-i-n junction cell on the TCO layer.

Owner:APPLIED MATERIALS INC

High frequency plasma CVD apparatus, high frequency plasma CVD method and semiconductor thin film manufacturing method

InactiveUS20100239757A1Solve the real problemEfficient solutionElectric discharge tubesChemical vapor deposition coatingHigh frequency powerSilicon solar cell

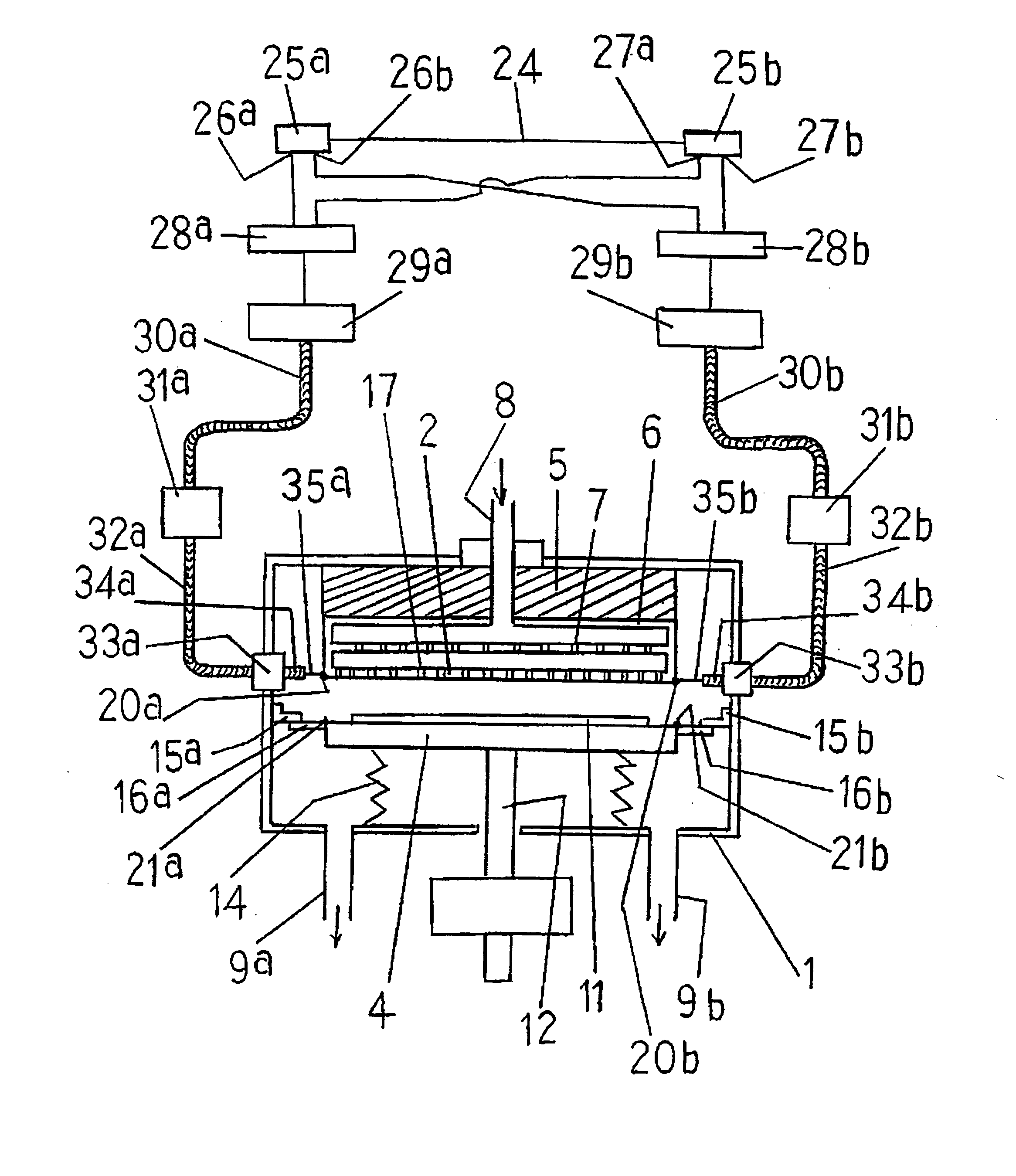

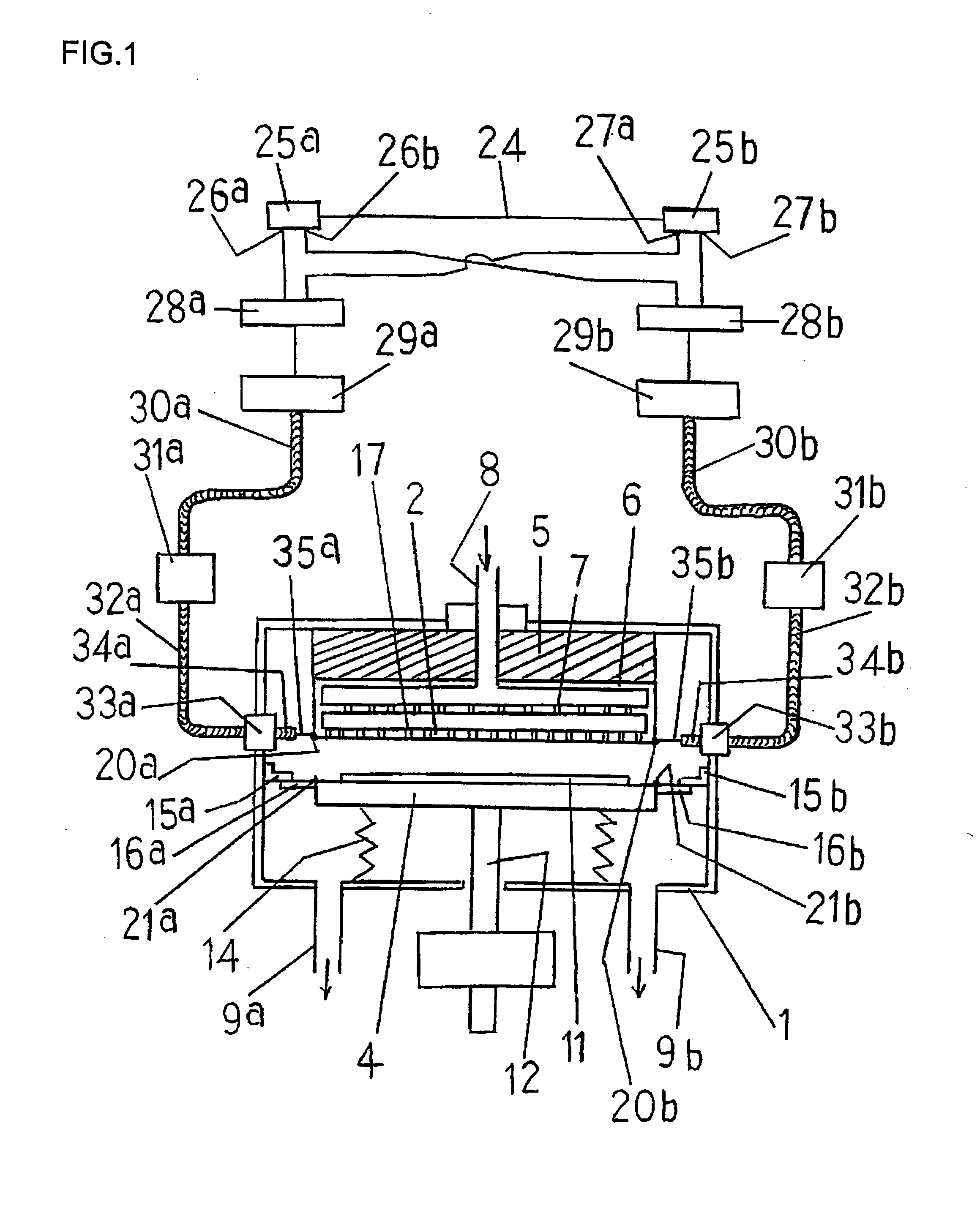

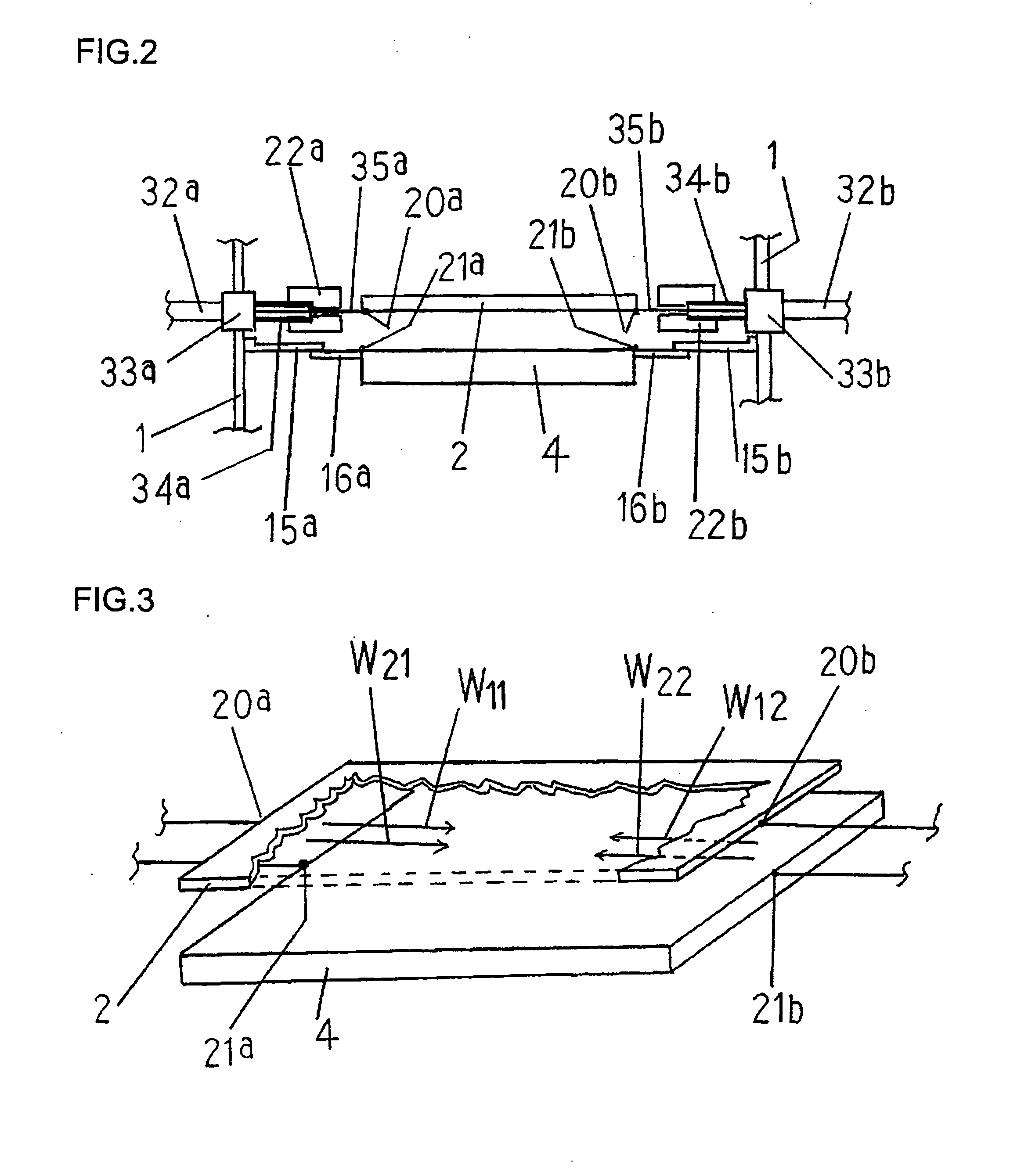

Provided are large area and uniform VHF plasma CVD apparatus and method wherein a plasma generating source constitutes the VHF plasma CVD apparatus for manufacturing a tandem-type thin film silicon solar cell, and influences of standing waves, generation of harmful plasma other than between a pair of electrodes and supply power consumption other than between the pair of electrodes are suppressed. First and second power feed points are arranged on an electrode at positions facing each other. A distance between the power feed points is set at an integral multiple of a half of the wavelength of the using power, and a pulse power separated in terms of time is supplied. The pulse power is outputted from two phase-variable double output high frequency power supplies which can perform pulse modulation. Thus, a first standing wave wherein the anti-node position matches with positions of the first and the second power feed points, and a second standing wave wherein the node position matches with positions of the first and the second power feed points are alternately generated in terms of time.

Owner:MURATA MASAYOSHI

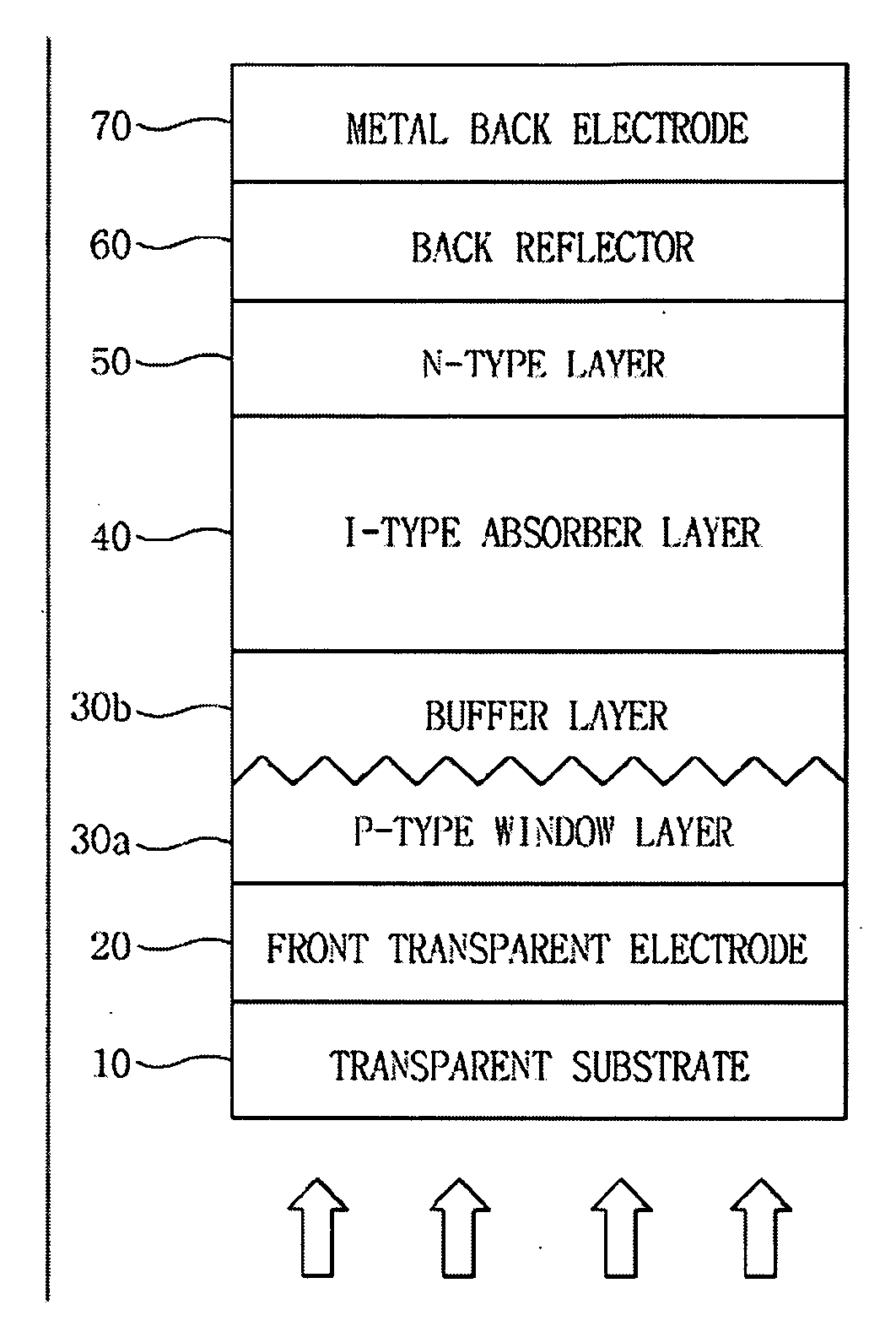

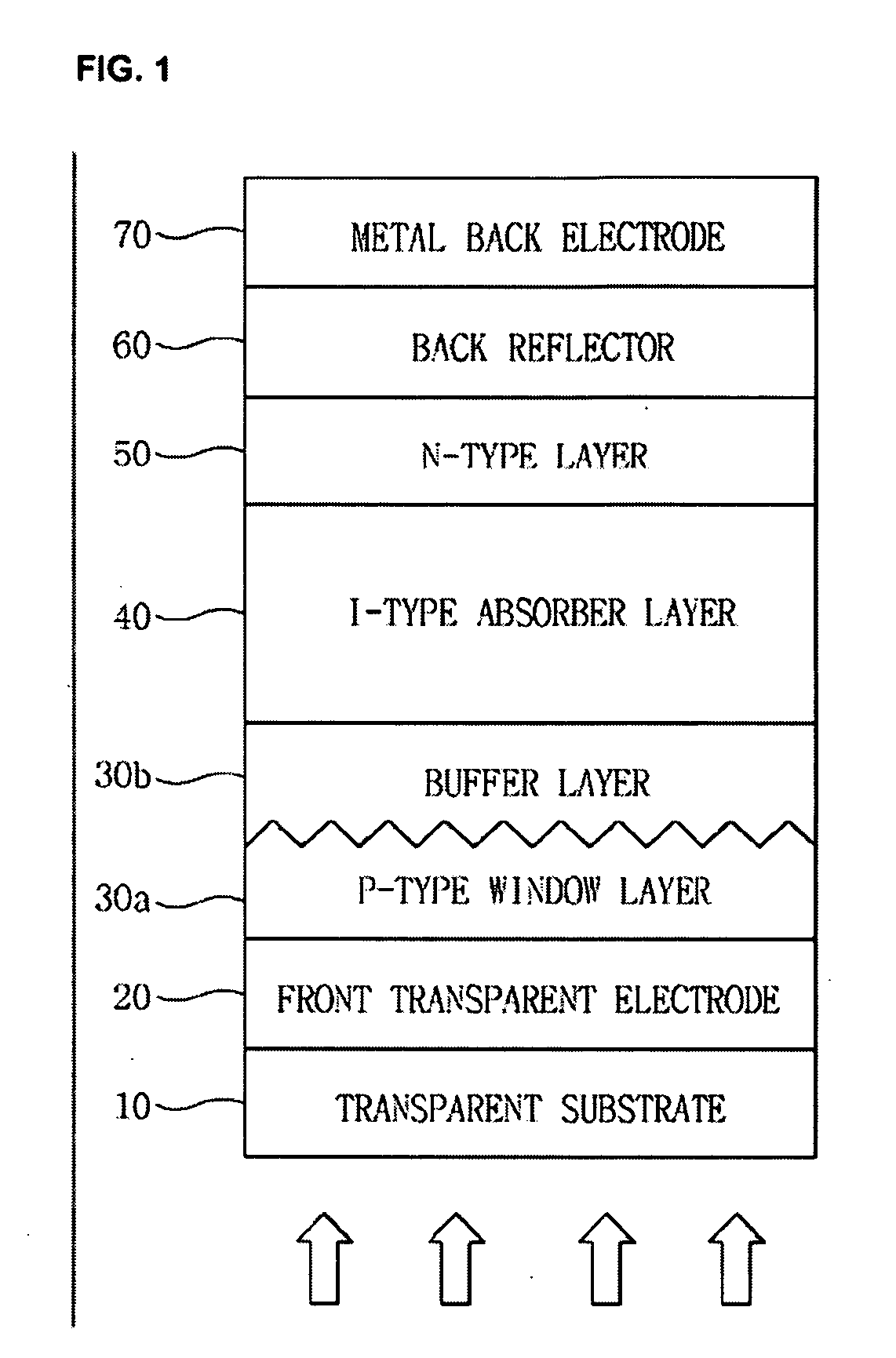

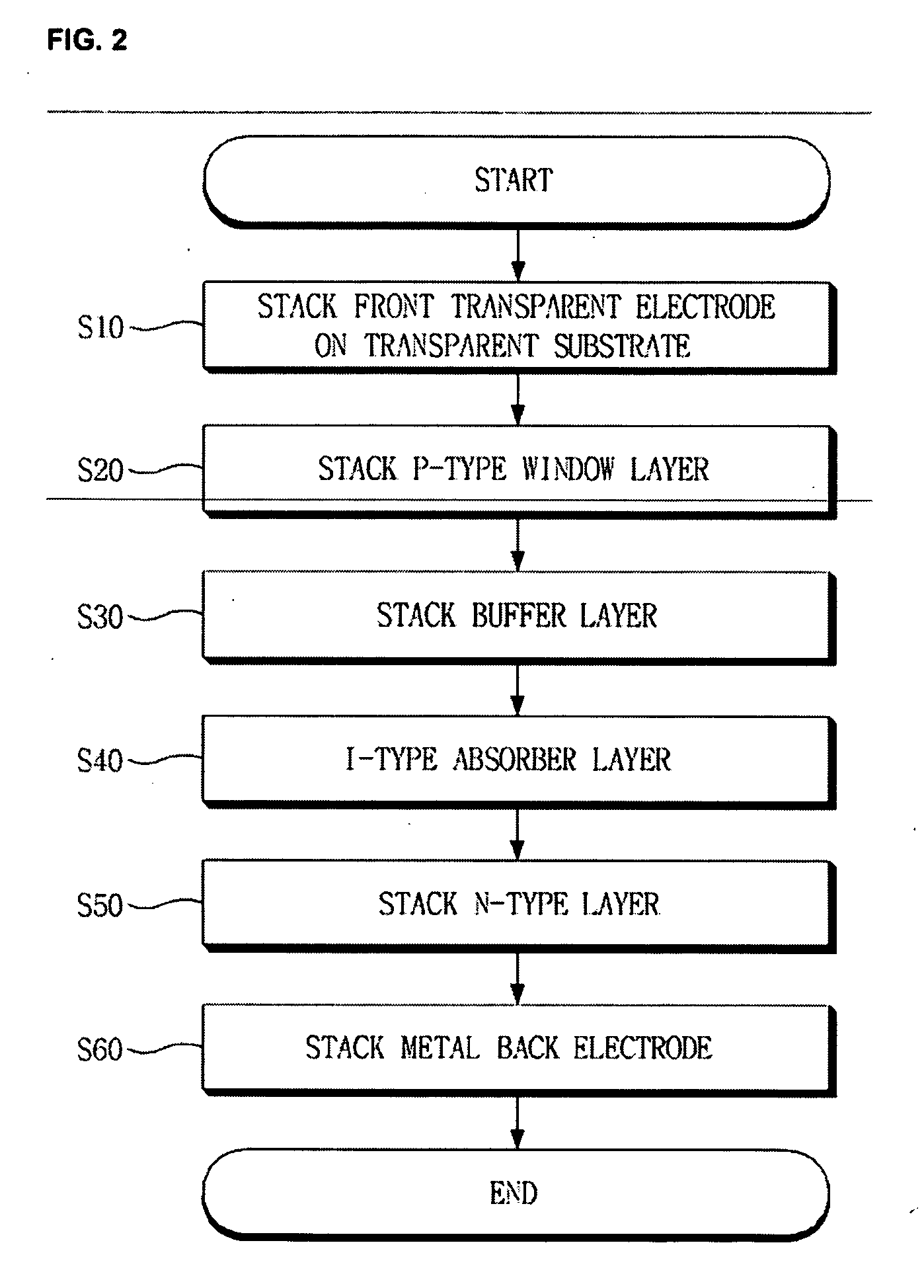

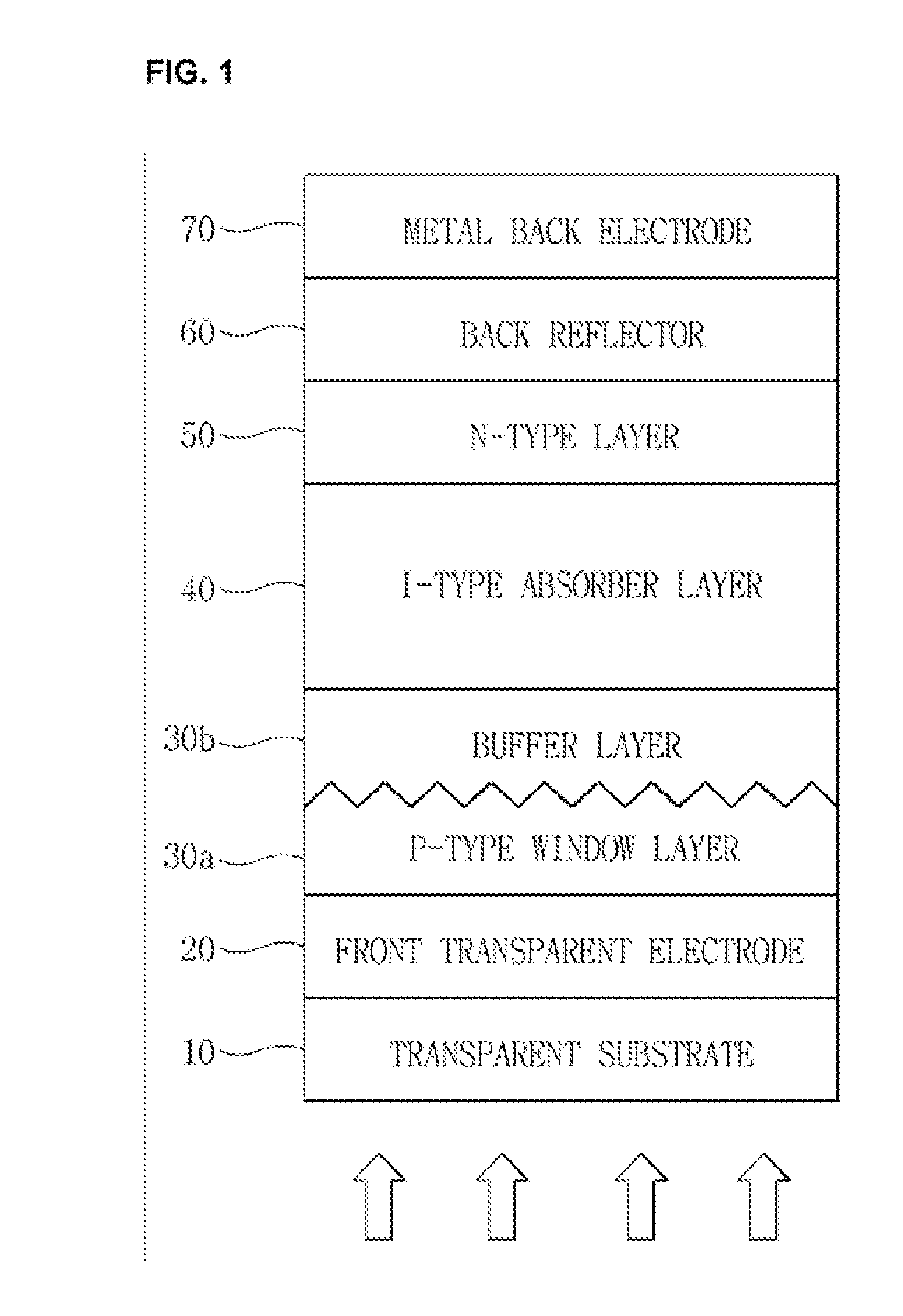

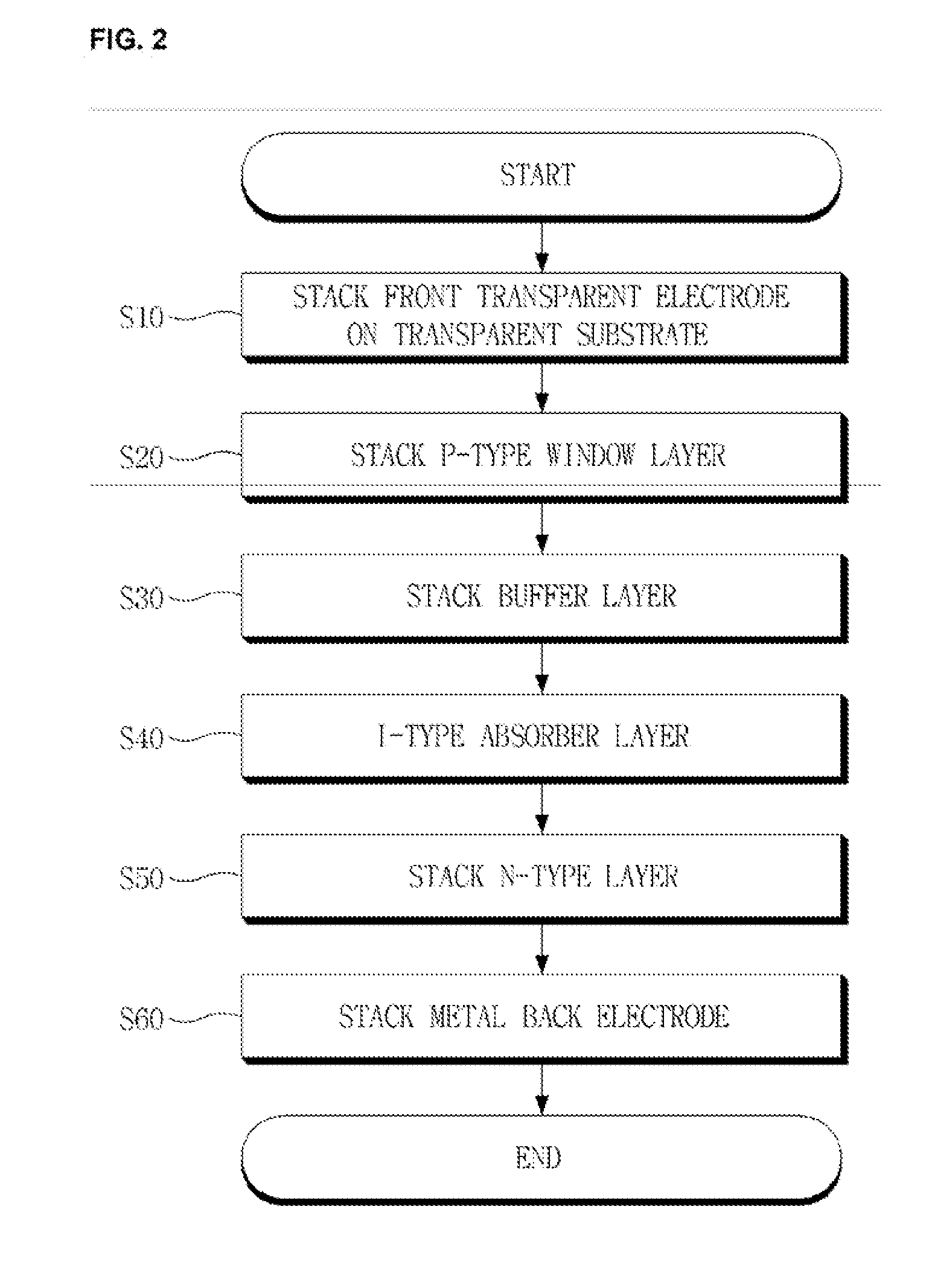

Thin film silicon solar cell and manufacturing method thereof

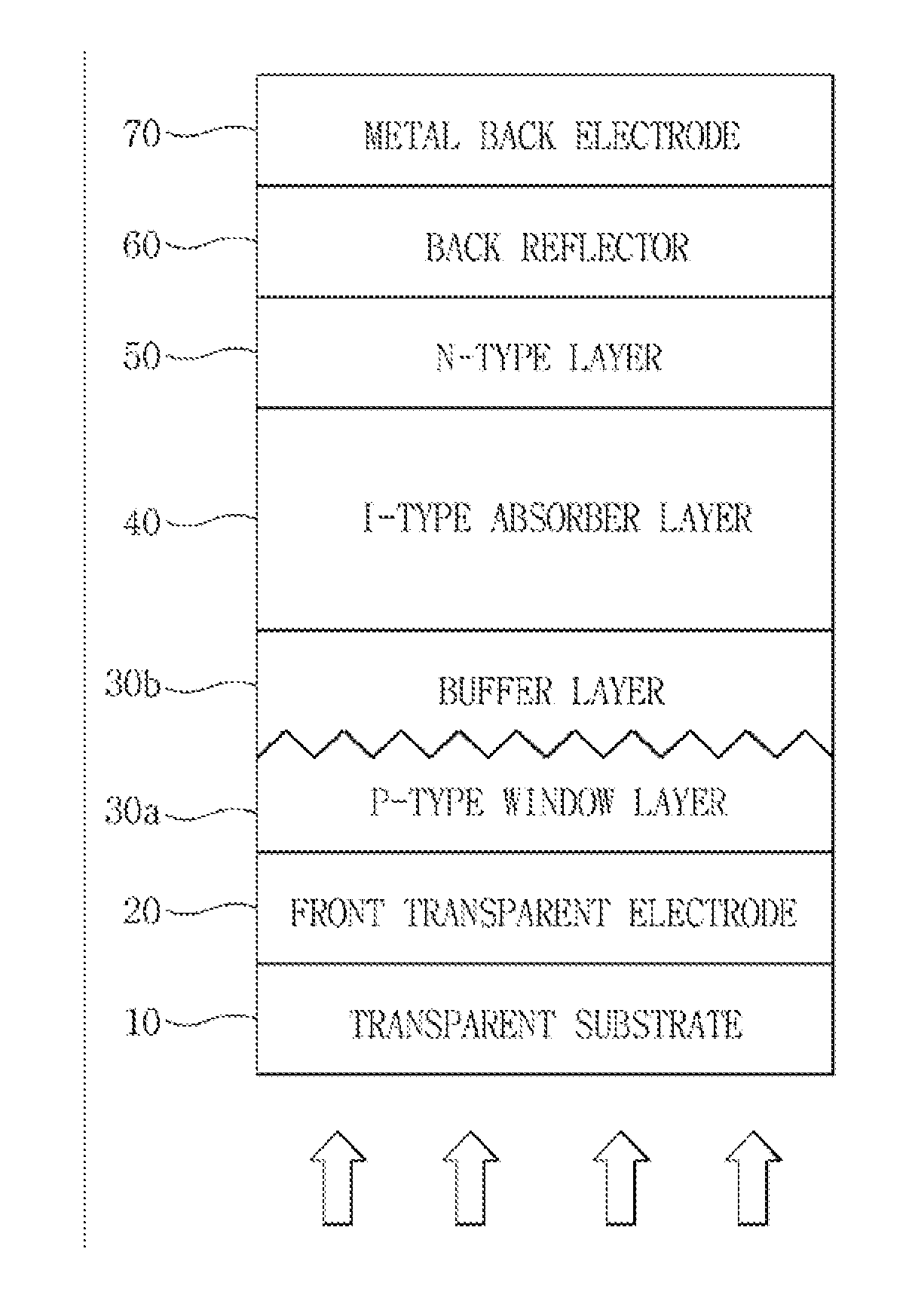

InactiveUS20090255581A1Chemical vapor deposition coatingPhotovoltaic energy generationElectrical batterySilicon solar cell

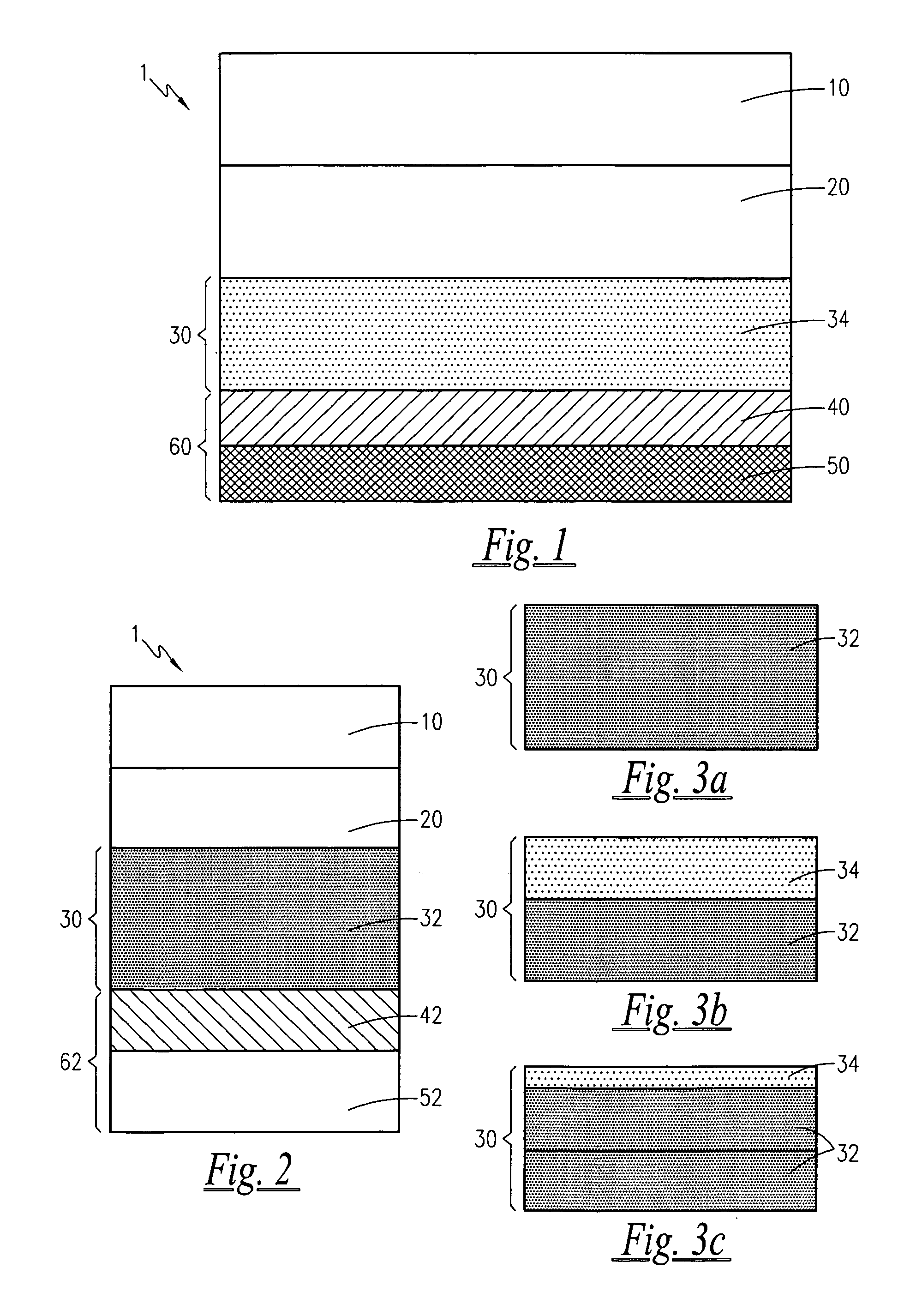

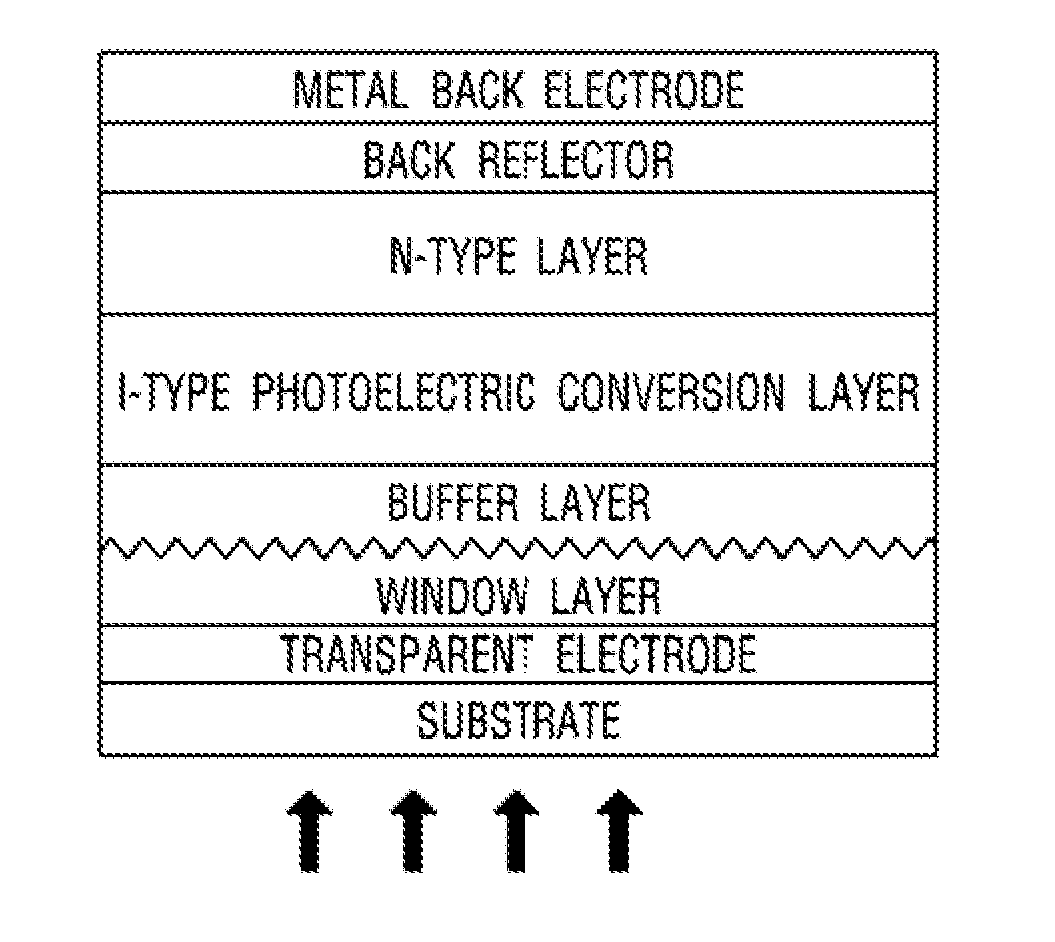

A thin film silicon solar cell comprises a front transparent electrode, a p-type window layer, a buffer layer, an i-type absorber layer, an n-type layer and a metal rear electrode. The front transparent electrode is stacked on a transparent substrate. The p-type window layer is stacked on the front transparent electrode, and has a thickness in a range of 12 nm to 17 nm. The buffer layer is stacked on the p-type window layer, and has a carbon concentration in a range of 0.5 to 3.0 atomic % and a thickness in a range of 3 to 8 nm. The i-type absorber layer is stacked on the buffer layer. The n-type layer is stacked on the i-type absorber layer. The metal rear electrode is stacked on the n-type layer.

Owner:KISCO CORP (KR)

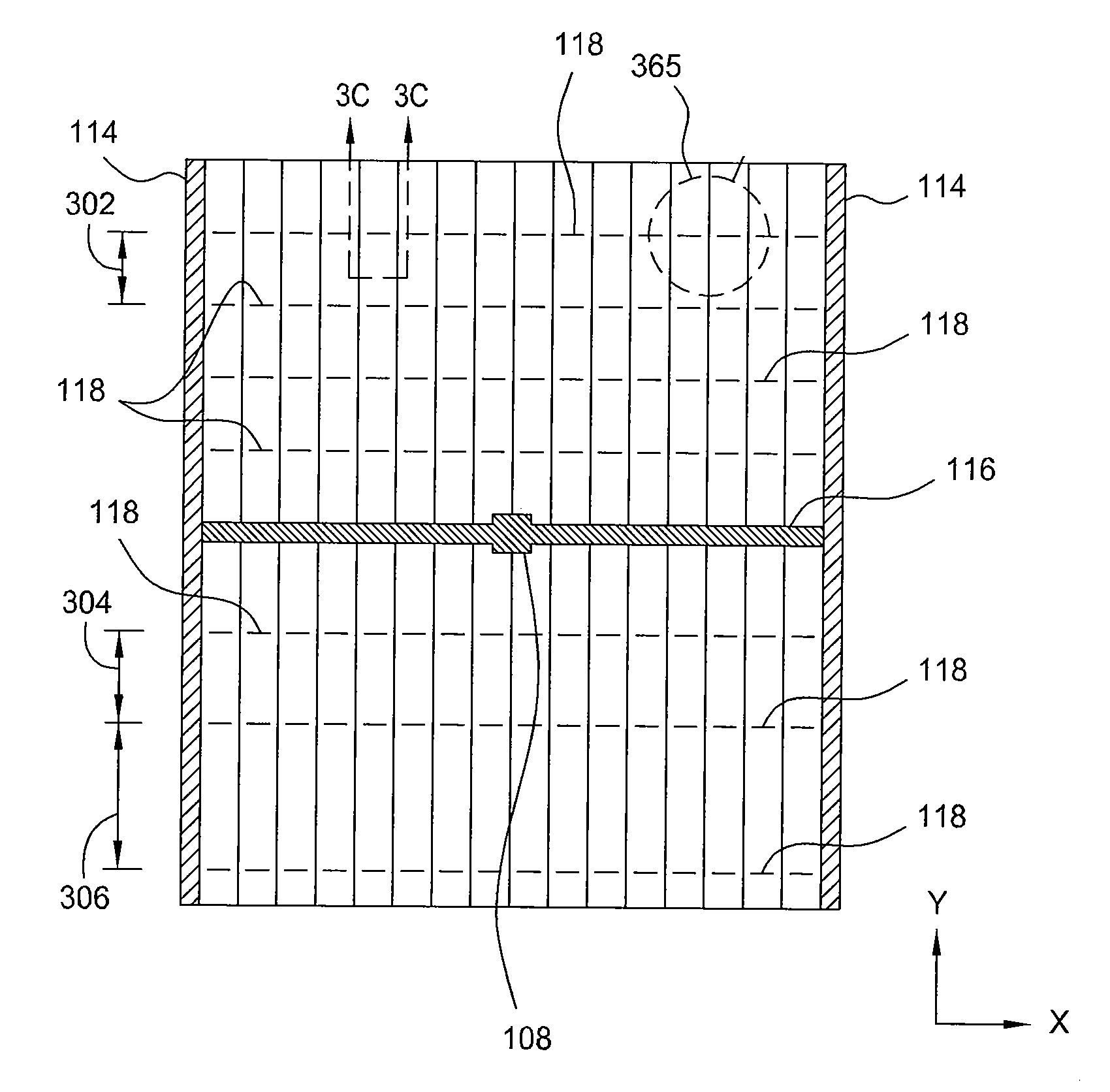

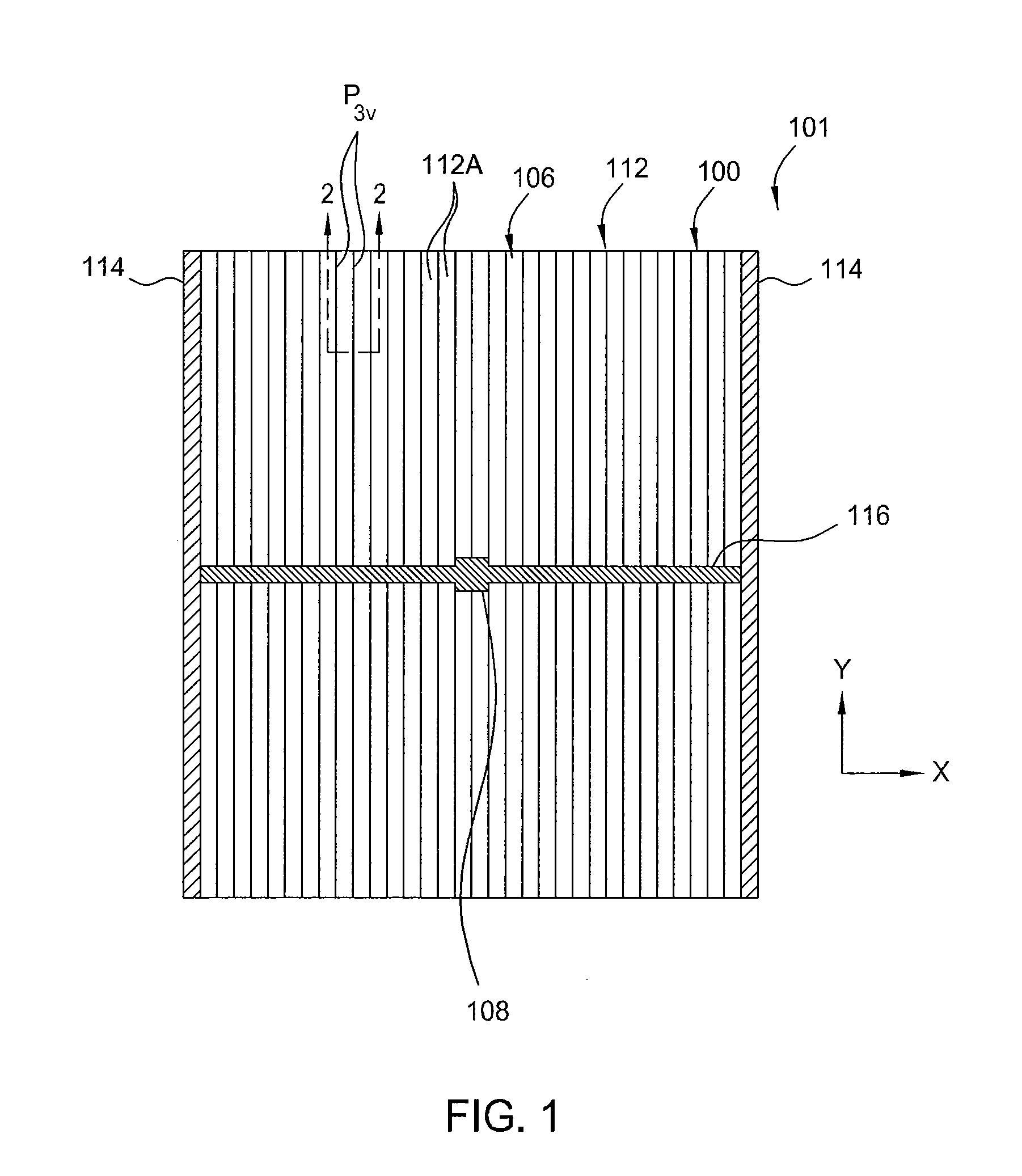

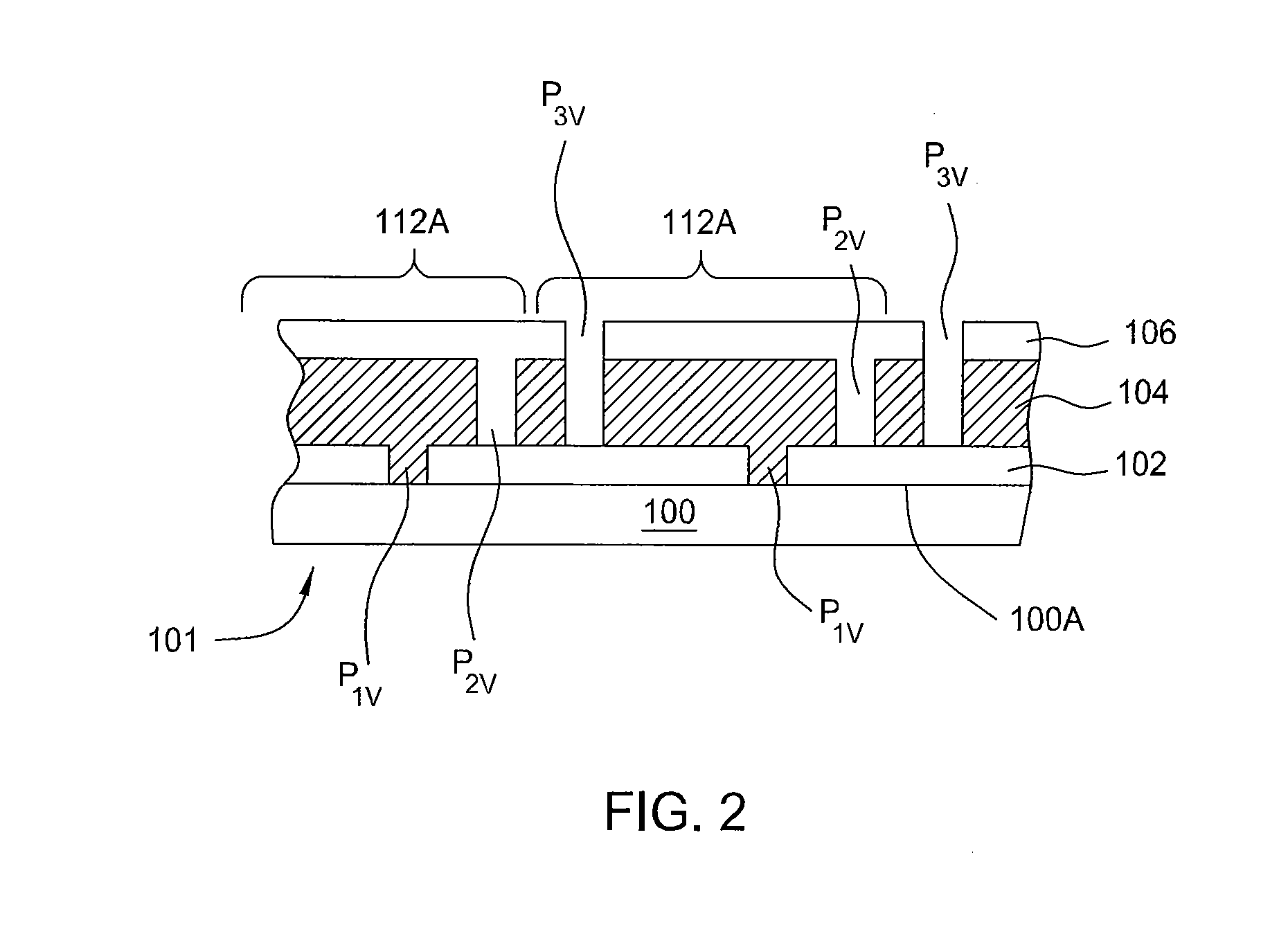

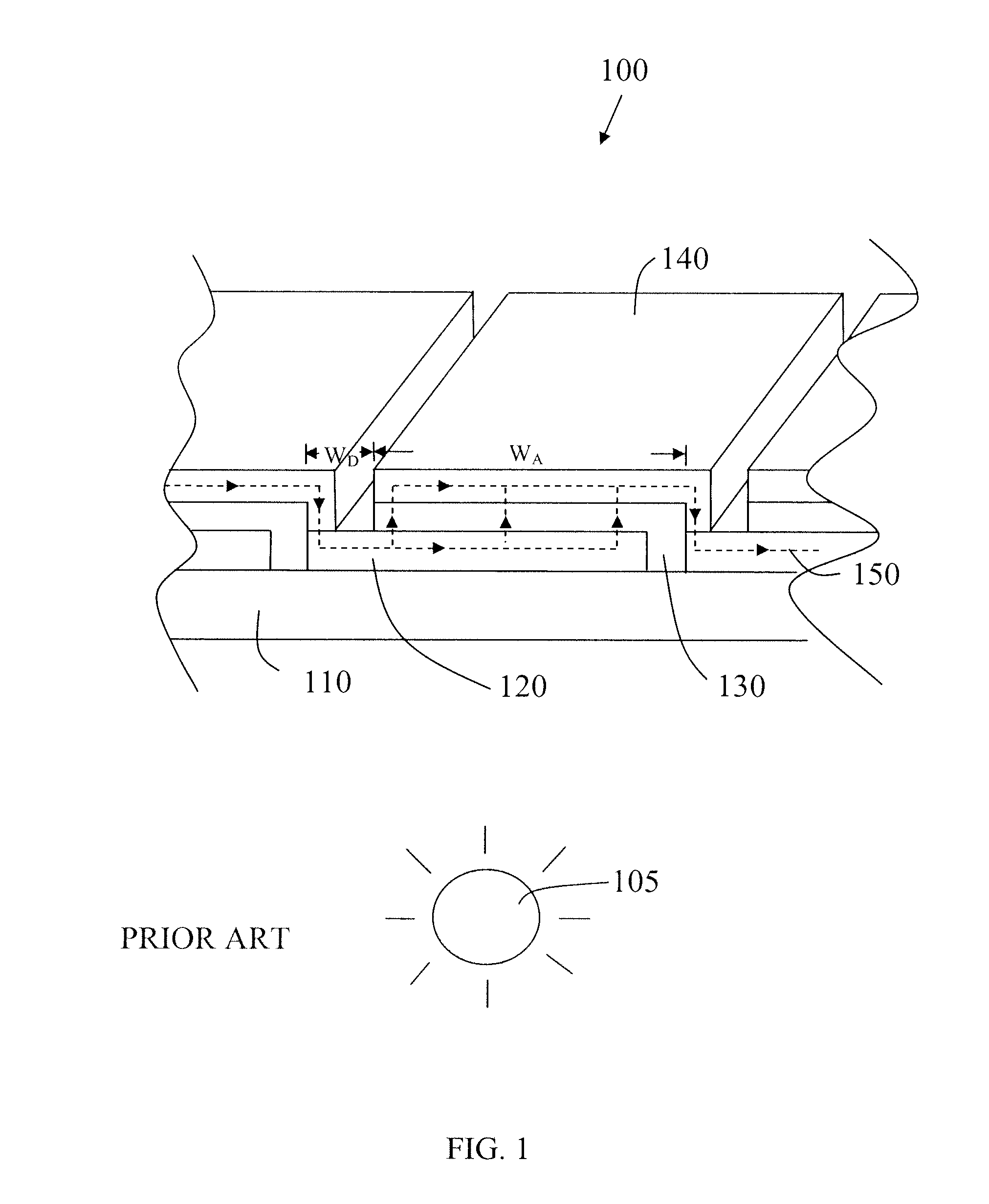

Floating grid module design for thin film silicon solar cells

InactiveUS20110180122A1Enhanced current conductionPV power plantsSemiconductor/solid-state device manufacturingEngineeringElectrical contacts

A photovoltaic device is provided. In one embodiment, a photovoltaic device includes a transparent conductive oxide (TCO) layer deposited over the substrate, and a plurality of electrical conductive paths disposed in electrical contact with the TCO layer, wherein the plurality of electrical conductive paths extend discontinuously across opposing sides of the substrate.

Owner:APPLIED MATERIALS INC

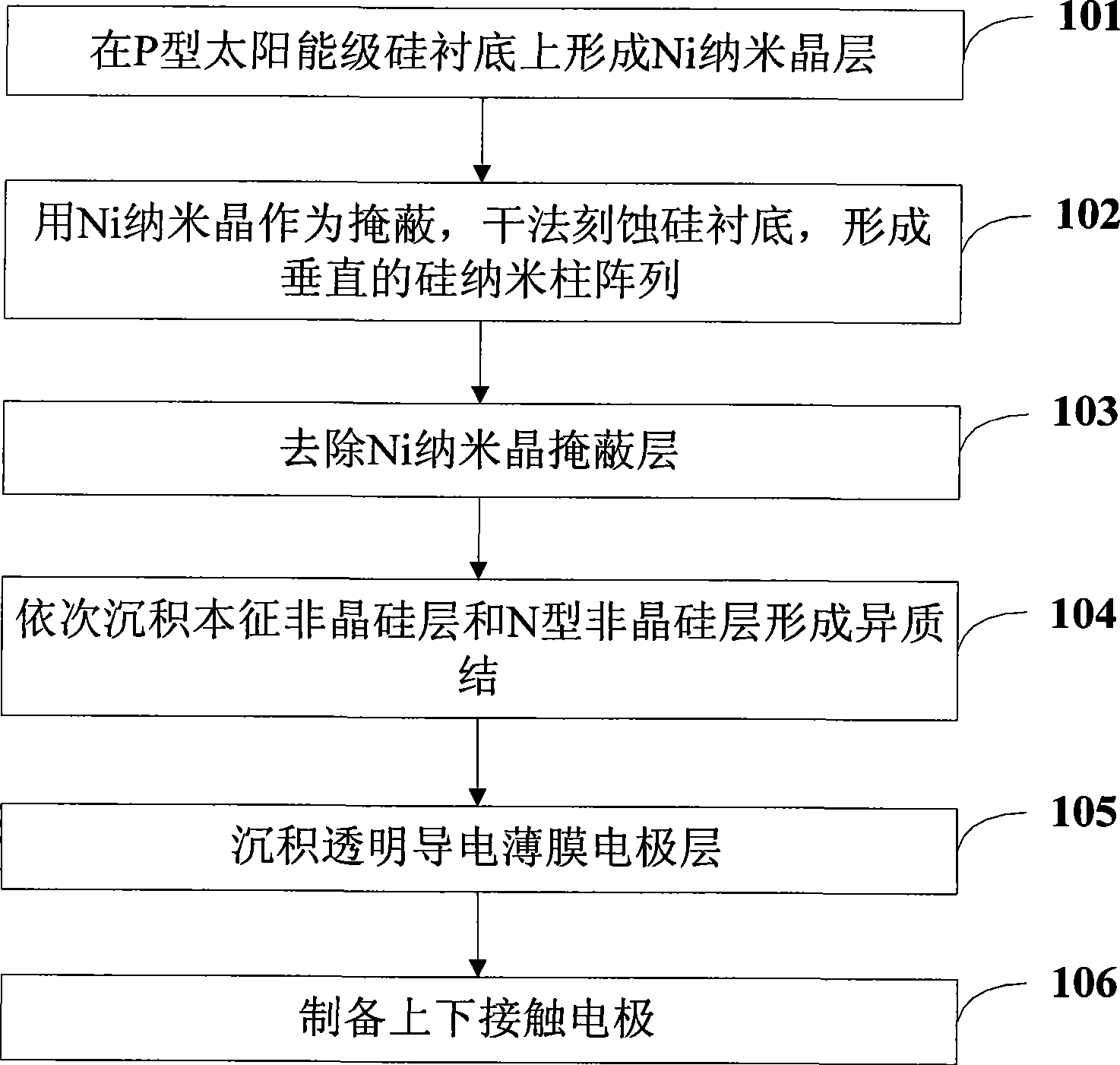

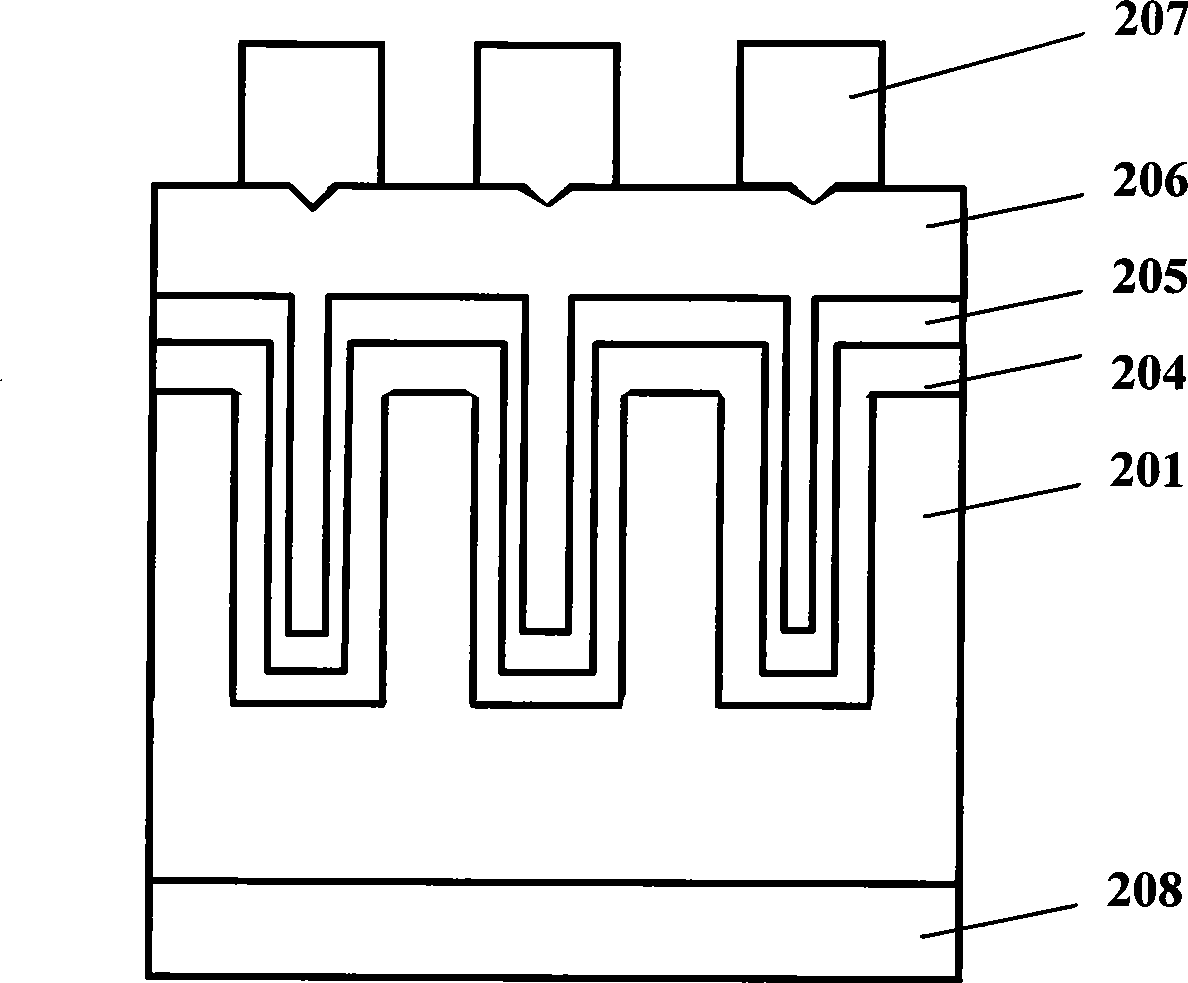

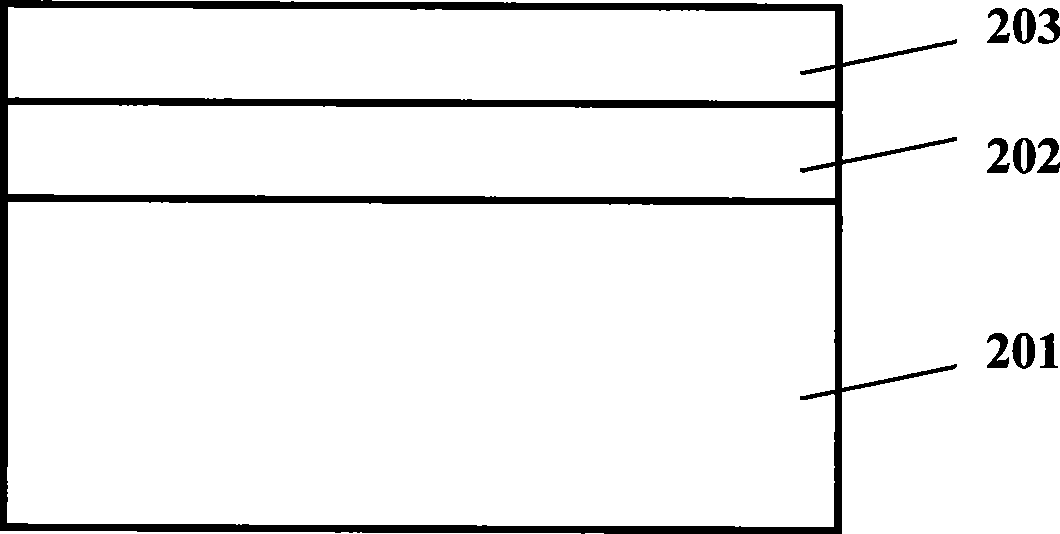

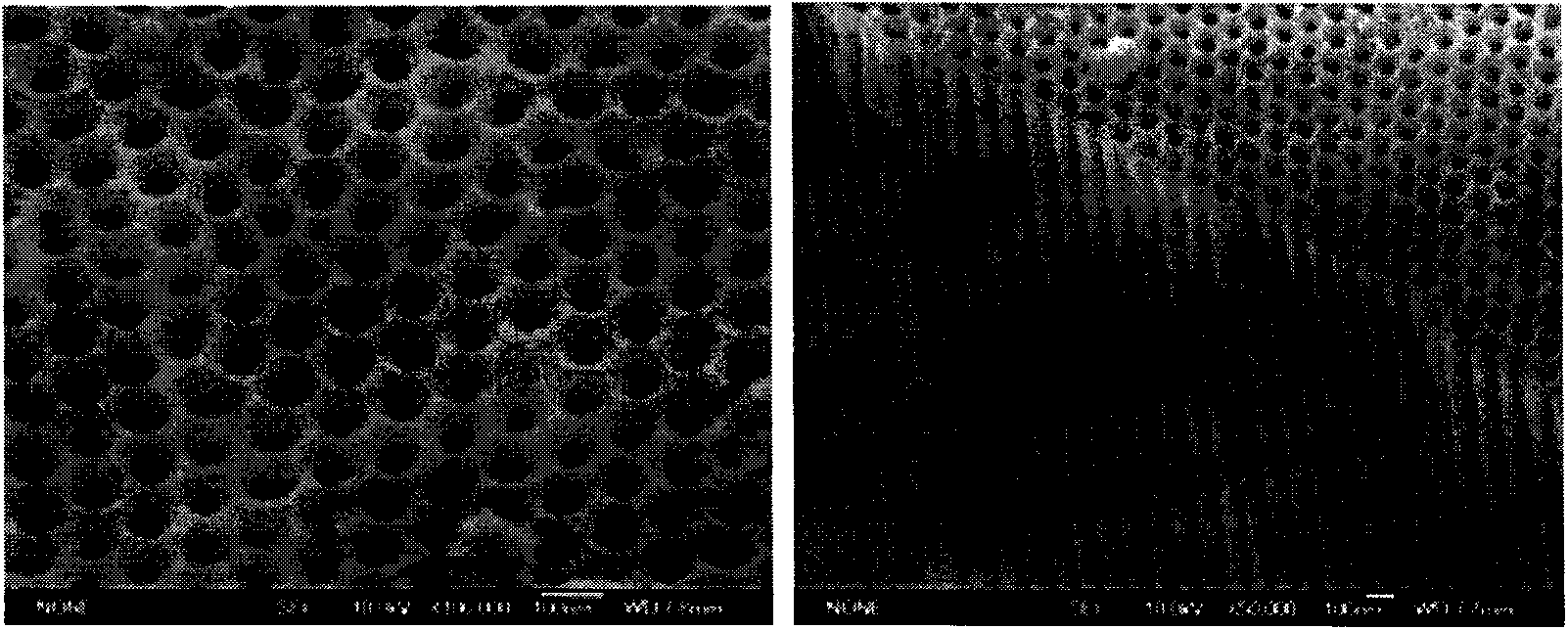

Silicon-based nanometer column array heterojunction film solar battery and preparation method thereof

InactiveCN101521239AShorten the transportation distanceIncreasing the thicknessFinal product manufacturePhotovoltaic energy generationHeterojunctionSolar battery

The invention discloses a silicon-based nanometer column array heterojunction film solar battery and a preparation method thereof, belonging to the field of solar battery manufacture. The method comprises the following steps: preparing a metal nanocrystalline masking layer on a P-type solar silicon substrate; using the metal nanocrystalline masking for masking, adopting a dry method to erode the silicon substrate and preparing a silicon nanometer column array; removing the metal nanocrystalline masking; sequentially depositing an intrinsic amorphous silicon layer and an N-type amorphous silicon layer and forming heterojunction; and finally, depositing a transparent conductive film layer and preparing an upper contact electrode and a lower contact electrode. The method can once prepare a solar battery array with a large area, greatly decreases the cost, has the advantages of simple preparation technology, low cost, favorable preparation efficiency and technological stability, has technological flows fully compatible with the preparation technology of the prior crystal silicon solar batteries and film silicon solar batteries and is easy to popularize on a large scale.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Thin film solar cells and manufacturing method thereof

InactiveUS20130061915A1Highly hydrogen-dilutedPhotovoltaic energy generationSemiconductor devicesHydrogenAmorphous silicon

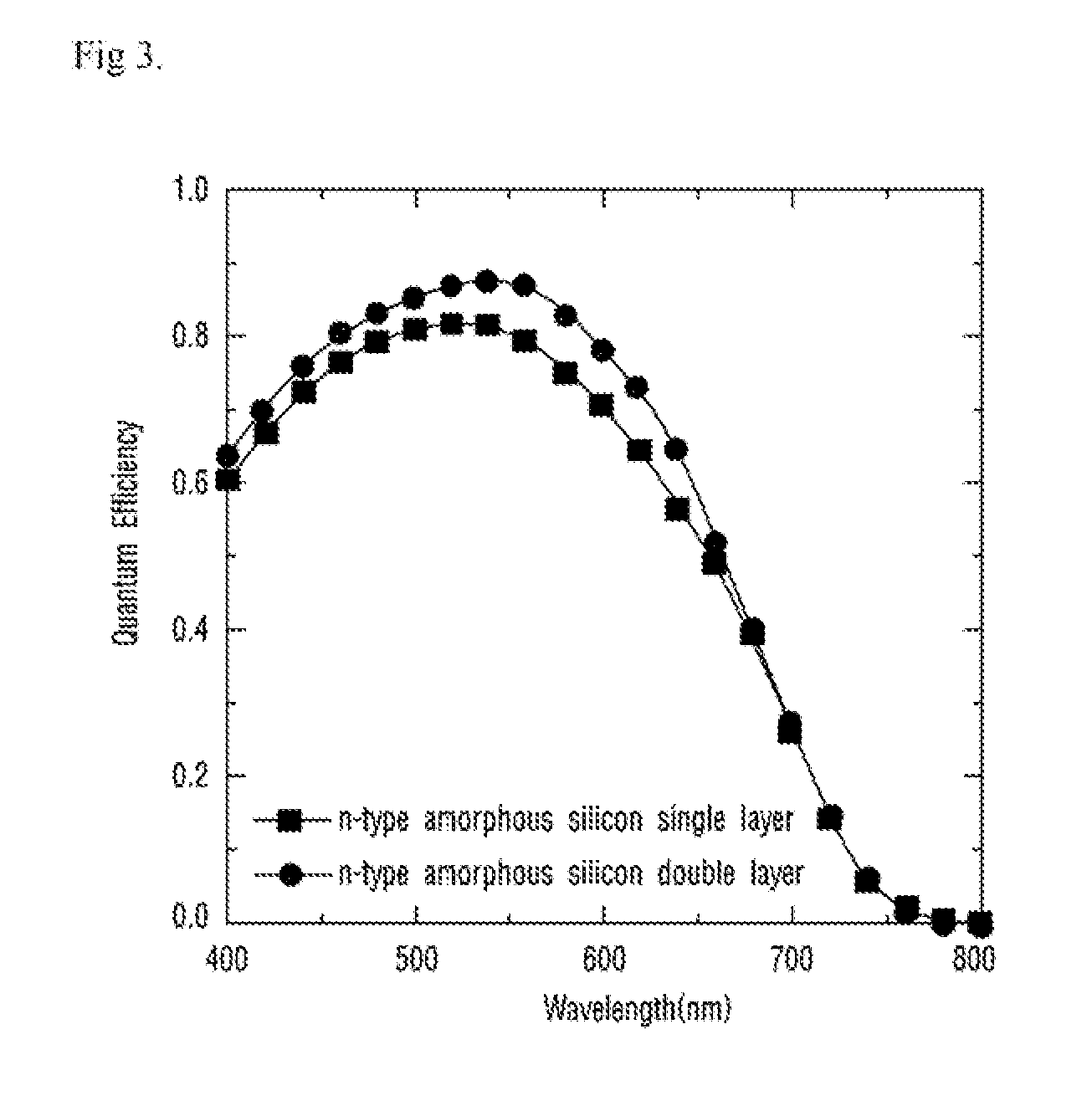

A thin film silicon solar cell including: a front transparent electrode stacked on a transparent insulating substrate; a p-type layer stacked on the front transparent electrode; an i-type photoelectric conversion layer stacked on the p-type layer; an n-type Saver stacked, on the i-type photoelectric conversion layer; and a metal back electrode layer stacked on the n-type layer, wherein the n-type layer includes: an n-type amorphous silicon first n layer which is stacked on the i-type photoelectric conversion layer and has a thickness of 3 nm to 7 nm; and an n-type silicon second n layer which is stacked on the first n layer and has a thickness of 15 nm to 30 nm and is more highly hydrogen-diluted than the first n layer.

Owner:KISCO CORP (KR)

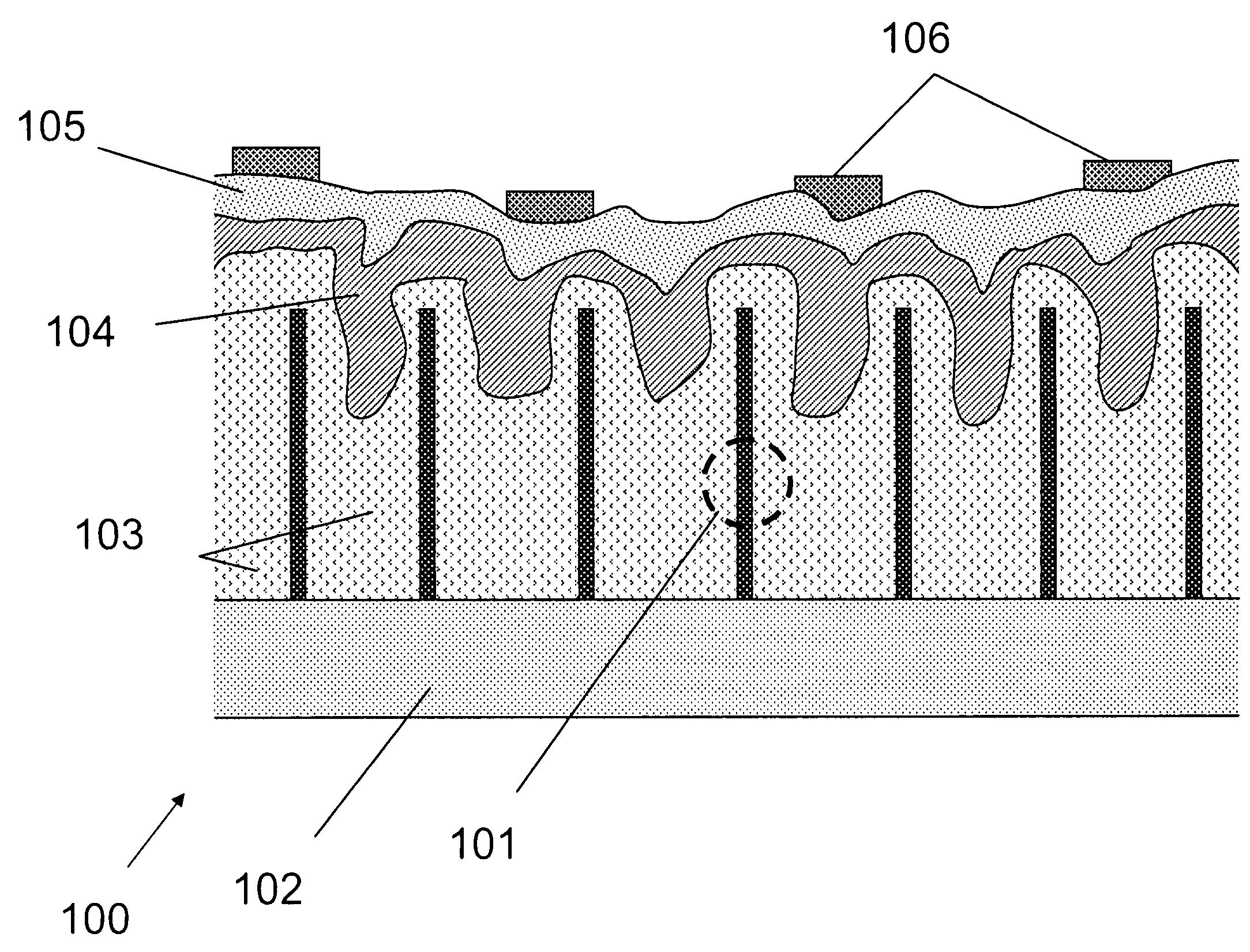

Nanowires in thin-film silicon solar cells

In some embodiments, the present invention is directed to photovoltaic (PV) devices comprising silicon (Si) nanowires as active PV elements, wherein such devices are typically thin film Si solar cells. Generally, such solar cells are of the p-i-n type and can be fabricated for front and / or backside (i.e., top and / or bottom) illumination. Additionally, the present invention is also directed at methods of making and using such devices, and to systems and modules (e.g., solar panels) employing such devices.

Owner:GENERAL ELECTRIC CO

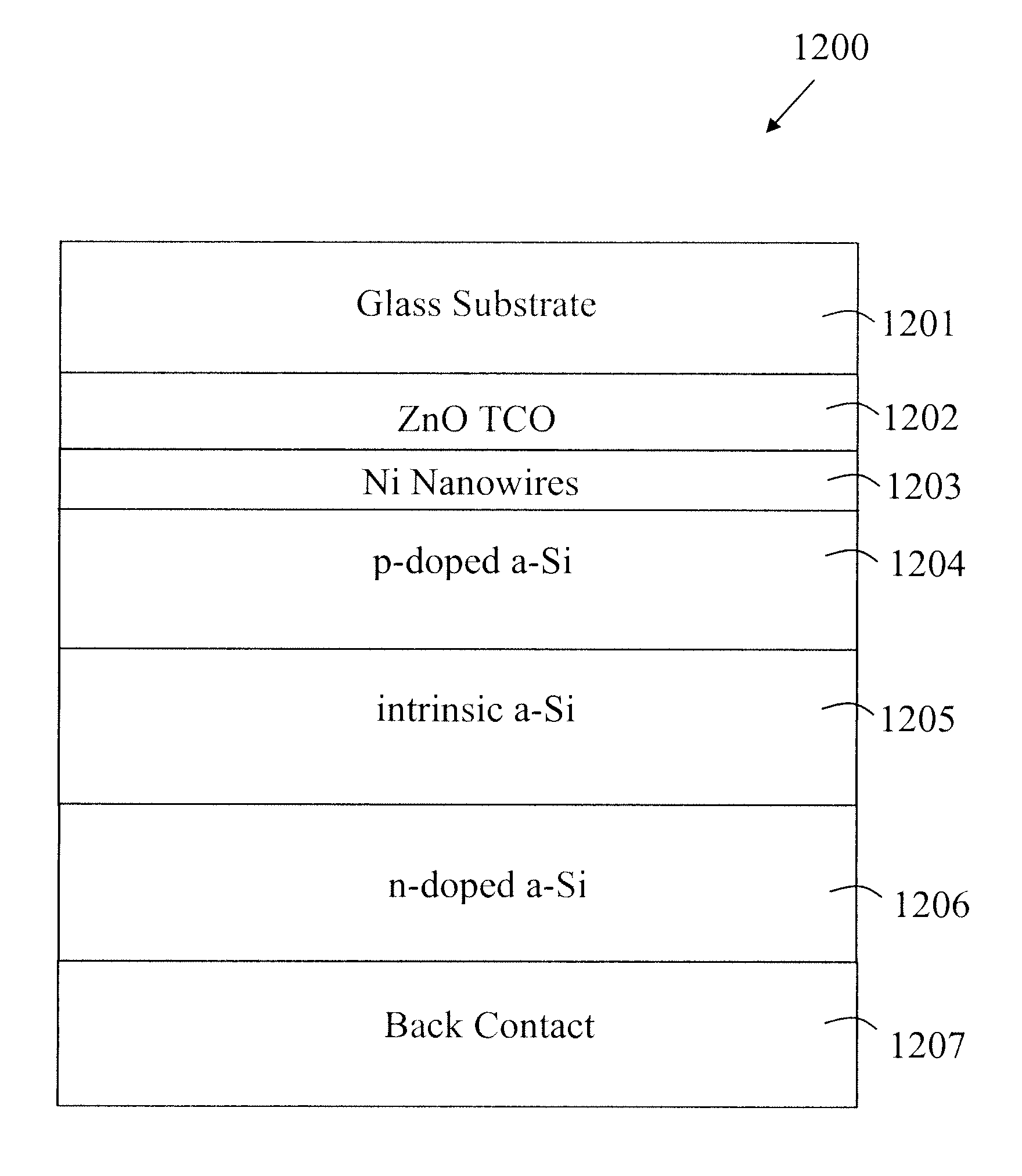

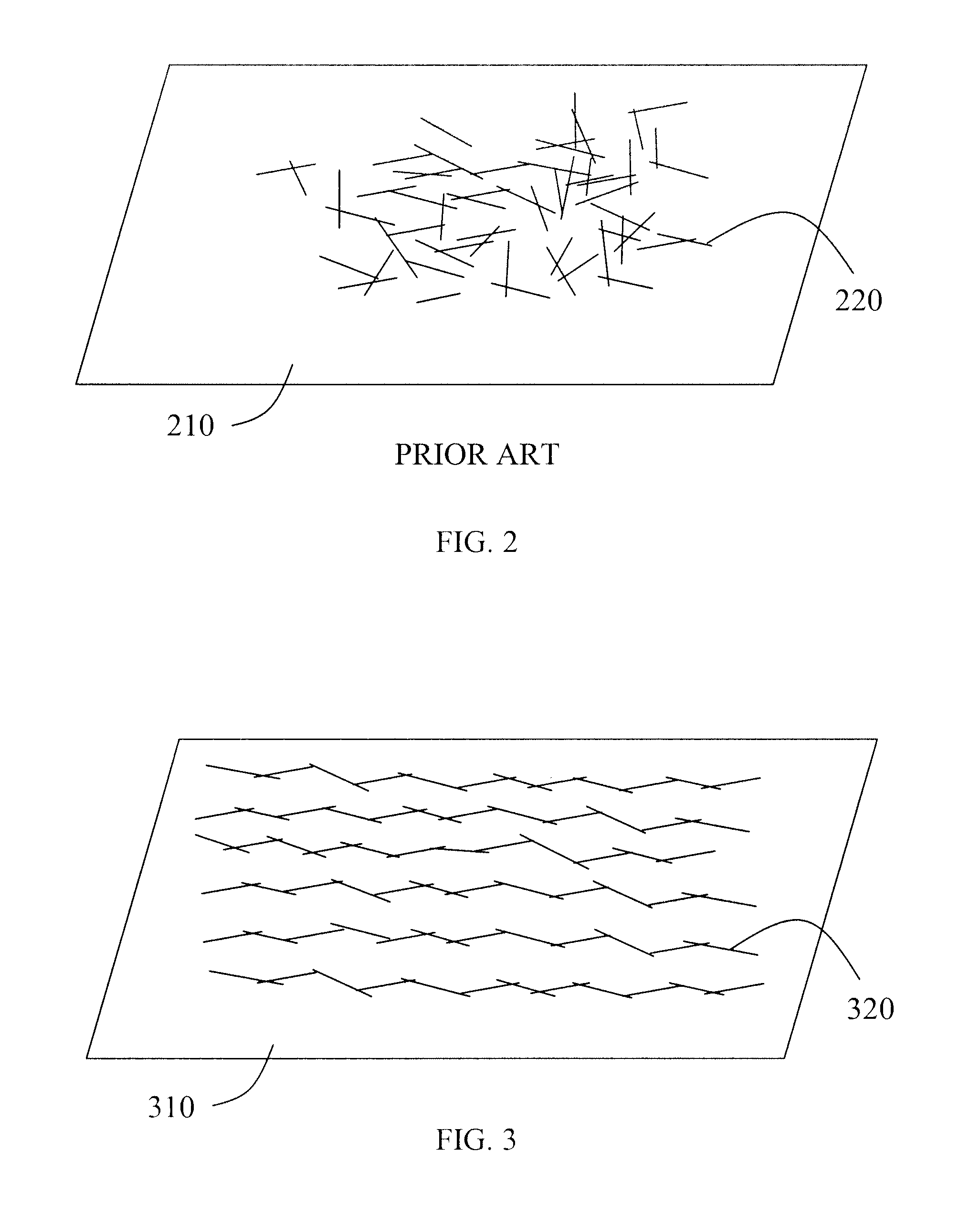

Enhanced Silicon-TCO Interface in Thin Film Silicon Solar Cells Using Nickel Nanowires

InactiveUS20110180133A1Increase heightImproved solar cell performanceNanomagnetismLiquid surface applicatorsOptical transparencyNanowire

This invention provides an optically transparent electrically conductive layer with a desirable combination of low electrical sheet resistance and good optical transparency. The conductive layer comprises a multiplicity of magnetic nanostructures in a plane, aligned into a plurality of roughly parallel continuous conductive pathways, wherein the density of the magnetic nanostructures allows for substantial optical transparency of the conductive layer. The magnetic nanostructures may be nanoparticles, nanowires or compound nanowires. A method of forming the conductive layer on a substrate includes: depositing a multiplicity of magnetic nanostructures on the substrate and applying a magnetic field to form the nanostructures into a plurality of conductive pathways parallel to the surface of the substrate. The conductive layer may be used to provide an enhanced silicon to transparent conductive oxide (TCO) interface in thin film silicon solar cells.

Owner:APPLIED MATERIALS INC

Method for manufacturing novel light-trapping synergetic antireflection structure on basis of LSP (localized surface plasma) effect

ActiveCN103022266AImprove conversion efficiencyReduce reflectivityFinal product manufactureVacuum evaporation coatingSolar batterySilicon thin film

The invention belongs to the technical field of solar cells, and particularly relates to a method for manufacturing a novel light-trapping synergetic antireflection structure on the basis of an LSP (localized surface plasma) effect. The method includes etching a cone shape on the surface of monocrystalline silicon by alkali; and depositing a layer of discontinuous silver nanoparticles on the surface of a cone by means of sputtering and annealing to obtain the novel light-trapping structure with the silver nanoparticles and a cone structure which are compounded with one another. The reflectivity of the novel light-trapping synergetic antireflection structure is reduced by 3.4% within the total solar spectrum range as compared with a pure cone structure. The method for manufacturing the effective light-trapping structure includes simple and practical silicon wafer cleaning and silver nanoparticle sputtering and depositing technological procedures, and a constant-temperature wet etching means is combined with the LSP effect, so that an excellent antireflection effect is realized as compared with the traditional structure manufactured by alkaline etching, and design and manufacturing processes of the method provide novel technical means for improving the efficiency of silicon and the efficiency of a thin film silicon solar cell.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

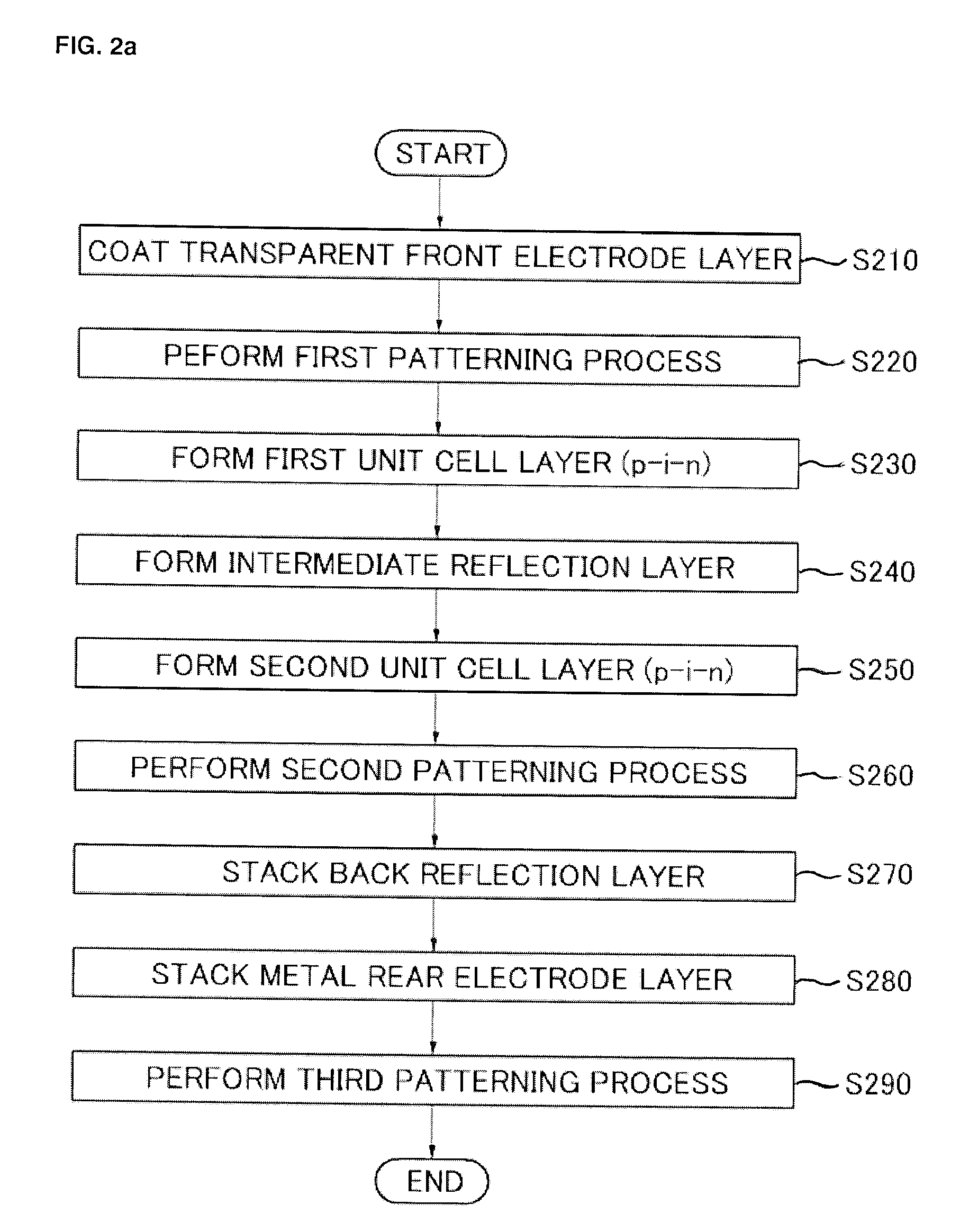

Tandem thin-film silicon solar cell and method for manufacturing the same

InactiveUS20120070935A1Final product manufactureSemiconductor/solid-state device manufacturingSilicon solar cellReflective layer

A tandem thin-film silicon solar cell comprises a transparent substrate, a first unit cell positioned on the transparent substrate, the first unit cell comprising a p-type window layer, an i-type absorber layer and an n-type layer, an intermediate reflection layer positioned on the first unit cell, the intermediate reflection layer including a hydrogenated n-type microcrystalline silicon oxide of which the oxygen concentration is profiled to be gradually increased and a second unit cell positioned on the intermediate reflection layer, the second unit cell comprising a p-type window layer, an i-type absorber layer and an n-type layer.

Owner:INTELLECTUAL DISCOVERY CO LTD

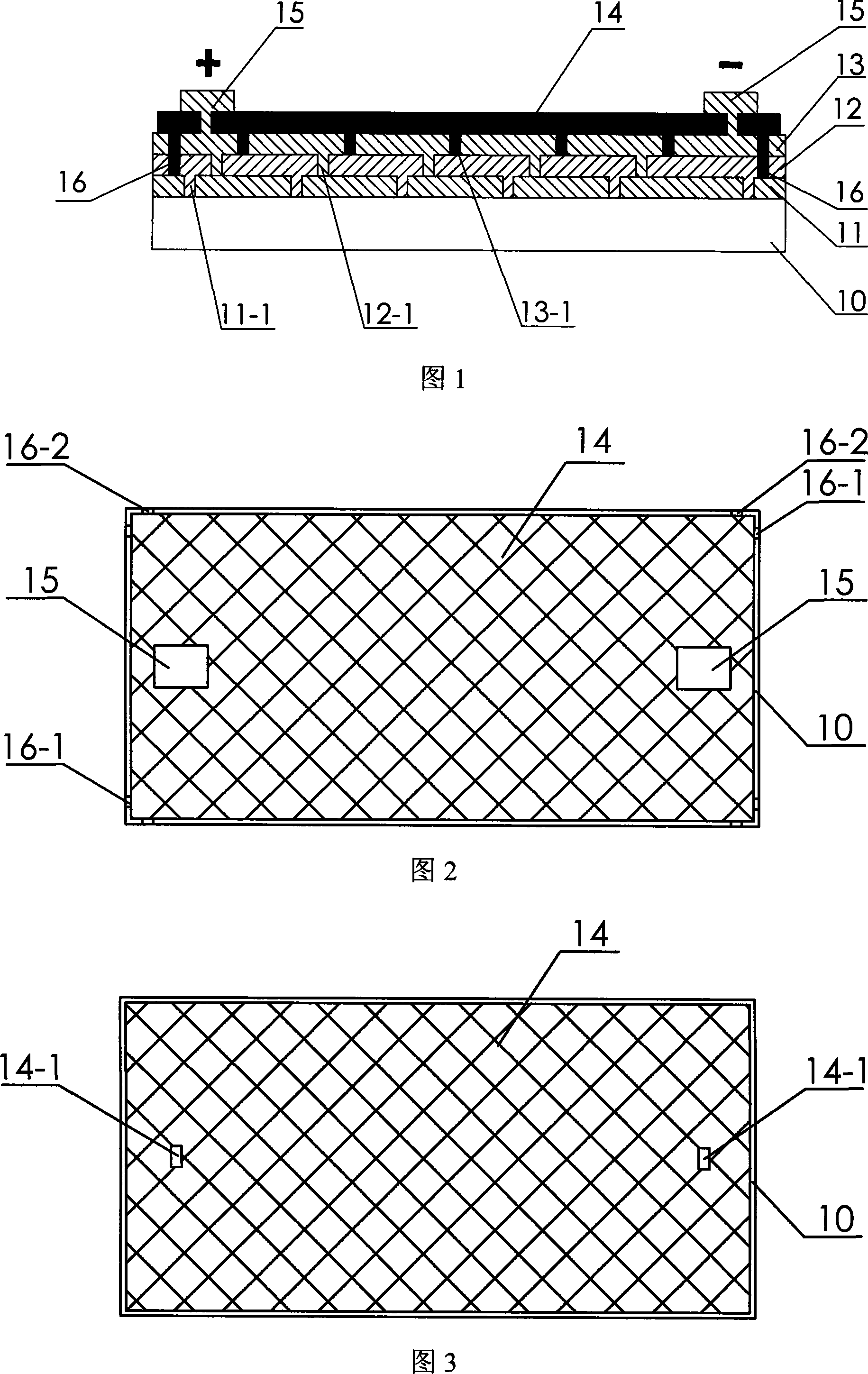

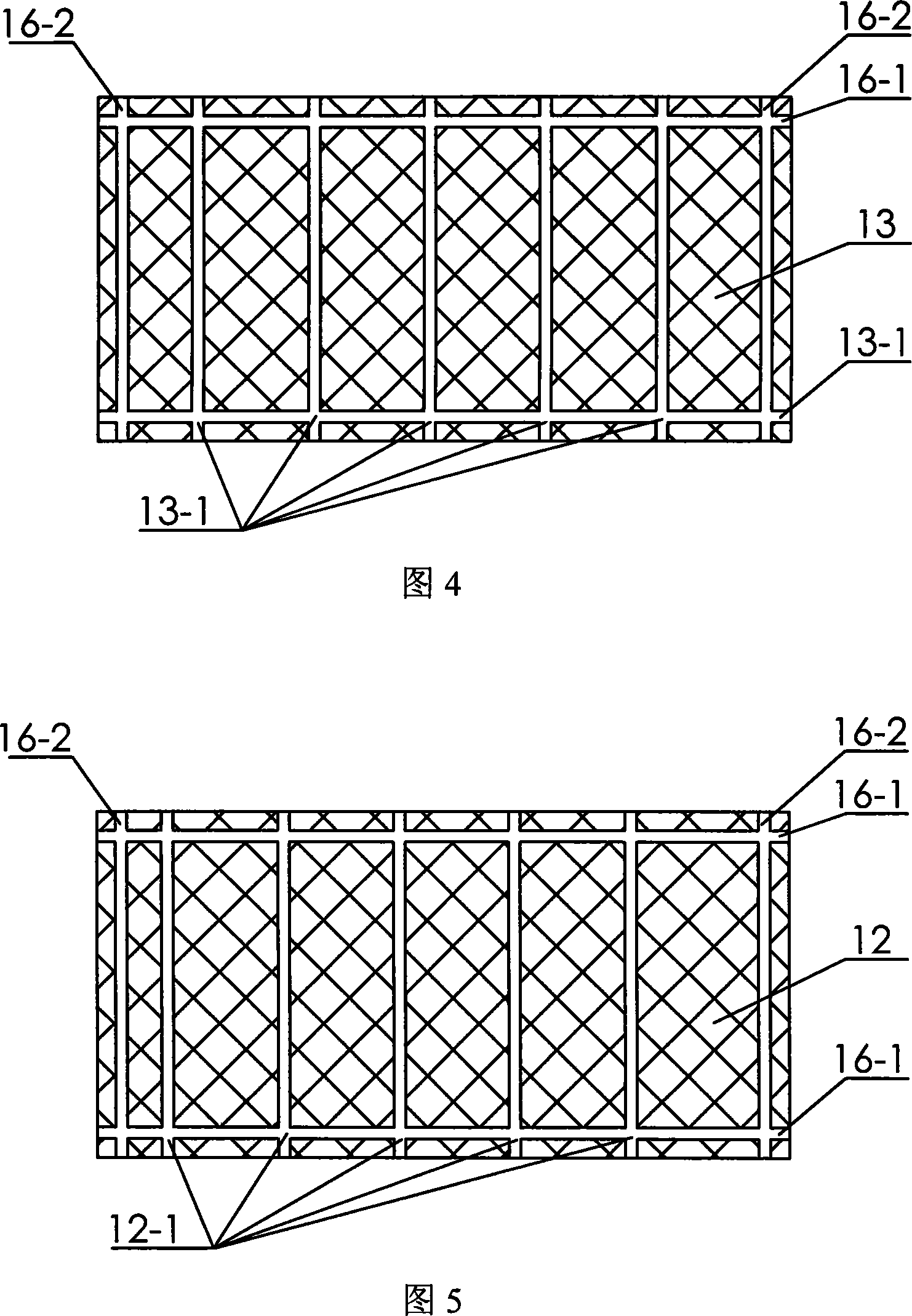

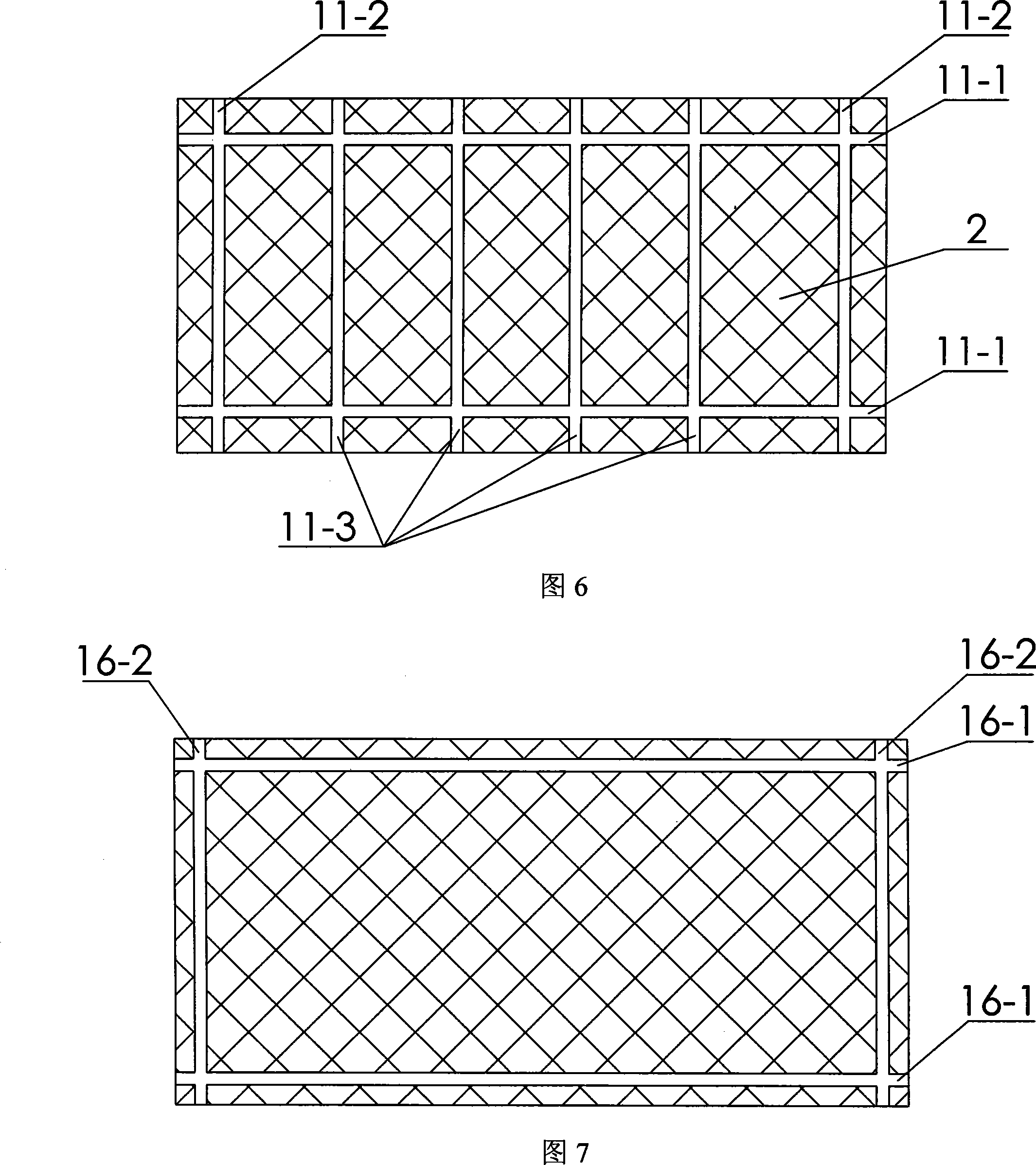

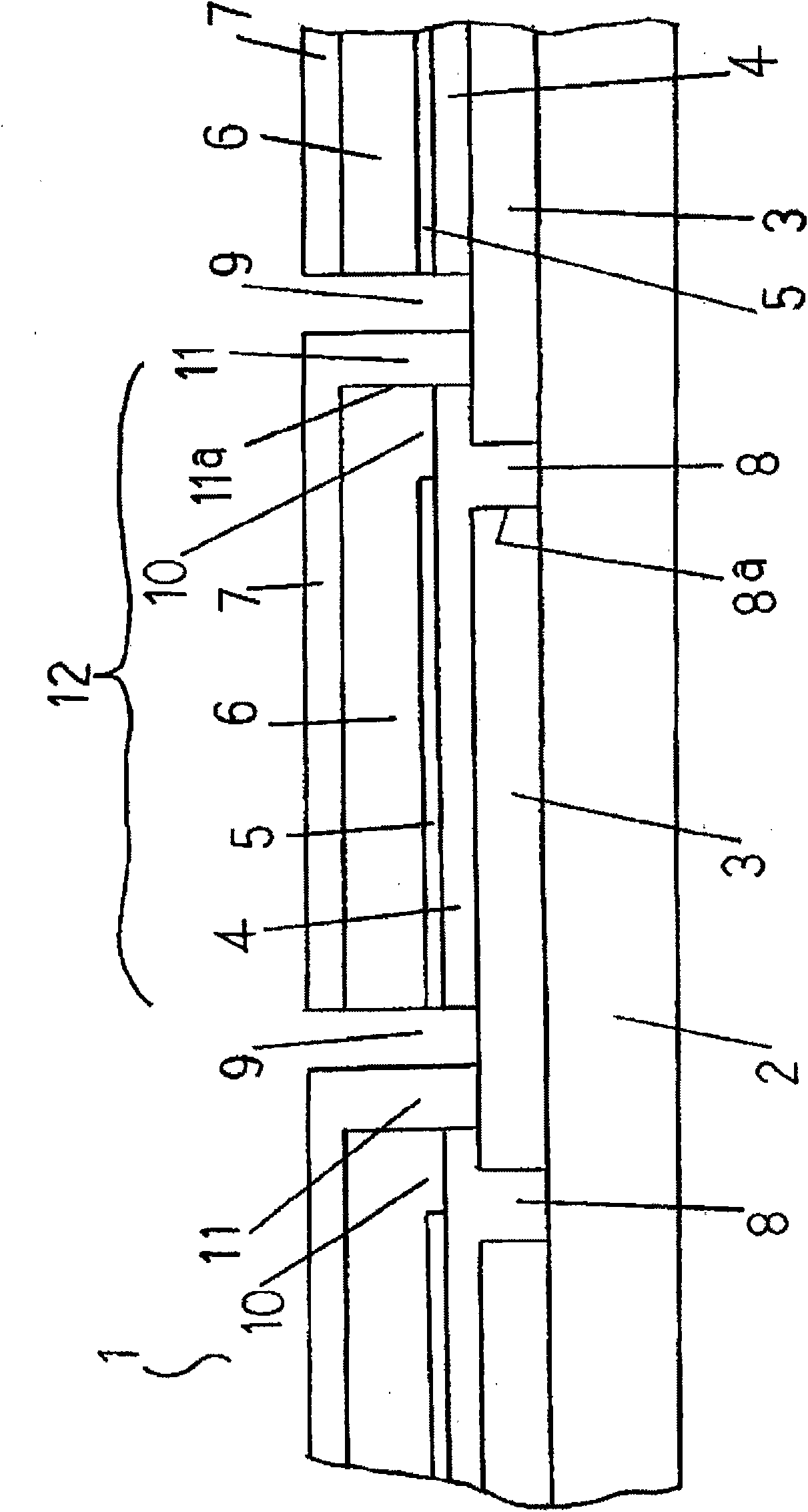

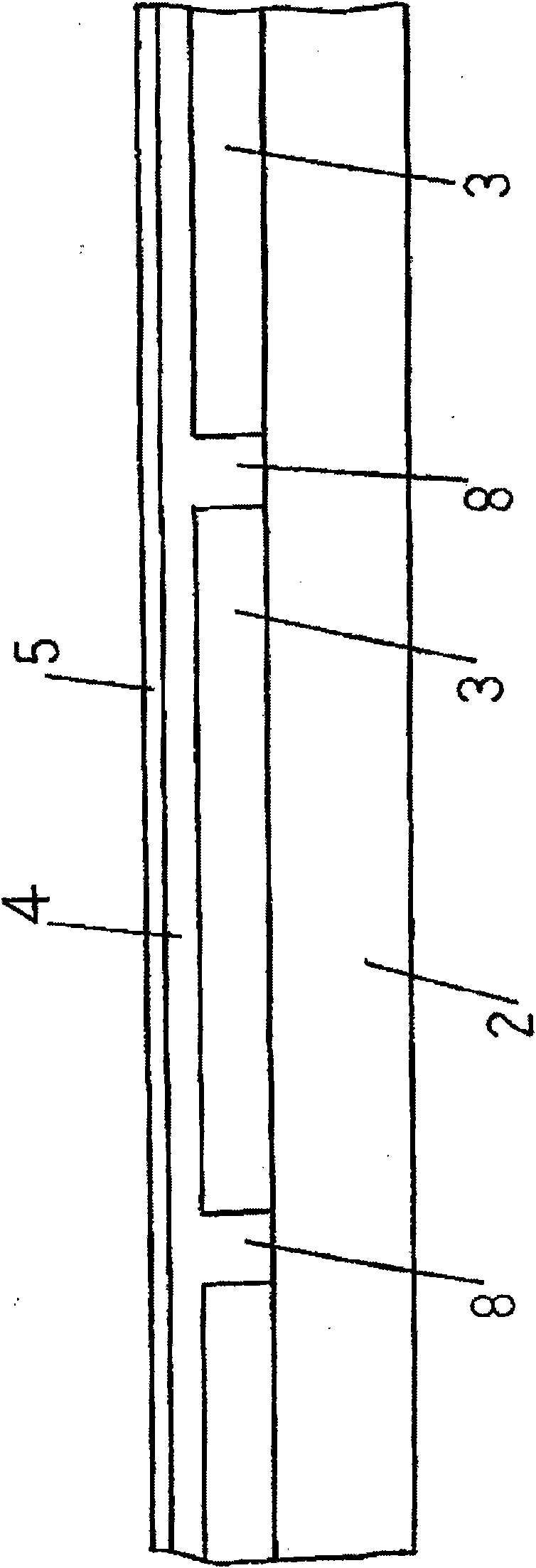

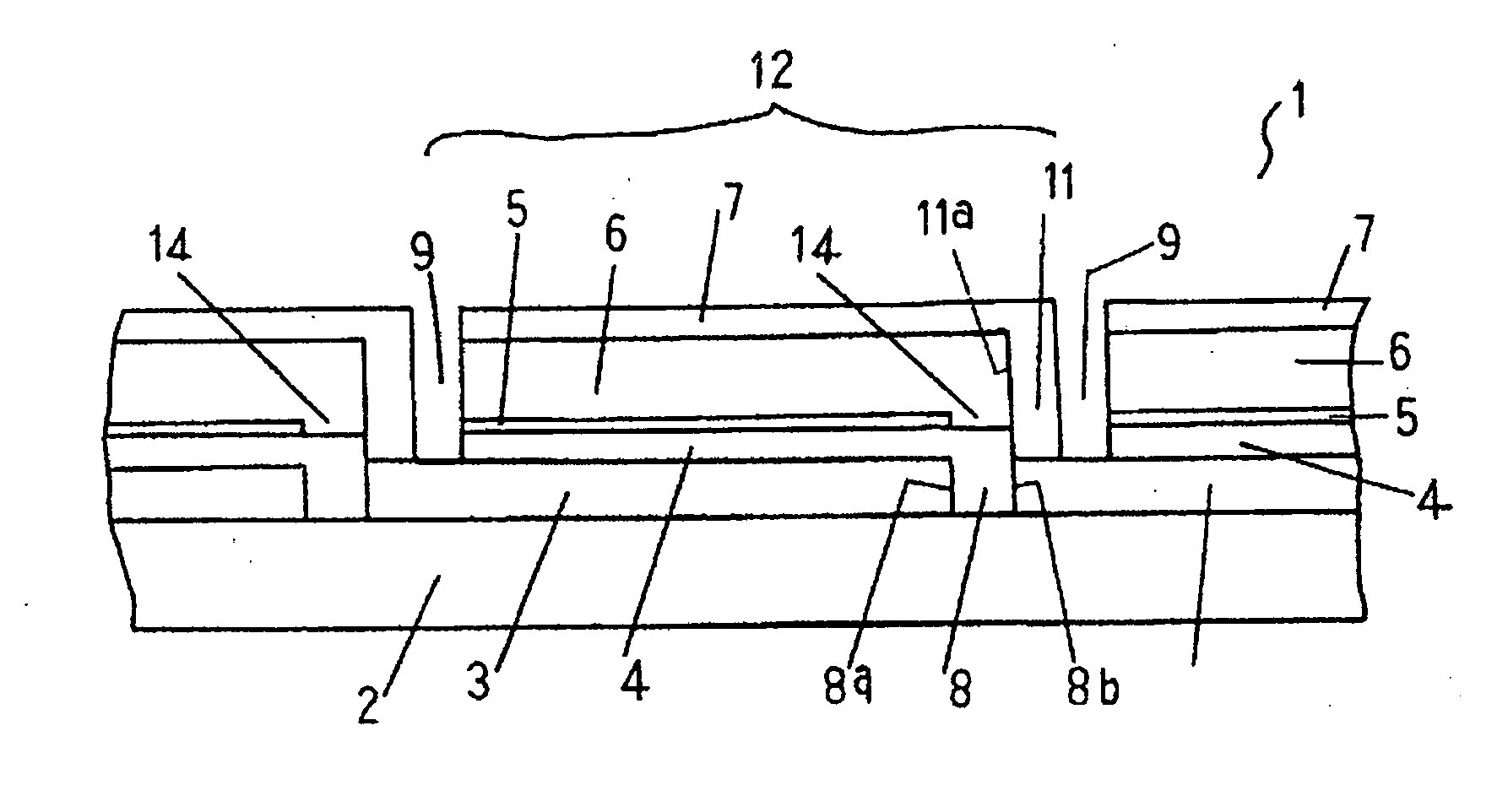

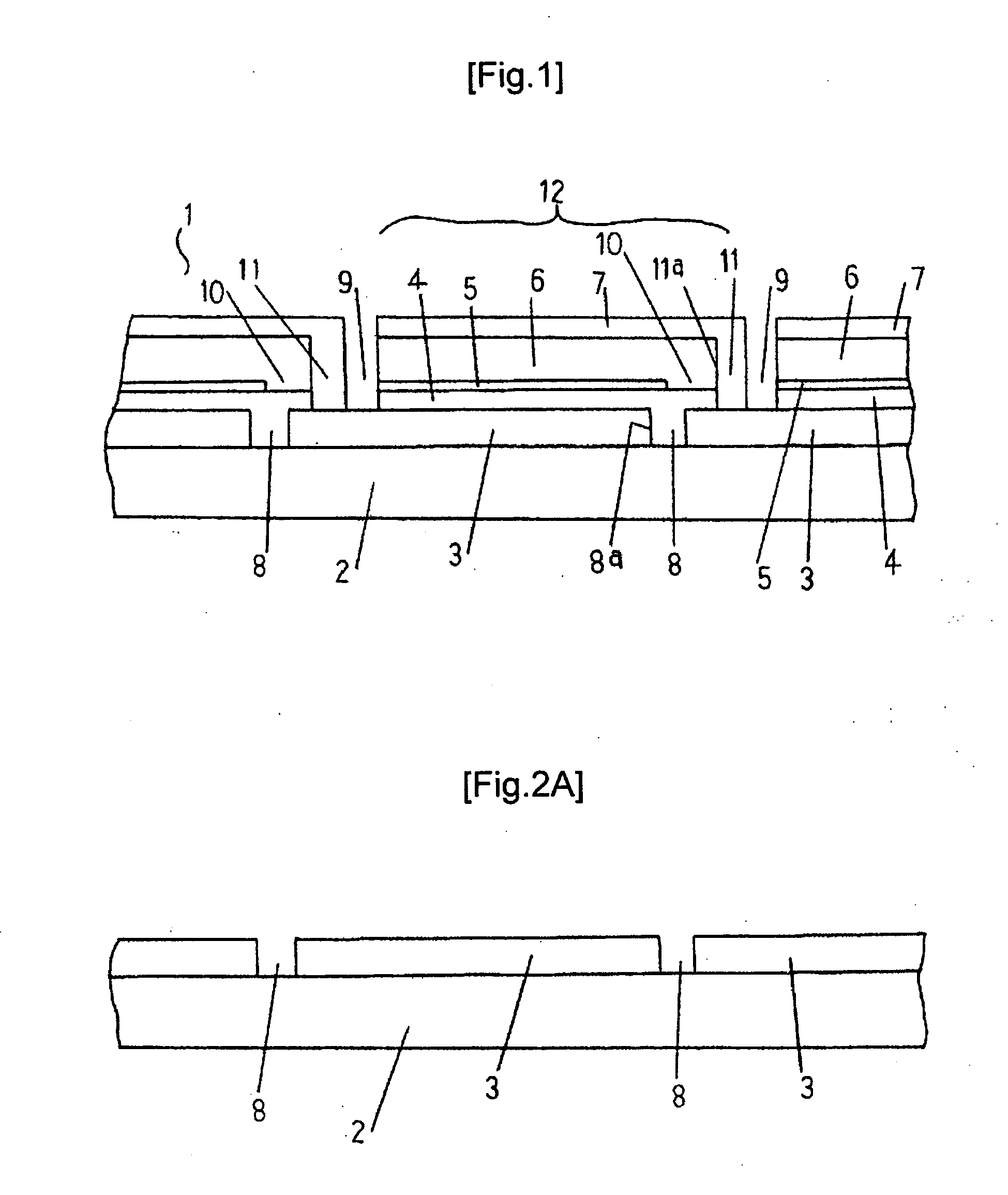

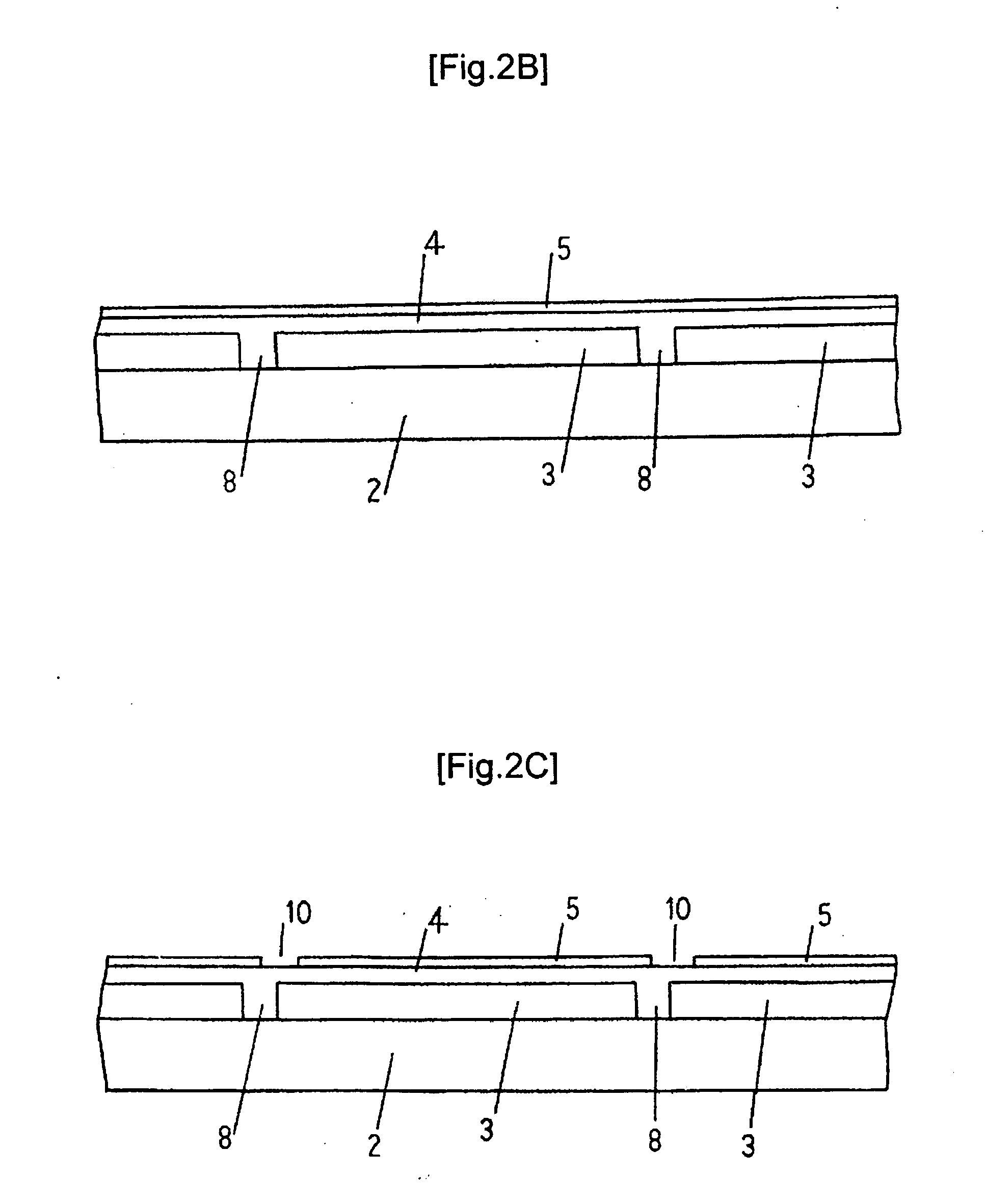

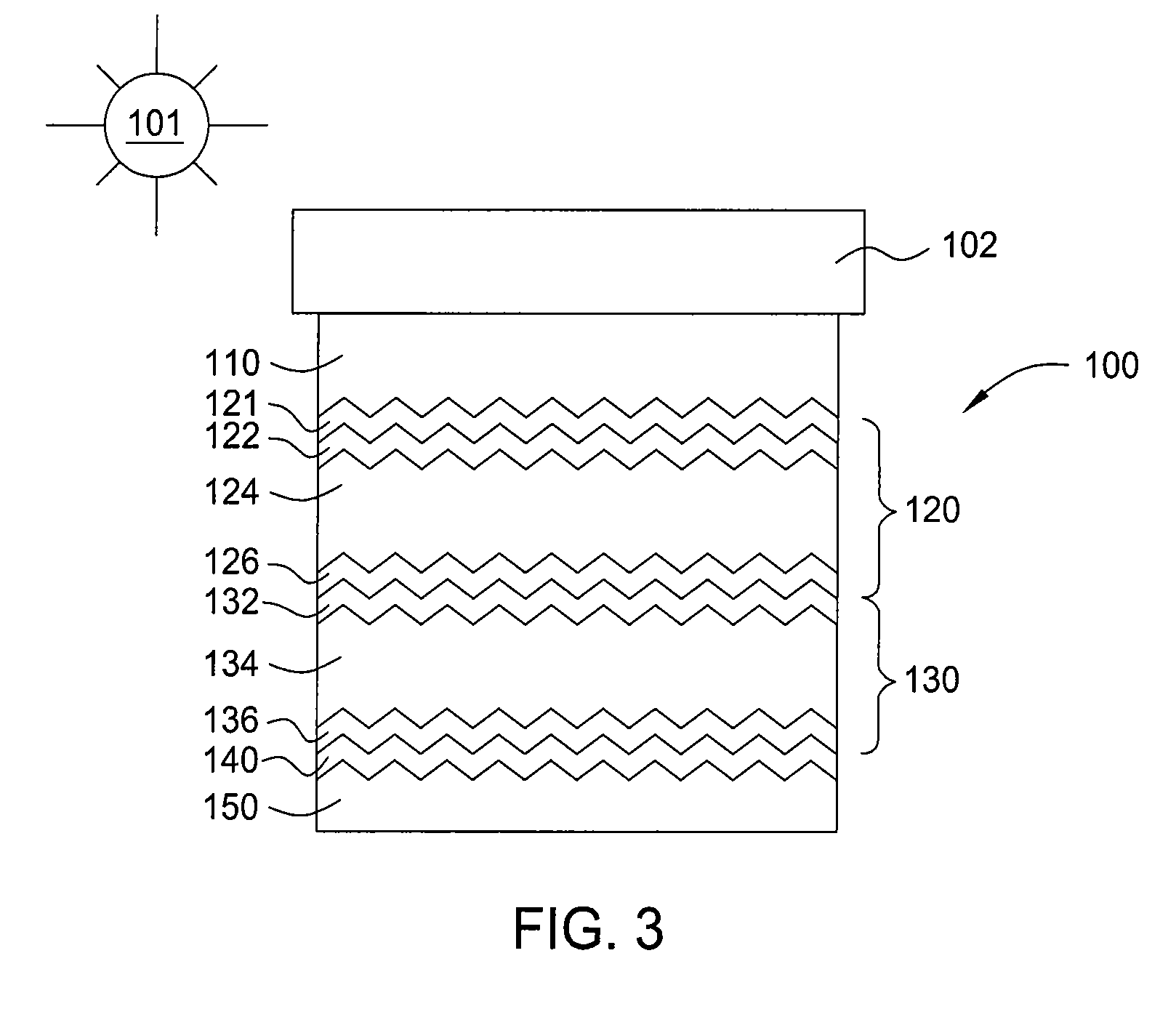

Integrated tandem-type thin film silicon solar cell module and method for manufacturing the same

InactiveCN101803036ASuppresses increase in dead areaSuppress leakage currentEnergy conversion devicesPhotovoltaic energy generationSilicon solar cellEngineering

The invention provides an integrated tandem-type thin film silicon solar cell module and a method for manufacturing the same. The tandem-type thin film silicon solar cell module has a structure wherein an interlayer layer is arranged. The module suppresses a problem of a current leak through the intermediate layer and has high light conversion efficiency by suppressing expansion of an ineffective area not contributing to power generation. A method for manufacturing such module is also provided. The module has a structure wherein a separating groove is arranged between the intermediate layer and a connecting groove, the separating groove is embedded with a crystalline silicon film, and a separating member does not exist between the separating groove and the connecting groove.

Owner:村田 正义

Multi-junction solar cells and methods and apparatuses for forming the same

InactiveCN101542745AFinal product manufacturePhotovoltaic energy generationAmorphous siliconEngineering

Embodiments of the present invention generally relate to solar cells and methods and apparatuses for forming the same. More particularly, embodiments of the present invention relate to thin film multi-junction solar cells and methods and apparatuses for forming the same. Embodiments of the present invention also include an improved thin film silicon solar cell, and methods and apparatus for forming the same, where one or more of the layers in the solar cell comprises at least one amorphous silicon layer that has improved electrical characteristics and mechanical properties, and is capable of being deposited at rates many times faster than conventional amorphous silicon deposition processes.

Owner:APPLIED MATERIALS INC

Integrated tandem-type thin film solar cell module and method for manufacturing the same

InactiveUS20110041889A1Improve productivityLow production costPV power plantsSemiconductor/solid-state device manufacturingEngineeringCrystalline silicon

Provided is a tandem-type thin film silicon solar cell module having a structure wherein an intermediate layer is arranged. The module suppresses a problem of a current leak through the intermediate layer and has high light conversion efficiency by suppressing expansion of an ineffective area not contributing to power generation. A method for manufacturing such module is also provided. The module has a structure wherein a separating groove is arranged between the intermediate layer and a connecting groove, the separating groove is embedded with a crystalline silicon film, and a separating member does not exist between the separating groove and the connecting groove.

Owner:MURATA MASAYOSHI

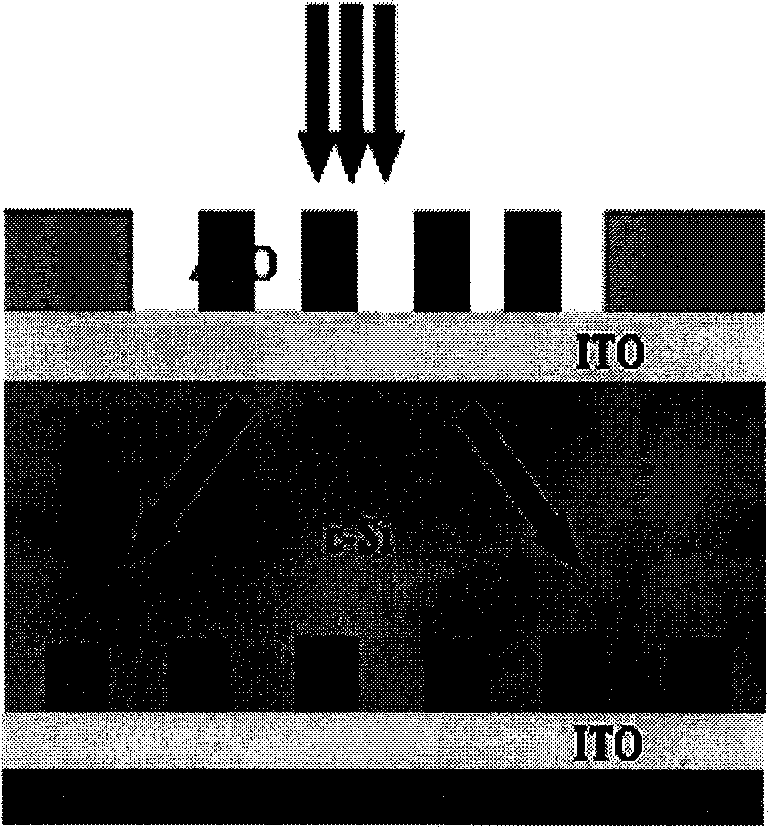

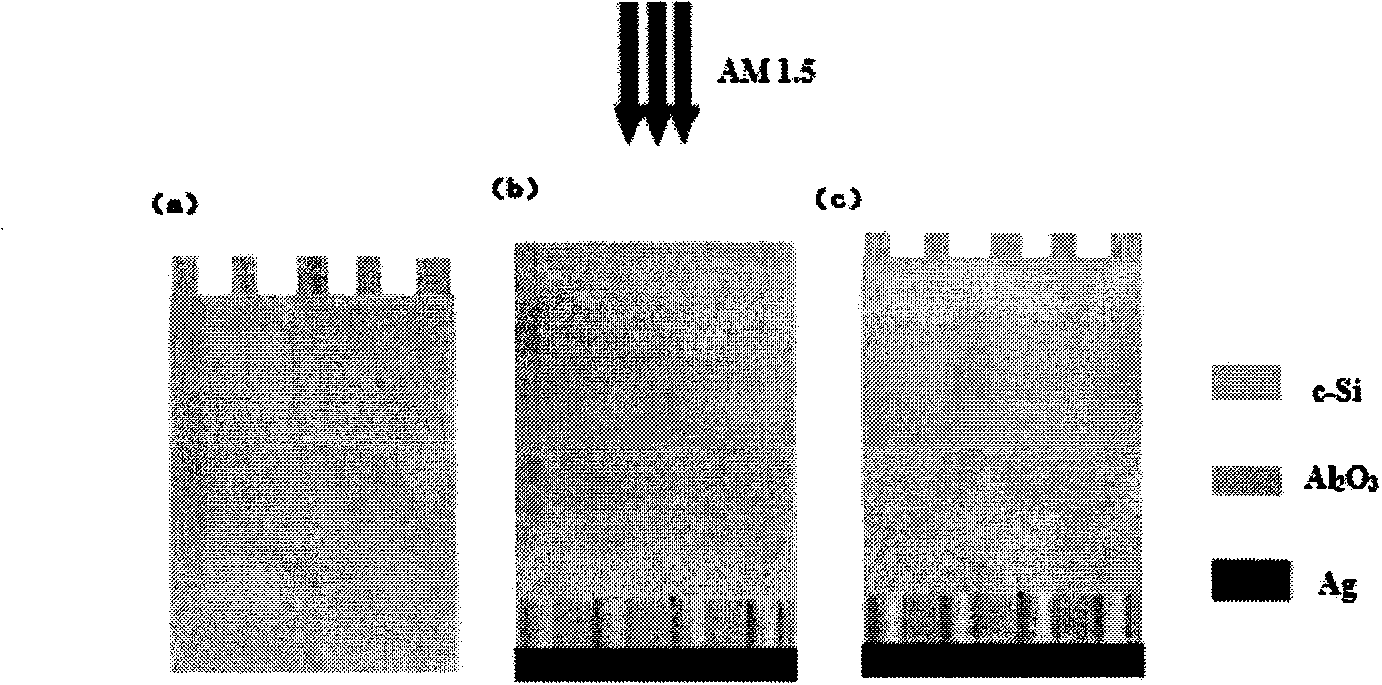

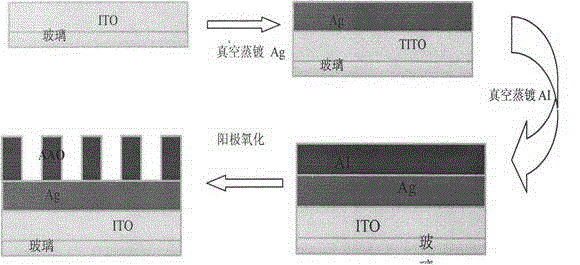

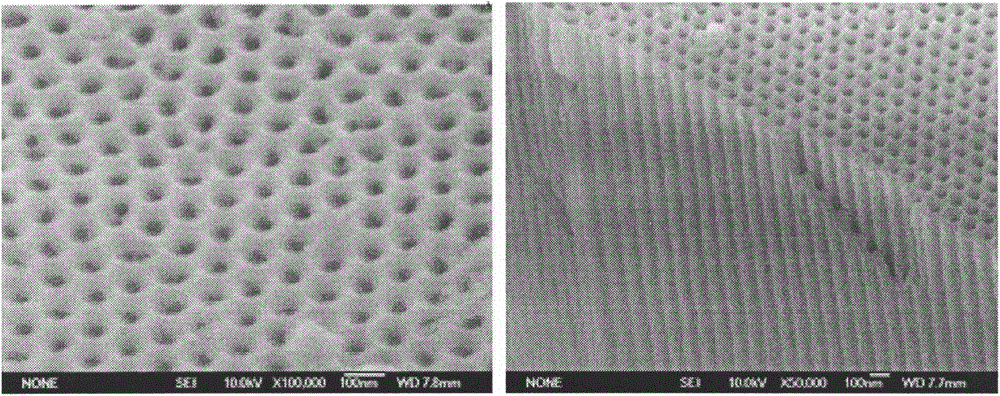

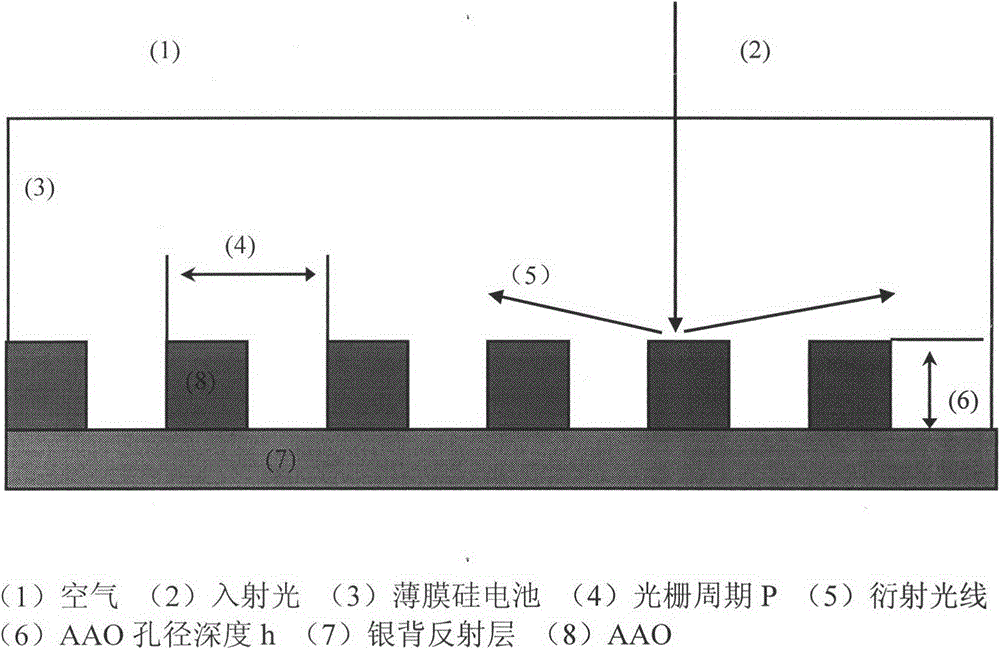

Novel solar cell double-trapping-light structure with AAO nanometer gratings

InactiveCN104064607AImprove photoelectric conversion efficiencyImprove light absorptionNanoopticsPhotovoltaic energy generationGratingSilicon solar cell

The invention provides a method for introducing an AAO template as a nanometer grating to a solar cell structure, and discloses a thin film silicon solar cell double-trapping-light structure with AAO nanometer gratings on the surface and the bottom. A surface decreasing structure of the double-trapping-light structure is composed of AAO and ITO, and a back reflection structure is composed of AAO, ITO and Ag. FDTD solution software is utilized for optimizing structural parameters of the AAO. According to the double-trapping-light structure, surface reflection losses of a solar cell can be effectively reduced, the light path of photons with the long wavelength in an absorbed layer can be improved, and therefore light absorption of the thin film silicon solar cell within the range of 280 nm to 1100 nm is increased, and the absorption can be relatively increased to reach 74.44 percent. Due to the fact that the AAO is easy and convenient to manufacture, low in cost and suitable for mass production, it is predicated that in the near future, the AAO will certainly play a bigger role in application of the thin film silicon solar cell.

Owner:TIANJIN POLYTECHNIC UNIV

Thin film silicon solar cell and manufacturing method thereof

InactiveUS20110126893A1Photovoltaic energy generationSemiconductor devicesSilicon solar cellThin film silicon solar cell

A thin film silicon solar cell comprises a front transparent electrode, a p-type window layer, a buffer layer, an i-type absorber layer, an n-type layer and a metal rear electrode. The front transparent electrode is stacked on a transparent substrate. The p-type window layer is stacked on the front transparent electrode, and has a thickness in a range of 12 nm to 17 nm. The buffer layer is stacked on the p-type window layer, and has a carbon concentration in a range of 0.5 to 3.0 atomic % and a thickness in a range of 3 to 8 nm. The i-type absorber layer is stacked on the buffer layer. The n-type layer is stacked on the i-type absorber layer. The metal rear electrode is stacked on the n-type layer.

Owner:KISCO CORP (KR)

Multi-junction solar cells and methods and apparatuses for forming the same

InactiveUS8203071B2Uniformly formedFinal product manufactureSemiconductor/solid-state device manufacturingAmorphous siliconSilicon solar cell

Embodiments of the present invention generally relate to solar cells and methods and apparatuses for forming the same. More particularly, embodiments of the present invention relate to thin film multi-junction solar cells and methods and apparatuses for forming the same. Embodiments of the present invention also include an improved thin film silicon solar cell, and methods and apparatus for forming the same, where one or more of the layers in the solar cell comprises at least one amorphous silicon layer that has improved electrical characteristics and mechanical properties, and is capable of being deposited at rates many times faster than conventional amorphous silicon deposition processes.

Owner:APPLIED MATERIALS INC

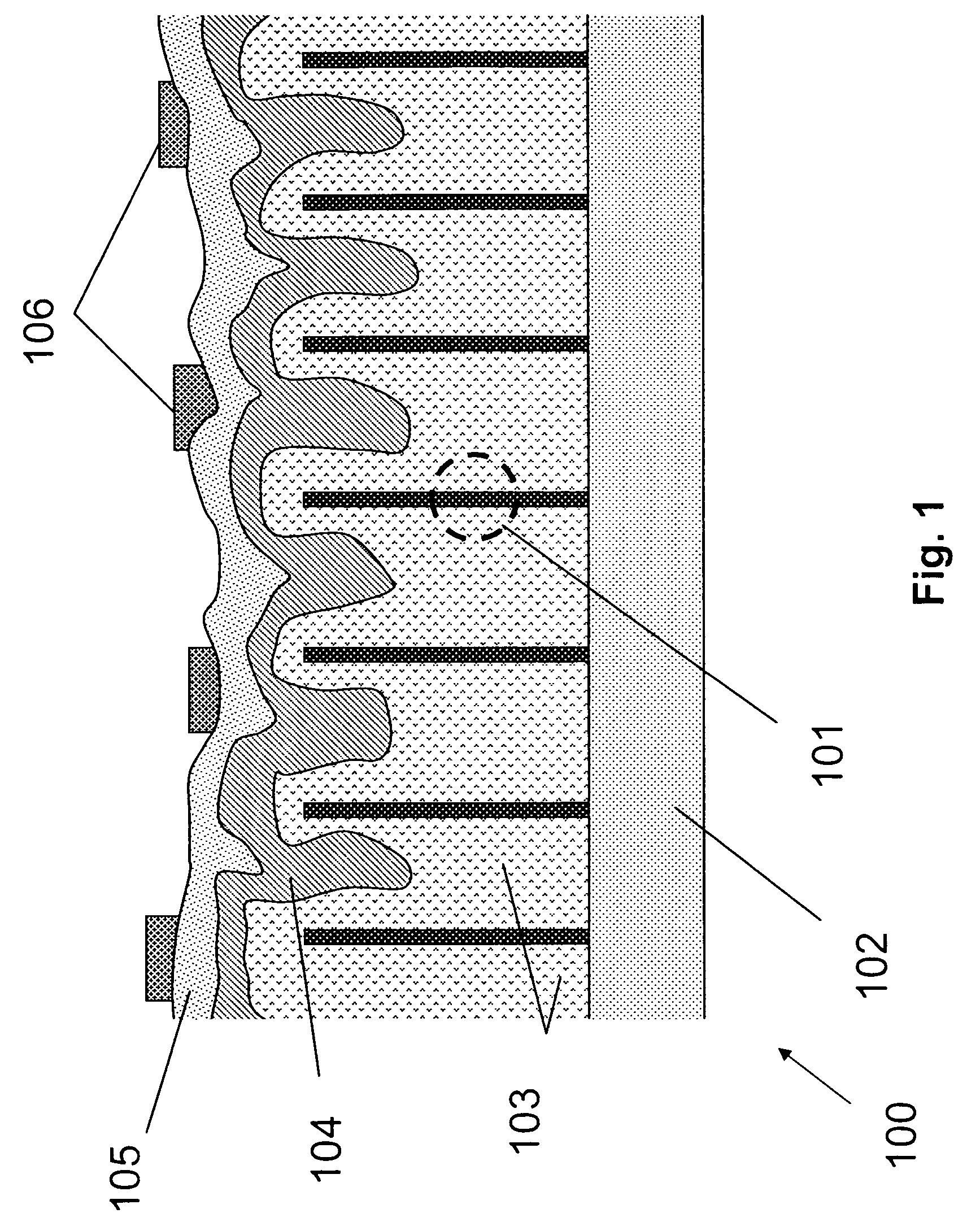

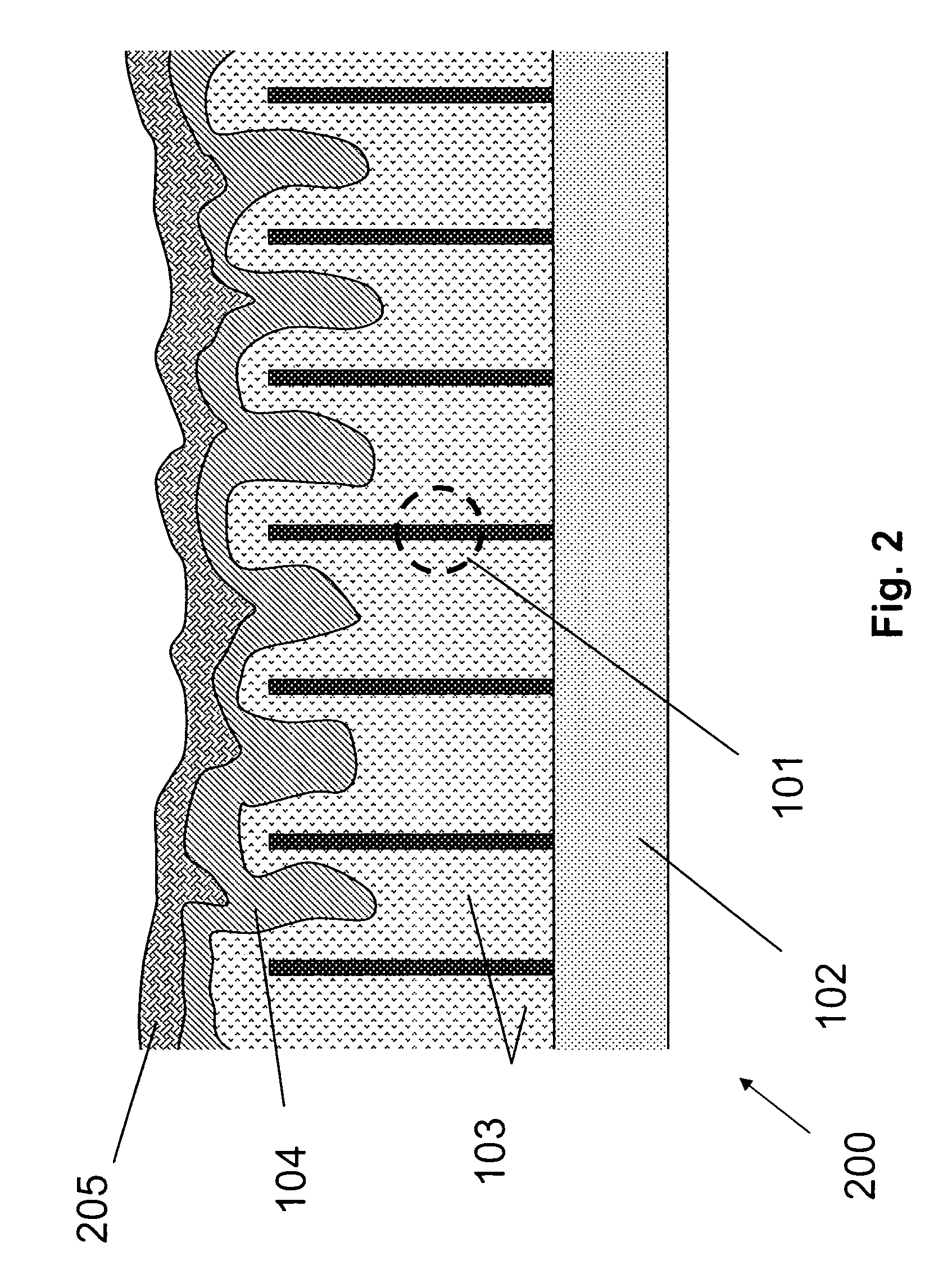

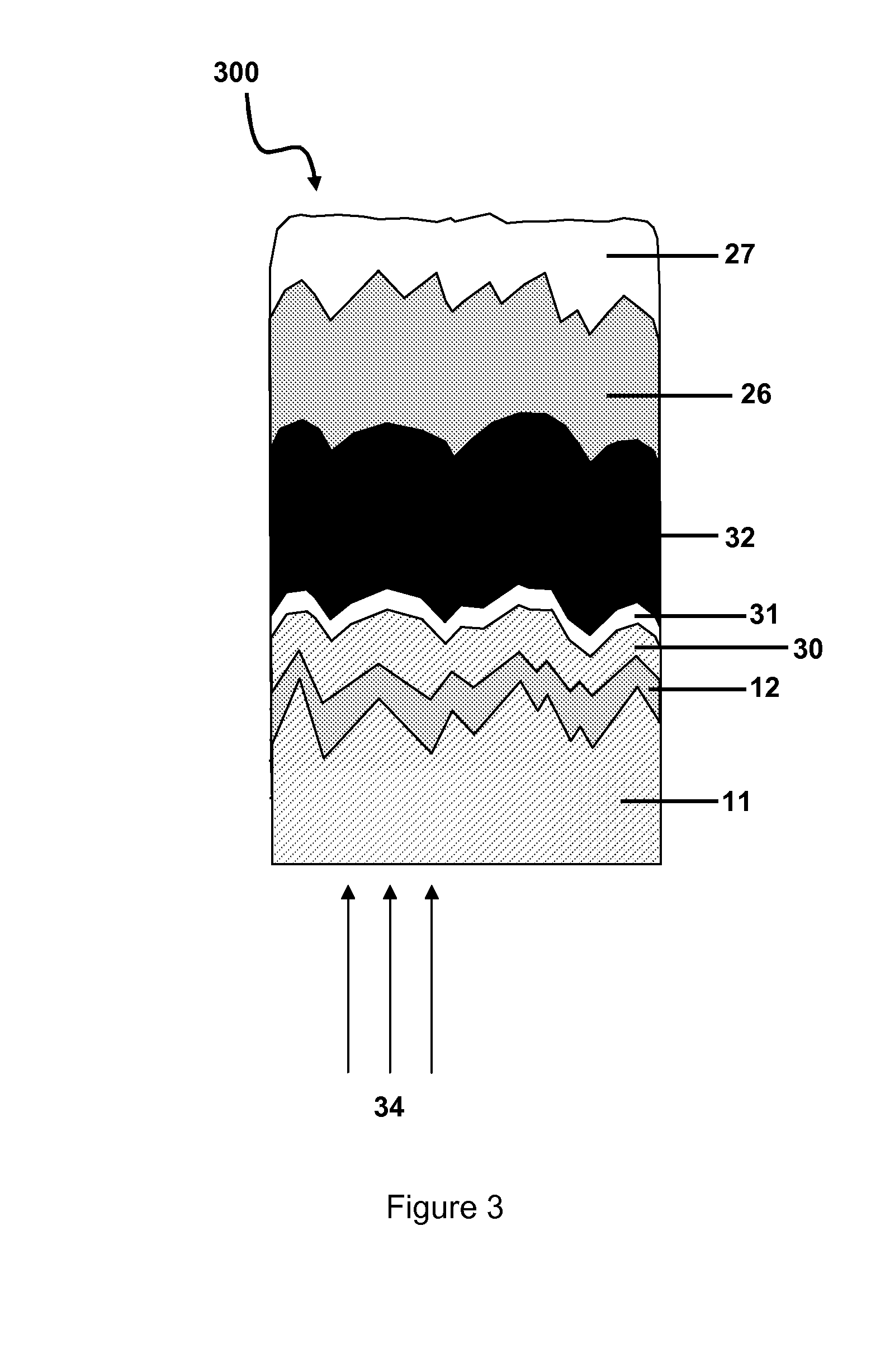

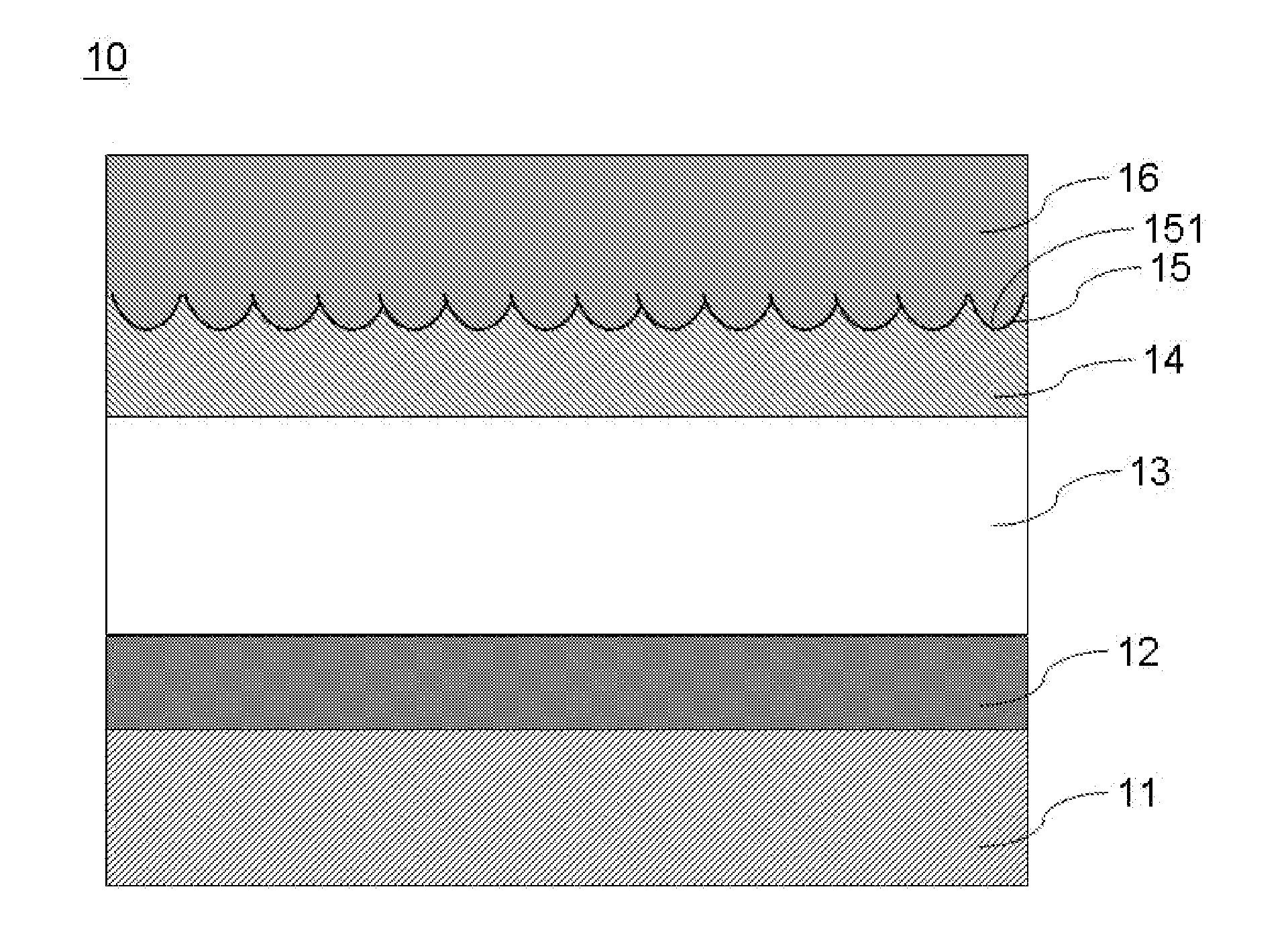

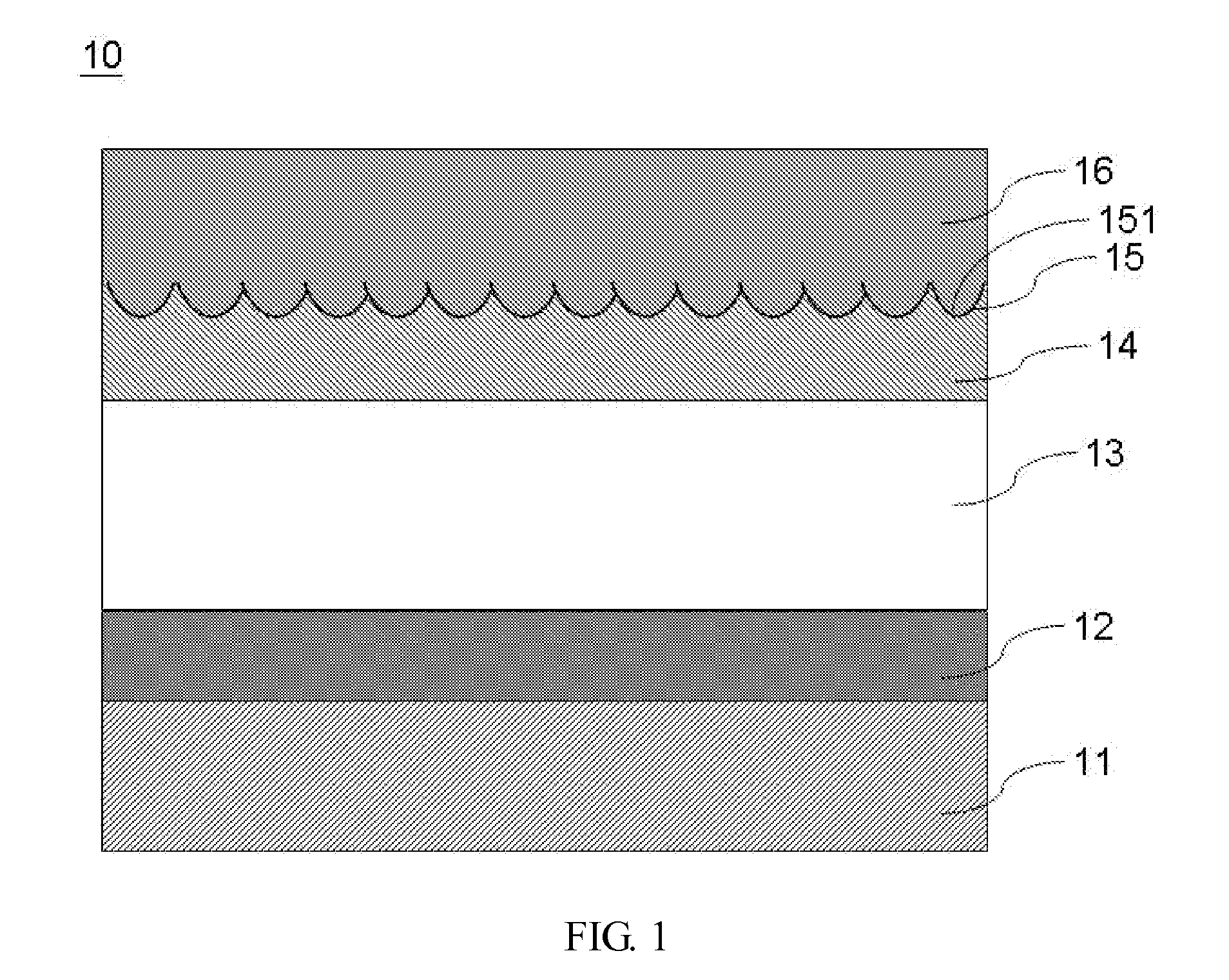

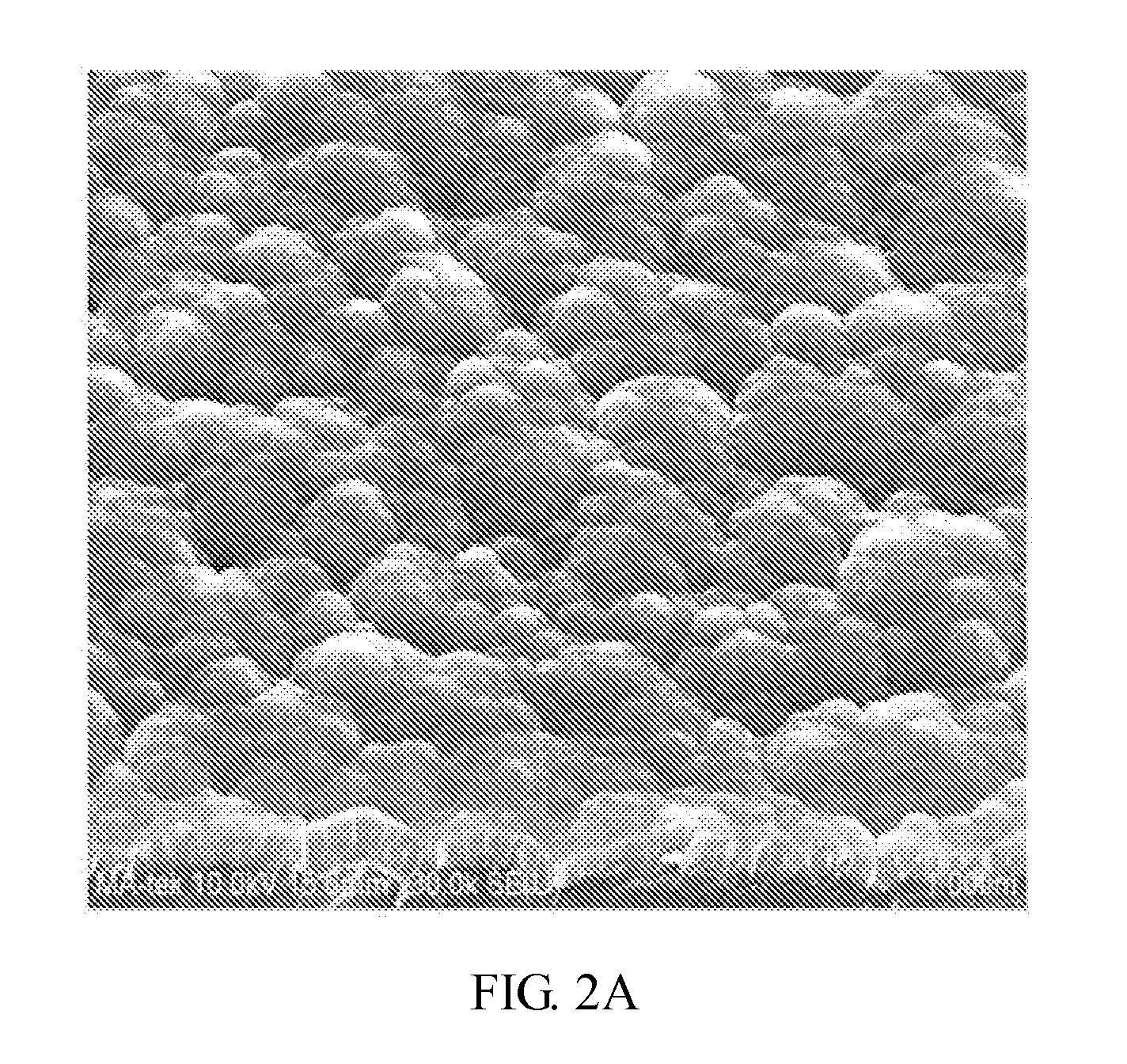

Thin film silicon solar cell in tandem junction configuration on textured glass

InactiveUS20130340817A1Photovoltaic energy generationSemiconductor devicesThin film solar cellPhysics

Solar cells or solar modules of the so-called tandem type, i.e. stacked arrangements of photovoltaic absorber devices on a substrate with a textured surface are described. The thin film solar cell has a substrate comprising a textured surface, and a front electrode layer comprising a transparent conductive oxide adjacent to the textured surface, wherein the electrode layer has a thickness less than the roughness of the textured surface.

Owner:CORNING INC +1

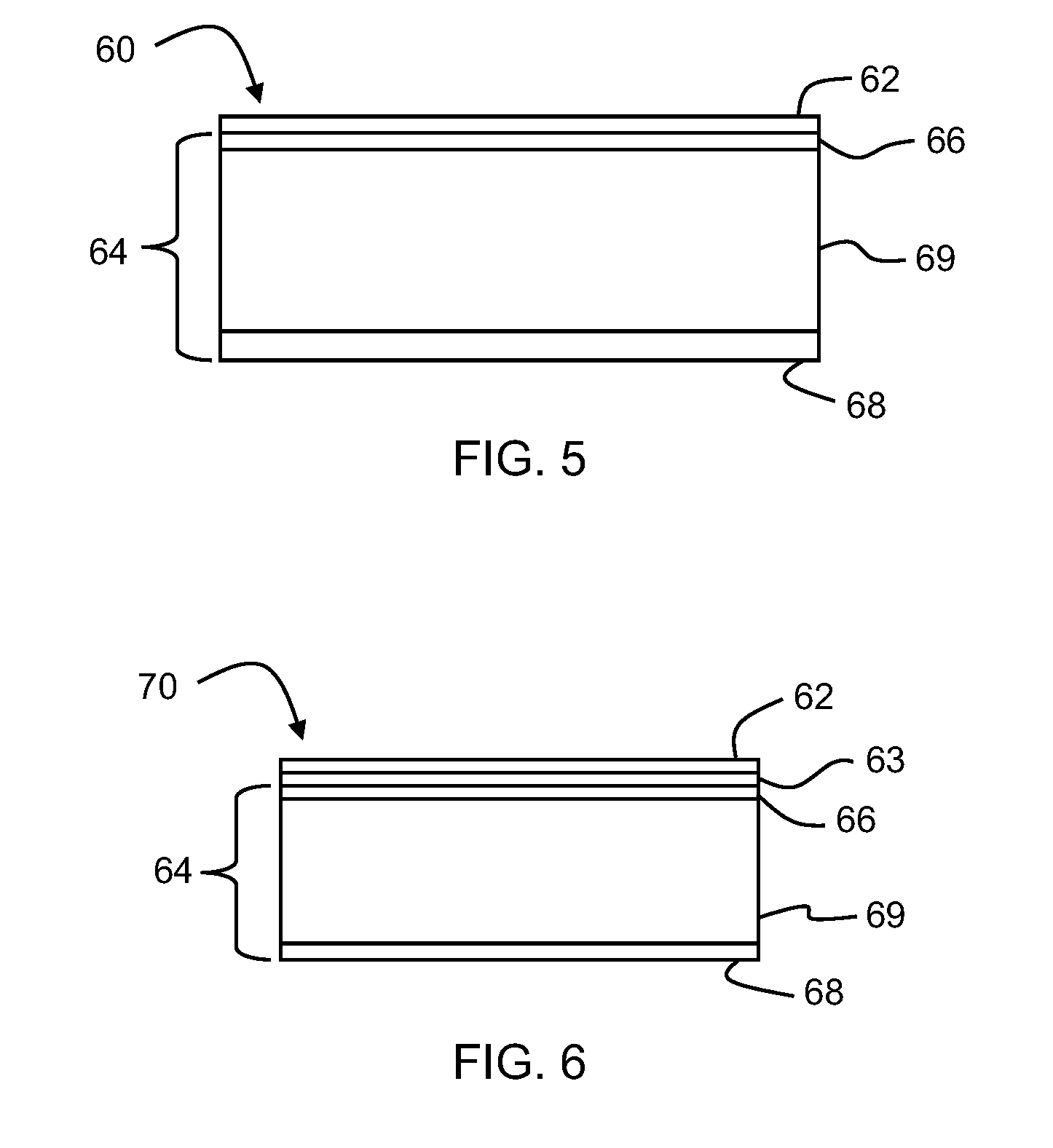

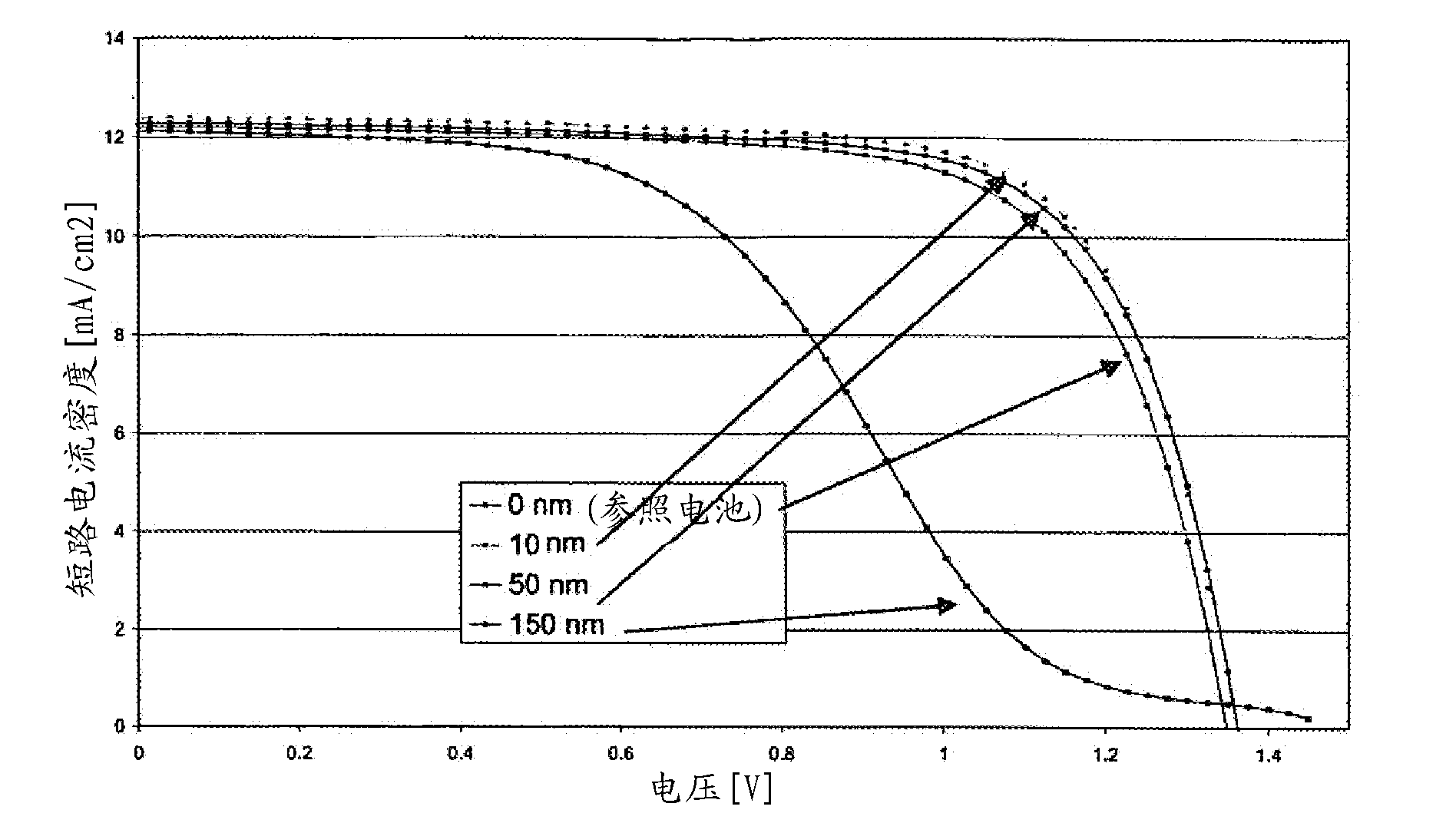

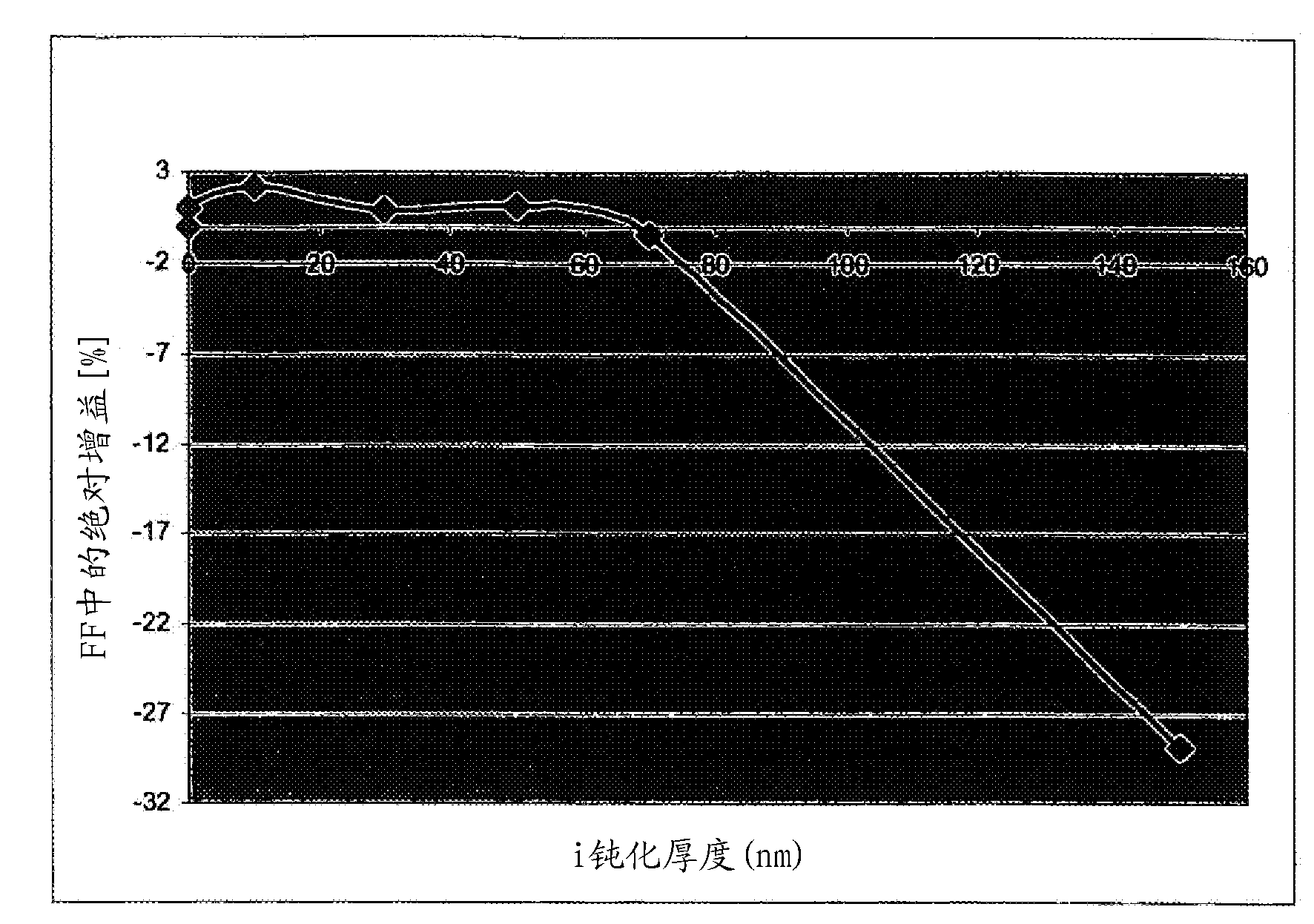

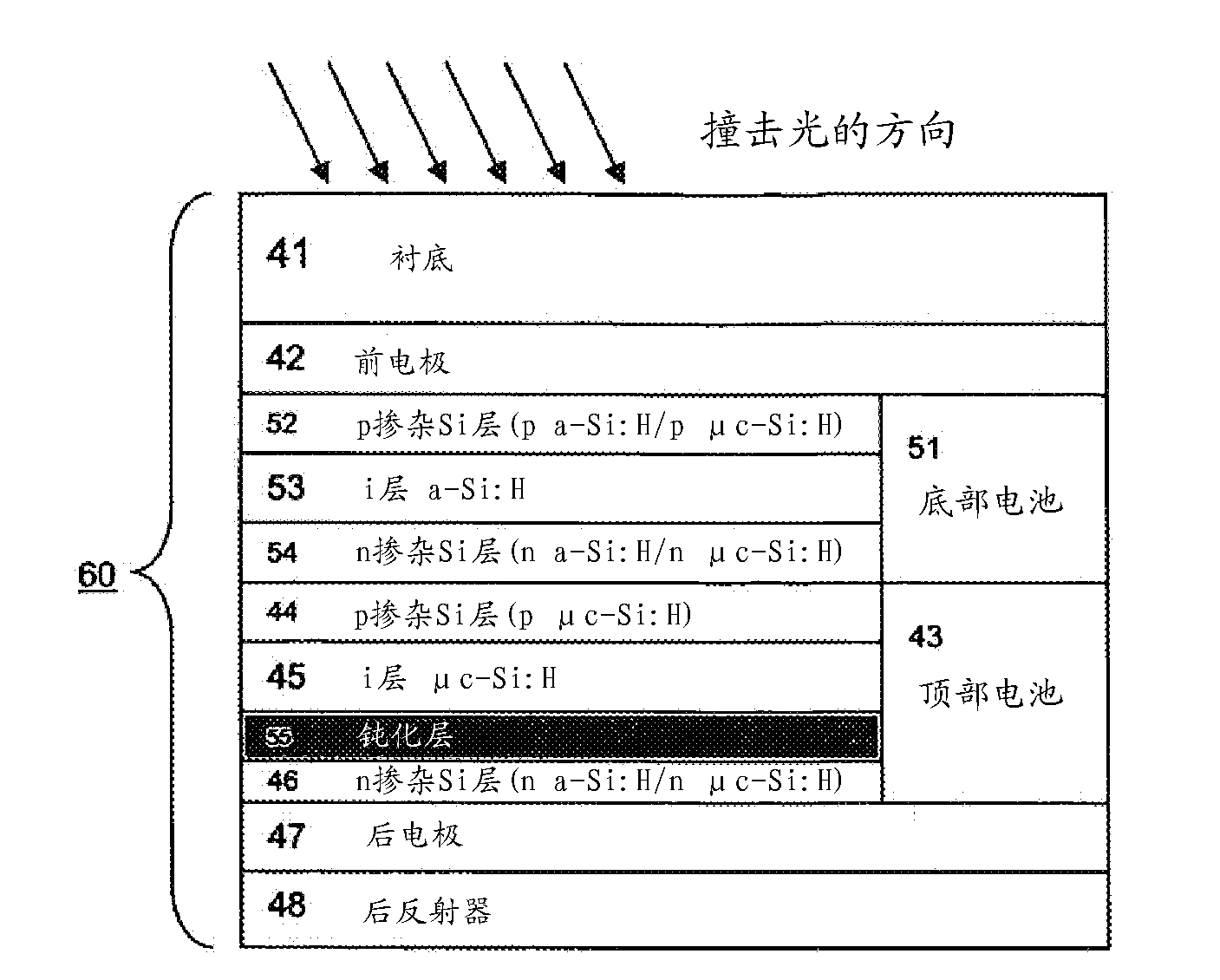

Thin film solar cell with microcrystalline absorpber layer and passivation layer and method for manufacturing such a cell

InactiveCN103038897APhotovoltaic energy generationSemiconductor devicesAmorphous siliconOptoelectronics

A Photovoltaic cell 60 includes a substrate 31, a front or first electrode 42 of transparent conductive oxide and at least one p-i-n junction 43 of microcrystalline silicon, said p-i-n junction 43 comprising a first n-doped silicon sub-layer 44 and a second p-doped silicon sub-layer 46 and a third sub-layer 45 with essentially intrinsic microcrystalline silicon. A passivation layer 45 comprising essentially intrinsic amorphous silicon is arranged a) between the microcrystalline intrinsic sub-layer 45 and n-doped silicon layer 46 or b) as a layer embedded in the microcrystalline intrinsic sublayer 45 or c) both. A method for manufacturing such a photovoltaic thin film silicon solar cell includes providing a transparent substrate 41 with a TCO front electrode 42 on it; depositing a p-doped Si layer 44, a microcrystalline silicon intrinsic layer 45, a passivation layer 55 from essentially intrinsic amorphous silicon, a n-doped Si layer 46 and a back electrode layer 48.

Owner:OERLIKON SOLAR AG (TRUEBBACH)

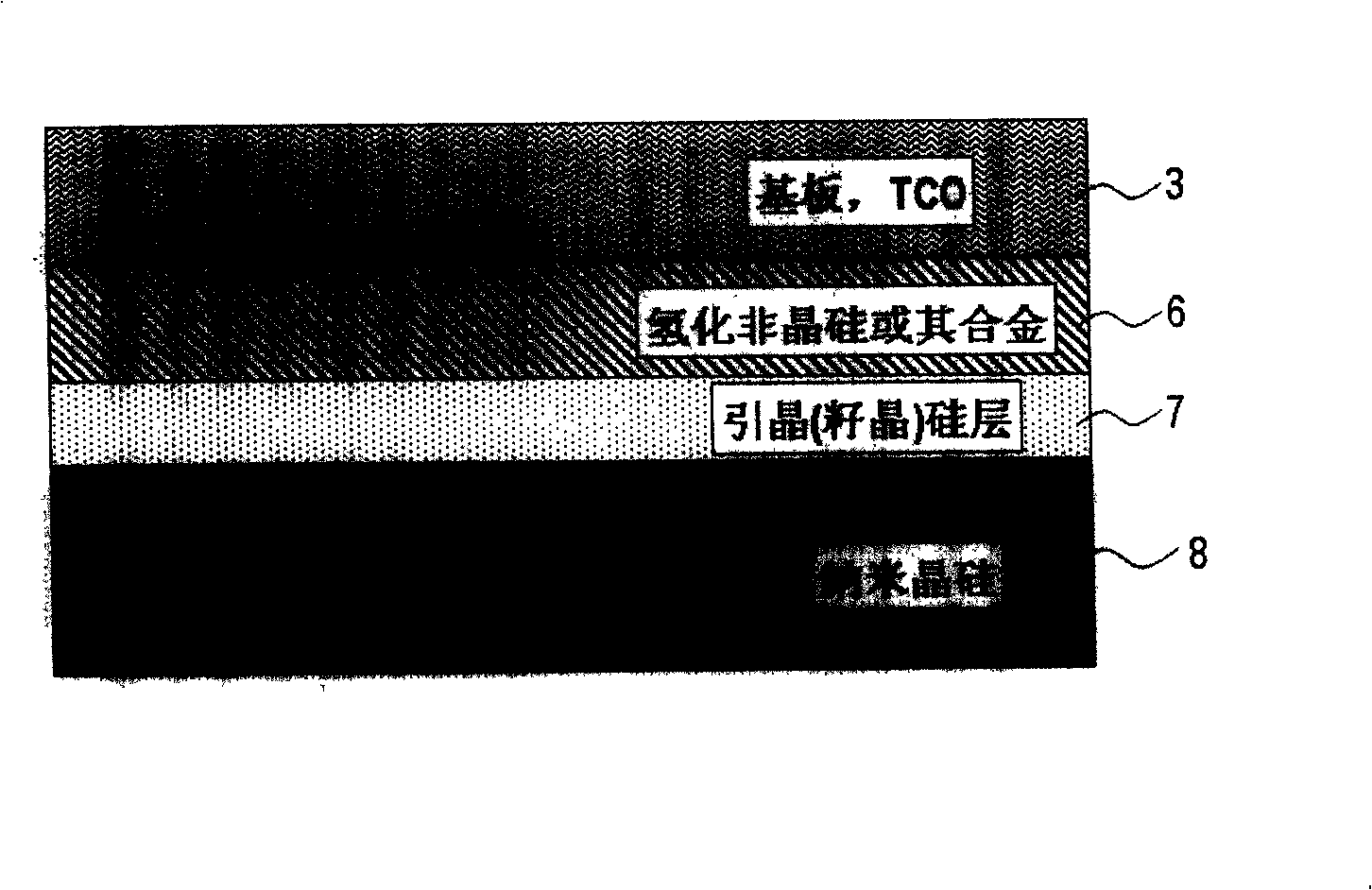

Nanocrystalline silicon forming method

InactiveCN101245489AShort exposure timePromote growthPolycrystalline material growthFrom chemically reactive gasesNanocrystalline siliconSilicon solar cell

The invention relates to the forming of a nanocrystalline silicon thin film without an amorphous latency layer, which consists of two plasma enhanced chemical vapor deposition stages, namely a dynamic equilibrium hydrogen ion etching preparation stage and a real growing stage thereafter. In a first etching stage, a moulding board which is composed of pint-sized seed crystals (crystal nucleus) forms on the surface based on the silicon thin film; in order not to form amorphous material and miscible thin film at the initial period of the growing stage, nanocrystalline silicon is immediately formed for preparation. The nanocrystalline silicon with an obvious abrupt interface is extremely important for the good transfer efficiency of a thin film silicon solar battery.

Owner:BEIJING XINGZHE MULTIMEDIA TECH

Thin Film Silicon Solar Cell and Manufacturing Method Thereof

InactiveUS20120017982A1Increase opportunitiesIncreasing short-circuit current densitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationOptoelectronicsSilicon solar cell

A thin film silicon solar cell and a manufacturing method thereof. The thin film silicon solar cell comprises a glass substrate, a first electrode layer, a light absorbing layer, a second electrode layer, and a metal electrode layer sequentially stacked on top of one another. The second electrode layer has a texture surface and concavities formed on the texture surface, and each of the concavities has a width falling within a range of 100 nm-1600 nm and a depth less than 800 nm.

Owner:NEXPOWER TECH

Multi-junction Thin-Film Silicon Solar Cells with a Recrystallized Silicon-based Sub-Cell

InactiveUS20150280049A1Final product manufactureSemiconductor/solid-state device manufacturingAmorphous siliconP type doping

This application relates to systems and methods for multi-junction solar cells that includes at least one recrystallized silicon layer. The recrystallized silicon lay may have a microcrystalline structure following a heat treatment or laser treatment of an amorphous silicon layer. The multi-junction solar cell may be a p-i-n or n-i-p structure that may include a p-type doped silicon layer, an intrinsic silicon layer, and an n-doped silicon layer. In one embodiment, the intrinsic layer in either type of structure may be the recrystallized silicon layer.

Owner:OERLIKON SOLAR AG (TRUEBBACH)

Novel solar cell back reflector with AAO nanometer grating structure

InactiveCN104900742AImprove photoelectric conversion efficiencyExtended propagation pathPhotovoltaic energy generationSemiconductor devicesBack reflectorGrating

The invention puts forward an idea that an AAO template serves as a nanometer grating which is introduced to a thin-film silicon solar cell structure, and designs and provides a novel solar cell back reflector with an AAO nanometer grating structure. The reflector is formed by a three-layer structure of a silver back reflection layer, the AAO nanometer grating and ITO conductive glass. According to a grating equation, the optimum AAO structure parameters are obtained through design and analysis. The reflector can effectively prolong light path inside a solar cell, improves long-wavelength photon utilization rate, and furthermore, improves photoelectric conversion efficiency of the solar cell. The reflector is simple in manufacturing process, low in cost, and suitable for batch production.

Owner:TIANJIN POLYTECHNIC UNIV

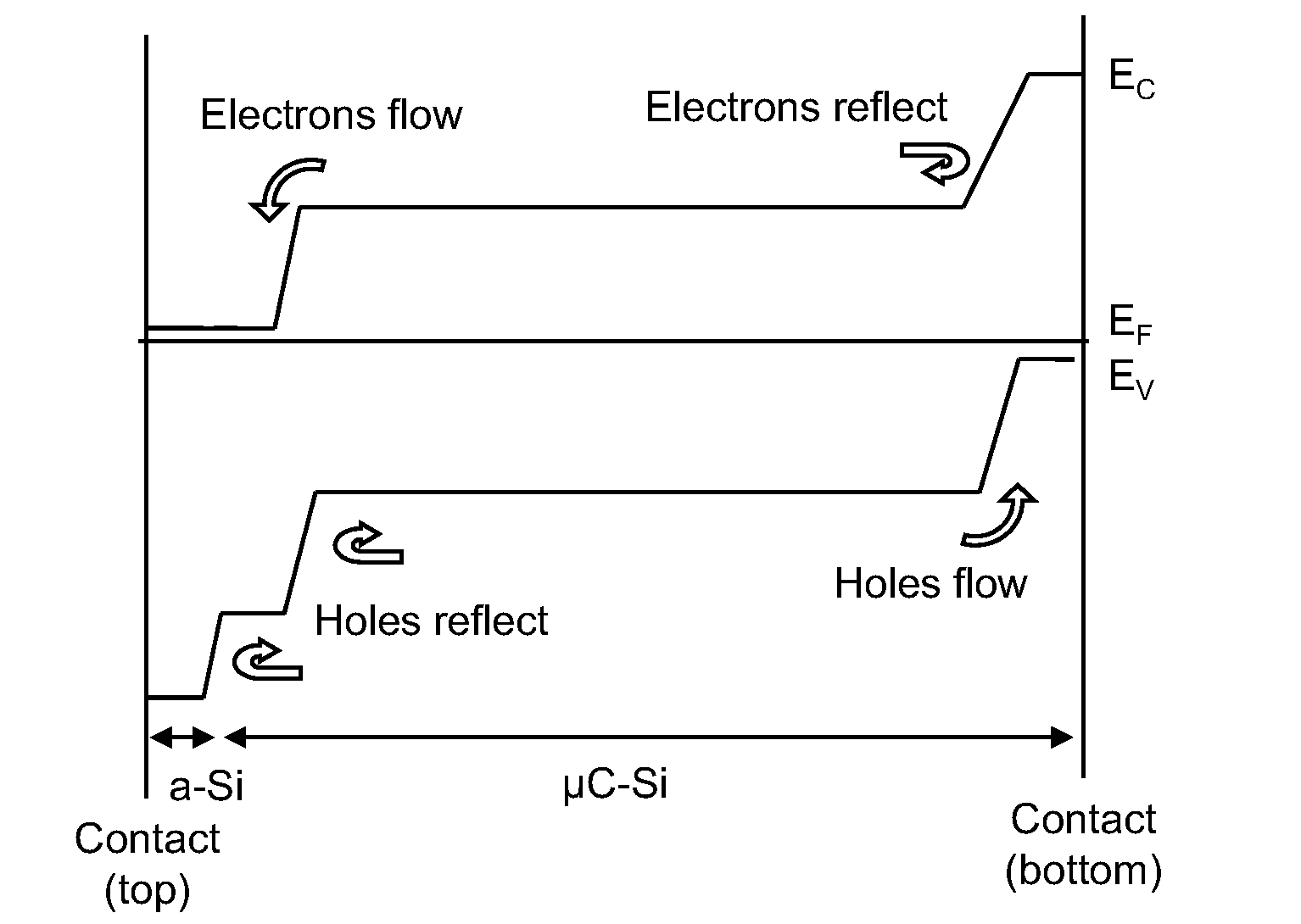

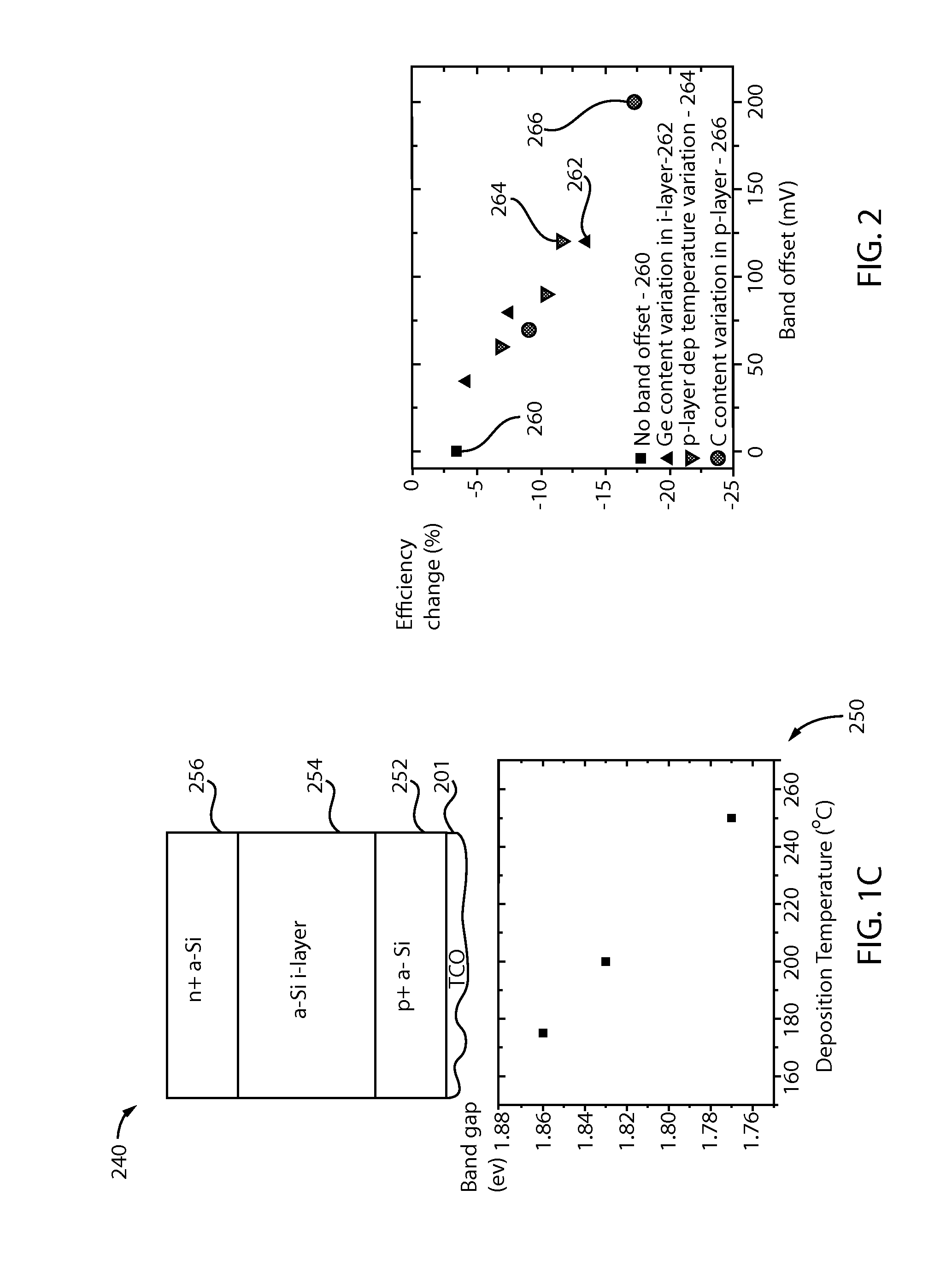

Reduction of light induced degradation in thin film silicon solar cells

InactiveUS20150270428A1Reduce degradationReduces a band offsetFinal product manufacturePhotovoltaic energy generationSilicon solar cellBand offset

A device and method for reducing degradation in a photovoltaic device includes adjusting a band offset of the device during one or more of forming an electrode, forming a first doped layer or forming an intrinsic layer. The adjusting reduces a band offset between one or more of the electrode, the first doped layer and the intrinsic layer to reduce light-induced degradation of the device. A second doped layer is formed on the intrinsic layer.

Owner:IBM CORP +1

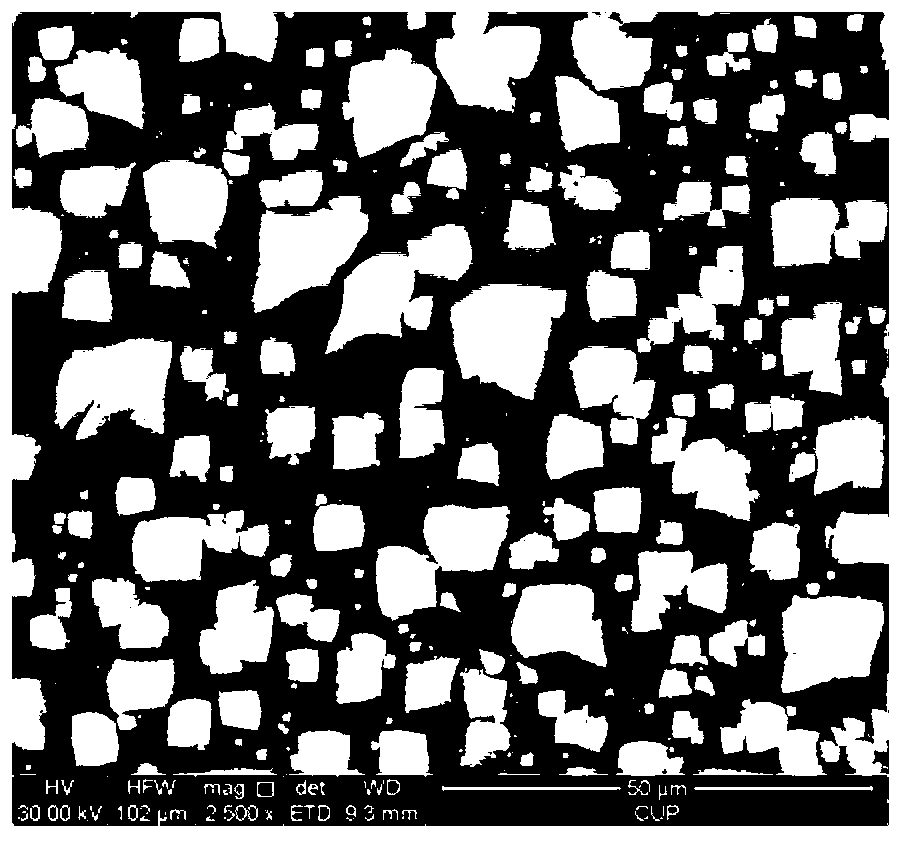

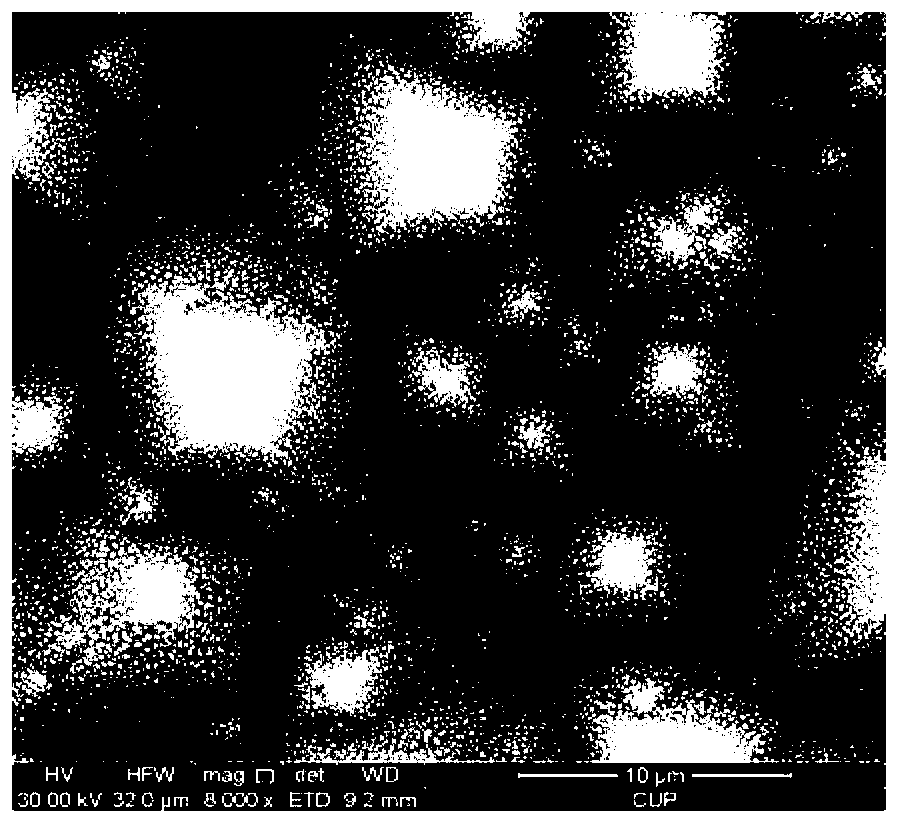

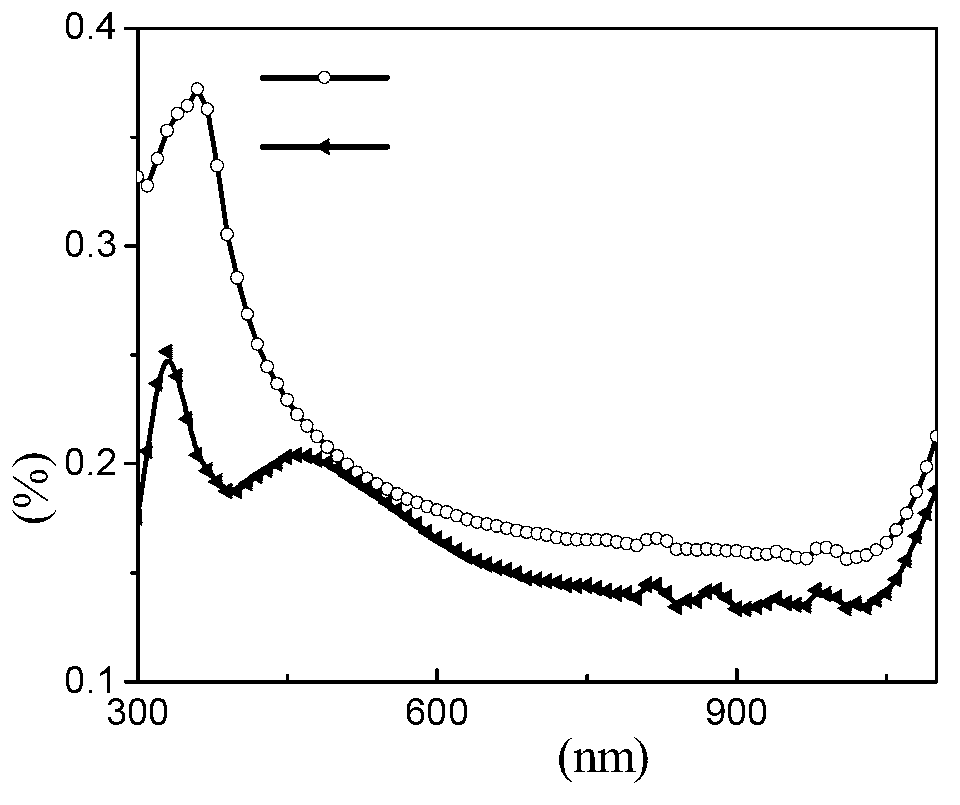

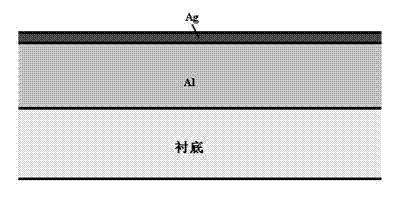

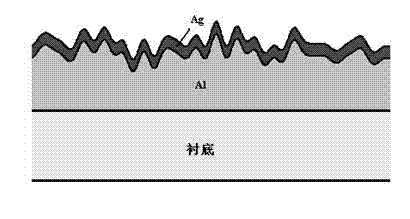

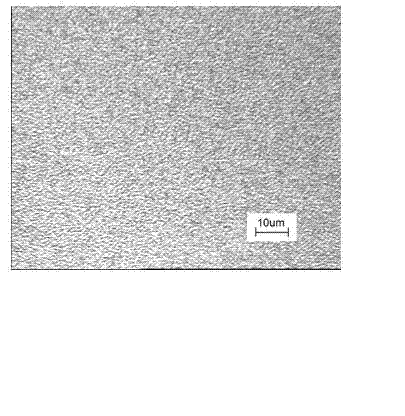

Back scattering surface of thin-film silicon solar cell and preparation method of back scattering surface

InactiveCN102420260AEasy to prepareEasy to implementFinal product manufacturePhotovoltaic energy generationComposite filmGas phase

The invention relates to a back scattering surface of a thin-film silicon solar cell and a preparation method of the back scattering surface. In the invention, a thin film which is used as the back scattering surface is a composite film and is compounded by a metal and an Ag film, wherein the metal is in direct contact with a substrate and has a shape which is easy to change at a lower temperature; the thickness of the metal film is in a range of 250-600 nm and the thickness of the Ag film is in a range of 20-50 nm; and the surface of the composite film is of a rough structure shape with a submicron size. The structure is prepared by adopting a physical vapor deposition method; in a high-vacuum environment, the method comprises the following steps of: under the condition of heating the substrate, depositing the metal film on the substrate and then depositing the Ag film to form the composite film; or under the condition of the room temperature, depositing the metal film on the substrate and then depositing the Ag film to form the composite film; and then carrying out vacuum heat treatment on the deposited composite film at a temperature in a range of 150-250 DEG C. According to the invention, the scattering property of the surface of the formed composite film is great, the temperature for changing the shape of the metal film is lower and the heat treatment temperature for reducing surface roughening is reduced; meanwhile, the consumption of the noble metal Ag is reduced and the manufacturing cost is reduced.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com