Thin film solar cell with microcrystalline absorpber layer and passivation layer and method for manufacturing such a cell

A passivation layer and microcrystalline technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as good Voc and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

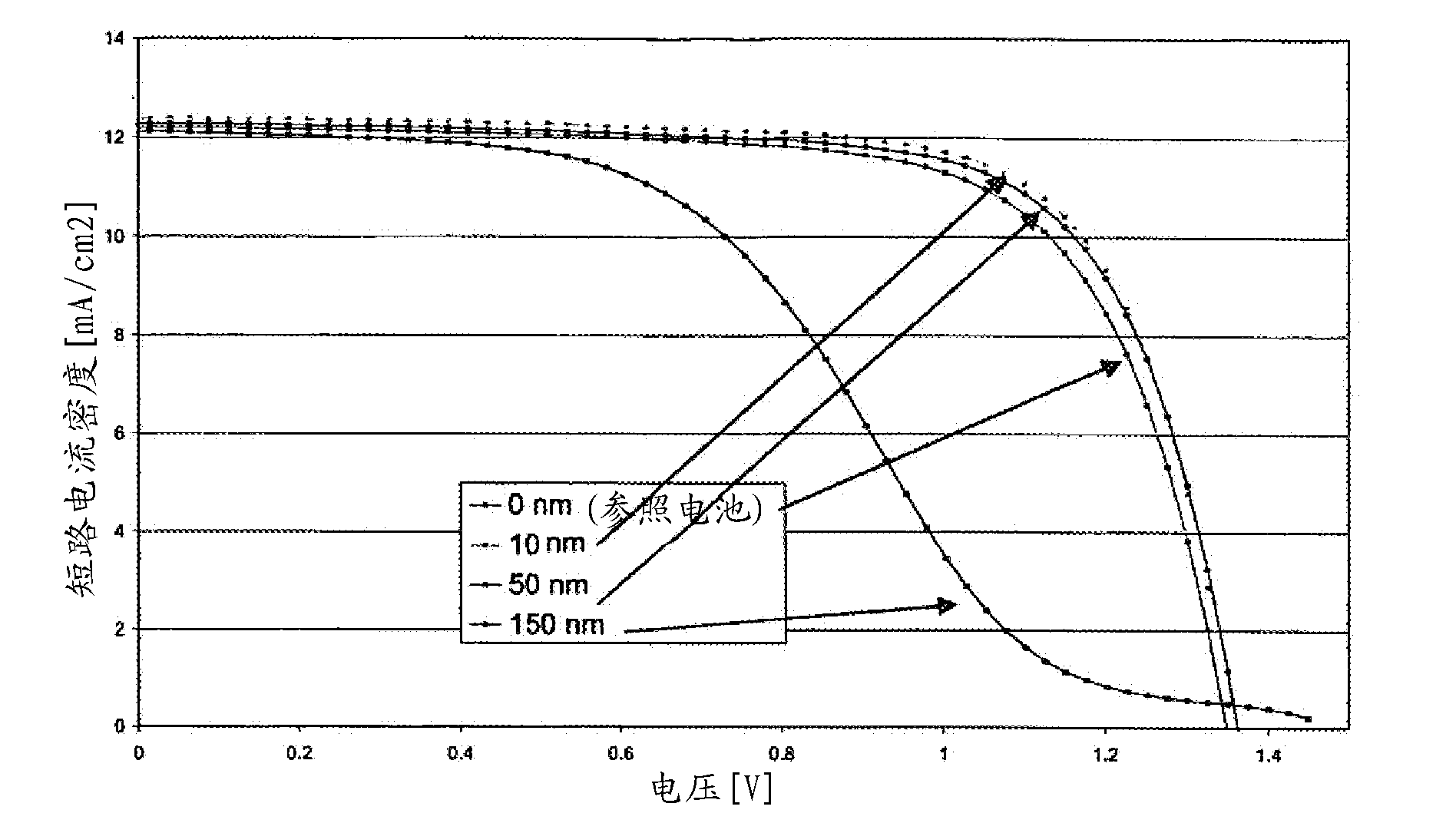

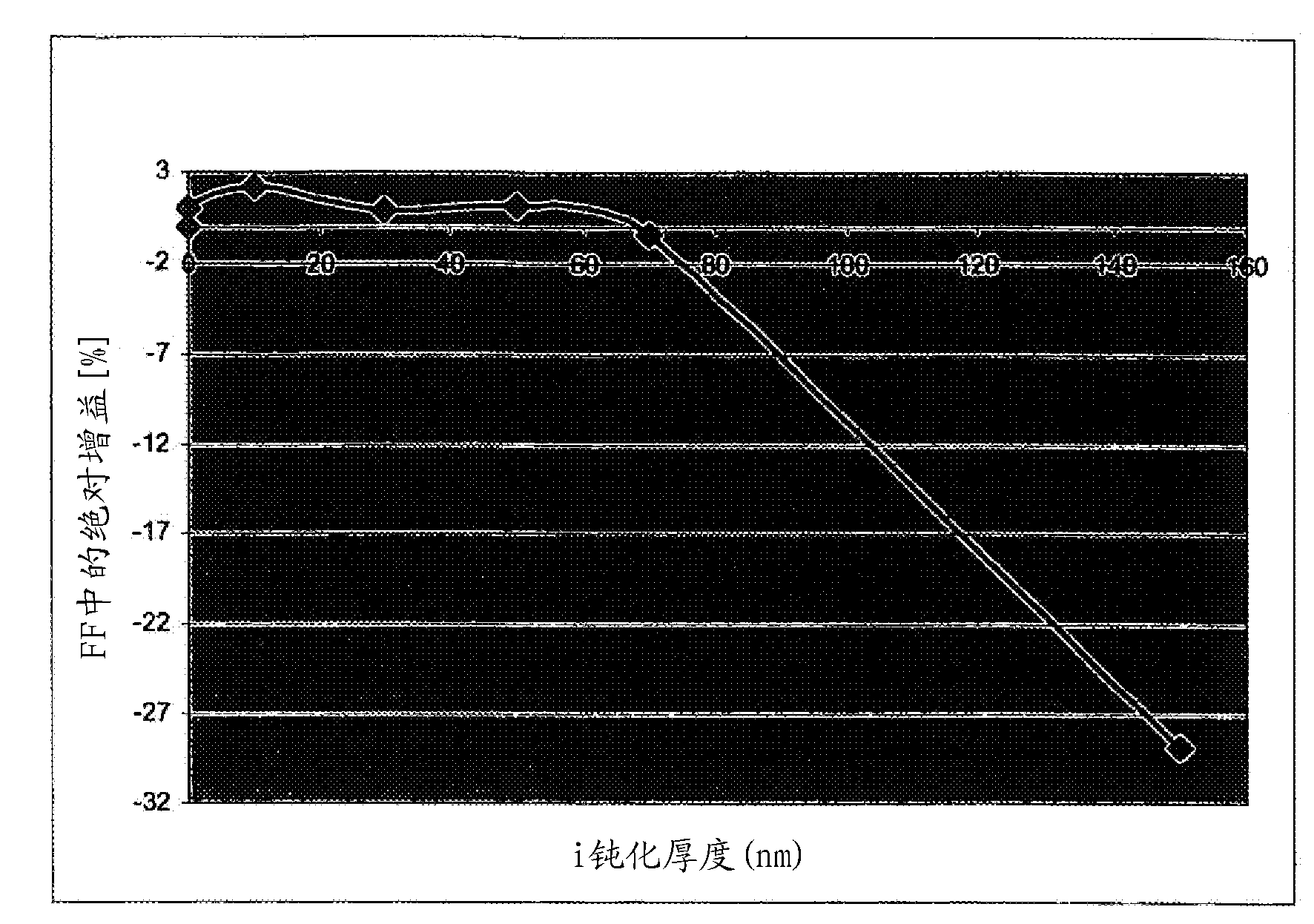

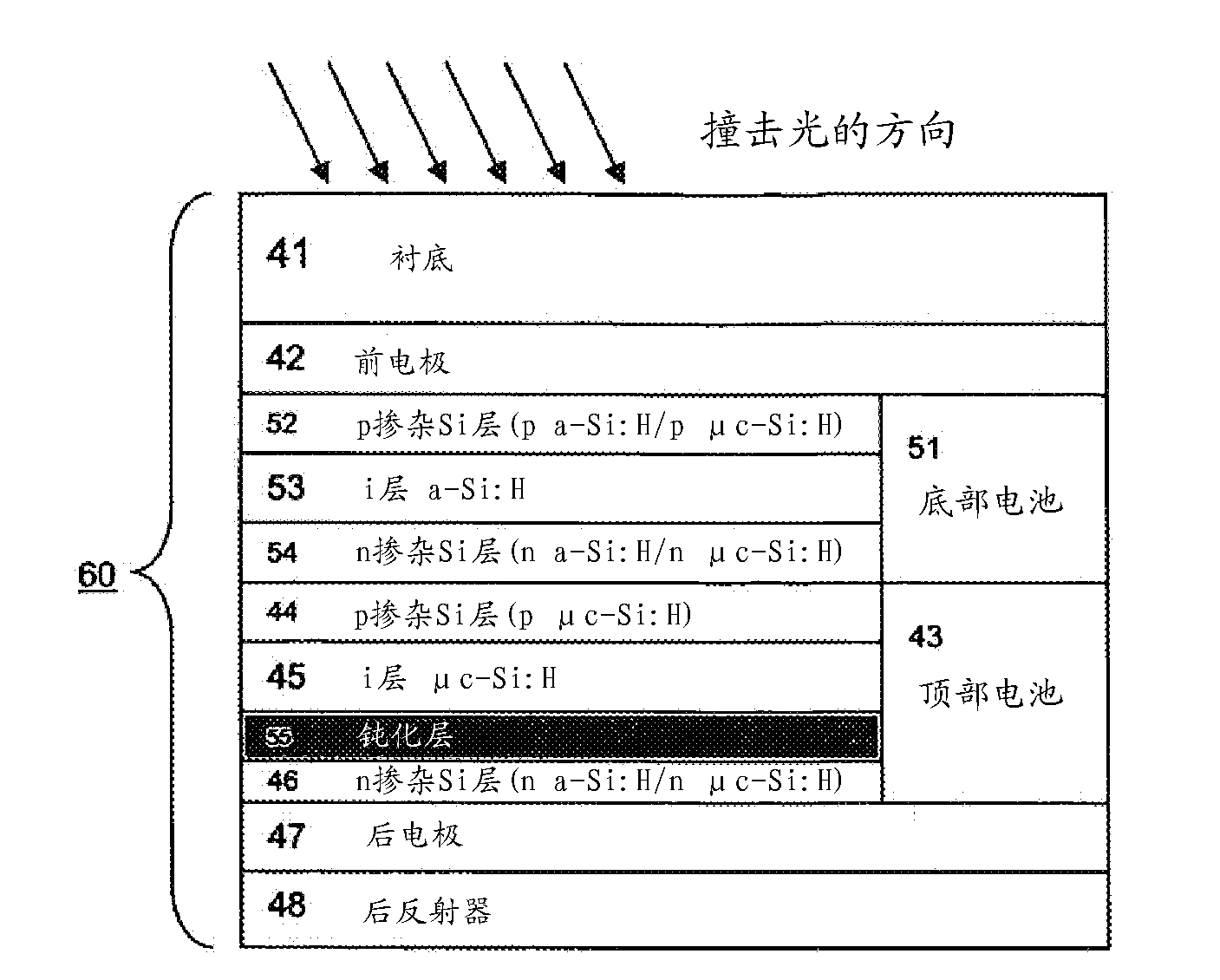

[0015] In the following illustrative examples, top-confined amorphous tandem cells were fabricated on native rough TCO (LPCVD-ZnO). A reference device 50 for comparison provides a top pin a-Si:H cell 51 with an i-layer 53 thickness of 250nm and 2000nm light with moderate crystallinity (50-55% bulk Raman crystallinity measured with a 780nm laser) The bottom μc-Si:H cell 43 of the active i-layer 45 . The passivation device 60 has the same i-layer thickness for the top and bottom cells, except that the deposition of the μc-Si:H i-layer 45 according to the invention is followed by the deposition of a fully amorphous i-layer 55 (passivation layer) of varying thickness. Passivated device 60 exhibits improved electrical performance (see FIG. 1 ). This suggests that the detrimental effects of certain defects in the underlying microcrystalline silicon layer are thus mitigated. In particular, recombination centers such as dangling bonds can be efficiently passivated with a-Si:H, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com