Silicon thin-film solar cell and manufacturing method therefor

A solar cell and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve the problems of low battery utilization rate, complex packaging process, poor bonding force between the packaging layer and the battery body, etc., to improve the weather resistance. performance and stability, simple packaging process, and the effect of meeting different requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

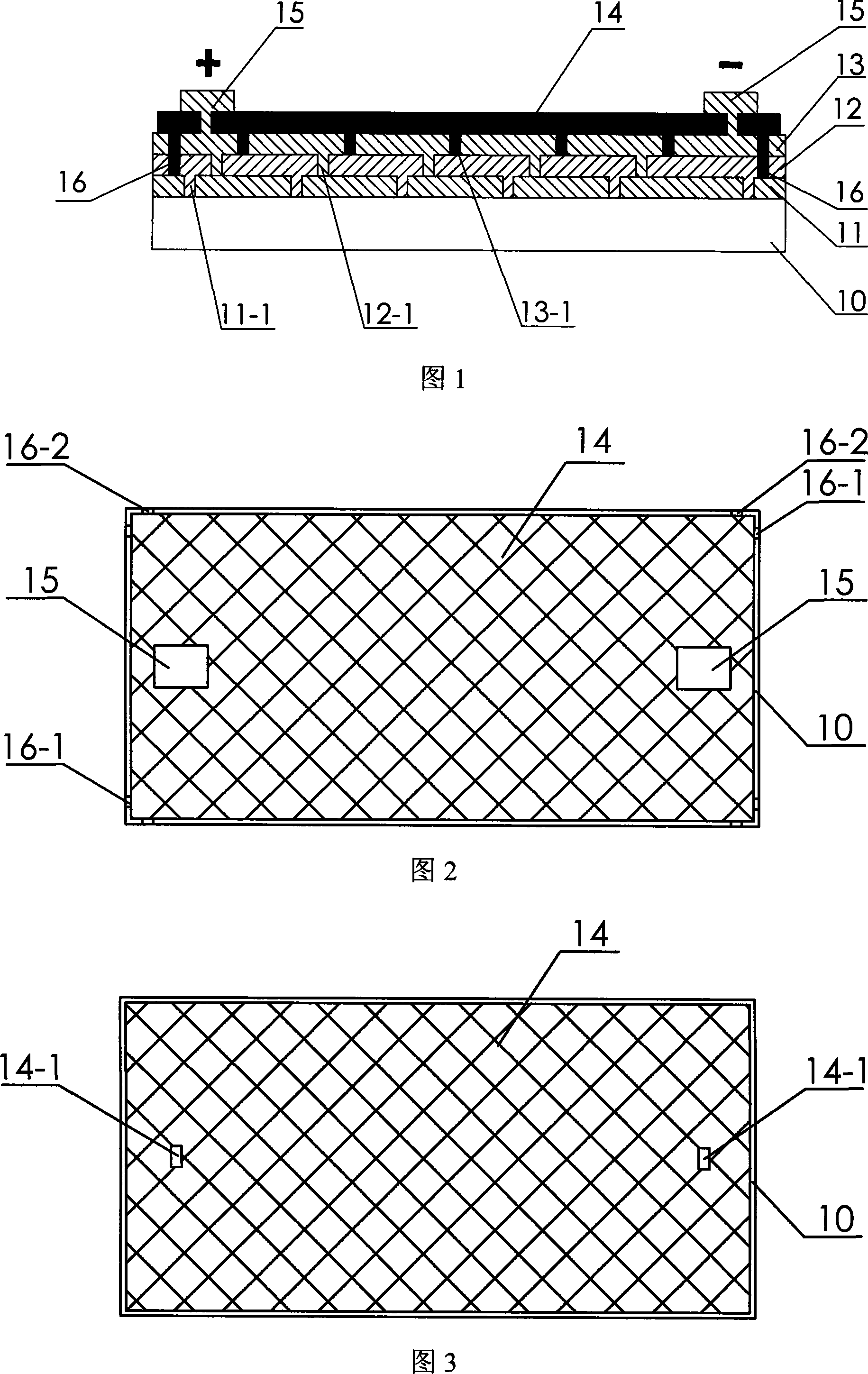

[0043] Example 1: Production of a small strong-light single-junction amorphous silicon solar cell with an outline of 50mm×50mm×3.0mm and a pitch of 10mm.

[0044] A silicon thin-film solar cell with a shape of 50mm×50mm×3.0mm is composed of 5 unit nodes with a pitch of 10mm. The process steps are as follows:

[0045] Step 1, front electrode 11 graphic production: use ITO or SnO with an array pitch of 50mm×50mm according to the design 2 The transparent conductive film glass is used as the substrate, and the continuous conductive film on the substrate is etched into independent small pieces with a spacing of 10mm by laser. Transverse groove; 11-2 is the longitudinal groove of the front electrode film layer; 11-3 is the segmented groove of the front electrode film layer, which constitutes the front electrode pattern.

[0046] Step 2. Deposit thin film battery layer 12: After the substrate with the front electrode pattern engraved is ultrasonically cleaned and dried, preheated, a...

example 2

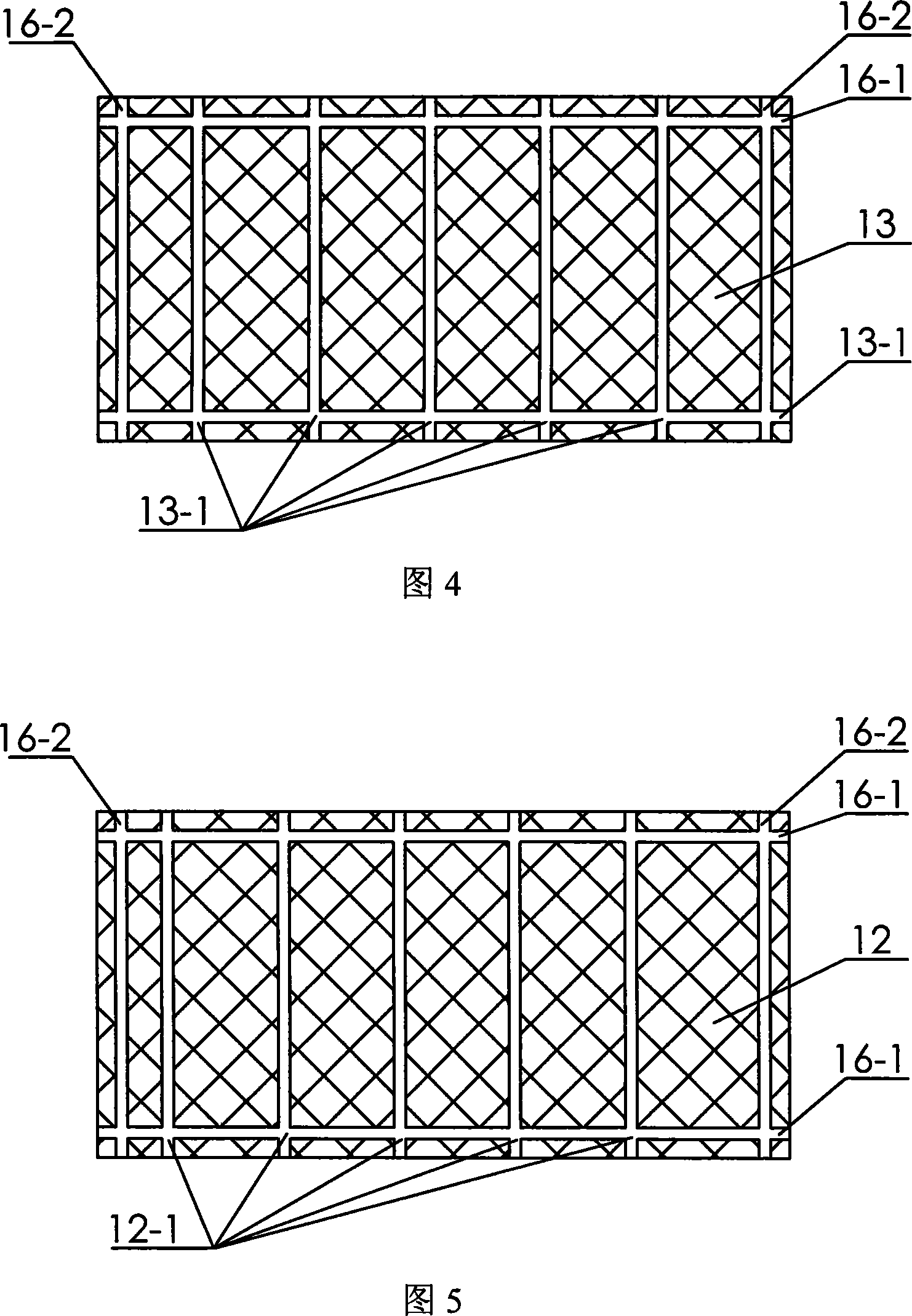

[0055] Example 2: Production of small strong light double-junction amorphous silicon solar cells with a shape of 60mm×60mm×3.0mm and a pitch of 12mm.

[0056] A silicon thin-film solar cell with a shape of 60mm×60mm×3.0mm is composed of 6 unit nodes with a pitch of 12mm. The process steps are as follows:

[0057] Step 1. Fabrication of front electrode 11 pattern: use ITO or SnO 2 The transparent conductive film glass is used as the substrate. Lasers are used to etch the continuous conductive film on the substrate into independent small blocks with a spacing of 12 mm. The small blocks are insulated from each other, as shown in the shaded part in Figure 6, which is the front electrode pattern.

[0058] Step 2. Depositing the double-junction amorphous silicon layer 12: After the substrate with the engraved front electrode pattern is ultrasonically cleaned and dried, preheated, and the top cell P is sequentially deposited on the substrate by plasma chemical vapor deposition (PECVD...

Embodiment 3

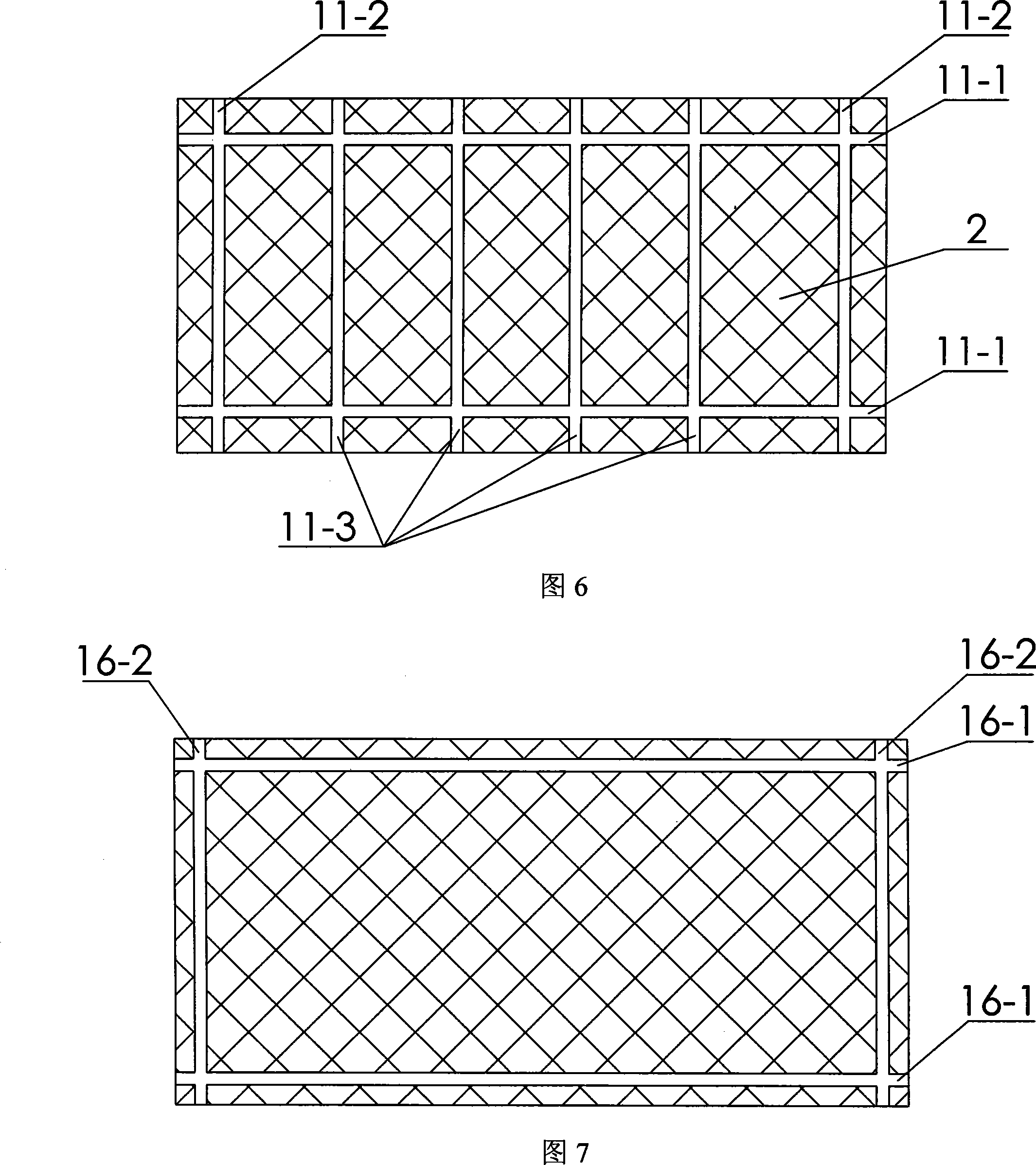

[0067] Example 3: Production of laminated thin-film solar cells with an outline of 350 mm×1220 mm×3.0 mm and a pitch of 20 mm.

[0068] Proceed as follows:

[0069] Step 1. Fabrication of the front electrode pattern: ITO or SnO with a size of 350mm×1220mm 2 The transparent conductive film glass is used as the substrate, and the continuous conductive film on the substrate is etched into independent small blocks with a spacing of 20 mm by laser scribing. The small blocks are insulated from each other, that is, the front electrode pattern.

[0070] Step 2. Deposition of the top cell: After ultrasonic cleaning and drying of the substrate with the engraved front electrode pattern, preheating, and the enhanced plasma chemical vapor deposition (PECVD) method is used to sequentially deposit P-type amorphous silicon on the substrate. Layer, I-type intrinsic amorphous silicon layer and N-type amorphous silicon doped layer, and lasers are used to engrave the corresponding position in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com