Novel solar cell back reflector with AAO nanometer grating structure

A technology of solar cells and nano gratings, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of unsuitability for mass production, high cost, harsh preparation conditions of gratings for thin-film silicon solar cells, etc., and achieve the goal of improving photoelectric conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

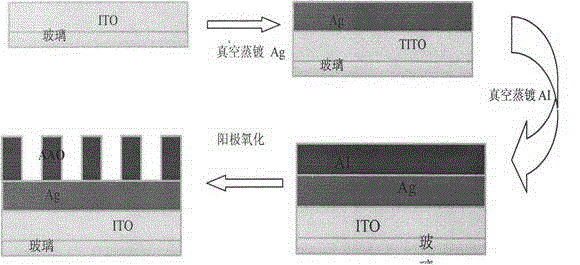

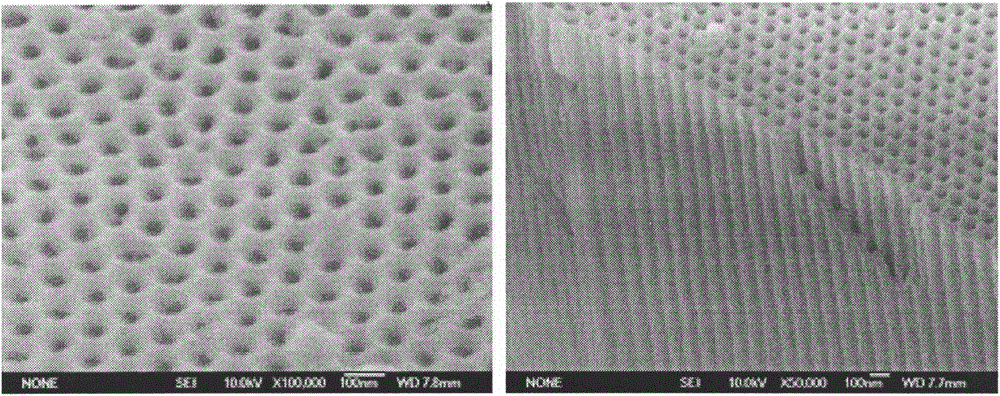

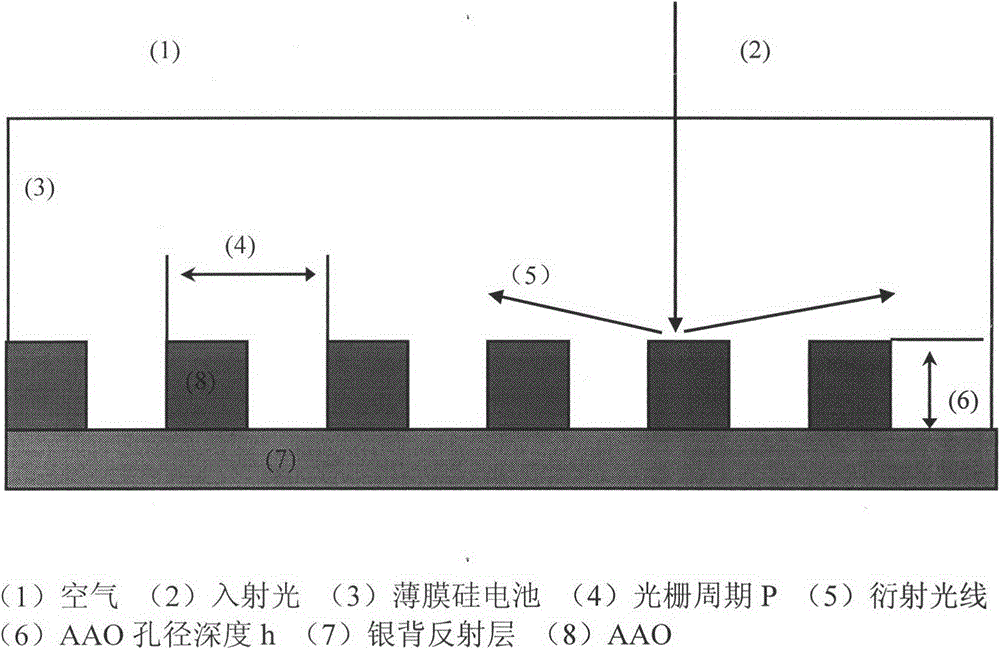

[0015] The back reflector designed by the patent of the present invention can be used in various solar cells such as thin film silicon and crystalline silicon. AAO nanograting structures such as figure 1 shown. The structure of the back reflector and the schematic diagram of the optical path are shown in figure 2 As shown, where P is the grating period, that is, the distance between the center points of the AAO apertures, and h is the grating aperture depth, that is, the AAO aperture depth.

[0016] working principle

[0017] The main function of the back reflector is to diffract light that is not absorbed by silicon back into the working substance through the grating, thereby increasing the distance of light propagation in silicon. The modulation of light by a grating can be described by the grating equation.

[0018] Grating structure parameter selection

[0019] Selection of the grating constant P: Take the vertical incidence of light as an example to design the grati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com