Multi-junction solar cells and methods and apparatuses for forming the same

A solar cell and multi-junction technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as low efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0107] The embodiments disclosed herein are illustrative in nature and are not intended to limit the scope of the invention unless explicitly set forth in the claims.

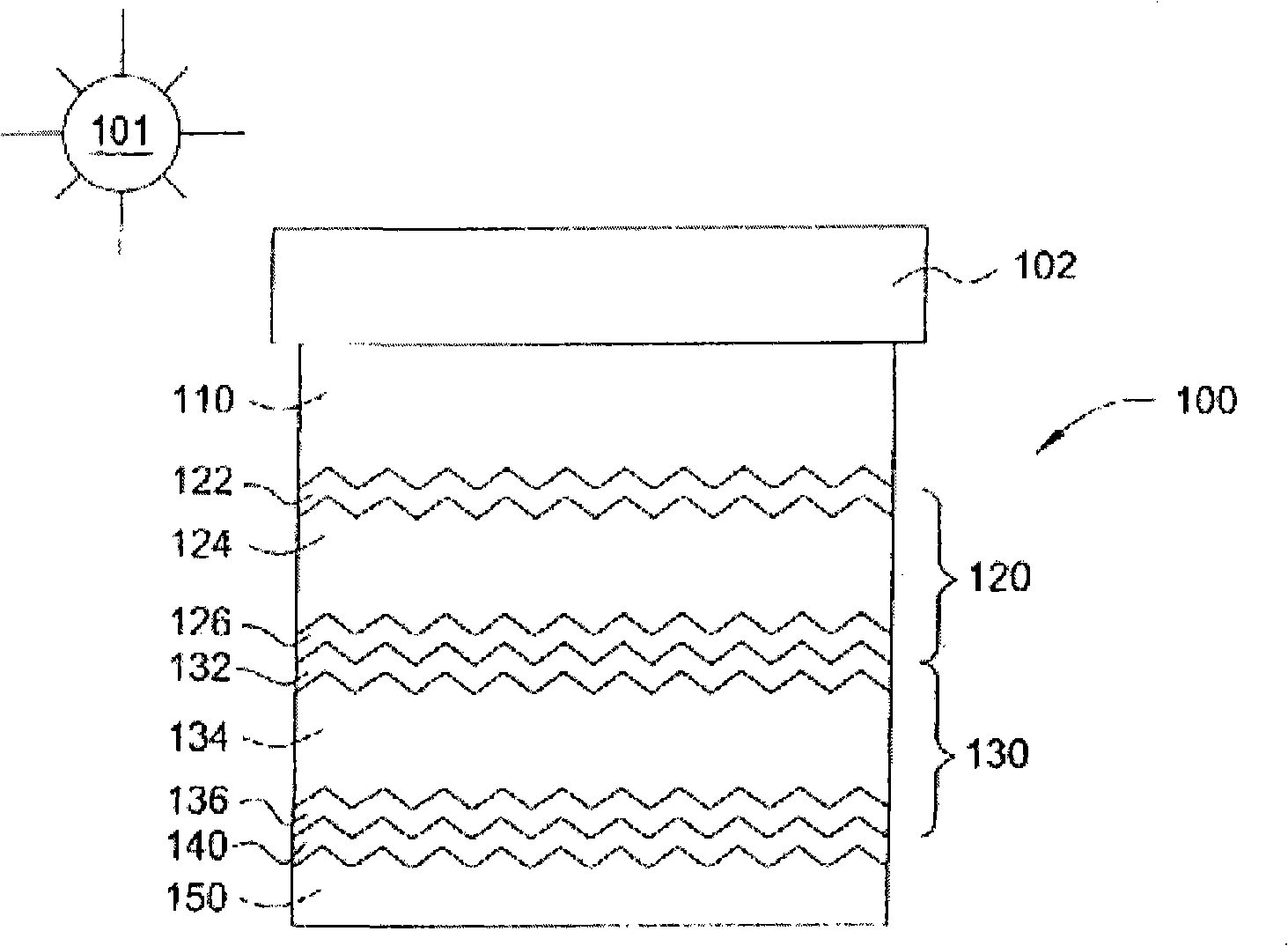

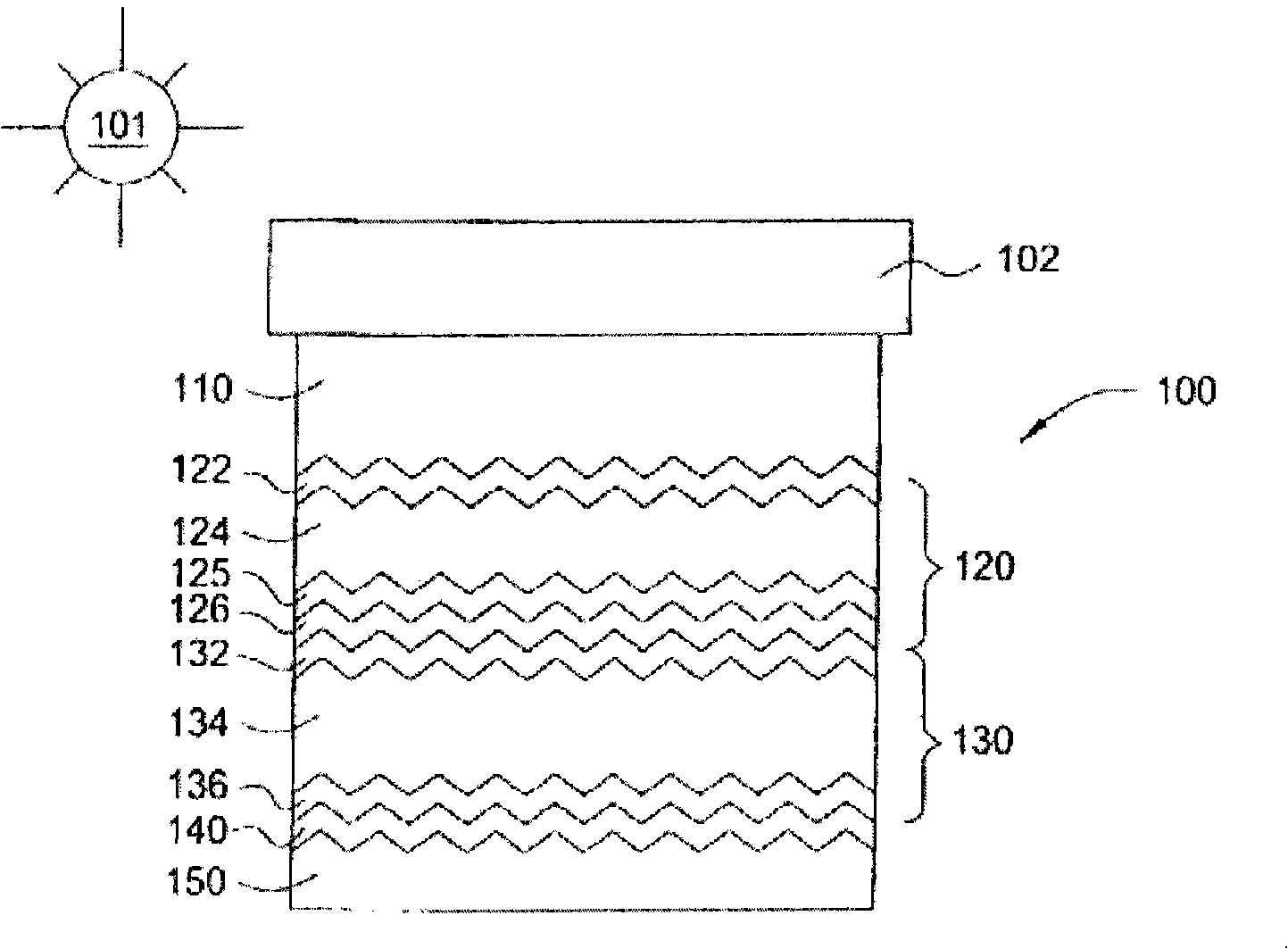

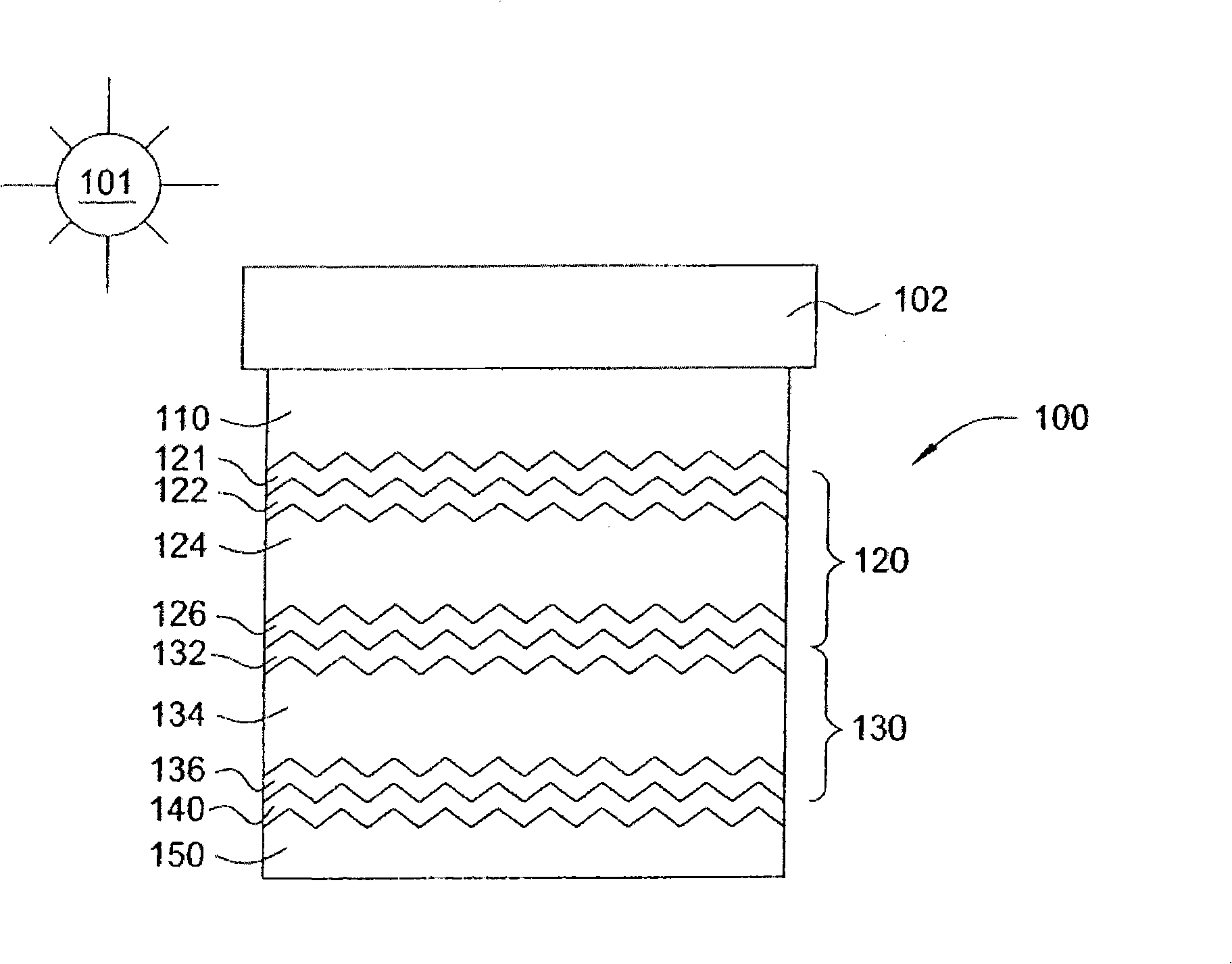

[0108] handle has a 4,320cm 2 surface area substrates, may be performed in an AKT 4300 PECVD system with an internal chamber volume of 130 liters, available from AKTAmerica Inc., Santa Clara, California. Layer 1 was deposited in the first chamber of the PECVD system. Layers 2-4 were deposited in the second chamber of the PECVD system. Layer 5 is deposited in the third chamber of the PECVD system. Layers 6-11 were deposited in the fourth chamber of the PECVD system. During the deposition of layers 1-11, the spacing was set at 550 mils and the substrate temperature was set at 200°C. Image 6 The deposition parameters set in are used to form tandem p-i-n junction solar cells. Phosphine was supplied as a 0.5% mixture in a hydrogen carrier gas. Trimethylboron was provided as a 0.5% mixture in a hydrogen carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com