Silicon-based nanometer column array heterojunction film solar battery and preparation method thereof

A technology of nano-column arrays and solar cells, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of poor masking effect of silicon nanocrystals, technical application of solar cells, corrosion of crystalline silicon nano-columns, etc., and shorten the transportation distance , Improve collection efficiency and reduce the consumption of silicon materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

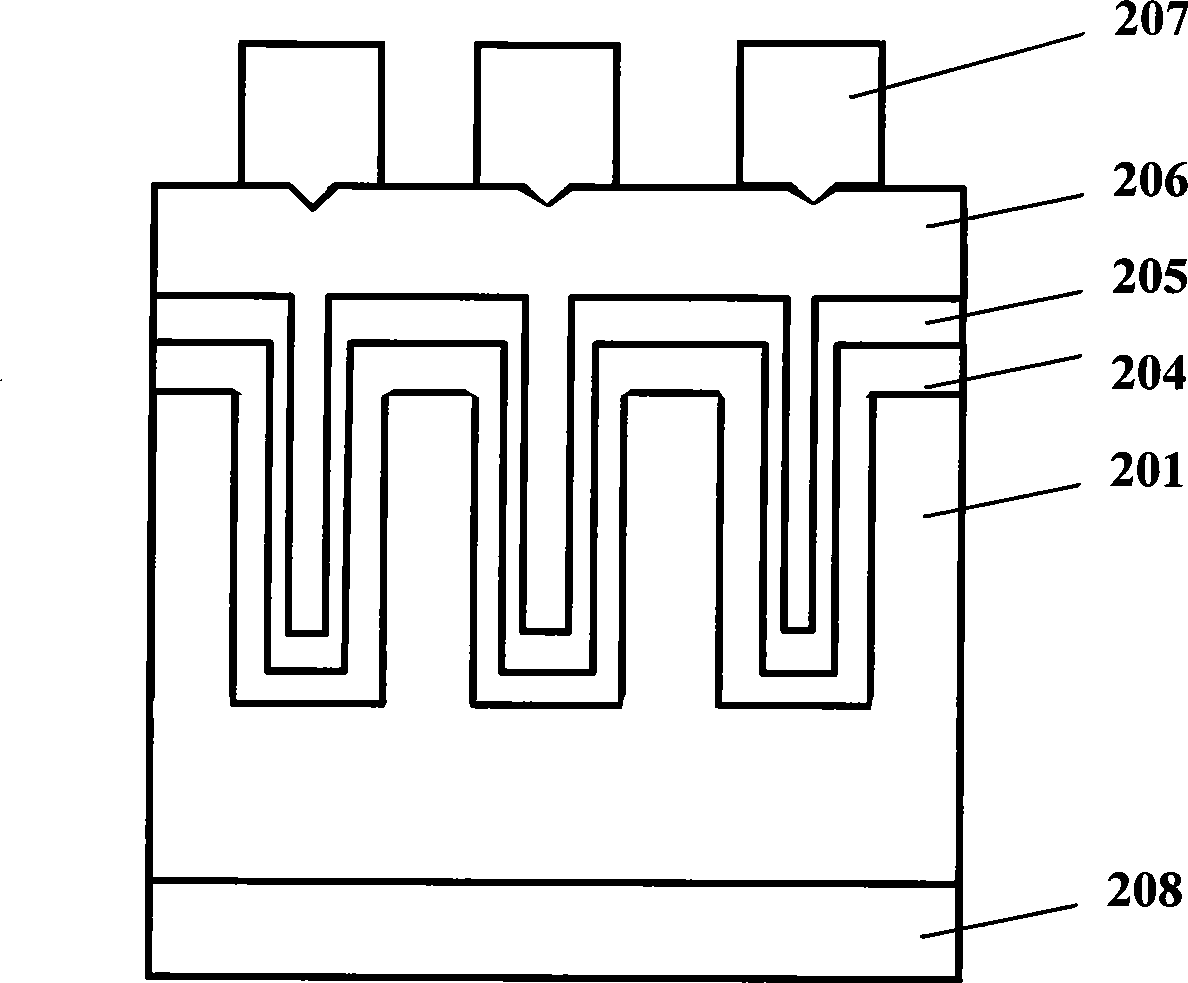

[0043] Such as figure 2As shown, the structure of the silicon-based nanocolumn array heterojunction thin film solar cell of the present invention includes a silicon nanocolumn array 201, an intrinsic amorphous silicon layer 204, an N-type amorphous silicon layer 205, a transparent conductive thin film layer 206, and an upper contact electrode 207 and lower contact electrode 208 .

[0044] The lowermost layer is a vertical silicon nanopillar array 201 . The silicon nanopillar array 201 is one-dimensional nanopillars formed by etching P-type single crystal silicon. The layer is prepared by dry etching technology with Ni nanocrystals as a mask. Since the diameter of the Ni nanocrystal itself is on the order of nanometers, an array of silicon nanopillars with a diameter on the order of nanometers can be obtained.

[0045] An intrinsic amorphous silicon layer 204 and an N-type amorphous silicon layer 205 are sequentially deposited on the silicon nanopillar array 201 . The intr...

Embodiment 2

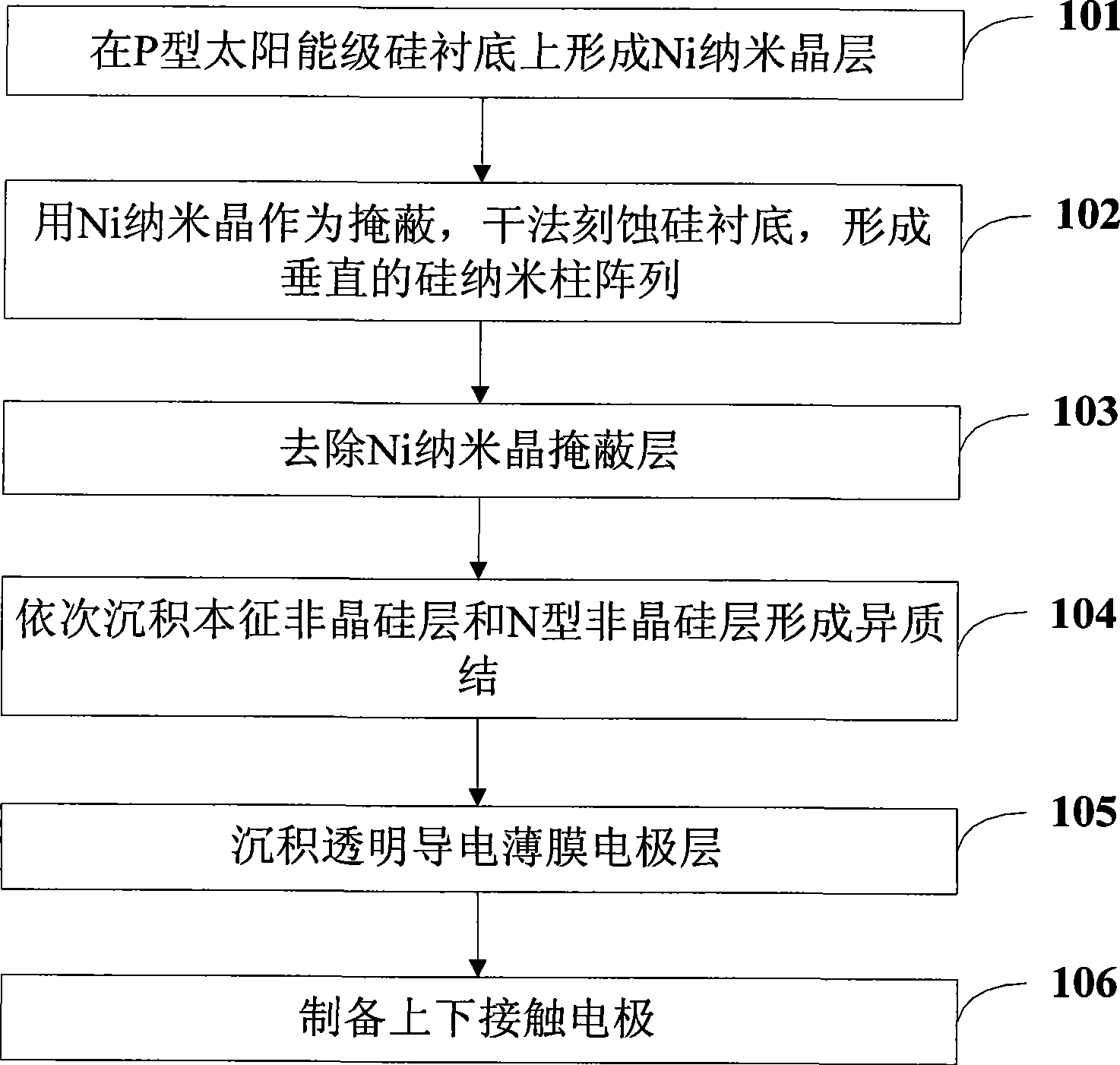

[0049] The invention also discloses a preparation method of the silicon-based nano-column array heterojunction thin-film solar cell.

[0050] Specific steps such as Figure 3 to Figure 9 Shown:

[0051] Step 101: forming a Ni nanocrystal layer on a P-type solar grade silicon substrate.

[0052] The selected P-type high-resistance silicon substrate has been diffused and doped with boron (B). The crystal orientation is ; the thickness is 200μm; the resistivity is ρ=3Ωcm -1 .

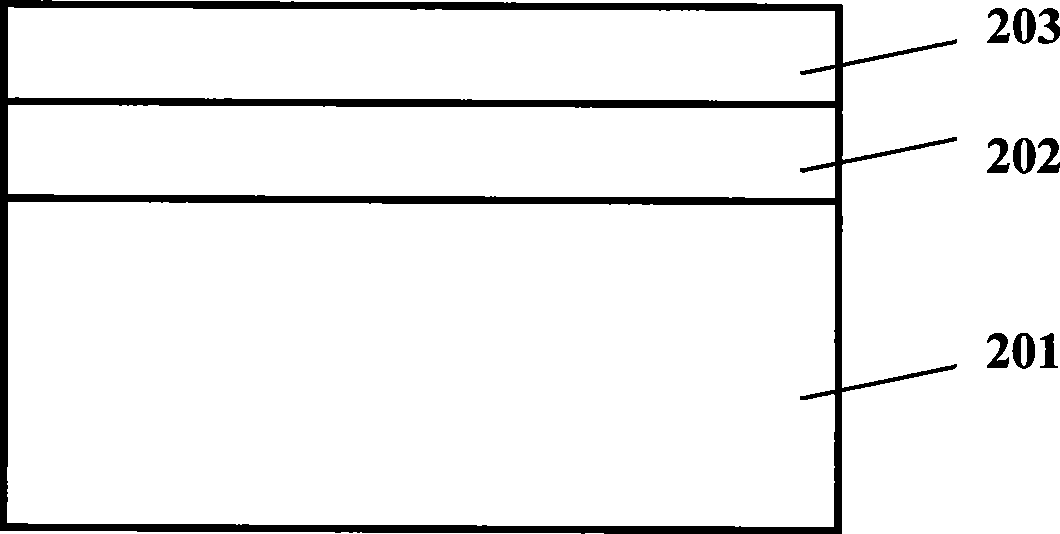

[0053] Such as image 3 As shown, the P-type solar-grade silicon substrate in this step is a P-type high-resistance silicon substrate after boron (B) diffusion doping. The metallic Ni layer is formed by electron beam evaporation. First, the EVP92 electron beam vacuum coating system is used on the silicon substrate 201 and the natural oxide layer 202, and the vacuum degree is 1.1×10 -6 Below Torr, the metal Ni layer was evaporated at room temperature. The thickness is preferably 2-3nm, and the evapo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com