Integrated tandem-type thin film silicon solar cell module and method for manufacturing the same

A technology of solar cells and manufacturing methods, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve problems such as area loss of solar cell module power generation, increase of ineffective area, power generation performance, and power leakage, so as to reduce product costs and suppress Effect of increase in ineffective area and high-efficiency power generation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

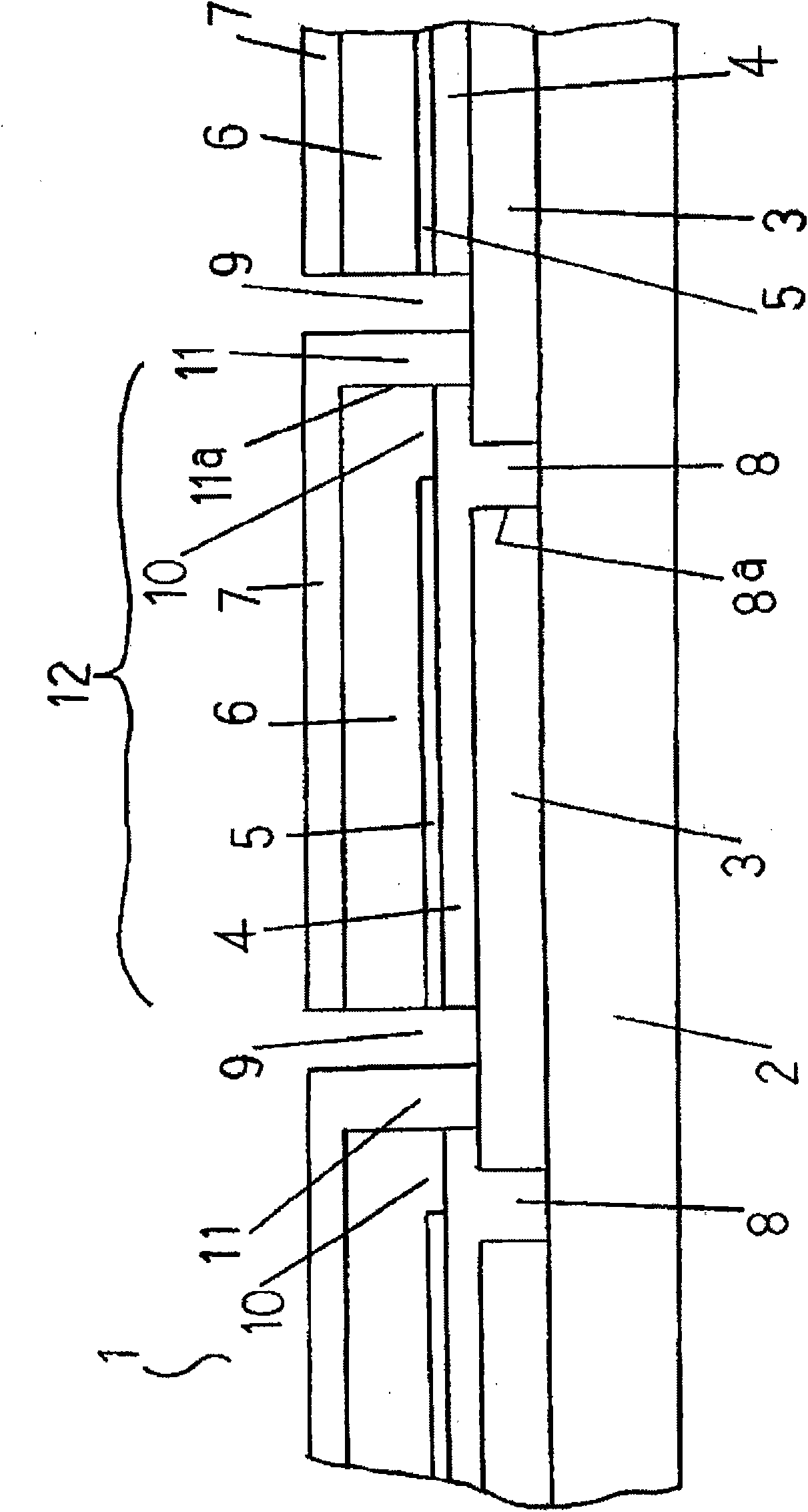

[0073] First, referring to the integrated tandem type thin-film solar cell module according to the first embodiment of the present invention, figure 1 and Fig. 2(a) to (g) for description.

[0074] figure 1 This is a configuration diagram schematically showing a cross-section of an integrated tandem-type thin-film solar cell module according to the first embodiment of the present invention. Figure 2(a) ~ Figure 2(g) It is a drawing showing the manufacturing process of the integrated tandem type thin-film solar cell module according to the first embodiment of the present invention.

[0075] exist figure 1 And in FIGS. 2( a ) to ( g ), symbol 1 is an integrated tandem thin film solar cell module.

[0076] Reference numeral 12 is a tandem-type thin-film solar battery cell, which has a structure: the following transparent electrode layer 3 is sequentially stacked on the following transparent substrate 2, and the first thin-film photoelectric conversion unit 4 having the follow...

Embodiment 2

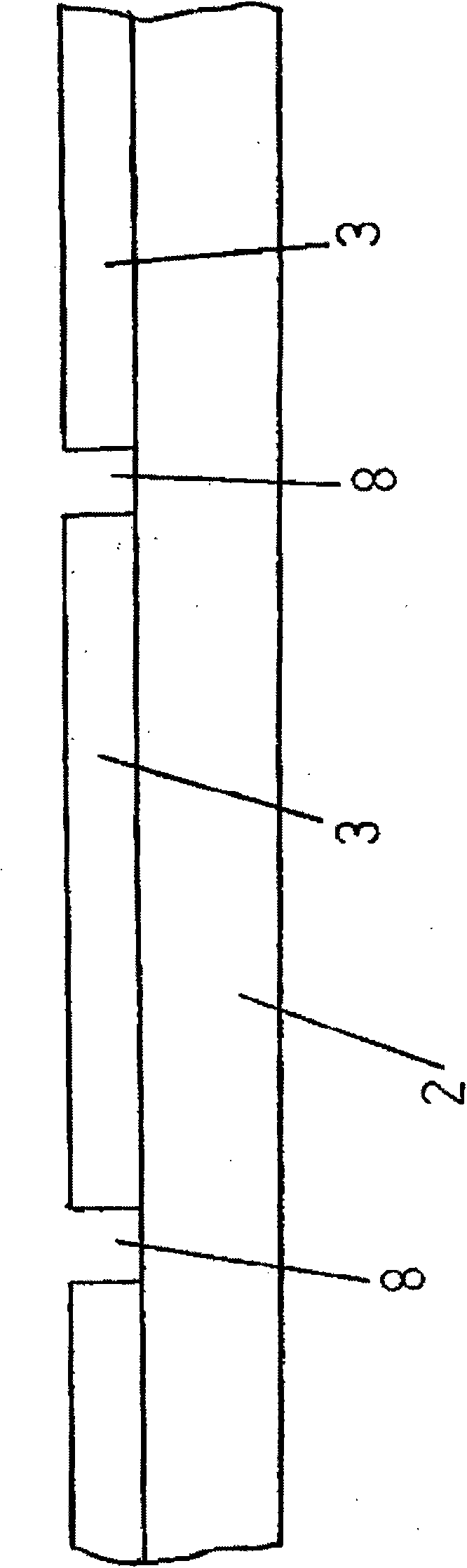

[0131] Then refer to image 3 4( a ) to ( g ), the integrated tandem thin film solar cell module according to the second embodiment of the present invention will be described.

[0132] image 3 This is a configuration diagram schematically showing a cross-section of an integrated tandem thin-film solar cell module according to a second embodiment of the present invention. Figure 4(a) ~ Figure 4(g) It is a figure showing the manufacturing process of the integrated tandem type thin-film solar cell module concerning 2nd Embodiment of this invention.

[0133] exist image 3 and Figure 4(a) ~ Figure 4(g) Among them, symbol 13 is the separation groove of the second intermediate layer, on the outside of the surface extending toward the normal direction of the upper surface of the transparent substrate 2 between the side 11a of the connection groove 11 and the side 8a of the first separation groove 8 (from the connection The direction away from the side surface 11a of the groove...

Embodiment 3

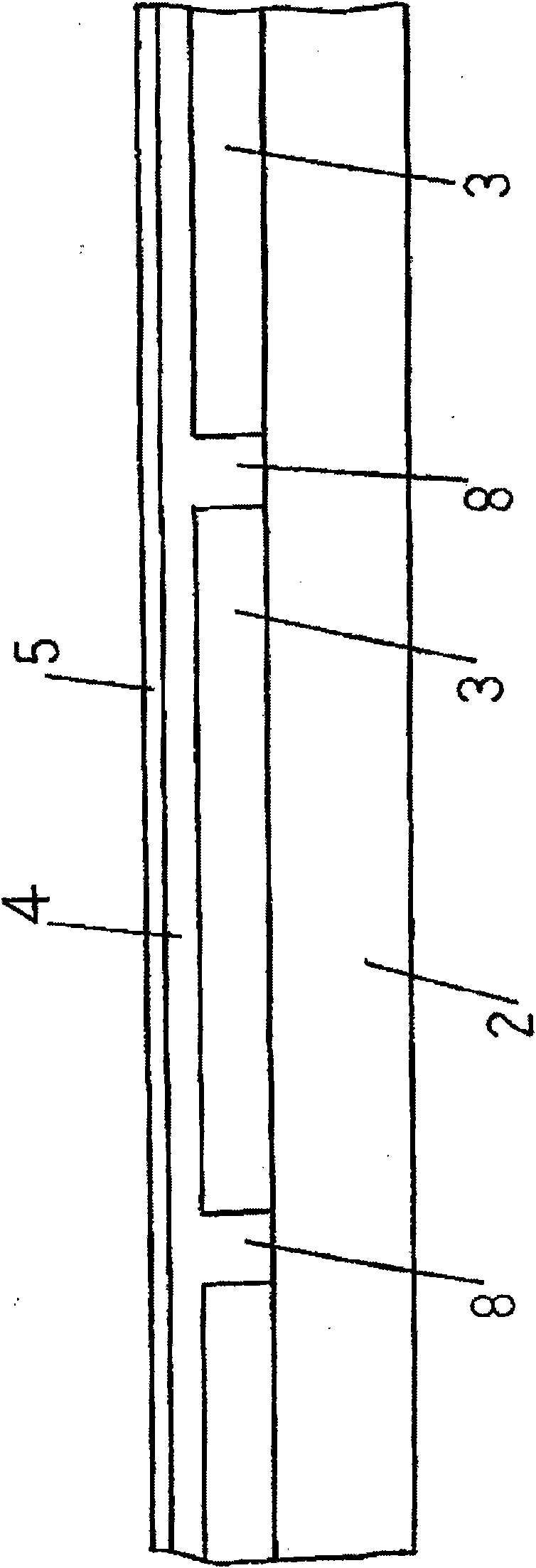

[0176] Then refer to Figure 5 An integrated tandem-type thin-film solar cell module according to a third embodiment of the present invention will be described.

[0177] Figure 5 This is a configuration diagram schematically showing a cross-section of an integrated tandem thin-film solar cell module according to a third embodiment of the present invention.

[0178] exist Figure 5 Among them, symbol 14 is the separation groove of the third intermediate layer, which has the following spatial structure: there is an opening on the interface between the intermediate layer 5 and the second thin-film photoelectric conversion unit 6, and the first intermediate layer 5 The interface with the first thin-film photoelectric conversion unit 4 has a bottom surface and is surrounded by surfaces extending along the normal direction of the upper surface of the transparent substrate 2 from the two side surfaces 8 a and 8 b of the first separation groove 8 . In addition, the side surface 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com