Nanocrystalline silicon forming method

A nanocrystalline silicon and nanotechnology, which is applied in the field of vacuum deposition of nanocrystalline silicon thin films, can solve problems such as damage to the performance of nanocrystalline silicon thin film devices, and achieve the effects of reducing cross-contamination and short exposure time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

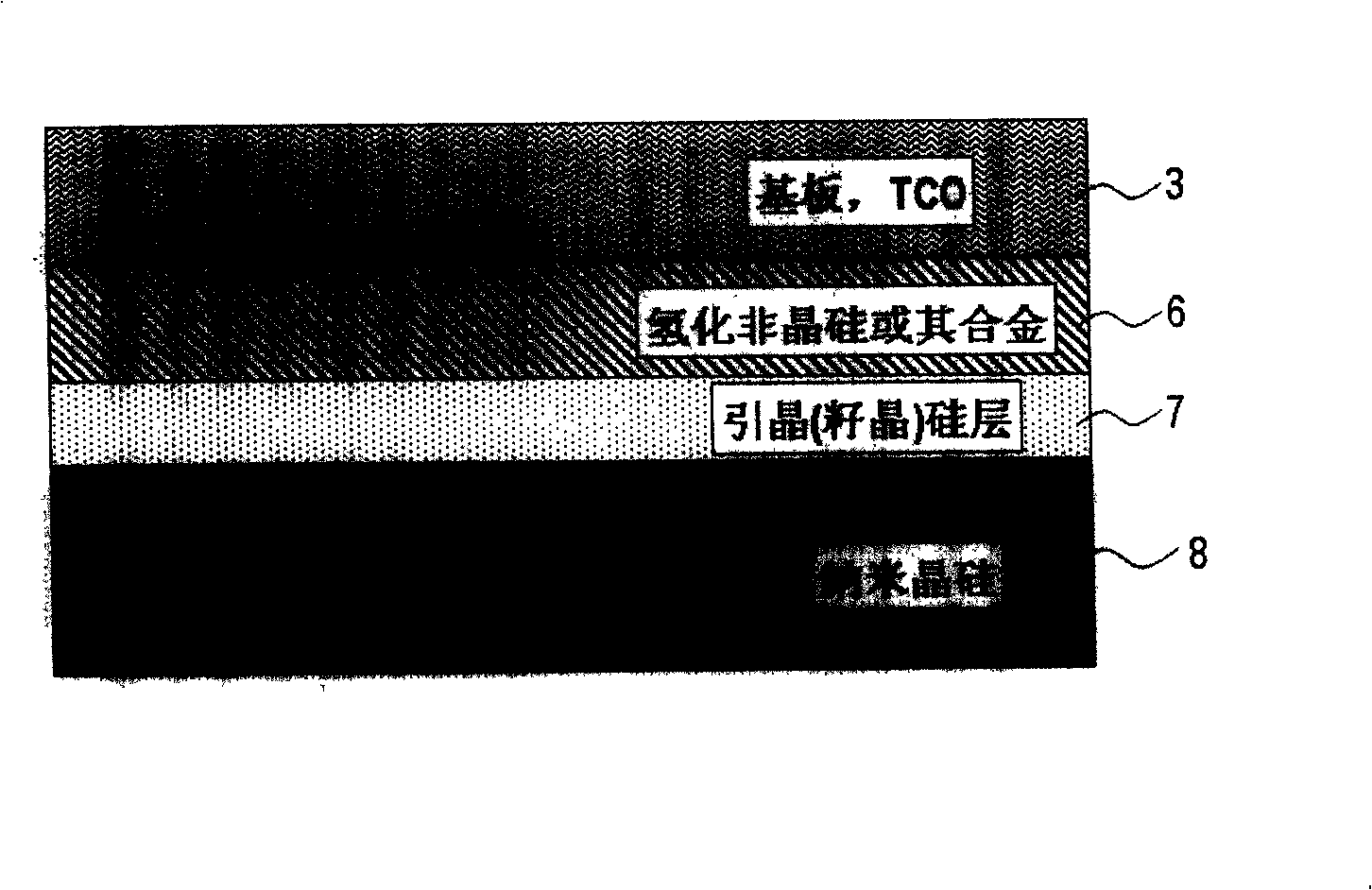

[0021] In the invention, two separate stages composed of different plasma conditions are used to carry out the plasma enhanced chemical vapor deposition process to form a nanocrystalline silicon film.

[0022] As shown in the figure, the first stage is the seeding stage of performing a near-static etching operation on the surface of the formed amorphous silicon film 6 . An intense plasma rich in hydrogen with a small amount of silicon species is maintained for a period of time between 30-600 seconds with a gas mixture high in hydrogen and at the same time silicon-containing gas. For example, a hydrogen and silane (H 2 +SiH 4 ) gas mixture. The gas pressure in the deposition chamber is kept in the range of 0.5-30mbar, preferably in the range of 2-10mbar. The plasma excitation method can be direct current, radio frequency or radio frequency (RF) or very high frequency (VHF). Greater than 150mW / cm 2 A fairly high plasma power density, preferably greater than 250mW / cm 2 , is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com