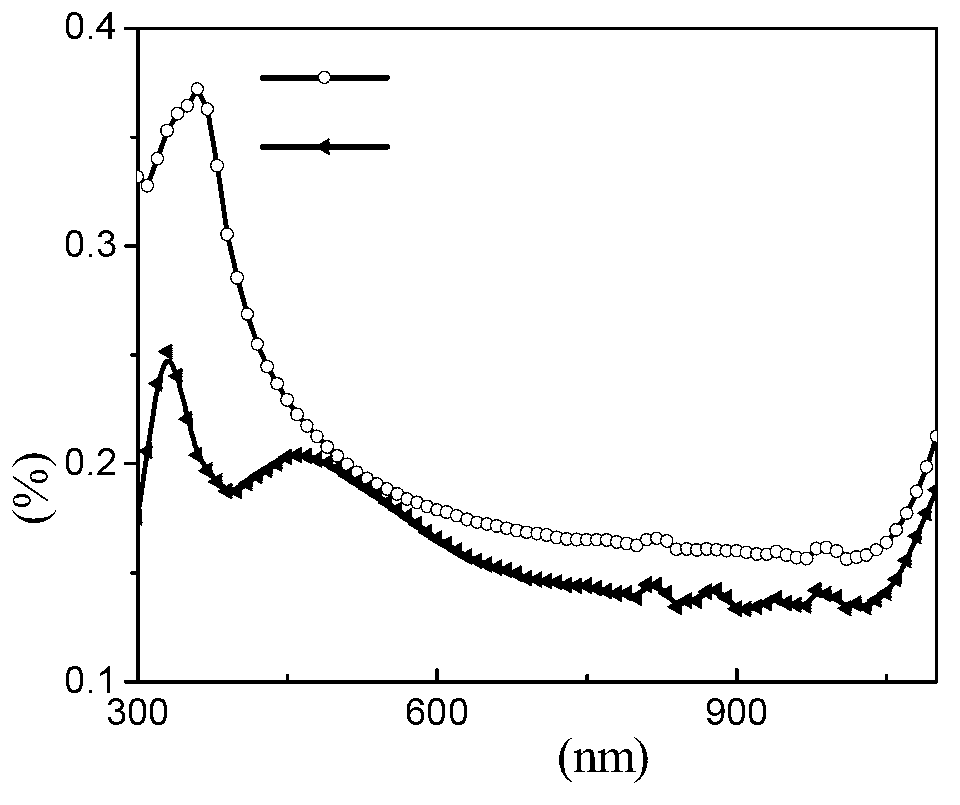

Method for manufacturing novel light-trapping synergetic antireflection structure on basis of LSP (localized surface plasma) effect

A new type of anti-reflection technology, applied in the field of solar cells, can solve the problems of high preparation cost, difficult operation, complex equipment, etc., and achieve the effect of simple method, simple equipment requirements and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Cut a (100) single crystal silicon wafer with a resistivity of 12 Ω·cm into 2×2 cm samples, then soak in acetone solution, ultrasonicate in a water bath at 35 °C for 10 min; then rinse with deionized water for 3 Sonicate in deionized water for 10 min after soaking in deionized water for 10 min; take out the sample, soak in CP4A cleaning solution at room temperature for 5 min; finally soak in 14% hydrofluoric acid solution for 2 min, take out the sample, and rinse with deionized water 3 times, then blow dry with nitrogen, and put it in a desiccator for later use.

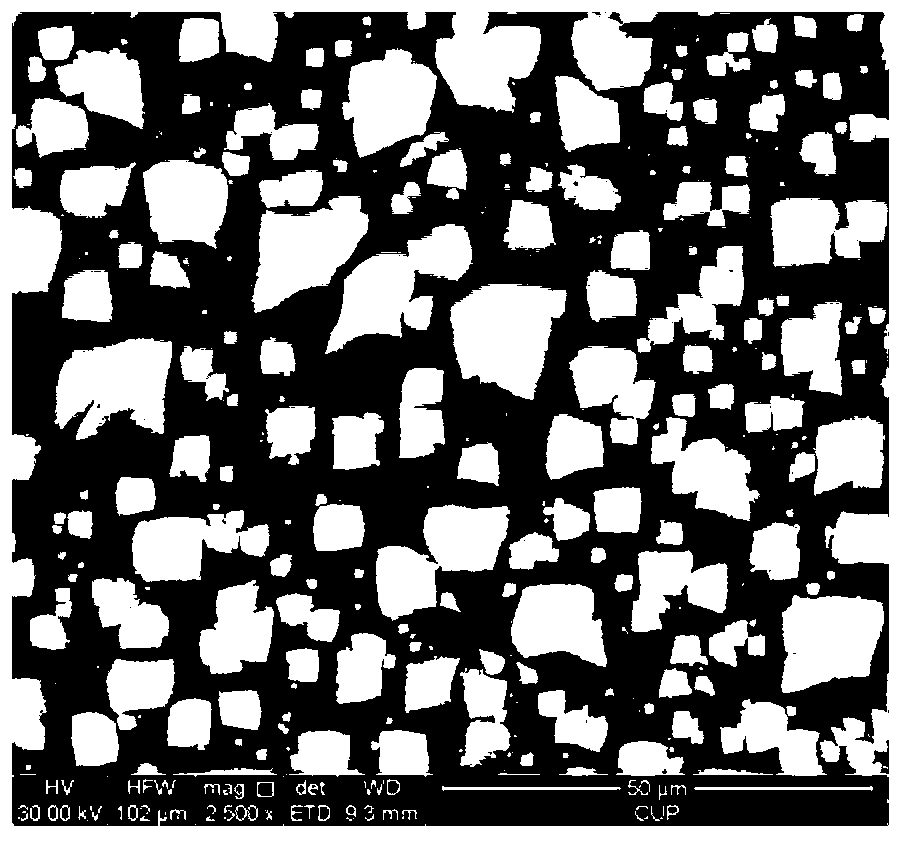

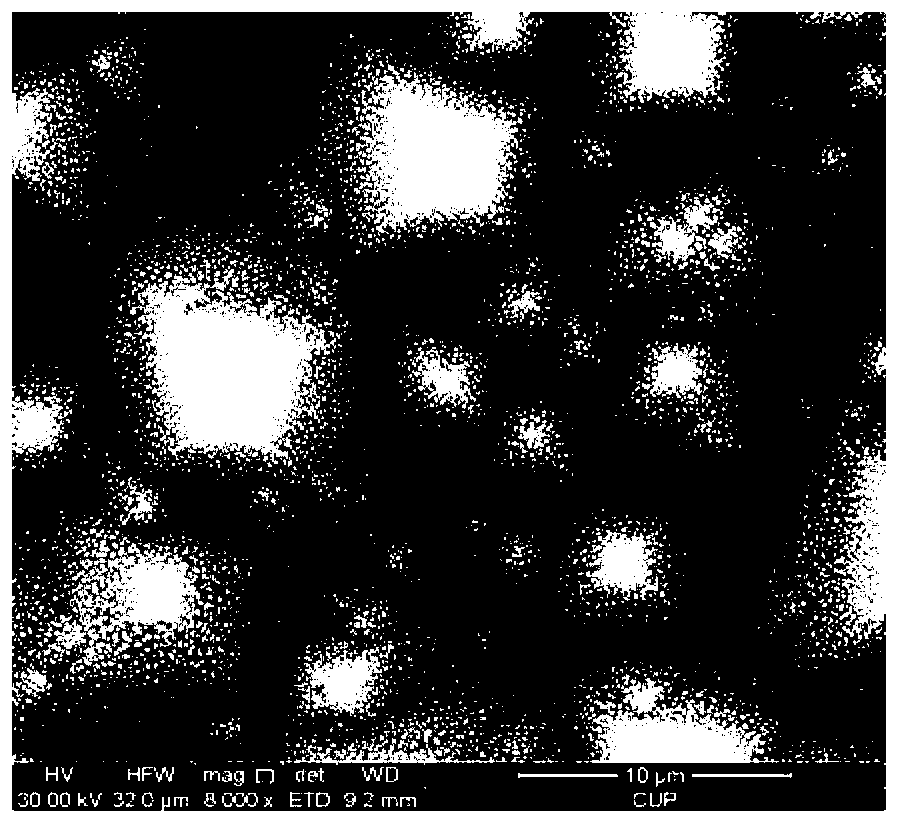

[0020] 2. Etch the sample treated in step 1 with an etching solution for 40 minutes in a water bath at 80 °C to obtain a silicon wafer with a pyramidal surface structure. During the etching process, a large number of bubbles can be observed on the surface and surroundings of the silicon wafer. As the etching time increases, the bright silicon surface gradually darkens and loses luster. After the etching, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com