Patents

Literature

180results about How to "No special requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vehicle child retention alarm device

InactiveCN102774285AEasy to useSolve the problem of personal safety without protective measuresPedestrian/occupant safety arrangementAlarmsVIT signalsTemperature induction

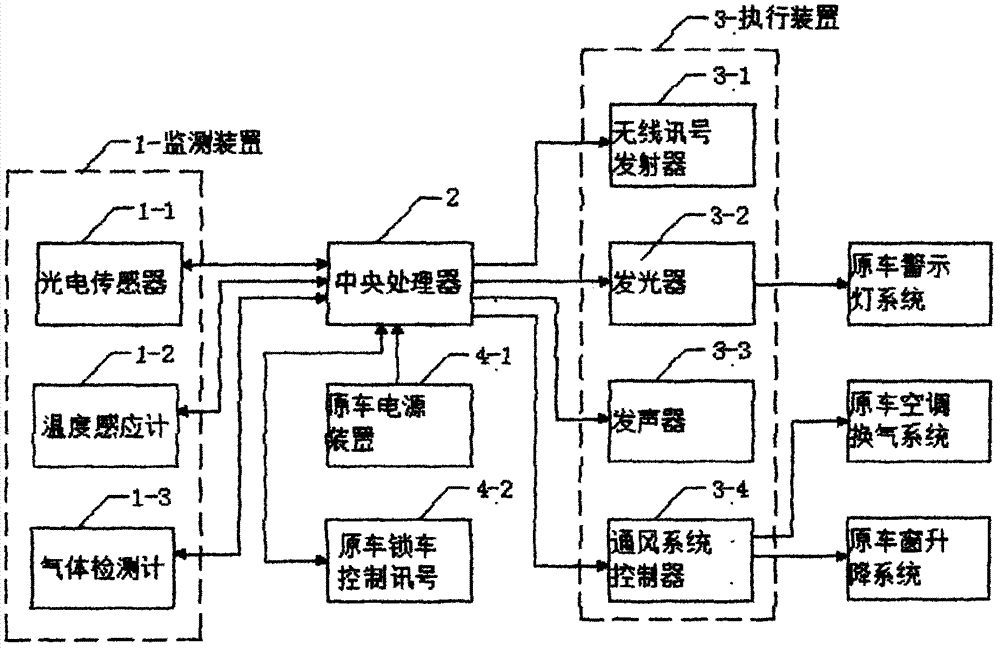

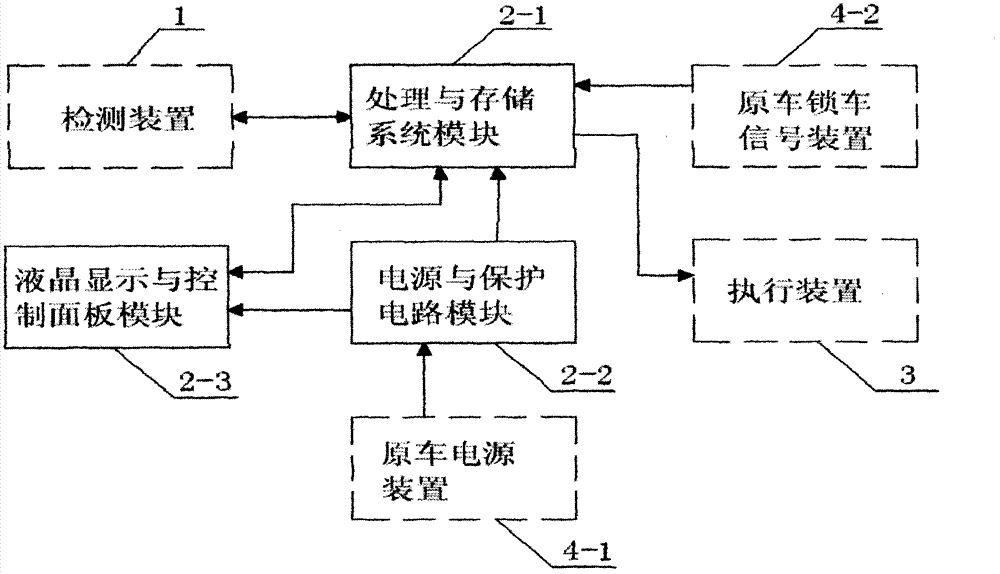

The invention discloses an alarm device, and relates to a vehicle child retention alarm device. The device is an alarm device for preventing a child from being retained in a vehicle so as not to cause a safety accident by using a photoelectric technology. The device comprises a detection device for signal acquisition and detection, a central processing unit and an execution device, wherein the detection device and the execution device are connected with the central processing unit through circuits respectively; the detection device comprises a photoelectric sensor, a temperature induction meter and a gas detector; the execution device comprises a wireless signal emitter, an illuminator, a sounder and a ventilation system controller; detected signals are transmitted to the central processing unit through the circuits by the photoelectric sensor, the temperature induction meter and the gas detector; after the received signals are processed by the central processing unit, and an alarm instruction is emitted to the wireless signal emitter, the illuminator and the sounder respectively and a ventilation equipment starting instruction is emitted to the ventilation system controller; the wireless signal emitter is used for emitting a wireless alarm signal to a mobile phone; and an original warning lamp is turned on by the illuminator, alarm sound is emitted by the sounder, and an original vehicle air conditioning ventilation system and an original vehicle window lifting system are turned on by the ventilation system controller respectively. The alarm device has the advantages of no special requirements on an implemented vehicle, convenience in use and capabilities of completely solving the problem of no protection measure for personal safety of the child in the vehicle after parking of the vehicle, displaying technical parameters, facilitating parameter adjustment, amending settings and realizing various functions.

Owner:周文海 +2

Shooting auxiliary training system and image-based bulls eye positioning method

InactiveCN101598520AHighlight substantiveReduce in quantityTraining adaptationWireless videoImage processing software

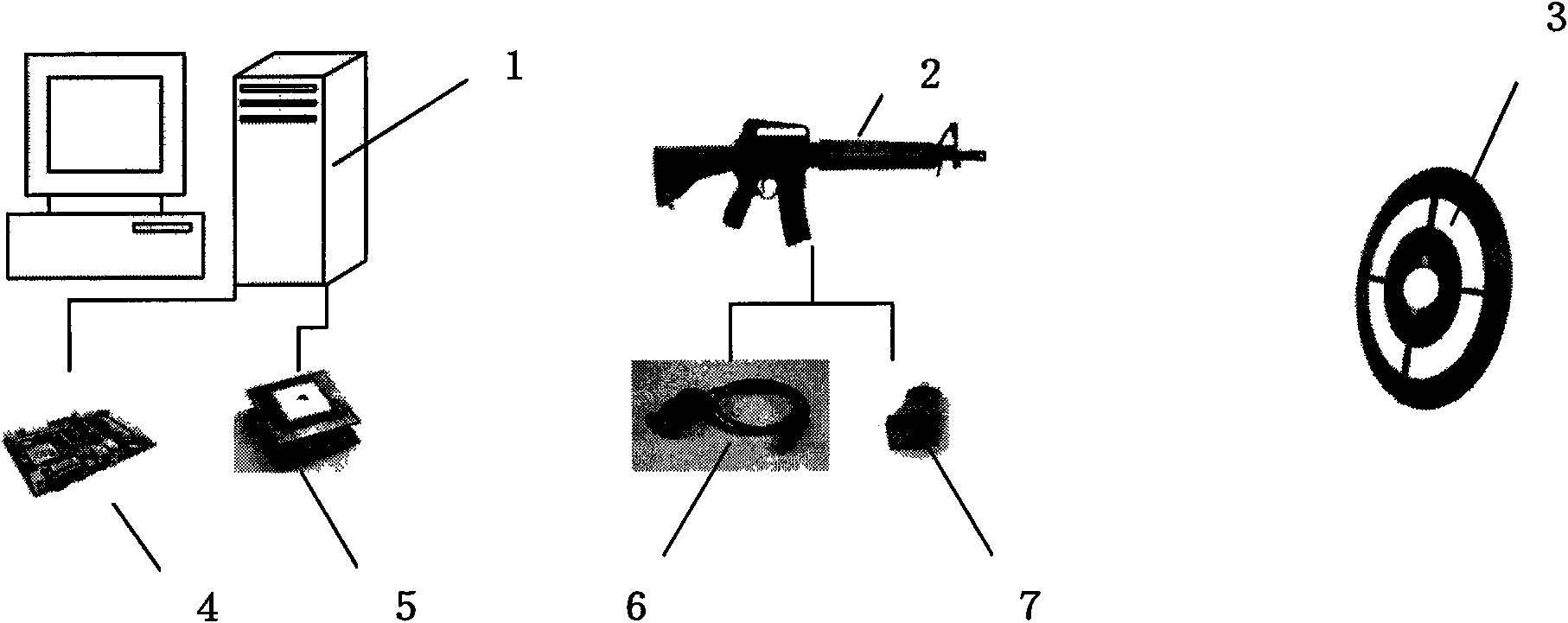

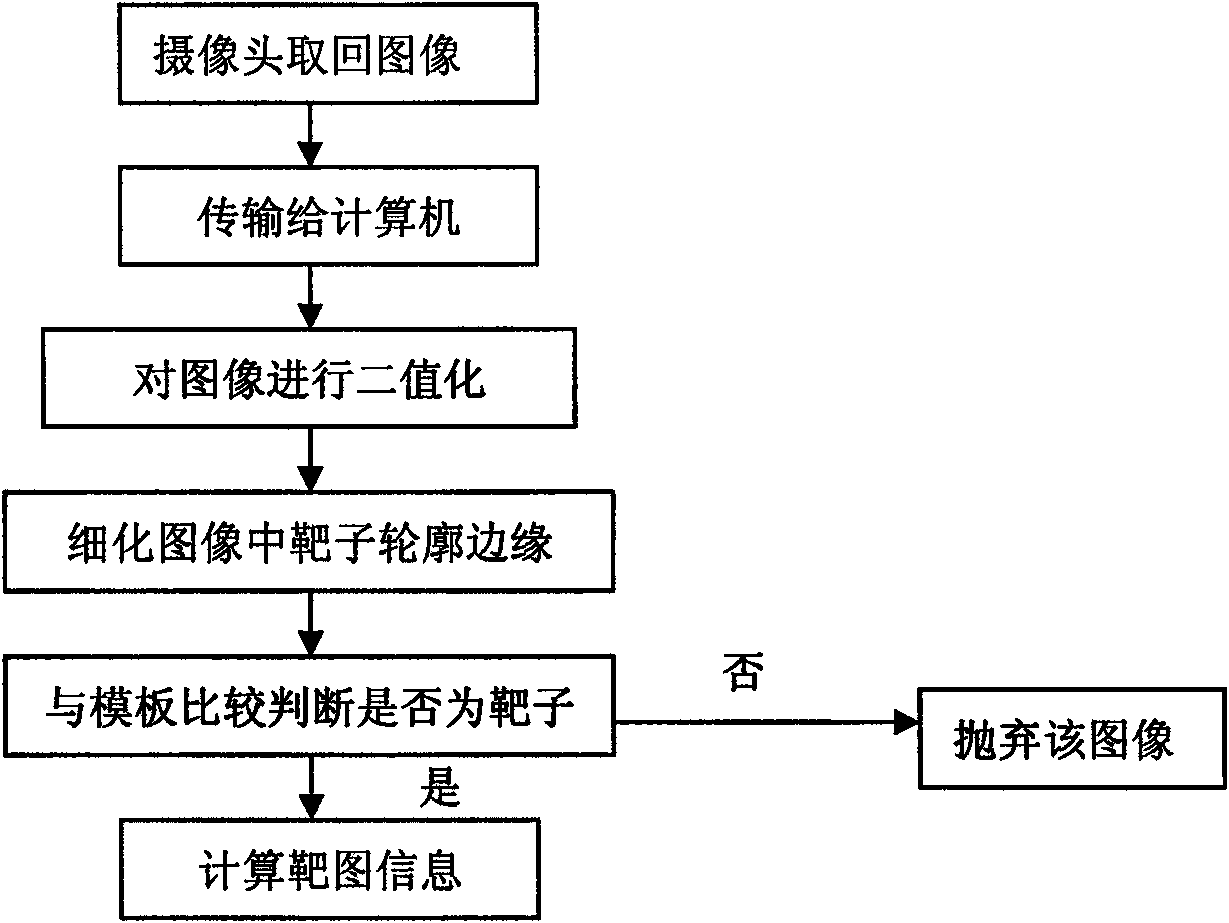

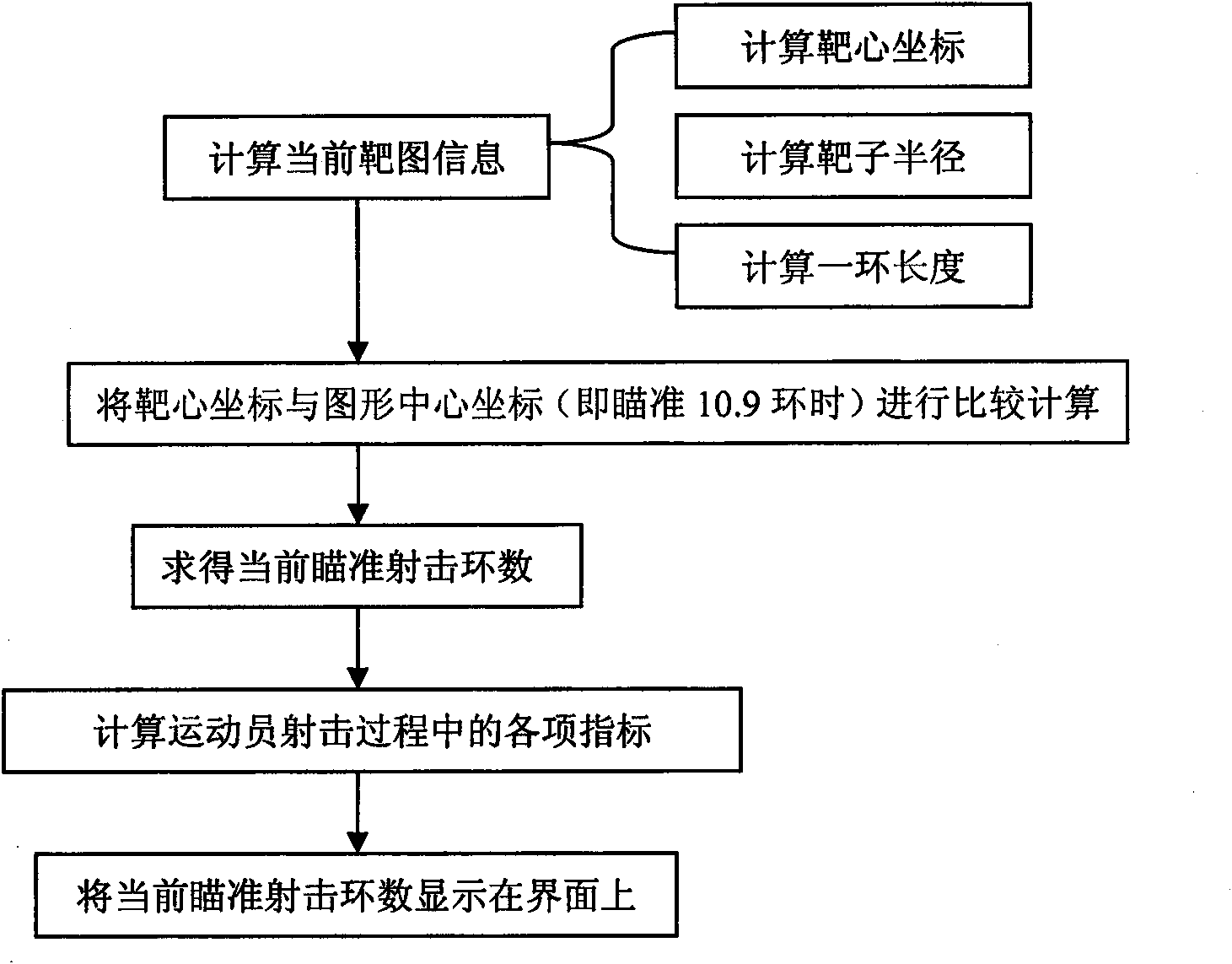

The invention relates to a shooting auxiliary training system and image-based bulls eye positioning method. The system mainly comprises a computer, a gun, a target, a wireless video capture card, a wireless trigger receiving device, a wireless micro camera and a wireless trigger. The method is characterized in that: (1) the up and down and the left and right of an image shot when the center of the camera aims at the center of a shooting object are symmetrical about the aiming point of the center of the camera; (2) when a shooter holds the gun and aims at the center of the target, the center of the image shot by the camera is coincided with the center of the target image; (3) the image is shot by the camera, and the contact ratio of the center of the target image and the central position of the image is processed by and image processing software in the computer, so as to determine the ring number aimed by the shooter at the moment. The system has no special requirement on the target, requires no ball firing and has simple device and low cost; the whole shooting process can be monitored, replayed and analyzed, and the technical parameters of the shooter can be analyzed by a path formed by the aiming point in the shooting process.

Owner:SHANXI UNIV

Method for manufacturing low-carbon TWIP steel through AOD (argon oxygen decarburization) furnace

ActiveCN103468874AEase of mass productionRaw materials are easy to getProcess efficiency improvementManufacturing technologySlag

The invention belongs to the field of metal smelting, and mainly relates to smelting manufacturing technology of low-carbon TWIP steel through an AOD (argon oxygen decarburization) furnace. The smelted TWIP steel comprises the following components in percentage by weight: 0%-0.06% of C, 20%-30% of Mn, 2.0%-3.0% of Si, 2.5%-3.5% of Al, and the balance of Fe. The particular technology procedures comprises the following steps: 1), the AOD furnace is adopted for oxygen decarburization process, once the carbon in the liquid steel is lower than 0.03%, the liquid steel is subject to alloying; 2), after the TWIP steel is subject to manganese alloying, ferrosilicon or / and metal aluminium is adopted to perform reduction reaction on manganese oxide, so that the yield of metal manganese is increased; the oxidation heat of silicon or / and aluminium is adopted to regulate the temperature of the liquid steel and compensate temperature drop of the liquid steel generated by the manganese alloying of the TWIP steel. The method is high in manufacturing efficiency, low in cost, stable in operation and easily-mastered in technology; the main raw material is easily accessible, and no specific requirement is needed; the realization of large-scaled industrialized production is facilitated.

Owner:UNIV OF SCI & TECH BEIJING

Method for purifying titanium white wastewater

InactiveCN101962239AReduce consumptionReduce decalcification costsMultistage water/sewage treatmentWater/sewage treatment by neutralisationSlagTechnical standard

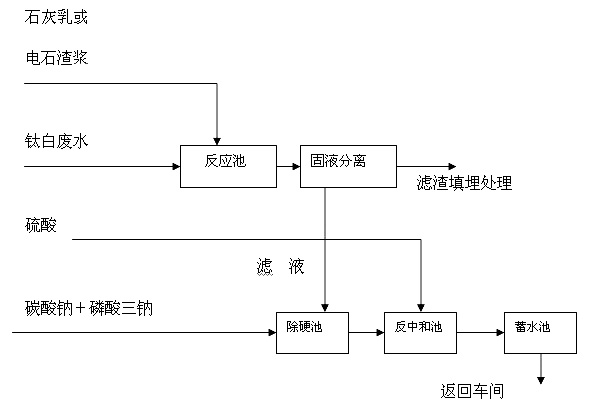

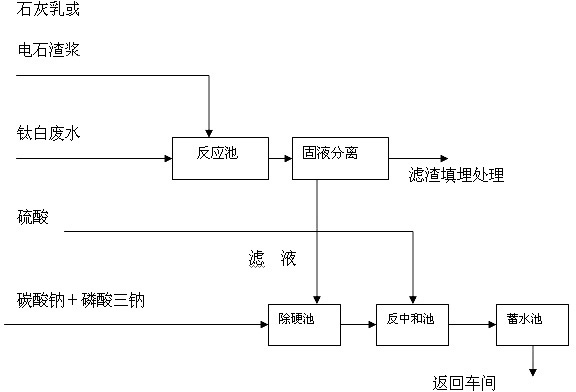

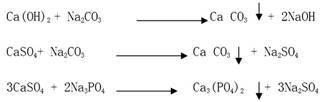

The invention relates to a method for purifying titanium white wastewater, which is characterized by comprising the following steps of: adding excess lime milk or carbide slag slurry, performing a neutralization reaction with stirring to obtain precipitate-containing wastewater, wherein the pH value of the wastewater is between 9 and 12; performing solid-liquid separation on the obtained precipitate-containing wastewater, adding sodium carbonate into filter liquor to perform a reaction for 30 to 50 minutes, and adding trisodium phosphate to perform a reaction, and decalcifying; adding sulfuric acid into the decalcified wastewater for reverse neutralization, and regulating the pH value to be between 6 and 9 to obtain purified water. The method has the characteristics of simple flow, no specific requirement on equipment, low consumption of raw materials and the like; and by the method, the treated wastewater can reach the technical standard of national recycling water, so that the wastewater is recycled to production departments, and for a large amount of the generated titanium white wastewater, the method solves the problem of high treatment cost, and has the technical and economic feasibility of industrial application.

Owner:HUNAN HEAO YUJIE ENVIRONMENT TECH CO LTD

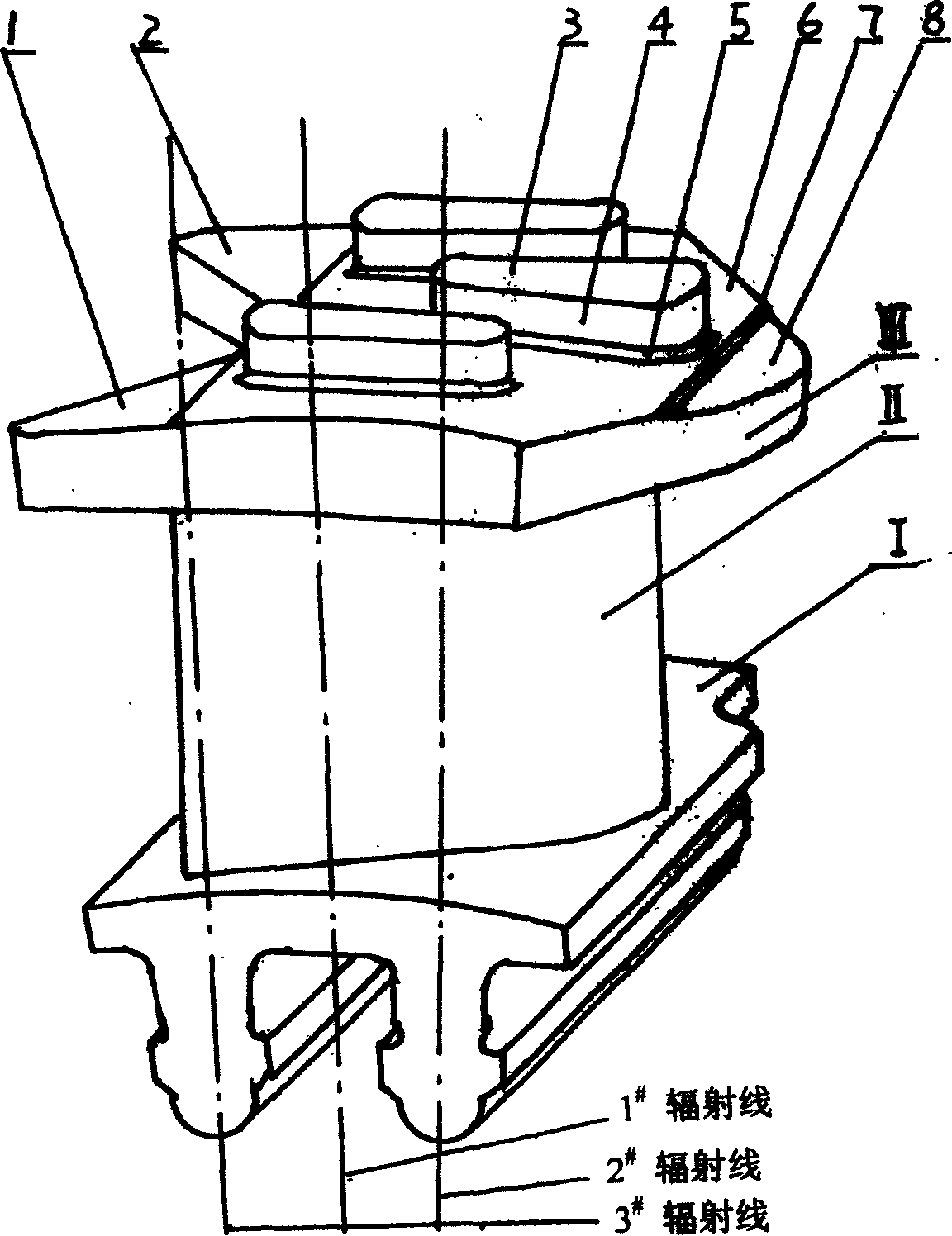

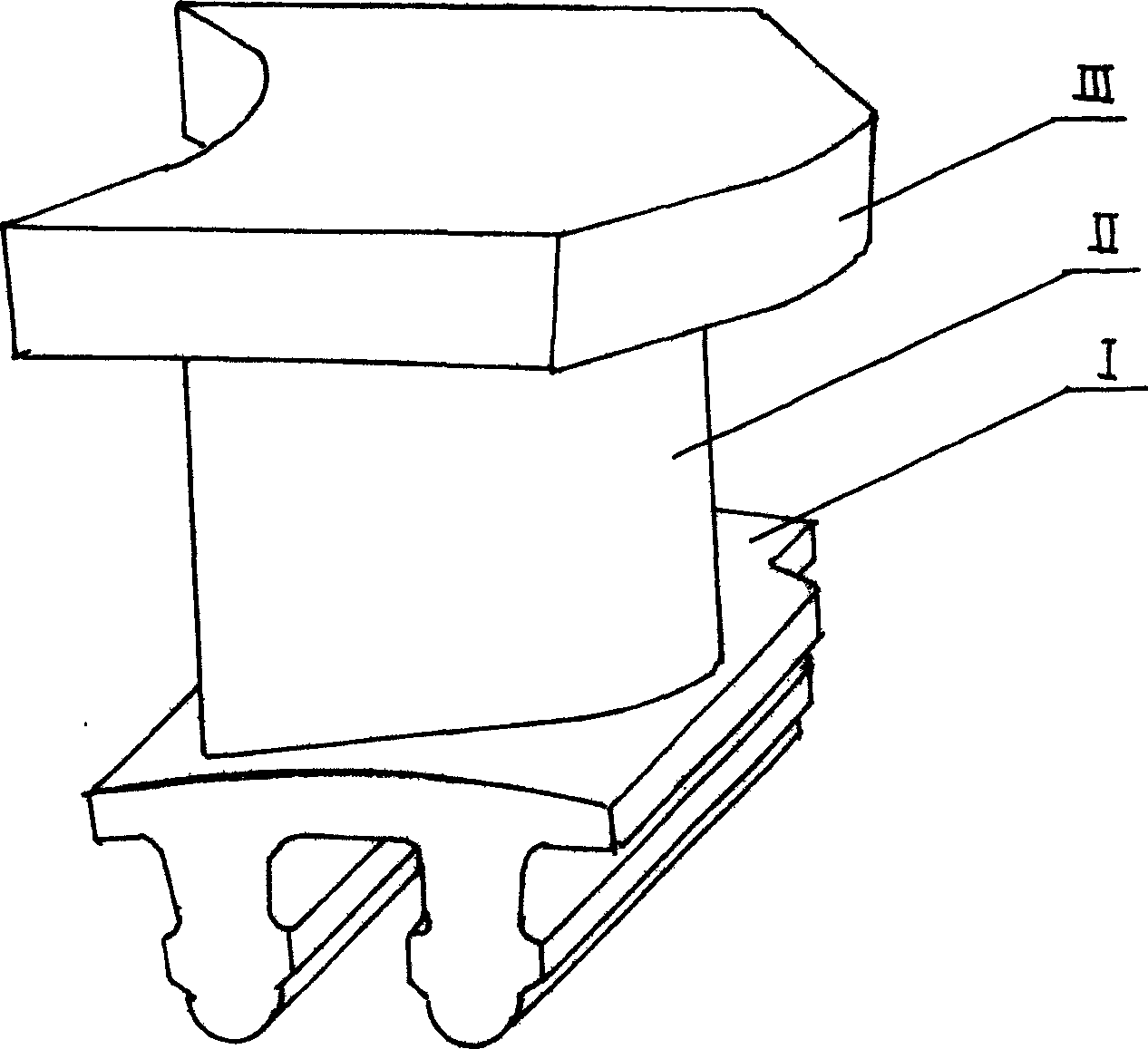

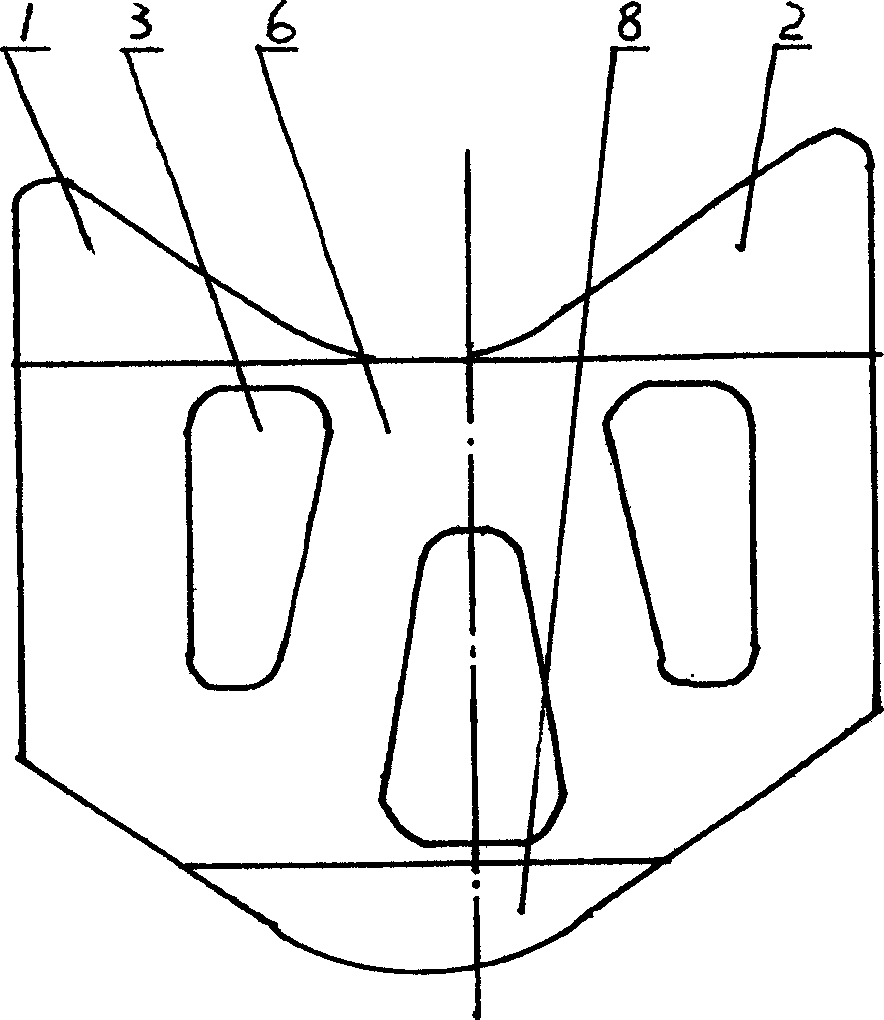

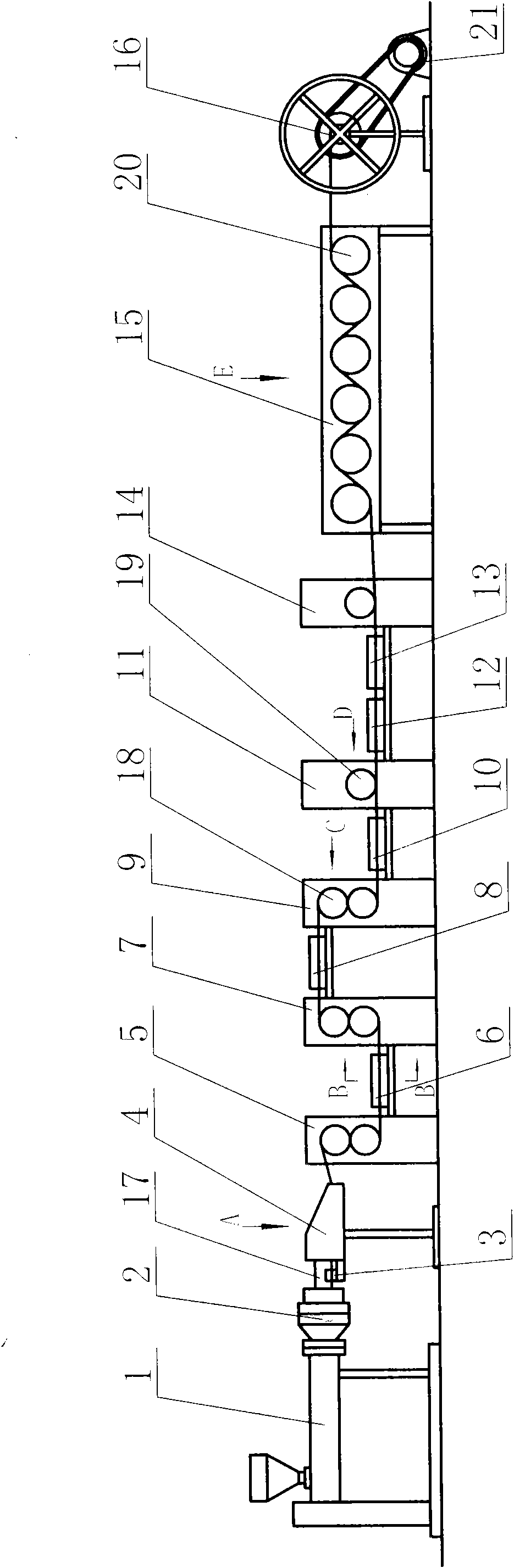

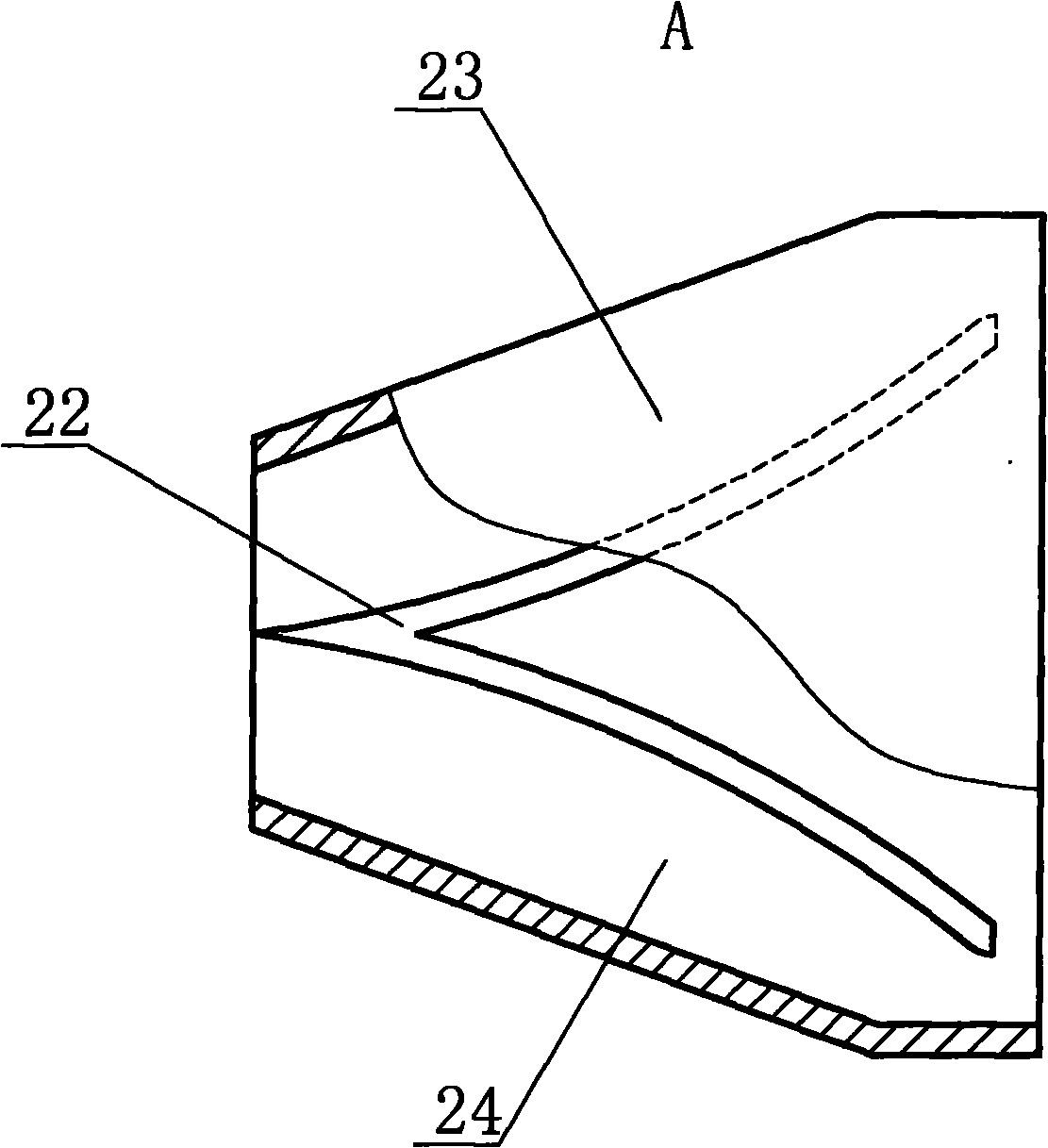

Processing method and device for adjusting blade and integral shroud by turboset

ActiveCN1631593ARealize localizationAccelerate the pace of localizationMilling equipment detailsControl lineEngineering

The invention discloses a crown turbine set adjusting grade active fin crown processing technique and the processing device. Its features are: adopting special clamp, on the horizontal four coordinate lathes, with the surface milling method in the PRO / E software, picking the edge of the fin as control line, picking the outline of the clinch head as examining plane so to process the cylinder plane of the fin crown; process the clinch heat outline with the track milling method in the PRO / E software, processing roundabout contracting to the center; by using the rotor work bench on the lathe to let the fin crown step inclined plane perpendicular with the lathe main shaft, process the fin crown step inclined plane in plane milling way. The advantages of the invention are that all the processing planes is processed with one clamping, high processing accuracy, high efficiency and achieves home production of the fin no longer relying on import.

Owner:DONGFANG TURBINE CO LTD

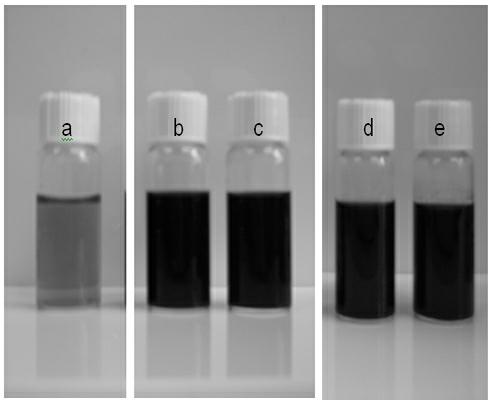

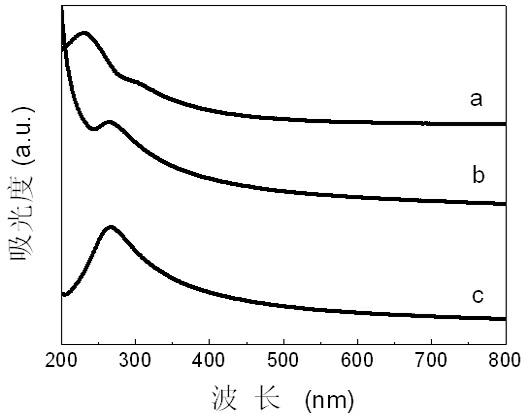

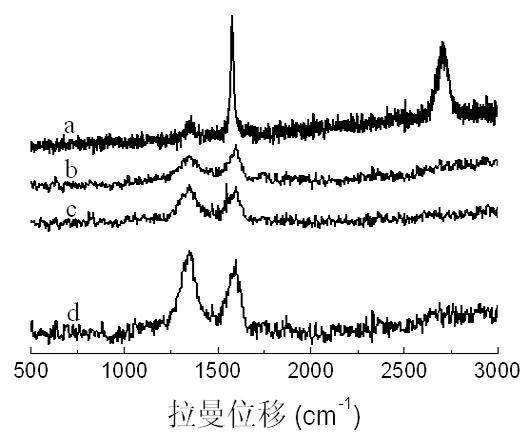

Reduction method for graphene oxide

The invention discloses a reduction method for graphene oxide. The method comprises the following steps: using acetone oxime, acetaldoxime or methyl ethyl ketoxime as a reducing agent, and then preparing the graphene by reducing the graphene oxide in a graphene oxide aqueous solution the pH value of which is 6-10, wherein the reaction temperature is 80-100 DEG C and the mass ratio of graphene oxide to the reducing agent acetone oxime, acetaldoxime or methyl ethyl ketoxime is 1: (0.2-5). The method is characterized in that the oximido having lower toxicity is used as the reducing agent and thegraphene is acquired by reducing the graphene oxide by using a chemical reduction method. The preparation method is simply and easily performed, the reaction process is easily controlled, no special requirement for equipment exists, the cost is low, the pollution is free, and the method is easily popularized and used.

Owner:NORTHWEST UNIV(CN)

Post-treatment method for plasma spraying hydroxyapatite coating

InactiveCN1483480AIncrease contentHigh crystallinityCoatingsHigh volume manufacturingHydroxyapatite coating

The present invention relates to an aftertreatment method of plasma spray-coated hydroxypatite coating, and is characterized by that the hydroxyapatite coating product obtained by adopting plasma spray-wating process is placed in a container connected with the steam generator, then said steam in the container is heated or (and) pressurized to make the hydroxyapatite coating product undergo the process of treatment for 2-6 hr. under the moist steam whose temp. is 100 deg.C-300 deg.C and pressure is 1-3 atms, then said hydroxyapatite coating product can be taken out and placed into the baking oven with 100-150 deg.C and baked for 0.5-2 hr. so as to implement its aftertreatment.

Owner:SICHUAN UNIV

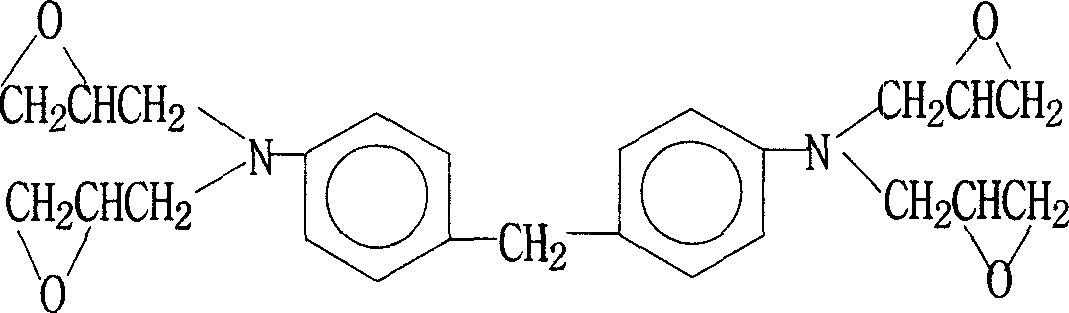

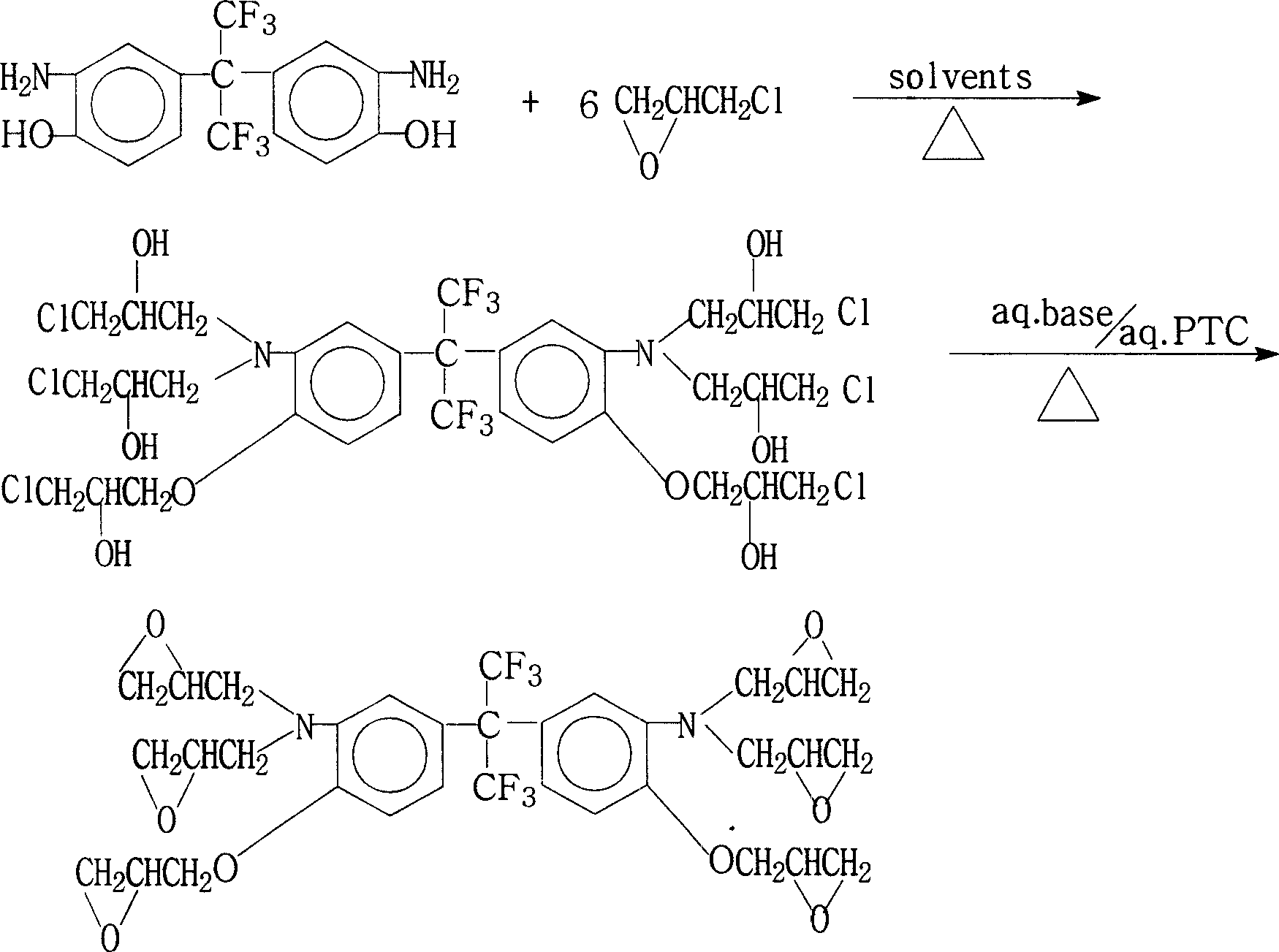

Method for preparing fluorine-contained multi-function epoxy resin

The invention discloses a manufacture method for multi-functional epoxy resin containing fluorine that includes the following steps: 2, 2-double (3- amino group-4 - hydroxy benzenes)-1, 1, 1, 3, 3, 3-BAHPFP and ECH reacting for 3-12 hours at 40-90 degree centigrade in water and organic solvent; cooling to 70 degree centigrade, adding PTC solution and alkali material solution, reacting for 2-10 hours at 40-70 degree centigrade, heating to 1-5 hours at 80-90 degree centigrade, adding wate and organic solvent, whisking and laying to gain organic layer, washing, separating to gain N, N, N', N', 0, 0'- hexa-glycidyl group- 2, 2- double (3- amino group-4- hydroxy benzenes)- 1, 1, 1, 3, 3, 3-HGBAHPFP. The invention has the advantages of easy to operate, good quality, high yield, little waste, etc.

Owner:DONGHUA UNIV

Method for preparing lithium nickel manganese oxide anode material

InactiveCN105118983AIncrease specific energyHigh specific powerCell electrodesSecondary cellsLithium compoundPolytetrafluoroethylene

The invention discloses a method for preparing a lithium nickel manganese oxide anode material. The method includes the steps that A, divalent nickel salt, divalent manganese salt and Li<+> compounds are evenly mixed and grinded, and a nickel, manganese and lithium mixture is obtained; B, persulfate with the molar weight larger than the sum of the molar weight of the divalent nickel salt and the molar weight of the divalent manganese salt and the mixture obtained in the step A are mixed and grinded, and a reaction mixture is obtained; C, the reaction mixture obtained in the step B is transferred into a polytetrafluoroethylene reaction kettle, water is added, a cover and a stainless steel reaction-kettle outer bush are arranged for sealing, the reaction temperature is controlled and kept, and reactants are obtained; D, the reactants obtained in the step C are taken out and washed with water till no sulfate radical is detected, suction filtration is carried out, and brown or black solid is obtained; E, the brown or black solid is transferred into a crucible, in the atmosphere environment, roasting is carried out, natural cooling is carried out, and the lithium nickel manganese oxide anode material is obtained. The raw materials are abundant, the price is low, environment pollution is avoided, and a brand new easy and convenient solid-liquid film phase reaction method with the easily-controlled conditions and the simple devices is adopted.

Owner:HUBEI UEE ENERGY TECH CO LTD +1

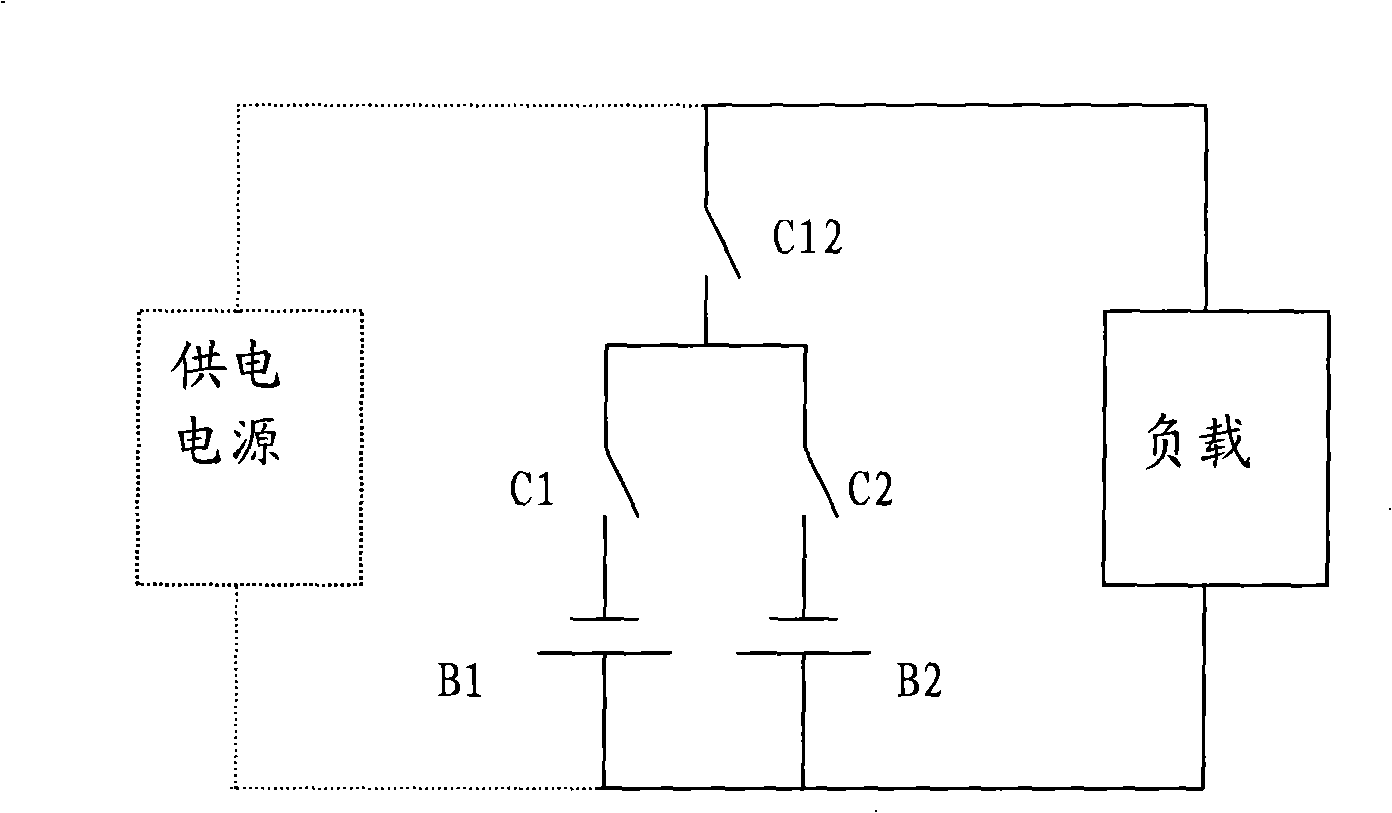

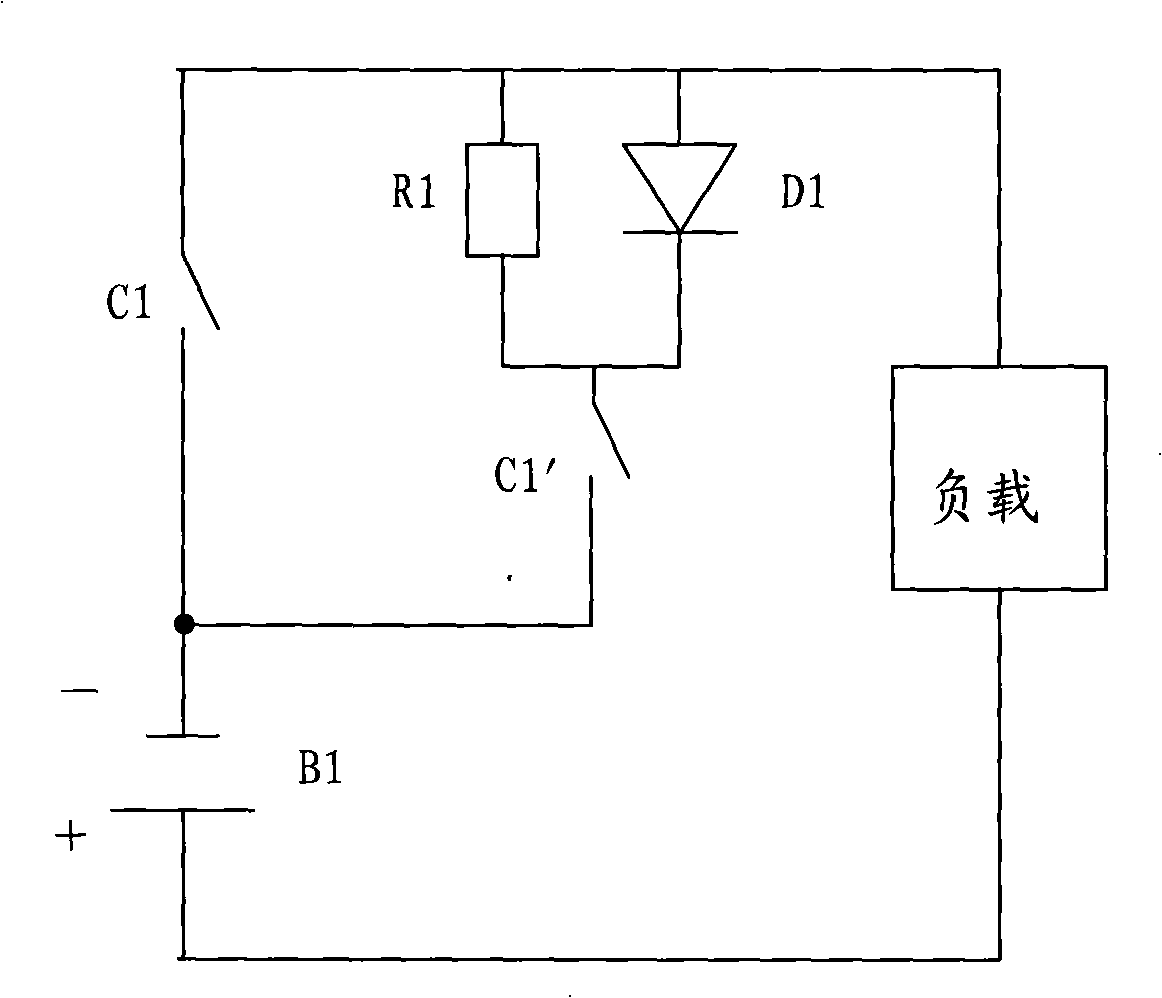

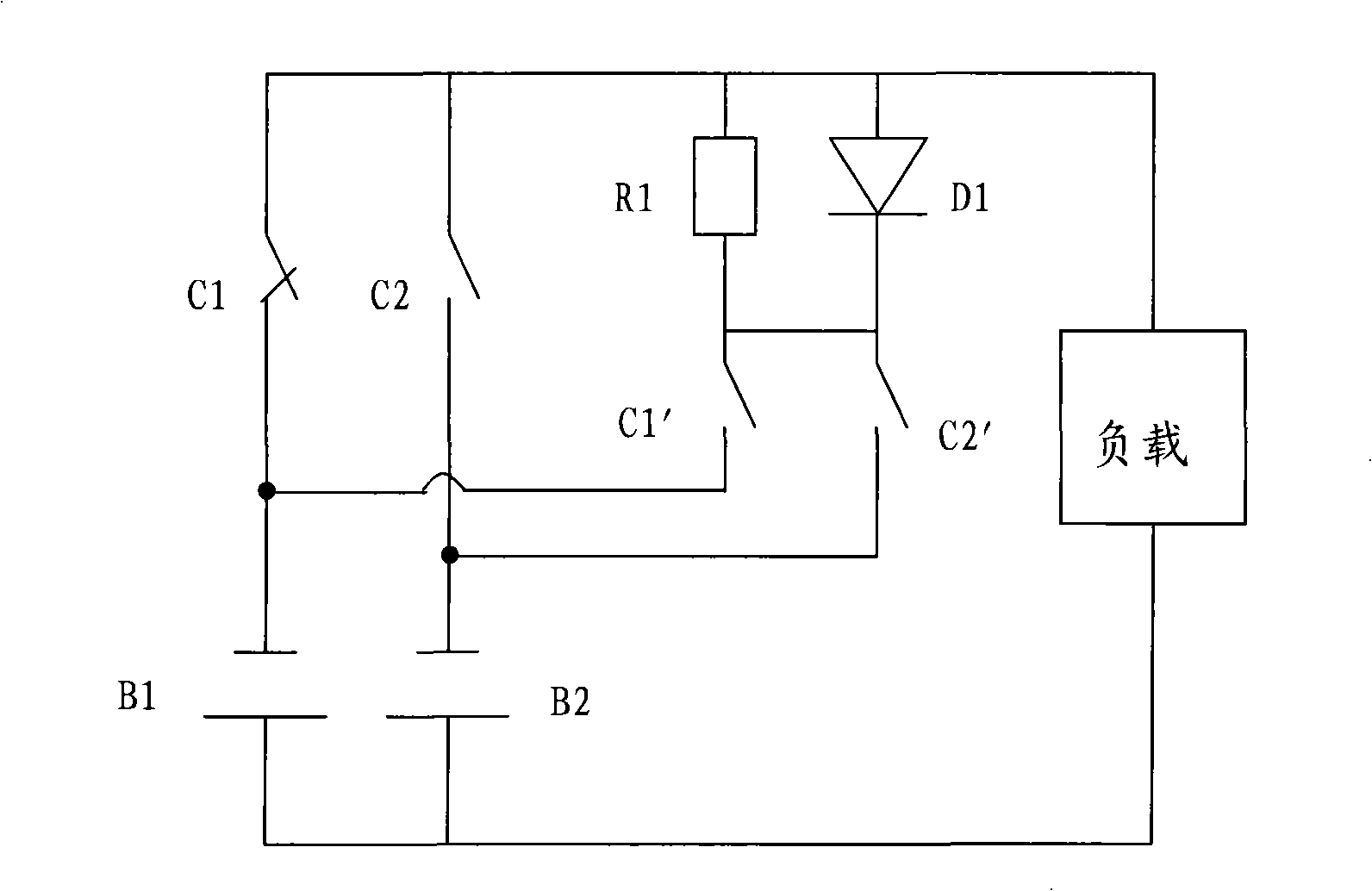

Power supply circuit and method

ActiveCN101295879AAvoid damageNo special requirementsBatteries circuit arrangementsSecondary cells charging/dischargingCurrent limitingAutomatic control

The invention provides a power supply circuit which comprises at least one main circuit and at least one assistant circuit; the at least one main circuit comprises at least one battery, a load and at least one main circuit switch controlling the connection of the main circuit; the at least one assistant circuit comprises a current limiting unit and a current pilot unit; the at least one assistant circuit is connected with the at least one main circuit and the load; the invention also provides a power supply method of the power supply circuit. The power supply circuit and the power supply method provided by the invention can realize the electrification of a plurality groups of batteries respectively; the current limiting unit is utilized for preventing the batteries from being damaged; the current pilot unit, such as a switching tube, etc. is utilized to ensure the normal power supply of the load; the invention does not rely on extra assistant equipment and manual operation, does not have special requirements for power supply source and the batteries, has no safety hidden danger, is convenient for realizing intelligent automatic control, has simple circuit and low cost and is convenient for promotion and use.

Owner:VERTIV CORP

Preparation method of aqueous single-layer graphene solution

The invention discloses a preparation method of an aqueous single-layer graphene solution. According to the method, natural graphite, calcium nitrate, potassium nitrate, concentrated sulfuric acid and potassium permanganate are mixed and processed to obtain a graphite oxide solution, and after the graphite oxide solution is prepared into an aqueous single-layer graphene oxide solution, a reducing agent is added for a reaction, and the aqueous single-layer graphene solution is obtained. According to the method, the aqueous single-layer graphene solution with high single layer rate, strong compositing feature and uniform dispersion is prepared finally after multiple times of ultrasonic stripping.

Owner:北京纳新天地科技发展有限公司

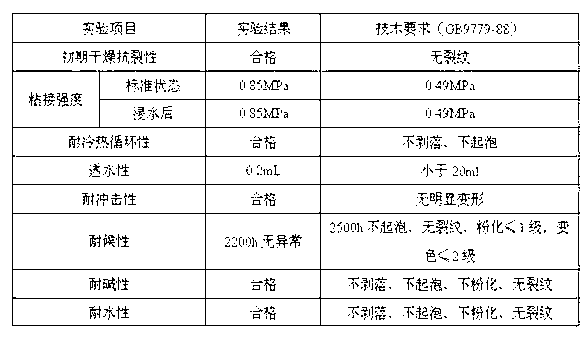

Dust-raise preventing spray covering bonding agent on surface of unit train and preparation method thereof

ActiveCN101851473ALow costNo special requirementsOther chemical processesStarch adhesivesSodium benzoateChemistry

The invention discloses a dust-raise preventing spray covering bonding agent on the surface of a unit train and a preparation method thereof. The bonding agent comprises sodium carboxymethylcellulose, pre-gelatinized starch, sodium benzoate and water. The preparation method comprises the following steps of: pre-adding the tap water into a stirring pot at the normal temperature, and adding and stirring the sodium carboxymethylcellulose, the pre-gelatinized starch and the sodium benzoate respectively until the sodium carboxymethylcellulose, the pre-gelatinized starch and the sodium benzoate are completely dissolved to obtain the finished product. The bonding agent has the advantages of low cost, production process finished at the normal temperature, no special requirement, simple and convenient process, long storage time, independent components and solution thereof without any toxic or side effect and corrosiveness, no secondary pollution and remarkable dustproof effect.

Owner:SCI INST HOHHOT ADMINISTRATION OF RAILWAY

Super-hydrophobic oil-proof self-cleaning aerosol and preparation method thereof

InactiveCN104877564ASimple production processEase of mass productionCoatingsAerosol sprayAerosol Mist

A super-hydrophobic oil-proof self-cleaning aerosol comprises, by weight, one or more of a fluorine-containing compound and a silicone-containing compound 0.1-15%, lanthanide series compound 0.1-5%, nano material 0.1-10%, dissolve promoter 5-40%, diluents 10-60% and propellants 15-40%. A preparation method of the super-hydrophobic oil-proof self-cleaning aerosol comprises the following steps of weighing raw materials according to a formula, stirring and evenly mixing all raw materials except the propellants, respectively filling the raw materials into an aerosol can or a tinplate can or an aluminum can, plugging a valve into a filled can, sealing an opening, filling the propellants, and conducting online weighing, water bath leakage detection and label adhesion on the canned aerosol. The super-hydrophobic oil-proof self-cleaning aerosol has the following advantages that a production process is simple, large-scale production is facilitated, product perniciousness is low, the aerosol is very convenient to carry and use and is especially suitable for application of a spray gun in a large-scale constriction site; the aerosol has no temperature requirement in use and has no special condition requirements, is colorless, tasteless, high in adhesion force, long in service life and wide in application range and is resistant to friction.

Owner:ANHUI SINOGRACE CHEM

Rock core water-containing analysis method

InactiveCN101059464AReduce dosageNo harmEarth material testingMaterial resistanceNon toxicityRock sample

The invention relates to a rock core water-bearing analysis method, in particular to an analysis of drilling well exploration rock core, belonging to oil gas geological technical field. The method comprises that breaking a rock core sample to be arranged into a test barrel, adding deionized water into the test barrel to submerge the rock core sample, sealing the test barrel, immerging the sample at normal temperature, using a test machine to find the mineralization rate K of the immerge liquid. The invention uses conductivity detect technique, to simplify the analysis process via rock core water-bearing saturation analysis processes and calculation equation, to quickly obtain the water-bearing saturation via little devices, while the chemical agent has reduced consumption, non toxicity, non damage on operation, non special protection demand, and non environment pollution. And the invention has quick analysis, with only one device, simple calculation, non special demand on operation and worker, and the application for rock core water-bearing quick analysis at drilling site.

Owner:鲍云杰

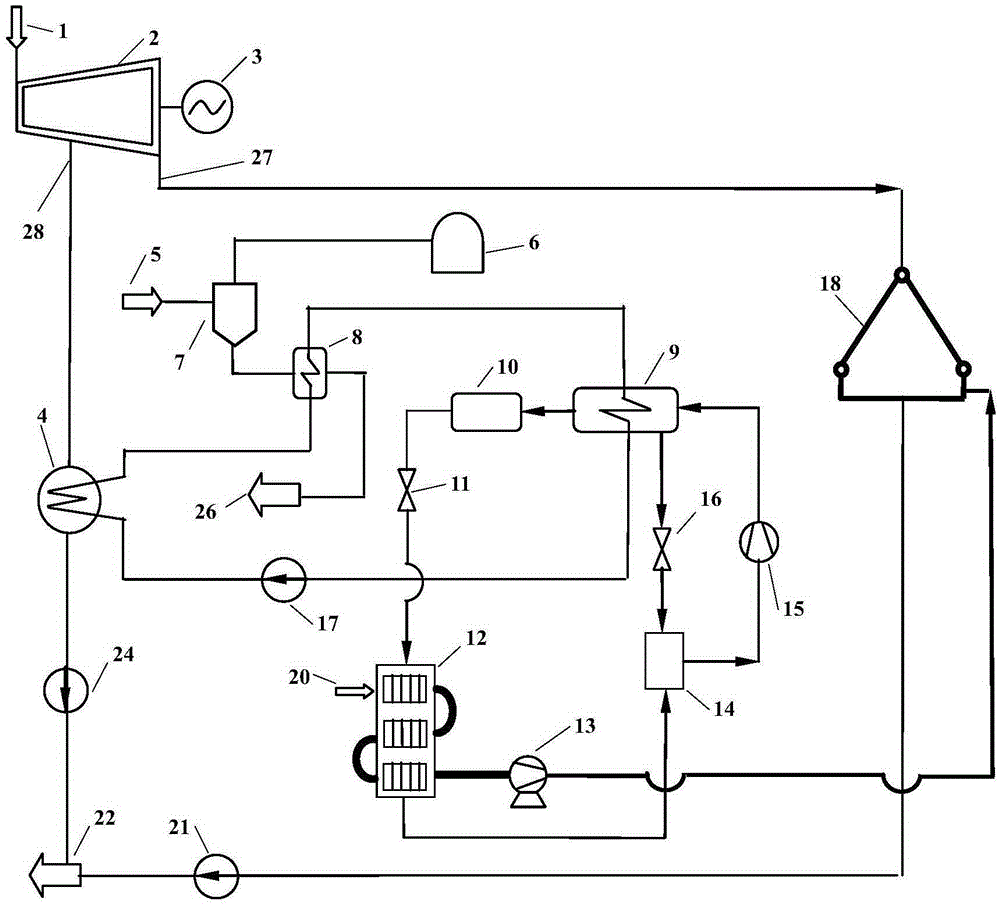

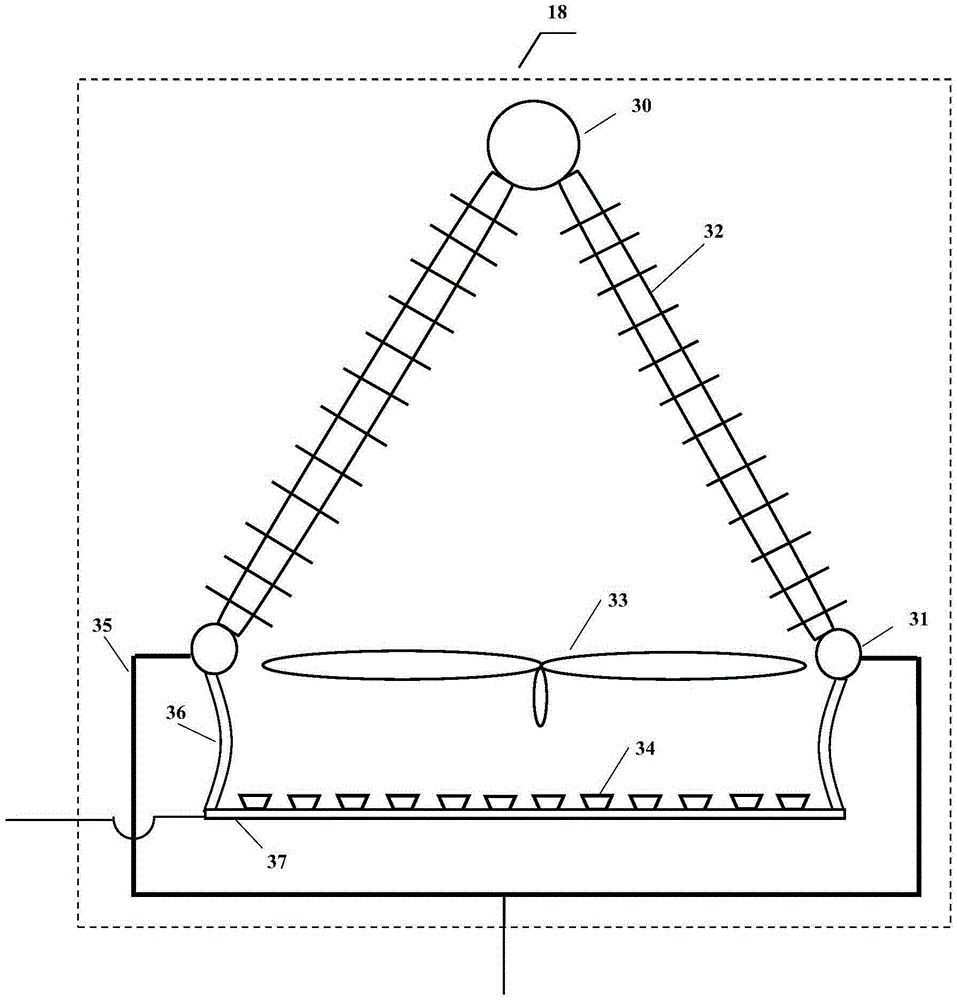

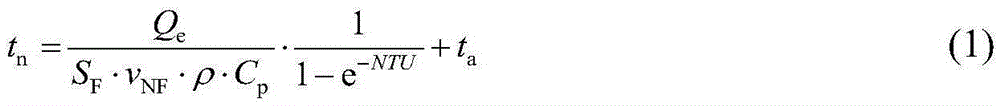

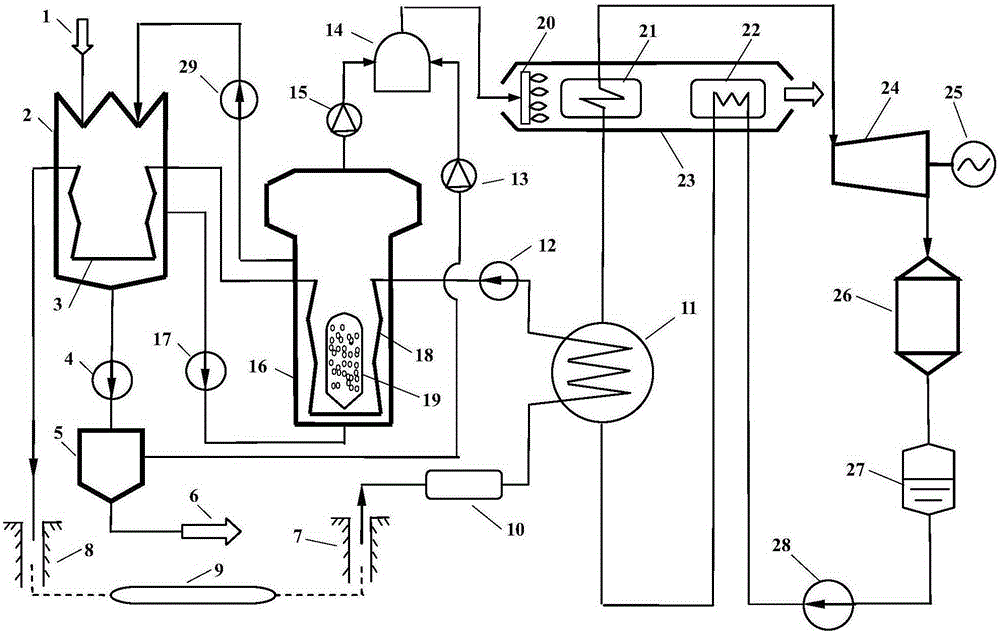

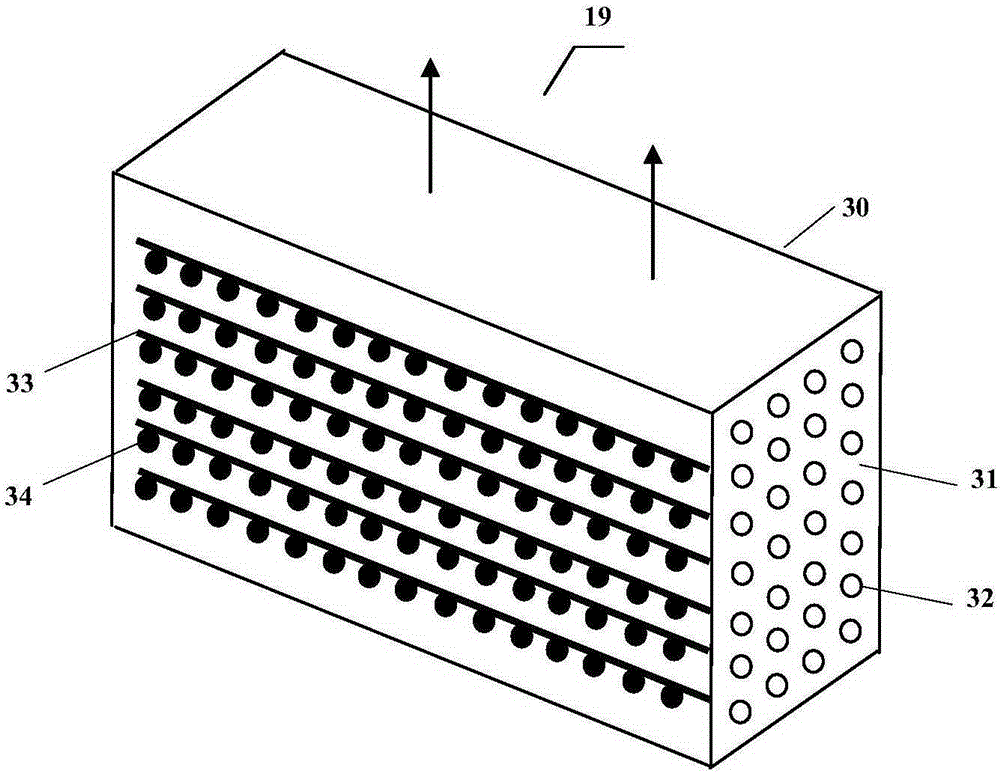

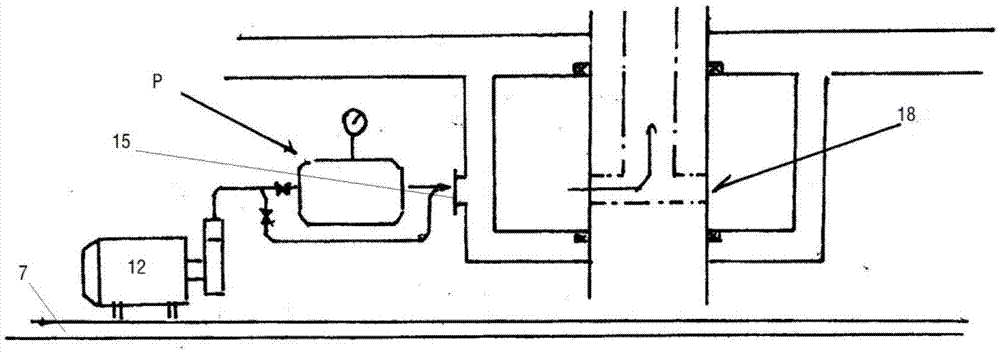

Power station air cooling system adopting combined refrigeration with shaft seal steam leakage of steam turbine and continuous blow-down waste heat of boiler as well as method for predicting heat-transfer coefficient of air-cooling condenser

ActiveCN105423772AReduce dust accumulationLower condensation temperatureHeat pumpsFeed water supplyEngineeringSuperheater

The invention discloses a power station air cooling system adopting combined refrigeration with shaft seal steam leakage of a steam turbine and continuous blow-down waste heat of a boiler. The system is characterized in that the steam turbine is communicated with a steam source, the steam turbine is connected with an electric generator, and the steam turbine is sequentially communicated with an air-cooling condenser, a condensate pump and boiler feedwater; the steam turbine is sequentially communicated with a steam leakage condenser, a steam leakage condensate pump and the boiler feedwater; boiler blow-down water is sequentially communicated with a flash tank, a deaerator, a working medium superheater and a drainage ditch; the steam leakage condenser is sequentially communicated with the working medium superheater, and a generator is communicated with the steam leakage condenser through a working medium circulating pump; the generator is sequentially communicated with a condenser, a first throttling valve and an evaporator, the evaporator is communicated with an absorber, and the generator is sequentially communicated with a second throttling valve, the absorber, a solution pump and a generator; and air is sequentially communicated with the evaporator, an induced draft fan and the air-cooling condenser. A method for predicting a heat-transfer coefficient of the air-cooling condenser is further provided.

Owner:NORTHEAST DIANLI UNIVERSITY

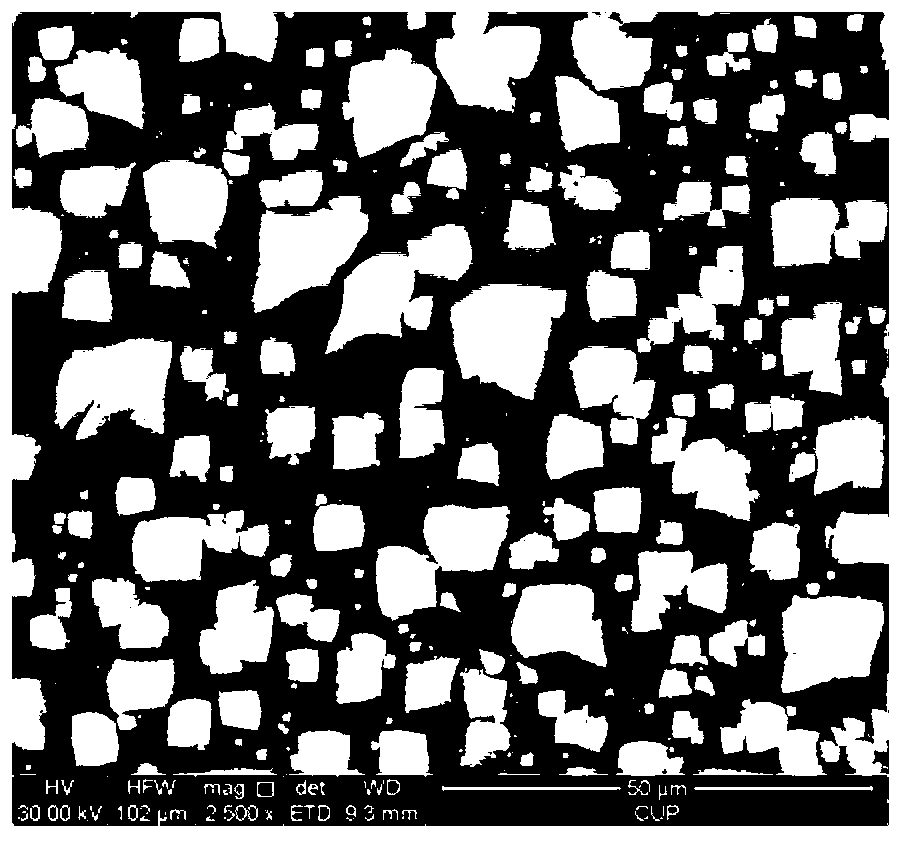

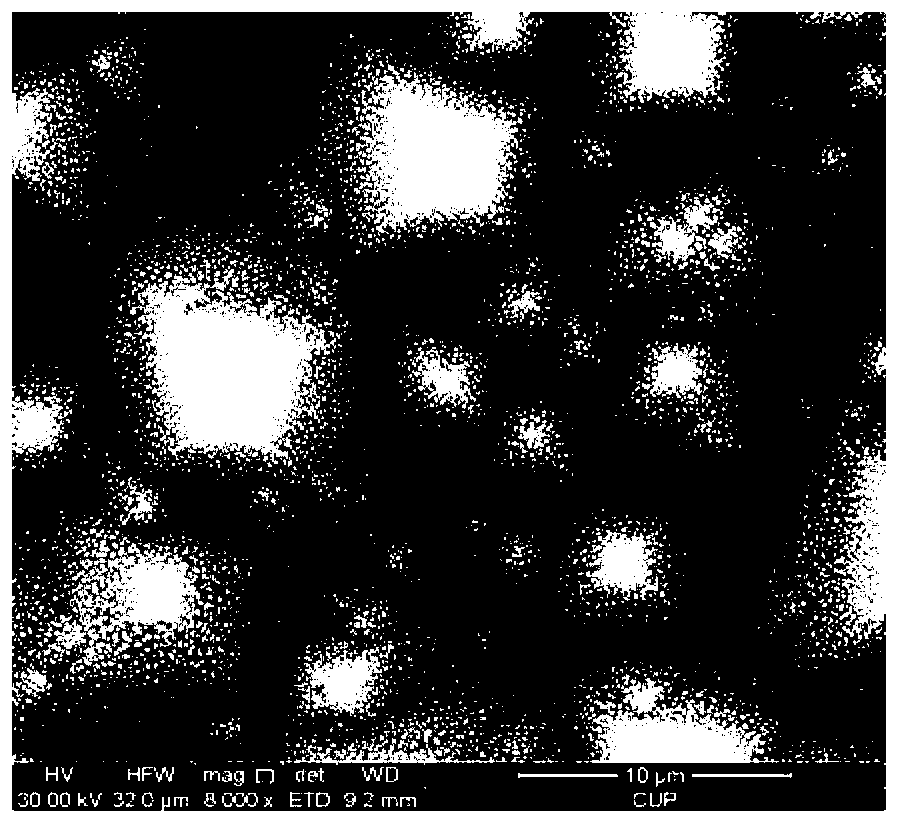

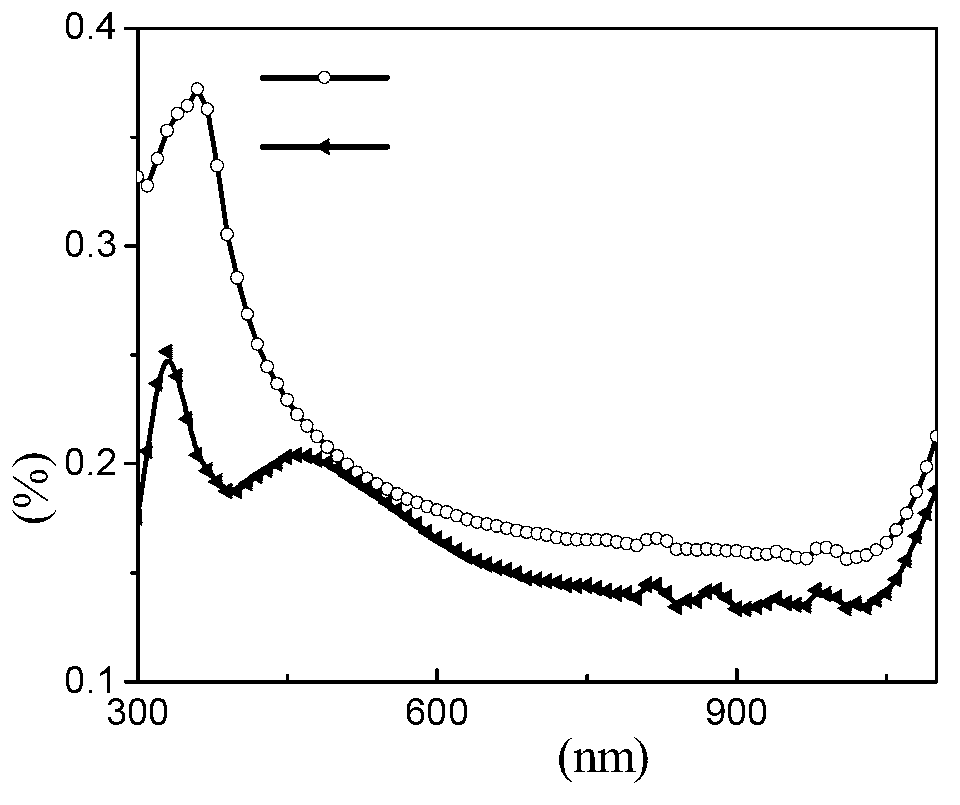

Method for manufacturing novel light-trapping synergetic antireflection structure on basis of LSP (localized surface plasma) effect

ActiveCN103022266AImprove conversion efficiencyReduce reflectivityFinal product manufactureVacuum evaporation coatingSolar batterySilicon thin film

The invention belongs to the technical field of solar cells, and particularly relates to a method for manufacturing a novel light-trapping synergetic antireflection structure on the basis of an LSP (localized surface plasma) effect. The method includes etching a cone shape on the surface of monocrystalline silicon by alkali; and depositing a layer of discontinuous silver nanoparticles on the surface of a cone by means of sputtering and annealing to obtain the novel light-trapping structure with the silver nanoparticles and a cone structure which are compounded with one another. The reflectivity of the novel light-trapping synergetic antireflection structure is reduced by 3.4% within the total solar spectrum range as compared with a pure cone structure. The method for manufacturing the effective light-trapping structure includes simple and practical silicon wafer cleaning and silver nanoparticle sputtering and depositing technological procedures, and a constant-temperature wet etching means is combined with the LSP effect, so that an excellent antireflection effect is realized as compared with the traditional structure manufactured by alkaline etching, and design and manufacturing processes of the method provide novel technical means for improving the efficiency of silicon and the efficiency of a thin film silicon solar cell.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

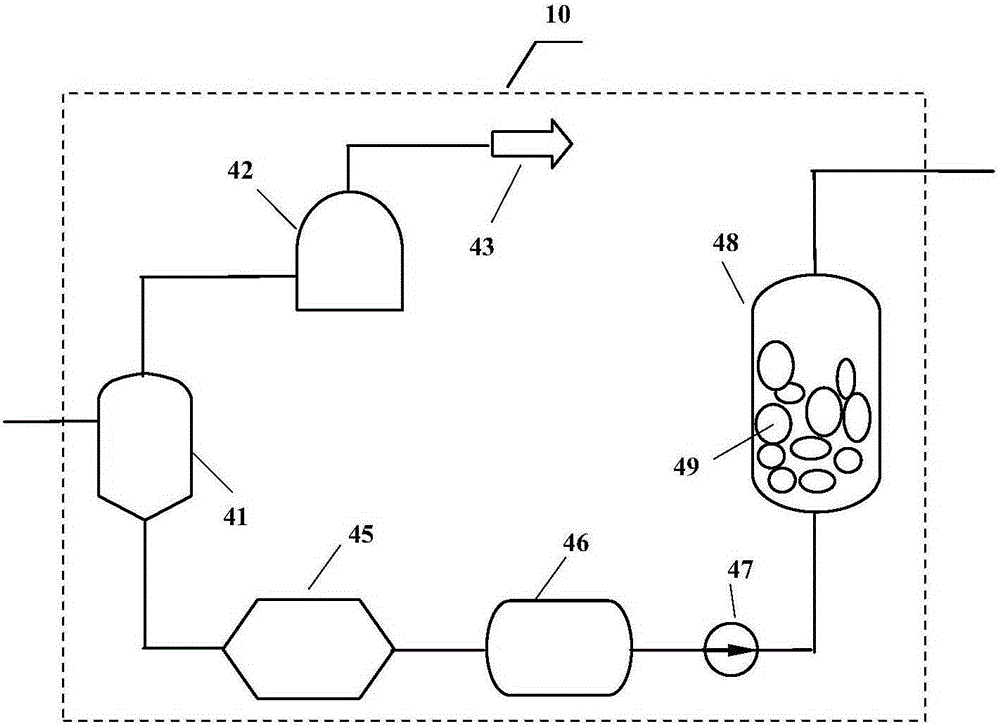

Medium-and-low temperature ground heat and biomass gas combined power generation system and power generation cost calculating method

ActiveCN105221363APrevent freezingStable and clean power generationGeothermal energy generationGeothermal systemsSuperheaterWater processing

A medium-and-low temperature ground heat and biomass gas combined power generation system is characterized in that a working medium evaporator is connected with a working medium superheater, a prime motor and a power generator of a gas boiler, the prime motor is communicated with a working medium condenser and a working medium storage tank, and the working medium storage tank is communicated with a working medium preheater of the gas boiler through a working medium booster pump; a production well is communicated with a ground heat water processing device and the working medium evaporator, and the working medium evaporator is communicated with a second inner heating pipe and a first inner heating pipe; the first inner heating pipe is communicated with an inverted well, an underground heat storage part and the production well; biomass is communicated with an acidification hydrolysis tank and communicated with a biogas residue fermentation tank and biogas fertilizer through a biogas residue circulation pump, and the biogas residue fermentation tank is communicated with a gas storage tank through a first gas booster pump; the acidification hydrolysis tank is communicated with an anaerobic digestor through an organic acid circulation pump; the anaerobic digestor is communicated with the gas storage tank and a combustor in the gas boiler through a second gas booster pump; and an anaerobic digester filling module is arranged in the anaerobic digestor. A power generation cost calculating method for the medium-and-low temperature ground heat and biomass gas combined power generation system is provided.

Owner:NORTHEAST DIANLI UNIVERSITY

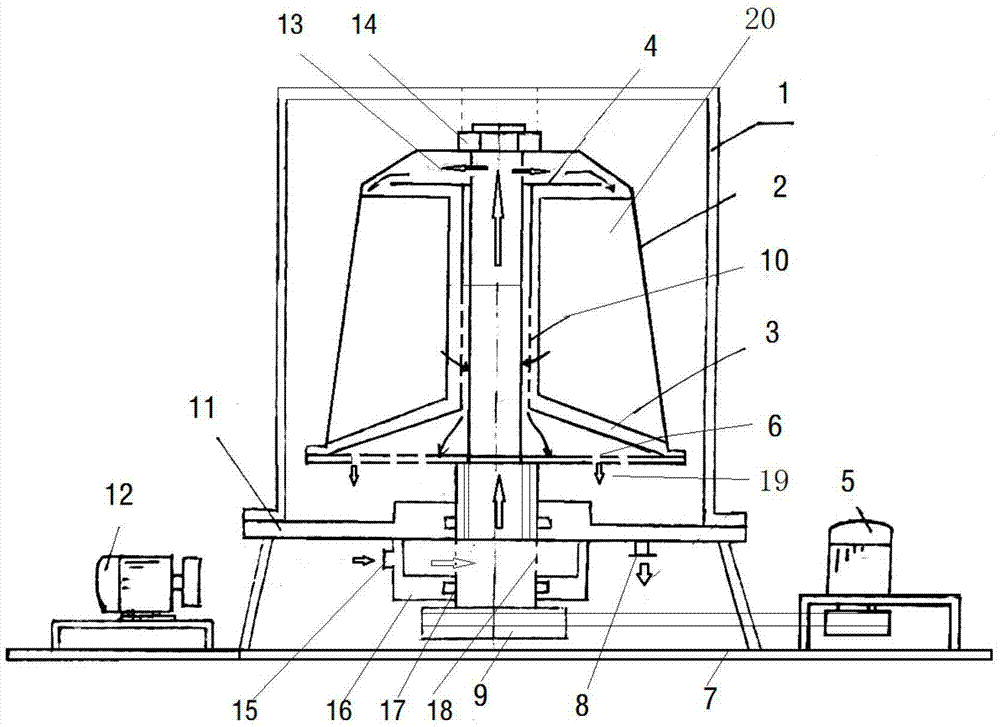

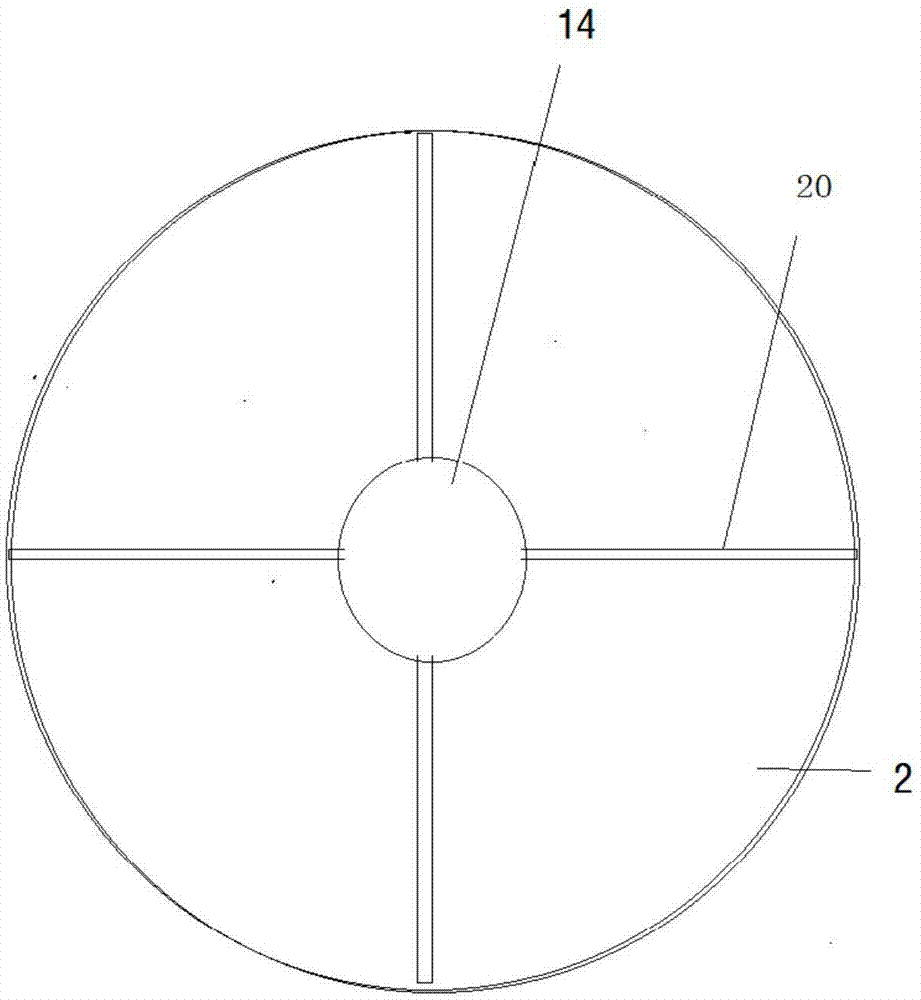

Centrifugation water treatment method and device

InactiveCN105435514ASimple structureReasonable structureMoving filtering element filtersMotor driveCentrifugation

The invention discloses a centrifugation water treatment device. The centrifugation water treatment device comprises a cylinder housing (1), a centrifugation rotating cylinder (2), a water separator (4), a motor (5), a core filter screen (10) of the centrifugation rotating cylinder, a centrifugation rotating cylinder base plate (6), a water pump motor and a water pump (12), water inlet shaft water outlet holes (13), a water inlet shaft fixing nut (14), a water pump water inlet, a water inlet tank, a water inlet shaft driving disc (9), a water inlet driving shaft and a water inlet shaft water inlet hole. The centrifugation rotating cylinder and the water separator are integrated and the vertical section of the integrated structure is in a shape of I. Inlet water is fed into a water tank through the water pump motor and the water pump. The water inlet tank is communicated with the water inlet driving shaft with the water inlet shaft water inlet hole and a hollow channel. A water outlet end of the water inlet shaft is connected to the water separator. Outlet water from the water separator is located at a position 150mm or more away from the radius of the water inlet shaft. The motor drives the water inlet shaft driving disc and the water inlet shaft so that the centrifugation rotating cylinder is driven to carry out high speed centrifugation separation.

Owner:WUXI YUXING BUILDING HARDWARE

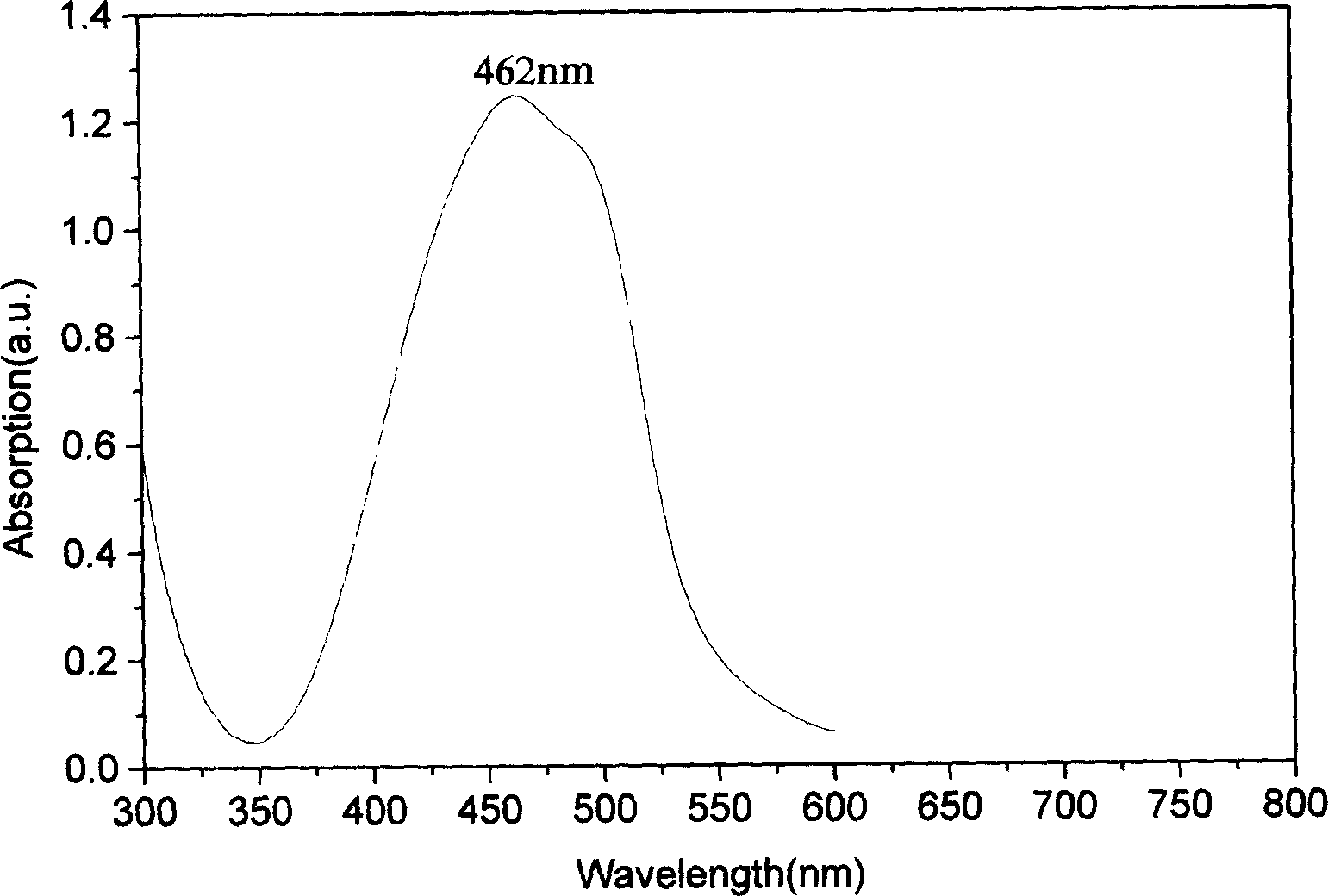

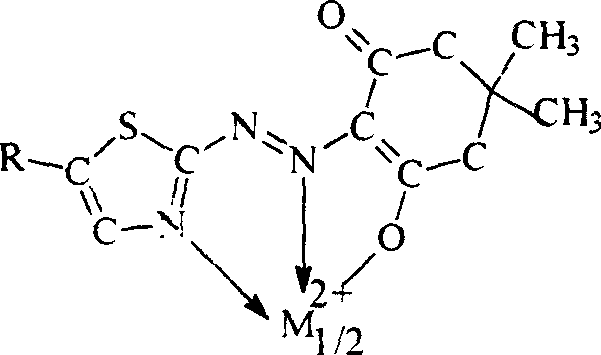

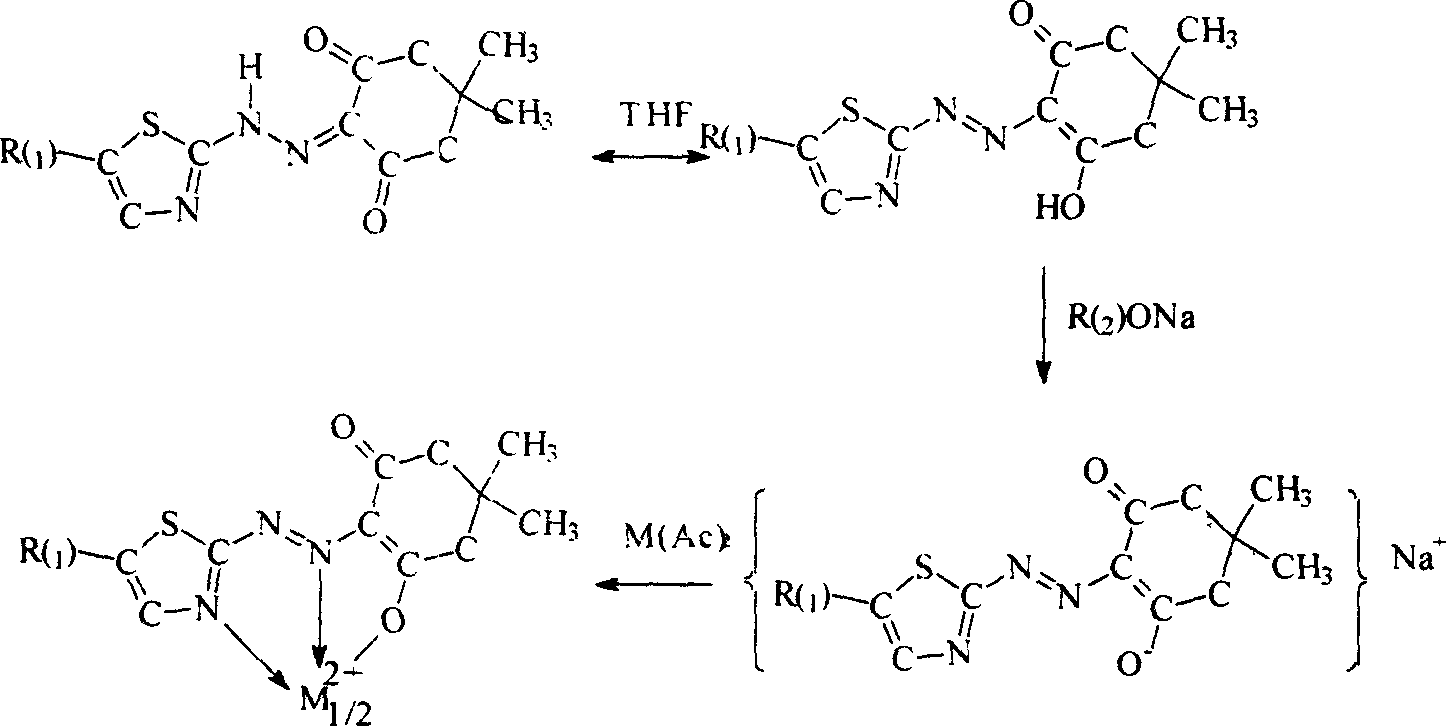

Metal chelate of short wavelength, and preparation method

InactiveCN1562987APromote generationWill not causeOrganic chemistryRecord information storageSolubilityOrganic solvent

This invention relates to short wavelength metal-chelate-alpha-(4-substituted-2-azothiazolcyclo)-beta-(4,4- dimethyl cyclohexadione) metal chelate with its structural formula as shown, where, C=carbon, N=nitrogen, R=alkyl, methyl, 1-4 carbon linear branched chain alkyl with t-butyl; M2+=Ni2+, Zn2+, Cu2+. This invention compound adsorbs short wavelength (400-500 nm), has solubility being not less than 3 wt% in much organic solvent, being suitable for forming membrane with rotating coating method with high stability, being matched with blue-green laser in working wavelength of 450-550 nm, being of organic storage medium of high thickness blue-green light recording-disc.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

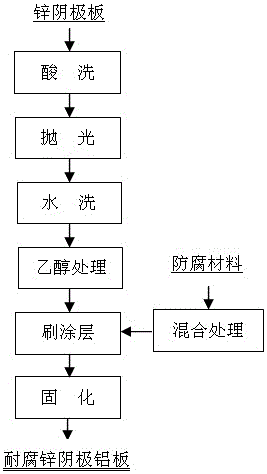

Preparation method for anticorrosive zinc cathode aluminum plate with coating

ActiveCN106757177AExtended service lifeAchieve drynessPhotography auxillary processesAnti-corrosive paintsZincEnergy consumption

The invention relates to a preparation method for an anticorrosive zinc cathode aluminum plate with a coating. Surface treatment is carried out on an ordinary zinc cathode aluminum plate, a deoiled and decontaminated zinc cathode aluminum plate with a clean surface is obtained, then, liquid coating which is mixed to be uniform is sprayed to the corrosive area of the zinc cathode aluminum plate in a spraying manner, and through curing treatment, the anticorrosive zinc cathode aluminum plate with the coating is obtained. According to the preparation method, the process investment is small, the process procedures are simple, no special requirement is made for equipment, the energy consumption is low, no pollution is caused, and the application prospects are wide.

Owner:湖南株冶有色金属有限公司

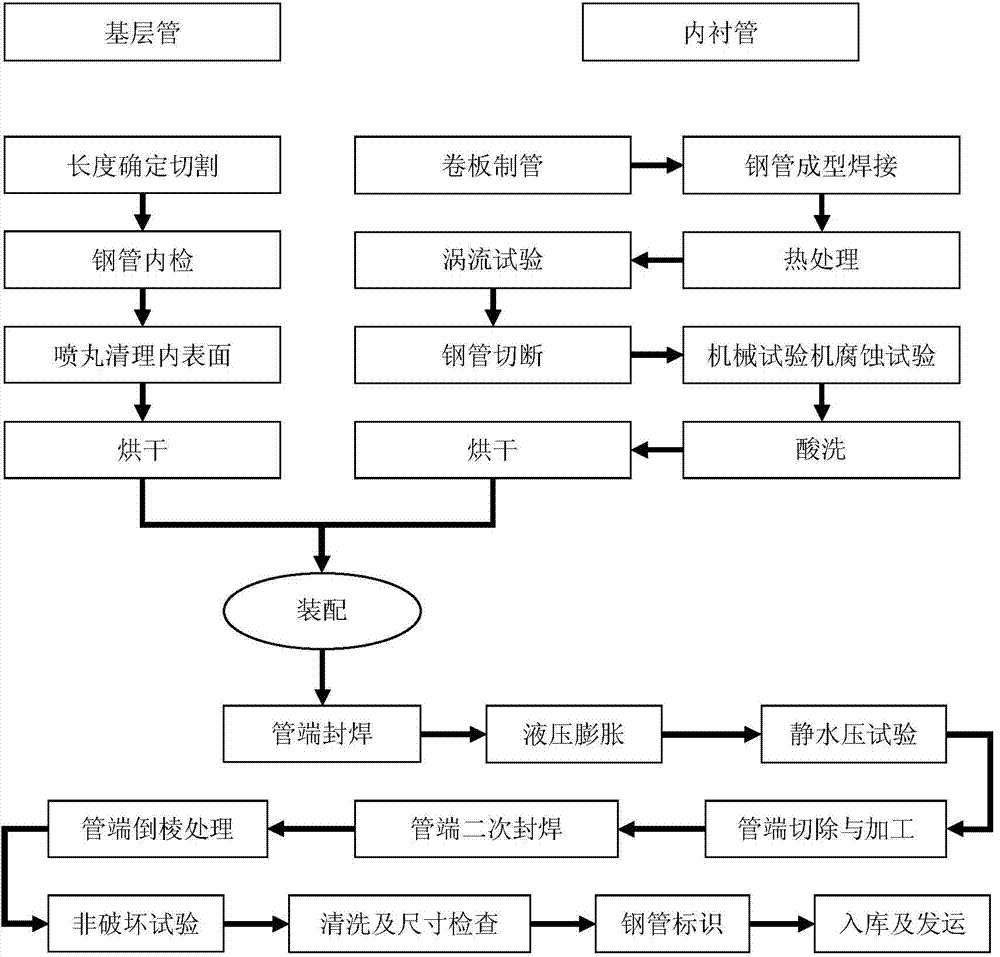

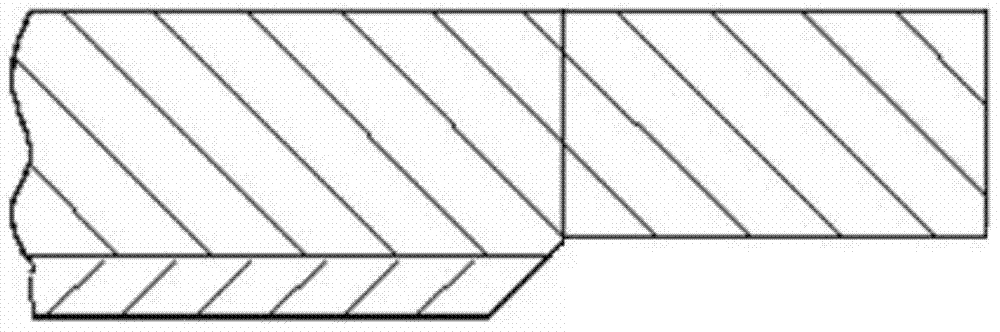

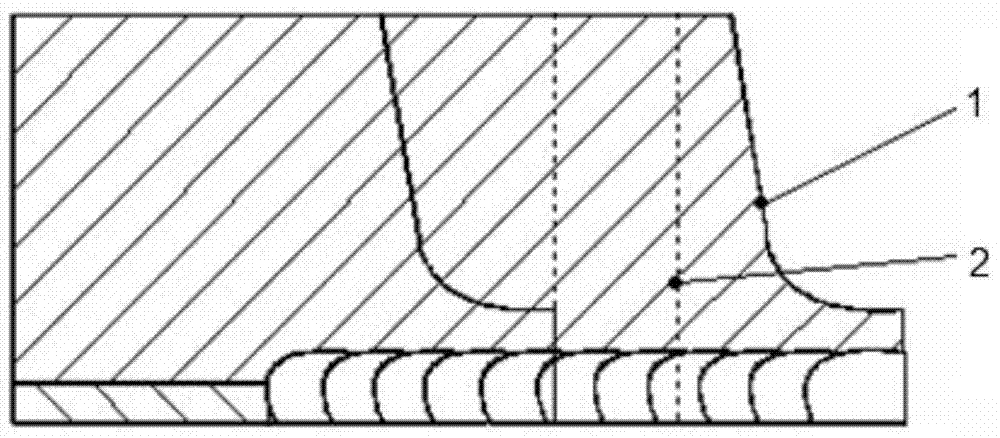

Hydraulic pressure expansion liner corrosion resistant alloy composite tube and manufacturing method thereof

InactiveCN103574220ASolve construction needsNo special requirementsCorrosion preventionPipe protection against corrosion/incrustationCorrosion resistant alloyLine tubing

The invention discloses a hydraulic pressure expansion liner corrosion resistant alloy composite tube which is composed of a corrosion resistant alloy inner tube and a mild steel outer tube. The corrosion resistant alloy inner tube and the mild steel outer tube are assembled and liquid pressure is applied on the interior thereof after the assembly to cause the outer surface of the corrosion resistant alloy inner tube and the inner surface of the mild steel outer tube to be tight connected. The wall thickness of the corrosion resistant alloy inner tube is 1-4mm, and the outer diameter of the corrosion resistant alloy inner tube is 70-600mm. The wall thickness of the mild steel outer tube is 6-15mm, and the outer diameter of the mild steel outer tube is 76-610 mm. The composite tube has the beneficial effects that by adopting the method disclosed by the invention, an oil and gas gathering and transporting pipeline can be built for a severe corrosion area, and the method has no special requirements on sites and technologies, so the generalization is convenient.

Owner:BAOJI PETROLEUM STEEL PIPE

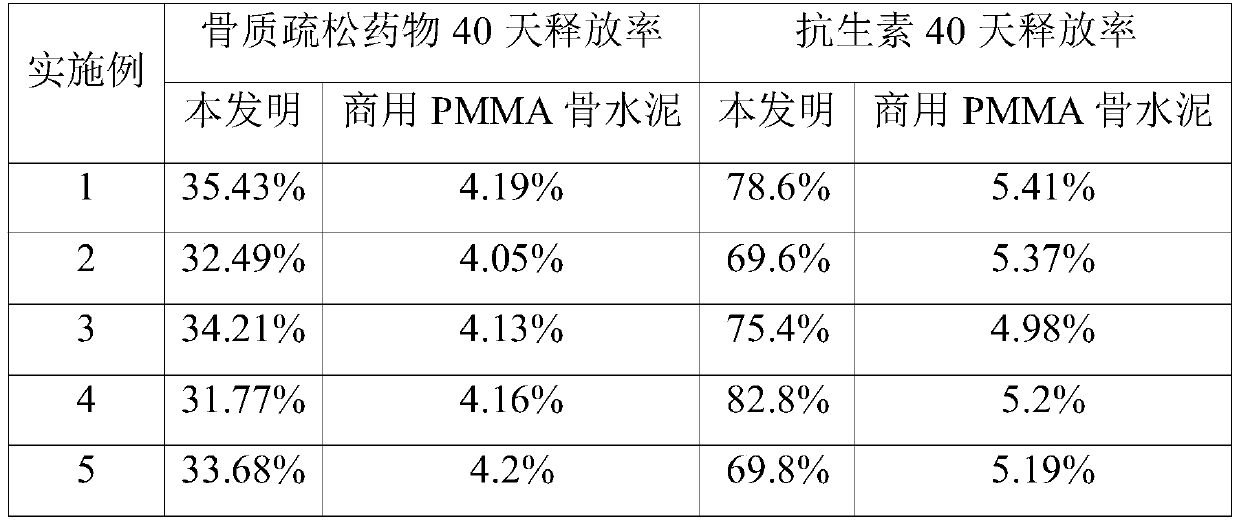

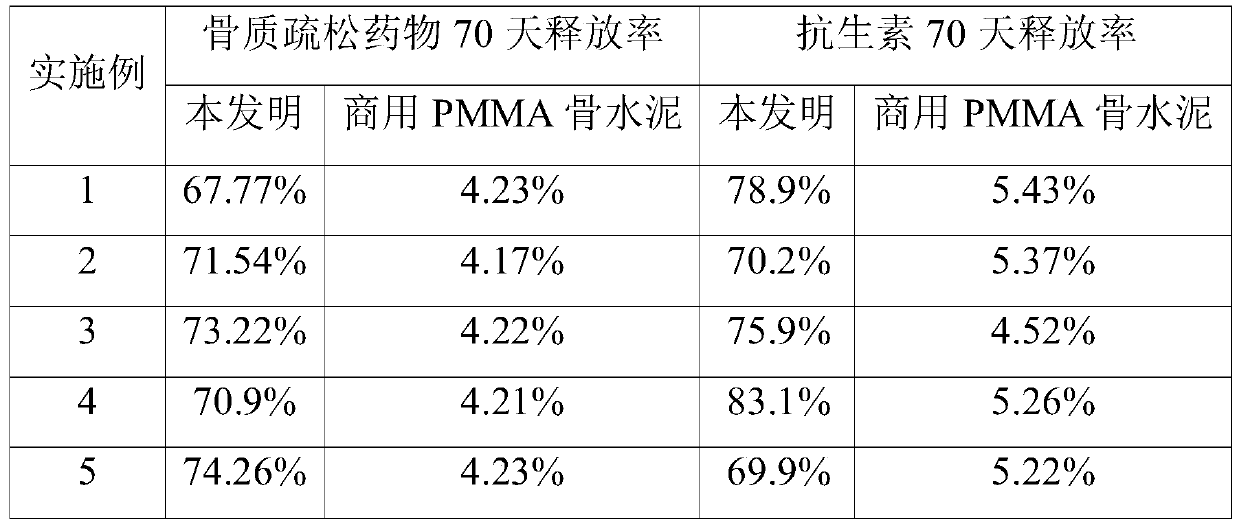

Double-drug release PMMA compound bone cement and preparation method thereof

ActiveCN110075351AIncrease release rateLow costTissue regenerationMicrocapsulesDrug releaseBone cement

The invention discloses a double-drug release PMMA compound bone cement and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing a surface porous osteoporosis drug-loading gelatin microsphere; loading an antibiotic drug onto the surface porous osteoporosis drug-loading gelatin microsphere, thereby acquiring a double-drug loaded gelatin microsphere;uniformly mixing the double-drug loaded gelatin microsphere with solid PMMA bone cement powder, thereby acquiring a solid phase of double-drug loaded PMMA compound bone cement; mixing the solid phasepowder of double-drug release PMMA compound bone cement with a PMMA bone cement liquid-phase reagent, thereby acquiring the double-drug release PMMA compound bone cement. In the double-drug release PMMA compound bone cement prepared according to the invention, the gelatin microsphere with double-drug loaded on interior and exterior is added into the solid phase; the staging release of double drugis realized; the double-drug release PMMA compound bone cement is antibacterial and anti-inflammation, has a certain curative effect to osteoporosis, is low-cost, has no special requirement for production equipment and has an excellent application prospect in clinic.

Owner:XIAN UNIV OF TECH

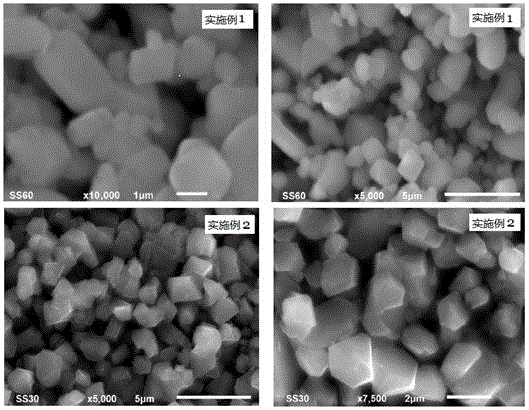

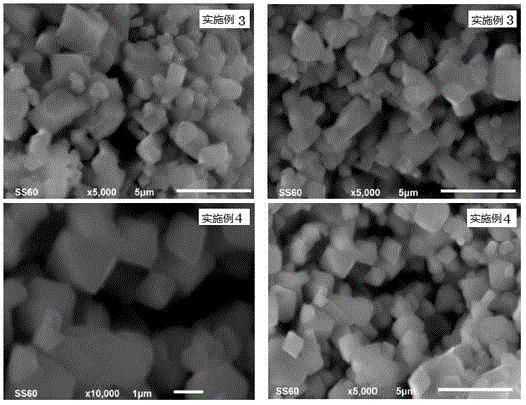

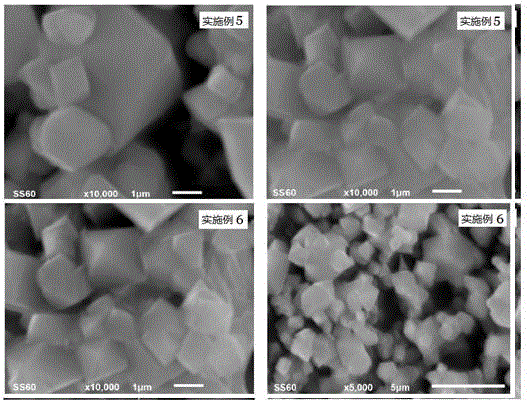

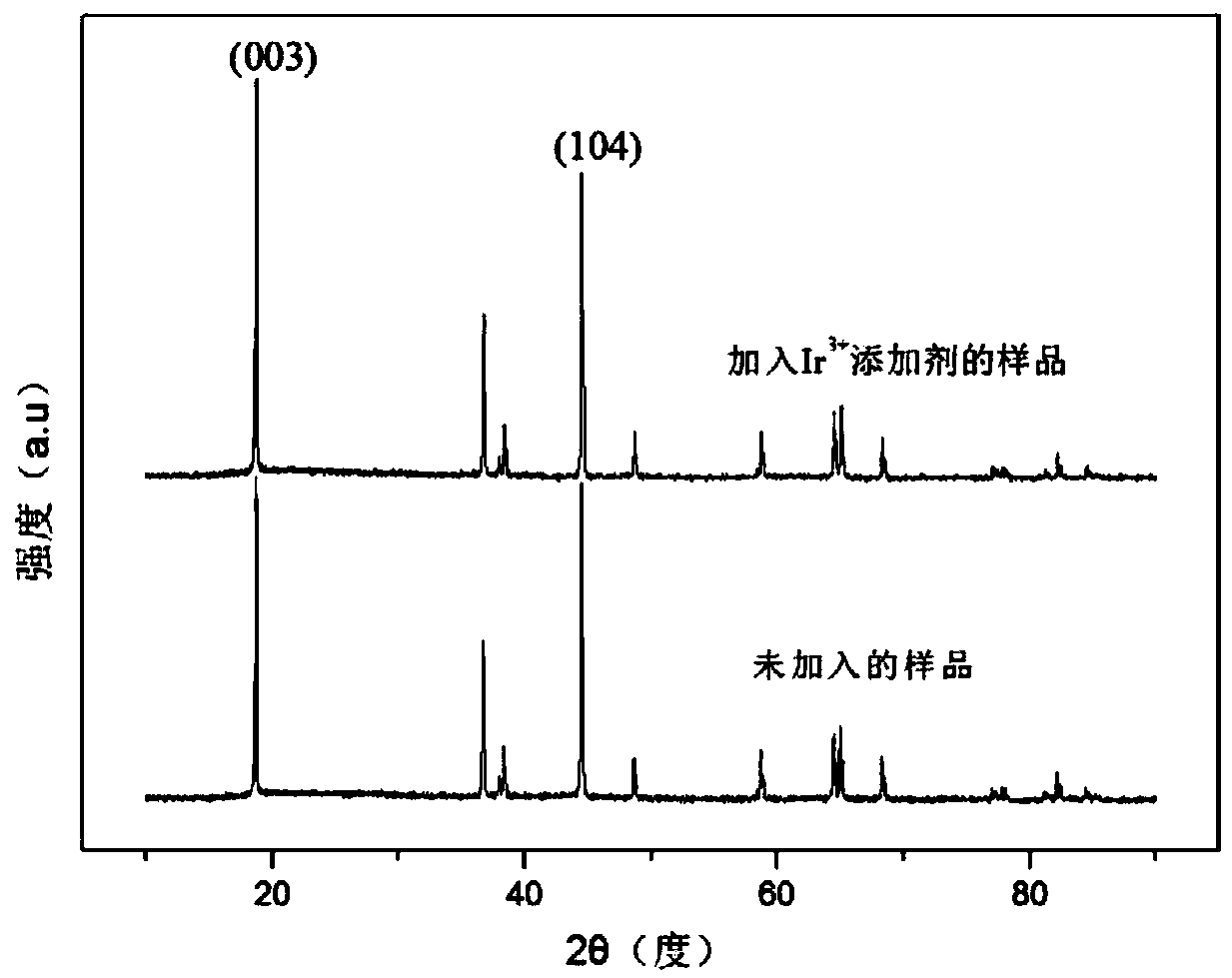

Single crystal ternary positive electrode material with good dispersibility, lithium-nickel mixed arrangement and low residual alkali, and preparation method and application thereof

ActiveCN110581259AReduce shufflingPromote formationCell electrodesSecondary cellsTe elementSingle crystal

The invention discloses a single crystal ternary positive electrode material with good dispersibility, lithium-nickel mixed arrangement and low residual alkali, and a preparation method and an application thereof. In the preparation process of the single crystal ternary positive electrode material, the raw materials comprise a cationic additive, and the cationic additive is any one or a combination of at least two of an iridium source, an yttrium source, a tellurium source, an indium source and a gallium source. By adding the cationic additives such as Ir<3+>, Y<3+>, Te<4+>, In<3+> and Ga<3+>,the surface energy of the ternary material can be promoted to be reduced on the one hand, so that the sintering temperature of the material is reduced, and the volatilization of lithium salt is reduced; and on the other hand, the lithium-nickel mixed arrangement can be reduced, the directional growth of the crystal face of the material is controlled, and the adsorption effect and reaction activity of the crystal face and CO2 and H2O in the air are inhibited, so that residual alkali on the surface of the ternary material is reduced, the processing performance of the material is improved, and the rate discharge capacity and cycle performance of the single crystal ternary material are improved.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

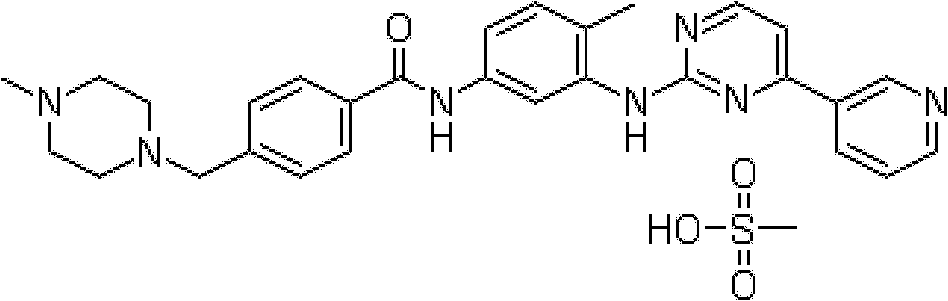

Inclusion compound of alpha crystal imatinib and preparation method thereof

InactiveCN102008734AFix instabilityImprove stabilityOrganic active ingredientsPharmaceutical non-active ingredientsInstabilitySemi solid

The invention relates to an inclusion compound of alpha crystal imatinib. The inclusion compound of alpha crystal imatinib is prepared by selecting cyclodextrin or derivatives thereof as an inclusion material and is characterized by comprising 0.1-0.3wt% of alpha crystal imatinib and 97.0-99.9wt% of cyclodextrin or derivatives thereof. In the preparation of the inclusion compound, a solvent method and a grinding method can be adopted. As the inclusion compound is prepared by adopting the cyclodextrin or derivatives thereof to include the alpha crystal imatinib, the sensitivity of the alpha crystal imatinib to light, temperature and heat is overcome, and the instability problem of the alpha crystal imatinib is solved. Liquid preparations, semi-solid preparations or solid preparations further prepared from the inclusion compound respectively have improved stability and convenience in operation. The inclusion compound is simple in preparation process, has no need of special requirements on preparation package and storage conditions, and is a novel alpha crystal imatinib preparation which has better liquidity, higher stability and lower moisture absorption and is suitable for clinical use.

Owner:SHENZHEN NEPTUNUS PHARM CO LTD

Method for preparing graphene by continuous peeling on basis of electrostatic repulsive force

The invention belongs to the technical field of preparation processes of graphene materials and particularly relates to a method for preparing graphene by continuous peeling on the basis of electrostatic repulsive force. The process comprises the following steps: multiple layered crystalline graphene materials, an ammonium source, a lithium source, strong alkali and water are mixed into alkali graphene slurry under the conditions of mechanical stirring and ultrasonic treatment; the alkali graphene slurry is sprayed out through a high-pressure atomizing nozzle provided with a point corona device to form an atomized shape, simultaneously the atomized slurry particles are treated by corona, negative charges are quickly gathered on the surfaces of graphite particles, burst occurs when the electrostatic repulsive force among the charges is larger than the interlayer van der waals force of the graphite particles, after collection, inorganic ions are removed by filtering and washing and then the graphene is obtained. In the method, the oxidation treatment process is avoided, and the graphite is peeled into one or more layers of graphene by high yield. The method can be scaled up to industrial production. Compared with other graphene preparation processes, the method has the advantages that the produced graphene sheet is fewer in defect and higher in electrical property, mechanical property and hydrophobic property.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

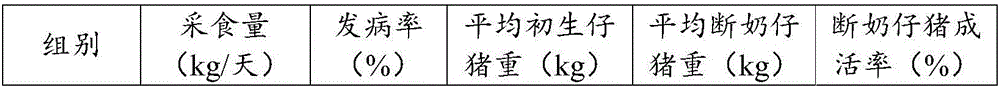

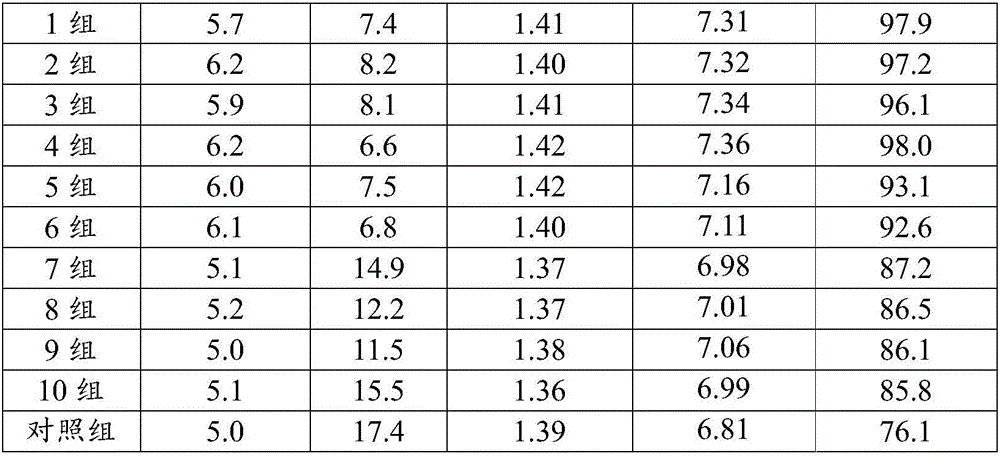

Compound feed for lactating sows and preparation method of compound feed

The invention discloses a compound feed for lactating sows and a preparation method of the compound feed, relating to the technical field of animal feeds. According to the compound feed, the technical problems in the prior art that the components in feeds are not reasonably matched, and the highest weight increment of piglets and good reproductive performance of the sows cannot be realized are improved. The compound feed contains a main material, wherein the main material is prepared from the following raw material components in parts by weight: 520-540 parts of corns, 40-60 parts of husked barley, 125-145 parts of bean pulp, 50-70 parts of extruded soybean, 40-60 parts of gold protein, 40-60 parts of fermentation vinasse, 40-60 parts of a biological fermentation feed and 10-30 parts of wheat bran; and the compound feed further contains 25-35 parts of a premix and 22-27 parts of an additive. The compound feed containing the gold protein, the fermentation vinasse and the biological fermentation feed has the very good effects of preserving health, promoting lactation, preventing constipation and improving palatability.

Owner:湘西芙蓉资源农业科技有限公司

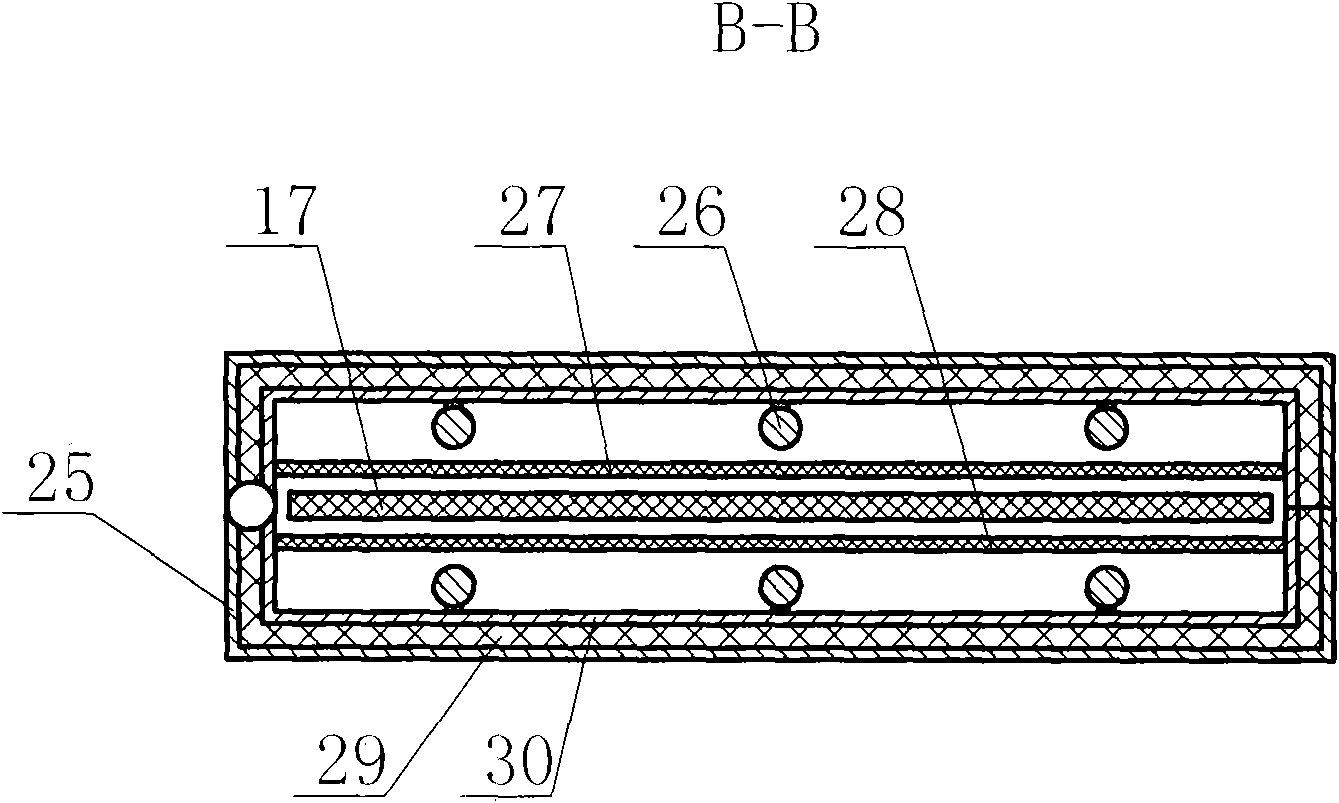

Superhigh molecular weight polyethylene monofilament and hot drawing processing method thereof

InactiveCN101962820AGuaranteed lubrication effectGuaranteed plasticityMonocomponent polyolefin artificial filamentStretch-spinning methodsAntioxidantPlasticizer

The invention discloses a superhigh molecular weight polyethylene monofilament and a hot drawing processing method thereof. Raw materials of the polyethylene monofilament comprise superhigh molecular weight polyethylene resin, polyethylene wax, a plasticizer and an antioxidant which are manufactured into a round-strip-shaped filament. The hot tensile processing method comprises the following steps of: taking the raw materials by weight ratios for later use; mixing the raw materials and putting the mixed raw materials into a single screw extruder for extruding a pipe; mounting a cutting cutter on the lower part of the single screw extruder to longitudinally split the pipe, and expanding the longitudinally split pipe into a plate type material; calendaring the plate type material to obtain a diaphragm type blank, wherein the diaphragm type blank is drawn when the diaphragm type blank passes through a first heating channel; leading the drawn diaphragm type blank into a heat channel for heating; leading the diaphragm type blank into a calendar to obtain a round-strip-shaped monofilament; leading the round-strip-shaped monofilament into a stretcher for stretching to obtain a semi-finished monofilament, and leading the semi-finished monofilament into the stretcher for stretching to obtain a finished monofilament; and finally, shaping and then rolling. The product processed by using the method has high production efficiency, wherein the diameter of the product is longer than 0.15 millimeter, the tensile strength can reach higher than 600MPa, the elastic modulus reaches higher than 200g / d, and the like.

Owner:SHANDONG DIHAO WEAR RESISTING PIPE

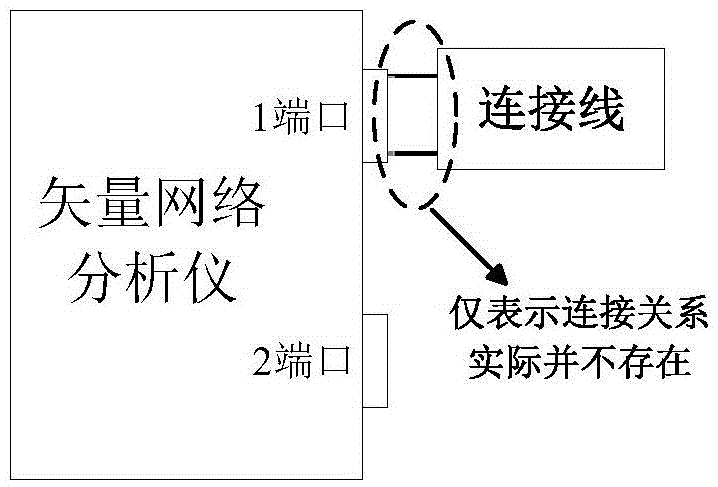

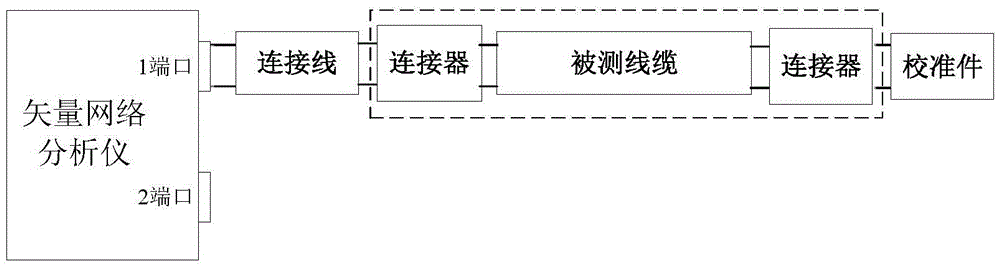

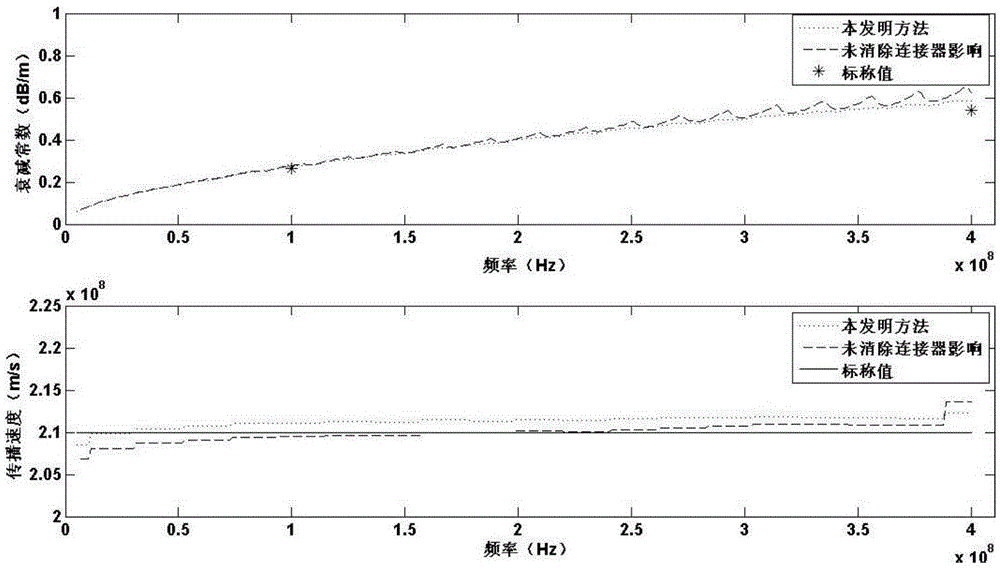

Method for in-situ test of broadband transmission line parameters of double-conductor type cable

ActiveCN105572480AEasy to testSimple test conditionsResistance/reactance/impedenceMeasuring interference from external sourcesElectromagnetic compatibilityBroadband transmission

The invention discloses a method for an in-situ test of broadband transmission line parameters of a double-conductor type cable, and belongs to the technical field of electromagnetic compatibility. The method includes: a connecting line is connected to a vector network analyzer for calibration, one end of a tested cable is connected with the connecting line, the other end of the tested cable is connected with a calibration member, and the test of a single-port scattering parameter is conducted; then a double-port scattering parameter of the tested cable without eliminating the influence of connectors is calculated; and finally, the double-port scattering parameter without the influence of the connectors is obtained via a parameter optimization process, and the transmission line parameters of the tested cable can be calculated. According to the method, extra engineering amount brought by dismounting and re-installation of the installed cable can be avoided, and the test process is convenient and fast; and the influence of the connectors is eliminated so that the transmission line parameters of the cable can be accurately obtained in the frequency range of hundreds of MHz.

Owner:BEIHANG UNIV

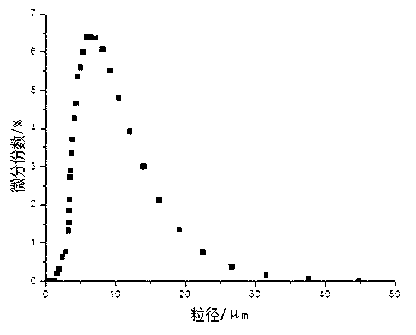

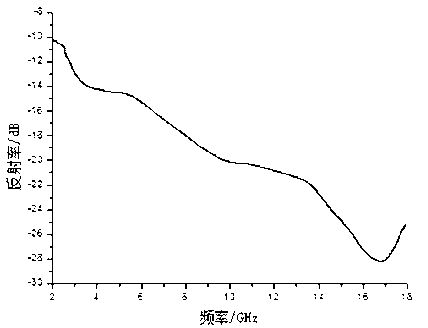

Indoor environment-friendly dry powder paint with microwave absorbing and flame-retardant functions, and preparation method and construction method thereof

InactiveCN103254696AHas harmControl damageFireproof paintsRadiation-absorbing paintsCelluloseMicrowave

The invention discloses an indoor environment-friendly dry powder paint with microwave absorbing and flame-retardant functions, and a preparation method and a construction method thereof. The indoor environment-friendly dry powder paint comprises the following components by weight percent: 20-50% of latex powder, 5-30% of titanium dioxide, 5-30% of calcium carbonate, 5-10% of silica, 5-10% of talcum powder, 10-40% of microwave-absorbing powder, 5-25% of halogen-free flame retardant, 5-15% of cellulose, 0.1-0.7% of solid defoaming agent, 2-8% of mildew preventive, 0.5-2% of assistant and 0.05-8% of paint. The obtained product has excellent microwave absorbing function and excellent flame-retardant effect; the flame-retardant effect can reach level V0; the dosage of the assistant is effectively reduced; and the VOC (volatile organic compound) emission of the dry powder paint is zero. Thus, the product is convenient to package, simple to transport, convenient to construct, free of special requirements, free of poison or pungent smell, and free of an injury to skin and a respiratory tract of a person, and can achieve ultra-thin construction; and the smallest coating thickness can be up to 20 microns.

Owner:熊丙志

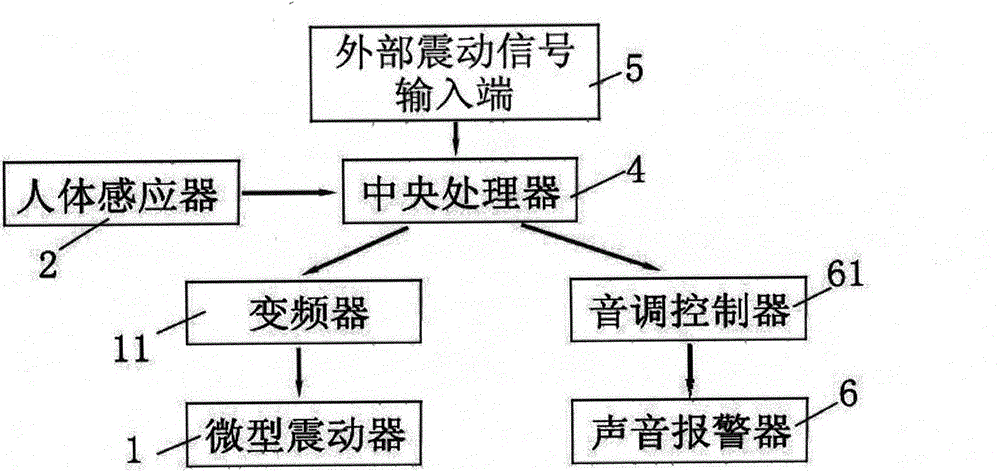

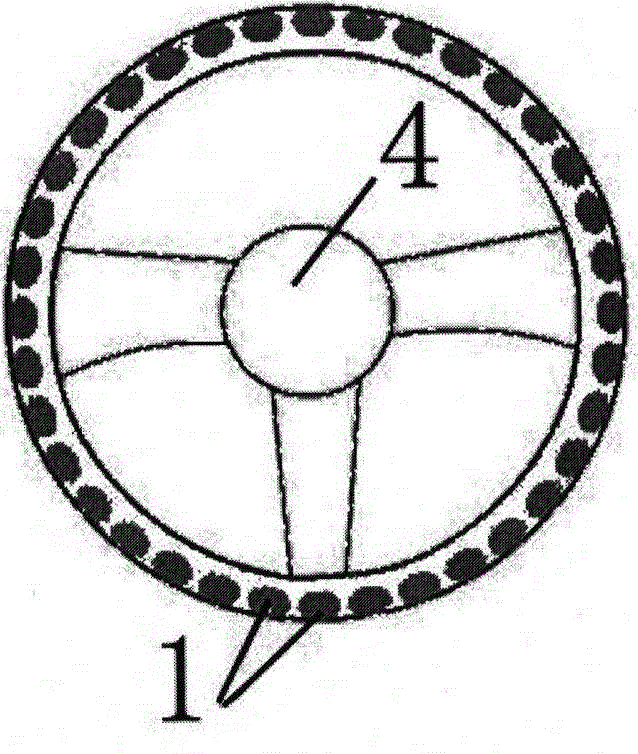

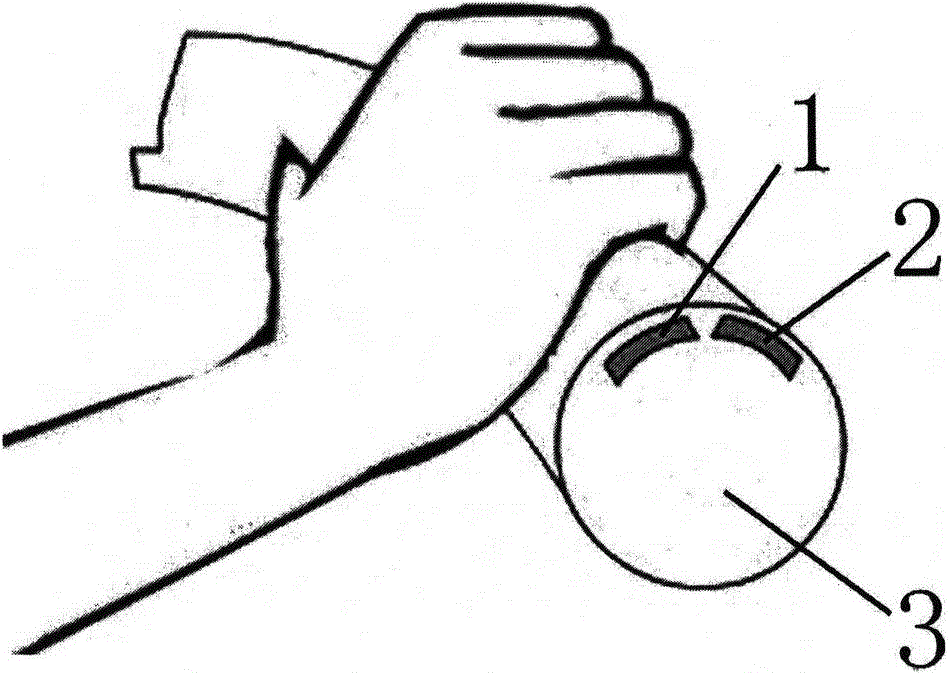

Intelligent vehicle prompt method and device

InactiveCN103600692APrompt function is timely and efficientSafety technology has no ill effectsAcoustic signal devicesSteering wheelEngineering

An embodiment of the invention relates to an intelligent vehicle prompt method and device. The method includes: setting a signal parameter for each of multiple external vibration signal input ends; allowing a body sensor to sense the locations of parts, held by a driver's hands, of a steering wheel, and transit the location information to a central controller; allowing the external vibration signal input ends to monitor states of a vehicle and transmit vibration signals to the central controller when monitoring the fact that the states of the vehicle meet the vibration signal parameter; allowing the central controller to control mini vibrators at the parts, held by the driver's hands, of the steering wheel to vibrate after receiving the vibration signals transmitted by the external vibration signal input ends. According to the method, the body sensor detects the parts, held by the driver's hands, of the steering wheel in real time; the central controller automatically triggers the mini vibrators under the hands; under control of the external vibration signals, the mini vibrators under the hands transmit various messages to the driver efficiently and timely by different-mode vibrations.

Owner:徐志兴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com