Method for purifying titanium white wastewater

A technology for titanium dioxide wastewater and wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of ensuring the effective removal of ferrous (iron) ions and other metal ions and It meets the requirements of relevant standards, does not realize the reuse of titanium dioxide wastewater, and the difficulty of controlling wastewater, and achieves good technical and economic feasibility, better calcium removal effect, and lower cost of calcium removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

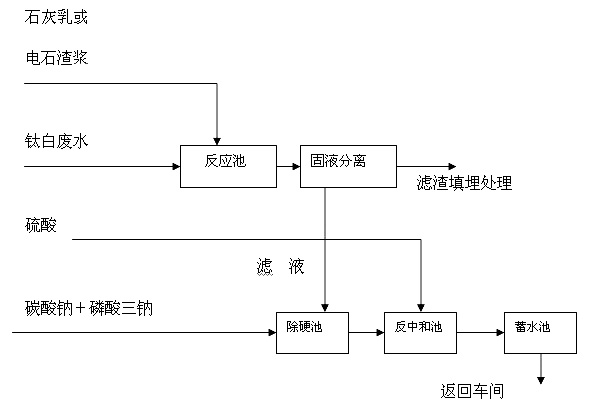

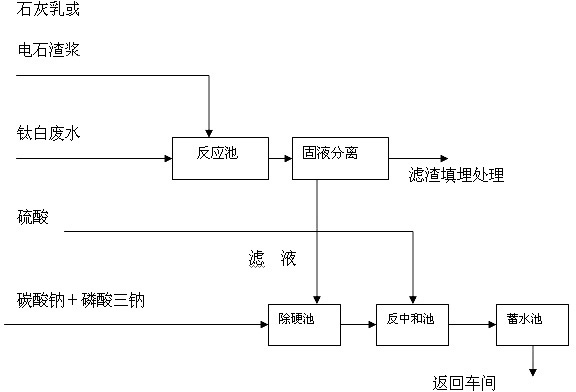

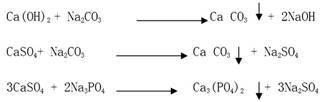

[0030] A treatment process for titanium dioxide wastewater up to standard reuse, the process flow chart is as follows figure 1 As shown, the composition (mg / l) of titanium dioxide wastewater is: Cu0.8, Mn1.1, Zn5.5, Cr0.02, S0.07, Fe3000, H 2 SO 4 20000, pH0.9, design flow rate of titanium dioxide wastewater is 400m 3 / h, the maximum flow rate is 600 m 3 / h, continuous flow into the reaction tank, adding excessive carbide slag with a solid content of 5% into the reaction tank, using mechanical stirring, the sulfuric acid entrained in the titanium dioxide wastewater is neutralized, ferrous ions and other metal ions and calcium carbide slag The reaction has generated a precipitate; the pH value after the reaction is 9; the analysis after solid-liquid separation shows that the calcium ion in the filtrate is 695 mg / l; add 1.6Kg / m in the hard pool first 3 sodium carbonate (sodium carbonate: total calcium in wastewater = 0.9:1 molar ratio), react for 30 minutes and then add 0.19...

Embodiment 2

[0032] A treatment process for titanium dioxide wastewater up to standard reuse, the process flow chart is as follows figure 1 As shown, the composition (mg / l) of titanium dioxide wastewater is:

[0033] Cu0.6, Mn0.9, Zn9.5, Cr0.05, S0.06, Fe4000, H 2 SO 4 30000, pH0.9. The design flow rate of titanium dioxide wastewater is 400m 3 / h, the maximum flow rate is 600 m 3 / h, continuously flowing into the reaction tank, adding an excess of milk of lime with a solid content of 6% in the reaction tank, so that the pH value after the reaction is 12; after solid-liquid separation, analysis shows that the calcium ion in the filtrate is 690 mg / l ; Add 1.74Kg / m to the hard pool first 3 Sodium carbonate (sodium carbonate: total calcium in wastewater = 0.95:1 molar ratio), react for 40 minutes and then add 0.15Kg / m 3 trisodium phosphate (trisodium phosphate: total calcium in waste water = 0.033:1 molar ratio); use 3.0Kg / h of concentrated sulfuric acid to neutralize, the final pH val...

Embodiment 3

[0035] A treatment process for titanium dioxide wastewater up to standard reuse, the process flow chart is as follows figure 1 As shown, the composition (mg / l) of titanium dioxide wastewater is: Cu0.5, Mn1.3, Zn3.5, Cr0.03, S0.05, Fe2000, H 2 SO 4 19000, pH1.0. The design flow rate of titanium dioxide wastewater is 400m 3 / h, the maximum flow rate is 600 m 3 / h, continuously flowing into the reaction tank, adding excessive calcium carbide slag with a solid content of 5% in the reaction tank, so that the pH value after the reaction is 10.5; after solid-liquid separation, analysis shows that the calcium ion in the filtrate is 700 mg / l ; Add 1.8Kg / m to the hard pool first 3Sodium carbonate (sodium carbonate: total calcium in wastewater = 0.93:1 molar ratio), react for 50 minutes and then add 0.13Kg / m 3 trisodium phosphate (trisodium phosphate: total calcium in waste water = 0.046:1 molar ratio); use 2Kg / h of concentrated sulfuric acid to neutralize, the final pH value of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com