Reduction method for graphene oxide

A technology of graphene and stone oxide, which is applied in the field of preparing stable graphene aqueous solution, can solve problems such as environmental pollution, and achieve the effects of simple and easy preparation method, easy control of reaction process, and easy popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Natural graphite was oxidized by Hummers' method (1. Kovtyukhova, N. I.; Ollivier, P. J.; Martin, B. R.; Mallouk, T. E.; Chizhik, S. A.; Buzaneva, E. V.; Gorchinskiy, A. D. Layer-by-layer assembly of ultrathin composite films from micron-sized graphite oxide sheets and polycations. Chem. Mater. 1999, 11, 771–778. 2. Hummers, W. S.; Offeman, R. E. Preparation of graphite oxide. J. Am. Chem. Soc. 1958, 80, 1339.), the obtained graphite oxide was prepared by ultrasonic dispersion method to prepare graphene oxide aqueous solution, the obtained solution was yellow or tan, and the unexfoliated graphite oxide was removed by centrifugation, and the concentration of graphene oxide was 0.05 wt%.

[0022] 2) Take 50ml of 0.05 wt% graphene oxide solution, adjust the pH to about 10 with ammonia water, then add 125 μL of 14 wt% acetone oxime aqueous solution, and reflux at 100 °C for 3 hours to obtain a black graphene aqueous solution.

Embodiment 2

[0024] Similar to the synthesis method of Example 1, the difference is that the same amount of hydrazine hydrate is used instead of acetone oxime, and the graphene aqueous solution is prepared by reduction.

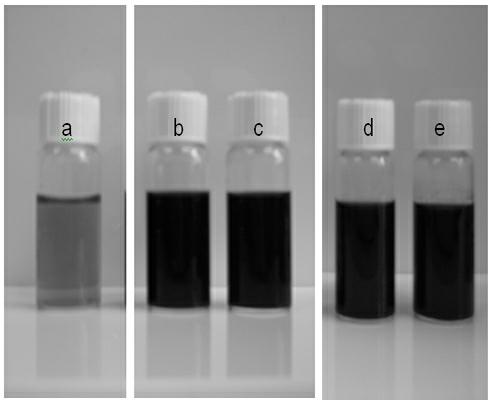

[0025] like figure 1 Shown, (a) is brownish yellow graphene oxide solution. (b) and (c) are graphene solutions obtained by chemically reducing graphene oxide using acetone oxime and hydrazine hydrate as reducing agents, respectively, and its color changes from the original brownish yellow to the current black. (d) and (e) are graphene solutions that have been placed for 2 months, and they still show good dispersion without significant sedimentation.

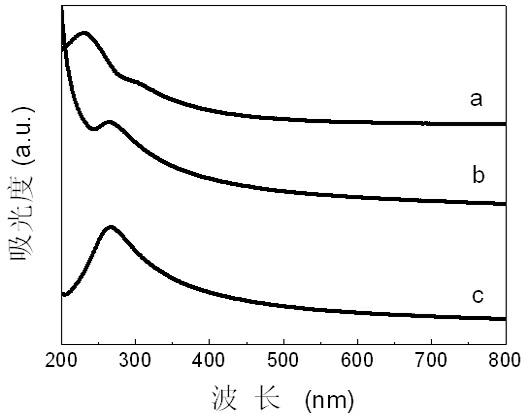

[0026] like figure 2 As shown, (a) is the UV-vis spectrum of graphene oxide, which shows the π→π of C-C bond at 231 nm * the absorption peak. (b) and (c) are the UV-vis spectra of the graphene solution obtained by reduction with acetone oxime (b) and hydrazine hydrate (c), respectively. It can be seen that when graphen...

Embodiment 3

[0035] Similar to Example 1, the difference is that graphene oxide was purchased from Nanjing Xianfeng Nano Material Technology Co., Ltd., and a black graphene aqueous solution was prepared according to the same reduction method. The characterization results were similar to those synthesized in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com