Single crystal ternary positive electrode material with good dispersibility, lithium-nickel mixed arrangement and low residual alkali, and preparation method and application thereof

A positive electrode material and single crystal technology, applied in the field of single crystal ternary positive electrode materials, can solve the problems of cycle performance degradation, serious agglomeration and decline of single crystal materials, and achieve the effect of reducing lithium-nickel mixing and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

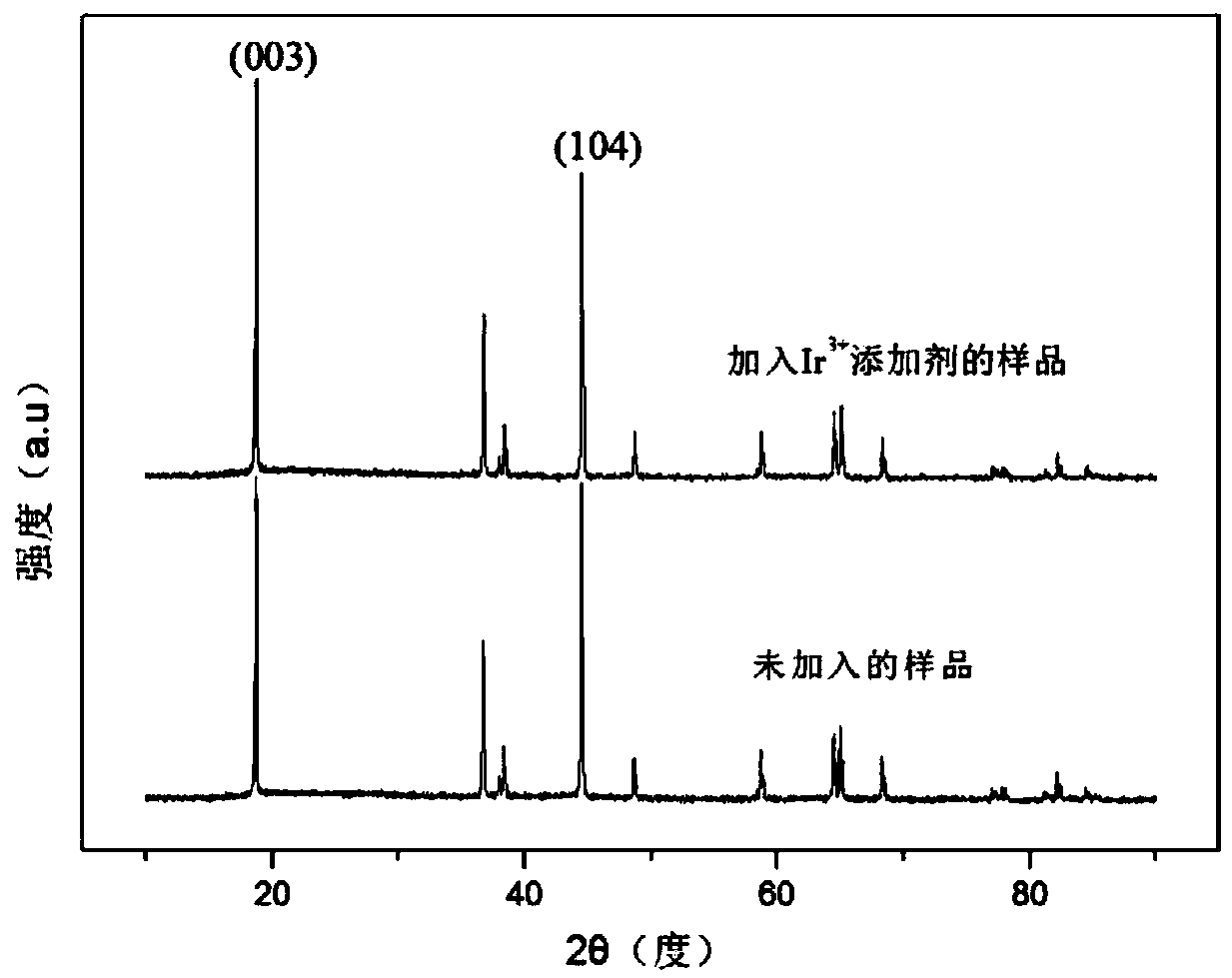

[0068] This embodiment uses Ir 2 o 3 Auxiliary synthesis of Li 1.04 Ni 0.5 co 0.2 mn 0.27 Zn 0.01 Ba 0.02 o 2 The single crystal material specifically includes the following steps:

[0069] (1) According to the stoichiometric ratio Li 1.04 Ni 0.5 co 0.2 mn 0.27 Zn 0.01 Ba 0.02 o 2 , weighed 38.42g lithium carbonate, 89.92gNi 0.5 co 0.2 mn 0.27 (OH) 2Precursor, 0.814g ZnO, 3.067g BaO and 0.06g Ir 2 o 3 Additives (Ir 3+ with you 0.5 co 0.2 mn 0.27 (OH) 2 The molar ratio is 0.000275:1), put it in a three-dimensional mixer, add polyurethane balls, and mix well.

[0070] (2) Put the uniformly mixed material in a sagger for heat treatment, and calcinate it in an oxygen atmosphere. At a rate of 4°C / min, first raise the temperature to 450°C and keep it for 3 hours, then raise the temperature to 900°C and keep it for 15 hours, and then heat it at 5°C / min to cool down to room temperature.

Embodiment 2

[0072] In this example, iridium nitrate and tellurium oxide are used to assist in the synthesis of Li 1.025 Ni 0.6 co 0.2 mn 0.15 B 0.04 V 0.01 o 2 The single crystal material specifically includes the following steps:

[0073] (1) According to the stoichiometric ratio Li 1.025 Ni 0.6 co 0.2 mn 0.15 B 0.04 V 0.01 o 2 , weighed 18.93g lithium carbonate and 21.5g lithium hydroxide, 89.24g Ni 0.6 co 0.2 mn 0.15 (OH) 2 Precursor, 2.785g B 2 o 3 , 1.82g V 2 o 5 , 0.2458g of iridium nitrate and 0.0319g tellurium oxide additive (Ir 3+ and Y 3+ with you 0.6 co 0.2 mn 0.15 (OH) 2 The molar ratios are 0.00065:1 and 0.0002:1 respectively), placed in a three-dimensional mixer, adding polyurethane balls, and mixing evenly.

[0074] (2) Put the uniformly mixed materials in a sagger for heat treatment, and calcined in an oxygen atmosphere. First, the temperature was raised to 500° C. for 2 hours at a rate of 3° C. / min, and then the temperature was raised to 880° C. ...

Embodiment 3

[0076] In this embodiment, iridium oxalate is used to assist in the synthesis of Li 1.0 Ni 0.55 co 0.25 mn 0.17 Ti 0.02 Bi 0.01 o 2 The single crystal material specifically includes the following steps:

[0077] (1) According to the stoichiometric ratio Li 1.0 Ni 0.55 co 0.25 mn 0.17 Ti 0.02 Bi 0.01 o 2 , weighed 36.95g lithium carbonate, 87.42g Ni 0.5 co 0.25 mn 0.17 (OH) 2 Precursor, 1.6g TiO 2 , 4.66g Bi 2 o 3 And 0.0648g iridium oxalate additive (Ir 3+ with you 0.5 co 0.25 mn 0.17 (OH) 2 The molar ratio is 0.0001:1), put it in a three-dimensional mixer, add polyurethane balls, and mix well.

[0078] (2) Put the uniformly mixed materials in a sagger for heat treatment, and calcined in an oxygen atmosphere. First, the temperature was raised to 450° C. for 2.5 hours at a rate of 3° C. / min, and then heated to 890° C. for 13 hours, and then heated for 8 hours. Cool to room temperature at a rate of °C / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com