Cerium-zirconium co-doped porous structure positive electrode material and preparation method thereof

A positive electrode material and porous structure technology, which is applied in the field of cerium-zirconium co-doped porous structure positive electrode materials and its preparation, can solve the problems of low sintering temperature of high-nickel materials, increase of production process and auxiliary materials, and increase of product manufacturing cost, etc. The effect of small particles, improved capacity and cycle performance, and accelerated growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing a cerium-zirconium co-doped porous structure positive electrode material, comprising the following steps:

[0041] (1) Prepare ternary solution, cerium-zirconium blended salt solution, precipitant solution and complexing agent solution for use;

[0042] (2) Prepare bottom liquid and stir;

[0043] (3) Inject the ternary solution, the mixed solution of cerium salt and zirconium salt, the precipitant solution and the complexing agent solution into the bottom solution, and carry out the reaction of stage I and stage II until the reaction reaches the target particle size, then stop feeding ;

[0044] (4) Centrifugal washing, drying, sieving, and iron removal of the reacted slurry to obtain a precursor;

[0045] (5) Mix the precursor with the lithium source and sinter to obtain the positive electrode material; preferably, mix the cerium-zirconium co-doped ternary precursor with the lithium source, and sinter at 700-1000°C for 10-20h in air or oxygen ...

Embodiment 1

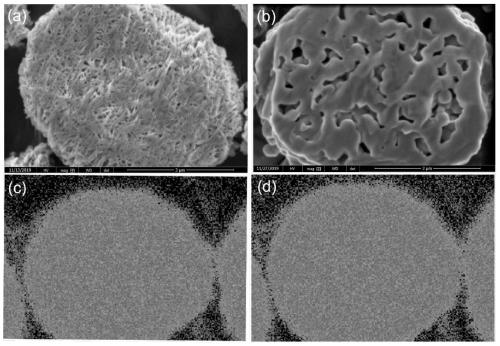

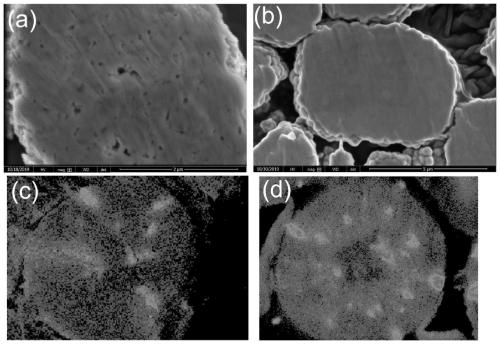

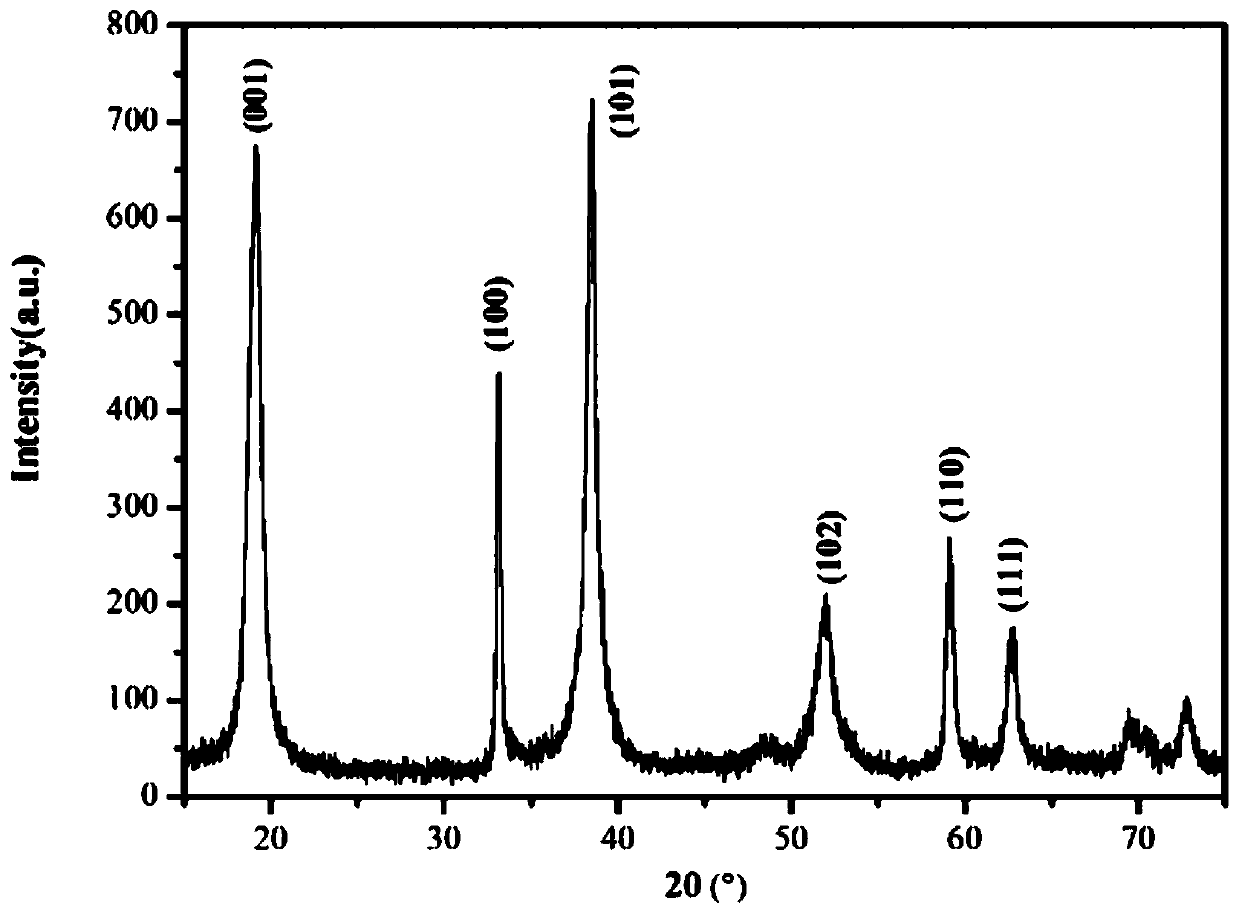

[0056] Preparation of Ce-Zr Co-doped NCM811 Porous Cathode Material

[0057] Methods as below:

[0058] Step 1. Nickel sulfate, cobalt sulfate and manganese sulfate are formulated into aqueous solution A with a total metal concentration of 2mol / L in a metal molar ratio of 8:1:1, and cerium sulfate and zirconium sulfate are formulated into a total metal concentration in a metal molar ratio of 1:2. The aqueous solution B with a concentration of 0.05mol / L adopts 32% industrial liquid caustic soda as precipitating agent C, and 17% ammonia water as complexing agent D.

[0059] Step 2, add 5000L pure water to the reactor and feed N 2 As a protective gas, use solution D to adjust the ammonia concentration of the bottom liquid to 10 g / L, and use solution C to adjust the pH of the bottom liquid to 11.9-12.0. The temperature was set at 60° C., and the stirring speed was set at 400 rpm.

[0060] Step 3. Add solution A, solution B, solution C and solution D to the reactor at the same t...

Embodiment 2

[0066] Preparation of Ce-Zr Co-doped NCM880606 Porous Cathode Material

[0067] Methods as below:

[0068] Step 1. Nickel sulfate, cobalt sulfate and manganese sulfate are prepared into aqueous solution A with a total metal concentration of 2mol / L by metal molar ratio 88:6:6, and cerium sulfate and zirconium sulfate are prepared by metal molar ratio 1:1 to make total metal The aqueous solution B with a concentration of 0.02mol / L adopts 32% industrial liquid caustic soda as the precipitating agent C, and 17% ammonia water as the complexing agent D.

[0069] Step 2, add 5000L pure water to the reactor and feed N 2 As a protective gas, use solution D to adjust the ammonia concentration of the bottom liquid to 7.5g / L, and use solution C to adjust the pH of the bottom liquid to 11.8-11.9. The temperature was set at 65° C., and the stirring speed was set at 380 rpm.

[0070] Step 3. Add solution A, solution B, solution C and solution D to the reactor at the same time at the speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com