Preparing method for spherical LiMn1-x-yNixCoyO2 anode material

A technology of nickel cobalt lithium manganate and positive electrode material, which is applied to battery electrodes, structural parts, electrical components, etc., can solve the problems of difficulty in obtaining impurity-free materials, reduction in comprehensive electrical properties, and difficulty in drying and dewatering. The effect of improving electrochemical cycle performance, improving quality, and reducing production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

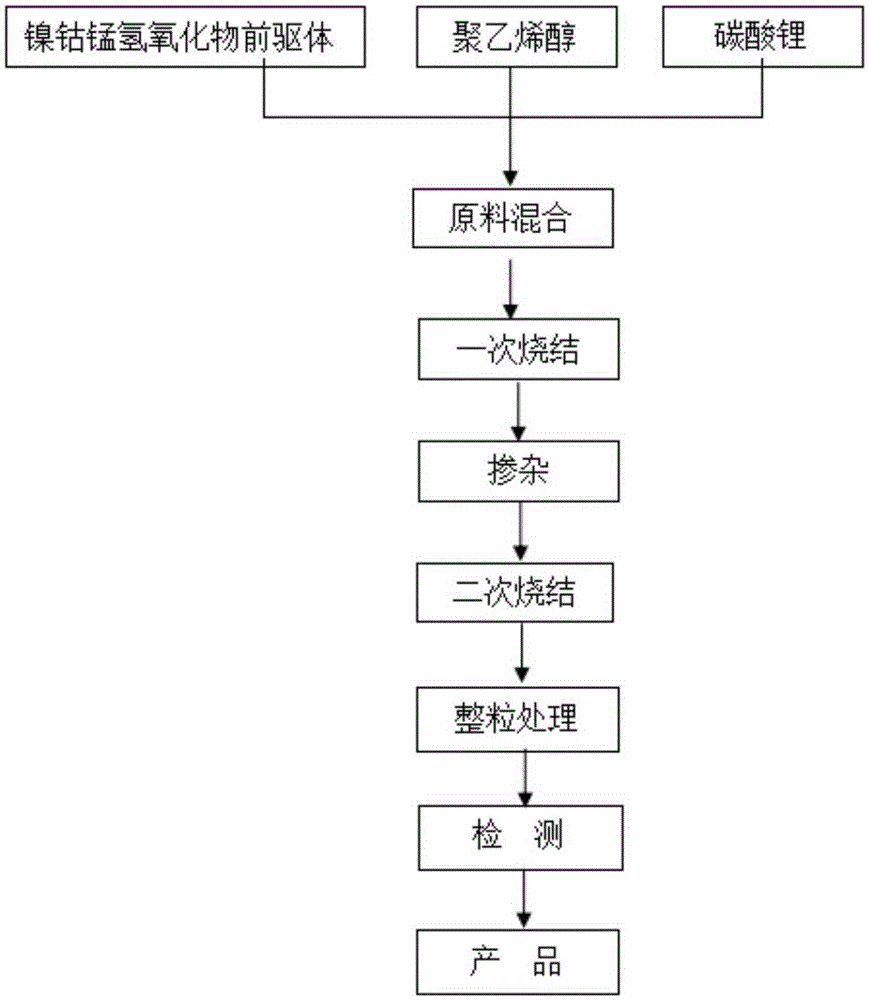

[0028] A preparation method of a spherical nickel-cobalt lithium manganese oxide positive electrode material, comprising the following steps:

[0029] (1) Mixing of raw materials: Using a three-dimensional high-efficiency oblique mixer and polyurethane balls as the mixing medium, weigh lithium carbonate, nano-spherical nickel-cobalt-manganese hydroxide precursor and the mass ratio of the total mixture according to the molar ratio of 1:0.53 Disperse, mix and pulverize 10% polyvinyl alcohol to form a uniform intermediate mixture, in which the proportion of polyurethane balls is 1.3, the ratio of balls to materials is 3:4:3, and the mixing time is 3 hours;

[0030] (2) Primary sintering: put the intermediate mixture obtained in step (1) into a sagger, send it into a pusher kiln for sintering, and produce nickel-cobalt-lithium manganese oxide material. The sintering process is filled with oxygen continuously, and the sintering temperature is 650 ℃, the sintering time is 3h;

[00...

Embodiment 2

[0035] (1) Mixing of raw materials: Using a three-dimensional high-efficiency inclined mixer and polyurethane balls as the mixing medium, weigh lithium carbonate, nano-spherical nickel-cobalt-manganese hydroxide precursors and the mass ratio of the total mixture according to the molar ratio of 1:0.535 Disperse, mix and pulverize 20% polyvinyl alcohol to form a uniform intermediate mixture, wherein the specific gravity of polyurethane balls is 1.5, the ball-to-material ratio is 3:4:3, and the mixing time is 3 hours;

[0036] (2) Primary sintering: put the intermediate mixture obtained in step (1) into a sagger, send it into a pusher kiln for sintering, and produce nickel-cobalt-lithium manganese oxide material. The sintering process is filled with oxygen continuously, and the sintering temperature is 700 ℃, the sintering time is 3h;

[0037] (3) Doping: choose nano Al 2 o 3 The nickel-cobalt lithium manganese oxide obtained in step (2) is doped, and is added to the nickel-cob...

Embodiment 3

[0041] (1) Mixing of raw materials: Using a three-dimensional high-efficiency oblique mixer and polyurethane balls as the mixing medium, weigh lithium carbonate, nano-spherical nickel-cobalt-manganese hydroxide precursors and 30% additives for dispersion at a molar ratio of 1:0.55 , mixing and crushing to form a uniform intermediate mixture, wherein the proportion of polyurethane balls is 1.4, the ball-to-material ratio is 3:4:3, and the mixing time is 4h;

[0042](2) Primary sintering: put the intermediate mixture obtained in step (1) into a sagger, and send it into a pusher kiln for sintering to produce nickel-cobalt-lithium manganate material. The sintering process is filled with oxygen continuously, and the sintering temperature is 750 ℃, the sintering time is 5h;

[0043] (3) Doping: choose nano TiO 2 The nickel-cobalt lithium manganese oxide obtained in step (2) is doped, and is added to the nickel-cobalt lithium manganese oxide obtained in step (2) at 0.2% of the total...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com