Patents

Literature

758 results about "Aerosol Mist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic atomization cigarette

ActiveUS20110168194A1Reduce cancer riskRespiratorsNervous disorderVapor–liquid separatorAerosol spray

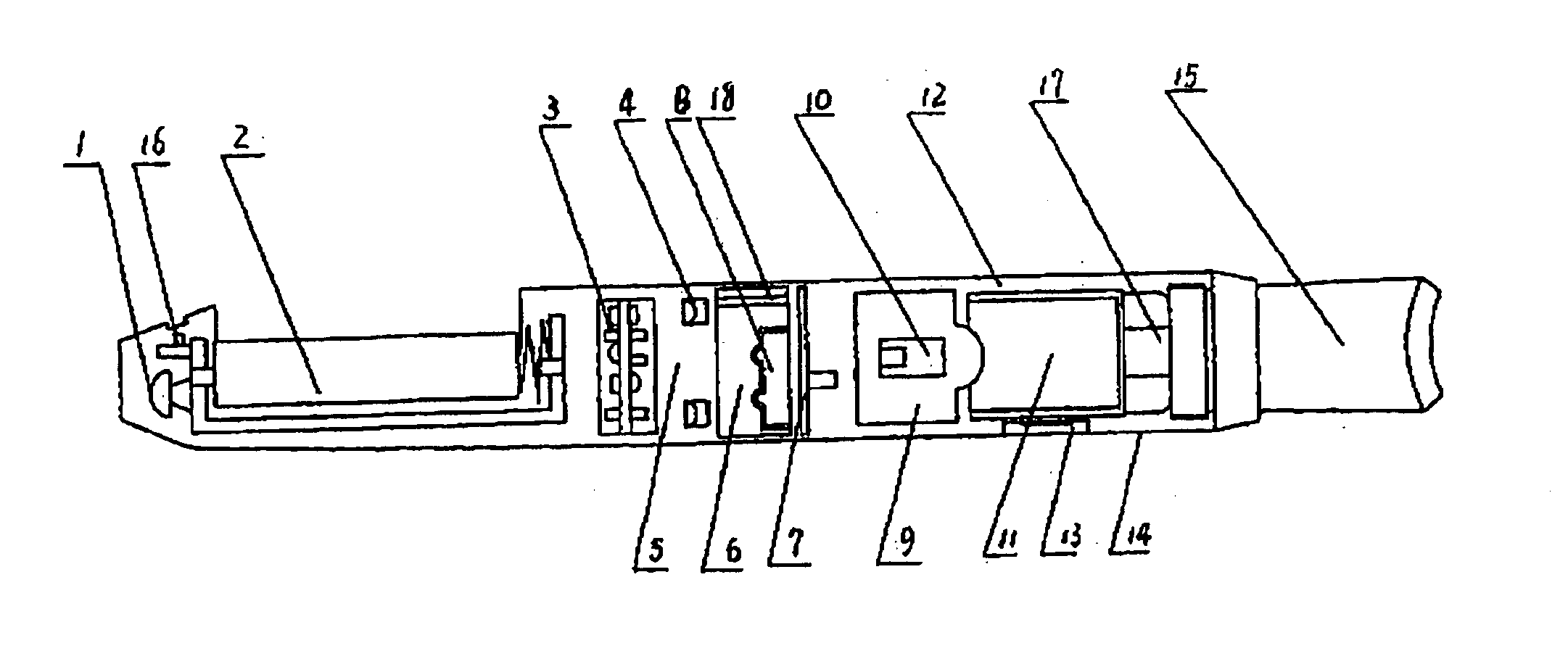

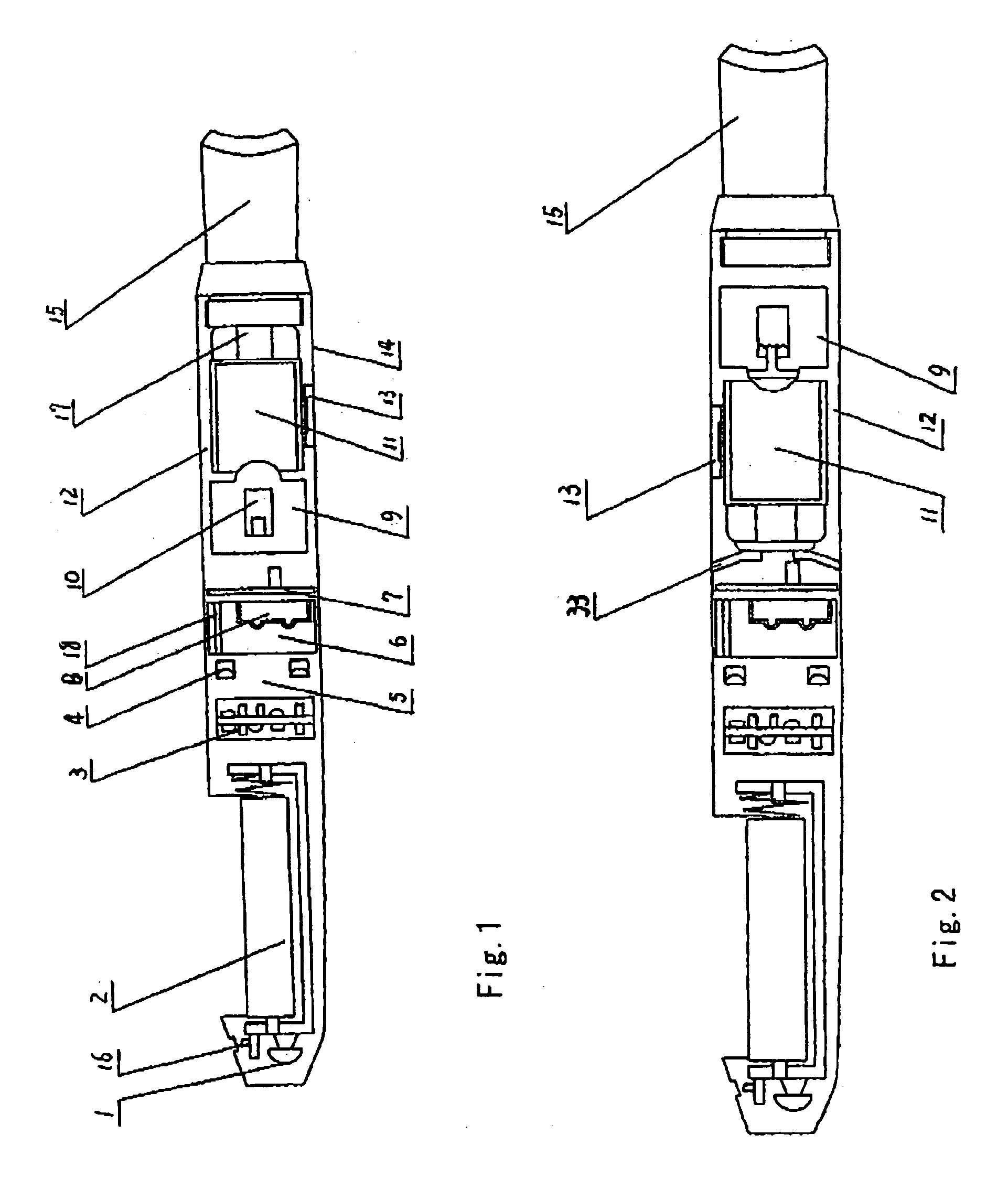

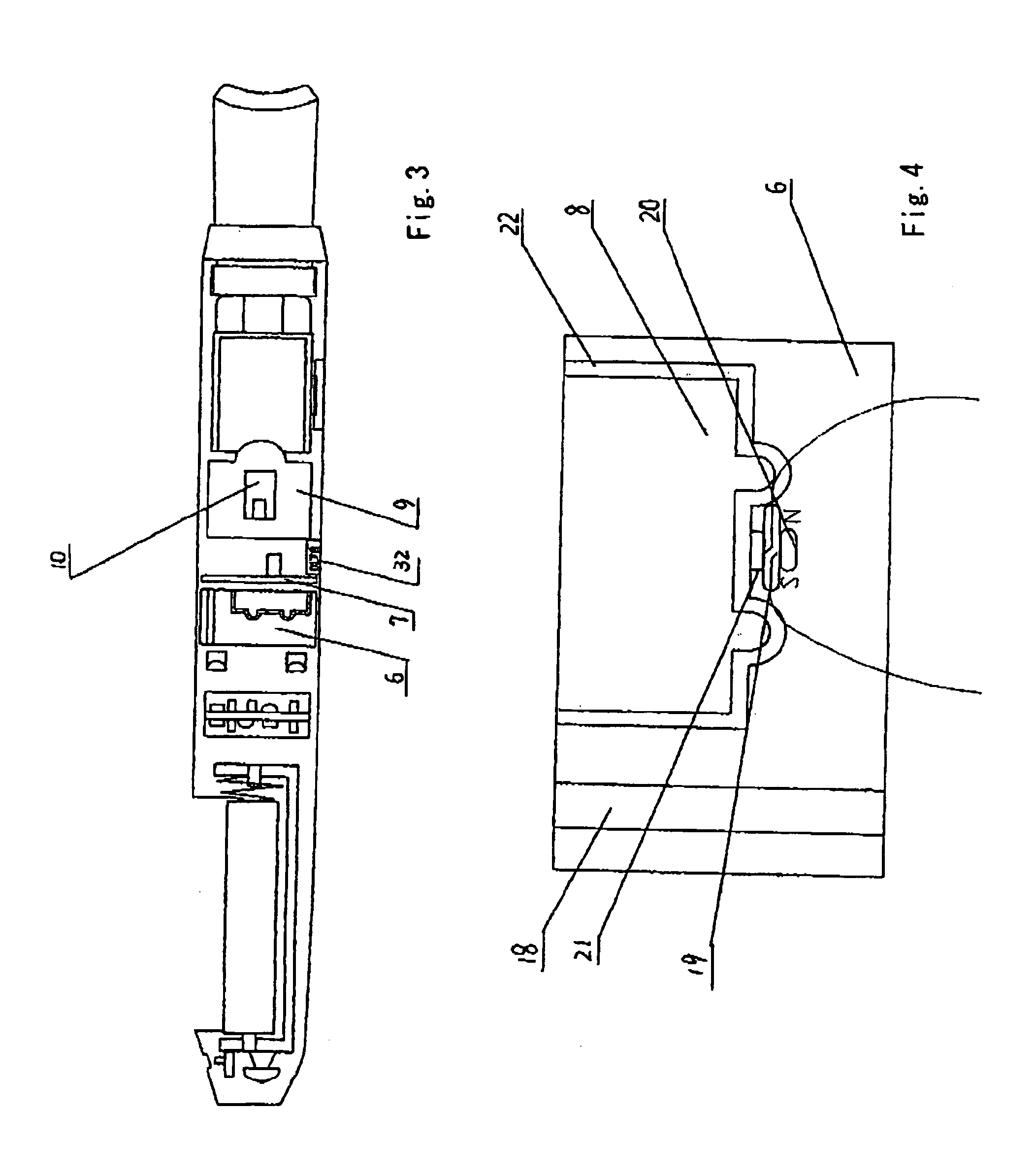

The present invention relates to an electronic atomization cigarette which only contains nicotine without harmful tar. The electronic atomization cigarette includes a shell and a mouthpiece. The external wall of the shell has an air inlet. An electronic circuit board, a normal pressure cavity, a sensor, a vapor-liquid separator, an atomizer, a liquid-supplying bottle are sequentially provided within the shell, wherein the electronic circuit board comprises an electronic switching circuit and a high frequency generator. A stream passage of the sensor is provided on one side of the sensor, and a negative pressure cavity is provided in the sensor. The atomizer and the liquid-supplying bottle is in contact with each other. An atomization cavity is arranged in the atomizer. A retaining ring for locking the liquid-supplying bottle is provided between one side of the liquid-supplying bottle and the shell, and an aerosol passage is provided on the other side of the liquid-supplying bottle. The air inlet, normal pressure cavity, vapor-liquid separator, atomizer, aerosol passage, gas vent and mouthpiece are sequentially interconnected. The advantages of the present invention include smoking without tar, significantly reducing the cancerogenic risk. Furthermore, users still feel as if they are smoking and experiencing the same excitement, and the cigarette is no need to be lit and is no fire risk.

Owner:FONTEM VENTURES

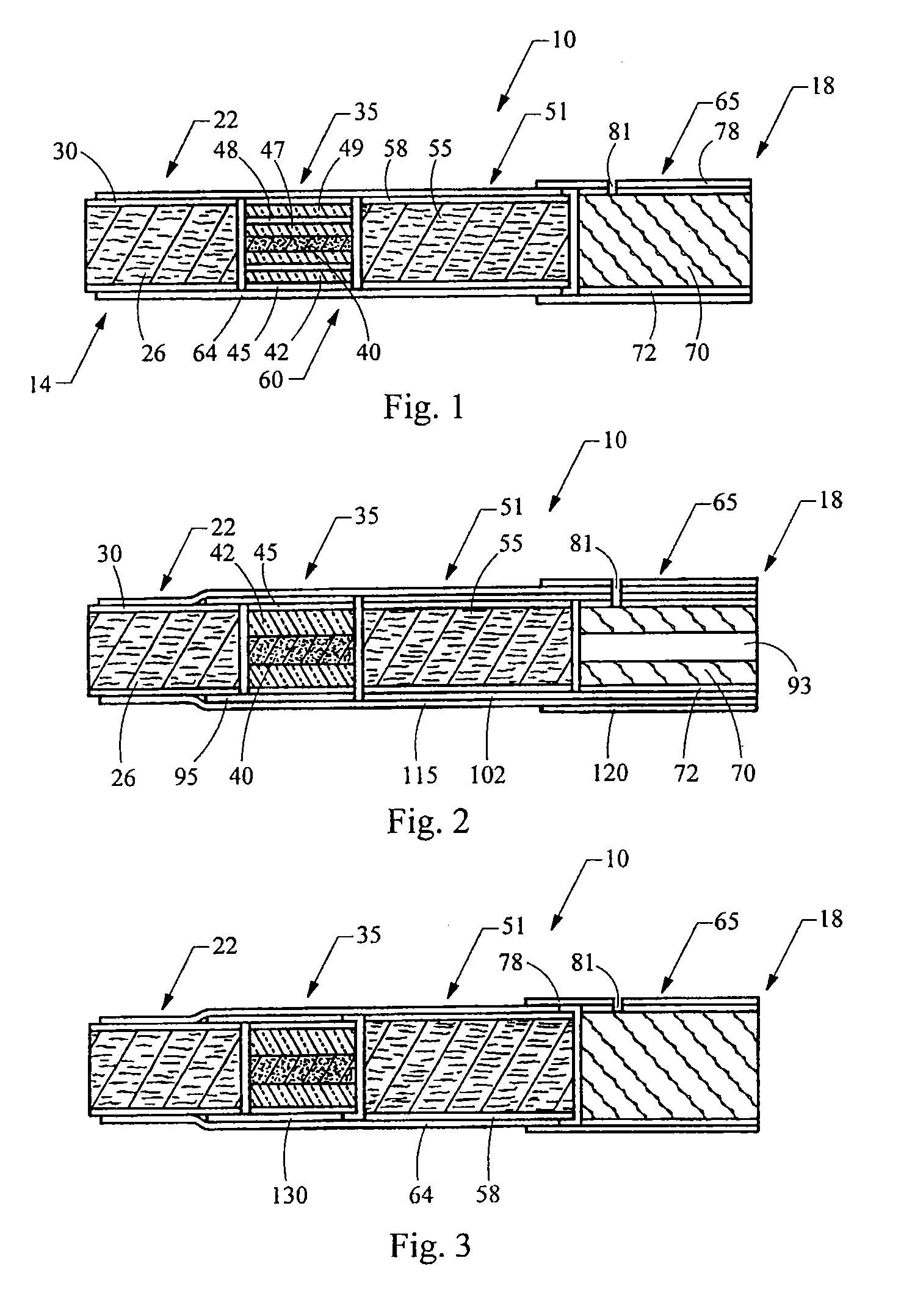

Smoking Article

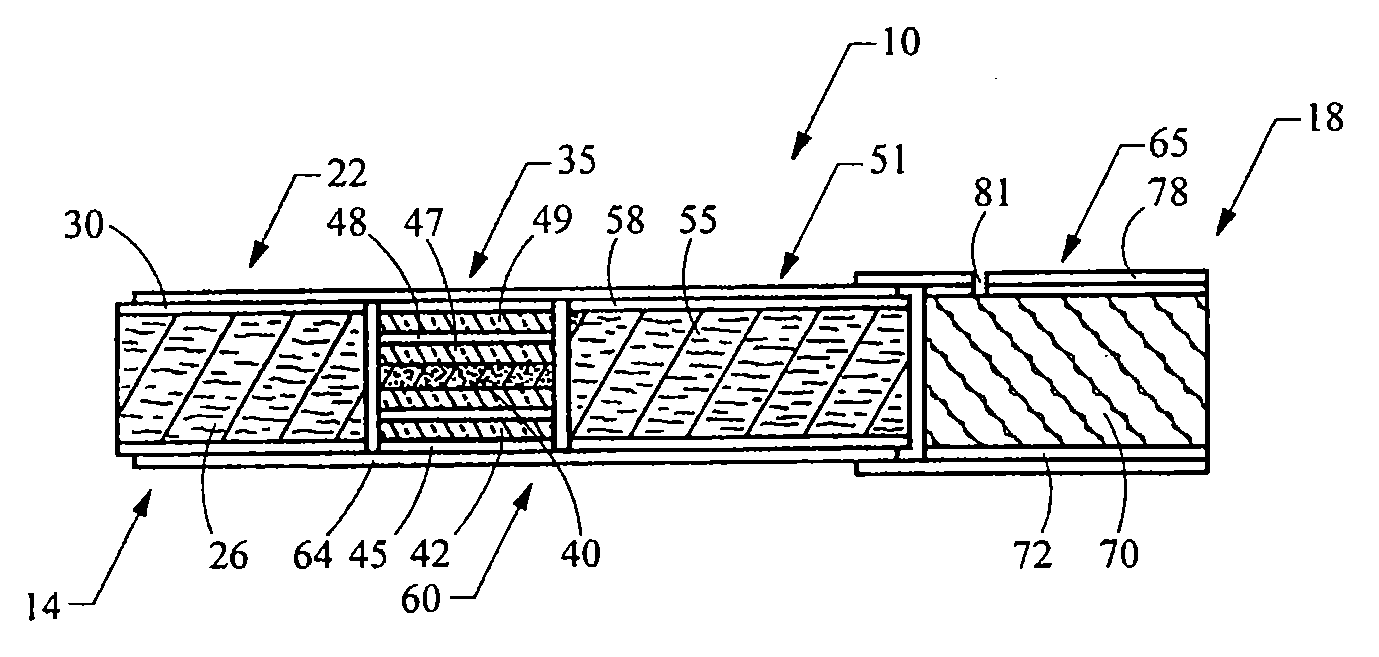

A smoking article, such as a cigarette, comprises a lighting end and a mouth end. The smoking article possesses an aerosol-generation system that includes (i) a heat generation segment, and (ii) an aerosol-generating region or segment. A mouth end piece segment can be located at the mouth end of the smoking article. A segment of tobacco cut filler, gathered tobacco paper, or other type of flavor source material, can be positioned between the mouth end piece segment and the aerosol-generation segment. Optionally, segment composed of tobacco cut filler can be positioned so as to provide a lighting end segment. The smoking article possesses an overwrap (e.g., a single paper overwrap) that extends over the longitudinally extending surface of the mouth end piece segment, the aerosol generation segment, at least a portion of the length of the heat generation segment, any segment located between the mouth end piece and aerosol generation segments, and at least a portion of the length of the optional lighting end segment. Alternatively, the smoking article possesses an overwrap (e.g., a single paper overwrap) that extends over the longitudinally extending surface of the aerosol-generating segment, at least a portion of the length of the heat generation segment, at least a portion of any segment located downstream from the aerosol-generating segment, and at least a portion of the length of the optional lighting end segment, thereby forming a cigarette rod; and the cigarette rod is connected or attached to a filter element using a tipping type of material and arrangement.

Owner:R J REYNOLDS TOBACCO COMPANY

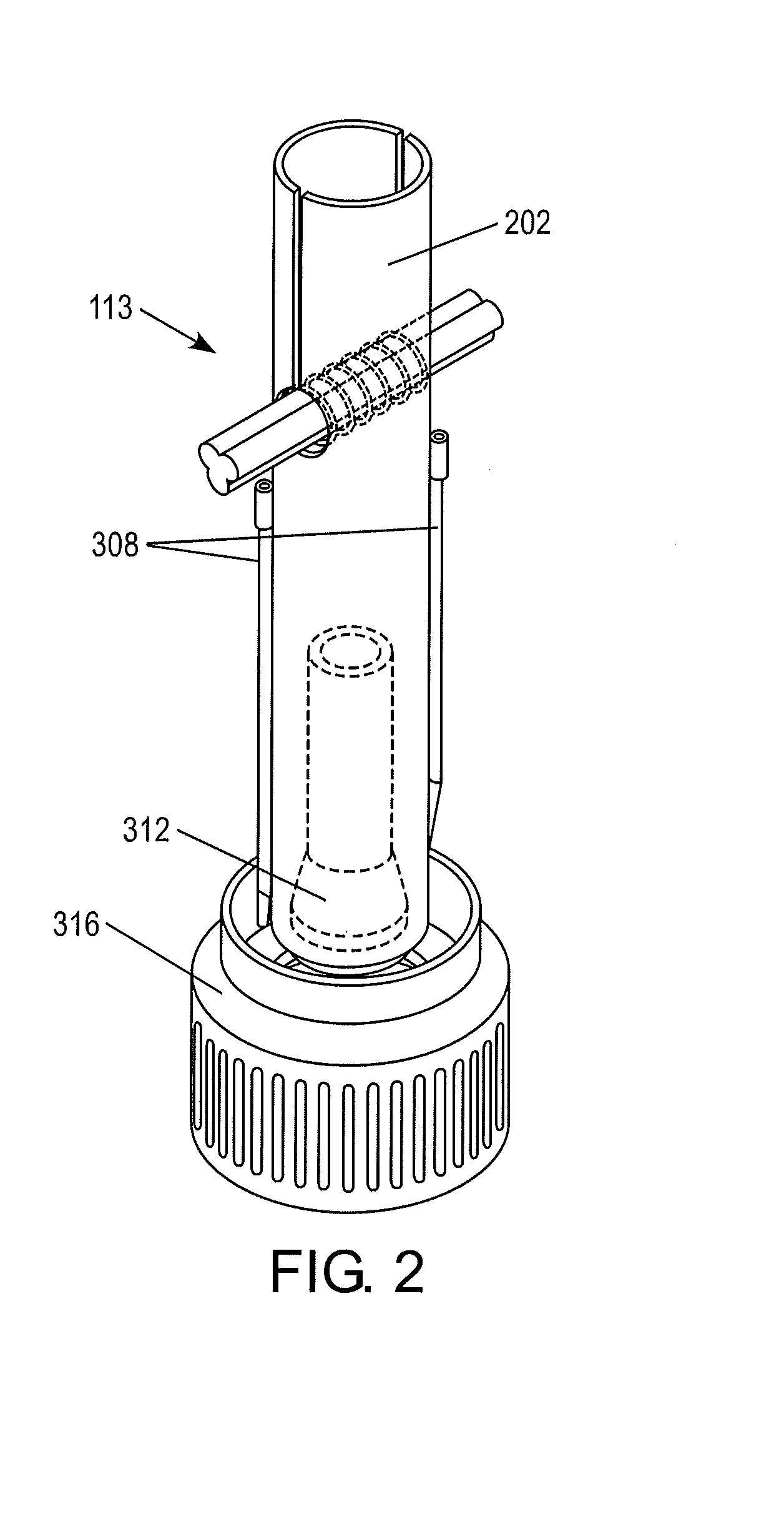

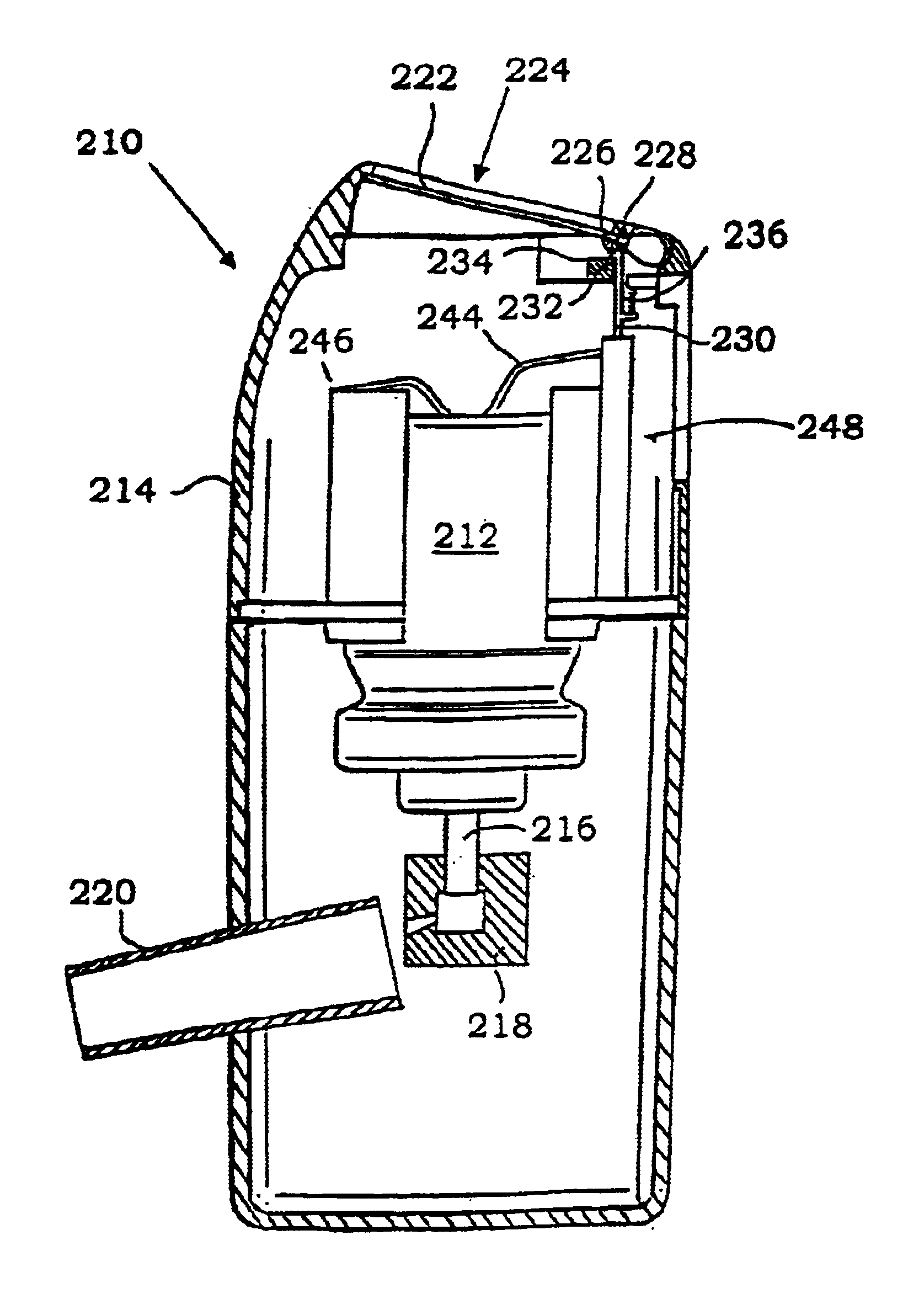

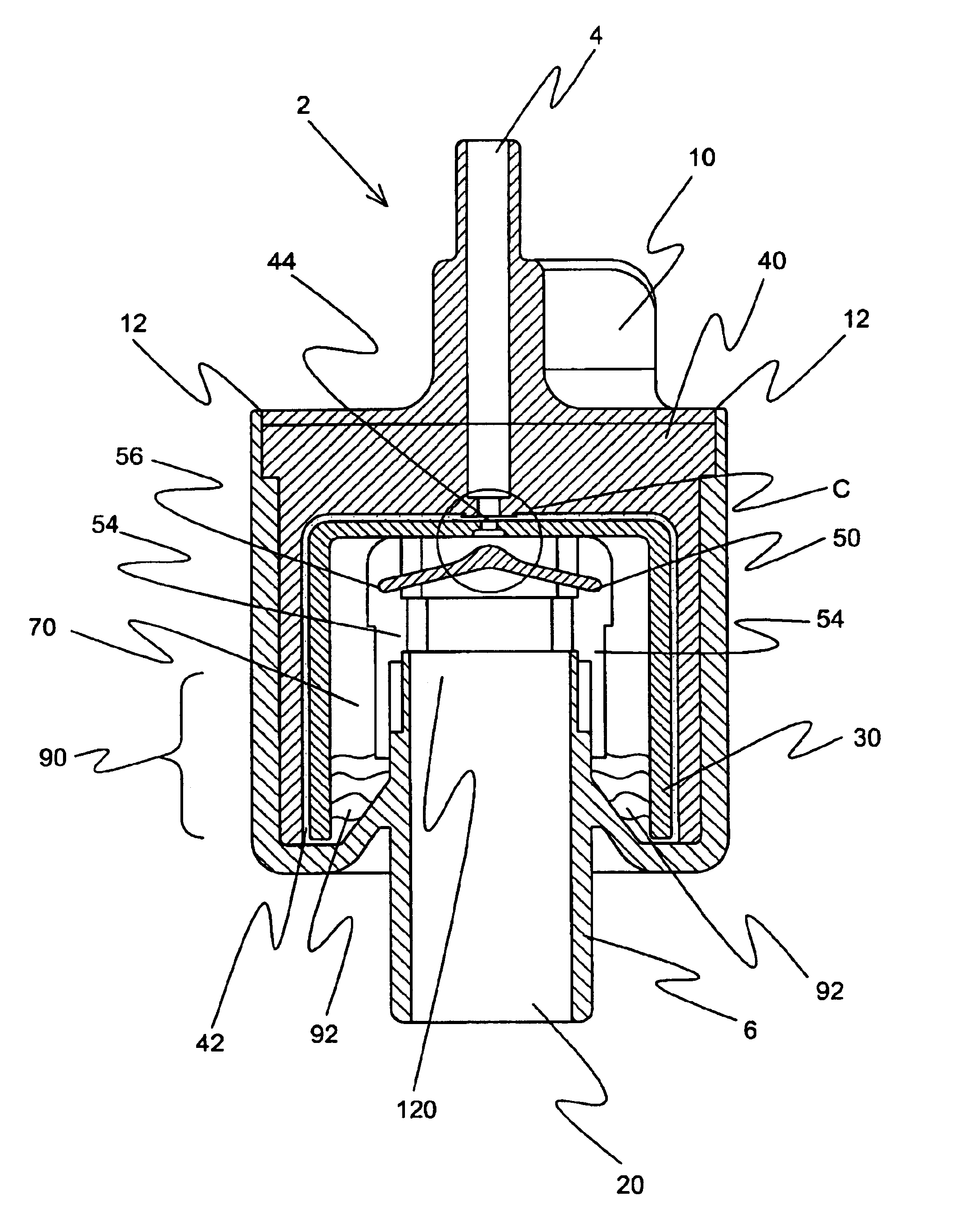

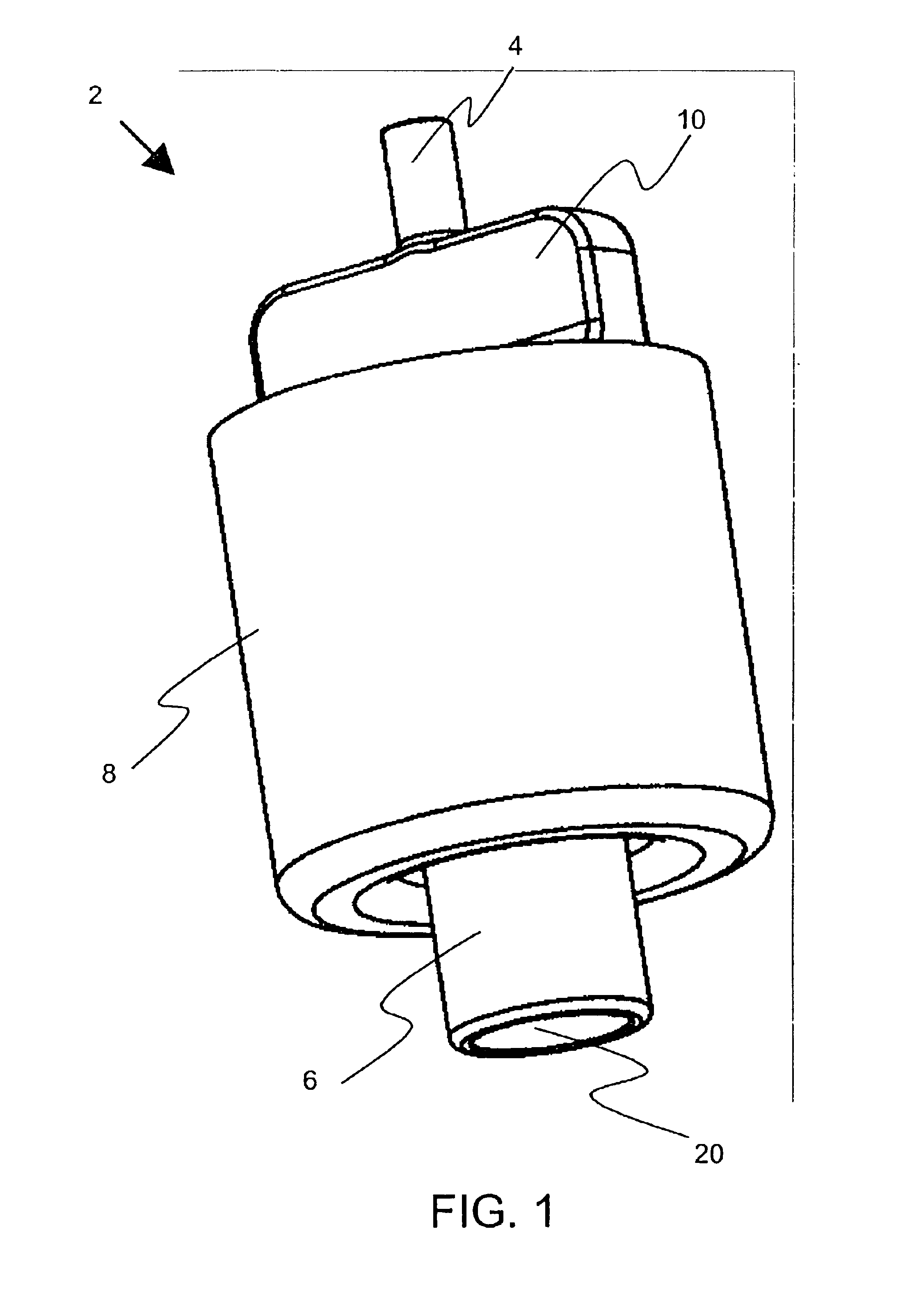

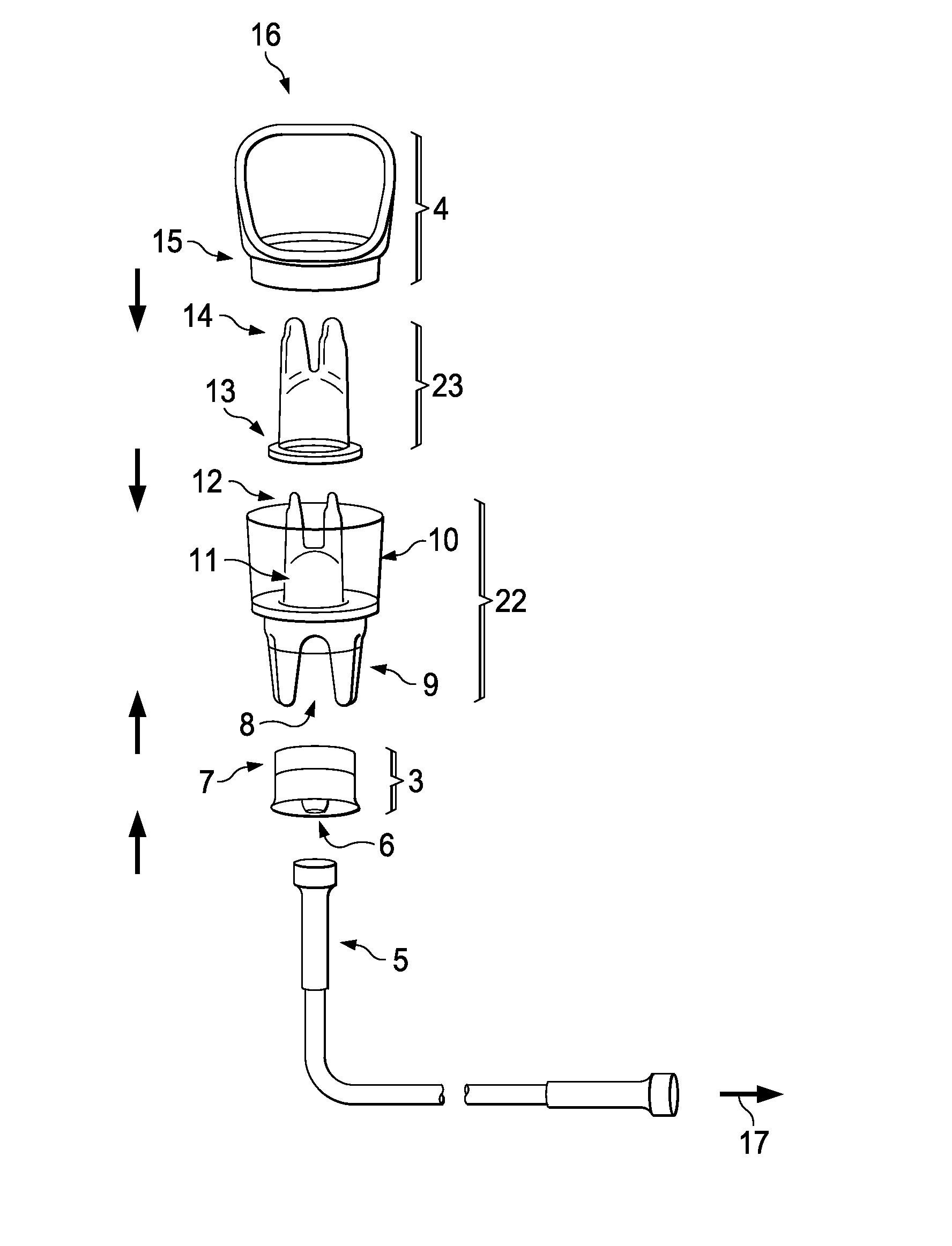

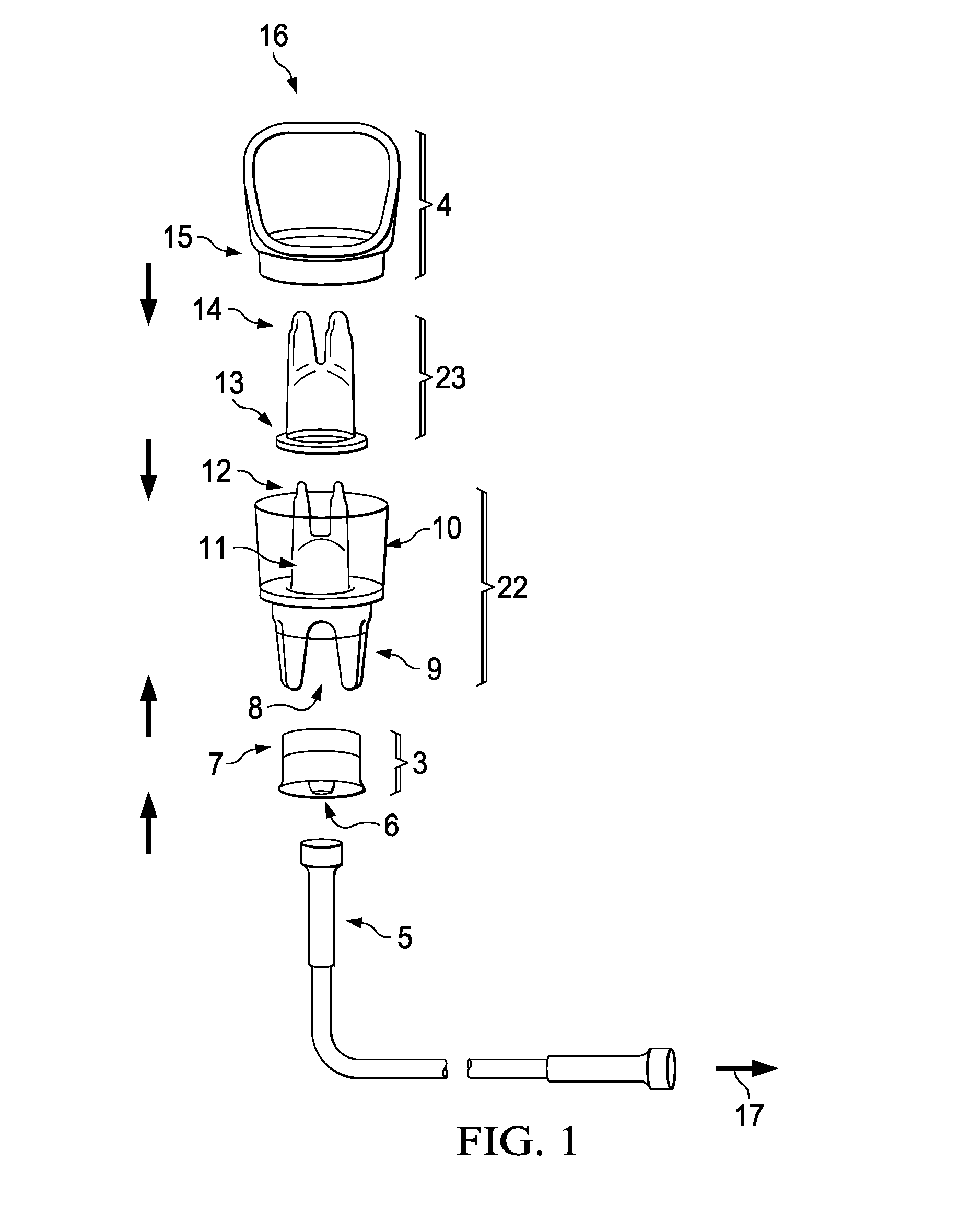

Cartomizer structure for automated assembly

InactiveUS20150027471A1Line/current collector detailsElectrically conductive connectionsAerosol MistVaporization

A cartomizer assembly of an electronic cigarette which is formed from automated assembly compatible parts comprises a container assembly including a container and a heater coil surrounding a wick in an airflow space of the container. The entire coil of the heater coil is inside the container and the heater coil is configured to heat liquid on the wick to generate an aerosol mist during a vaporization process. A liquid storage space is in liquid communication with the wick and is operable to supply liquid to the wick. The heater, the wick, and the container are shaped such that the heater and wick can be dropped into the container during automated assembly thereof and be directed to and located at a desired location in the container.

Owner:AKRIA CLIENT SERVICES LLC

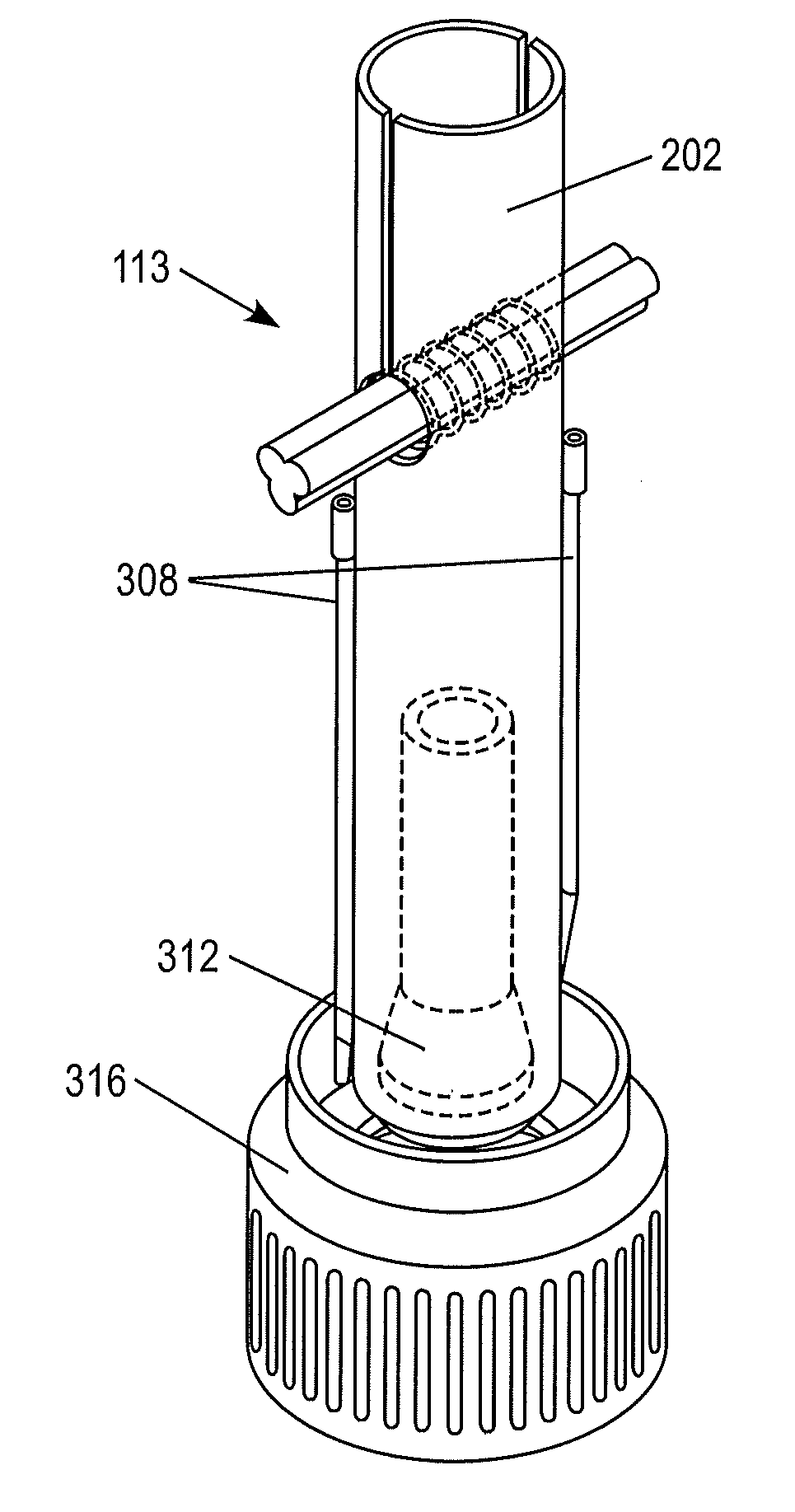

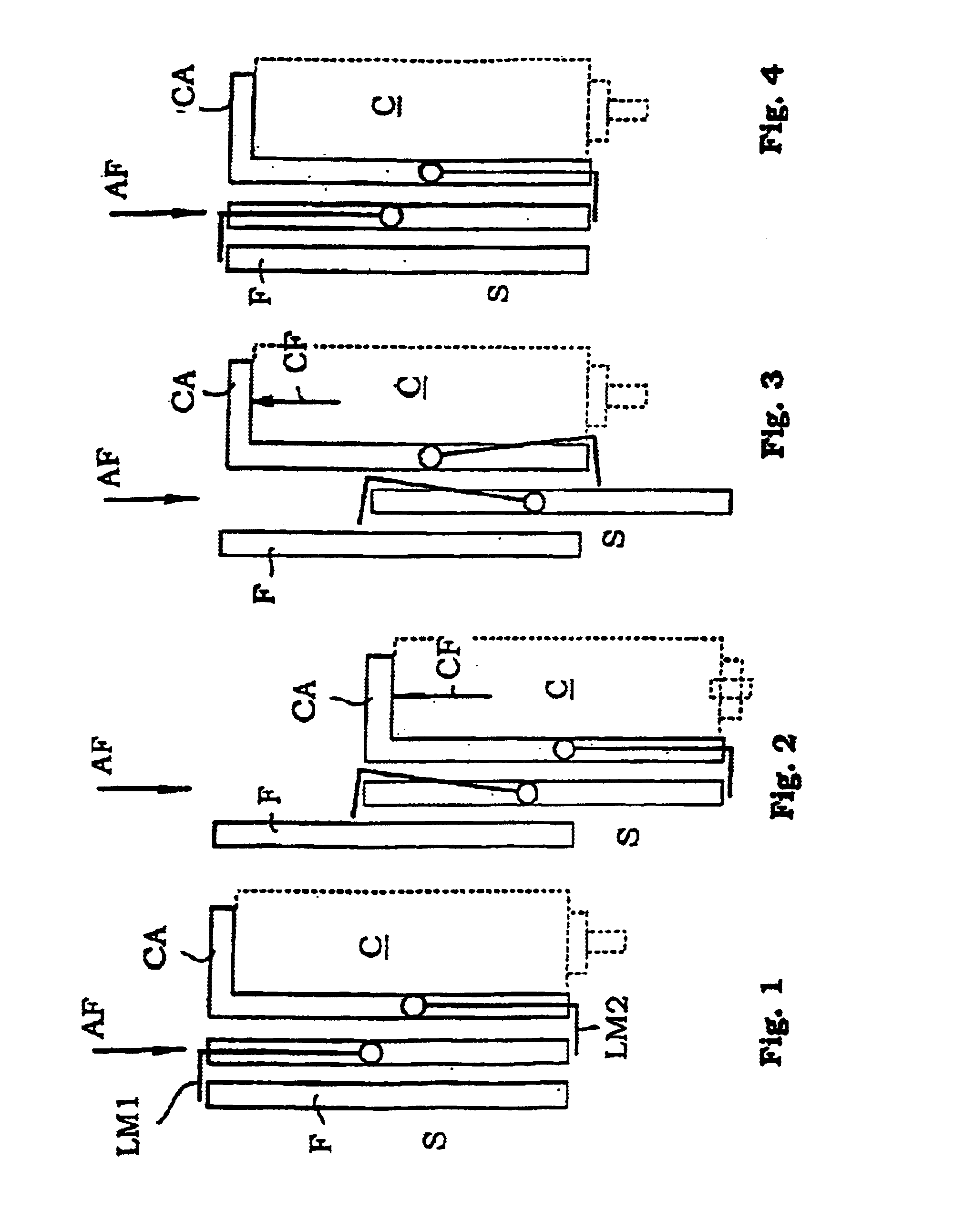

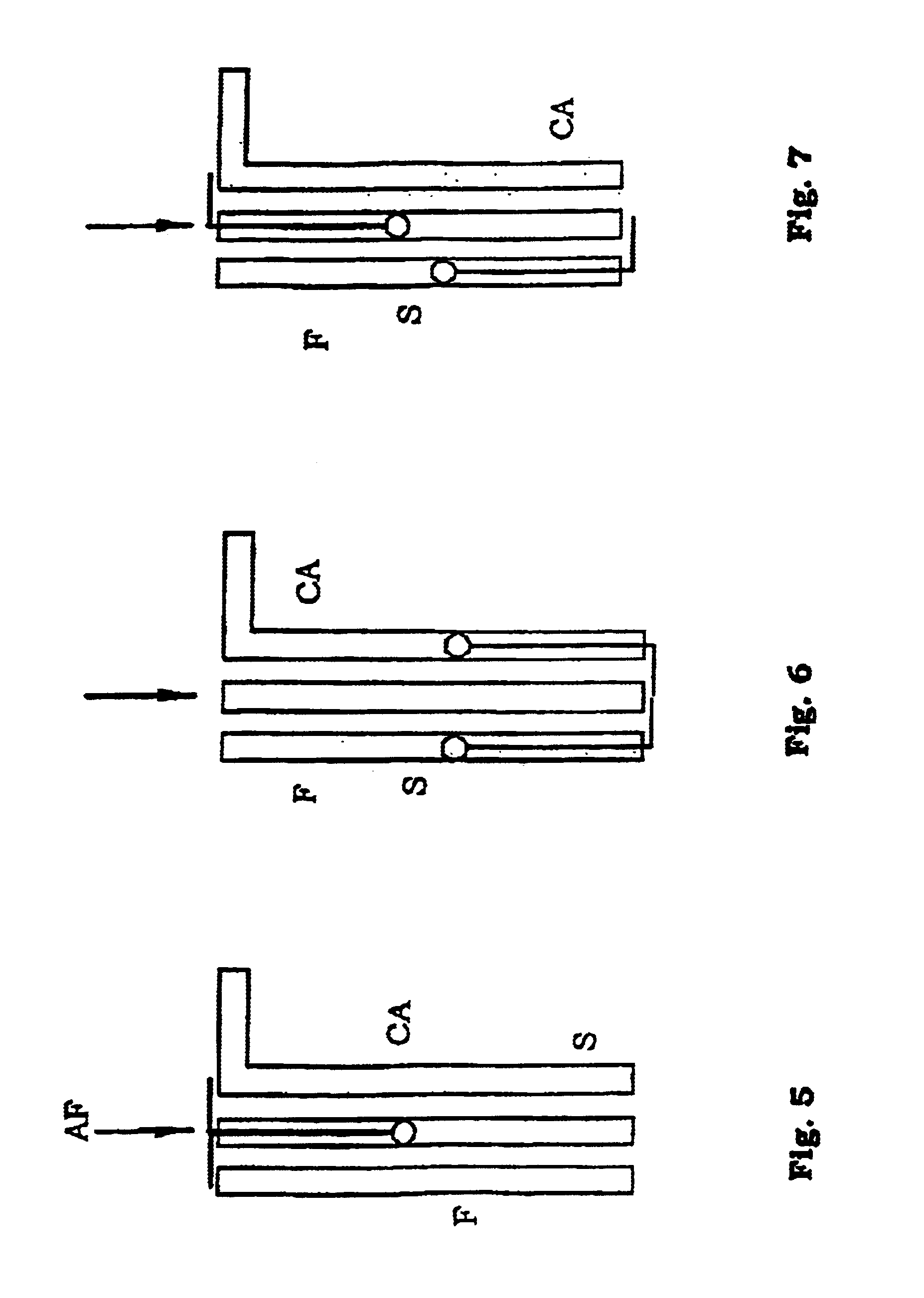

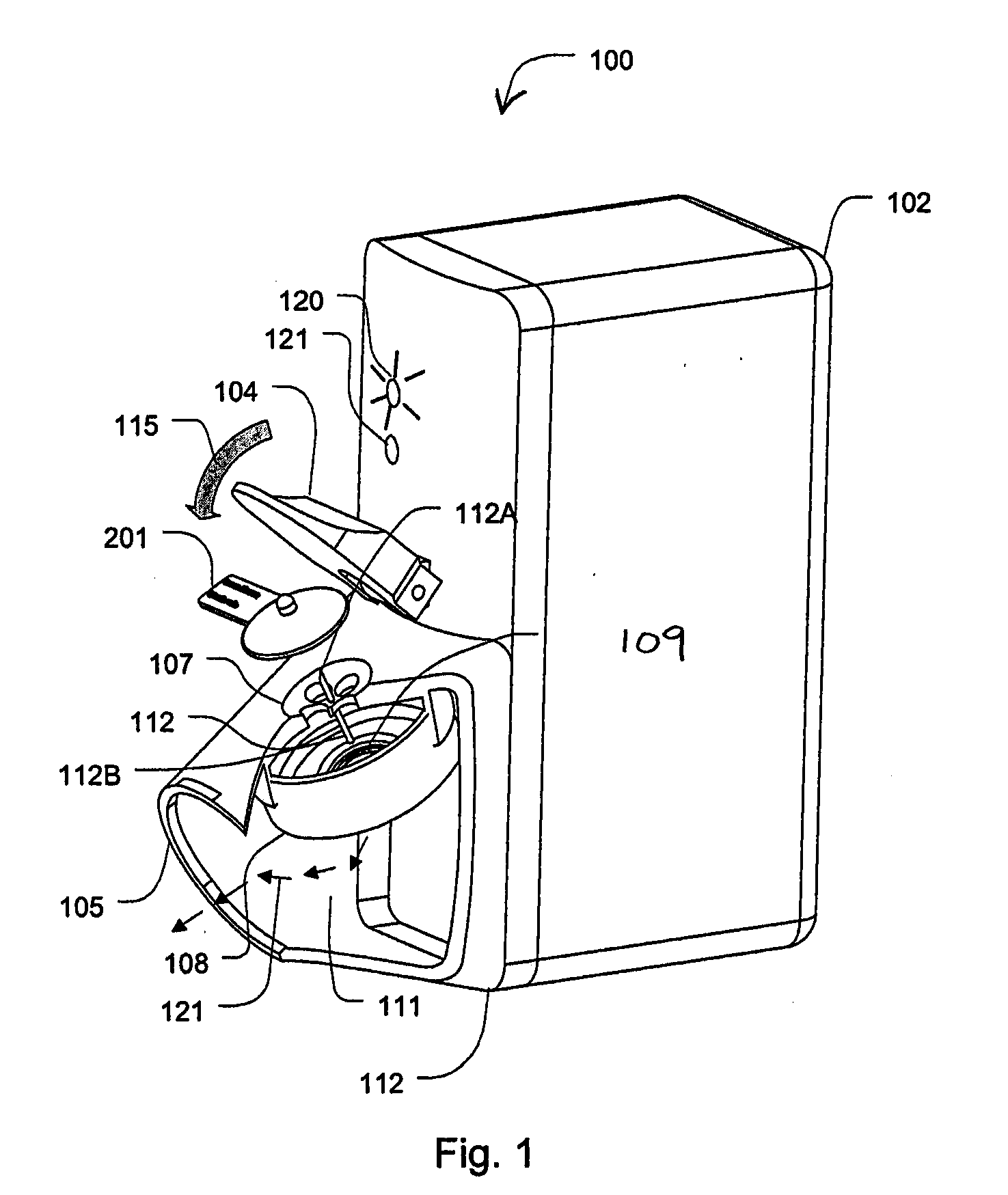

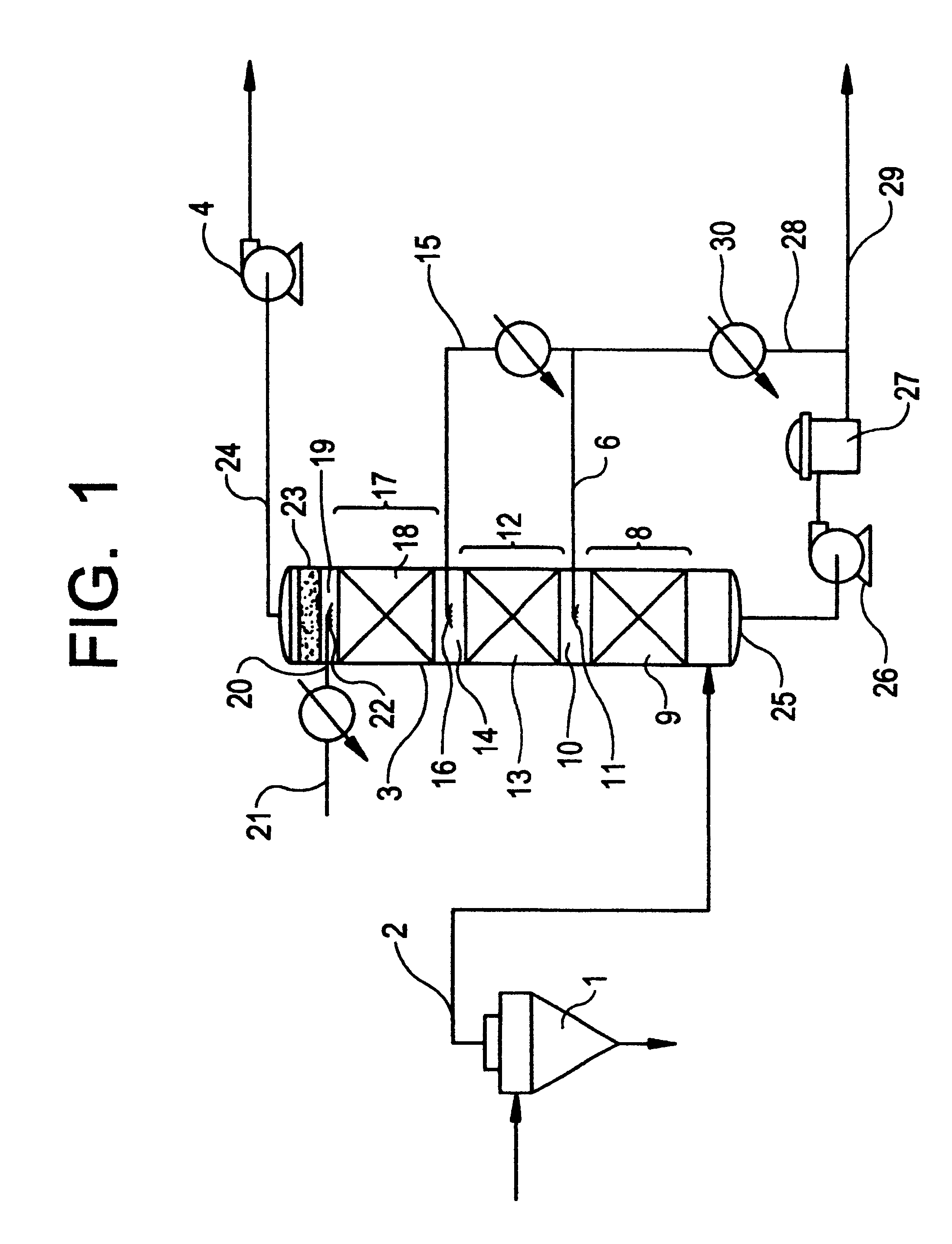

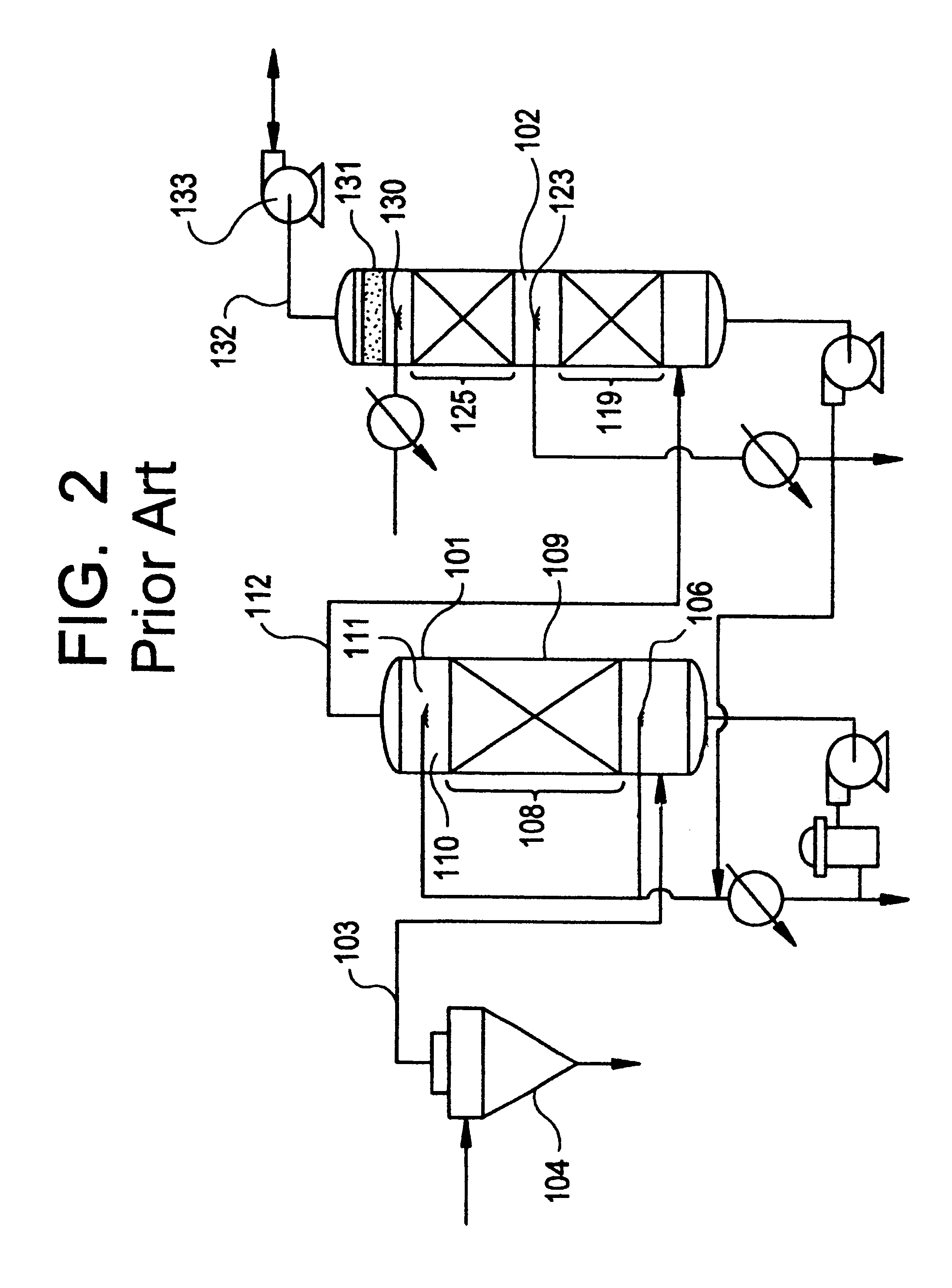

Smoking device and method for aerosol-generation

ActiveUS20170280771A1Reliable and consistent amountLess powerTobacco devicesLiquid spraying apparatusControl systemAerosolize

A smoking device for aerosol-generation may comprise a device housing, a surface acoustic wave-atomizer (SAW-atomizer), a supply element, and a control system. The device housing may include a storage portion for an aerosol-forming substrate. The SAW-atomizer may include an atomization region, a first transducer, and / or a second transducer. The first transducer is configured to generate first surface acoustic waves that propagate along a surface of the SAW-atomizer. The supply element is arranged to supply the aerosol-forming substrate from the storage portion to the atomization region of the SAW-atomizer. The control system is configured to operate the SAW-atomizer to atomize the aerosol-forming substrate in the atomization region to generate an aerosol. A cartridge for such a smoking device and a method for generating an aerosol in a smoking system are also provided.

Owner:AKRIA CLIENT SERVICES LLC

Inhaler

InactiveUS6866037B1Quality improvementRespiratorsIntravenous devicesInhalationBiomedical engineering

Device for use with an inhaler, the inhaler having a body, an aerosol canister arranged in the body containing medicament, including a metered dose chamber and able to dispense a metered dose of the medicament, a nozzle in fluid communication with the canister, an opening for dispensing of the medicament in fluid communication with the nozzle. The device includes elements for activating the canister to open and dispense the medicament in response to an airflow in the inhaler caused by inhalation of a user through the opening, return elements for deactivating the canister to close it, characterized in that the return elements deactivate the canister when the airflow drops below a certain threshold value.

Owner:SHL GRP AB

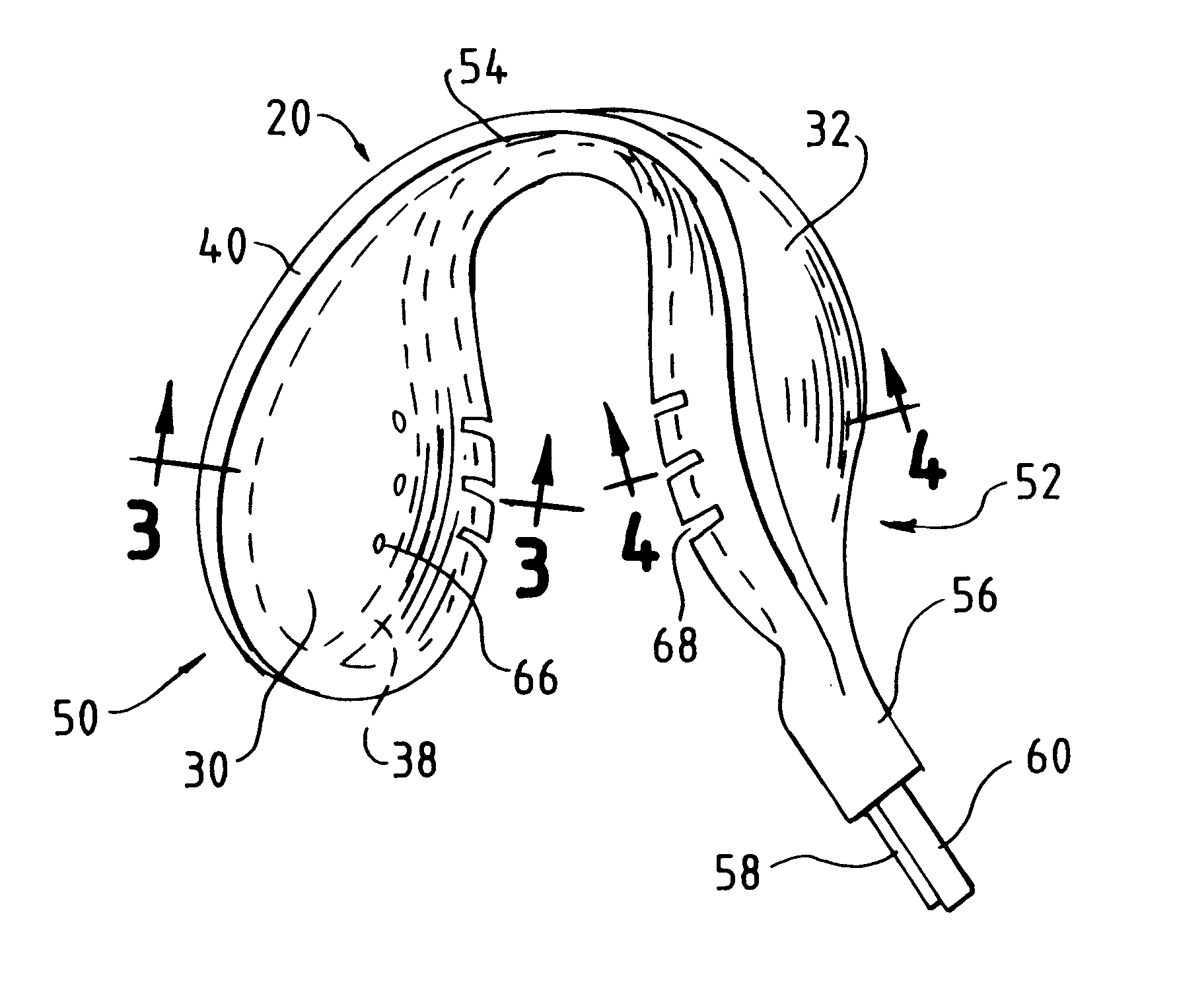

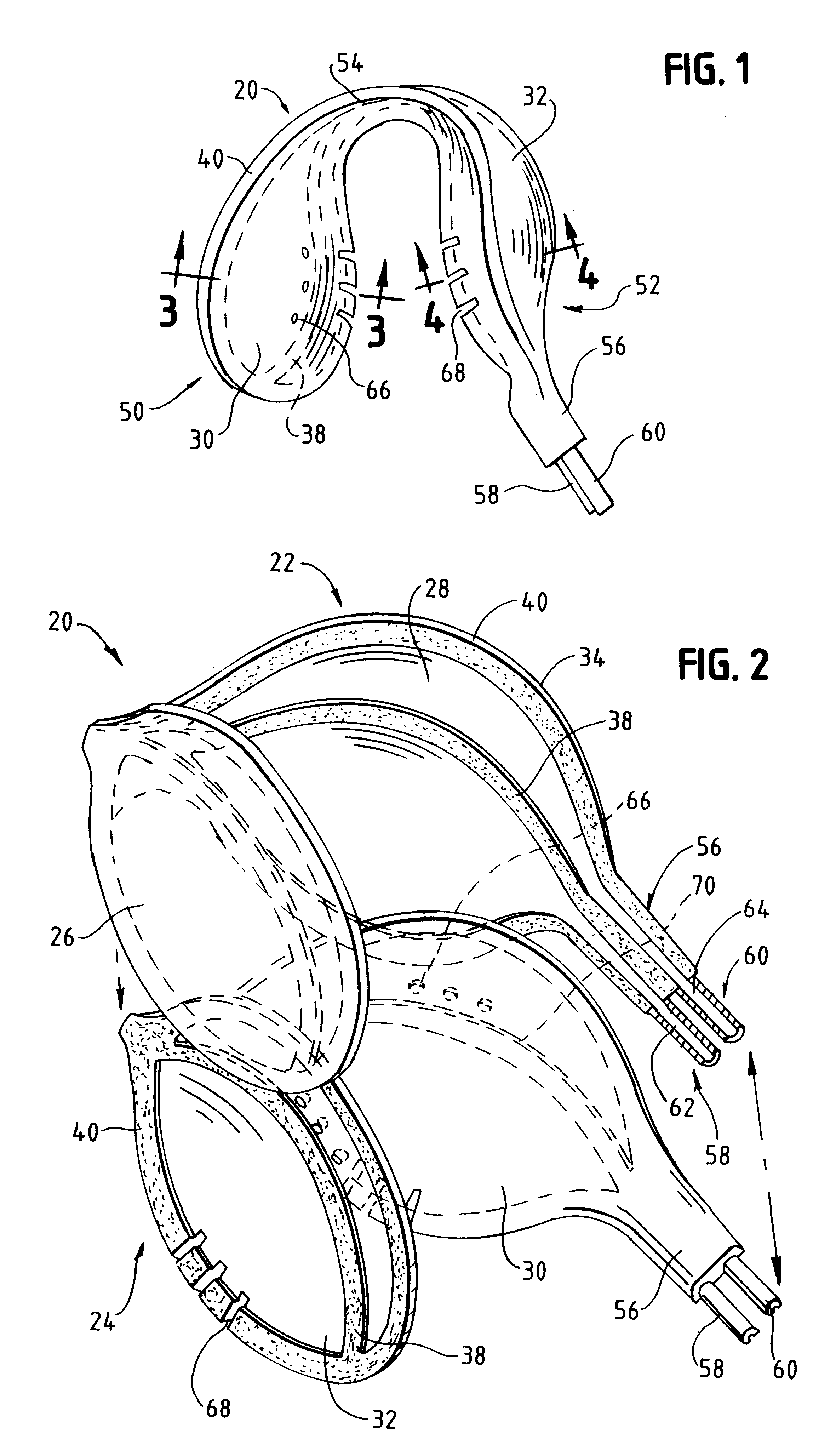

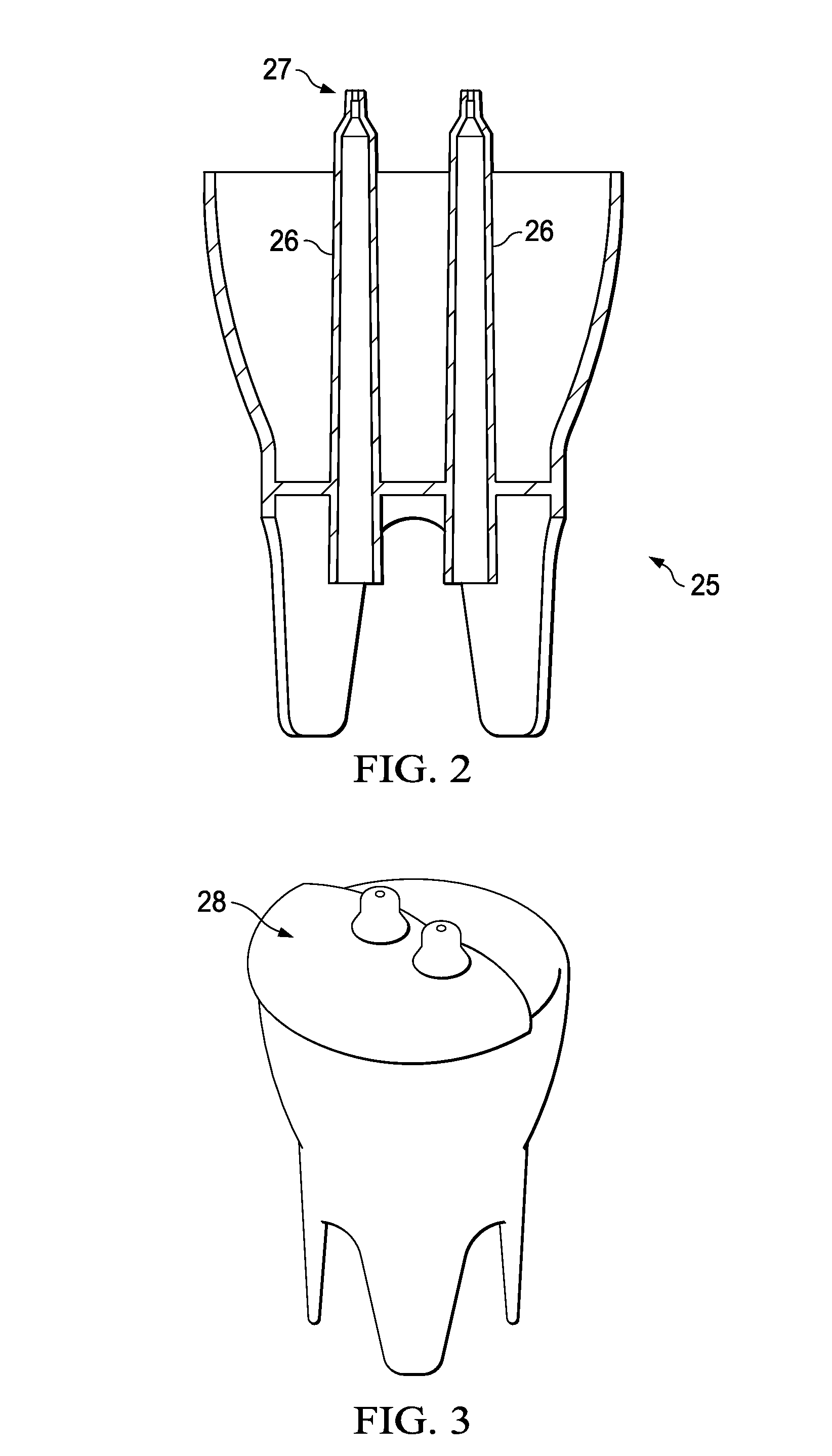

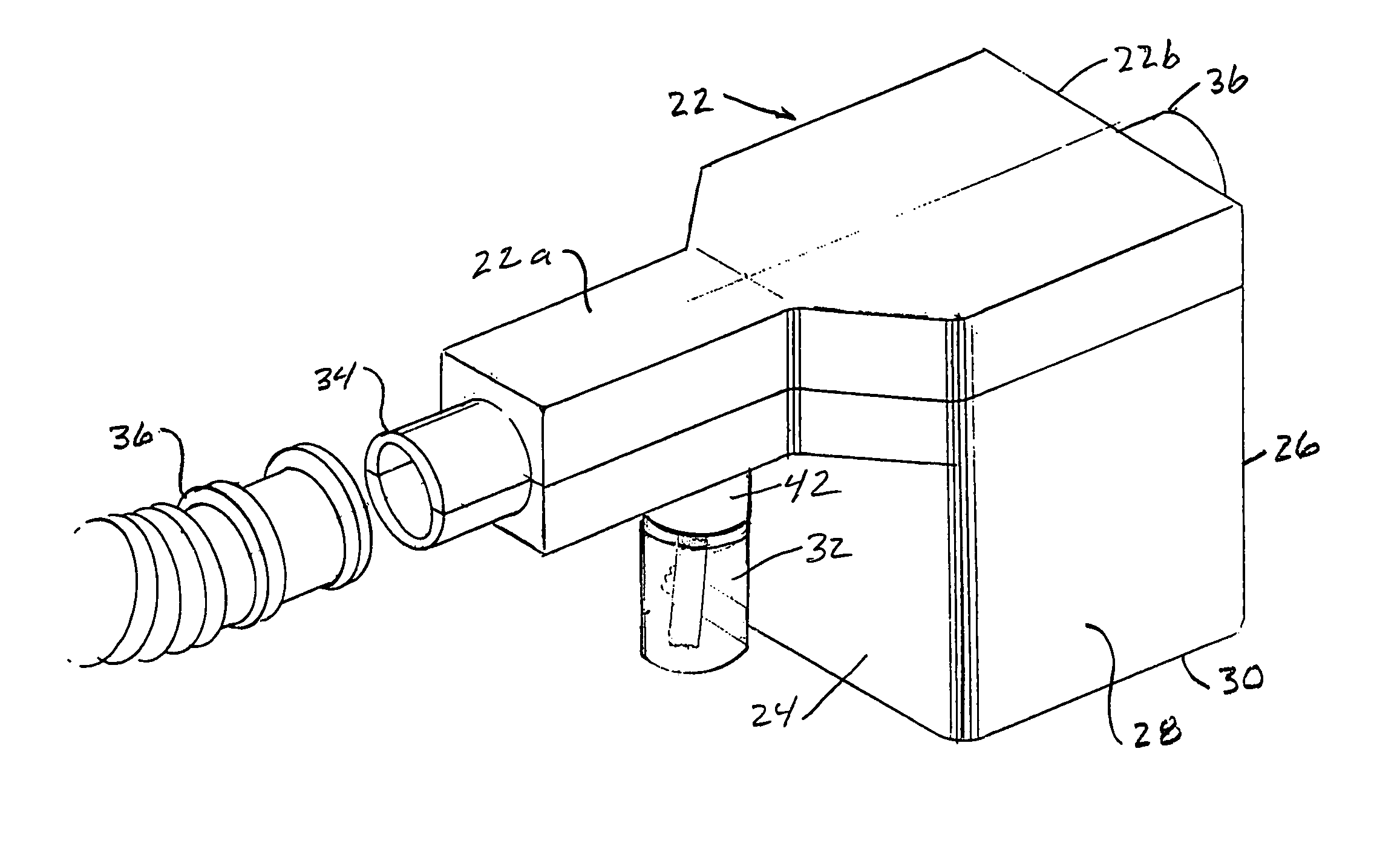

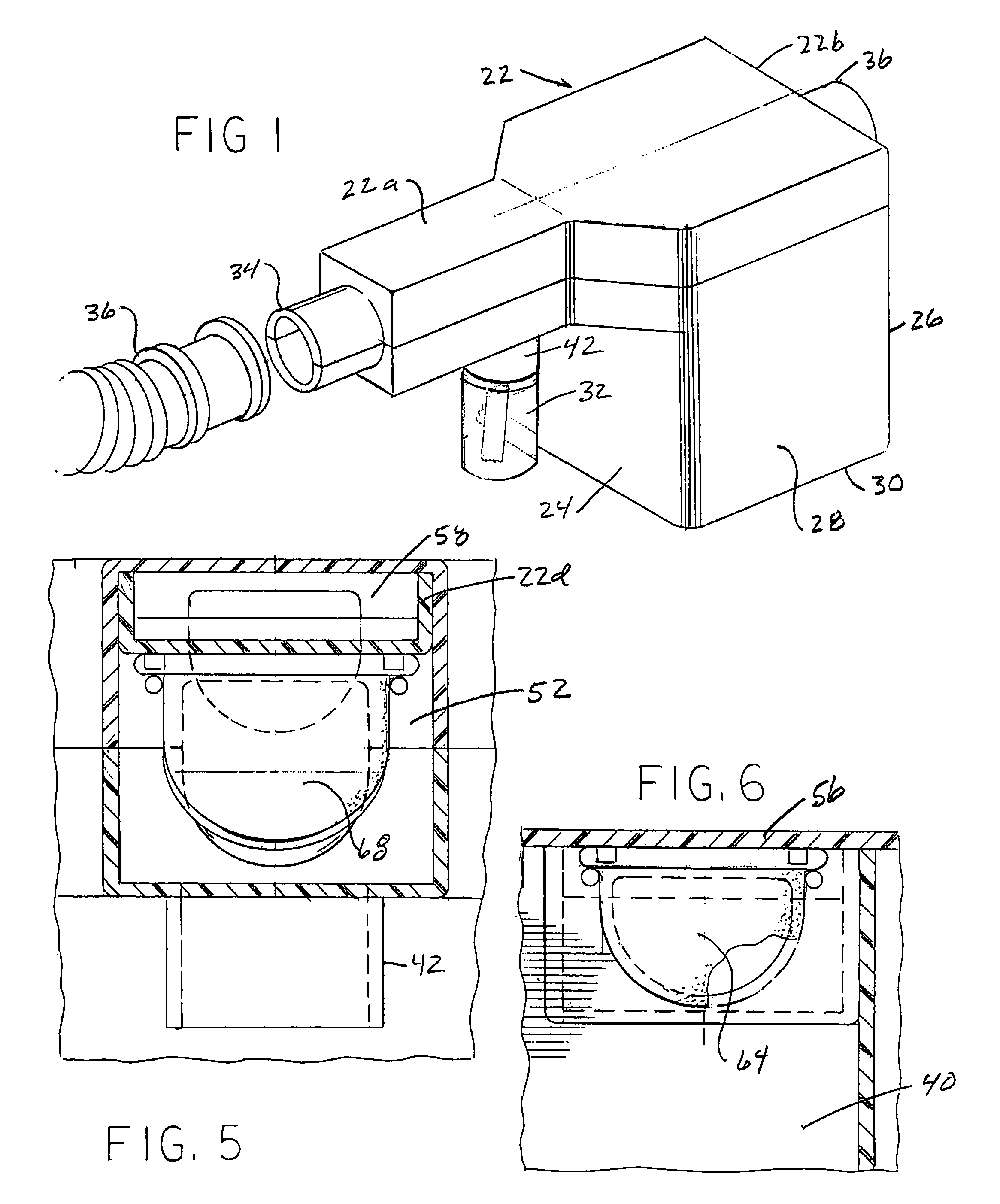

Oral isolation device with evacuation chambers

An essentially a U-shaped oral isolation device having a tongue arm, a buccal arm, and a hinge section is provided. The device is an essentially hollow member having an upper suction chamber and a lower suction chamber within the hollows of the oral isolation device. Each chamber further comprising suction inlet apertures through which saliva, fluid, aerosol mist, and debris can be evacuated from the operative site, and a suction outlet chamber through which the collected saliva, fluid, and debris are removed from the device. A U-shaped hinge member joins the buccal arm and the tongue arm. It has position memory which permits the user to squeeze the arm members toward one another for placement in the mouth and upon release, the arm members exert opposing positional influence against the tongue and cheek. Also provided is a method of use for the device in which the tongue arm and buccal arms are forced toward one another. The hinged member is then inserted into the patient's oral cavity and placed around the rearmost tooth. Upon proper placement of the device, the user releases the pressure on the arms of the device, the arms thereby exerting opposing positional influence against the cheek and tongue, resulting in retraction of the tongue and cheek, thereby creating a clear operative field. A reduced pressure high volume device is then attached to the upper chamber suction outlet and a low pressure reduced volume device is attached to the lower chamber outlet.

Owner:PREMIER DENTAL PRODS +1

Preservative-free single dose inhaler systems

An aerosolization system includes a squeezable container having a resilient container body. The container is configured to deliver a unit dosage of a liquid when squeezed a single time. The system also includes an aerosolizer that is constructed of a housing defining a mouthpiece, and an aerosol generator disposed in the housing. The aerosol generator comprises a vibratable membrane having a front face and a rear face, and a vibratable element used to vibrate the membrane. Further, the housing includes an opening that is adapted to receive a unit dosage of the liquid from the container. The opening provides a liquid path to the rear face of the vibratable membrane.

Owner:AERAMI THERAPEUTICS INC

Aerosol-generating systems with liquid level determination and methods of determining liquid level in aerosol-generating systems

An electrically operated aerosol-generating system may include a liquid storage portion configured to store a liquid from which aerosol may be generated, an electric heater, a capillary wick extending between the liquid storage portion and the electric heater and configured to convey liquid from the liquid storage portion to the electric heater and electric circuitry connected to the electric heater. The electric circuitry may be configured to: activate the electric heater for a first heating time period in response to an input to vaporize liquid in the capillary wick, activate the electric heater for a second heating time period upon the elapse of a first cooling time period after the first heating time period, record a temperature measurement of the electric heater during the second heating time period, and determine an amount of liquid in the liquid storage portion based on the temperature measurement.

Owner:AKRIA CLIENT SERVICES LLC

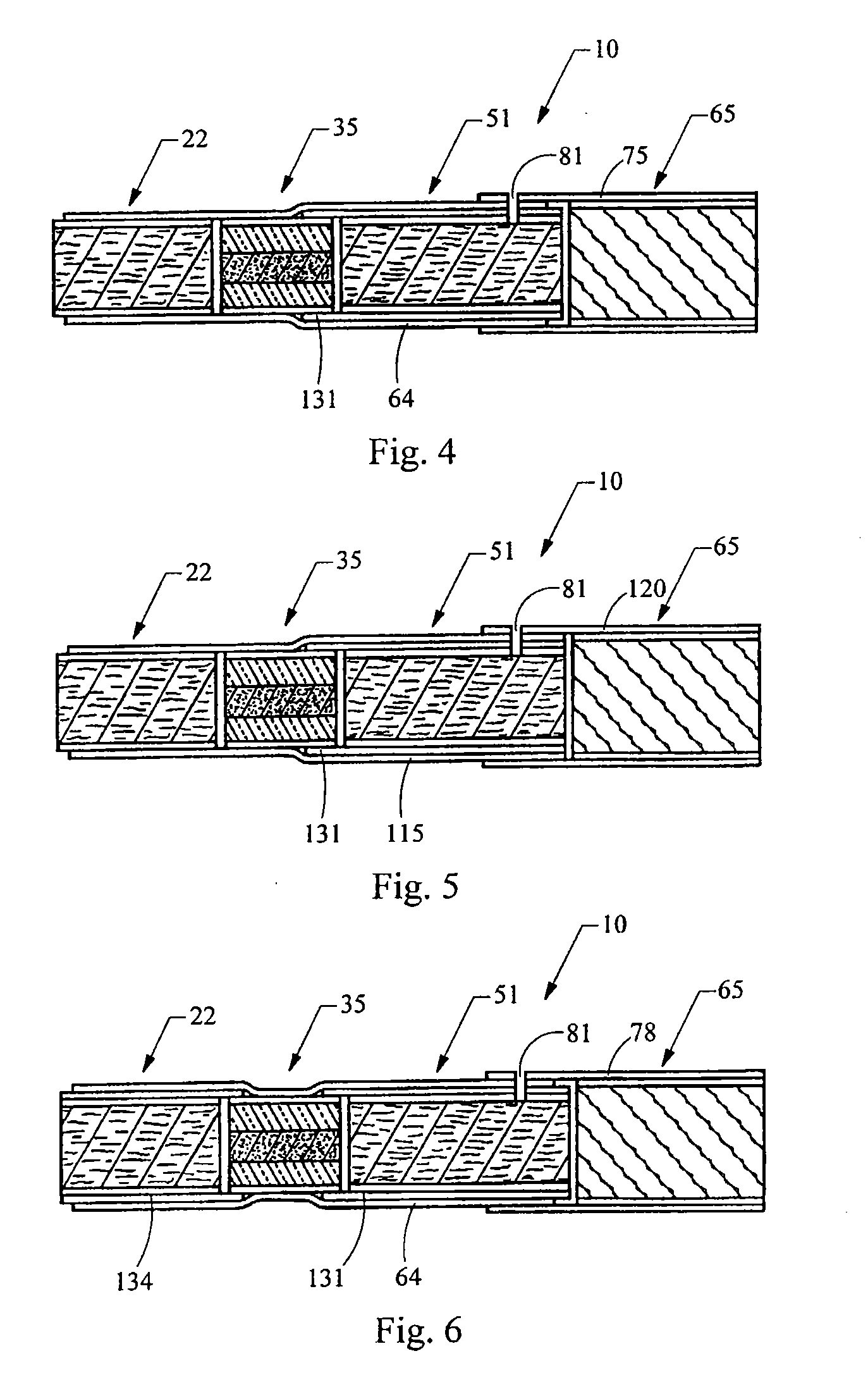

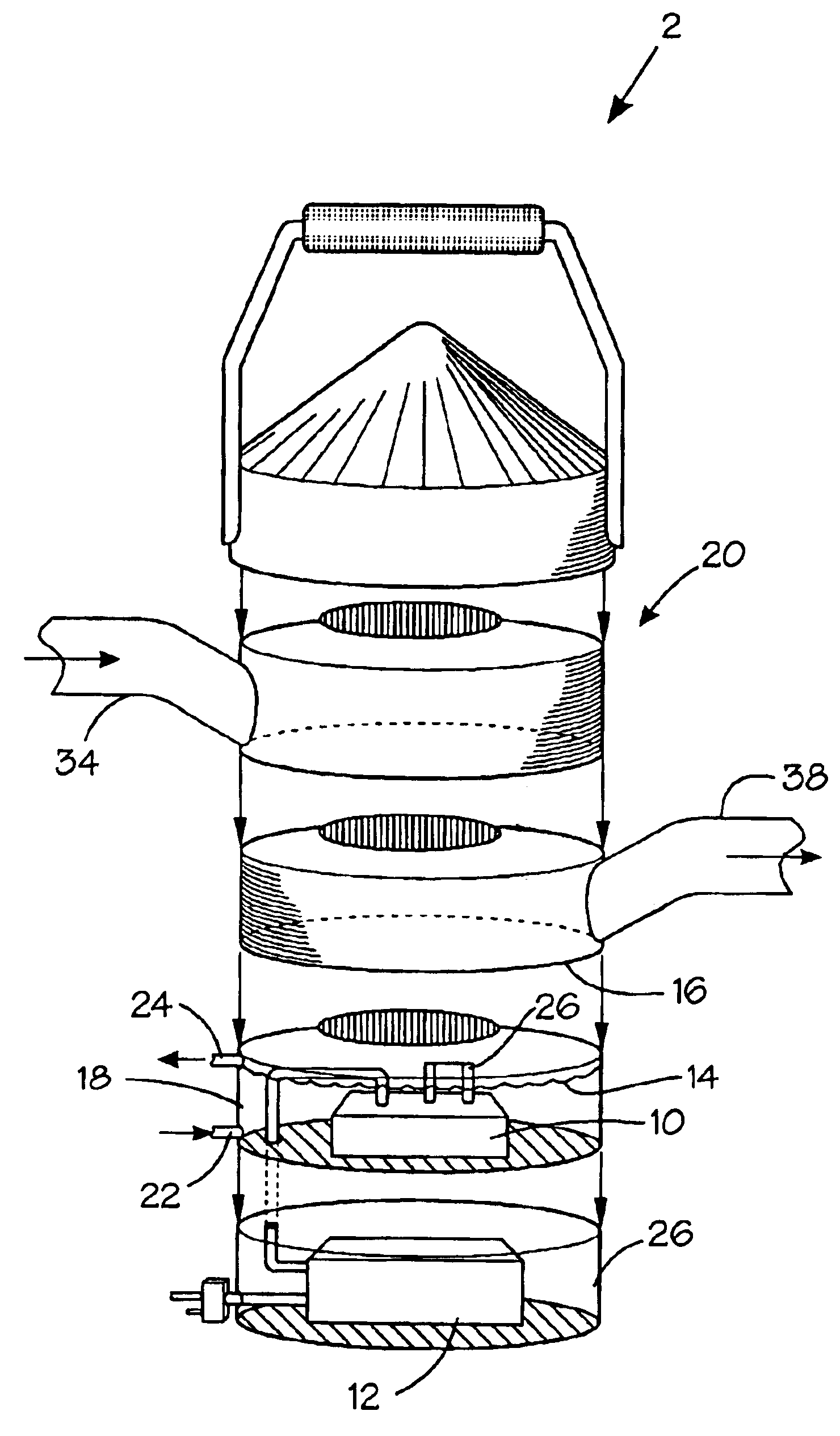

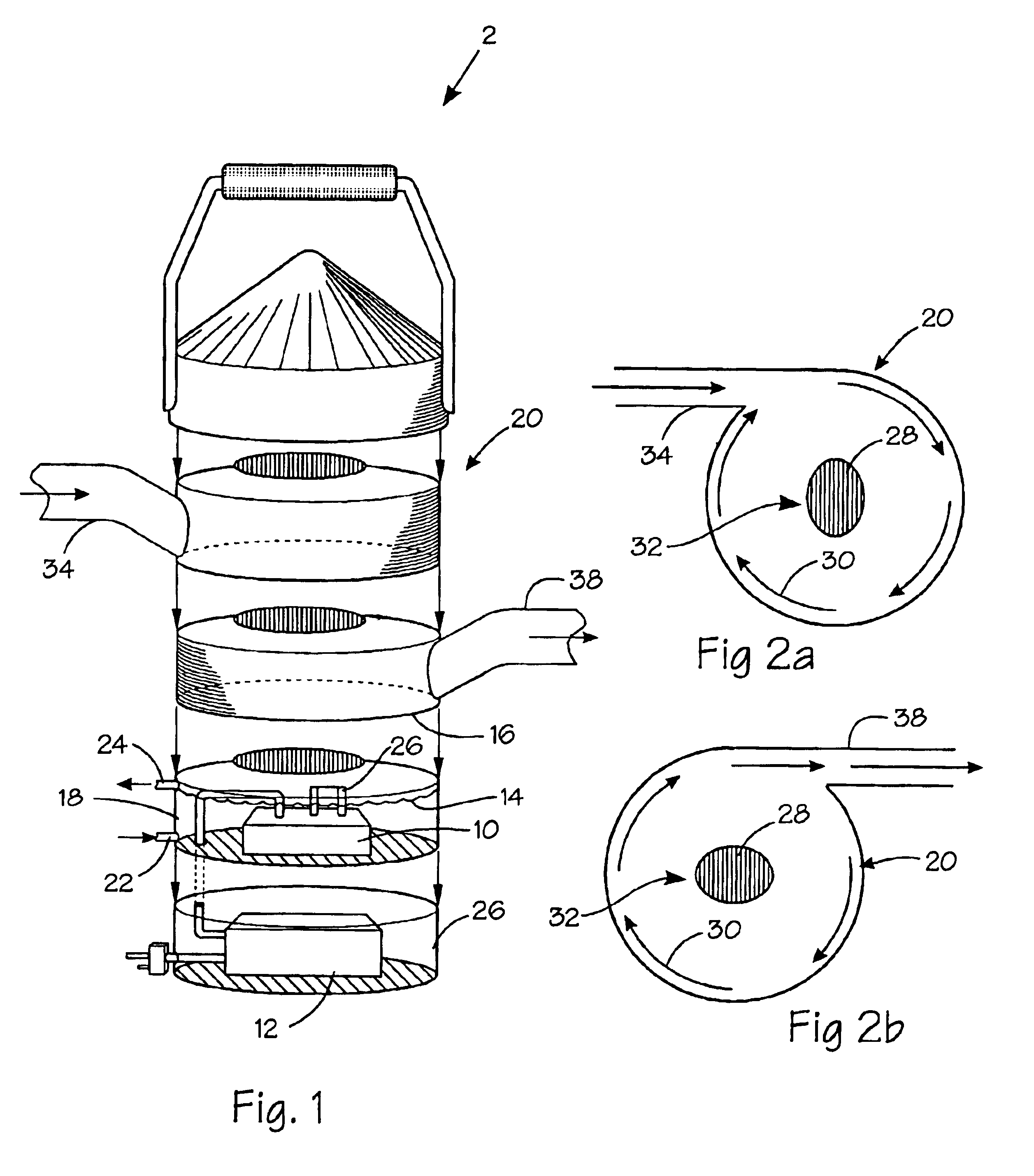

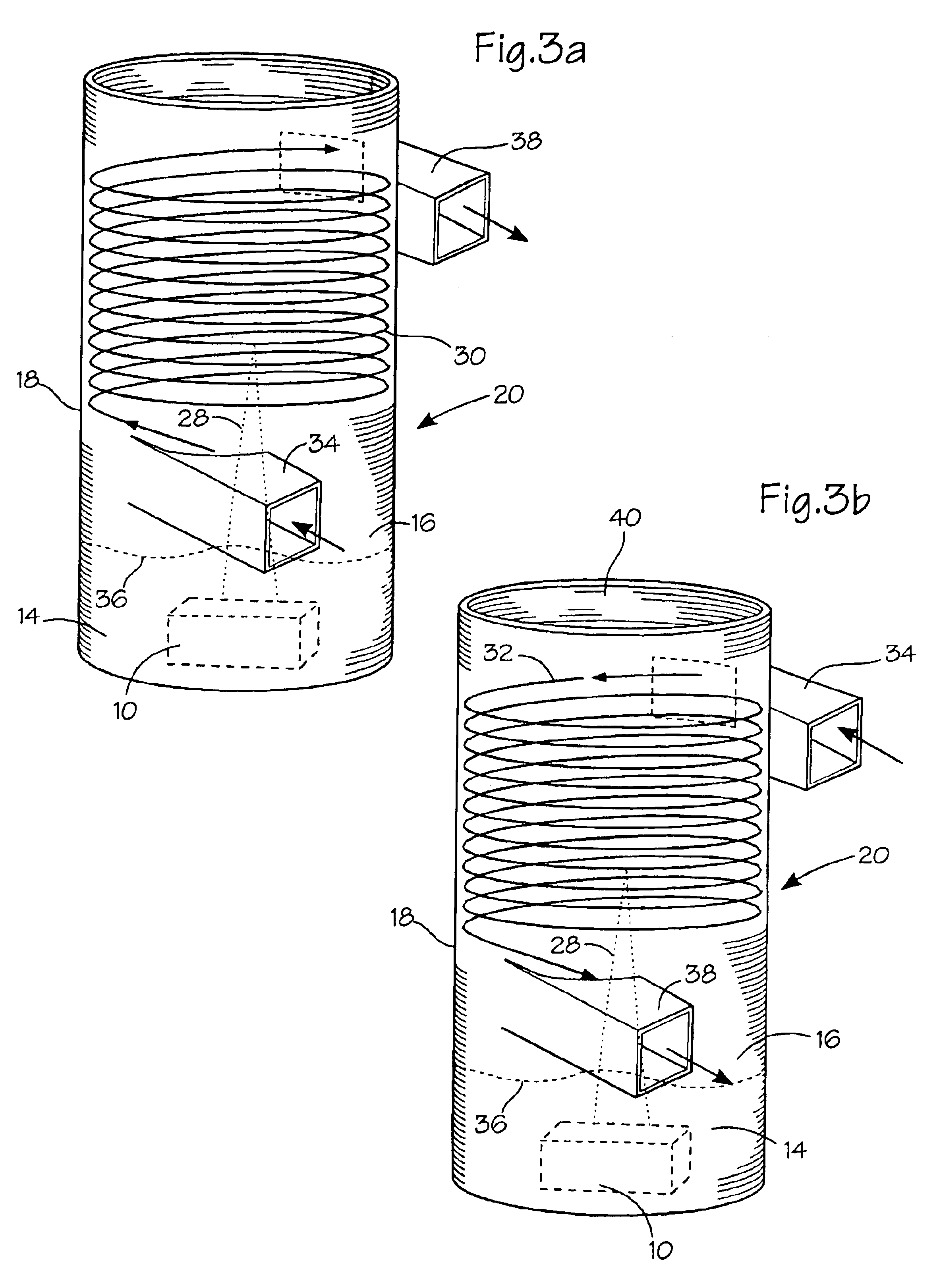

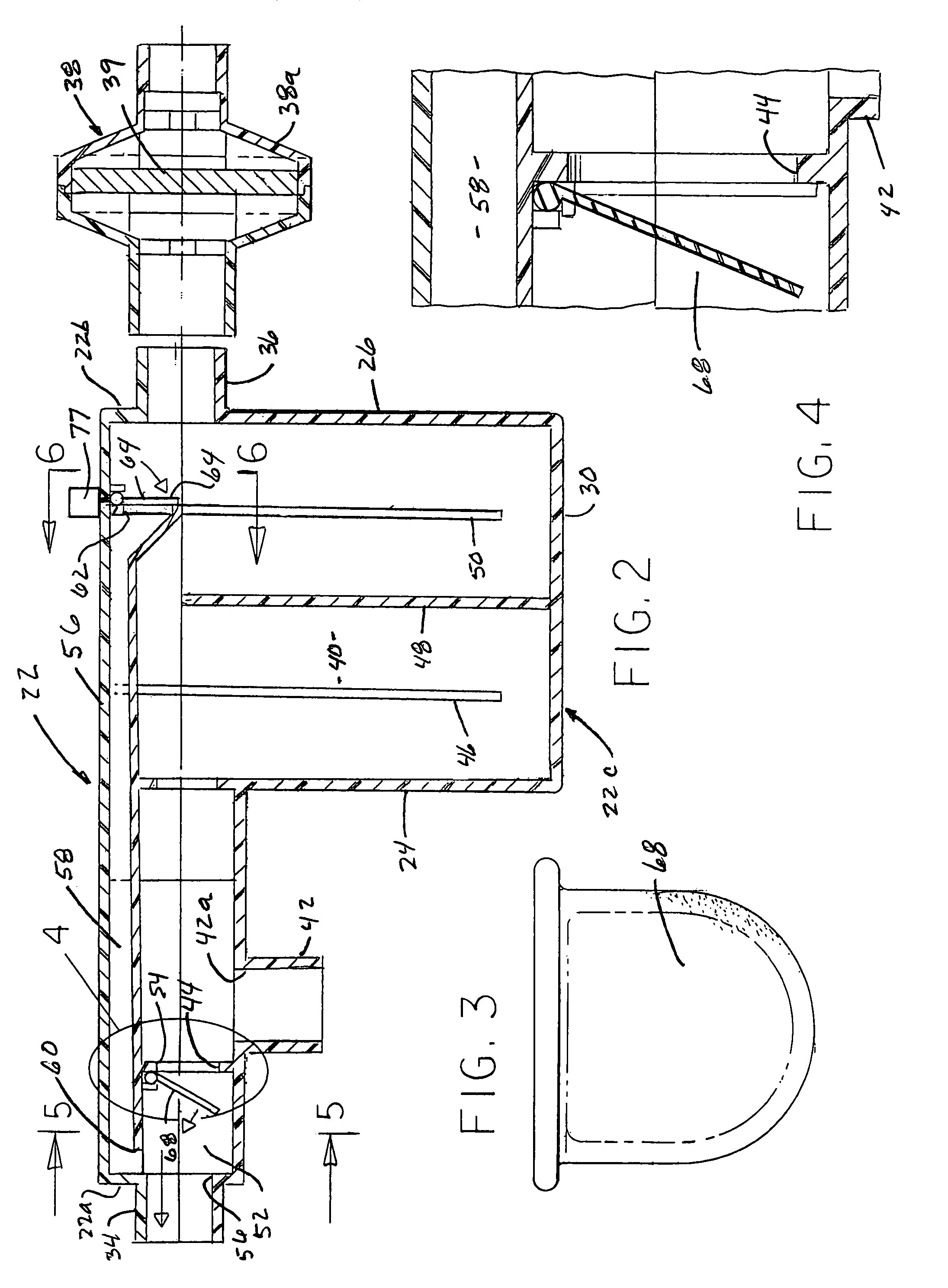

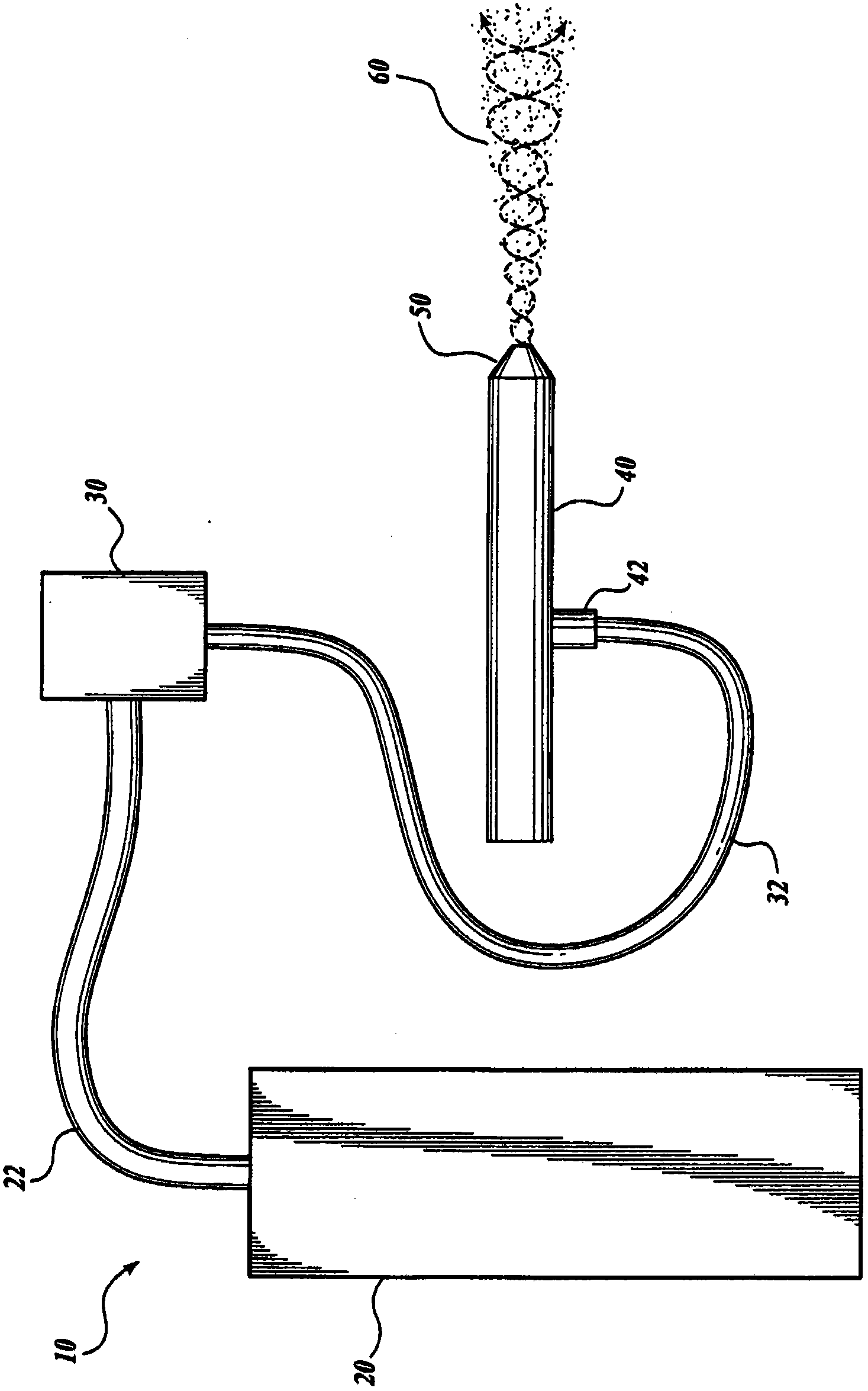

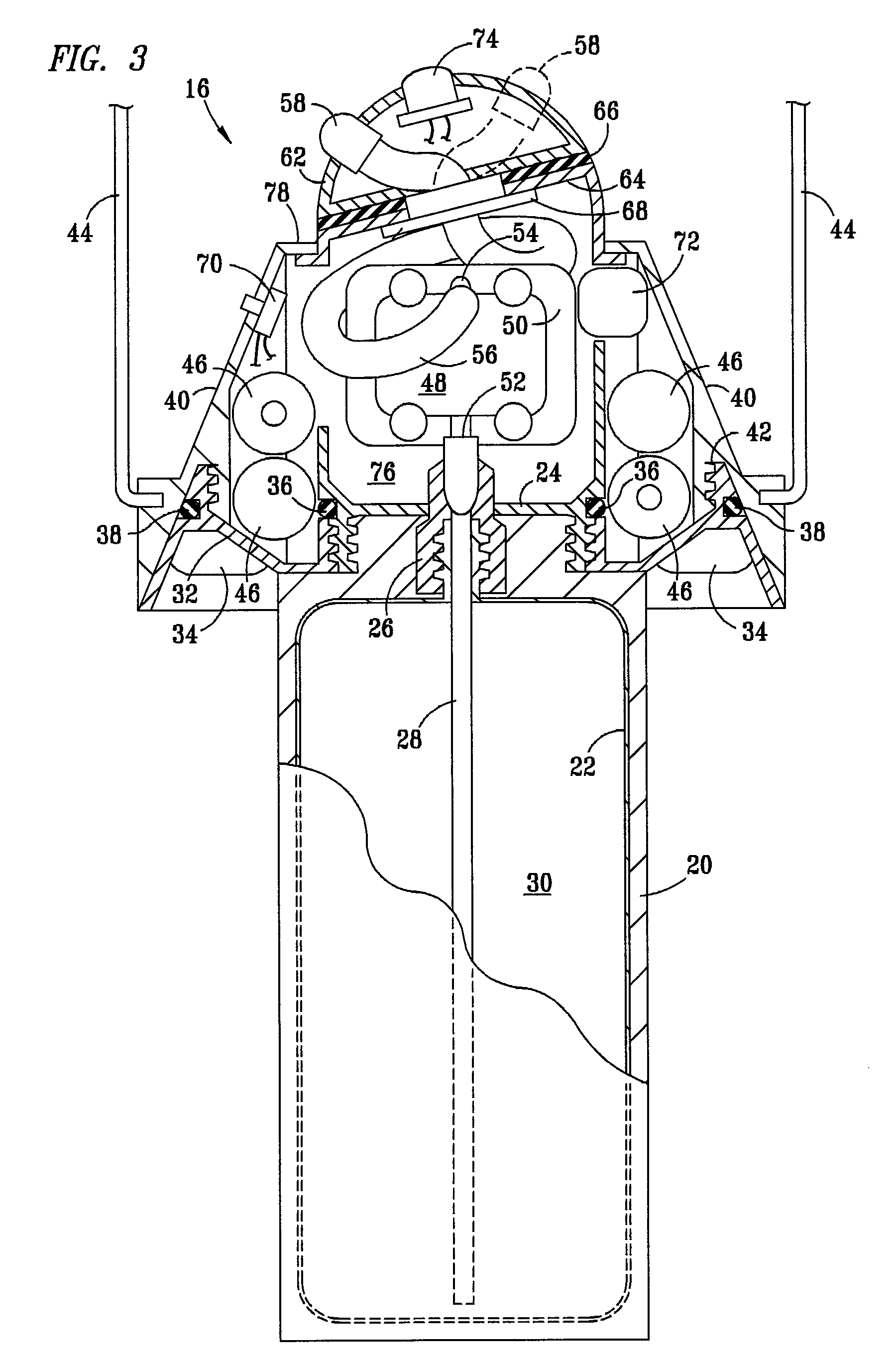

Method and device for production, extraction and delivery of mist with ultrafine droplets

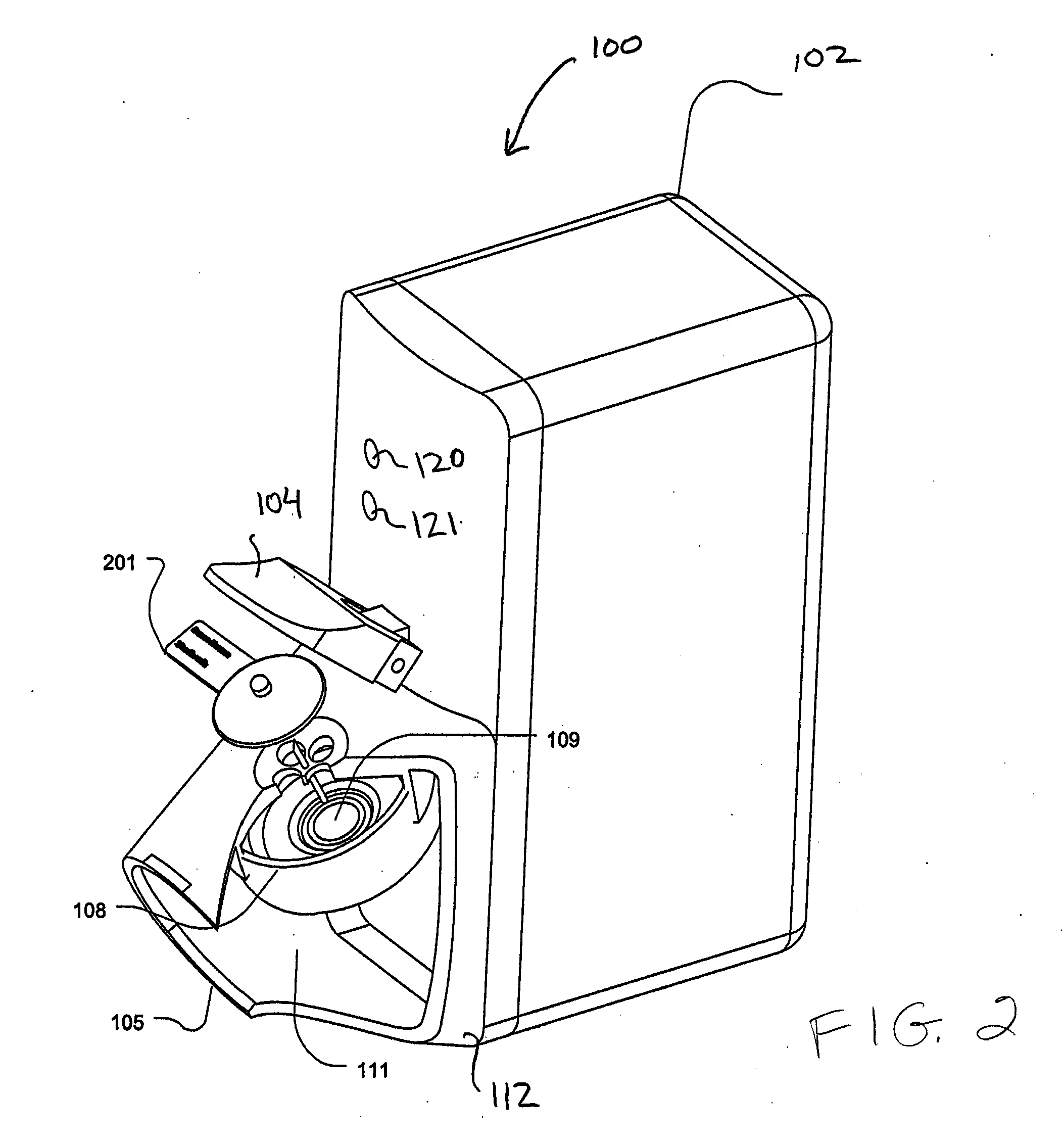

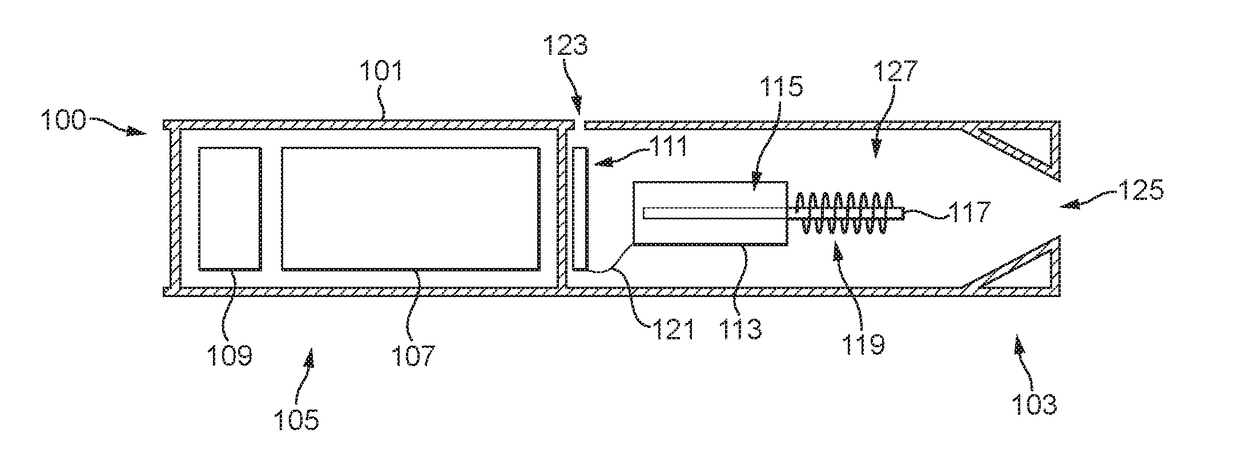

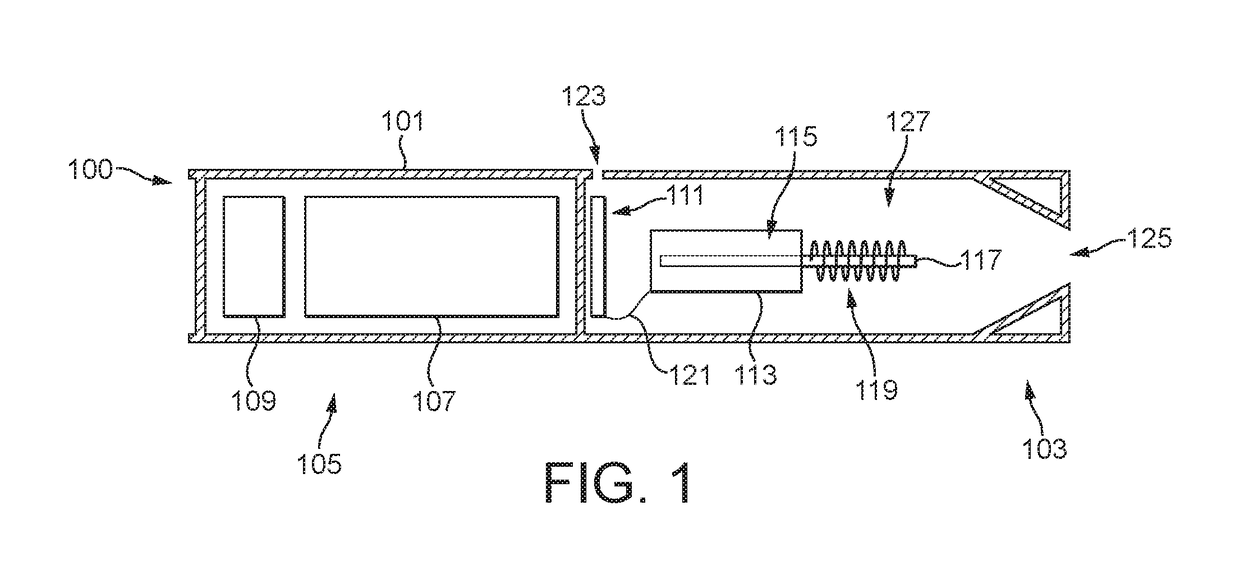

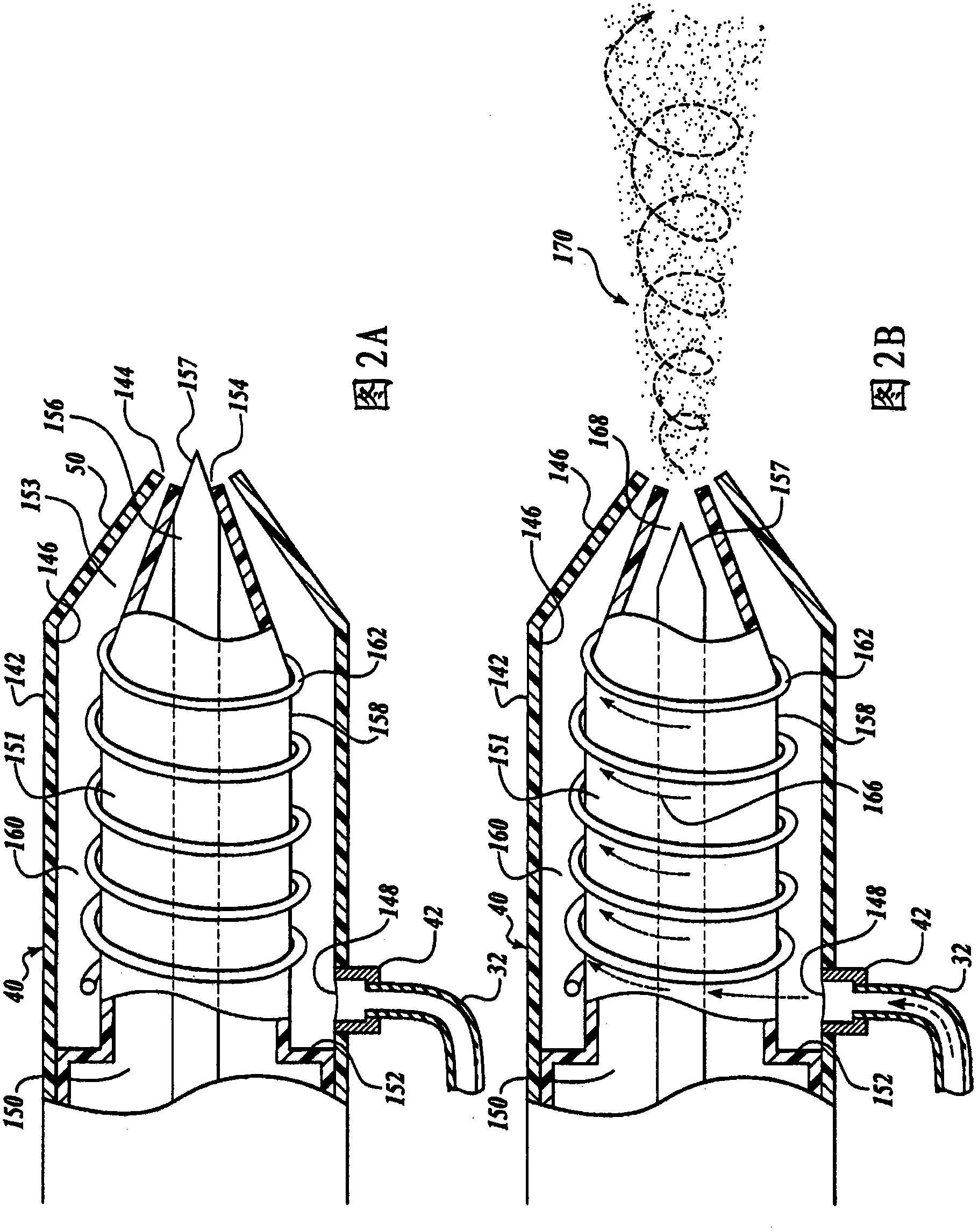

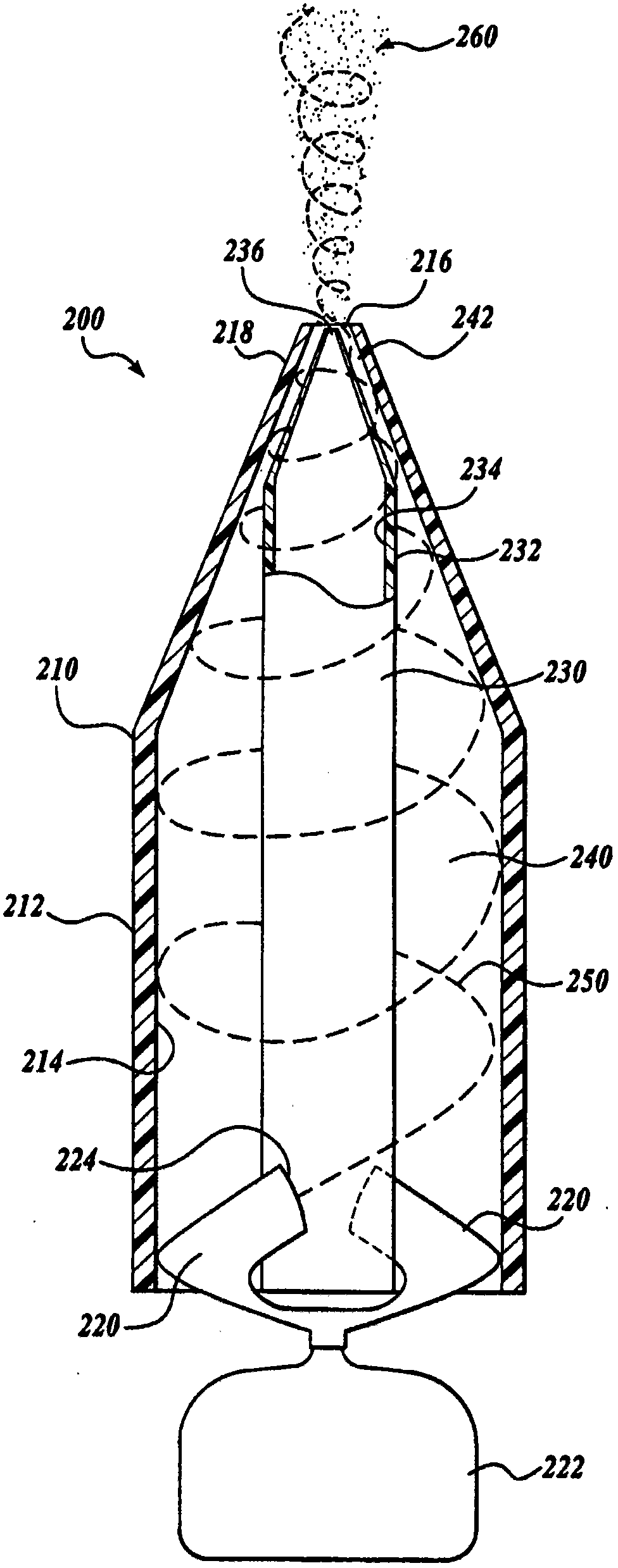

InactiveUS6883724B2Improve carrier gas flowEnhanced ejectionSteam generation heating methodsMovable spraying apparatusAerosol MistEngineering

The present invention provides a method and device for production, extraction and delivery of an aerosol mist with ultrafine droplets. A high frequency wave generating device or other process generates very small particles or droplets from a reservoir of liquid or material to be atomized. A helical flow of a carrier gas medium such as air is directed into a container and creates a high throughput aerosol of air and fine droplets. The aerosol is delivered through a suitable outlet such as by deflecting the aerosol upwards and providing a tube centrally situated with respect to the helical flow such that the aerosol will discharge through the tube in high quantity of throughput and high quality of stable aerosol of very fine mist droplets. The methods described utilize in-situ extraction of fine mist droplets using helical flow behavior as opposed to forced convection ejection of mist or inertial separation of droplets by separators.

Owner:NANOMIST SYST

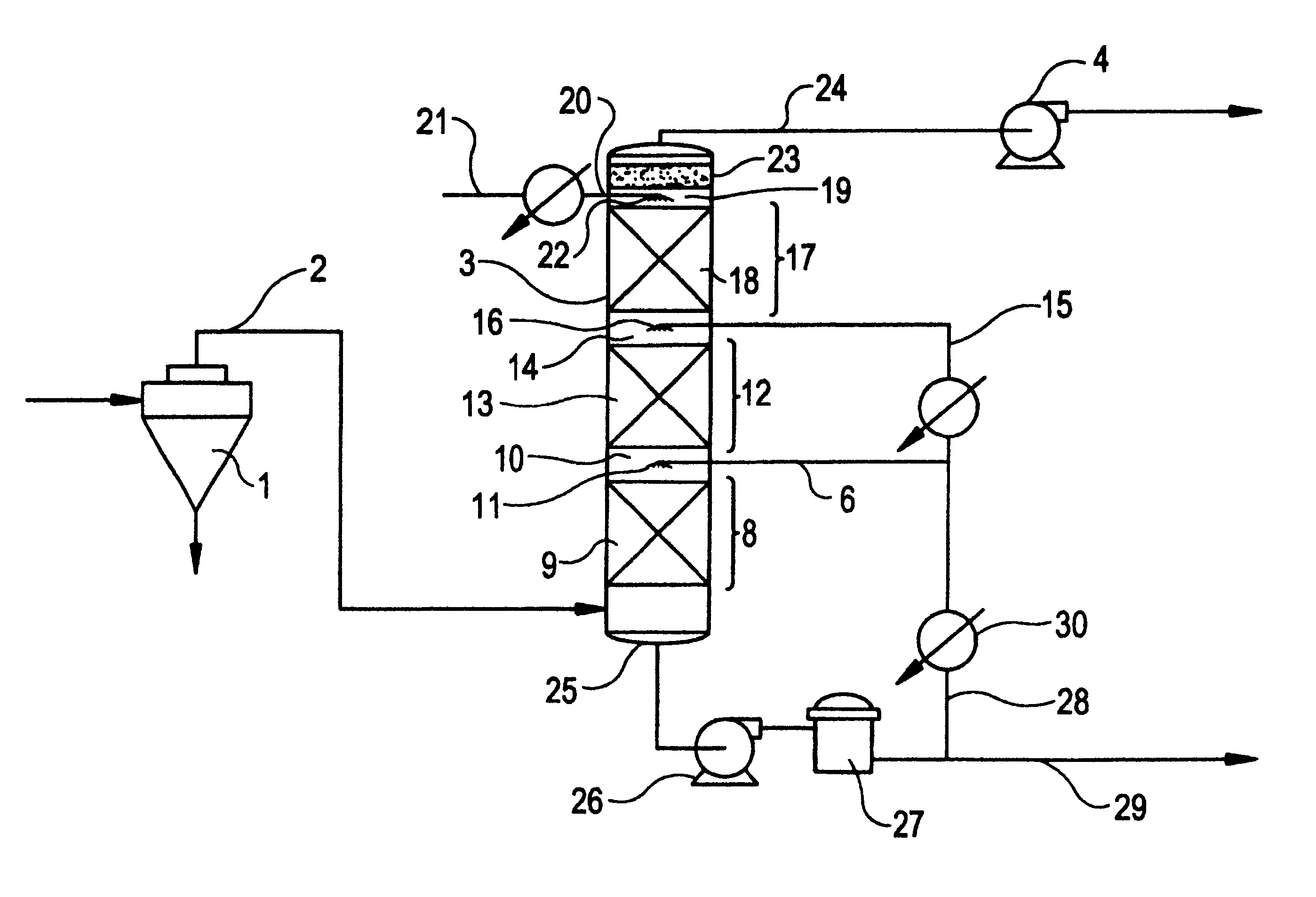

System to quench gasses and remove condensables

A method and apparatus for quenching and scrubbing a hot gas using a liquid in a single packed column while controlling mist formation. Hot gas is introduced at the bottom of the column and drawn upward countercurrent to the scrubbing liquid. The column has three stages, each packed and fed liquid from above. The first stage is a quench region wherein the gas flow rate, liquid flow rate and liquid temperature are controlled such that the quench rate does not exceed 5.4° C. / ft2 of packing to prevent formation of an aerosol mist. The second and third stages for scrubbing employ packed regions separately supplied with increasingly cooler and purer liquid.

Owner:INVISTA NORTH AMERICA R L

Downdraft nebulizer

A pneumatic nebulizer for the delivery of medications that produces aerosol mist in a downward direction. A gas inlet introduces a high velocity gas that passes through a venturi orifice producing a venture effect. A liquid stored in a reservoir is drawn into the orifice, atomizing forming droplets. The droplets are further atomized by hitting a baffle. The mist formed substantially circumscribes the baffle.

Owner:BABYS BREATH LTD

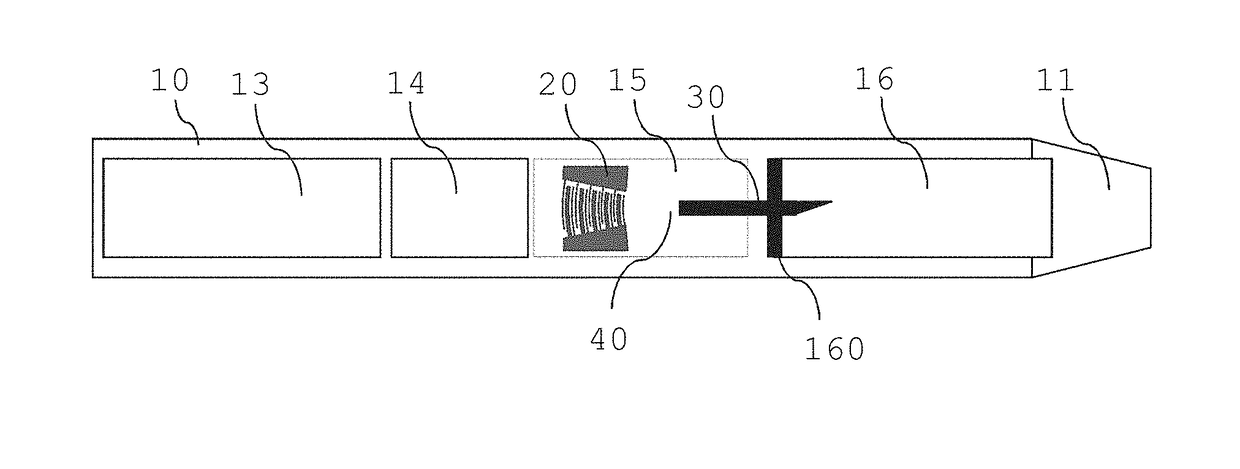

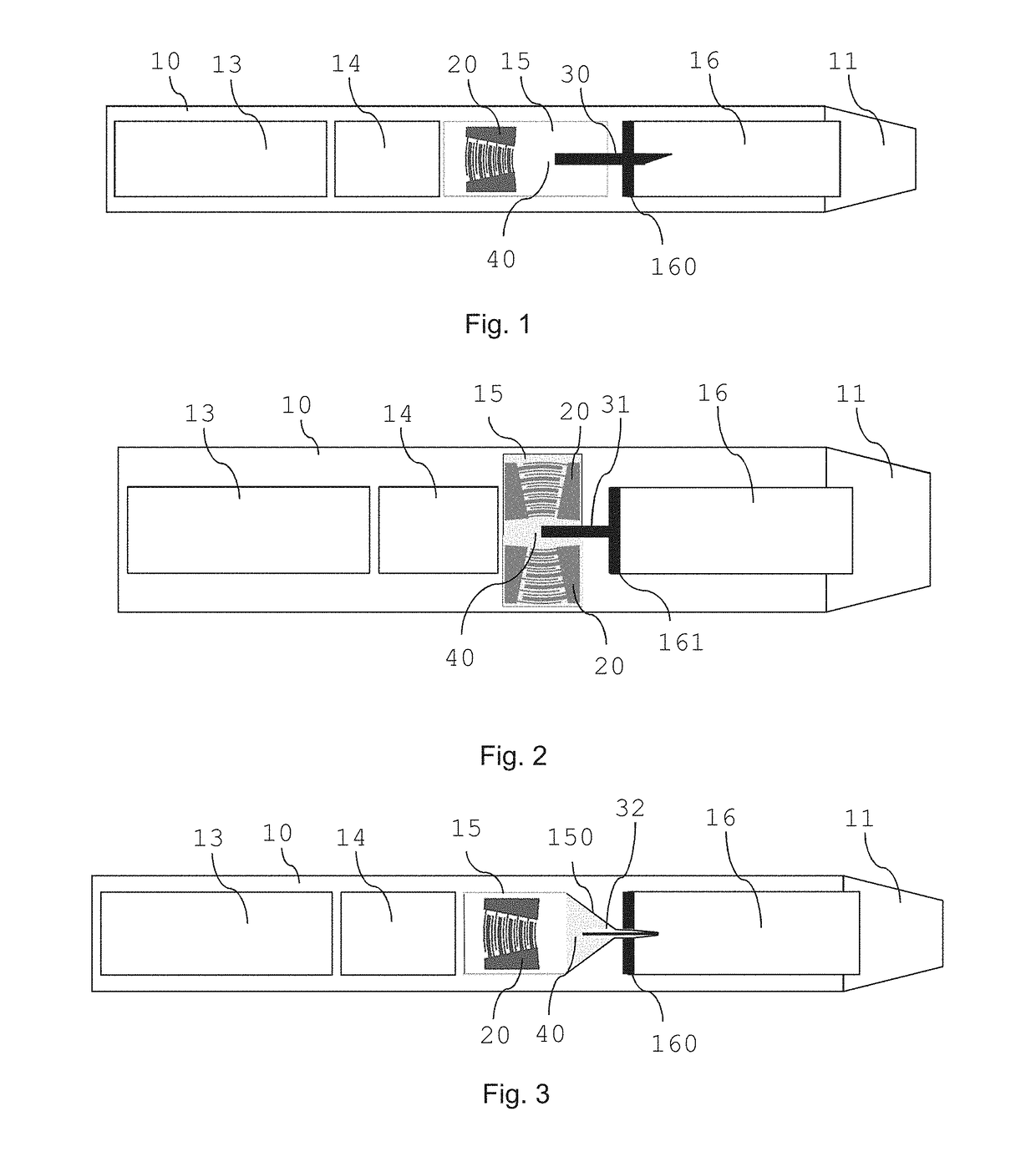

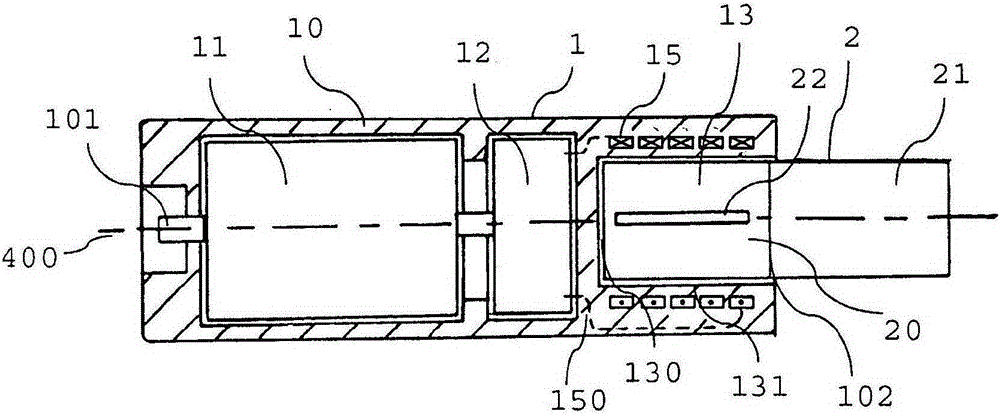

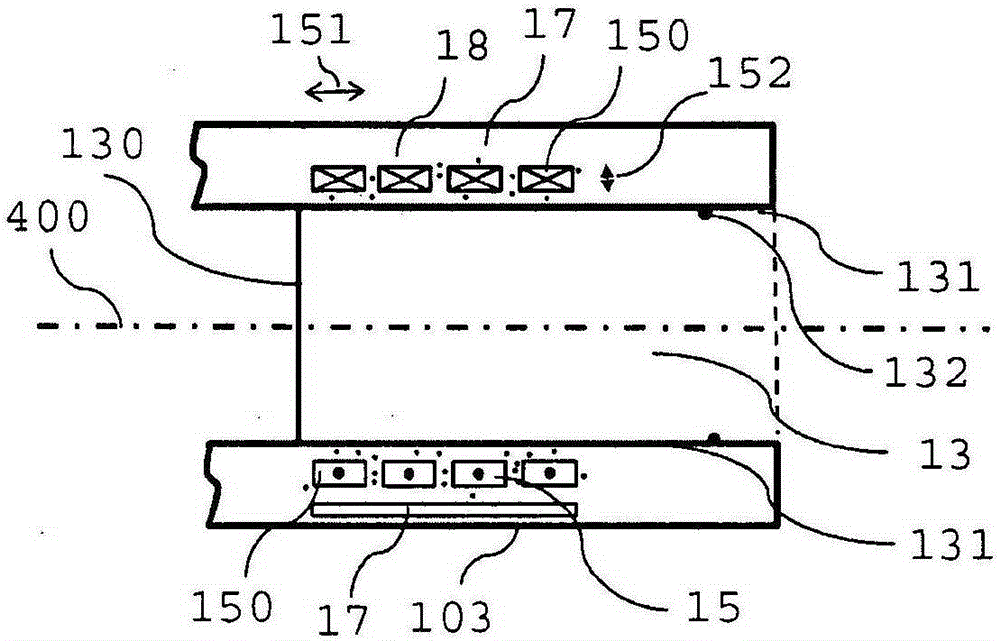

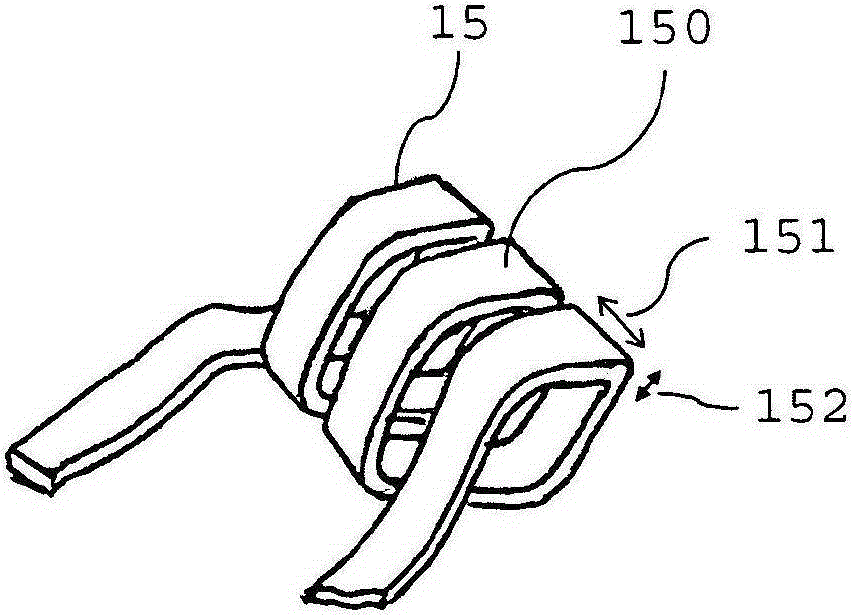

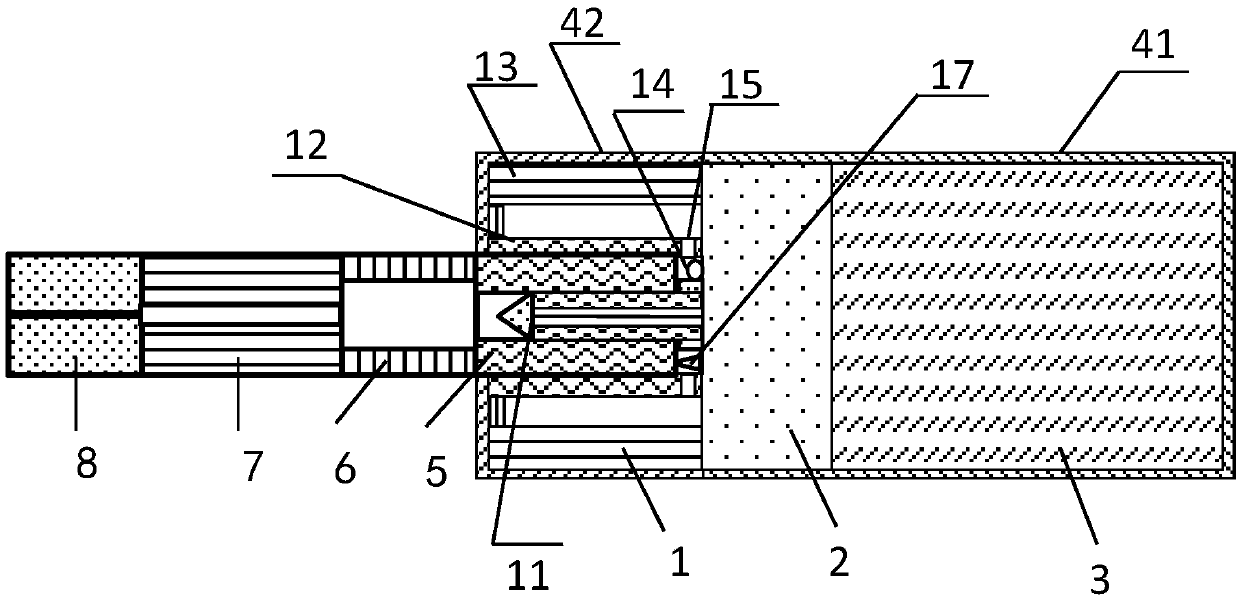

Inductive heating device and system for aerosol generation

The inductive heating device (1) for aerosol-generation comprises a device housing comprising a cavity (13) having an internal surface for receiving at least a portion of an aerosol-forming insert (2) comprising an aerosol-forming substrate and a susceptor. The device housing further comprises an induction coil (15) having a magnetic axis, the induction coil (15) being arranged such as to surround at least a portion of the cavity (13). The device (1) yet further comprises a power source (11) connected to the induction coil (15) and configured to provide a high frequency current to the induction coil (15). Therein, a wire material forming the induction coil has a cross-section comprising a main portion, the main portion having a longitudinal extension in a direction of the magnetic axis and a lateral extension perpendicular to the magnetic axis, which longitudinal extension is longer than the lateral extension of the main portion.

Owner:PHILIP MORRIS PROD SA

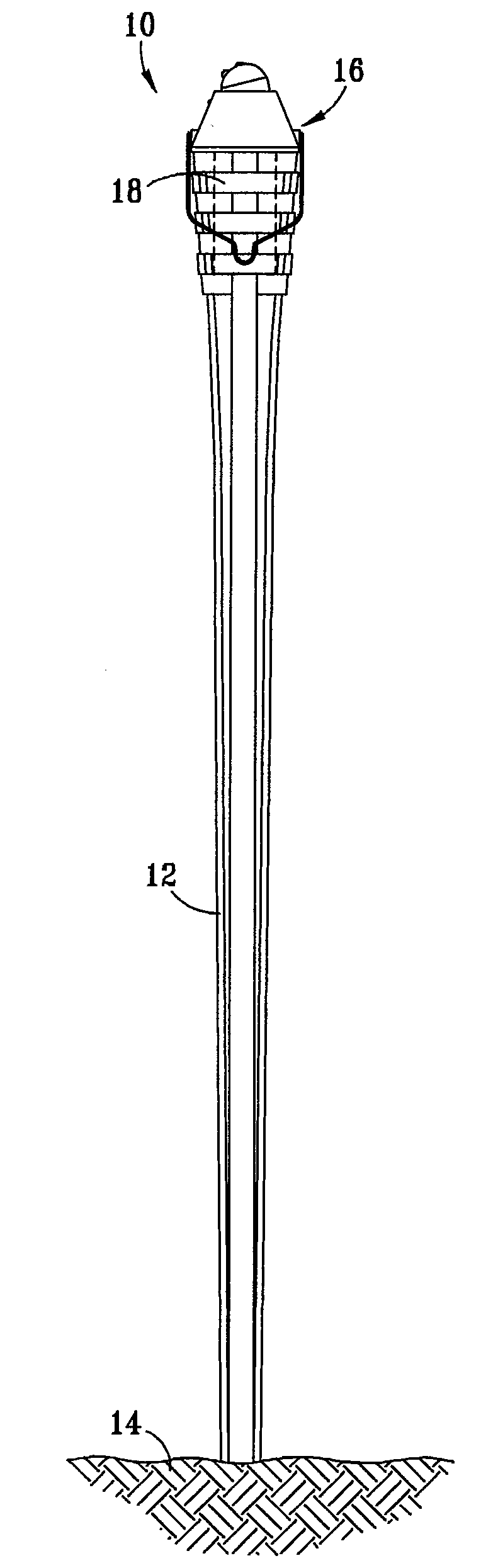

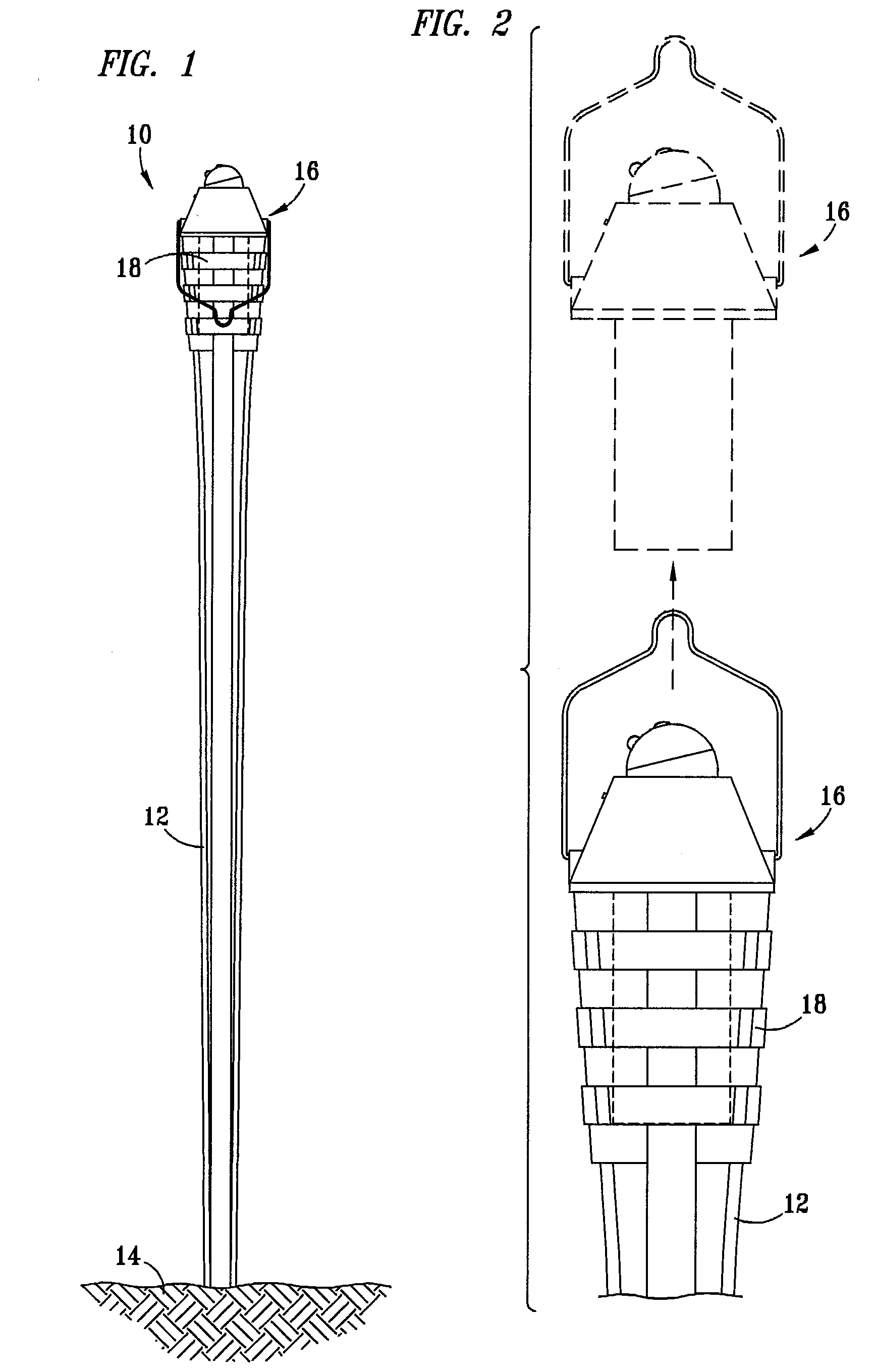

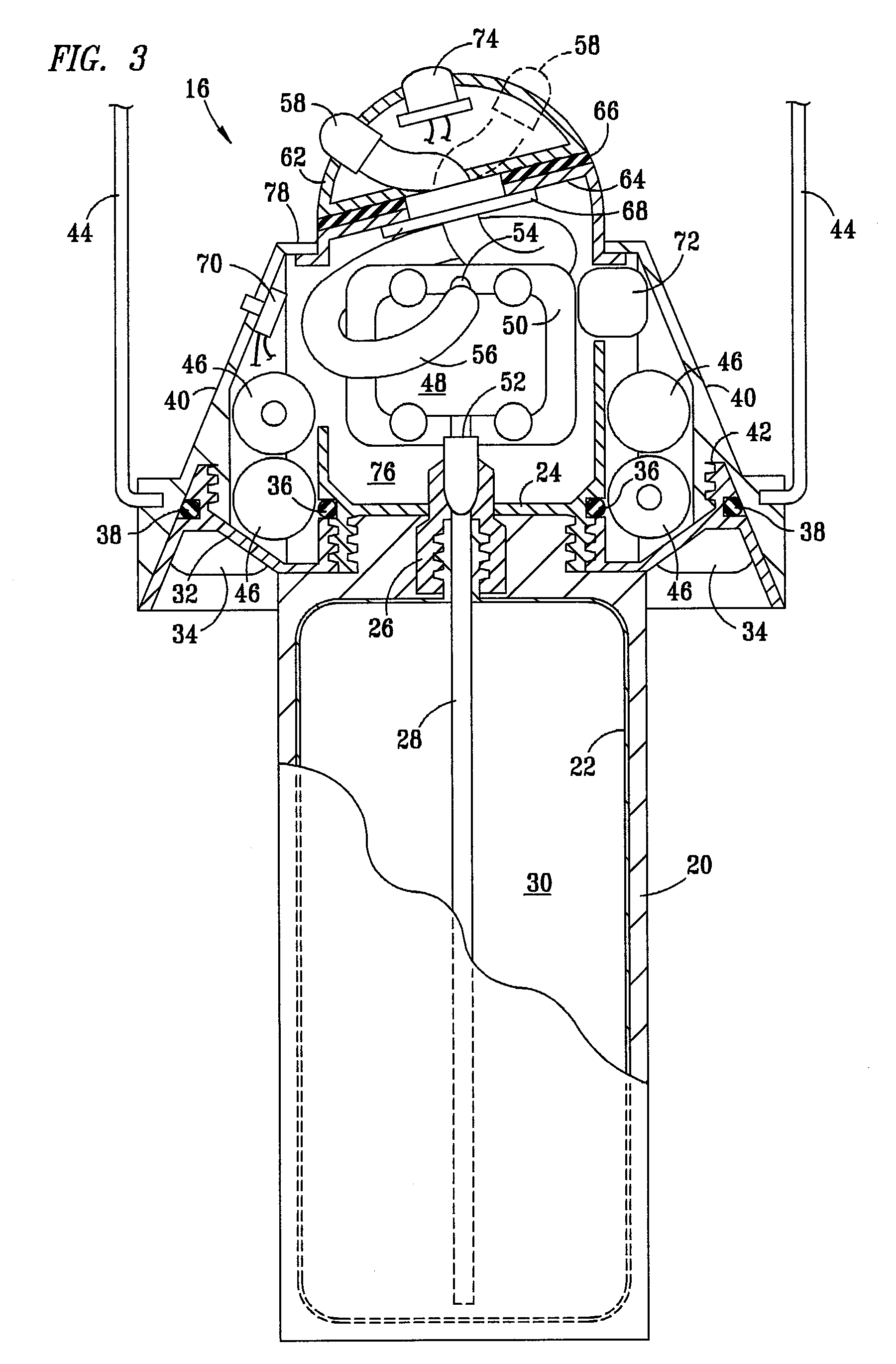

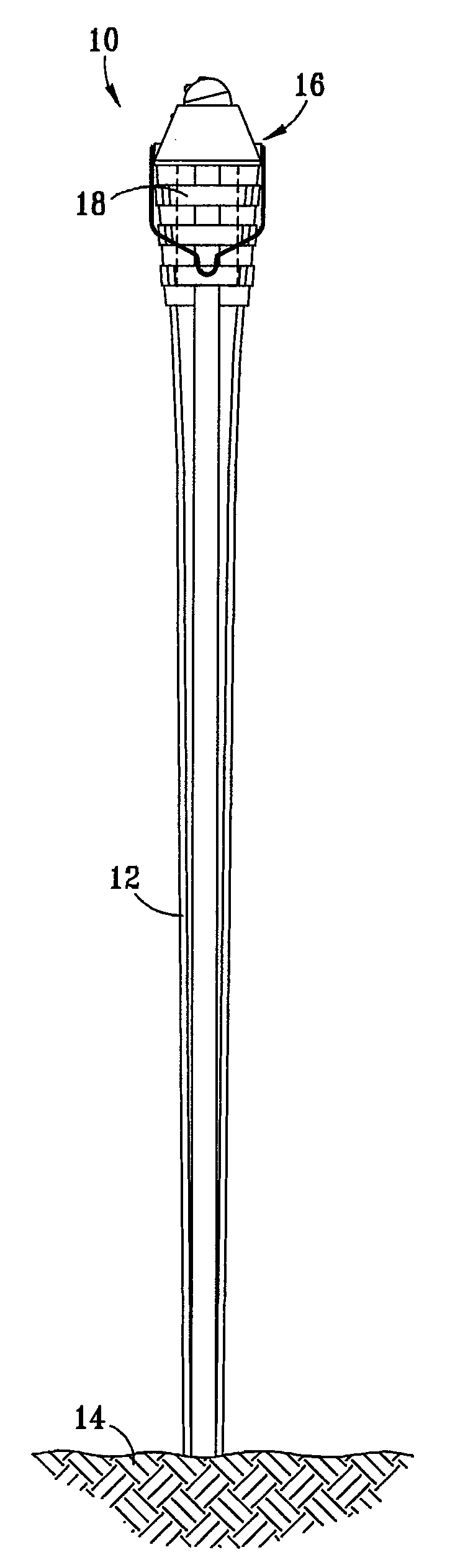

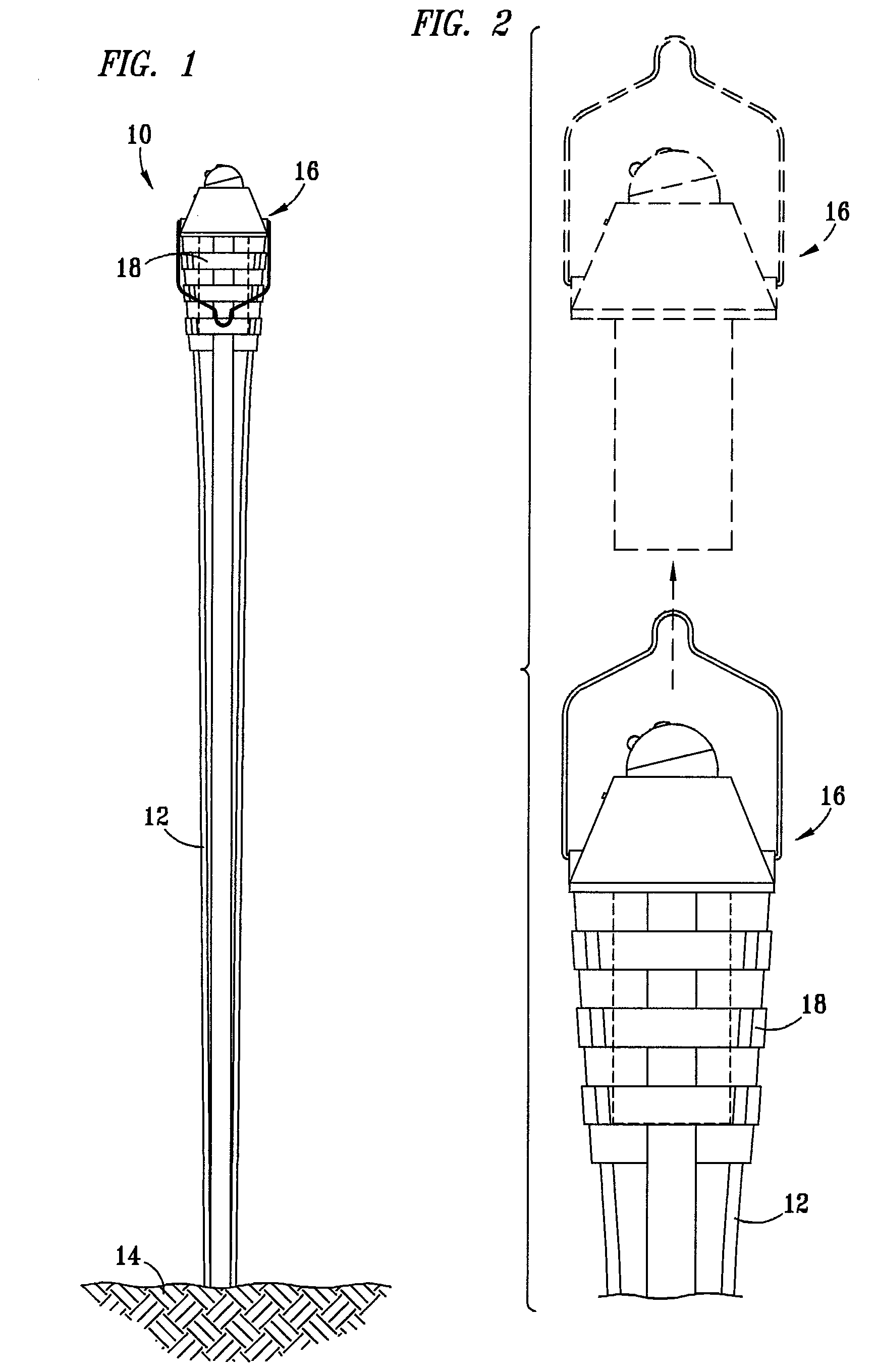

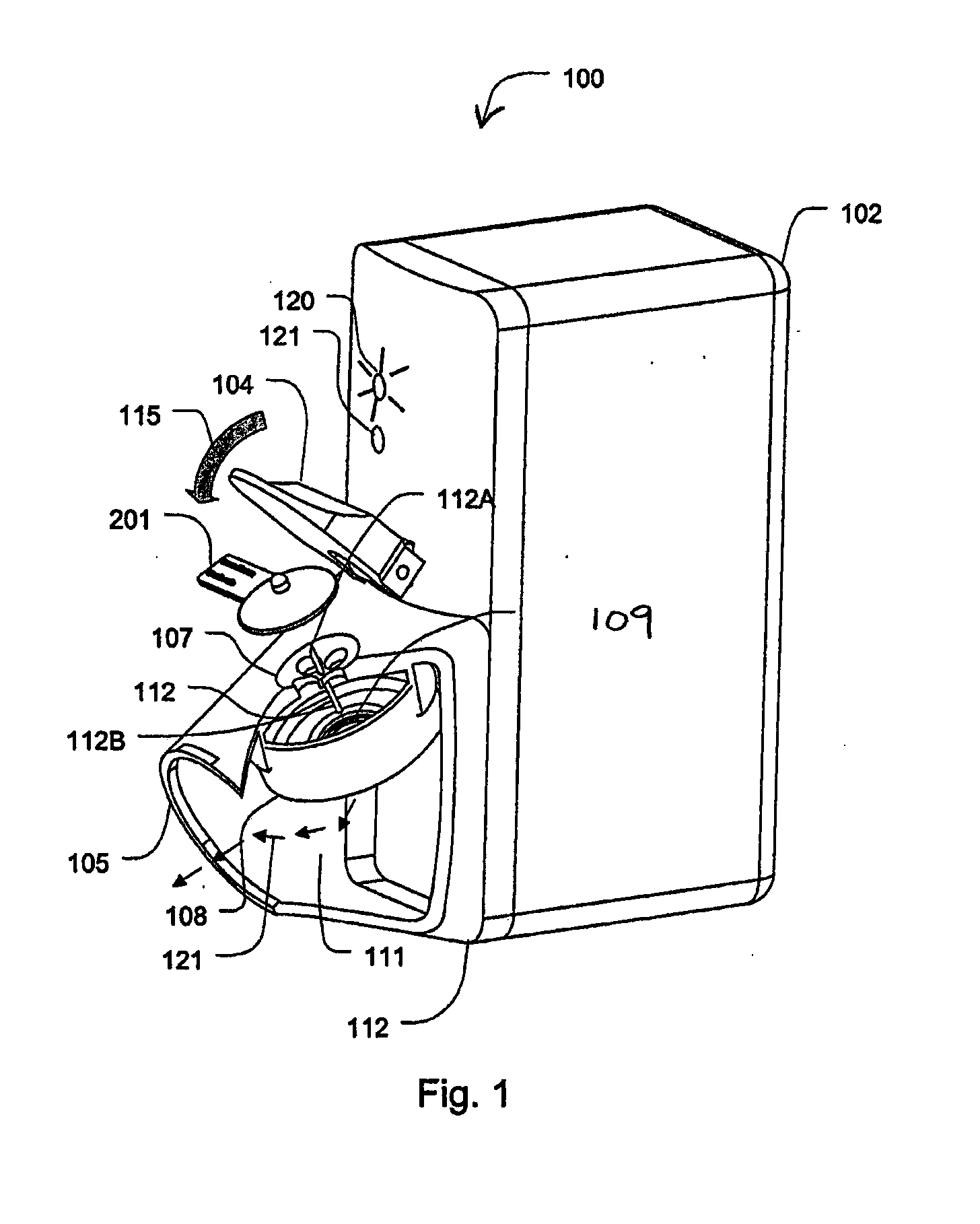

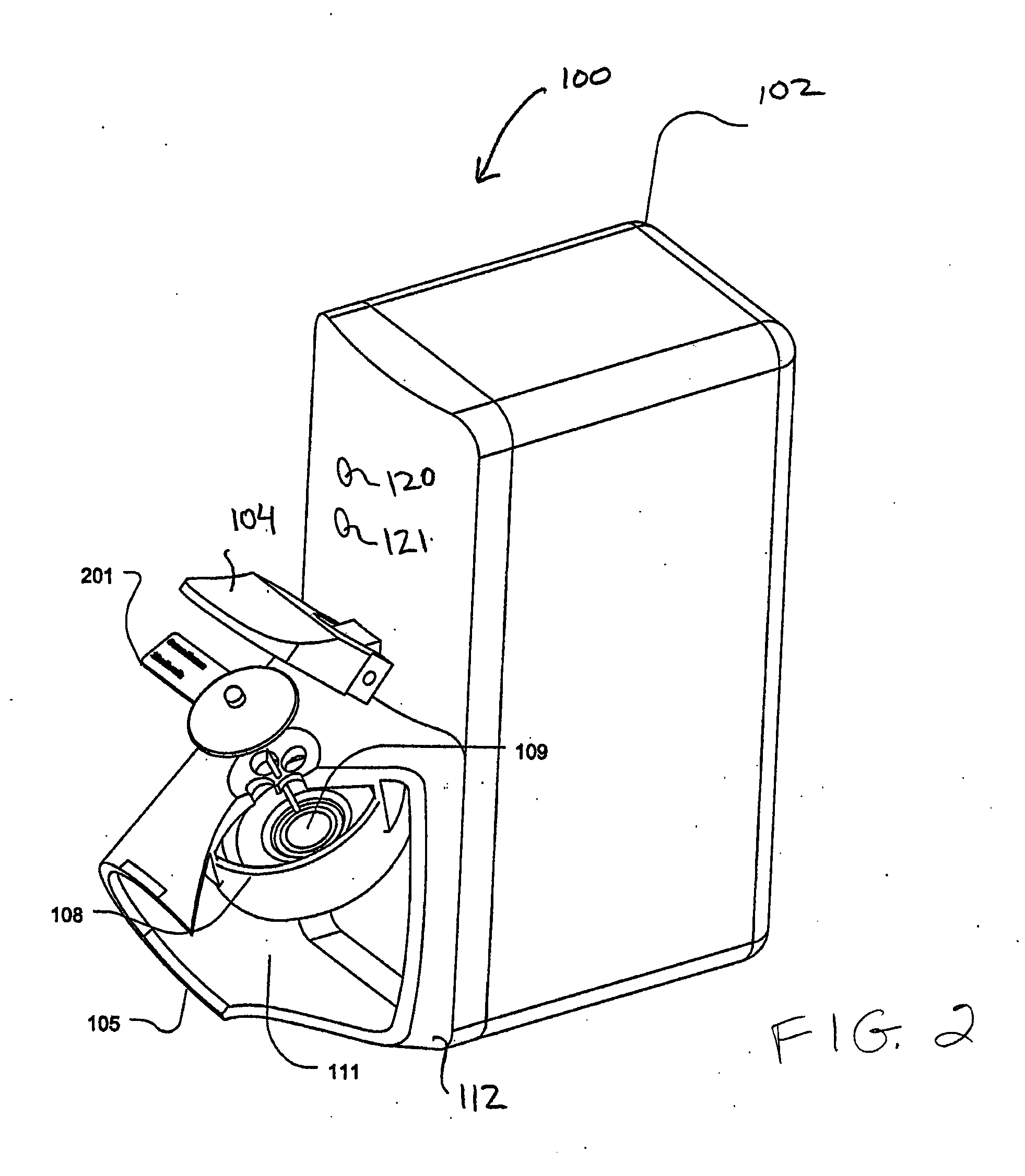

Light-Activated Portable Aerosol Mist Sprayer Device

ActiveUS20080210772A1Easily and effectively and reliably usedReduce the amount requiredSelf-acting watering devicesSpray nozzlesSprayerAerosol Mist

A portable, light-activated, mist sprayer system comprising direct current power supply, an ambient light sensor, electronic circuitry that evaluates an electrical signal received from the light sensor to determine whether a “dusk” or “dawn” light condition exists; a container of treating fluid at a desired concentration; a motor and pump that are activated at the appropriate time as determined by the sensed light condition; at least one sprayer nozzle that will dispense a mist containing the treating fluid whenever the pump is operating; and a timer that turns off the pump after a preset interval to terminate the spraying cycle. A preferred utility for the system of the invention is spraying dilute solutions of insecticide or insect repellent during the periods of significant insect activity that typically occur around dusk and dawn. An RF receiving unit is also disclosed for optional activation using a remote transmitter.

Owner:OUTDOOR SOLUTIONS

Method for Esophageal Drug Delivery

To deliver a medication and its active ingredients to the esophagus, a nasal irrigator, which is capable of delivering medicated fluid that coats the whole nasal and paranasal sinus cavities, is used. The nasal irrigator forces an aerosol mist of the medicated fluid into the nasal cavity above the inferior turbinate, independent of a user's breathing in. Mucociliary clearance from the nasal cavity then delivers the medication to the throat and it is then topically introduced onto the esophagus over an extended period of time.

Owner:MONAGHAN MEDICAL

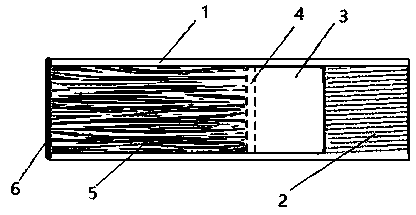

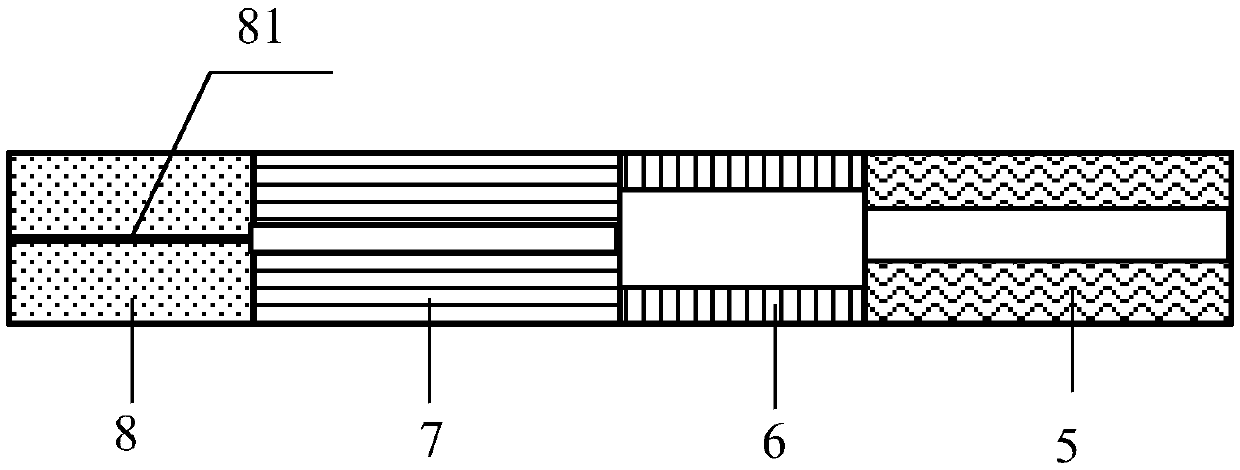

Preparation method of hollow tube filling type heating non-combustible fuming product with sealing film and application

InactiveCN109512022ASimplify the manufacturing processReduce turnoverCigar manufactureTobacco devicesEngineeringFog

The invention provides a preparation method of a hollow tube filling type heating non-combustible fuming product with a sealing film and application. The hollow tube filling type heating non-combustible fuming product with the sealing film is composed of a circular hollow tube, a filter section, a supporting section, an obstruction piece, a fuming section and the sealing film, wherein the circularhollow tube is filled with the filter section, the supporting section, the obstruction piece, the fuming section and the sealing film which are sequentially connected, and the method comprises the steps that the sealing film torn by an easily-heated piece or needle is used for sealing one end of the circular hollow tube at first, then, the circular hollow tube is filled with the fuming section, and then filled with the obstruction piece axially provided with a plurality of through holes, a cavity is reserved behind the obstruction piece as the supporting section, the supporting section is filled with the filter section for sealing, and the fuming product is prepared. The sealing film torn by the easily-heated piece or needle is adopted for being inserted into the fuming section of the fuming product for heating to generate aerial fog, and a consumer sucks heated aerial fog at the near-lip filter section.

Owner:陈征

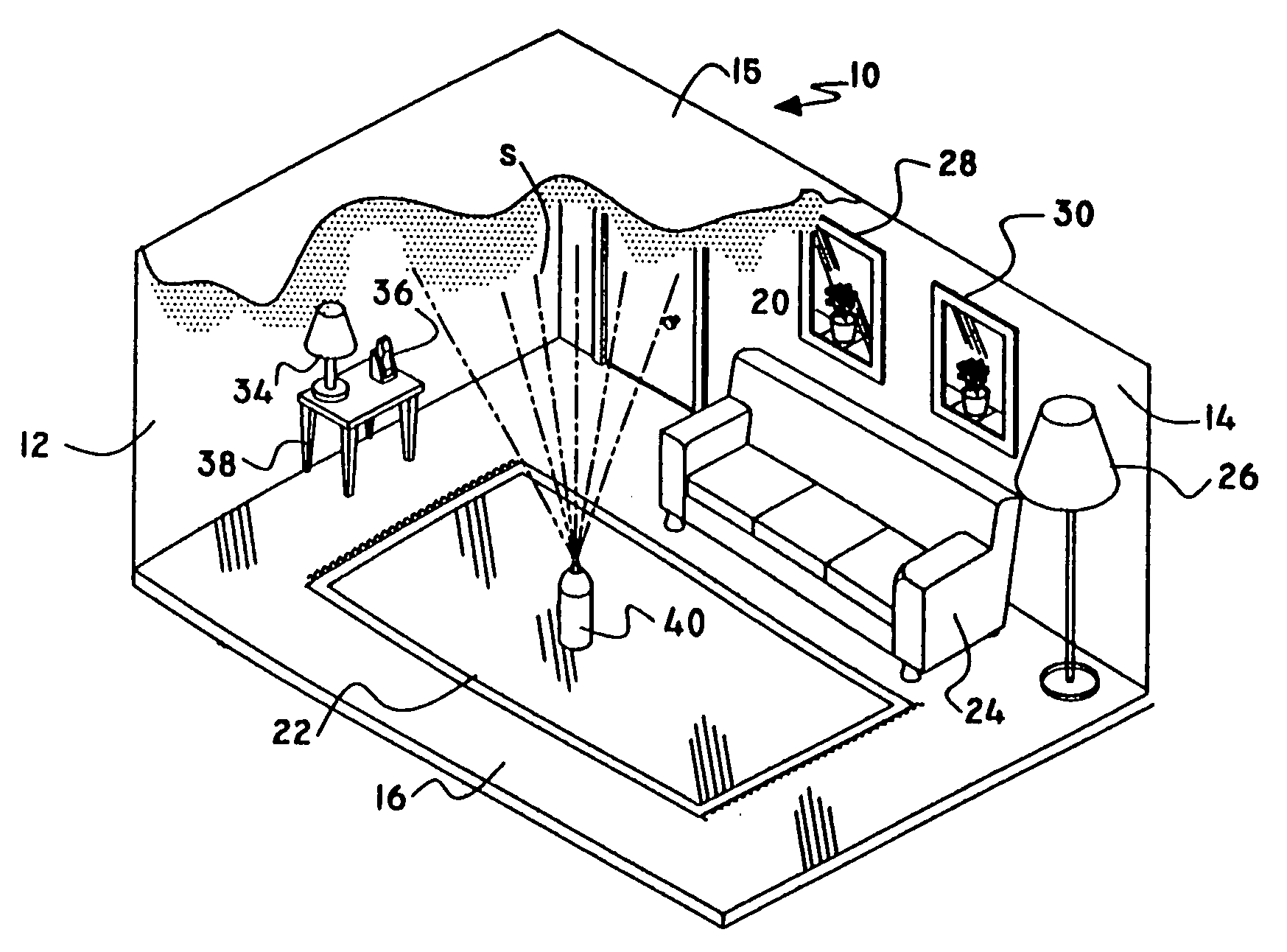

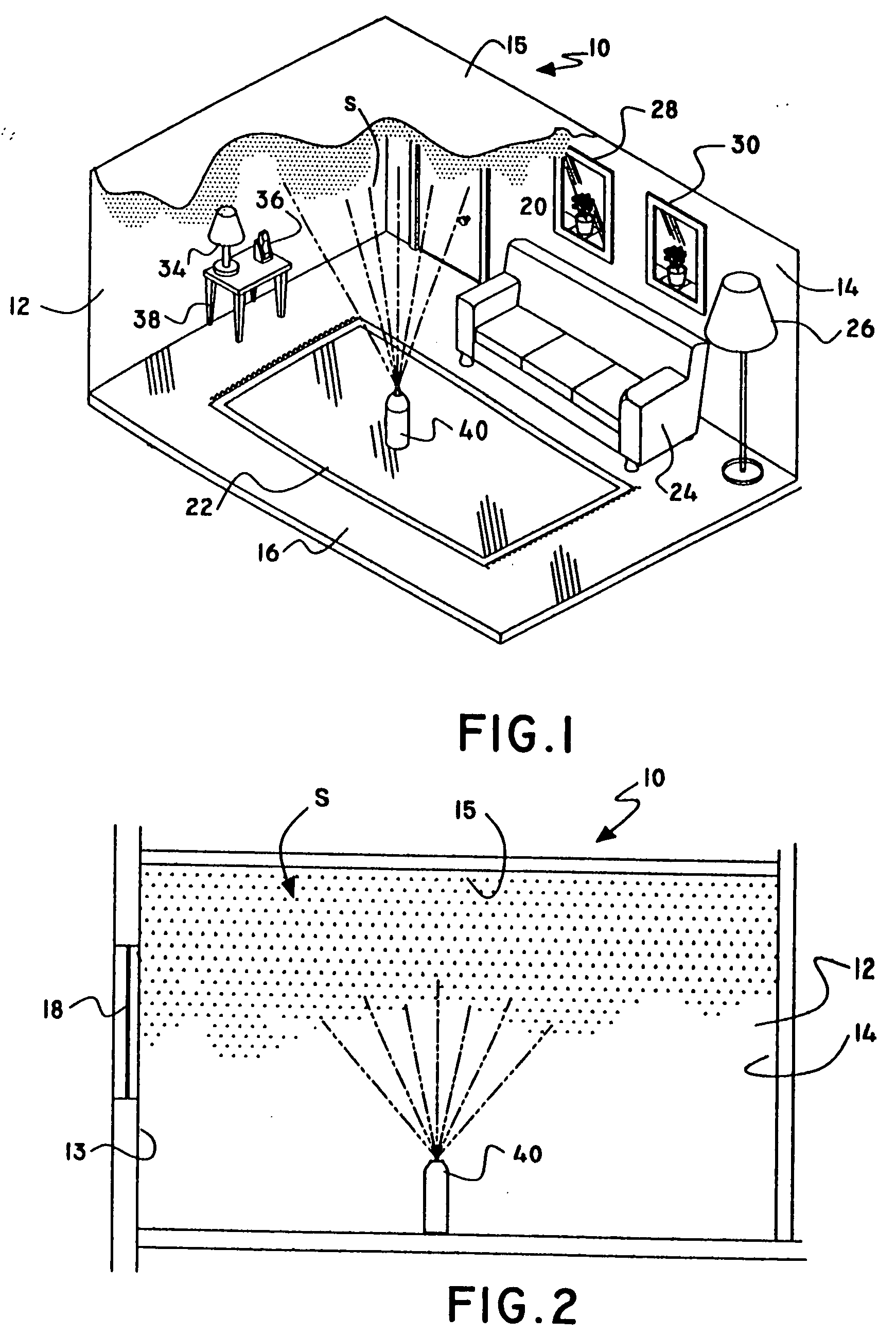

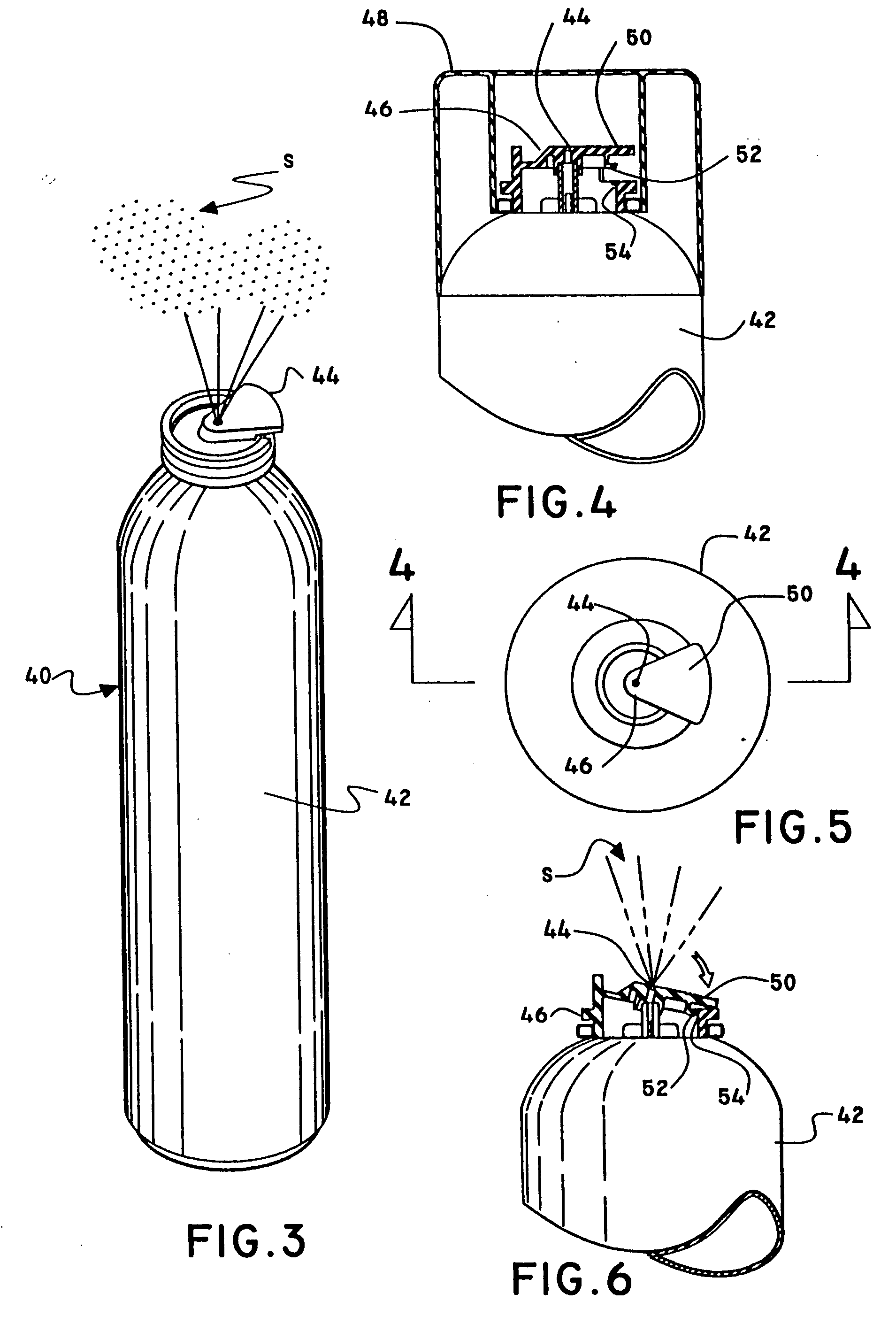

Room sanitizing method and apparatus

InactiveUS20050112022A1Easily and quickly sanitized and disinfectedReduce riskBiocideLavatory sanitoryAerosol MistDisinfection methods

An aerosol canister containing sanitizing liquid and propellant is provided to sanitize exposed surfaces in a room in a short period of time. The canister is placed in a closed room and its dispensing valve is actuated to dispense the sanitizing liquid in an aerosol mist of droplets which expand to fill the room in mere minutes. The canister can include a weighted rounded base to enable the canister to be tossed into the room and assume an upright dispensing position. The base can be filled with weighting material just before use. One embodiment can be rolled into the room.

Owner:MORGAN DAVID M

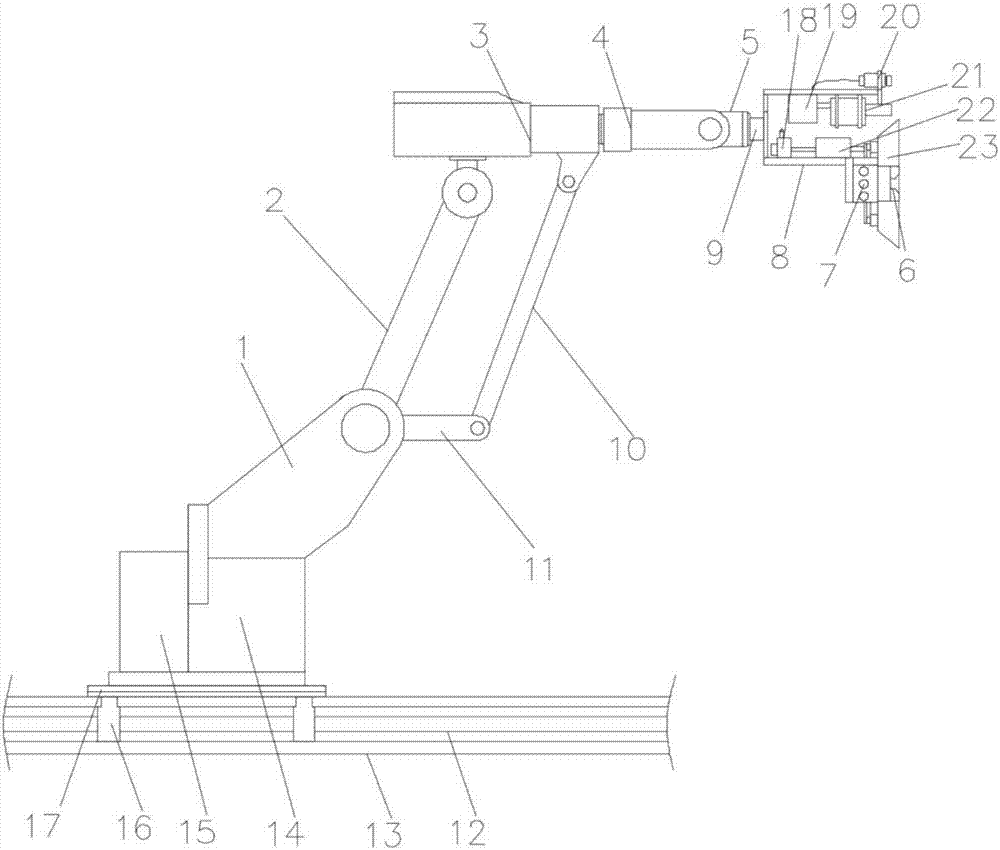

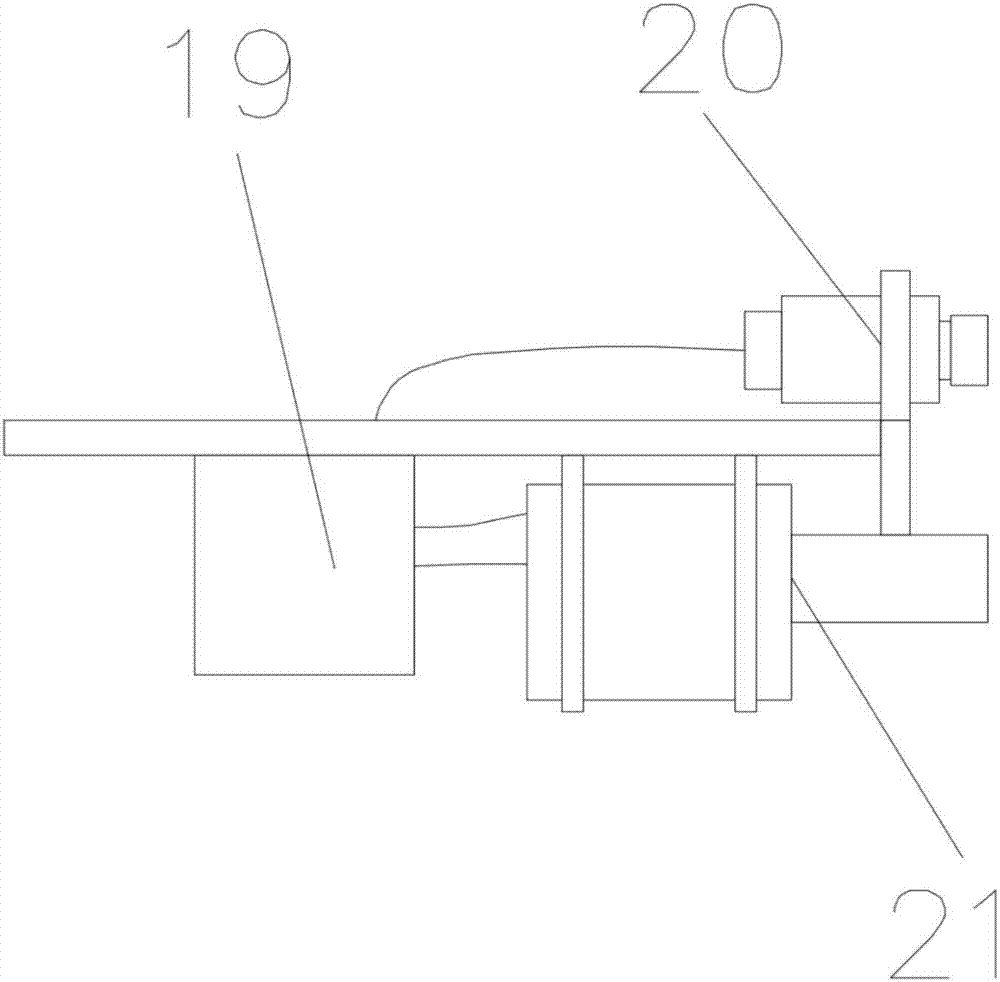

Multifunctional spraying robot

PendingCN107321523ATimely recyclingStable structureLiquid spraying apparatusManipulatorAspiratorAerosol Mist

The invention discloses a multifunctional spraying robot. The multifunctional spraying robot comprises a bottom plate which is arranged on a slide base, wherein a threaded slide block which is fixedly connected with the bottom plate is arranged in the slide base; the threaded slide block is connected on a threaded rod; a fixed mechanical arm is arranged at the inclined upper side of a base; the fixed mechanical arm is hinged with a movable mechanical arm; the movable mechanical arm is hinged with a first rotary mechanical arm; the fixed mechanical arm is hinged with an auxiliary small arm; the auxiliary small arm is hinged with a second auxiliary small arm; the second auxiliary small arm is hinged with the first rotary mechanical arm; the front end of the first rotary mechanical arm is rotatably connected with a rotary mechanical arm; the front end of the rotary mechanical arm is hinged with a second rotary mechanical arm; the second rotary mechanical arm is connected with a spraying bracket through a rotary table; the front end of the spraying bracket is connected with a spray head; the front end of the spraying bracket is equipped with an infrared ray scanner and a camera; a gas collecting cover is connected with an aerosol recycling tank; the aerosol recycling tank is connected with a micro aspirator pump; and the camera and the infrared ray scanner are connected with a control module. The multifunctional spraying robot is stable in structure, is stable in operation, and realizes automatic spraying and processing, and free travelling.

Owner:车急修汽车科技有限公司

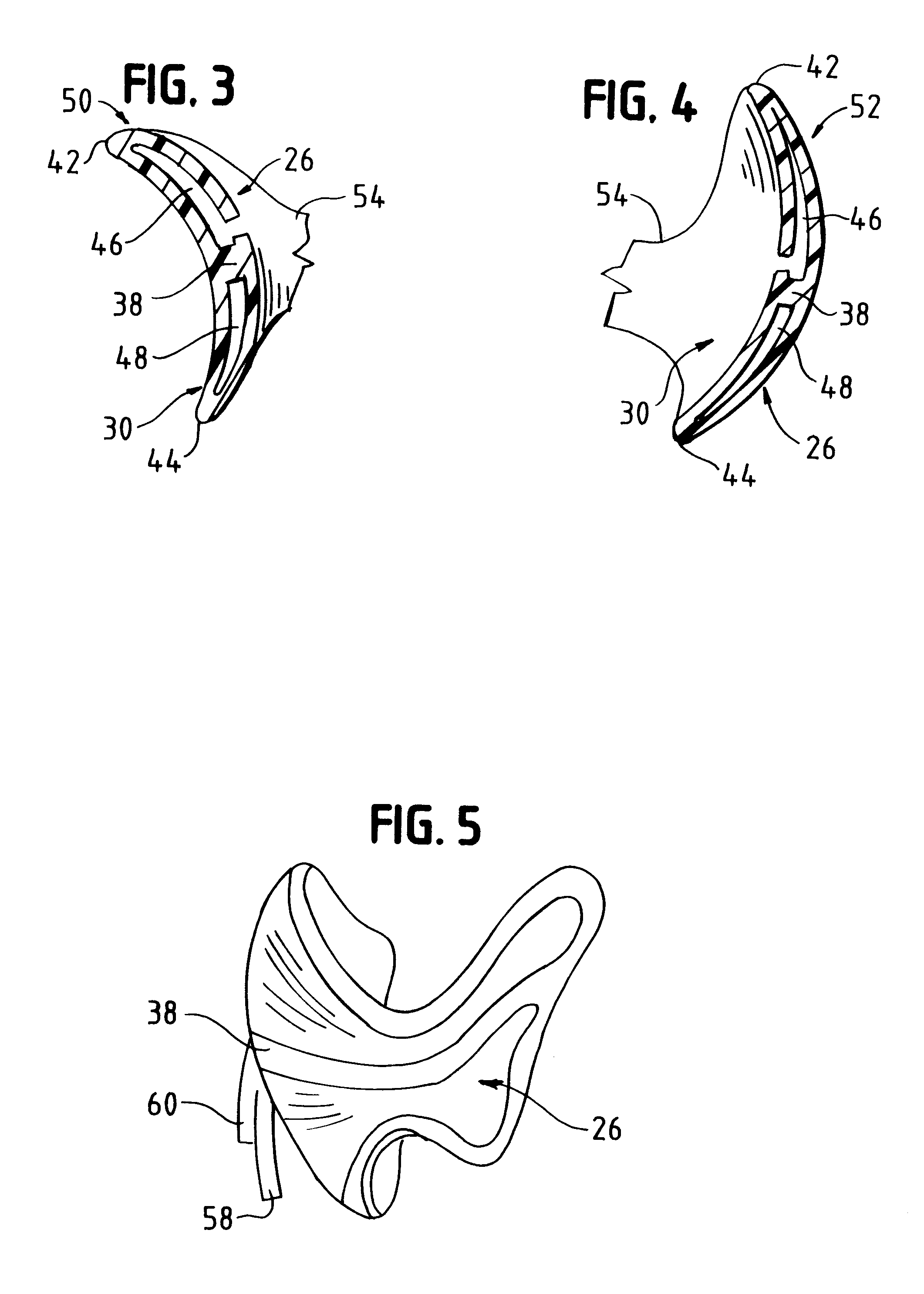

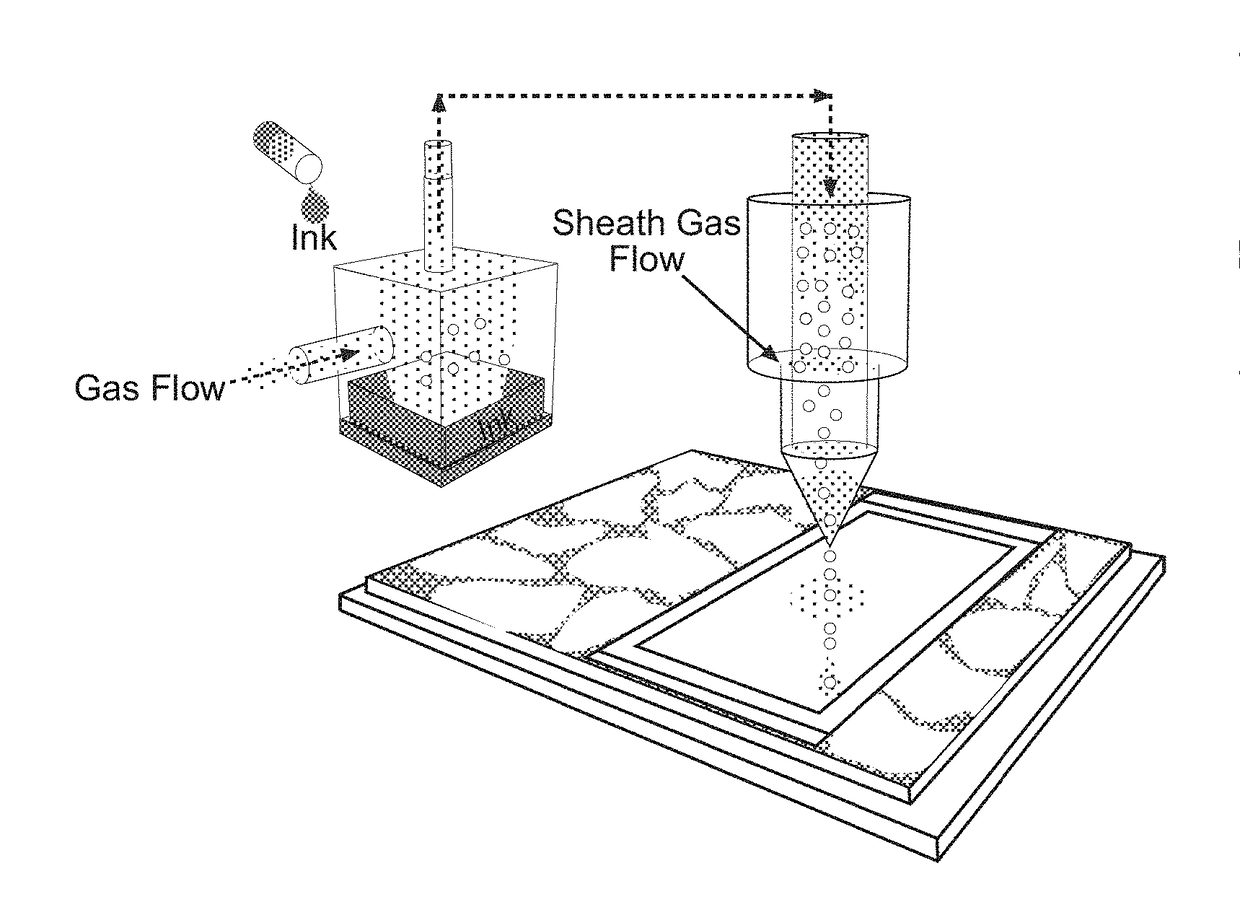

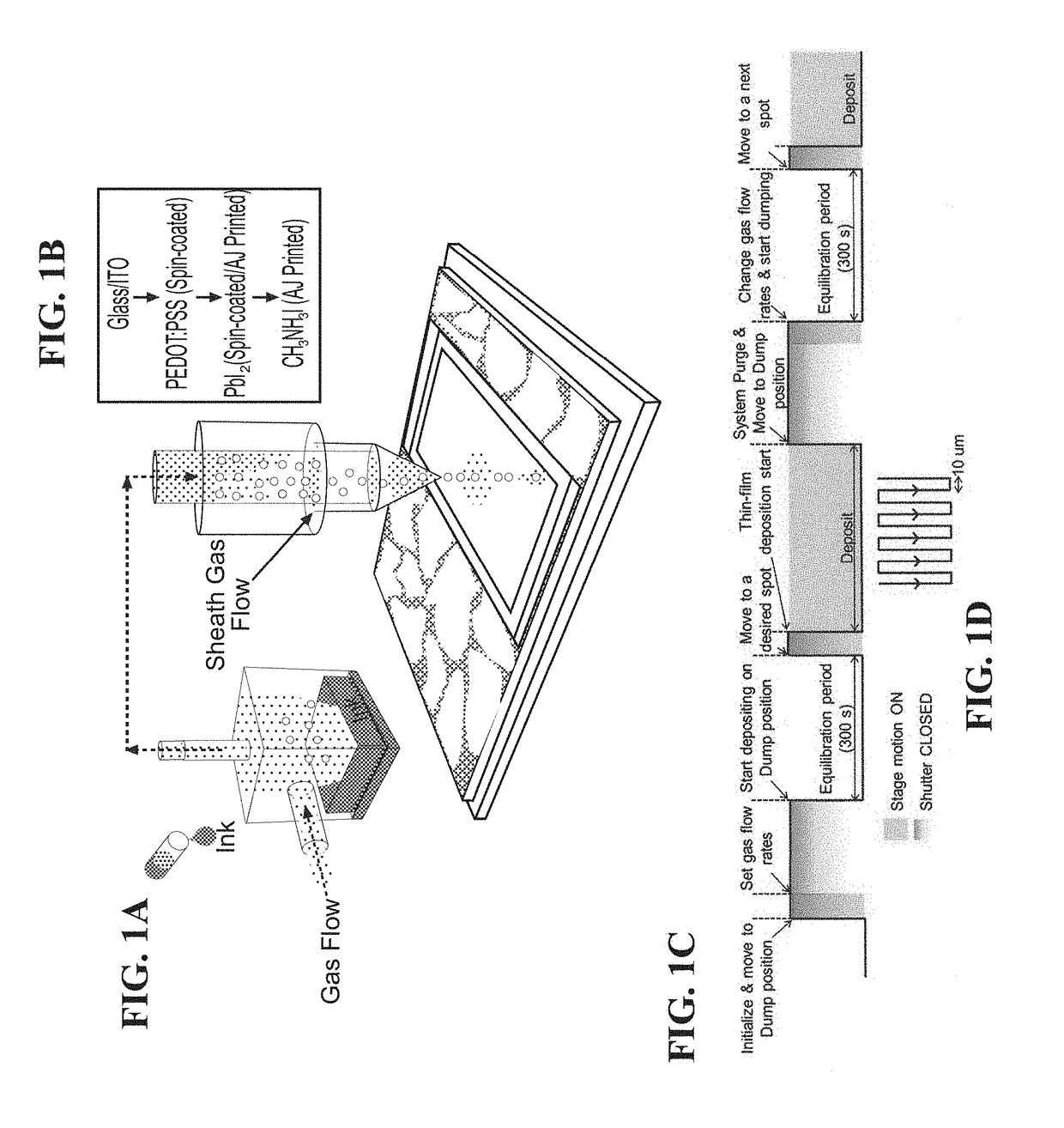

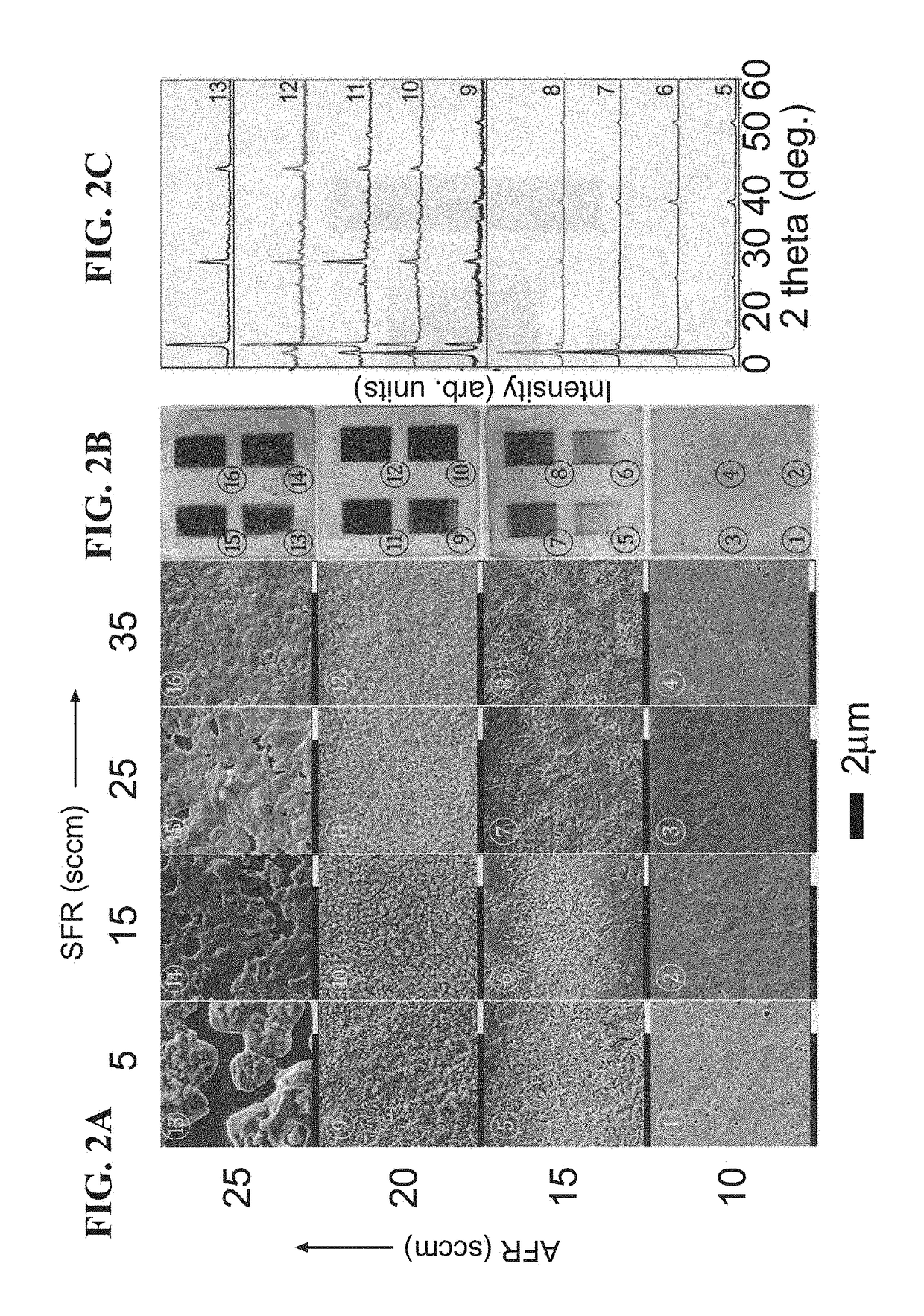

Defect mitigation of thin-film hybrid perovskite and direct writing on a curved surface

ActiveUS20180261394A1Reduce harmSimple materialLight-sensitive devicesFinal product manufactureIodideGas phase

A method for aerosol jet printing a layered perovskite structure comprises applying a PEDOT:PSS layer to a substrate; applying a layer of lead iodide (PbI2) to the PEDOT:PSS layer; and applying an aerosol mist of methylammonium iodide (CH3NH3I) atop the PbI2 layer with an aerosol jet nozzle to form a CH3NH3PbI3 perovskite film layer. The substrate may be an ITO glass substrate, and the PEDOT:PSS layer may be applied by a process selected from spin-coating, inkjet-printing, slot-die-coating, aerosol jet printing, physical vapor deposition, chemical vapor deposition, and electrochemical deposition. The PbI2 layer may be applied by a process selected from spin-coating, aerosol jet printing, inkjet-printing, slot-die-coating, physical vapor deposition, chemical vapor deposition, and electrochemical deposition, and the PbI2 for application to the PEDOT:PSS layer may be in a solution of DMF, DMSO, γ-butyrolactone, or a combination thereof. The annealing of the PbI2 layer may be performed at about 80° C. or lower.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Inhalation apparatus

Owner:HEALTHLINE MEDICAL

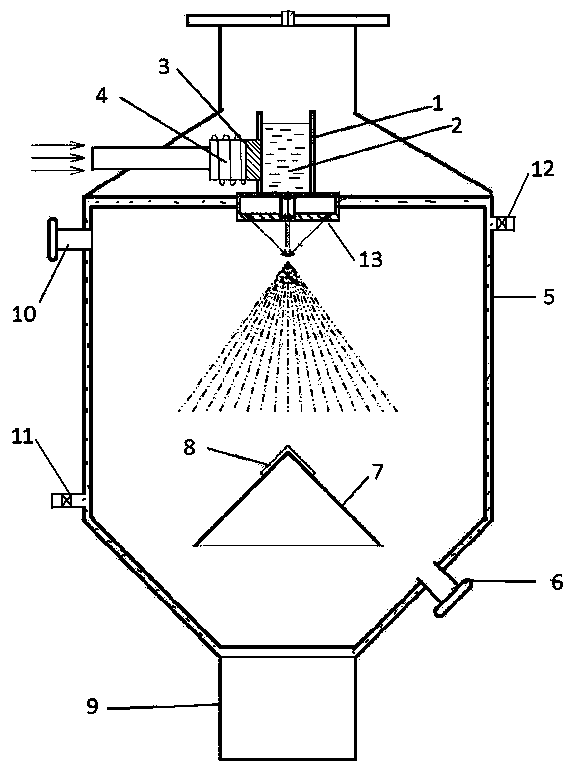

Preparation method and device of ceramic particle reinforced metal matrix composite powder

The invention discloses a preparation method of ceramic particle reinforced metal matrix composite powder. A metal matrix and a ceramic particle reinforced raw material are put in a high-frequency inductive smelting furnace for smelting; ceramic reinforced particles are uniformly distributed in molten metal by an ultrasonic generator; a valve at the bottom of the high-frequency inductive smelting furnace is opened; the molten metal freely drops down; inert gas sprayed out from a high-pressure airflow nozzle crushes the molten metal to form spherical metal droplets; and the spherical metal droplets drop into a powder collecting tank after cooling and solidification. The preparation device comprises the high-frequency inductive smelting furnace and an aerosol can; the high-frequency inductive smelting furnace and the ultrasonic generator are arranged in the top center of the aerosol can; the ultrasonic generator is mounted on the side wall of the high-frequency inductive smelting furnace, and is connected with an amplitude transformer; and the bottom of the aerosol canis connected with the collecting tank. The metal matrix composite powder with uniformly distributed reinforced particles can be obtained by metal aerosol melting and ultrasonic stirring; and the preparation device is simple in operation and low in cost, and can effectively prevent physical damage to the matrix powder or the reinforced particles in the powder preparation process.

Owner:石京

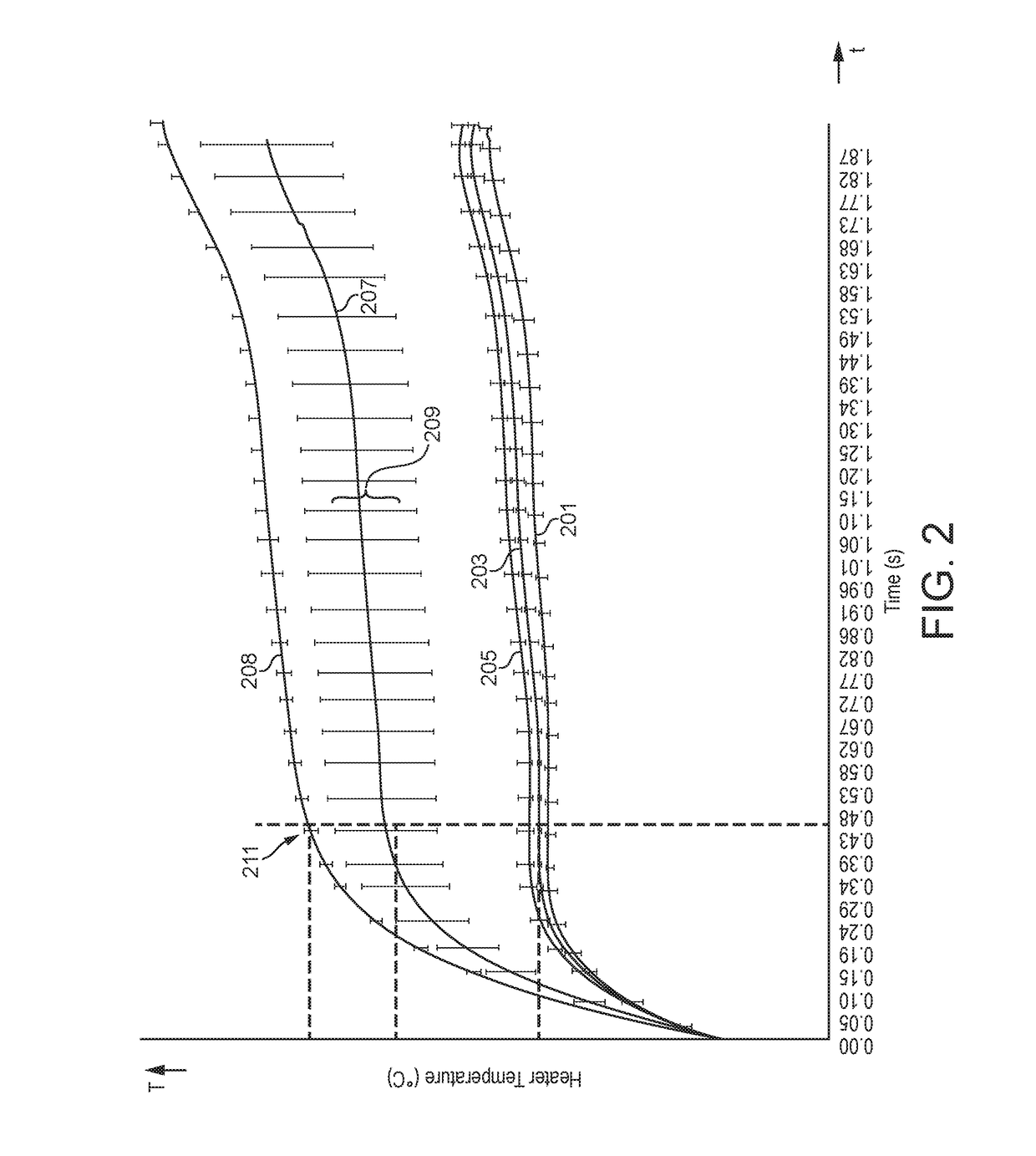

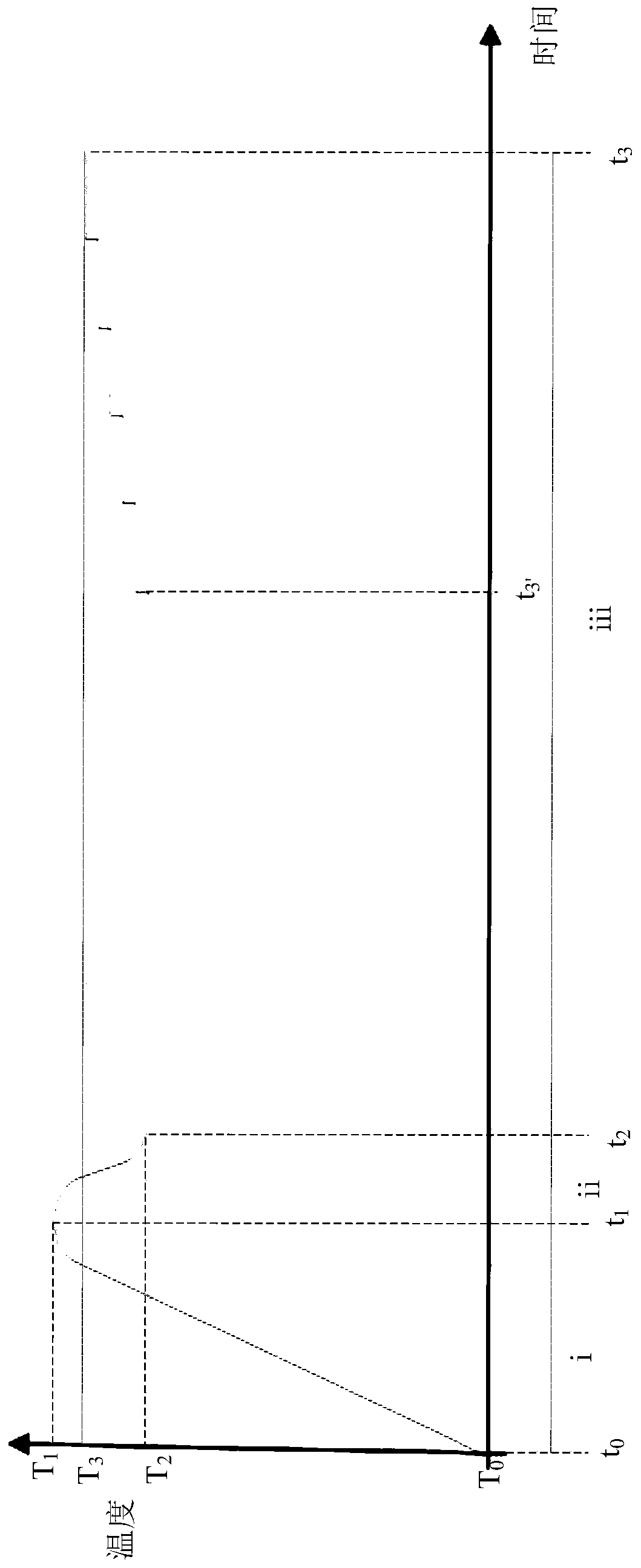

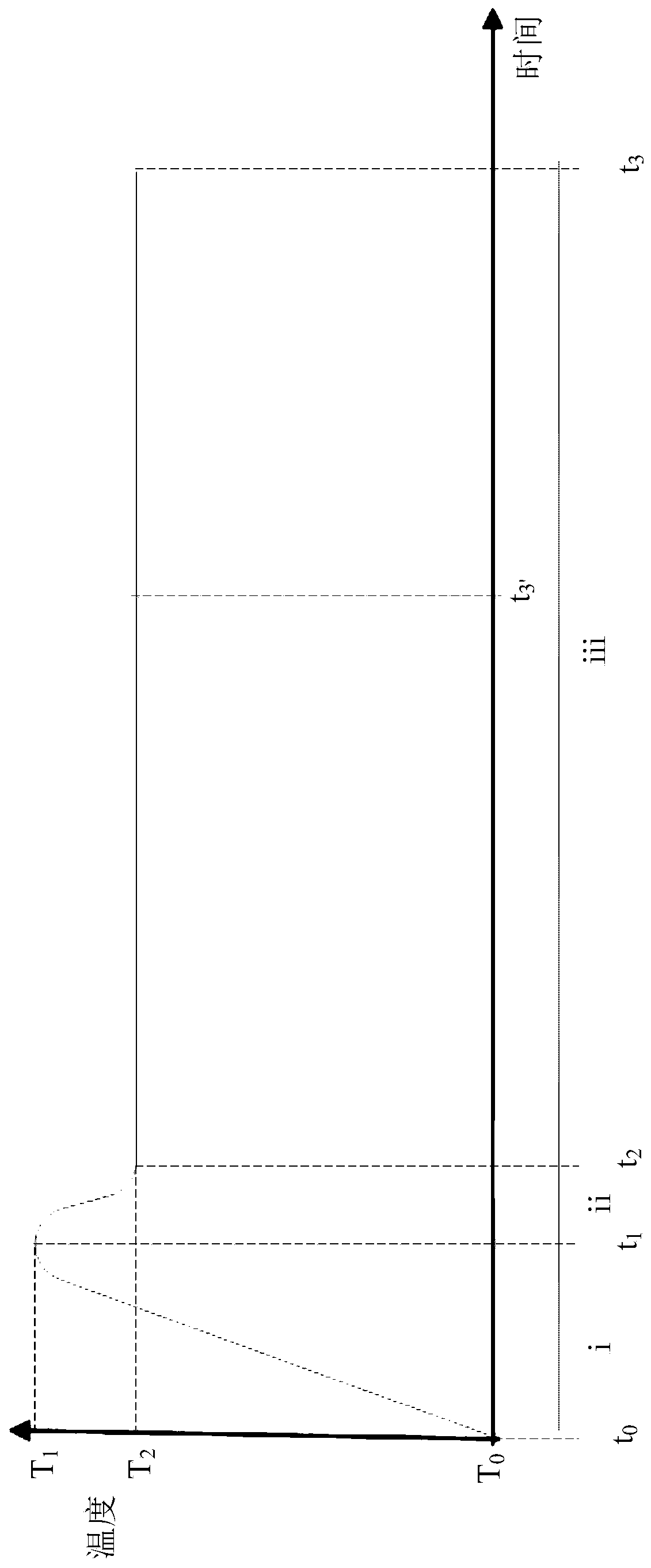

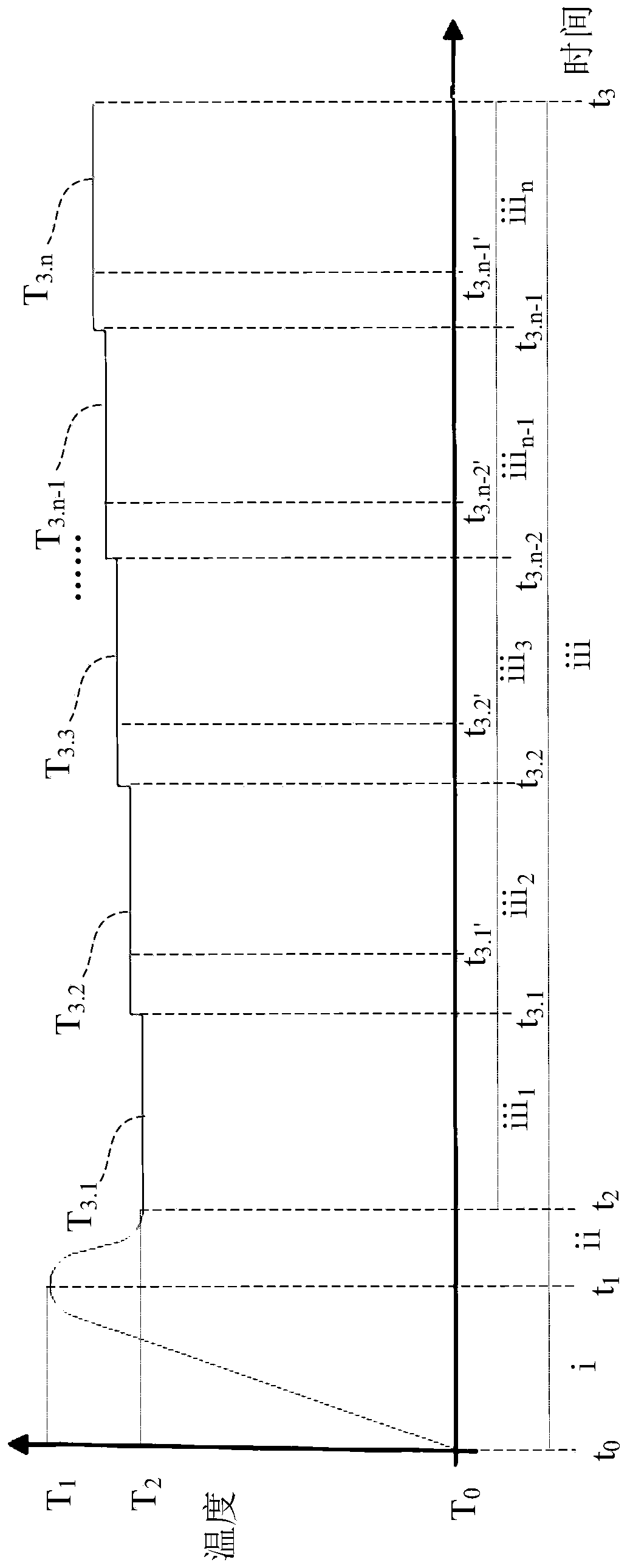

Temperature control method, aerial fog production device and aerial fog production system

ActiveCN110367593AGuaranteed supplyAvoid wastingTobacco devicesTransportation and packagingTemperature controlAerosol Mist

The invention provides a temperature control method applied to an aerial fog production device. The aerial fog production device comprises a detection element and a heating element for heating an aerial fog production base material. The specific temperature control method comprises the steps of in a first stage, controlling the heating element to rise a temperature from an initial temperature to afirst temperature; in a second stage, controlling the heating element to decrease the temperature from the first temperature to a second temperature; and in a third stage, controlling the heating element to carry out constant temperature operation at a second temperature, and controlling the heating element to rise the temperature to a third temperature if the detection element detects suction. The invention also provides the aerial fog production device and an aerial fog production system. Temperature change of the heating element is controlled according to a suction behavior of a consumer;in the third stage, the temperature of the heating element is risen only when the suction is detected; aerial fog supply quantity produced when the consumer sucks is guaranteed to satisfy a requirement all the time; and electric energy and the aerial fog production base material are prevented from being wasted. The temperature control method is relatively intelligent. Suction experience of the consumer is improved.

Owner:SHANGHAI NEW TOBACCO PRODUCTS RESEARCH INSTITUTE CO LTD

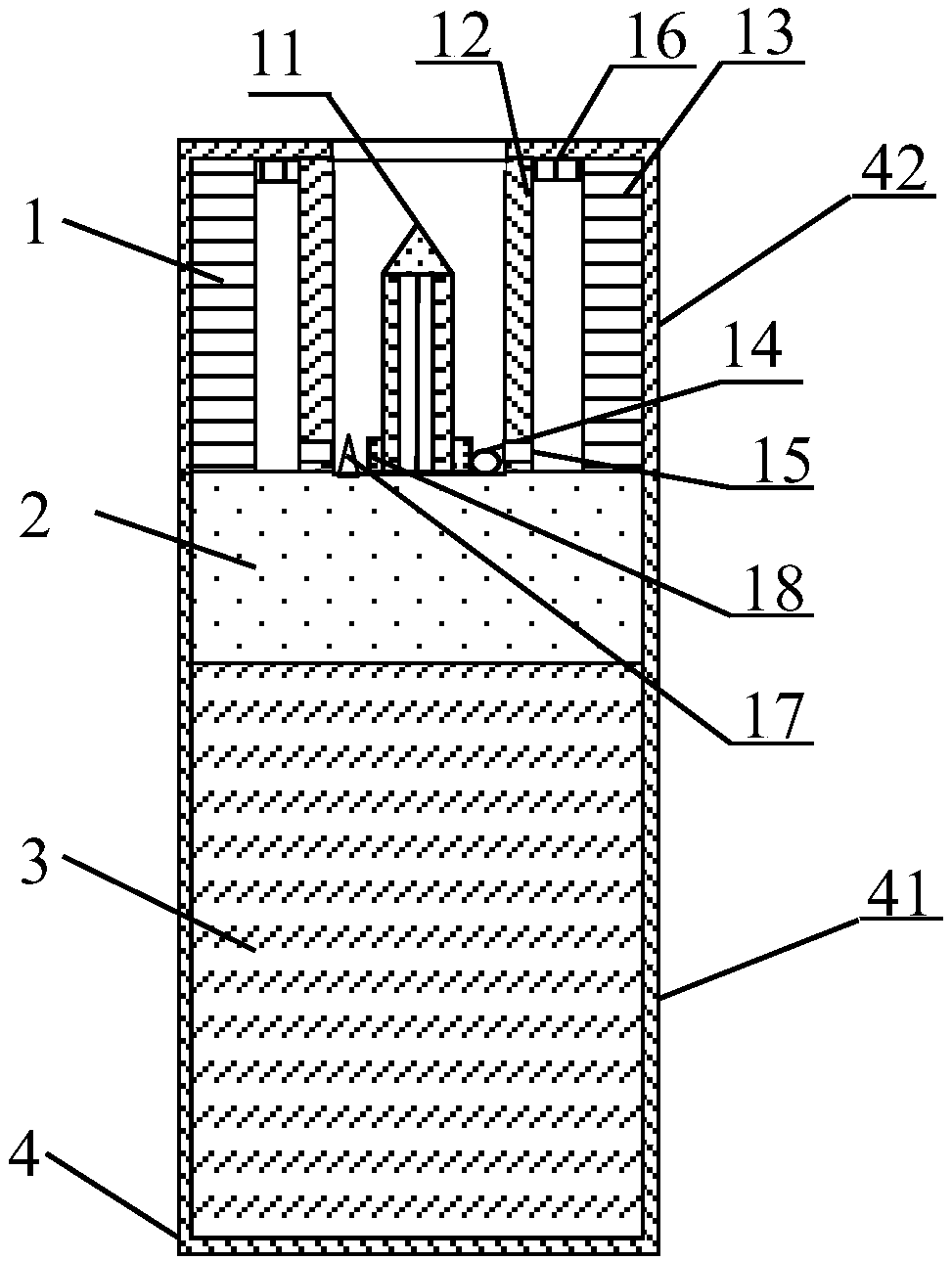

Inner core type infrared radiation heating aerosol generation system

PendingCN109674093AOvercome uniformity issuesOvercoming easy local overheating and carbonizationTobacco devicesThermodynamicsThermal insulation

The invention discloses an inner core type infrared radiation heating aerosol generation system which comprises an infrared radiation heating tobacco stem and a cartridge inserted into the infrared radiation heating tobacco stem, wherein the infrared radiation heating tobacco stem comprises an infrared radiation heating component, a control component and a battery component arranged in sequence from top to bottom, and a shell component for packing the previous three components into a whole; the infrared radiation heating component comprises a cartridge chamber, an infrared radiation heating column and a thermal insulation component; the cartridge chamber is used for enabling the cartridge to be inserted; the infrared radiation heating column is arranged in the cartridge chamber; the thermal insulation component is encircled at the periphery of the cartridge chamber; a smoke releasing part of the cartridge is of a hollow structure, so that when the cartridge is inserted into the cartridge chamber, the infrared radiation heating column is contained in the hollow structure of the smoke releasing part. The system disclosed by the invention is uniform and thorough in heating, and the defects existing in a resistance heating technology such as non-uniform heating, easy local overheating carbonization and long preheating time are overcome.

Owner:CHINA TOBACCO ANHUI IND CO LTD

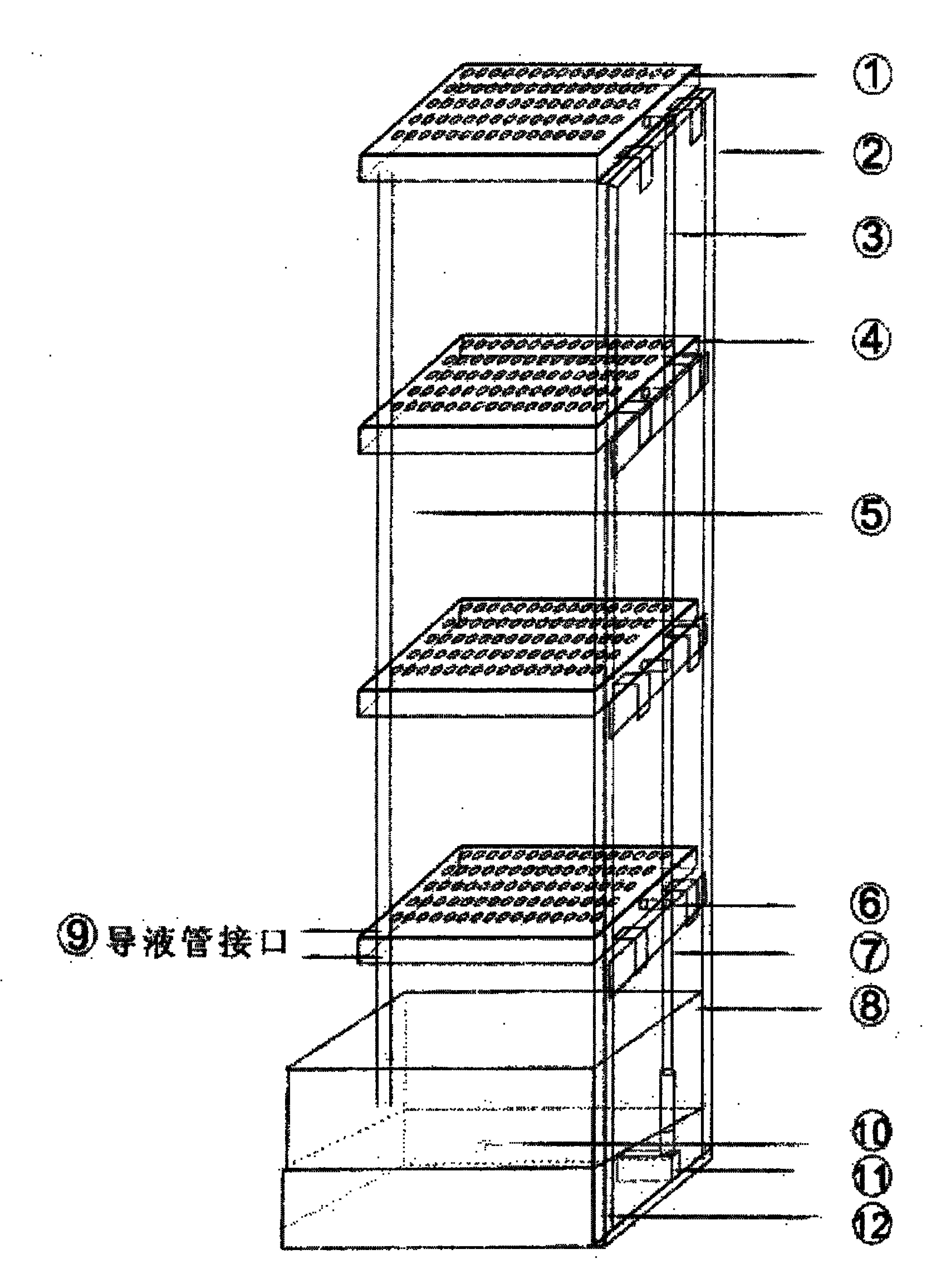

Vertical ultrasonic aeroponic culture device

InactiveCN101803561ASmooth water supplyUniform moisture supplyAgriculture gas emission reductionLiquid spraying apparatusLiquid storage tankAerosolize

The invention discloses a vertical ultrasonic aeroponic culture device. The device comprises culture box main bodies, stainless steel frames, a liquid guide pipe, a mist guide pipe, a filter screen, a liquid return tank, a liquid storage tank and an ultrasonic atomizer. The culture device is characterized in that: the culture box main bodies are hung on the stainless steel frames; the liquid guide pipe is connected with upper liquid guide pipe interfaces and lower liquid guide pipe interfaces of the culture box main bodies; the bottom of the liquid guide pipe is connected with the liquid return tank; and the mist guide pipe is connected with the ultrasonic atomizer and is connected with the culture box main bodies in series. The culture device consists of an upper part and a lower part; the upper part is for culturing and nourishing; the lower part is for ultrasonic atomization of nutrient solution and is connected with the liquid return tank and the liquid storage tank; and the ultrasonic atomizer is arranged in the liquid storage tank.

Owner:金芝

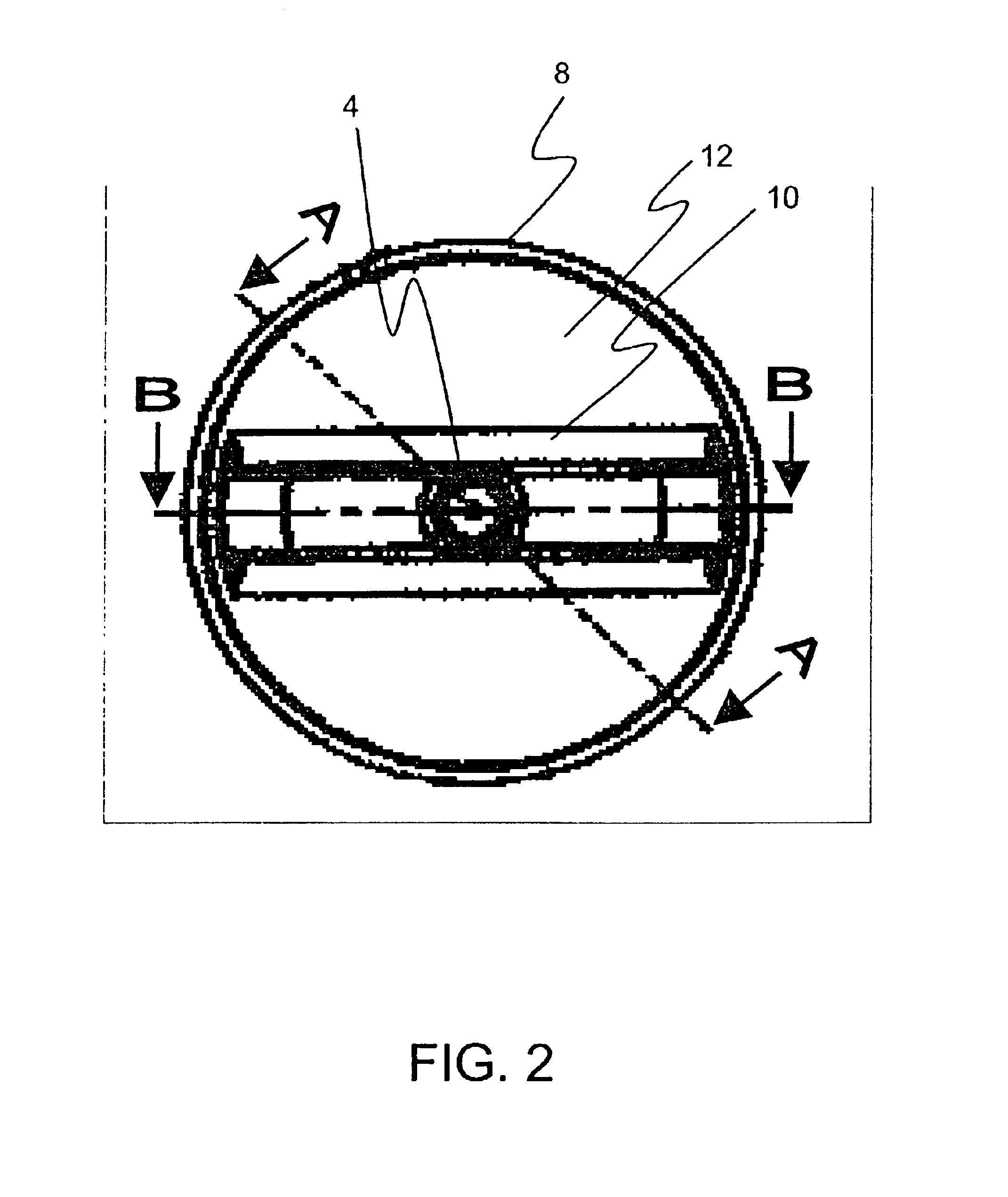

Circumferential aerosol device

The present application discloses devices and methods for delivering a therapeutic compound to the olfactory epithelium of an animal or human. The device having one or more channels for imparting a circumferential and axial velocity to the discharged fluid, and an outlet that discharges an aerosol spray having a circumferential and axial velocity as it enters the nasal cavity of a user. The device is designed to displace the air in the upper nasal cavity in order to specifically deposit a therapeutic agent on the olfactory epithelium while minimizing pressure and discomfort experienced by the user.

Owner:UNIV OF WASHINGTON

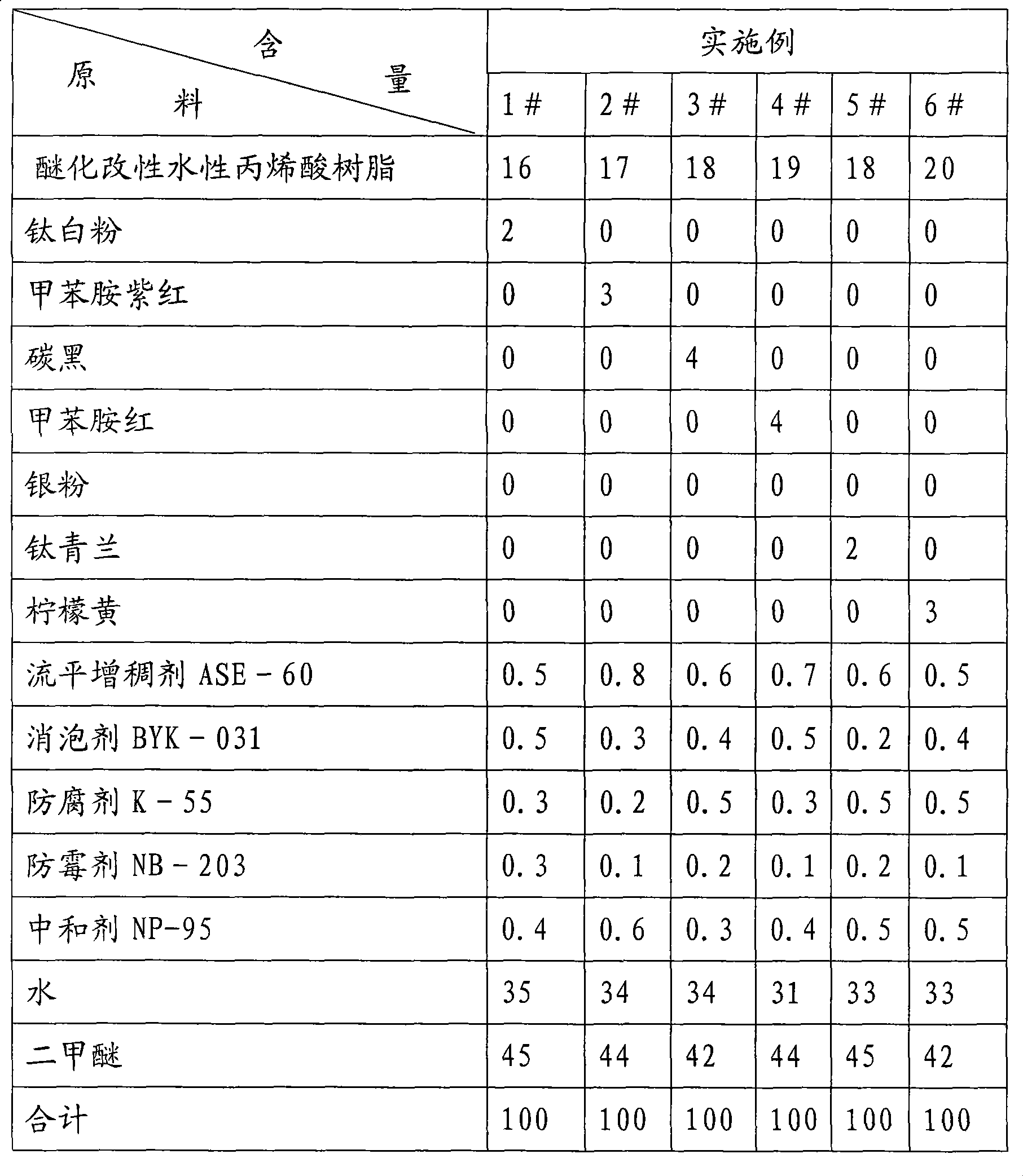

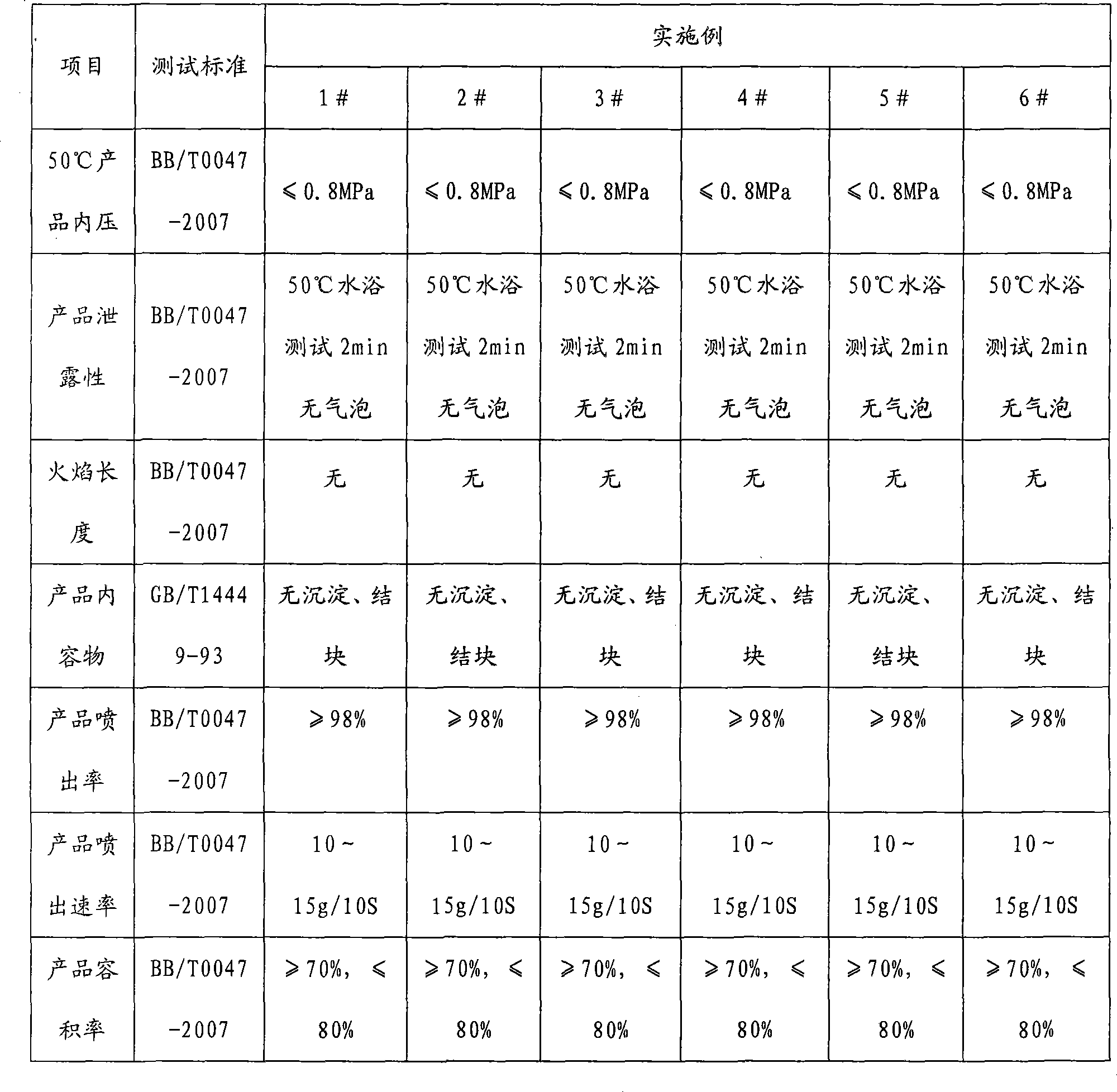

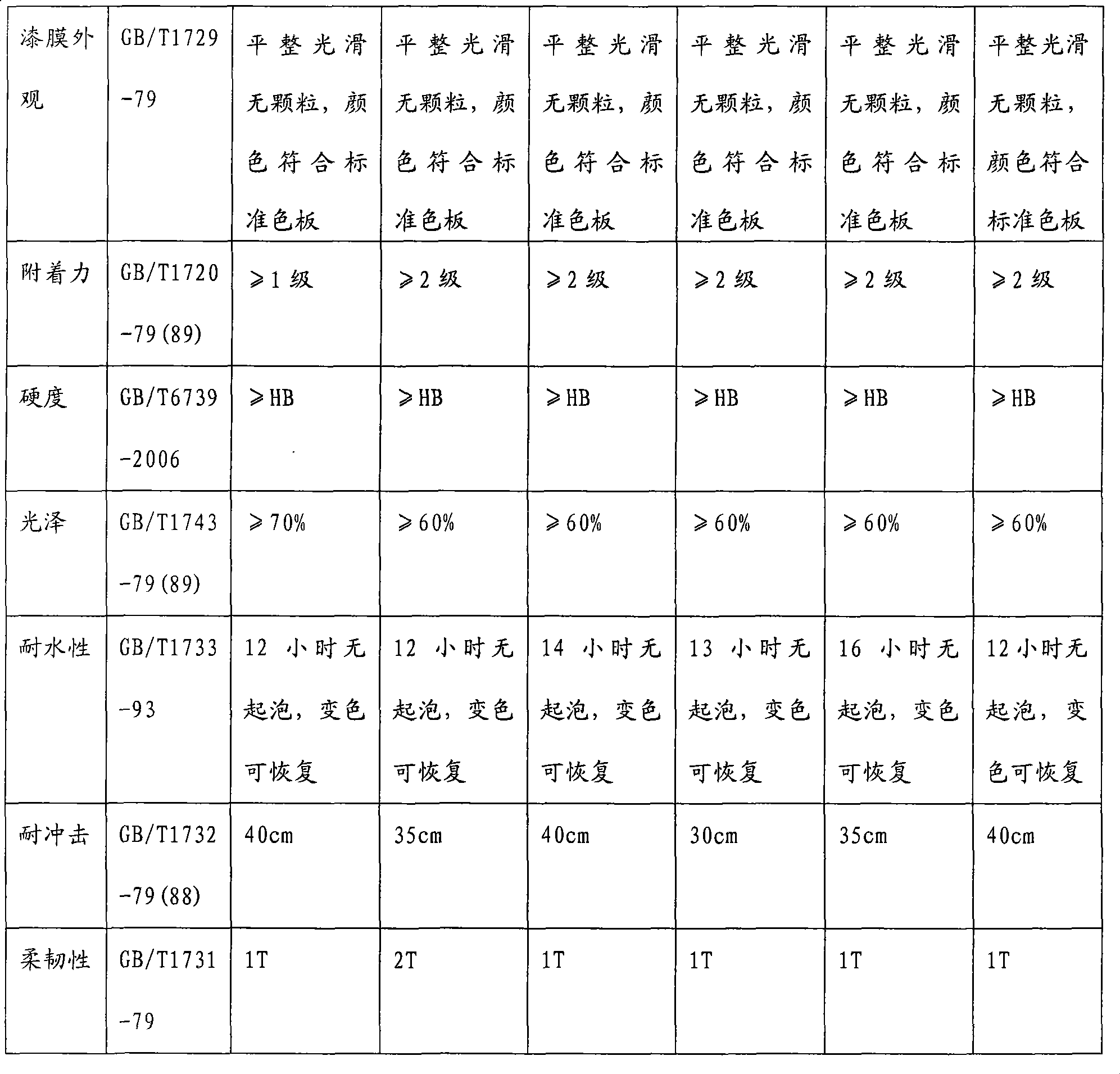

Water-soluble acroleic acid aerosol paint and preparation method thereof

InactiveCN101362873AFix compatibility issuesEliminate lossesCoatingsChemical compositionAtmospheric ozone

The invention relates to acrylics, in particular to aqueous acrylic acid aerosol paint. The aqueous acrylic acid aerosol paint includes the chemical components (counted in weight percentage) as follows: 15 to 20wt percent of etherified-modified aqueous acrylic acid resin, 2 to 5wt percent of coloring dye, 0.1 to 1.0wt percent of flatting thickening agent, 0.1 to 0.5wt percent of foam killer, 2 to 15wt percent of latent solvents, 20 to 35wt percent of water, 40 to 45wt percent of dimethyl ether as well as 0.5 to 1.0wt percent of addition agent. The invention also provides a preparation method of the aqueous acrylic acid aerosol paint, solves the compatibility problem between a propellant and the material of an aqueous aerosol, eliminates the loss of an atmospheric ozone layer, greatly reduces the content of VOC, lightens the pollution to the environment, also eliminates the problem of the flame length for product burning, leads the whole production process to be more environment-friendly and safer as well as is beneficial to the body health of a worker.

Owner:广州保赐利化工有限公司

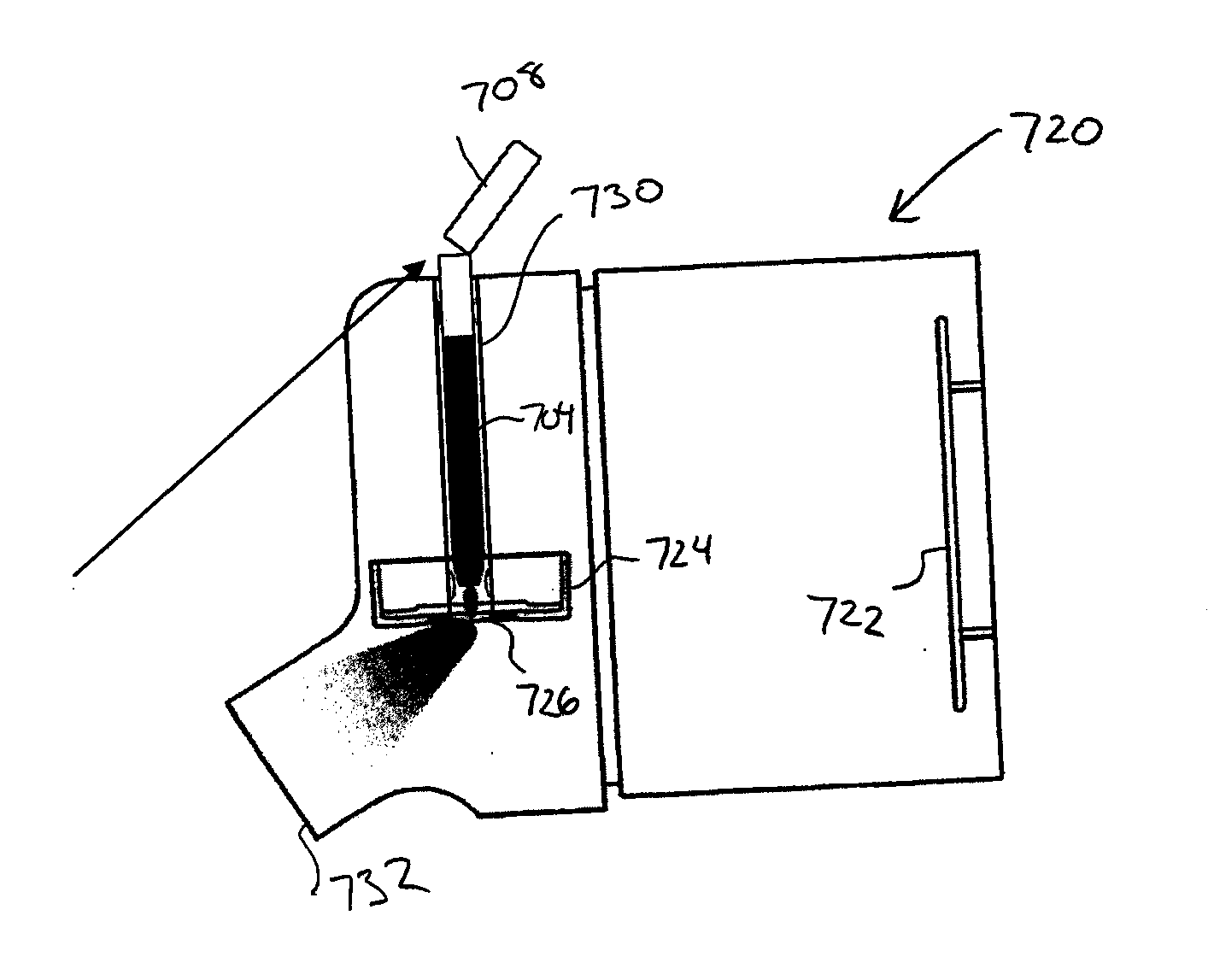

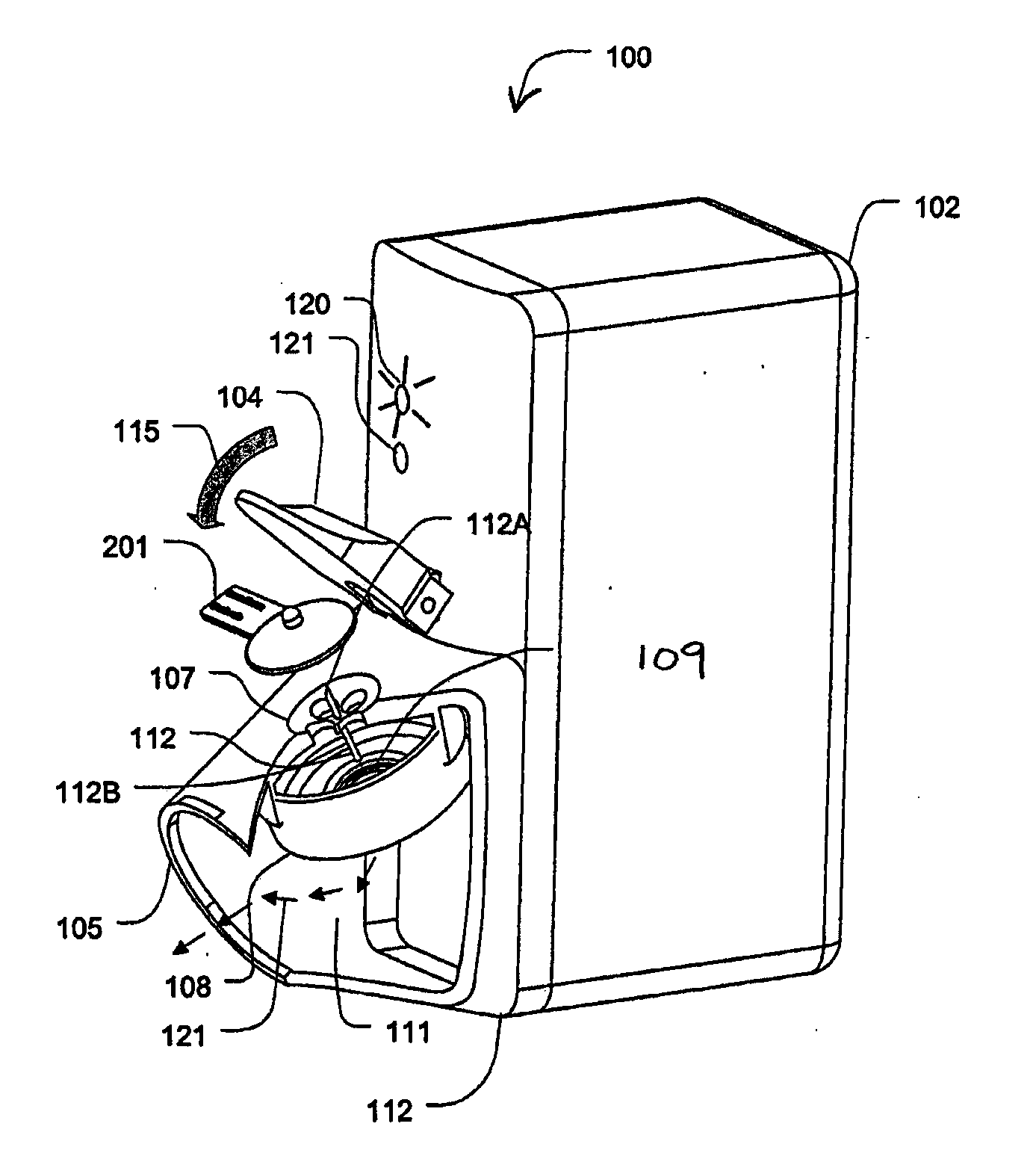

Light-activated portable aerosol mist sprayer device

ActiveUS8430337B2Reduce the amount requiredPromote resultsSelf-acting watering devicesSpray nozzlesSprayerAerosol Mist

A portable, light-activated, mist sprayer system comprising direct current power supply, an ambient light sensor, electronic circuitry that evaluates an electrical signal received from the light sensor to determine whether a “dusk” or “dawn” light condition exists; a container of treating fluid at a desired concentration; a motor and pump that are activated at the appropriate time as determined by the sensed light condition; at least one sprayer nozzle that will dispense a mist containing the treating fluid whenever the pump is operating; and a timer that turns off the pump after a preset interval to terminate the spraying cycle. A preferred utility for the system of the invention is spraying dilute solutions of insecticide or insect repellent during the periods of significant insect activity that typically occur around dusk and dawn. An RF receiving unit is also disclosed for optional activation using a remote transmitter.

Owner:OUTDOOR SOLUTIONS

Pharmaceutical Formulations

An aspect of the present invention provides for a medicament including a solution containing pleconaril or a pharmaceutically acceptable salt thereof, wherein at least one solvent comprising said solution is a pleconaril-dissolving glyceride oil, and the solution is suitable for inhalation administration as an aerosol mist.

Owner:SCHERING CORP

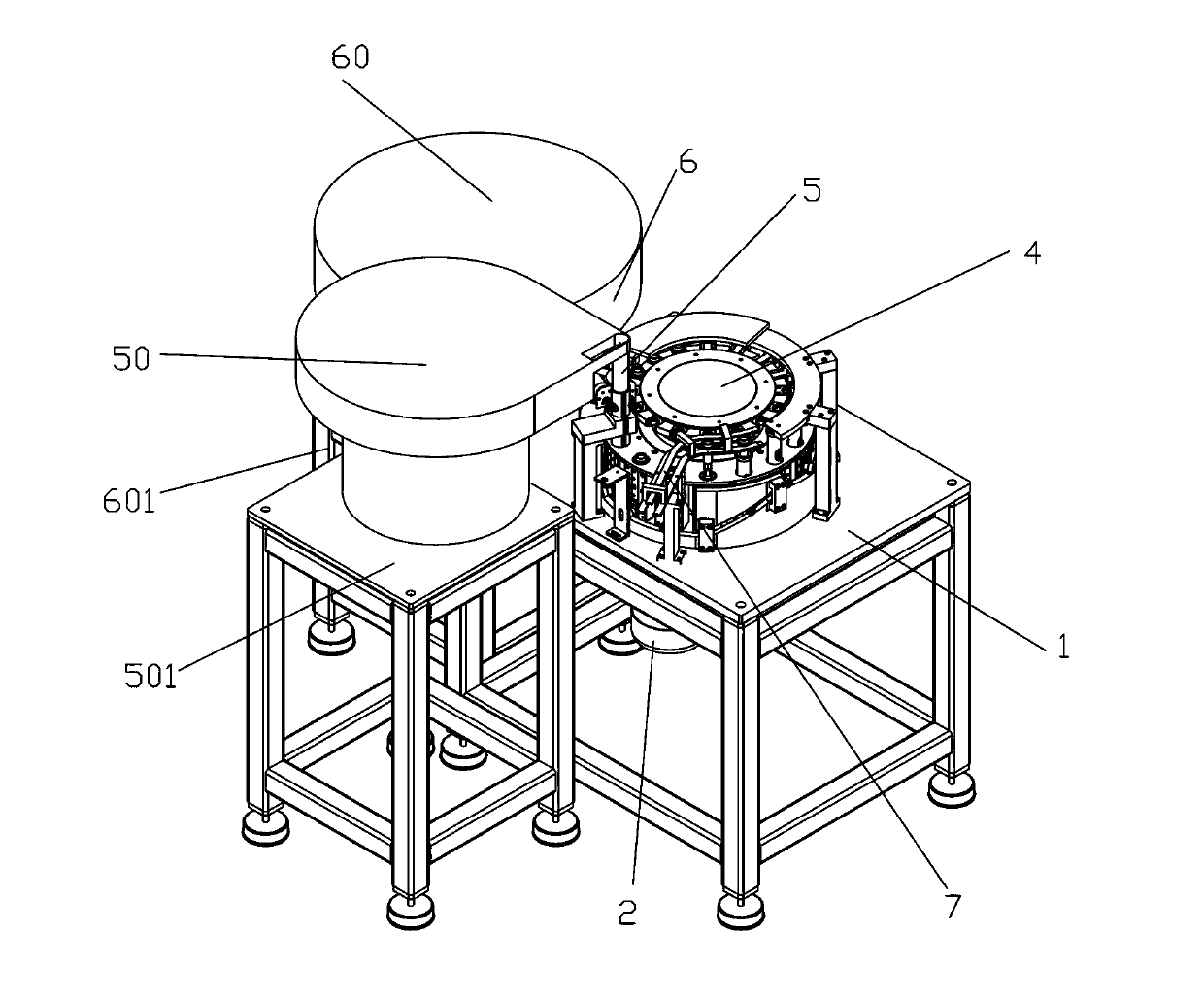

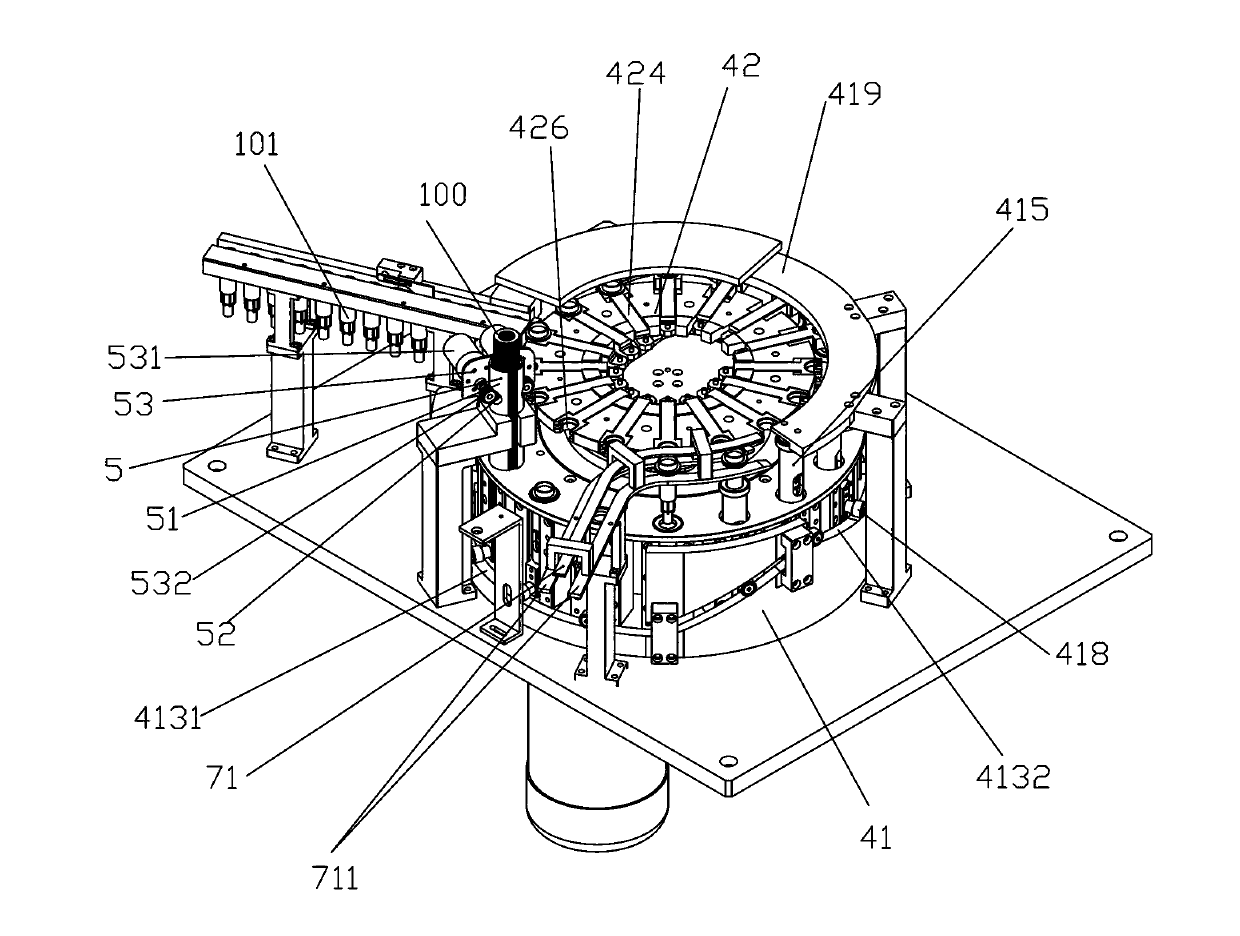

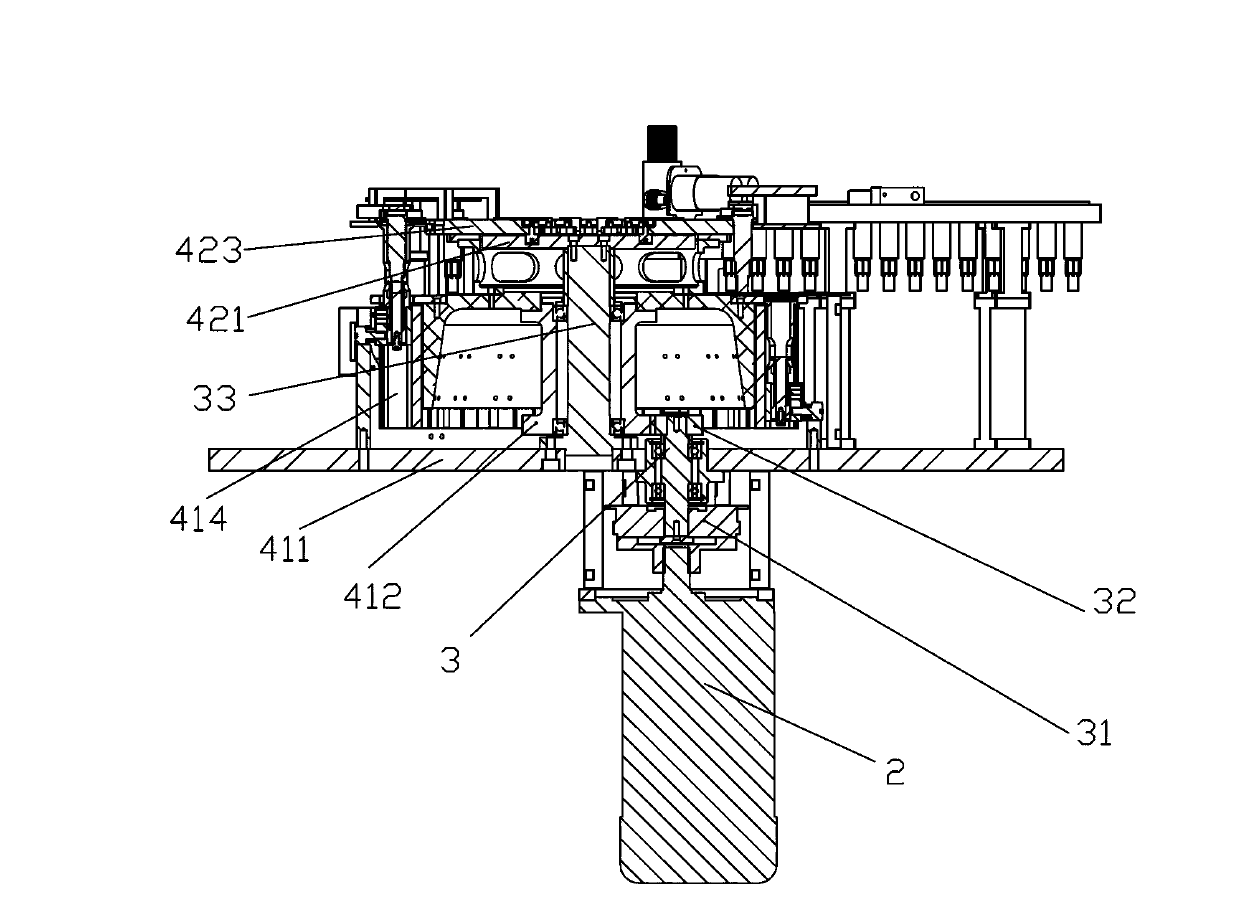

Gasket sleeving machine for aerosol valve

ActiveCN102990350AFast assemblyImprove efficiencyMetal working apparatusElectric machineryAerosol Mist

The invention discloses a gasket sleeving machine for an aerosol valve. The gasket sleeving machine comprises a frame, wherein a motor is arranged on the frame, and a transmission gear is connected with an output end of the motor; a gasket sleeving device connected with the transmission gear is also arranged on the frame; a gasket feeding device for feeding a gasket into the gasket sleeving device is also arranged on the frame; and a pump pipe feeding device for feeding a pump pipe into the gasket sleeving device, and a discharge device are also arranged on the frame. By adopting the gasket sleeving machine, the mechanical automation of operations of assembling the pump pipe and the gasket is completely realized, the assembling speed is high, the efficiency is high, and the cost is reduced.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

Preservative-free single dose inhaler systems

An aerosolization system includes a container that is configured to deliver a unit dosage of a liquid when squeezed a single time. The system also includes an aerosolizer that is constructed of a housing defining a mouthpiece, and an aerosol generator disposed in the housing. The aerosol generator includes a vibratable membrane having a front face and a rear face, and a vibratable element used to vibrate the membrane. Further, the housing includes an opening that is adapted to receive a unit dosage of the liquid from the container. The opening provides a liquid path to the rear face of the vibratable membrane.

Owner:AERAMI THERAPEUTICS INC

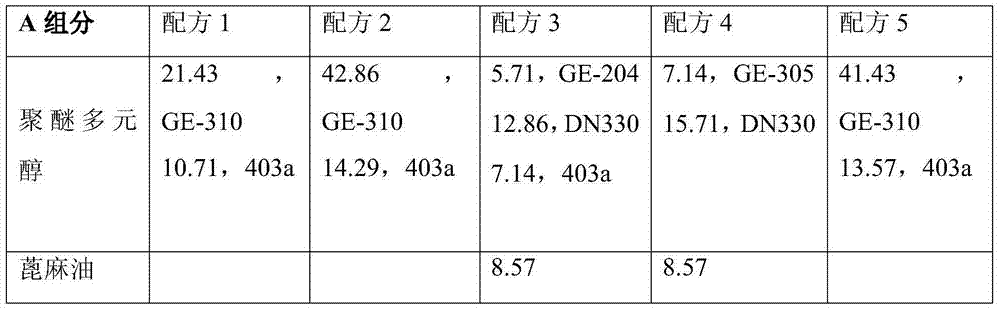

A portable polyurethane two-component foam caulking compound

A portable polyurethane two-component foam caulking compound and a preparing method thereof are disclosed. The foam caulking compound comprises an A component and a B component. The A component comprises polyether polyol or polyester polyol, castor oil, a plasticizer, triethanolamine, a foam stabilizer, a catalyst and a foaming agent. The B component comprises polyisocyanate, a plasticizer, a foam stabilizer and a foaming agent. The preparing method includes 1) a step of preparing the A component, namely a step of fully mixing the polyether polyol or the polyester polyol, the castor oil, the plasticizer, the triethanolamine, the foam stabilizer and the catalyst, feeding the uniformly mixed materials into a specially-used aerosol pot, closing a valve, feeding the foaming agent, and shaking the pot until the materials are uniformly mixed, then the mixture can be used in match with the B component; and 2) a step of fully mixing the polyisocyanate, the plasticizer and the foam stabilizer, feeing the mixture into a specially-used aerosol pot, closing a valve, feeding the foaming agent, and shaking the pot until the materials are uniformly mixed, then the mixture can be used in match with the A component. The foam caulking compound is high in curing speed, low in environment dependence, high in density and good in toughness and elasticity, and meets requirements the industry of construction.

Owner:锋泾(中国)建材集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com