Preparation method of hollow tube filling type heating non-combustible fuming product with sealing film and application

A technology for heat-not-burn and smoking products, applied in the application, smoker's products, tobacco and other directions, can solve the problems of high equipment and operating costs, high requirements for filter rod compound machines, and complicated preparation procedures, and achieves simplified preparation procedures, The effect of reducing production cost and simple molding equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

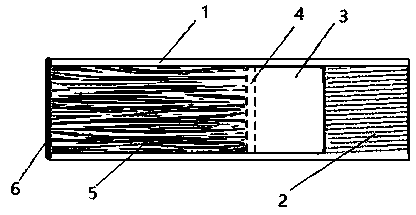

[0019] A method for preparing an empty tube-filled heat-not-burn smoking product with a sealing film. The empty tube filling method is used to fill each functional structural section of the heat-not-burn smoking product into a circular empty tube to prepare a smoking product.

[0020] Specifically: first use high-permeability paper that is easy to be pierced by a heating needle or sheet as the sealing film 6, and seal one end of the circular empty tube 1 with an external diameter of 7.0 mm, a wall thickness of 0.4 mm, and a length of 45 mm. Then fill the granular smoking material as the smoking section 5 until the length of the smoking section is 15mm, and then pack the barrier sheet 4 made of heat-resistant plastics with a plurality of air holes in the axial direction and a thickness of 2mm. A cavity with a length of 13mm is used as the supporting section 3, and finally a polylactic acid fiber filter section 2 with a length of 15mm is filled and sealed to prepare a smoking pro...

Embodiment 2

[0022] A method for preparing an empty tube-filled heat-not-burn smoking product with a sealing film. The empty tube filling method is used to fill each functional structural section of the heat-not-burn smoking product into a circular empty tube to prepare a smoking product.

[0023] Specifically, first use a perforated aluminum foil that is easy to be pierced by a heated needle or sheet as the sealing film 6, and seal one end of a circular empty tube of aluminum foil material with an external diameter of 7.3 mm, a wall thickness of 0.6 mm, and a length of 60 mm. Then fill the filamentary smoking material as the smoking section 5 until the length of the smoking section is 20mm, and then fill the barrier sheet 4 made of ceramic material with a plurality of air holes in the axial direction and a thickness of 5mm. A cavity with a length of 20mm is used as the support section 3, and then 10-20 mesh polyethylene glycol particles are filled in the cavity of the support section as a ...

Embodiment 3

[0025] A method for preparing an empty tube-filled heat-not-burn smoking product with a sealing film. The empty tube filling method is used to fill each functional structural section of the heat-not-burn smoking product into a circular empty tube to prepare a smoking product.

[0026] Specifically, first use a perforated high-temperature-resistant plastic film that is easy to be pierced by a heating needle or a sheet as the sealing film 6, and seal one end of a circular empty tube of ceramic material with an external diameter of 6.8 mm, a thickness of 1 mm, and a length of 70 mm. Afterwards, a cylindrical smoking material with a honeycomb three-dimensional structure and ventilation is filled as the smoking section 5, and the length is 20mm, and then a plurality of air holes are provided in the axial direction, and the thickness is 1mm. Aluminum barrier sheet 4, leaving a cavity with a length of 19mm behind the barrier sheet as a support section 3, and filling the cavity of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outside diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com