Gasket sleeving machine for aerosol valve

An aerosol valve and gasket technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, time-consuming labor, increased labor cost and production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

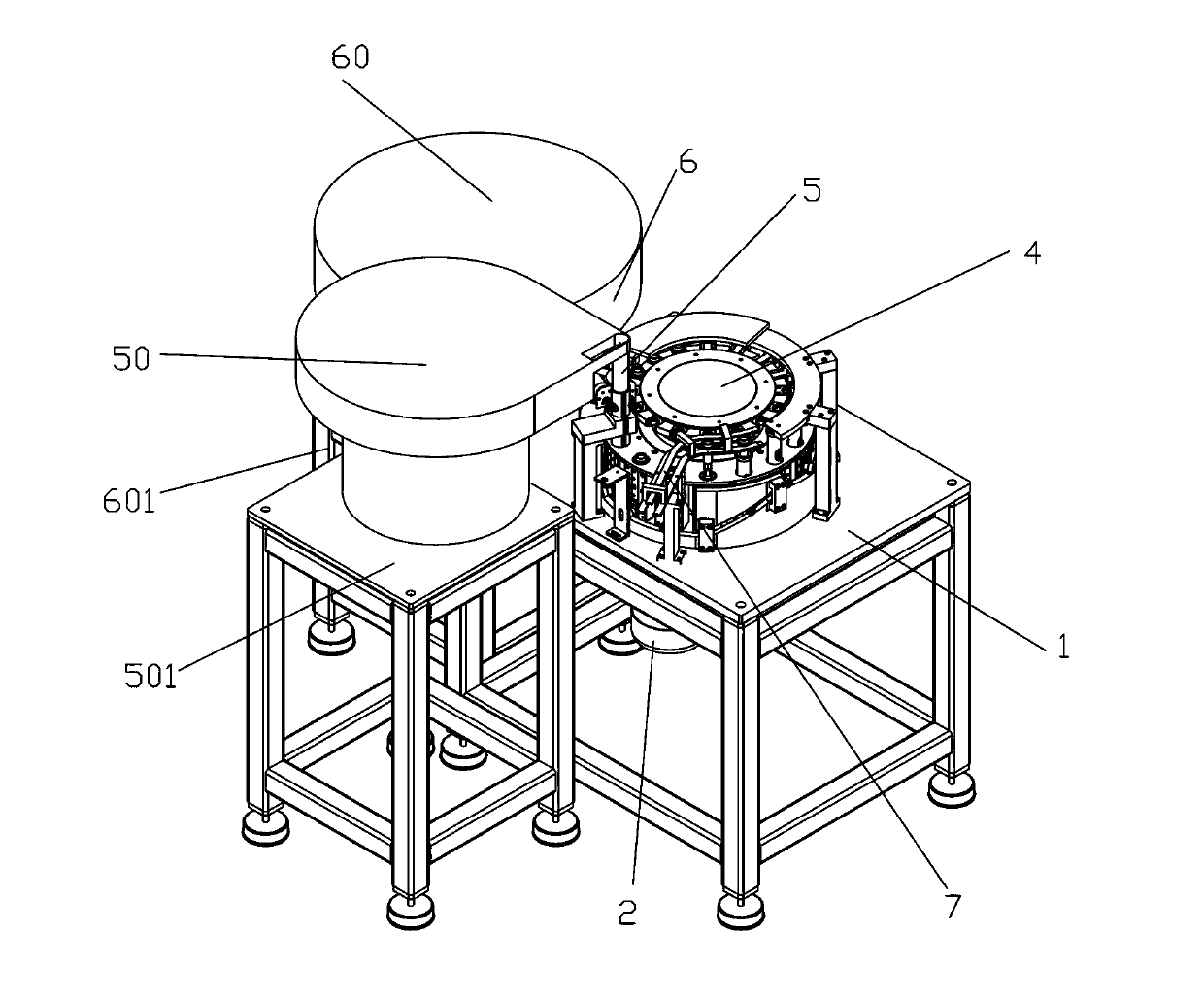

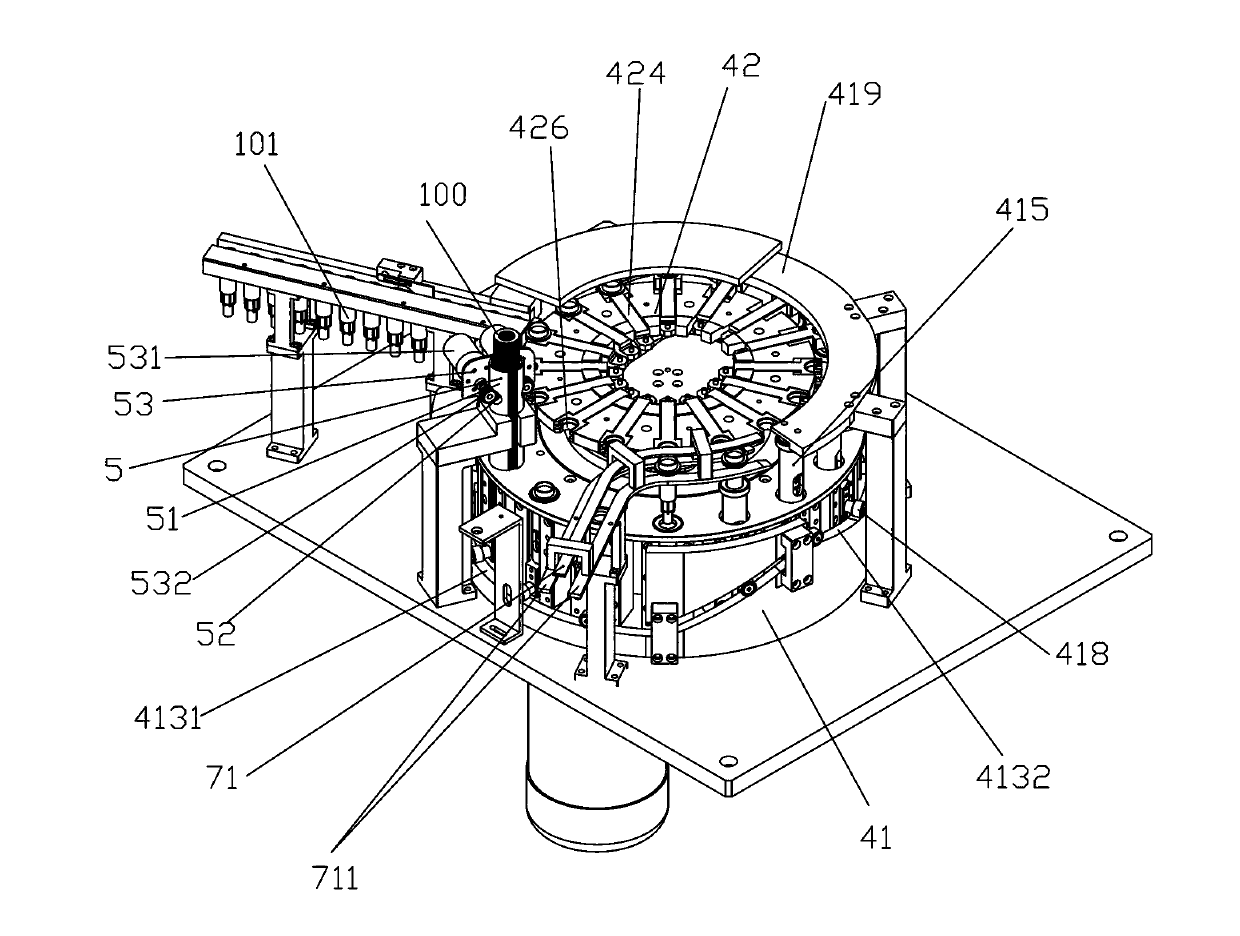

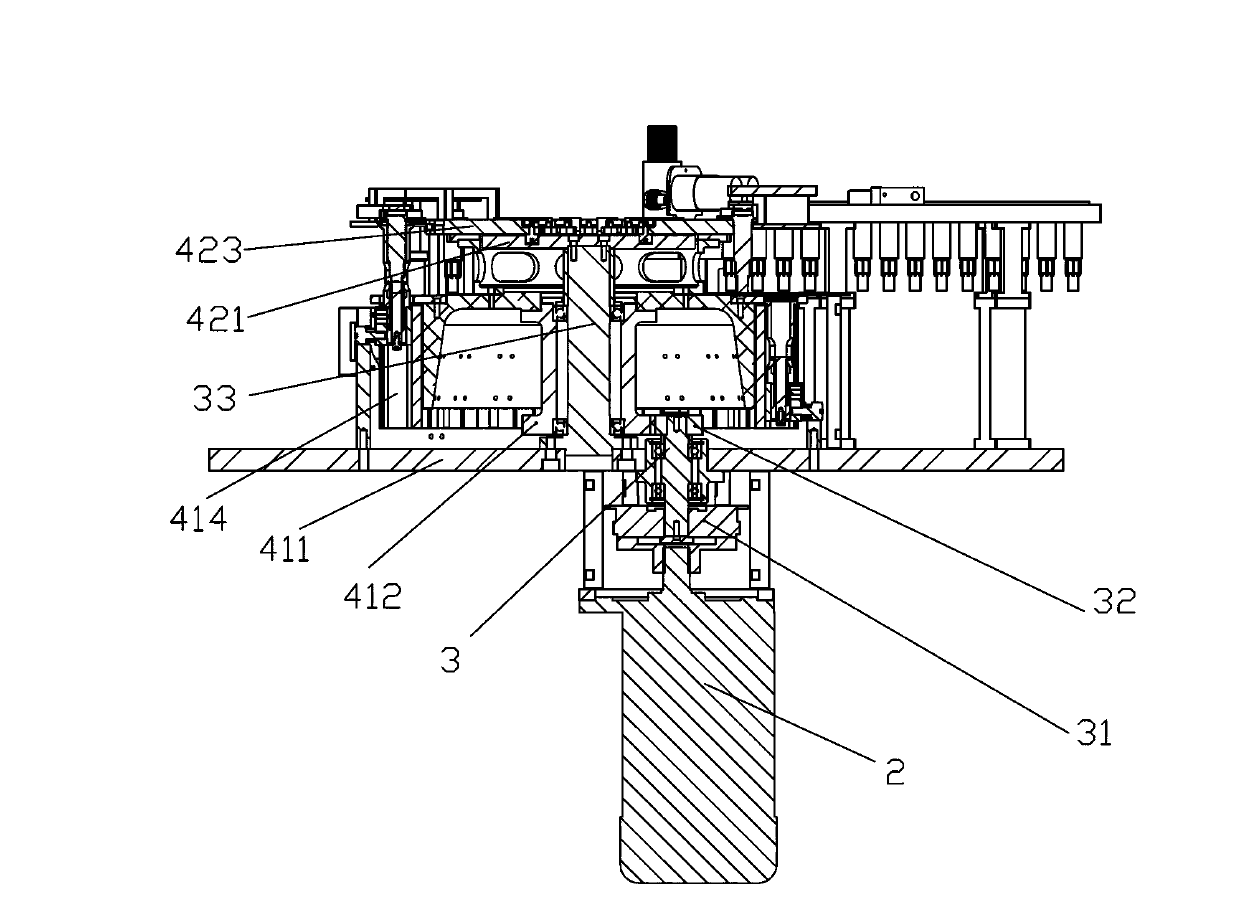

[0020] The gasket machine for aerosol valves includes a frame 1, a motor 2 is provided on the frame 1, and a transmission device 3 is connected to the output end of the motor, and a gasket connected to the transmission device 3 is also provided on the frame 1 The gasket device 4, the frame 1 is also provided with a gasket delivery device 5 for sending the gasket 100 into the gasket device 4, and a pump tube device 6 for sending the pump tube 101 into the gasket device 4 , and discharging device 7.

[0021] The gasket device 4 includes a pump tube rotary pushing assembly 41 and a pump tube pushing component 42 connected to the transmission device 3. The pump tube pushing component 42 is arranged on the upper end of the pump tube rotary pushing component 41. The pump tube pushing component 42 includes an upper end. The pump tube base 421 is provided with an upper pump tube groove 422 on the upper pump tube base 421. The upper pump tube groove 422 includes a locking section 4221 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com