Large-span continuous steel truss multi-point synchronous automatic cyclic alternating sliding shoe push system and construction method thereof

A synchronous automatic, jacking construction technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of main structure damage, unsatisfactory non-equal cross-section main beam structure, local stress increase, etc., to avoid construction Damage and destruction, save time for manual disassembly and assembly, and improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

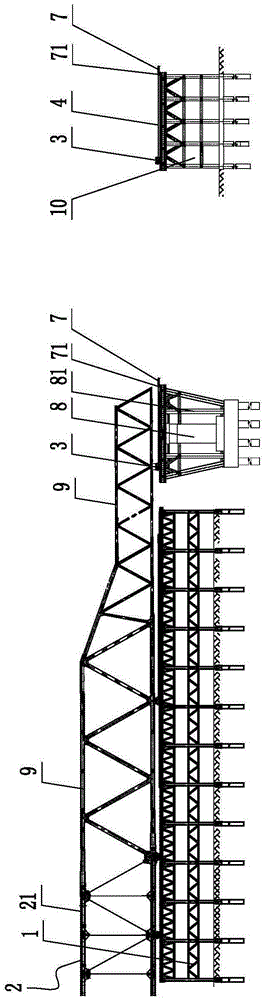

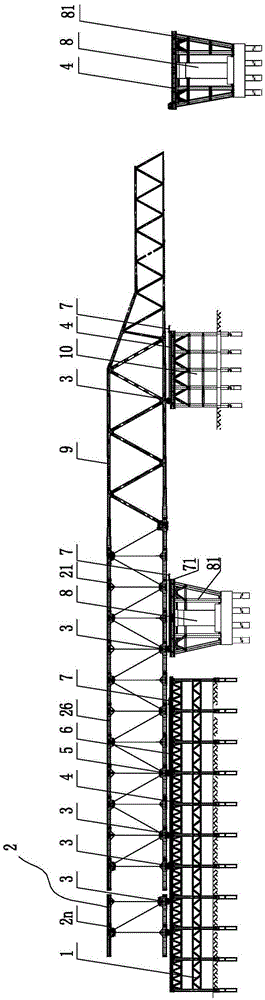

[0069] A long-span continuous steel truss girder multi-point synchronous automatic circulation alternate pushing sliding shoe pushing system, such as Figure 1-2 As shown, the long-span continuous steel truss girder multi-point synchronous automatic circulation alternate pushing sliding shoe pushing system includes: a steel truss girder assembly platform 1 for steel truss girder segmental assembly and butt joint forming, a steel guide beam 9, Temporary pier 10, push shoe 3, slideway 4 and control system;

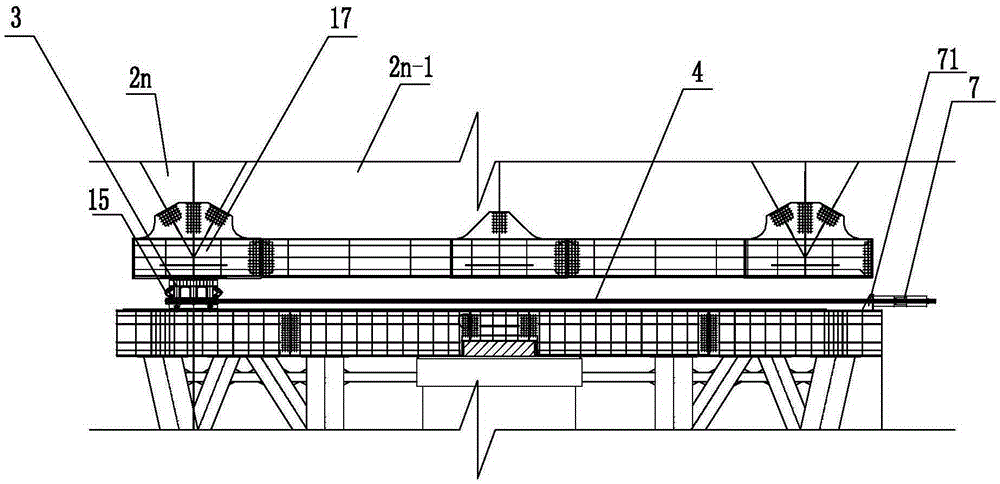

[0070] Such as image 3 As shown, the slideway includes a main slideway 41 and an auxiliary slideway 42. The main slideway 41 is also called a push slideway, which is used to bear the dead load of the steel truss girder, and the auxiliary slideway is used to bear the front and rear of the push slide shoe. Alternately, each set of slideways 4 (including the main slideway 41 and the auxiliary slideway 42) is provided with two sets of vertically adjustable pusher shoes 3, and ...

Embodiment 2

[0079] A long-span continuous steel truss girder multi-point synchronous automatic circulation alternately pushing sliding shoe jacking construction method, which is to use the long-span continuous steel truss girder multi-point synchronous automatic circulation alternating pushing sliding shoe jacking described in the first embodiment The system realizes the method of multi-point synchronous automatic circulation and alternating pushing and sliding shoe jacking construction of long-span continuous steel truss girders, including the steel truss girder assembly platform and the setting of slideways on the platform for the steel truss girders to be pieced together in sections and butt-jointed. ; The layout and design method of the jacking steel guide beams and temporary piers, as well as the design regulations and settings of the slideway on the temporary piers, steel truss beam assembly platform and permanent piers; the setting of the jacking shoes that can automatically compensa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com