A portable polyurethane two-component foam caulking compound

A technology of foam caulking agent and polyurethane, which is applied in the field of portable polyurethane two-component foam caulking agent and its preparation, can solve the problems of slow curing reaction and long curing time, and achieve fast curing speed, good elasticity and toughness, and high density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

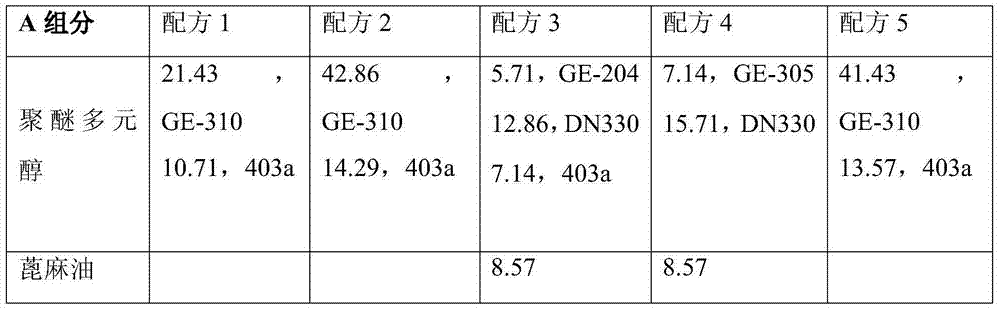

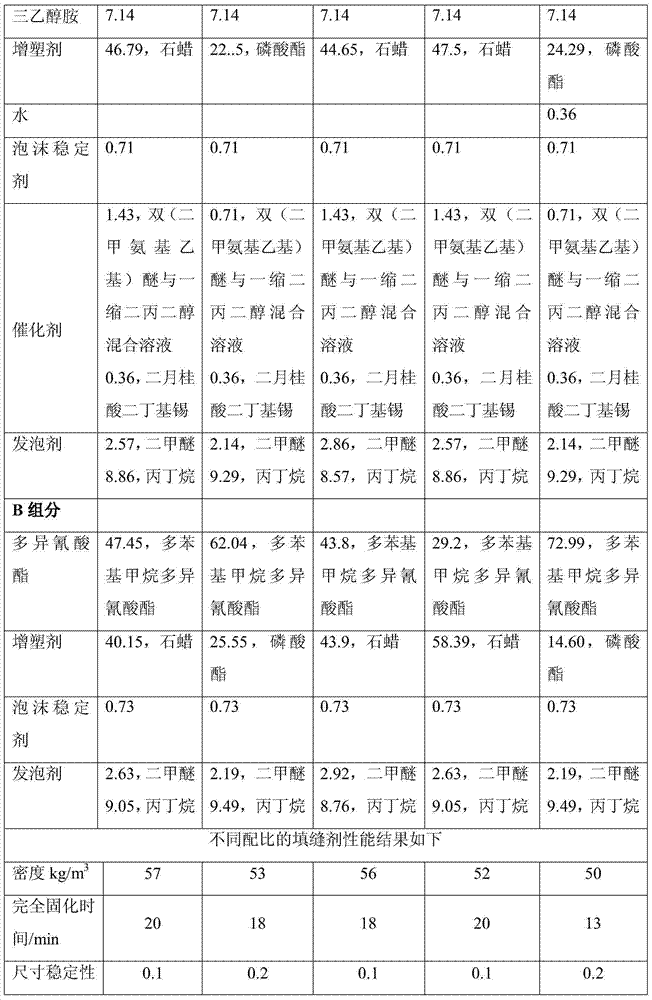

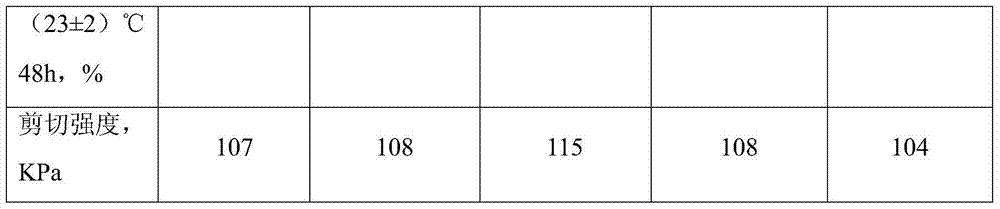

[0026] Embodiment 1 Portable polyurethane two-component foam sealant formula performance comparison

[0027] The preparation process of formula 1 is as follows:

[0028] Component A: According to formula 1, mix polyether polyol, triethanolamine, plasticizer, foam stabilizer, catalyst and other components evenly to make a combined material; pour the combined polyether into an aerosol can, and press the valve , fill in dimethyl ether and propylene butane in turn, and shake well; B component: mix polyphenylmethane polyisocyanate, phosphoric acid ester, foam stabilizer and other components according to formula 1, and prepare B component black material, Pour the black material into a special aerosol tank and press the valve, fill in dimethyl ether and propylene butane in turn, shake well; test the product performance.

[0029] Formula 2~5:

[0030] According to the formula listed in Table 1, the technological process is the same as that of Example 1. 2-5 can also produce a portab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com