Multifunctional spraying robot

A spraying robot and multi-functional technology, applied in the field of robots, can solve problems such as unsatisfactory use requirements, single function, lack of availability, etc., and achieve the effect of convenient control, stable structure and diverse functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

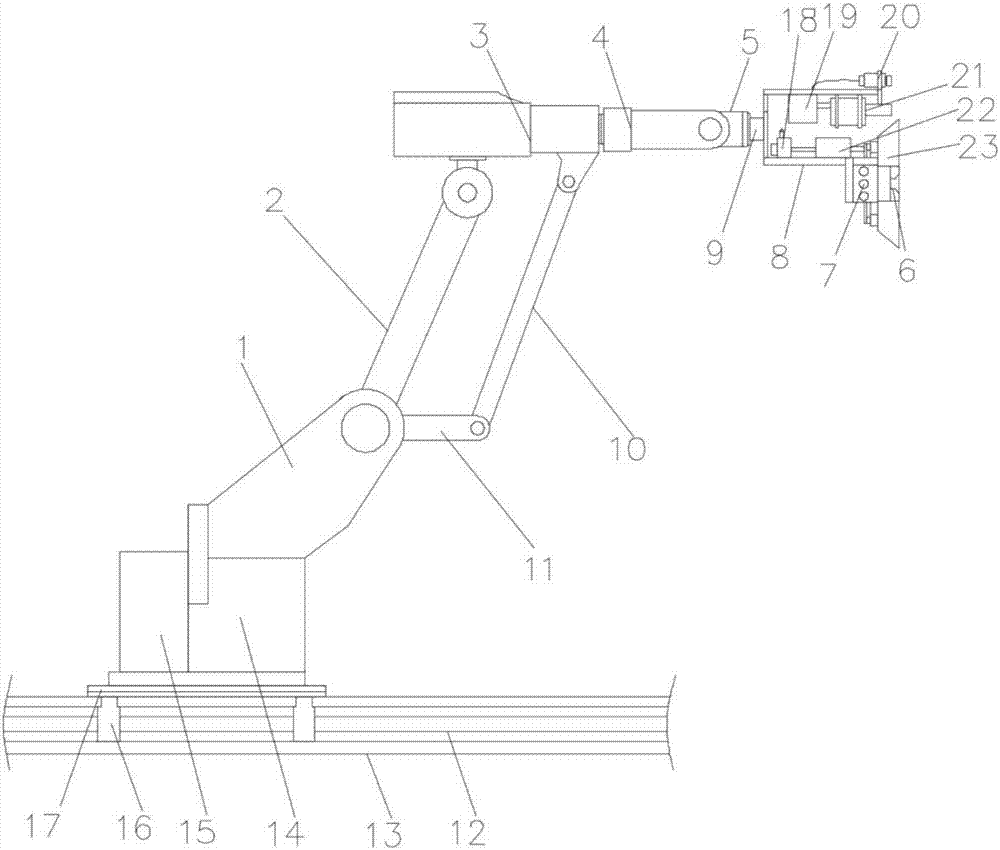

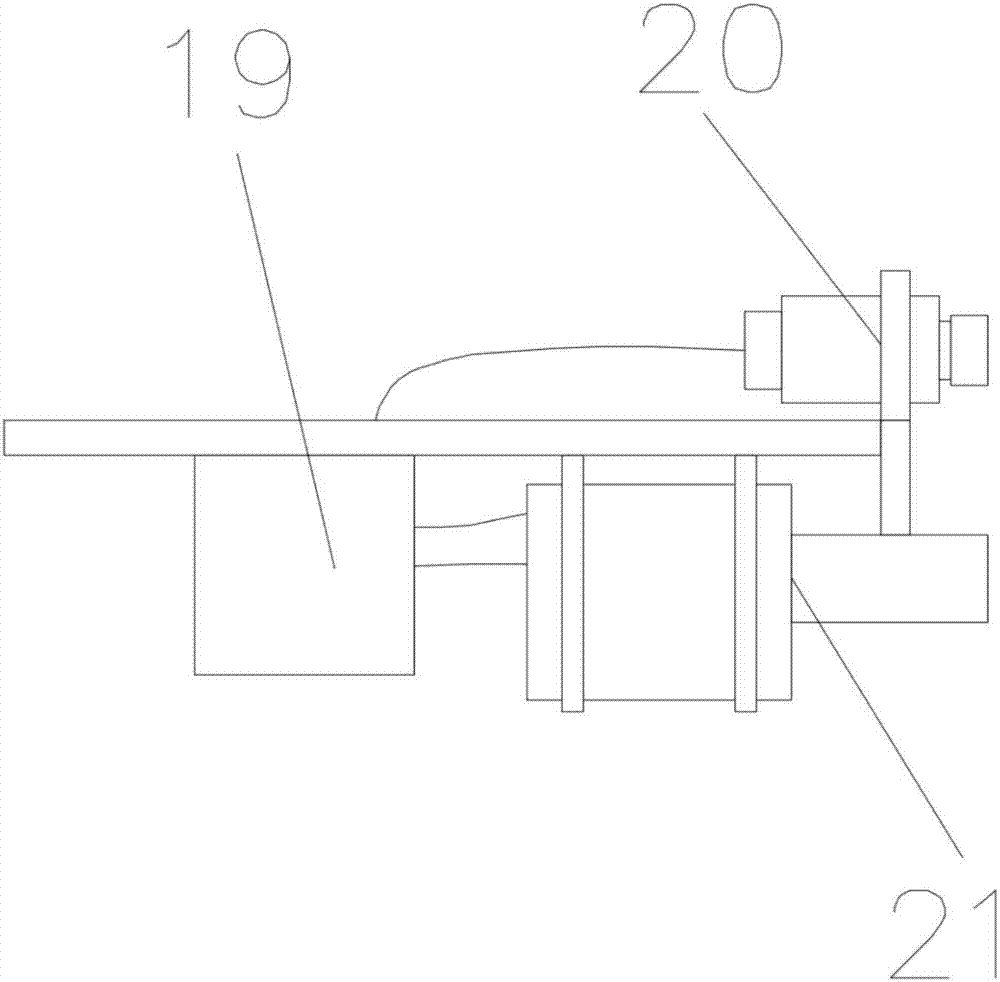

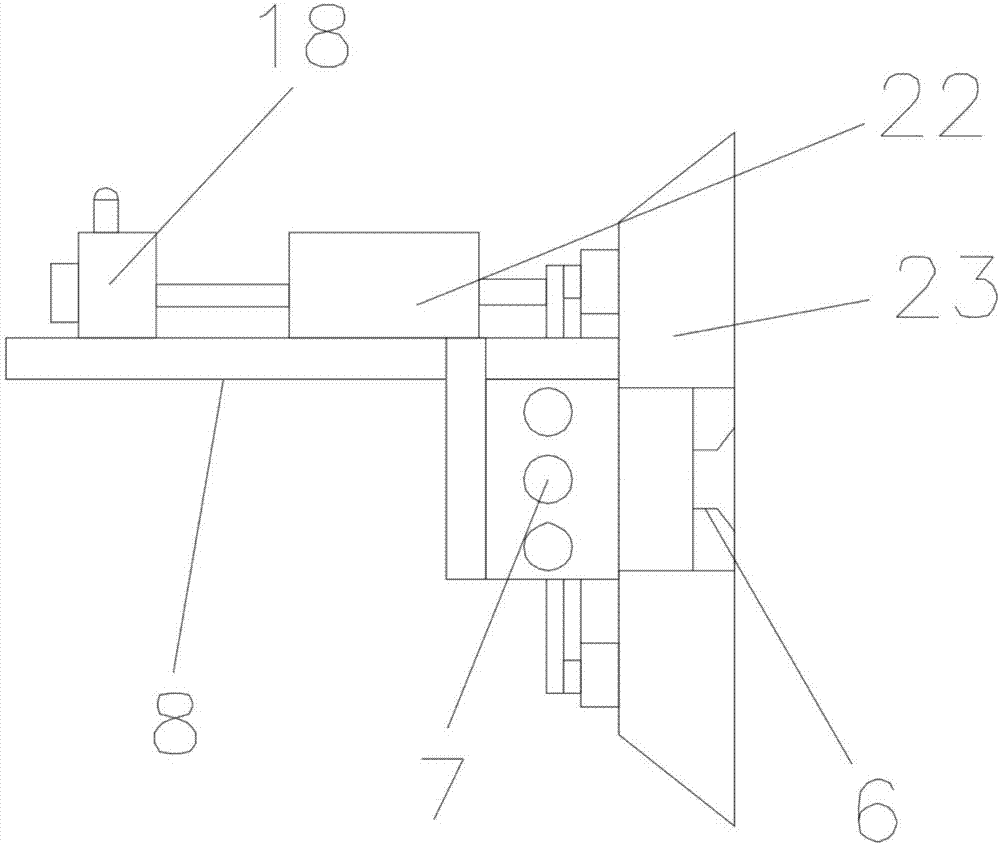

[0029]In the embodiment of the present invention, the multi-functional spraying robot includes a bottom plate 17, and the bottom plate 17 is arranged on a slide seat 13. A threaded slider 16 affixed to the bottom plate 17 is installed in the slide seat 13, and a threaded rod is arranged in the slide seat 13. 12. The threaded slider 16 is connected to the threaded rod 12, the upper end of the bottom plate 17 is provided with a base 14, and a fixed mechanical arm 1 is arranged obliquely above the base 14, and the fixed mechanical arm 1 is hinged to the movable mechanical arm 2, and the movable mechanical arm 2 is The first rotating mechanical arm 3 is articulated, the fixed mechanical arm 1 is articulated with the auxiliary arm 11, the auxiliary arm 11 is articulated with the second auxiliary arm 10, the second auxiliary arm 10 is articulated with the first rotating arm 3, and the first rotating arm The front end of the arm 3 is connected to the rotating mechanical arm 4 by rotat...

Embodiment 2

[0031] In the embodiment of the present invention, the multi-functional spraying robot includes a bottom plate 17, and the bottom plate 17 is arranged on a slide seat 13. A threaded slider 16 affixed to the bottom plate 17 is installed in the slide seat 13, and a threaded rod is arranged in the slide seat 13. 12. The threaded slider 16 is connected to the threaded rod 12, the upper end of the bottom plate 17 is provided with a base 14, and a fixed mechanical arm 1 is arranged obliquely above the base 14, and the fixed mechanical arm 1 is hinged to the movable mechanical arm 2, and the movable mechanical arm 2 is The first rotating mechanical arm 3 is articulated, the fixed mechanical arm 1 is articulated with the auxiliary arm 11, the auxiliary arm 11 is articulated with the second auxiliary arm 10, the second auxiliary arm 10 is articulated with the first rotating arm 3, and the first rotating arm The front end of the arm 3 is connected to the rotating mechanical arm 4 by rota...

Embodiment 3

[0033] In the embodiment of the present invention, the multi-functional spraying robot includes a bottom plate 17, and the bottom plate 17 is arranged on a slide seat 13. A threaded slider 16 affixed to the bottom plate 17 is installed in the slide seat 13, and a threaded rod is arranged in the slide seat 13. 12. The threaded slider 16 is connected to the threaded rod 12, the upper end of the bottom plate 17 is provided with a base 14, and a fixed mechanical arm 1 is arranged obliquely above the base 14, and the fixed mechanical arm 1 is hinged to the movable mechanical arm 2, and the movable mechanical arm 2 is The first rotating mechanical arm 3 is articulated, the fixed mechanical arm 1 is articulated with the auxiliary arm 11, the auxiliary arm 11 is articulated with the second auxiliary arm 10, the second auxiliary arm 10 is articulated with the first rotating arm 3, and the first rotating arm The front end of the arm 3 is connected to the rotating mechanical arm 4 by rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com