Processing method and device for adjusting blade and integral shroud by turboset

A regulating stage, steam turbine technology, applied in metal processing equipment, manufacturing tools, details of milling machine equipment, etc., can solve the problems of high size, shape and position accuracy, difficult processing and assembly, and achieve high processing accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

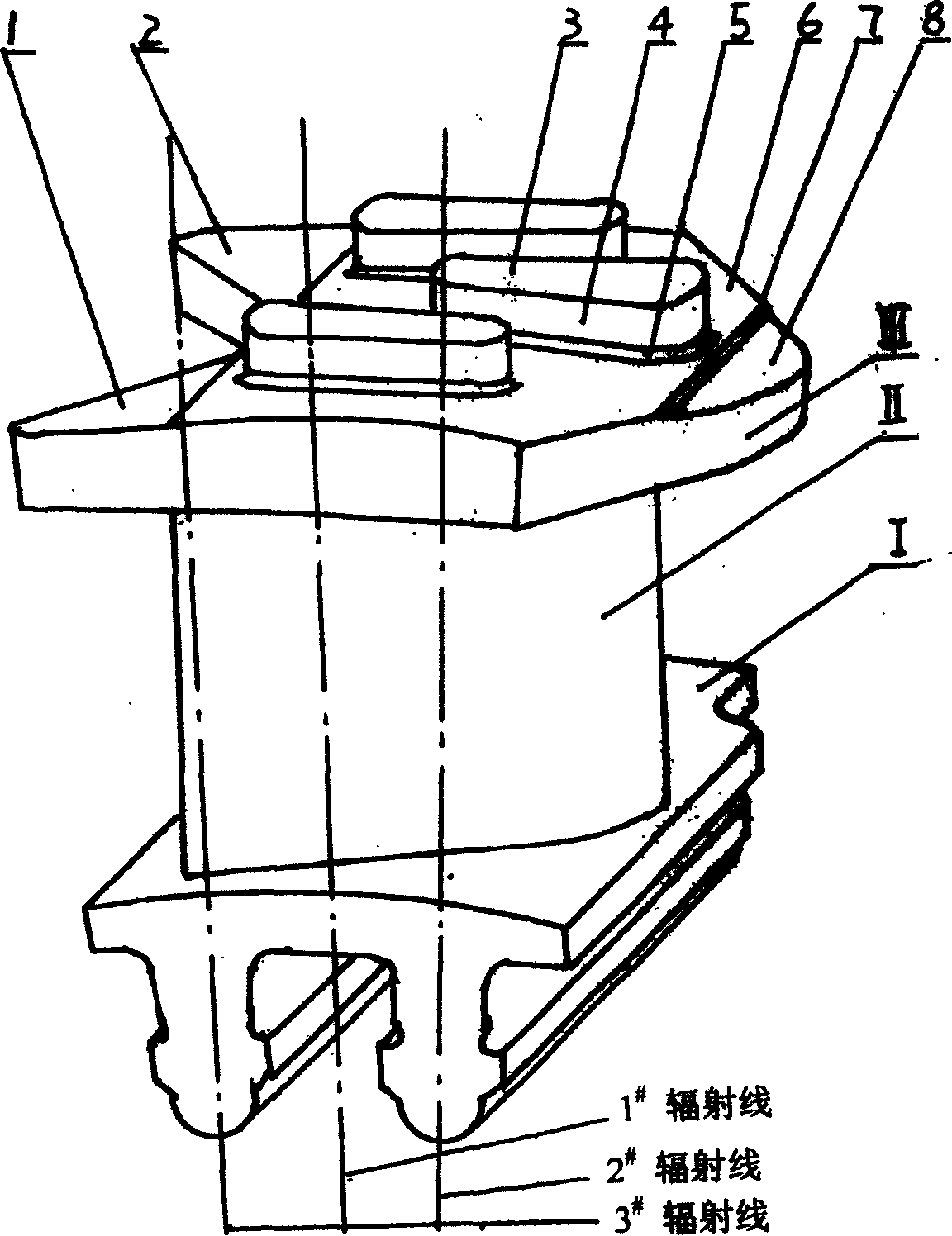

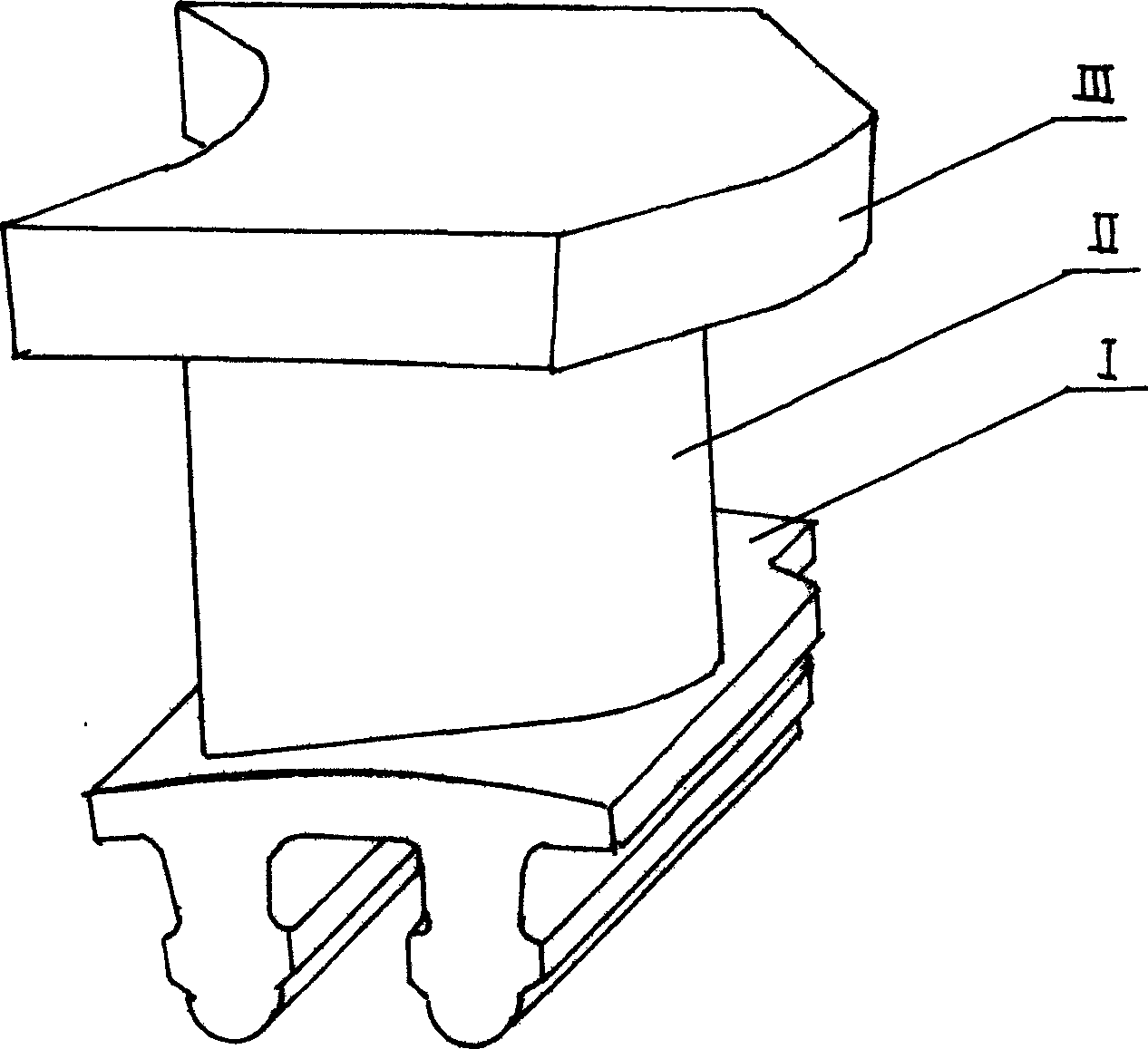

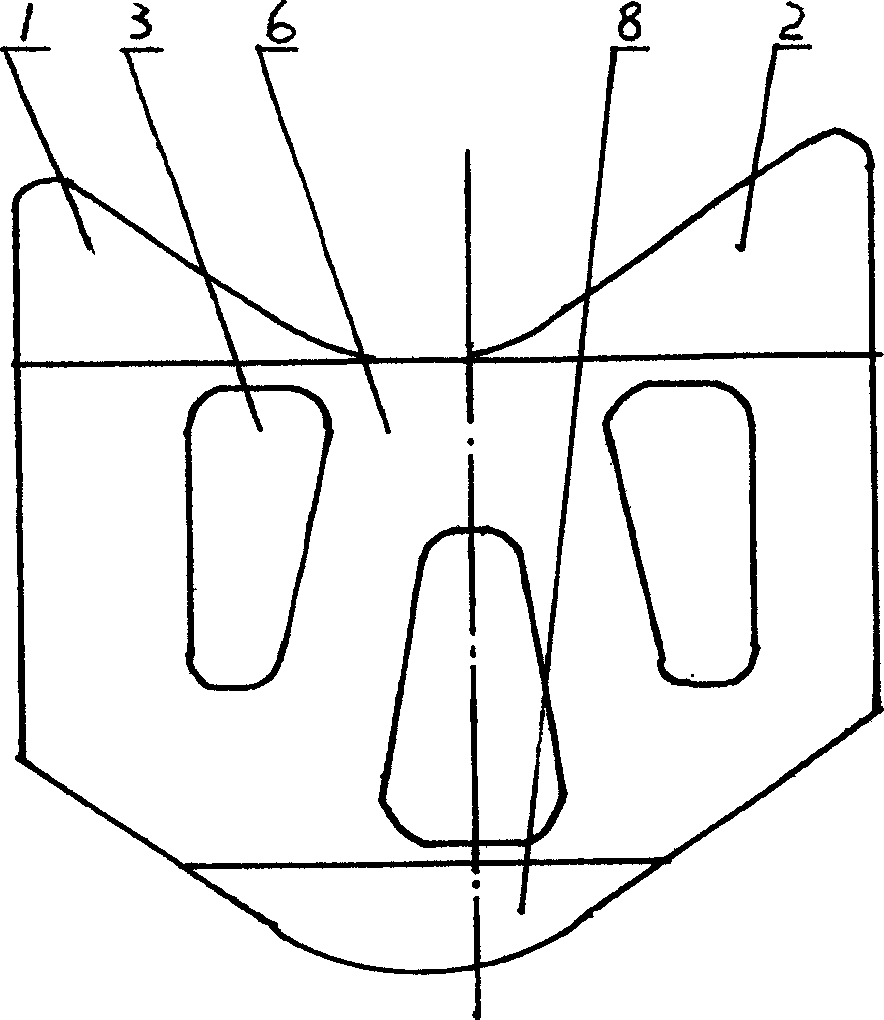

[0043]First of all, it needs to be explained that the contours of the blade root I, blade body II and blade crown III of the regulating stage rotor blade of the 600MW unit are processed according to the conventional method to make them into Figure 4 Shape, the present invention carries out on this basis to the processing of leaf crown:

[0044] The processing method of leaf crown

[0045] See Figure 8, Figure 9 :Will Figure 4 The blade shown is clamped on the THX-6340 four-axis four-coordinate horizontal machine tool with a fixture. The plane is the positioning reference, so that the rotation center of the blade is consistent with the rotation center of the machine tool table. When designing the fixture, pay attention to the following points:

[0046] (1) In order to maintain the consistency of the direction of the part and the installation tool position with the machine tool coordinate system and the programming coordinate system, the fixture should ensure directional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com