Preparation method of optical fiber covering quartz capillary perform and continuous melting furnace equipment

A quartz capillary and preform technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems of products failing to meet the international quality standards of similar products, air bubbles, gas lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

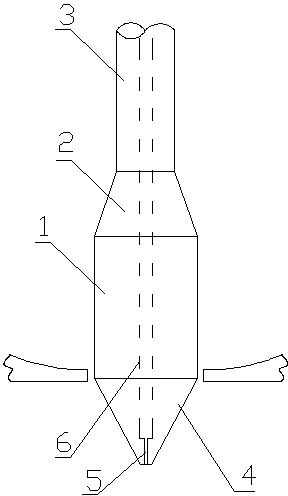

Image

Examples

Embodiment Construction

[0019] A method for outsourcing an optical fiber with a quartz capillary preform,

[0020] Preparation of High Purity Quartz Sand

[0021] The rough stone is crushed to a quartz stone with a block diameter of less than 30mm, then acid-leaved for 48 hours, taken out and dried, put into a furnace, quenched with deionized water, and then dried at 250°C;

[0022] Put the dried quartz stone into the roller machine for crushing, sort out the quartz sand with a mesh number between 30 and 100 mesh and put it into a mixed acid for 24 to 36 hours. The mixed acid is hydrochloric acid, hydrofluoric acid, etc. The mixed acid of acid and oxalic acid, wherein the mass ratio of hydrochloric acid: hydrofluoric acid: oxalic acid is 1:1~10:1~3, the mass percentage concentration of mixed acid is 10~20%; the amount of mixed acid is the mass of quartz sand 20~25%;

[0023] Wash the quartz sand soaked in mixed acid with deionized water, then dry it, go through multi-stage high gradient magnetic se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com