Bus chassis articulated system for urban bus rapid transit system and working method thereof

A bus system and bus chassis technology, which is applied to vehicle components, steering mechanisms of front and rear tandem vehicles, steering mechanisms, etc. The effect of low cost and convenient upgrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

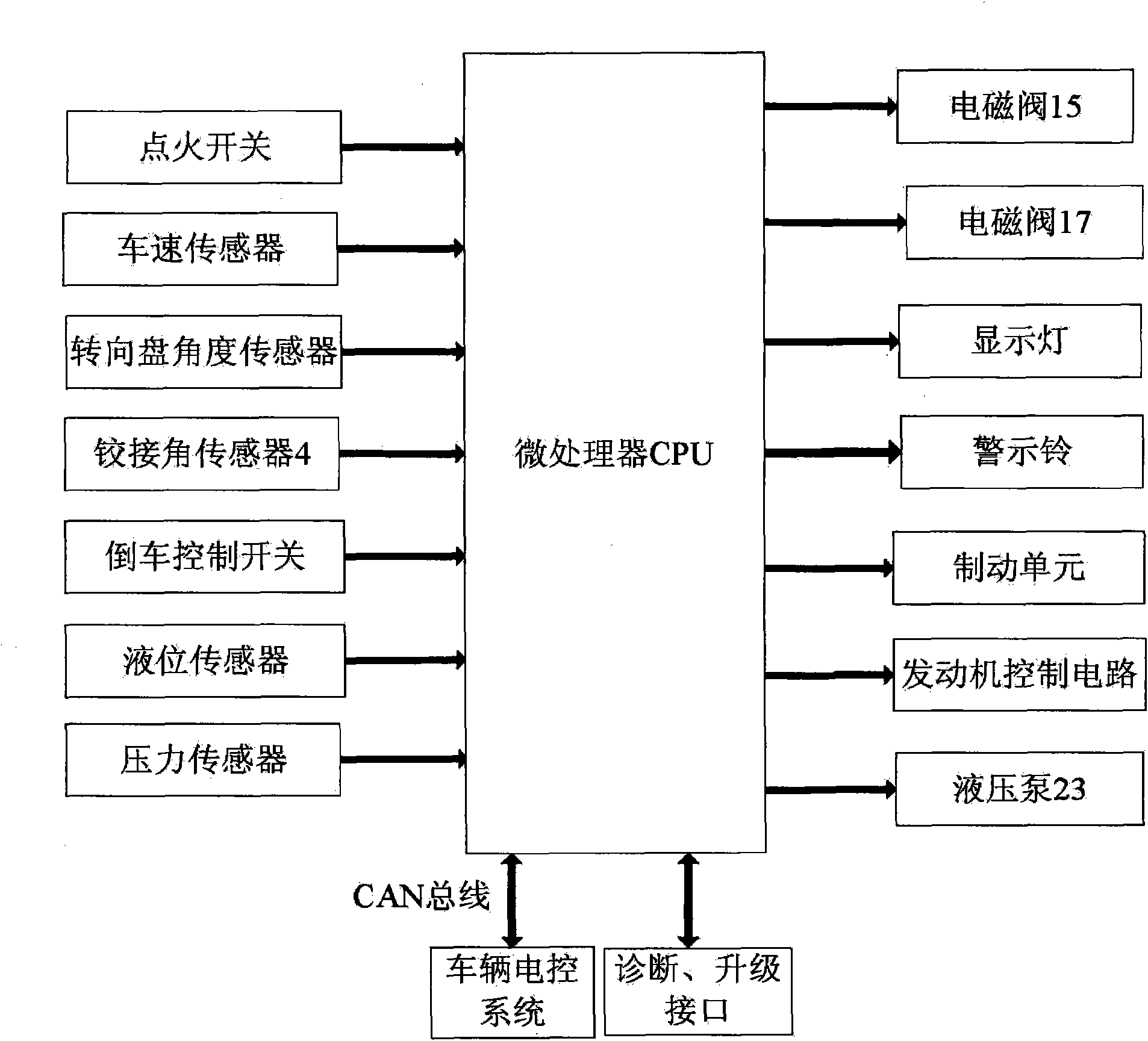

[0015] The passenger car chassis hinge system of the urban rapid transit system of the present invention is composed of a turntable device, a hydraulic system and a system control unit ECU.

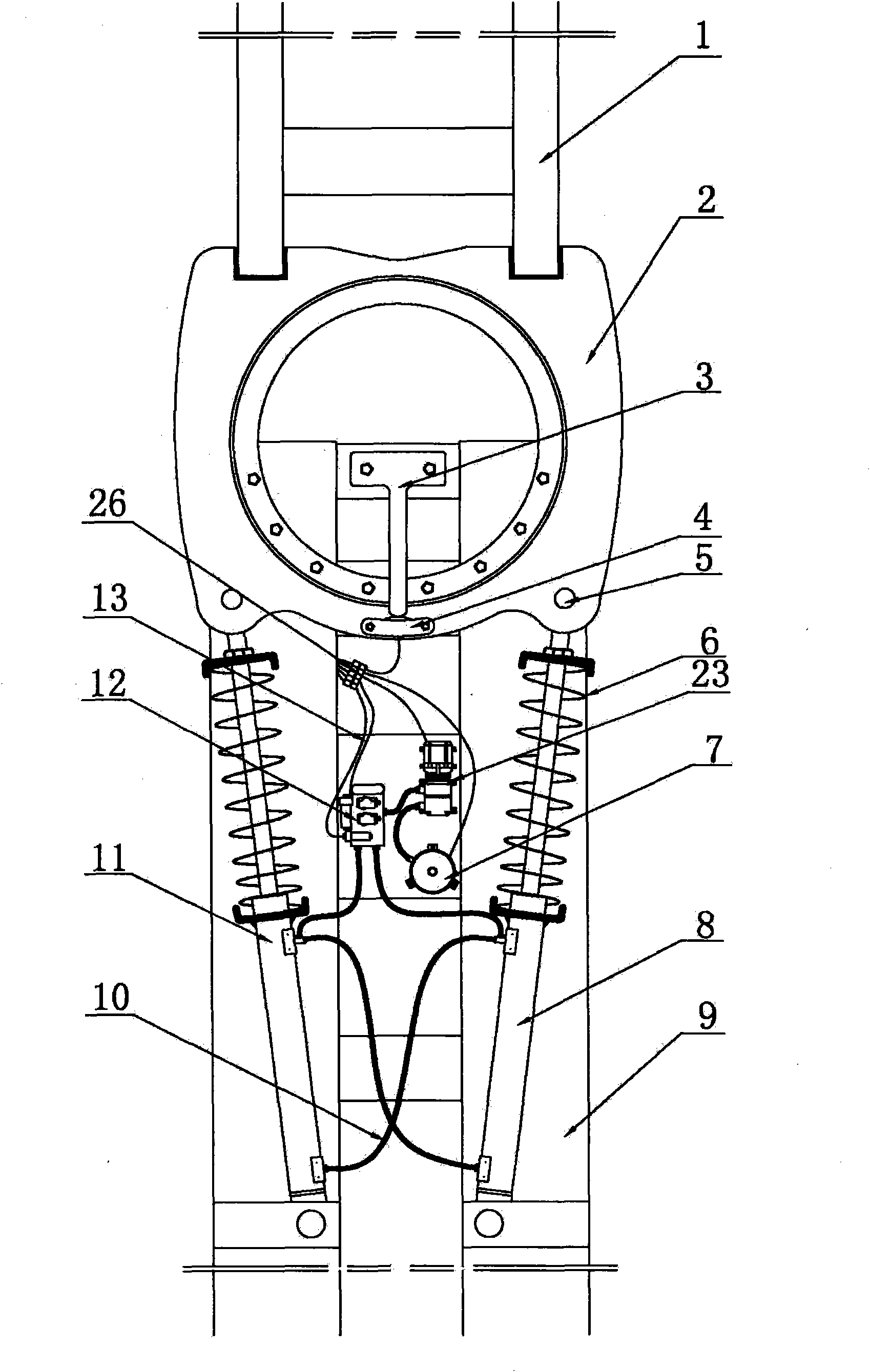

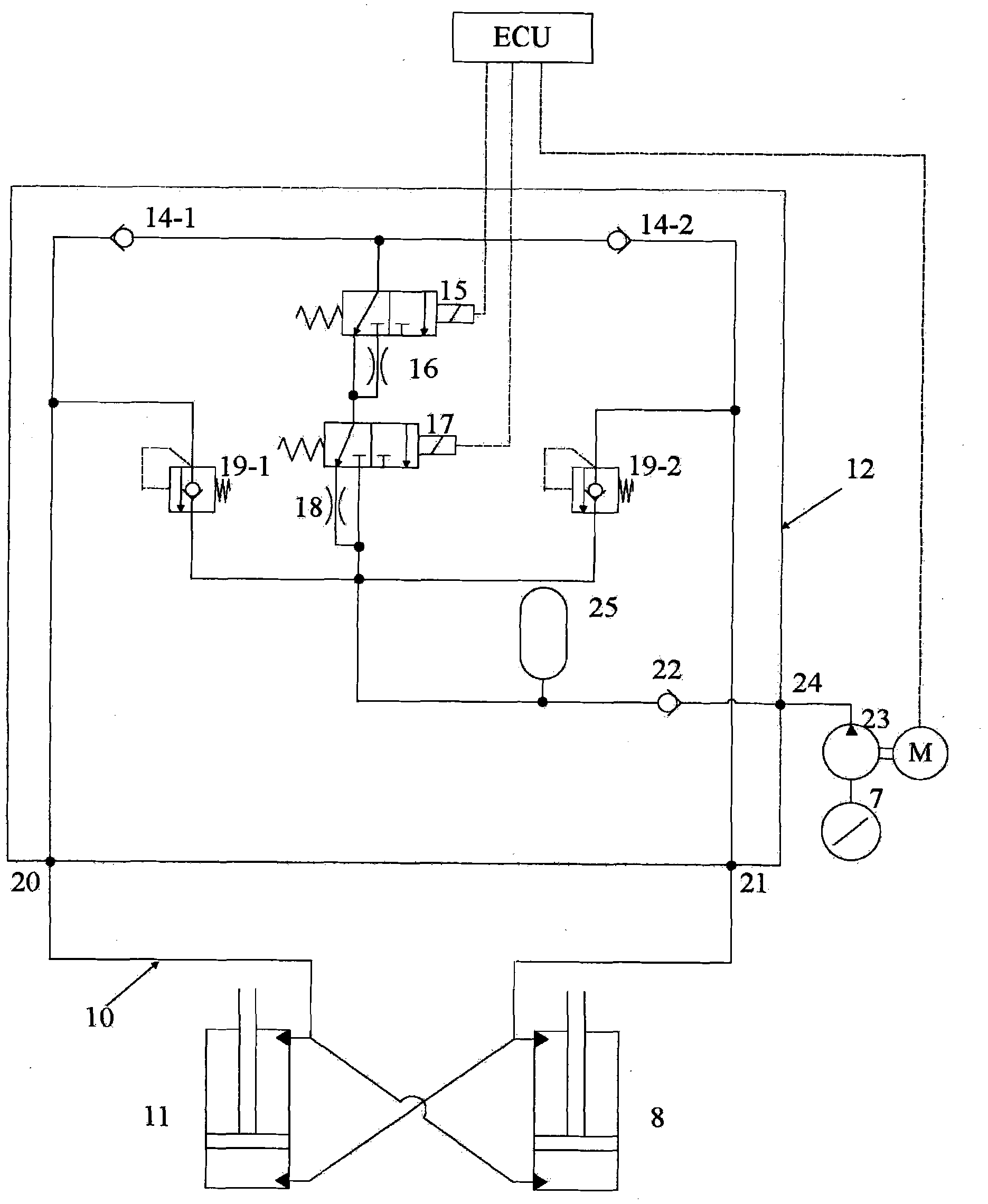

[0016] Such as figure 1 , turntable device comprises turntable 2, the front turntable frame 1 that links to each other with front car body and the rear turntable frame 9 that links to each other with rear car body, and turntable 2 is connected between front turntable frame 1 and rear turntable frame 9. The hydraulic system includes a hydraulic pump 23 , a left hydraulic cylinder 11 and a right hydraulic cylinder 8 . Two cylindrical helical compression springs 6 are sleeved on the hydraulic arms of the left hydraulic cylinder 11 and the right hydraulic cylinder 8 respectively. When the articulation angle is 0°, the cylindrical helical compression springs 6 are sleeved on the left hydraulic cylinder 11 and the right hydraulic cylinder in a free state. 8 on the hydraulic arm. The front and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com