Patents

Literature

44results about How to "Will not cause" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

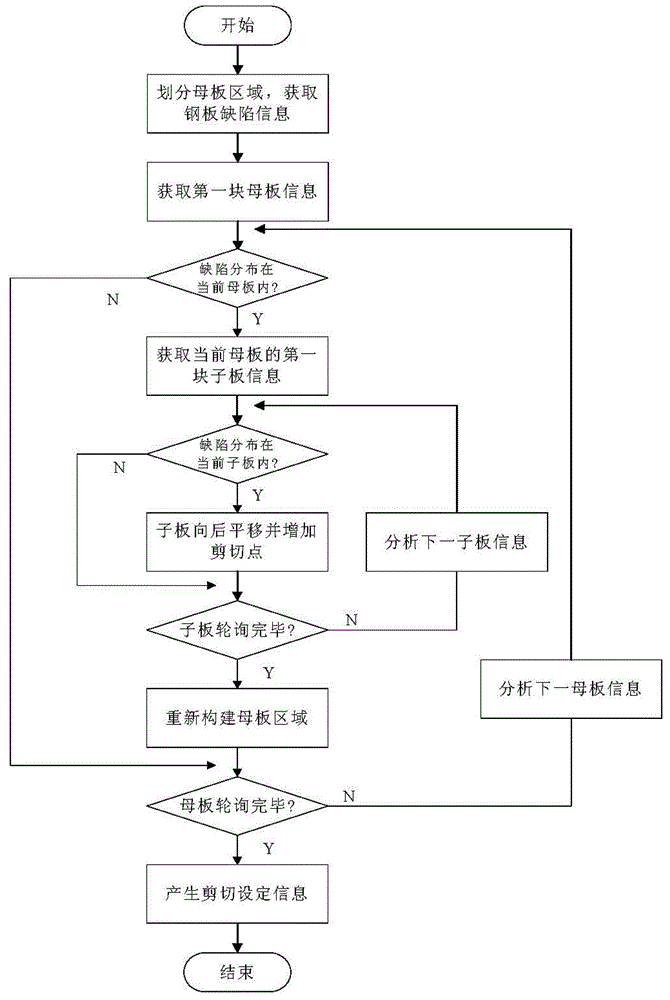

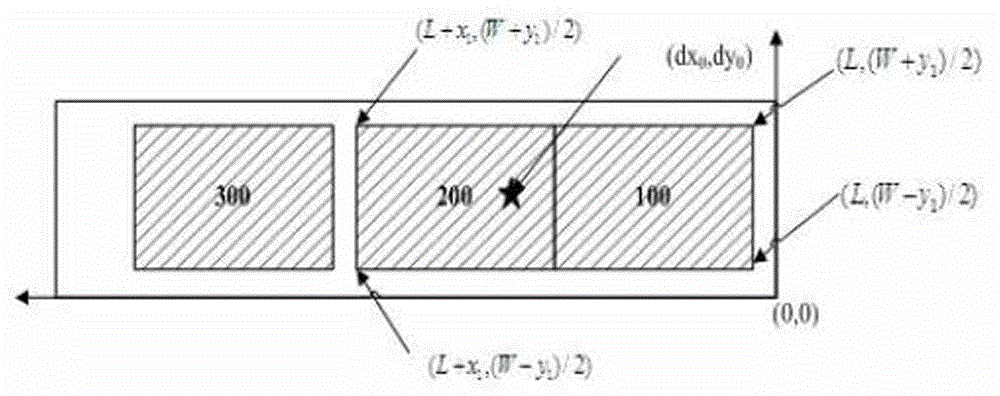

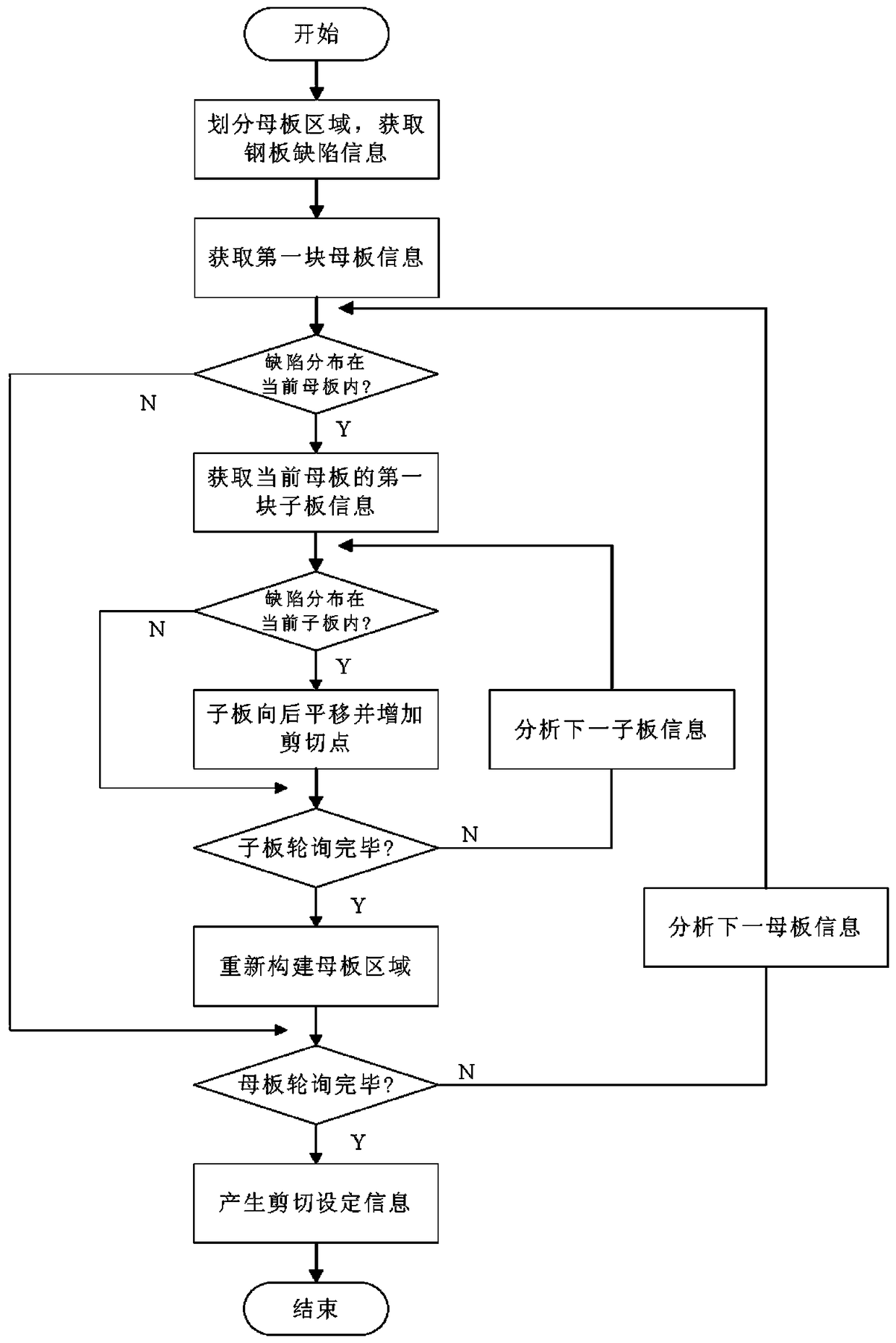

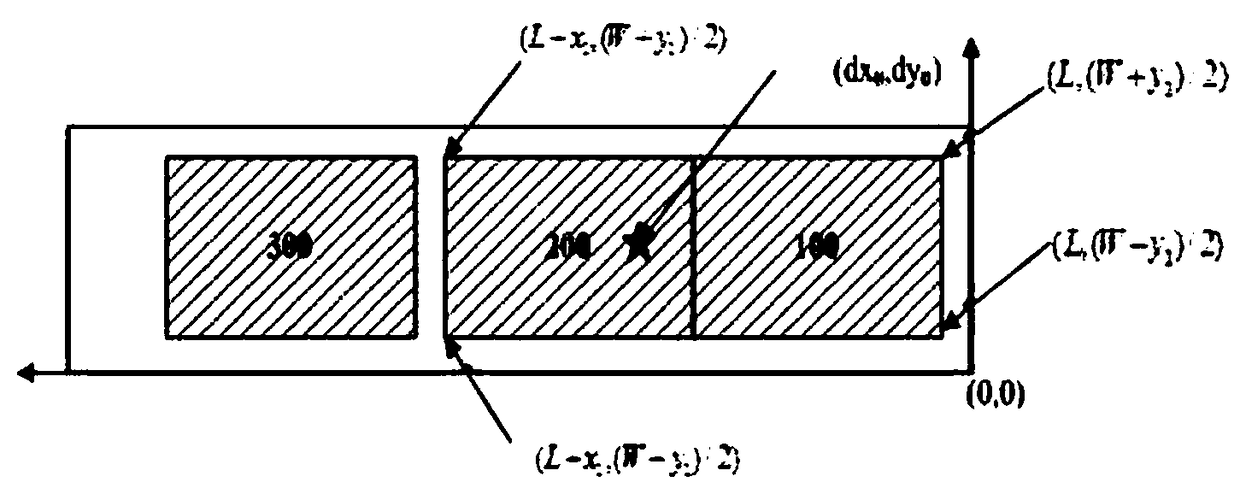

Online optimal shearing method for defective steel plates

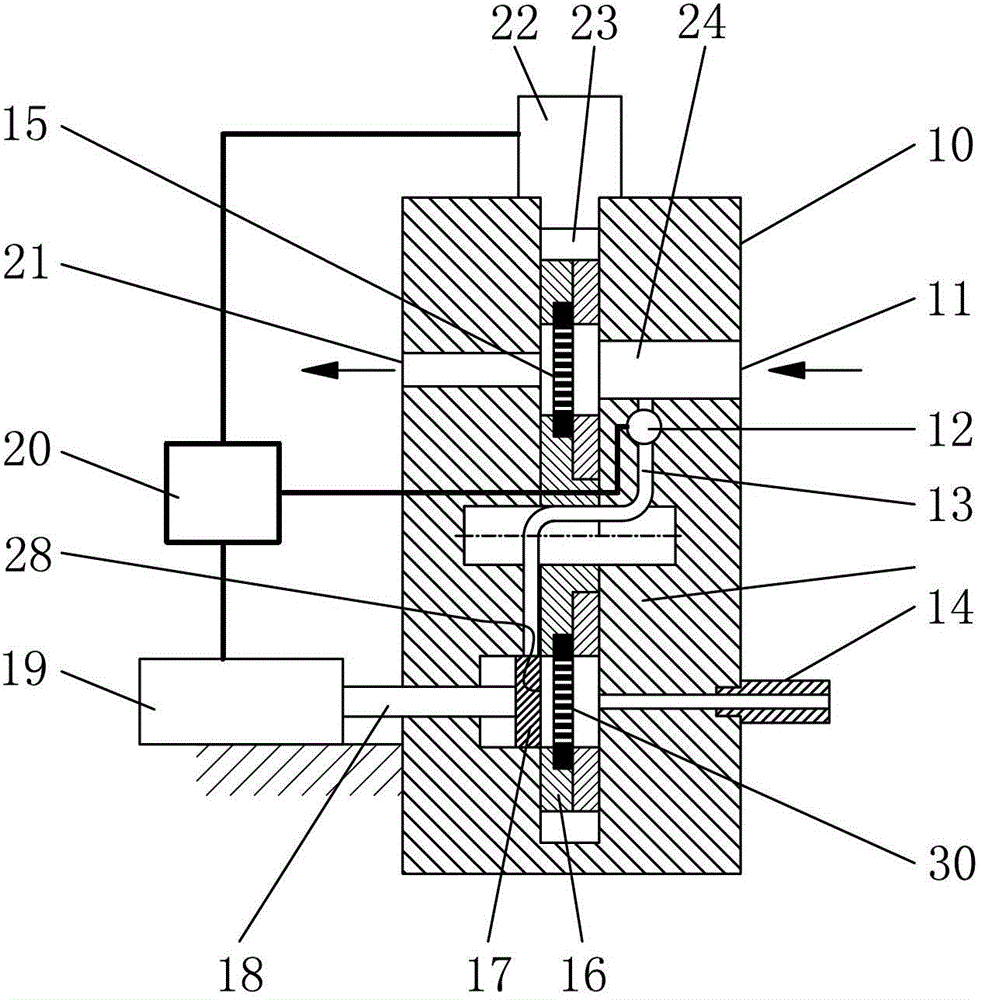

The invention relates to an online optimal shearing method for defective steel plates. The shearing method is characterized in that areas of a mother plate are divided, and at least one sub-plate is divided in each mother plate area, so that coordinates of a defect position on a rolling big plate are searched; edge coordinates of all the mother plate areas are inquired, so that the mother plate areas in which defects are distributed can be determined; different shearing strategies are formulated for sequence-type A group plates, partition-type S group plates and flame-cutting type G group plates; and all the defective sub-plates are avoided. In this way, the yield rate of the defective steel plates can be increased, and the feeding cost can be reduced. The method solves the problems in the prior art that the steel plate becomes shorter during shearing if the defect position is far from the head and tail of the rolling big plate; a lot of scrap plates can be generated; defects cannot be processed effectively; and the yield rate of the steel plates is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

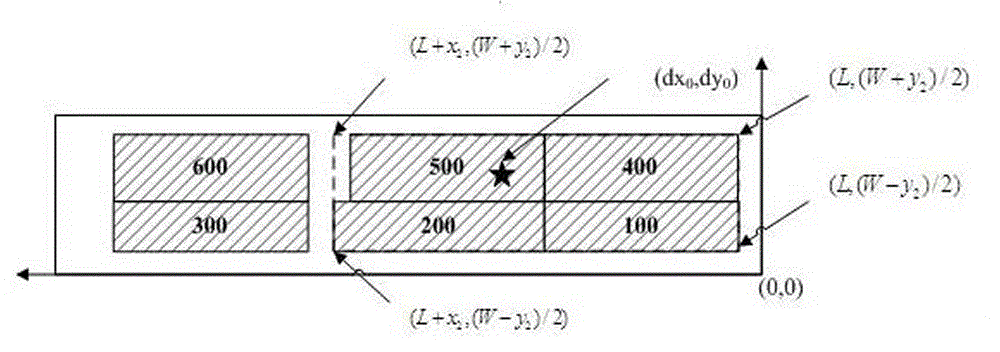

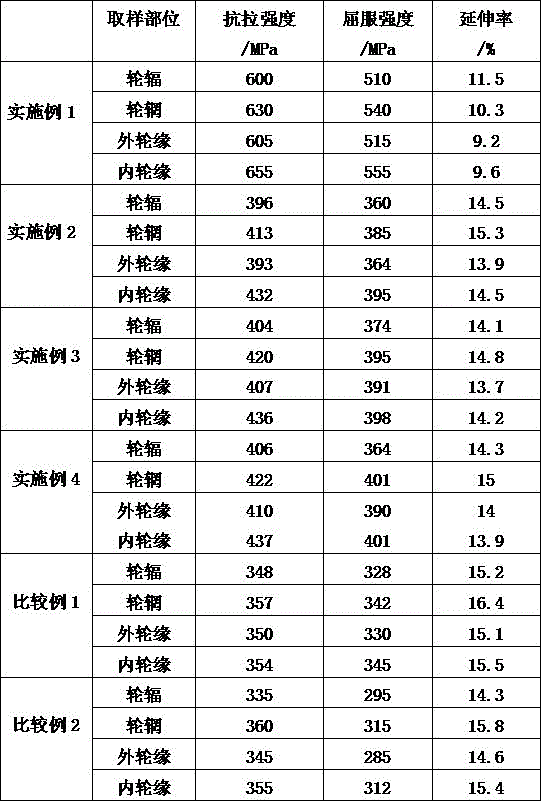

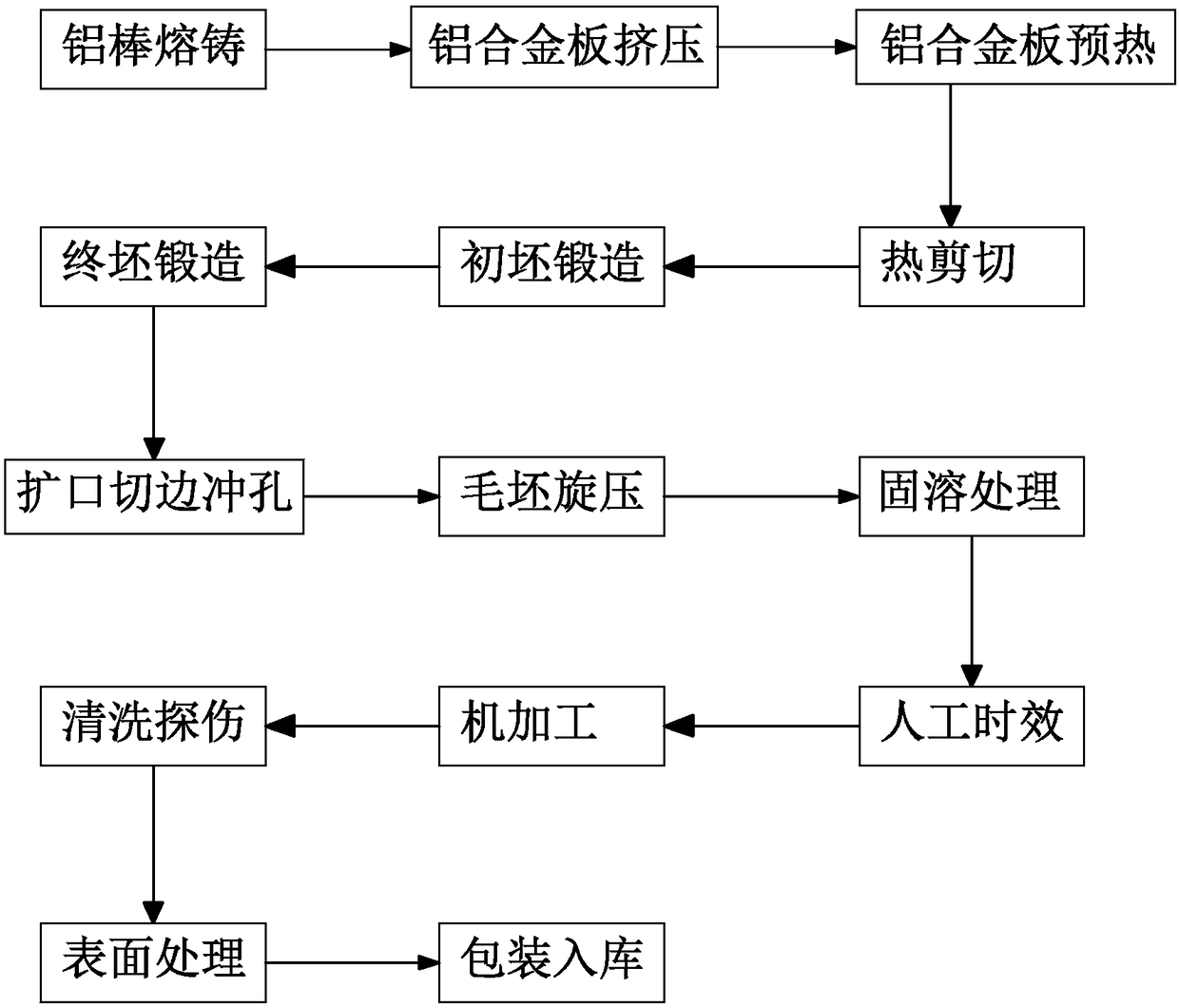

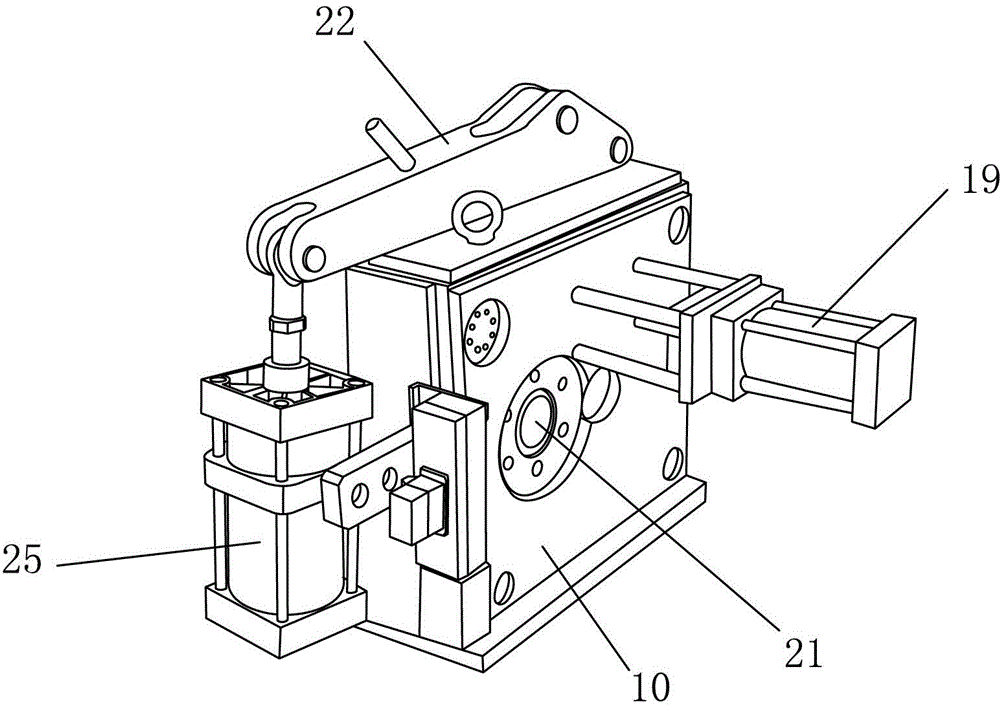

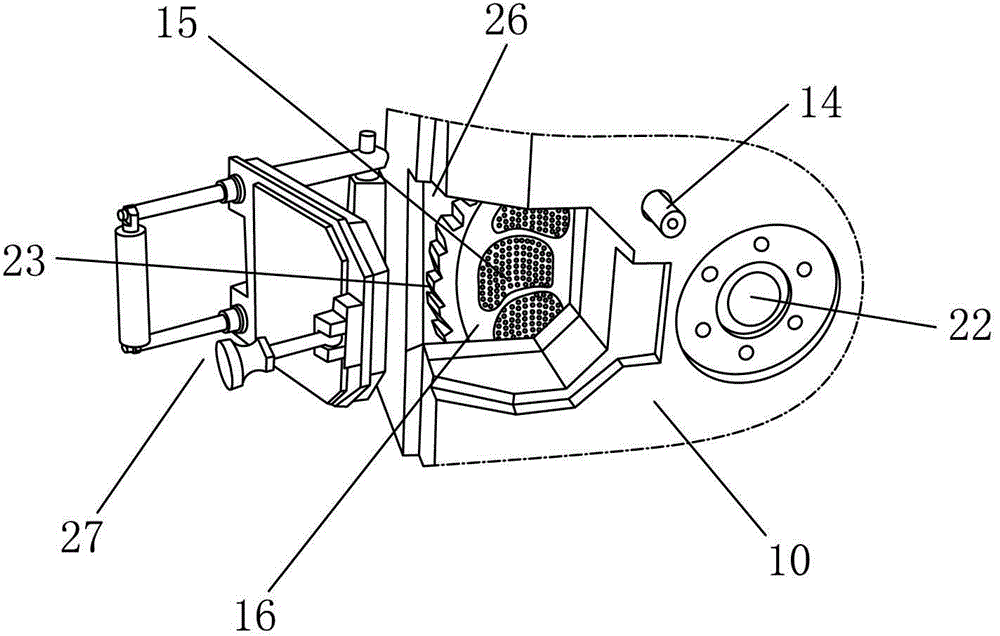

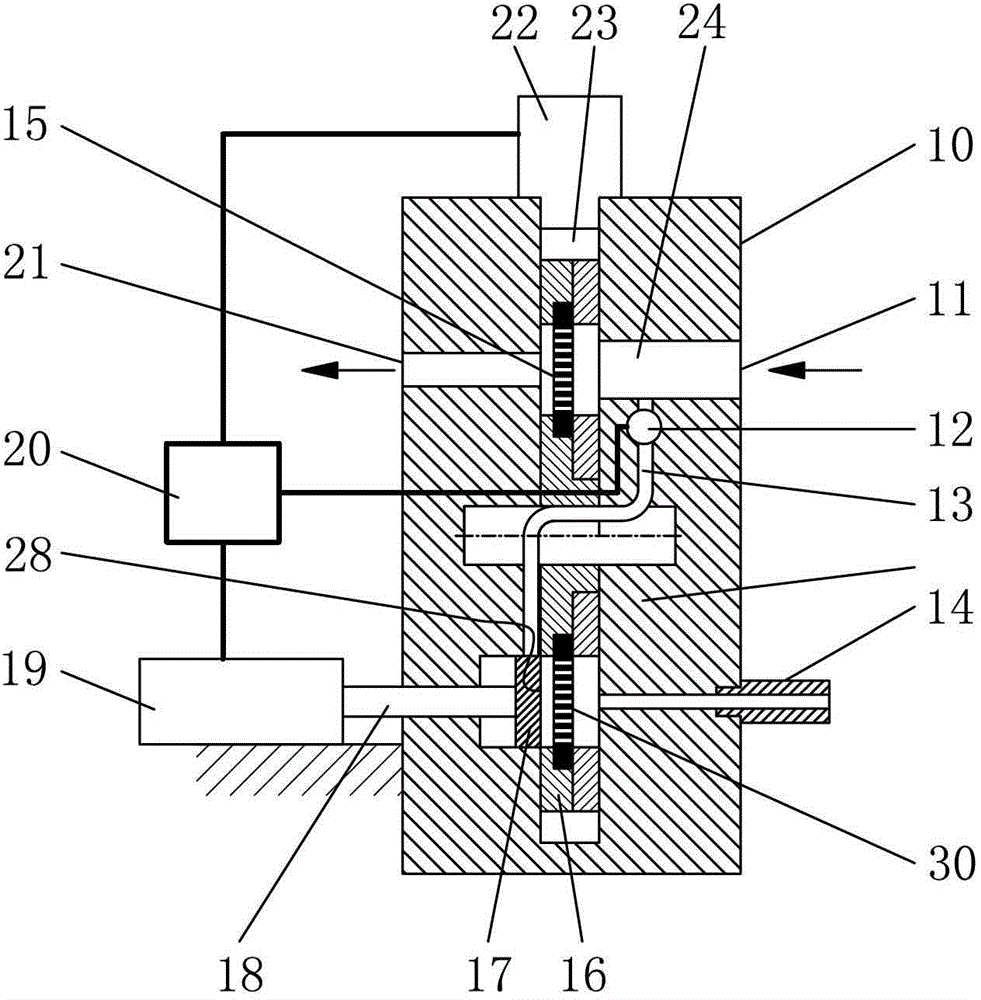

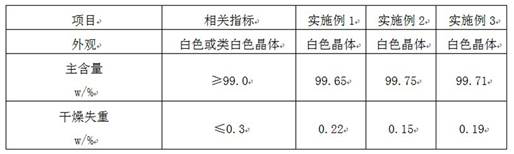

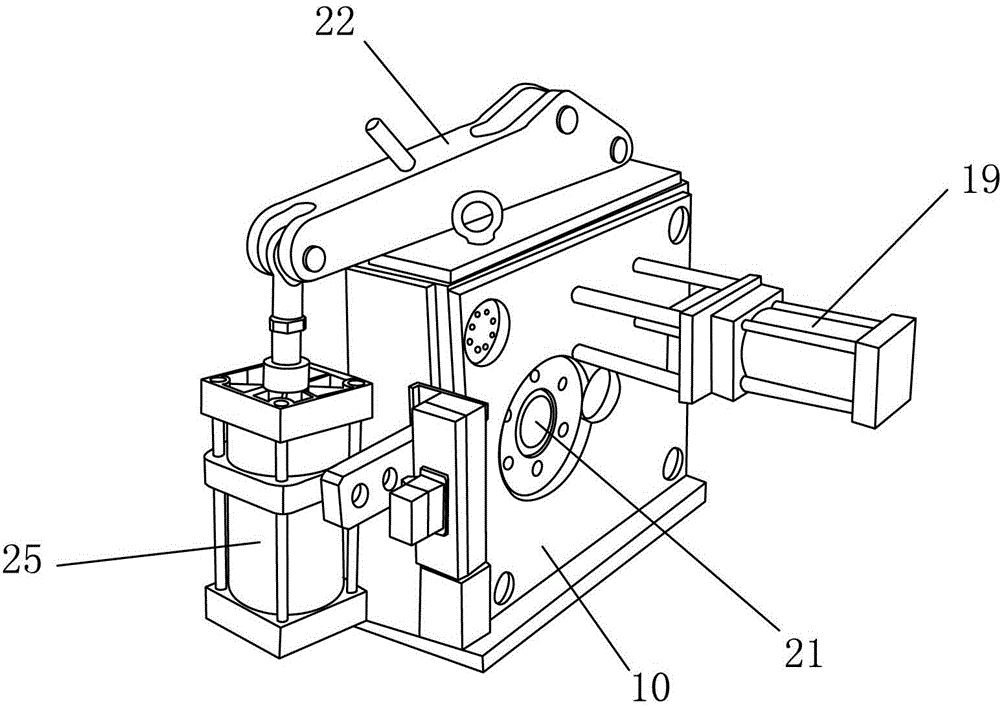

Hub forging method

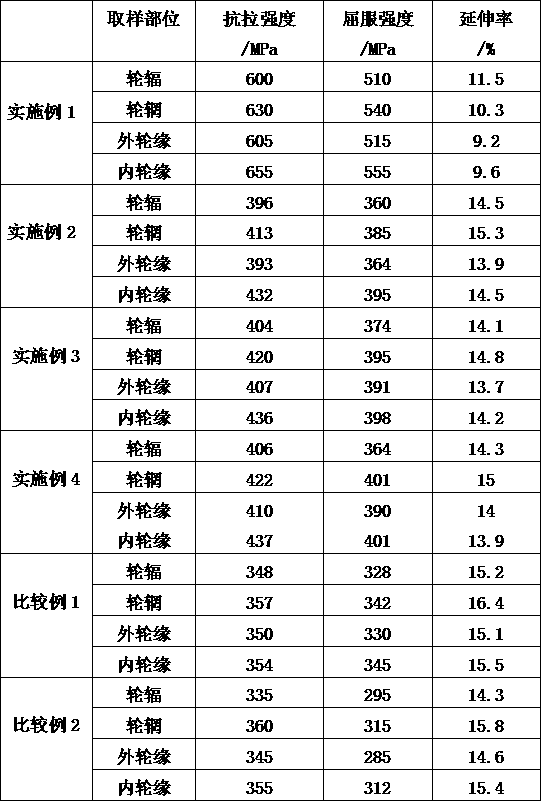

ActiveCN106216952AImprove compactnessSimple structureVehicle componentsPunchingVolumetric Mass Density

The invention discloses a hub forging method which comprises the following steps: a. profile extrusion: extruding an aluminum alloy plate with set thickness and width by an extruding machine; b. preheating: continuously online heating the aluminum alloy plate extruded by the extruding machine through heating equipment; c. hot cutting: cutting the preheated aluminum alloy plate which goes out from the heating equipment into a preset length to form a square-shaped blank by adopting the hot cutting technology; d. forging: putting the blank after being hot cut into a die, and forging and pressing the blank to form a disk shape; e. punching and bulging the disk-shaped blank; f. putting an enamel blank after being punched and bulged into a spinning machine, and carrying out spinning forming; and g. carrying out heat treatment and machining on the enamel blank after spinning forming to obtain a finished hub product. With adoption of the hub forging method, the efficiency of forging the hub, the utilization ratio of a raw material and the density of a product are higher.

Owner:宁波路威汽车轮业有限公司

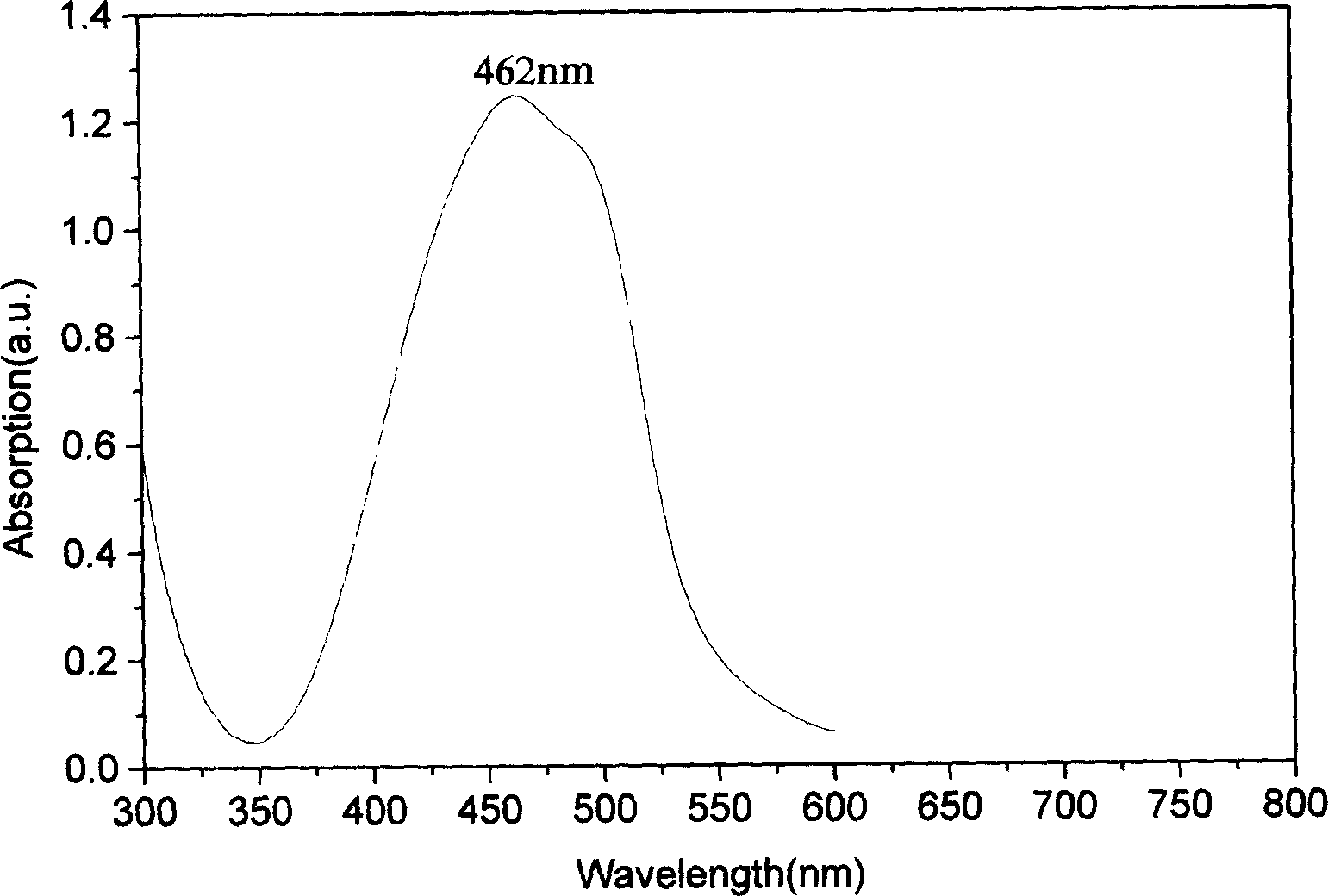

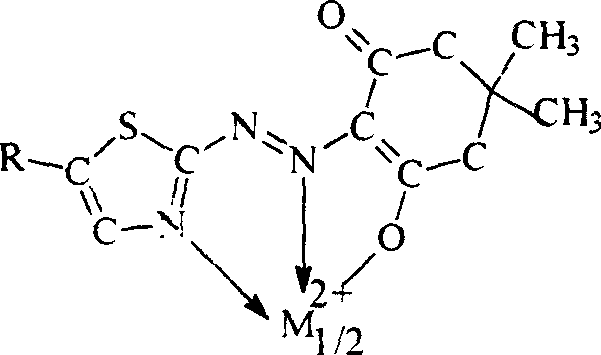

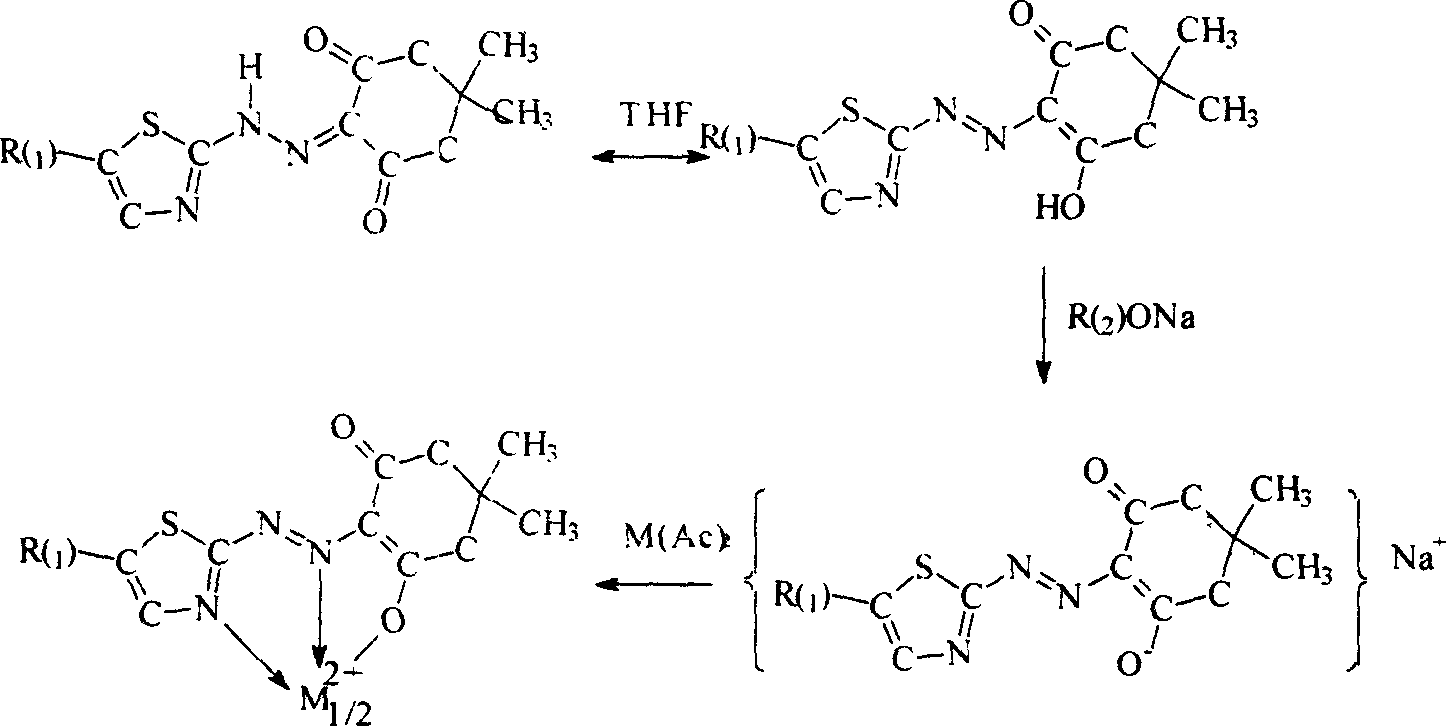

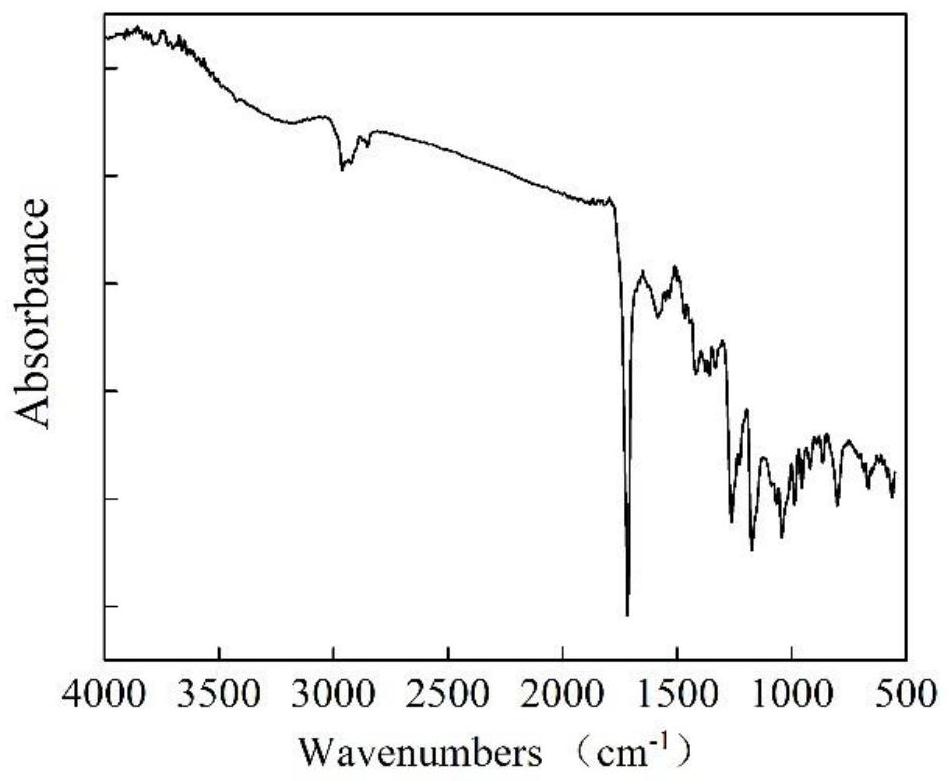

Metal chelate of short wavelength, and preparation method

InactiveCN1562987APromote generationWill not causeOrganic chemistryRecord information storageSolubilityOrganic solvent

This invention relates to short wavelength metal-chelate-alpha-(4-substituted-2-azothiazolcyclo)-beta-(4,4- dimethyl cyclohexadione) metal chelate with its structural formula as shown, where, C=carbon, N=nitrogen, R=alkyl, methyl, 1-4 carbon linear branched chain alkyl with t-butyl; M2+=Ni2+, Zn2+, Cu2+. This invention compound adsorbs short wavelength (400-500 nm), has solubility being not less than 3 wt% in much organic solvent, being suitable for forming membrane with rotating coating method with high stability, being matched with blue-green laser in working wavelength of 450-550 nm, being of organic storage medium of high thickness blue-green light recording-disc.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

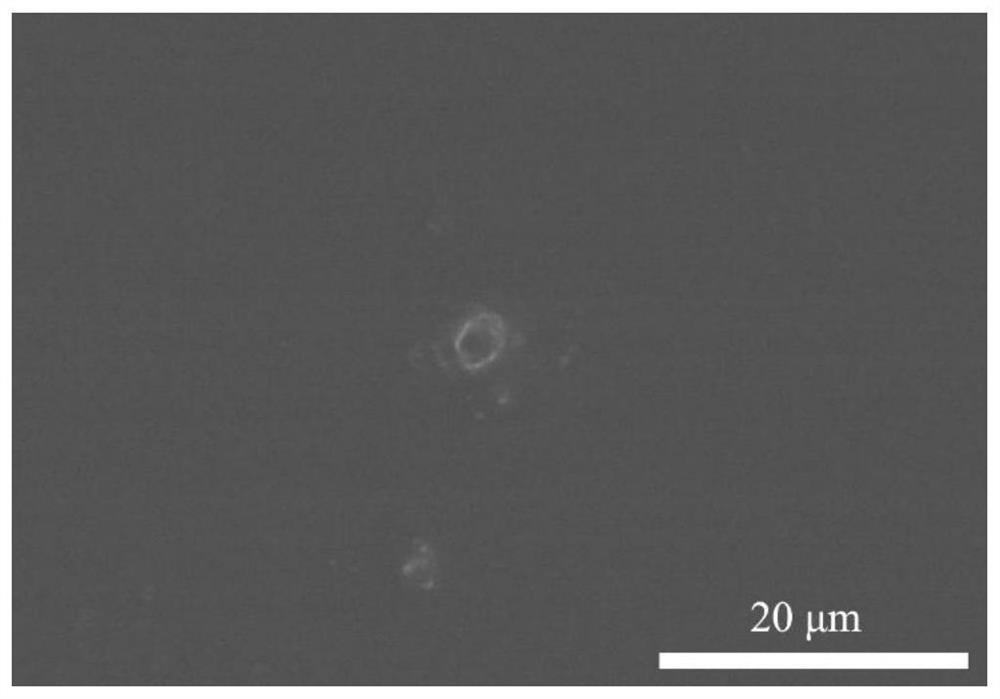

Hydrogel microcapsule with anti-wrinkle effect

InactiveCN104434549AHas anti-wrinkle effectCrystal clear visual senseCosmetic preparationsToilet preparationsPolymer scienceGreen Tea Polyphenols

The invention provides a hydrogel microcapsule with an anti-wrinkle effect. The hydrogel microcapsule is a core-shell microcapsule, wherein the microcapsule wall is yellow and transparent, the capsule wall material comprises gel materials, a water-soluble film-forming material and natural uranidin; the capsule core is non-transparent and the core material comprises a grease material and anti-wrinkle components which include procyanidine, papaya sulfhydryl enzyme or green tea polyphenol; the hydrogel microcapsule is prepared through a dropping method. The hydrogel microcapsule with the anti-wrinkle effect is beautiful and unique in appearance, good in anti-wrinkle effect, light and thin in texture and incapable of causing generation of fat granules, and has immeasurable market prospect.

Owner:CHONGQING PELLETS TECHN & TRADE

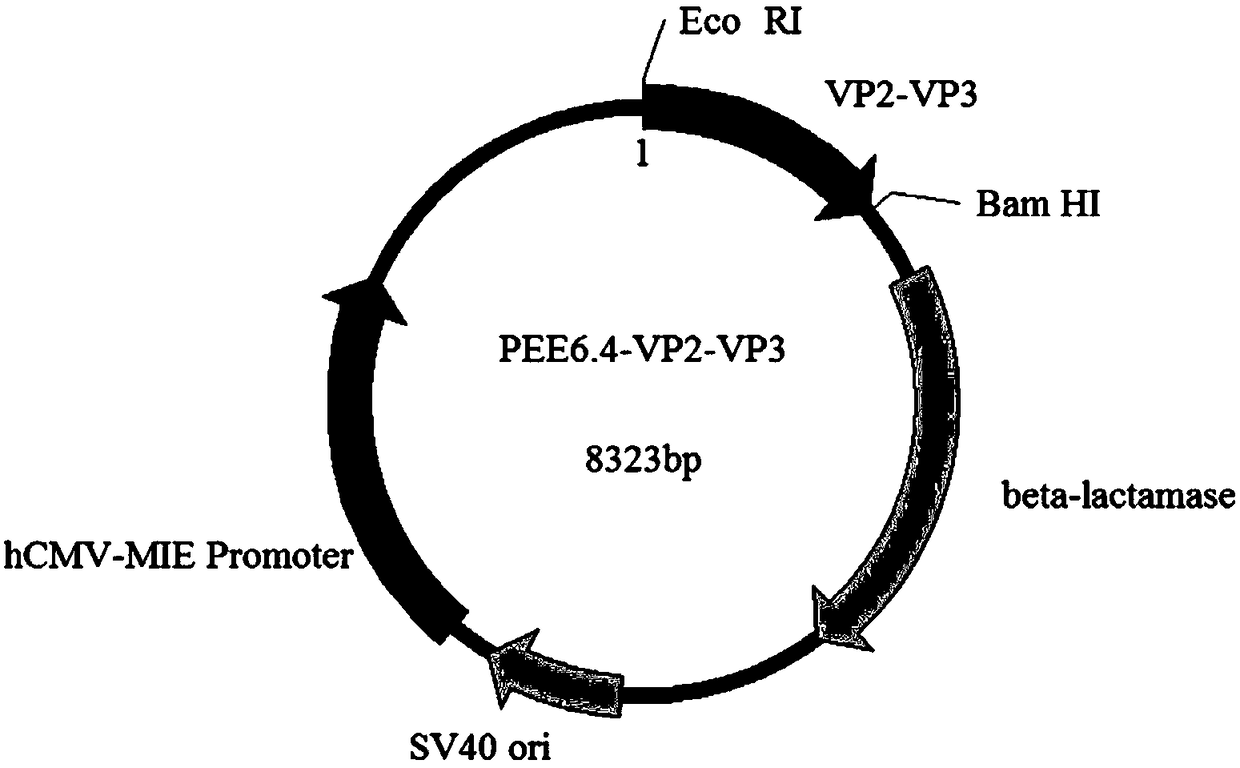

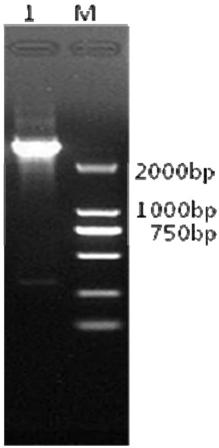

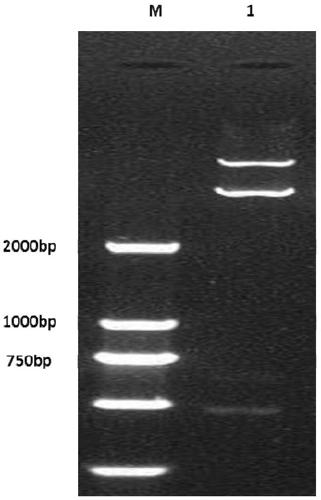

Fusion protein of infectious bursal disease virus, preparation method, application, expression system of fusion protein and vaccine comprising fusion protein

InactiveCN109134668AImprove securityWill not causeAntibody mimetics/scaffoldsVirus peptidesSide effectInfectious bursitis

The invention relates to the technical field of biology, and particularly provides a fusion protein of an infectious bursal disease virus, a preparation method, application, an expression system of the fusion protein and a vaccine comprising the fusion protein. The fusion protein comprises a VP2 section and a VP3 section, wherein the VP2 section is expressed by a nucleotide sequence shown in SEQ ID NO.1, the VP3 is expressed by a nucleotide sequence shown in SEQ ID NO.2. The fusion protein is obtained by tandem expression of the gene sequences of the VP2 and the VP3 of the infectious bursal disease virus. By analyzing the gene sequences of the VP2 and the VP3 and selecting zones high in antigenicity and easy for high expression to link tandemly, the obtained fusion protein has the advantages of high antigenicity and high expression amount. By adopting the fusion protein as an antigen to prepare the vaccine, the prepared vaccine has the advantages of good safety, stable potency and no toxic and side effects. The invention further provides the preparation method and application of the fusion protein, and the vaccine prepared from the fusion protein.

Owner:TECON BIOLOGY CO LTD

Preparation method and application of antibacterial silicone rubber

ActiveCN107286339AWill not causeNo drug resistanceCosmetic preparationsToilet preparationsEscherichia coliFiber

The invention discloses a preparation method of antibacterial silicone rubber. The preparation method comprises the following step: inducing ring opening polymerization of amino acid N-carboxylic acid anhydride in situ by virtue of amino on the surface of silicone rubber, so as to obtain the silicone rubber with the surface containing a polyamino acid copolymer or a polyamino acid homopolymer. According to the antibacterial silicone rubber prepared by virtue of the preparation method, the problems that existing antibacterial silicone rubber easily generates drug resistance and is poor in biocompatibility are solved, and the antibacterial silicone rubber has good application prospects. The antibacterial rate of the prepared antibacterial silicone rubber to bacteria including escherichia coli, staphylococcus aureus, staphylococcus epidermidis, pseudomonas aeruginosa, Candida albicans, pneumococcus and the like exceeds 90%, and the cytotoxicity of mouse fibroblast does not exceed level 1.

Owner:泰州度博迈医疗器械有限公司

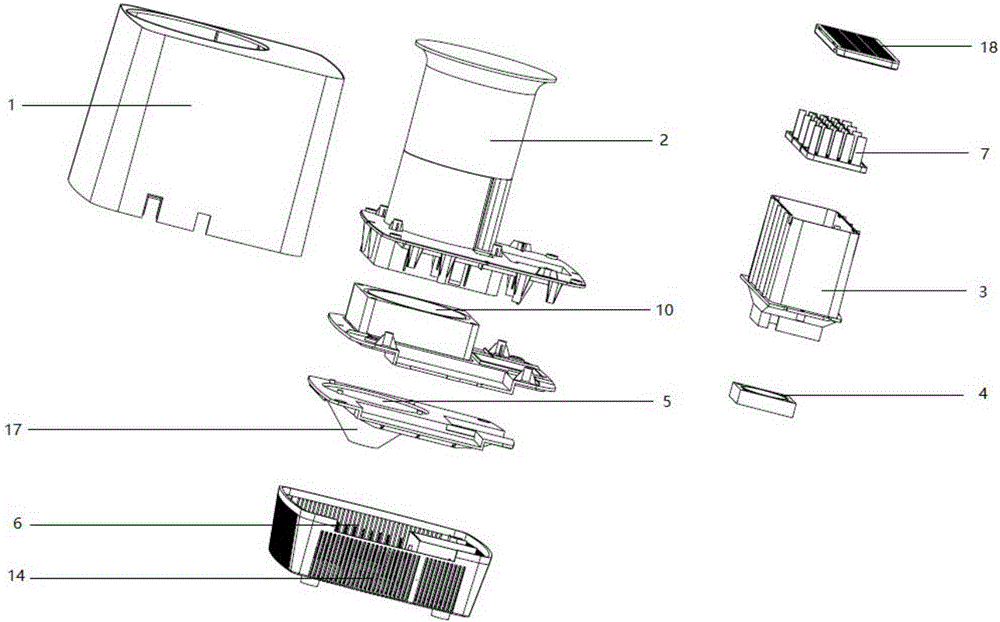

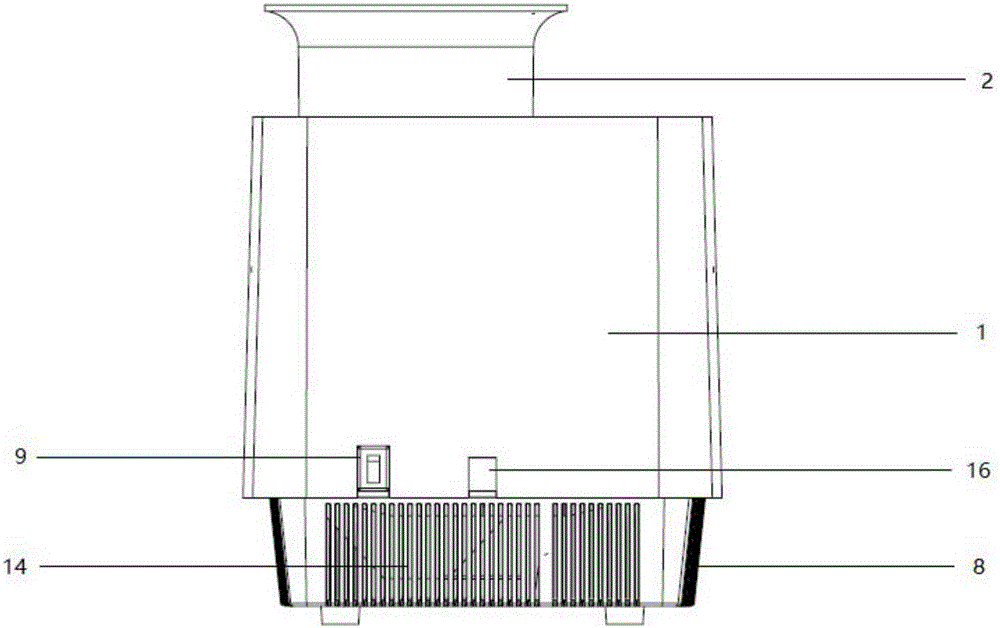

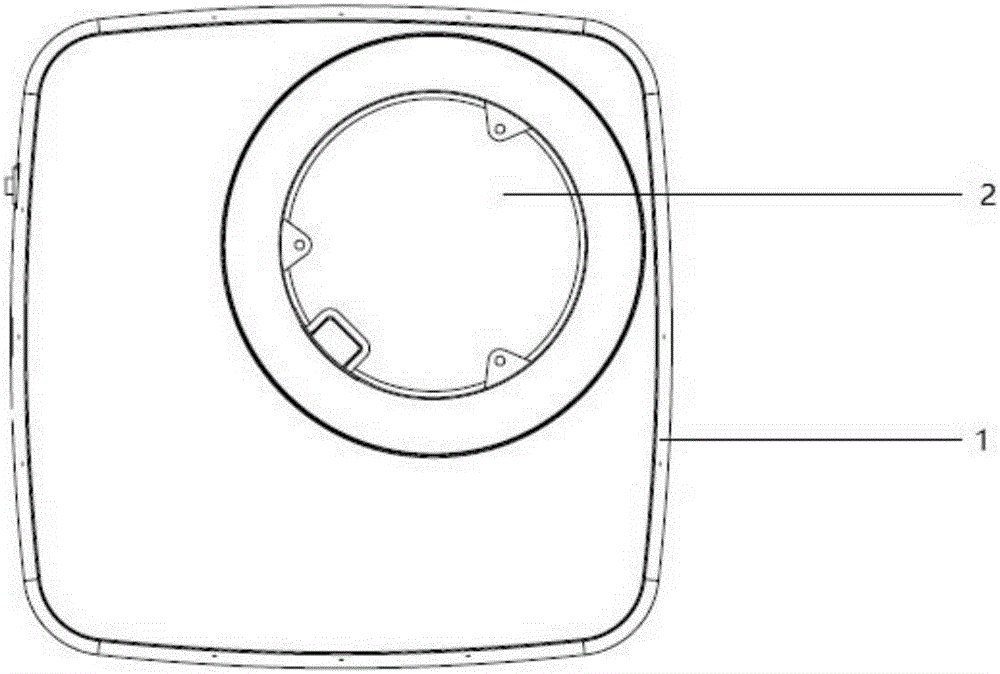

A kind of wheel hub forging method

The invention discloses a hub forging method which comprises the following steps: a. profile extrusion: extruding an aluminum alloy plate with set thickness and width by an extruding machine; b. preheating: continuously online heating the aluminum alloy plate extruded by the extruding machine through heating equipment; c. hot cutting: cutting the preheated aluminum alloy plate which goes out from the heating equipment into a preset length to form a square-shaped blank by adopting the hot cutting technology; d. forging: putting the blank after being hot cut into a die, and forging and pressing the blank to form a disk shape; e. punching and bulging the disk-shaped blank; f. putting an enamel blank after being punched and bulged into a spinning machine, and carrying out spinning forming; and g. carrying out heat treatment and machining on the enamel blank after spinning forming to obtain a finished hub product. With adoption of the hub forging method, the efficiency of forging the hub, the utilization ratio of a raw material and the density of a product are higher.

Owner:宁波路威汽车轮业有限公司

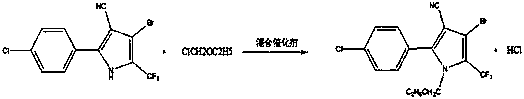

Production process for catalytic synthesis of chlorfenapyr with mixed catalyst

The invention provides a production process for catalytic synthesis of chlorfenapyr with a mixed catalyst. The production process comprises steps of material addition, chloric ether dropping, heat-preservation reactions and solid-liquid separation. 4-bromine and chloric ether are adopted as main raw materials, acetonitrile is adopted as a reaction solvent, potassium carbonate and solid caustic soda are adopted as a mixed catalyst for catalytic synthesis of chlorfenapyr, after reactions are completed, solid-liquid separation is carried out, a reaction solvent is evaporated off, a refining solvent is further used to carry out refining, and thus the chlorfenapyr is prepared. A small dosage of the mixed catalyst is used in the production process, the amount of the catalyst is reduced by 60% when being compared with that of a conventional process, a small amount of solid wastes is generated, the solid wastes are reduced by 55% when being compared with those of a conventional process, the cost is reduced by 15-20% when being compared with that of conventional process, the solvent can be circulated and mechanically applied, pollution and waste can be reduced, and very good economical efficiency and environment-friendliness can be achieved.

Owner:山东潍坊双星农药有限公司

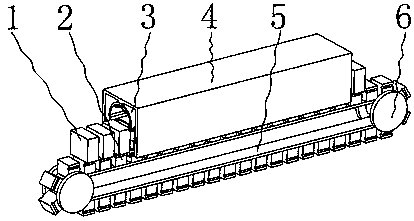

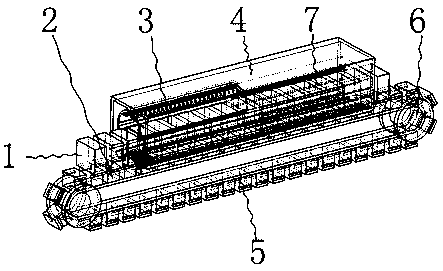

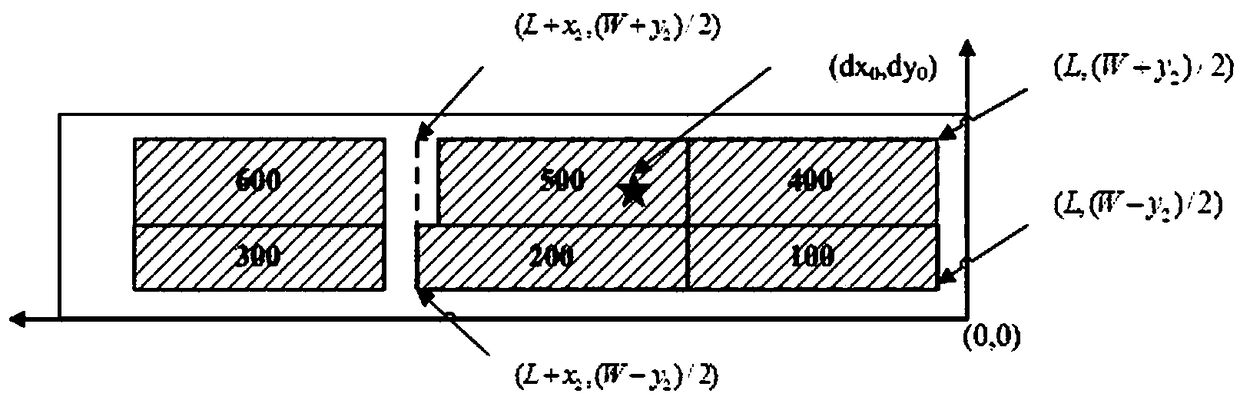

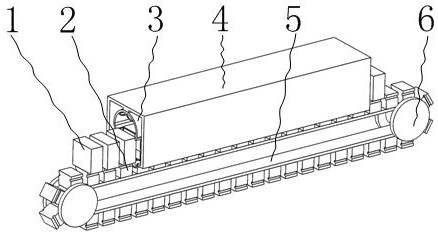

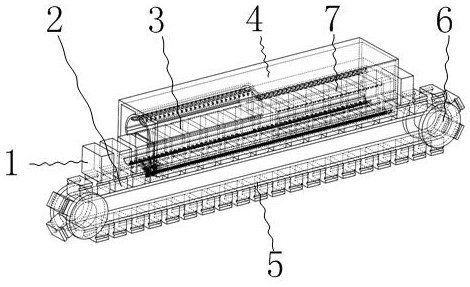

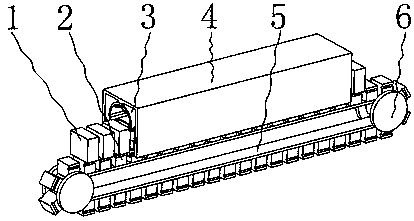

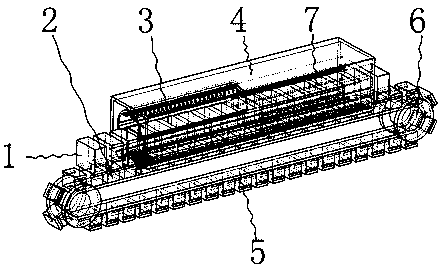

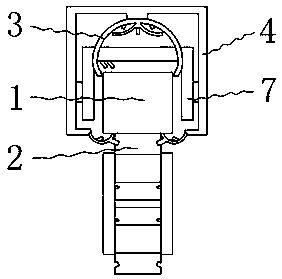

Automatic washing and blow-drying device for storage battery

ActiveCN108636906AProtect the working environmentSave cleaning fluidDrying gas arrangementsDrying machines with progressive movementsDrive wheelWorking environment

The invention belongs to the technical field of washing and blow-drying of storage batteries, and particularly relates to an automatic washing and blow-drying device for a storage battery. The automatic washing and blow-drying device comprises a supporting mechanism, a washing supporting shell, a mounting shell, a belt, two driving wheels and a blow-drying supporting shell; in the process of usingthe washing and blow-drying device for the storage battery, when a driving motor works, the driving motor drives the driving wheel which is connected with the driving motor to rotate through the output shaft, and the driving wheel rotates and drives the belt to move; the belt moves and drives the supporting mechanism which is mounted on the belt to move, and the supporting mechanism moves and then drives the storage battery to move; in the moving process of the storage battery, the storage battery is cleaned up and blow-dried through first nozzles, second nozzles, third nozzles and an air blowing opening, and washing solution is saved; and meanwhile, irritating gases like SO2 produced from the heating and decomposing process of sulfuric acid cannot be generated, and the working environment around the conveyor belt is protected.

Owner:浙江杰斯特电器有限公司

Environment protection type energy-saving mixed non-azeotropic refrigerant

InactiveCN1390909AImprove the coefficient of performanceNon-destructiveChemical industryHeat-exchange elementsEngineeringHeat pump

An energy-saving environment protection type composite non-azeotropic refrigerant contains (R1270 (C3H6) (3-40 wt.%), R152a (CH3CHF2) (20-85), R600 (C4H10) and R600a (C4-H10). Its advantages are no damage to ozonosphere and saving energy by 25-45%.

Owner:顾雏军

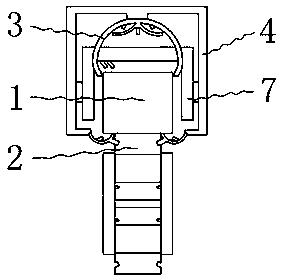

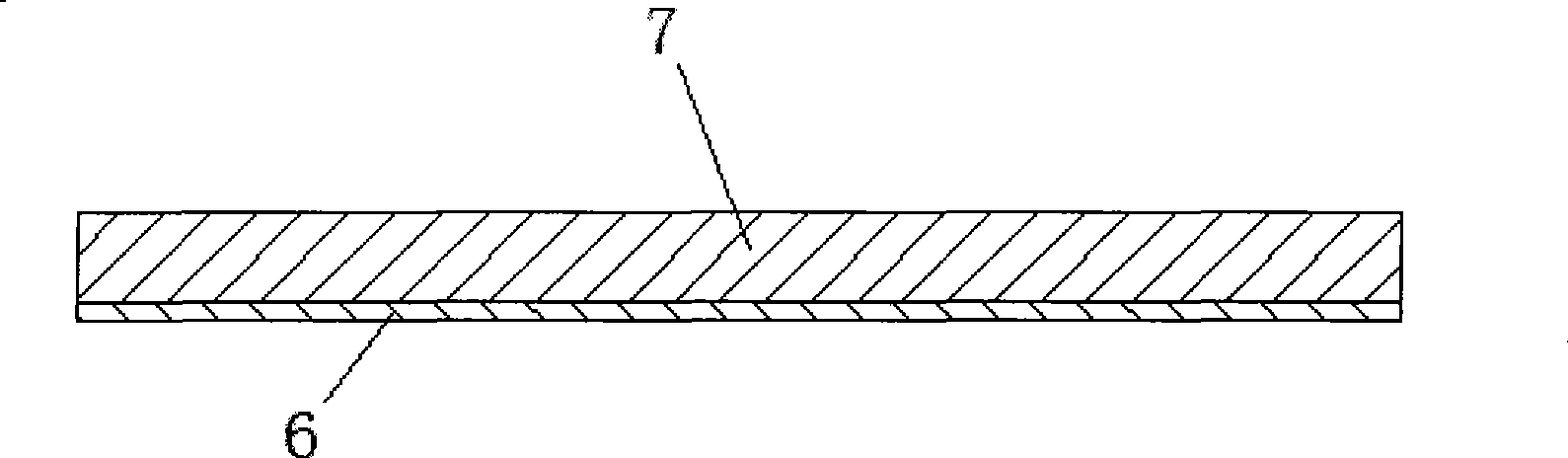

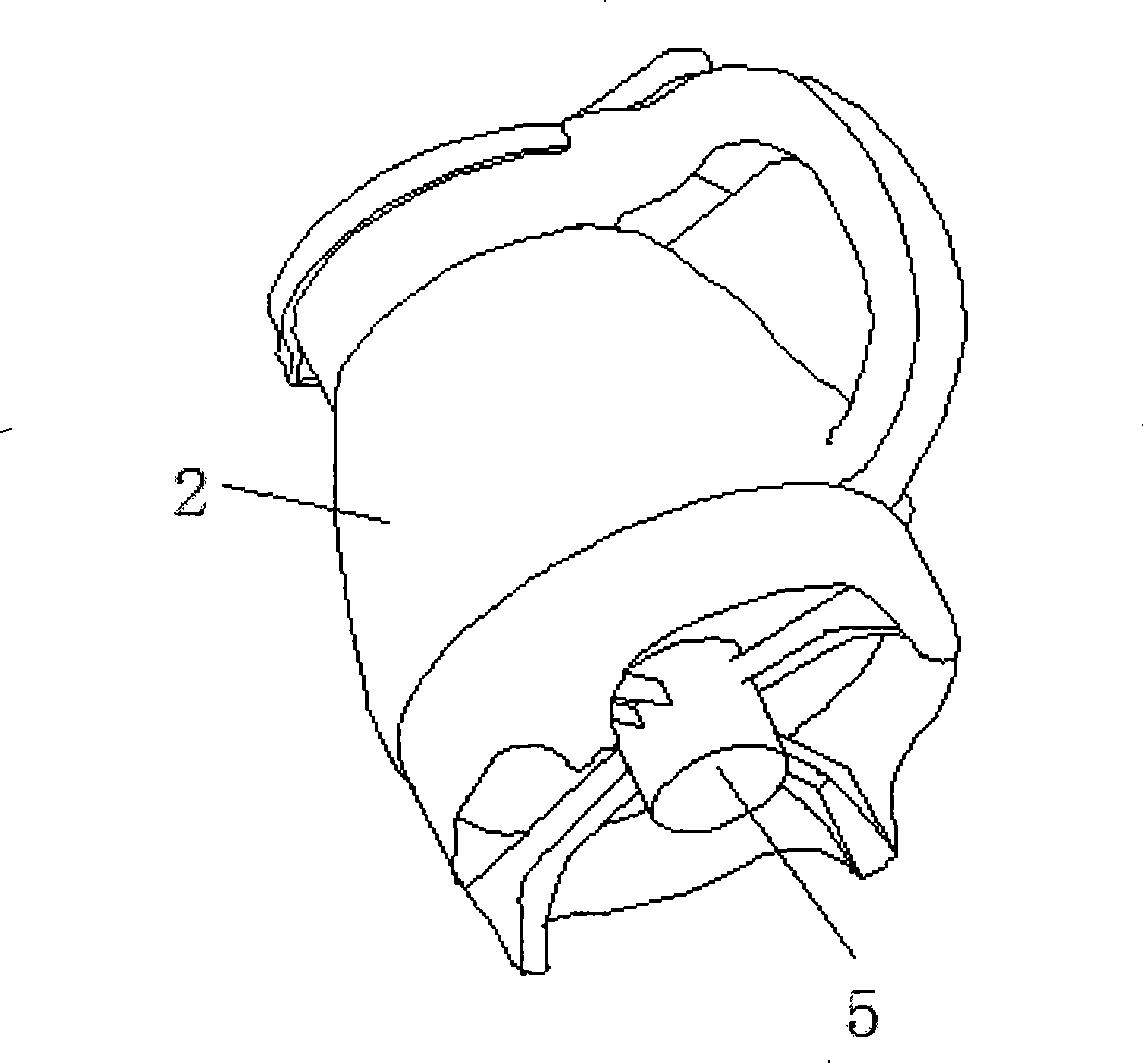

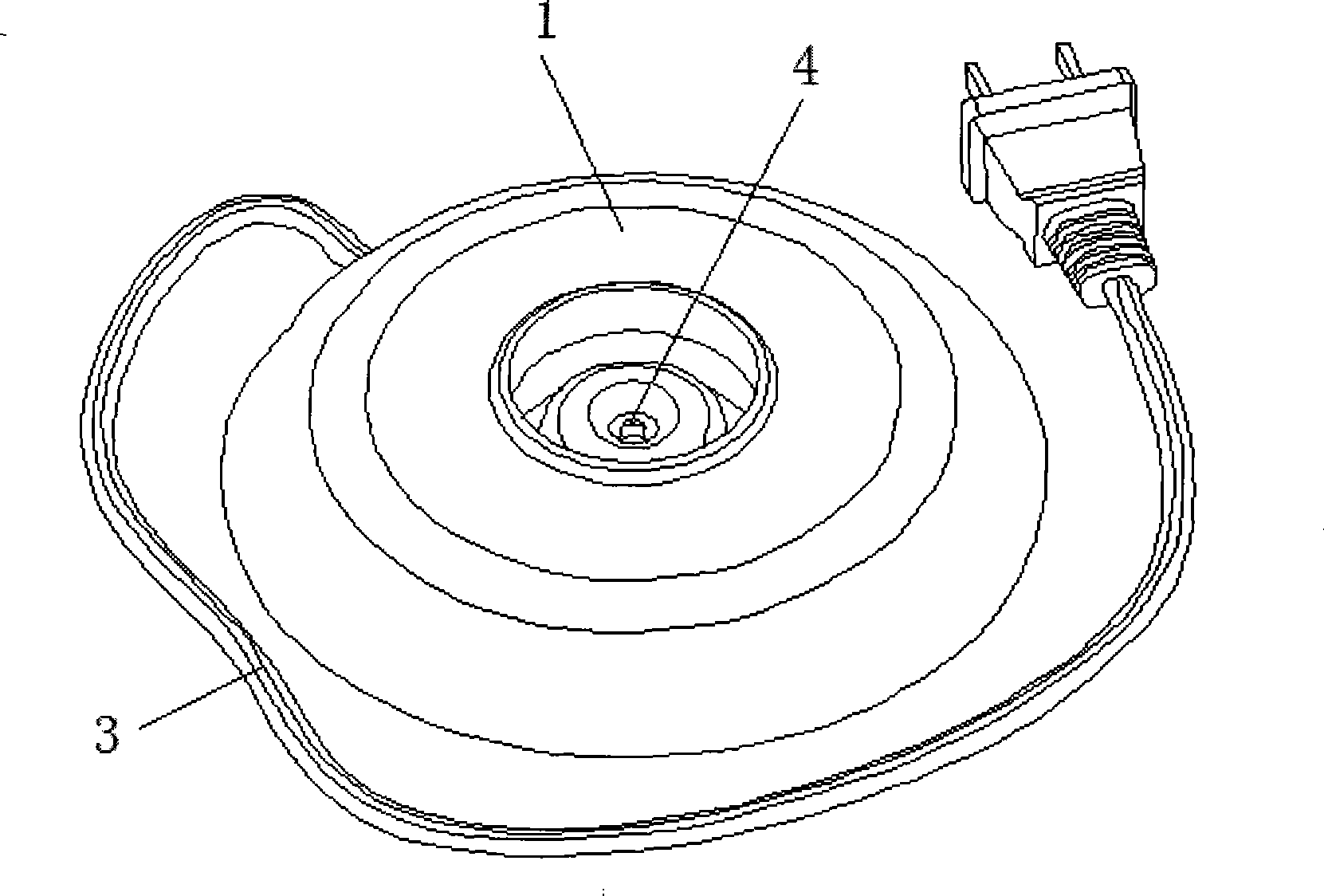

Heating plate and method of manufacturing the same and electric heating kettle using the same

InactiveCN101370327AEliminate sheddingWon't happenWater-boiling vesselsOhmic-resistance heatingHazardous substanceMetallurgy

A heating plate body comprises substrate which is glass or ceramic and is covered with a binded electric-heating film. Manufacture method for the heating plate body comprises following steps: preparing film-spraying liquid, heating substrate to 400-700 DEG C, spraying prepared film-spraying liquid on substrate, baking substrate sprayed with film-spraying liquid under 200-700 DEG C for 1-5 minutes then cooling it. The heating plate is applied to electric heating kettle whose bottom employs the heating plate. The inventive heating plate adopts electric-heating film for heating, which is energy-saving and environment-friendly; The inventive method is adopted to manufacture heating plate body for firmly binding electric-heating film with substrate; that heating plate body serves as kettle bottom, and electric heating film heats can not arouse filth and filth accumulation, and not produce harmful substance. The inventive product is high in heating efficiency and beautiful in appearance.

Owner:傅秋芬

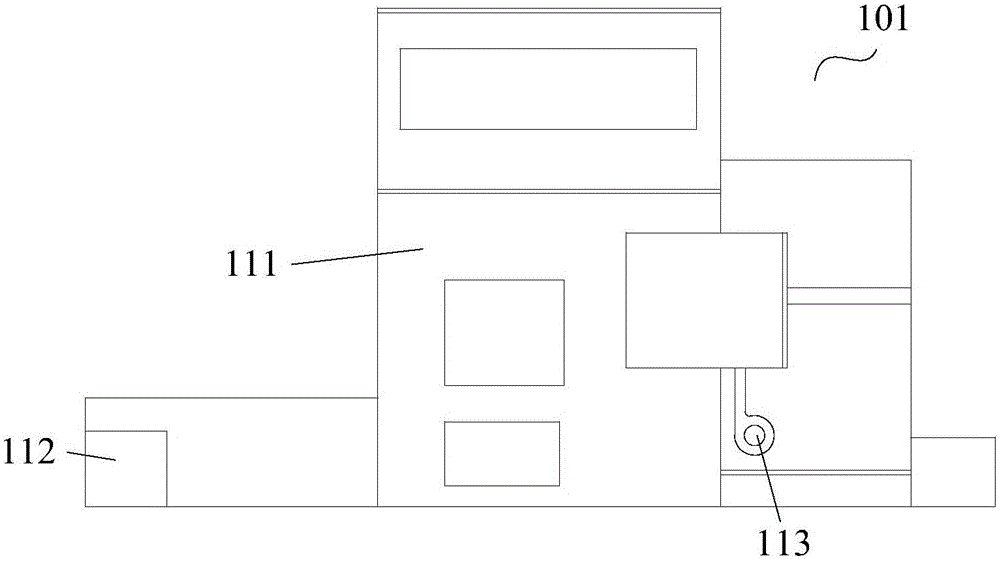

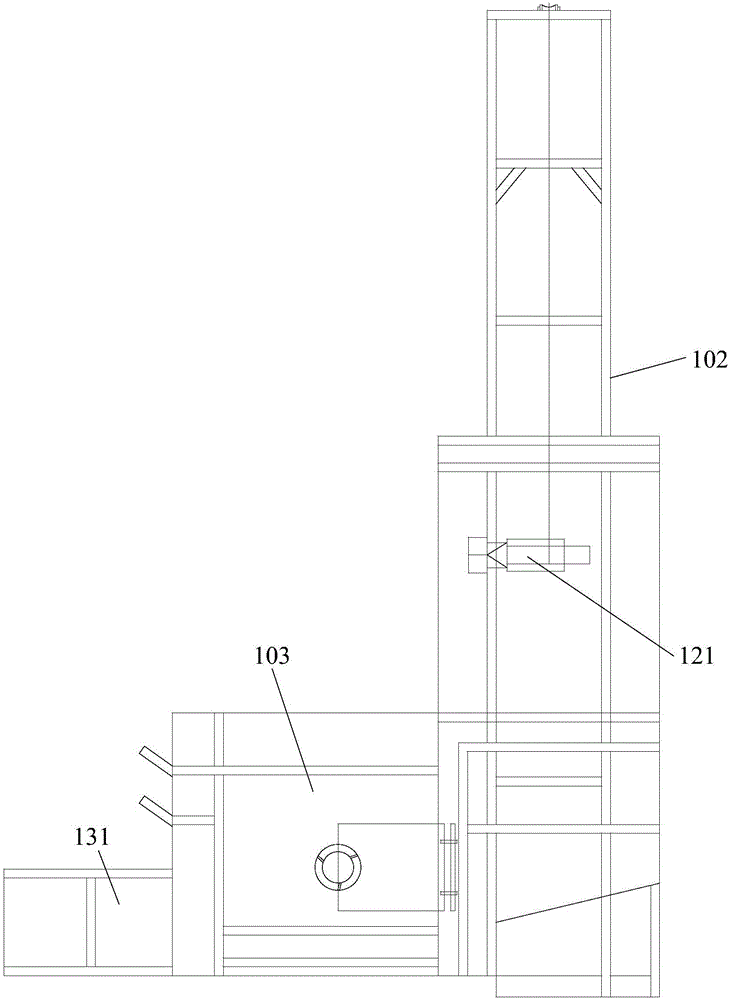

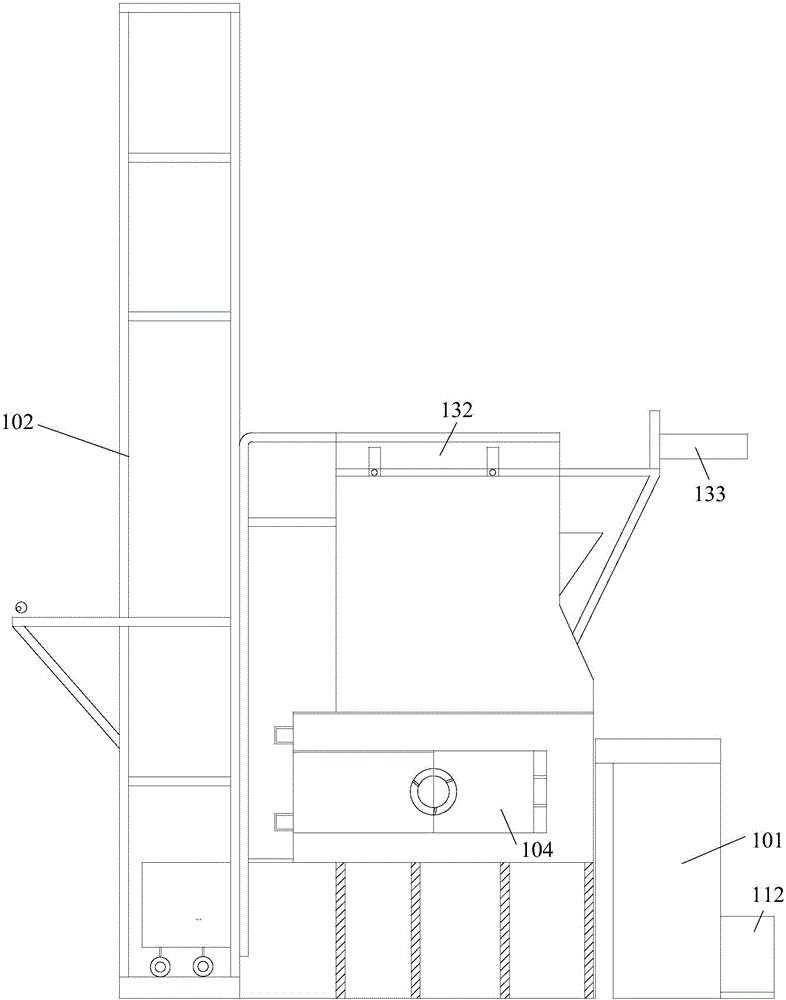

Smelting furance and aluminum smelting method

InactiveCN106595305AReduce usageReduce manufacturing costCharge composition/stateCharge treatment typeFuel gasMaterials science

The invention discloses a smelting furnace. The smelting furnace comprises a preheating chamber, a melting chamber and a combustion engine, wherein the preheating chamber is used for preheating aluminum raw materials; the melting chamber is used for enabling the preheated aluminum raw materials to be molten; and according to the combustion engine, biomass particles serve as a fuel, and smoke generated by the combustion engine passes through the melting chamber and the preheating chamber in sequence. In the smelting furnace, the biomass particles serve as the fuel of the combustion engine, the whole smelting furnace can be used for smelting the aluminum raw materials through heat generated through combustion of the biomass particles, fuel gas is prevented from being used, and the production cost can be lowered. The invention further discloses an aluminum smelting method which is applied to the smelting furnace and can be used for lowering the production cost of aluminum smelting.

Owner:CHONGQING ZHENHUA BRAKE

Filter device of automatic-deslagging plastic film extruder

InactiveCN103144276AOutstanding and Beneficial Technical EffectsQuality improvementPlastic filmReplacement window

The invention belongs to the technical field of plastic film extruders, and relates to a filter device of an automatic-deslagging plastic film extruder. The filter device comprises a shell, a filter disc, a rotating device, filter sheets, a filter sheet replacement window, a window cover, a feed port and a discharge port, wherein a feed channel positioned between the feed port and one filter sheet is provided with a deslagging channel; the discharge port of the deslagging channel is dead against the filter sheet which is not dead against the feed port; the deslagging channel or the feed channel is provided with a pressure sensor and a one-way valve; one side of the feed port is provided with a deslagging pipe communicated with the opposite surface of the filter sheet which is dead against the outlet of the deslagging channel; and a controller receives a pressure signal transmitted by the pressure sensor and controls the opening and closing of the one-way valve to achieve automatic deslagging. The filter device disclosed by the invention has the advantages of stability in product quality, long service life of the filter sheets, no raw material waste, non-stop automatic deslagging, time saving, high efficiency, low cost and suitability for plastic extrusion equipment of various types.

Owner:浙江瑞宏塑胶有限公司

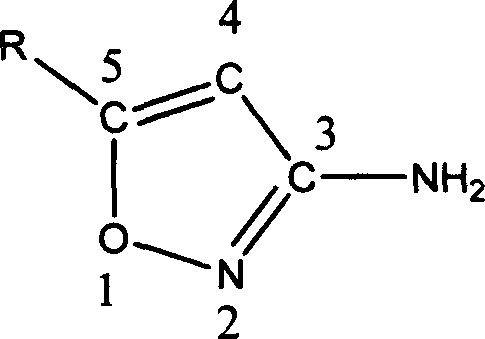

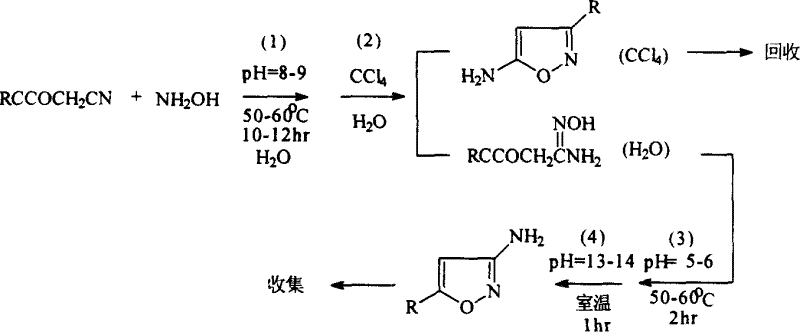

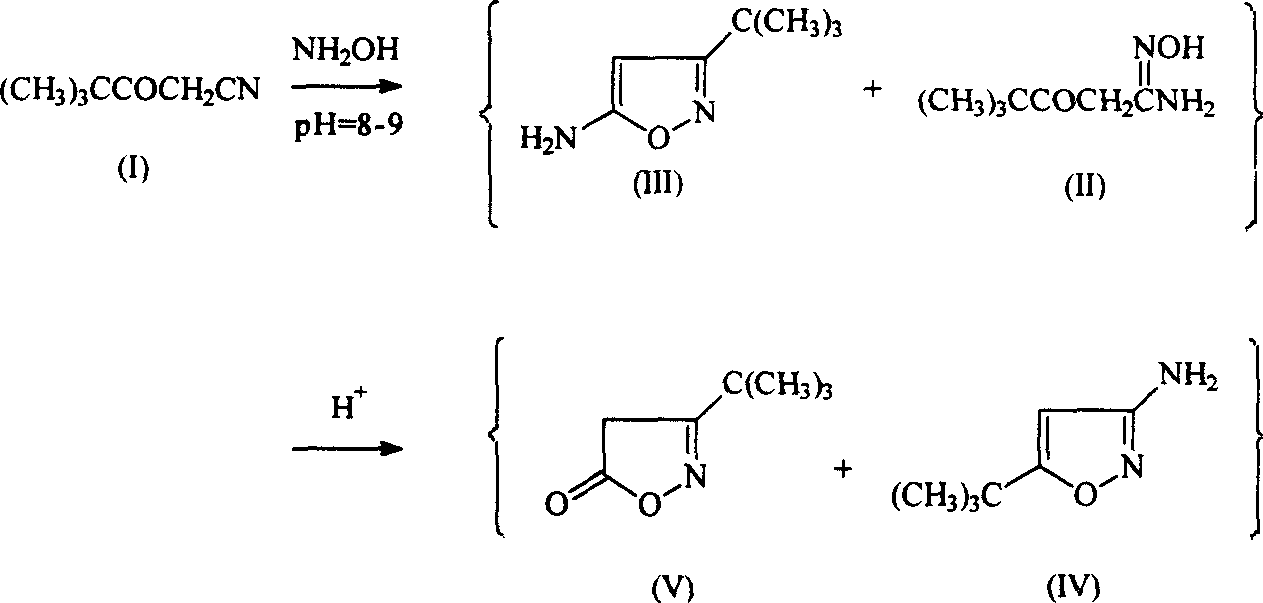

Method for preparing compound of 5-substitution-3-amido isoxazole

InactiveCN1562985AMild reaction conditionsEasy temperature controlOrganic chemistryAcetonitrileSolvent

In this invention, said product has its structural formula as shown, where: C=carbon, R=1-4 alkyl. Substituled acetyl acetonitrile reacts with oxammonium hydrochloride in weak alkaline condition to obtain amino oxime and side-product 5-amino-3-substituted isooxazole compound mixture. Then, its extracted by solvent to rmove side-product. Amino oxime proceeds cyclization in weak acid condition to obtain final product-5-substituted-3-amino-isooxazole with high pureness.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

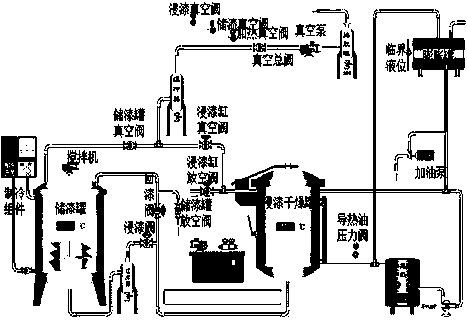

FGH sequence full-automatic vacuum heat conducting oil heating and dipping paint drying equipment and process thereof

The invention discloses FGH sequence full-automatic vacuum heat conducting oil heating and dipping paint drying equipment and a process thereof. A refrigeration unit is connected with a paint storagetank, is connected with a vacuum pump, and is connected with a vacuum condensation tank; the paint storage tank is connected with a paint storage tank vacuum valve through a pipe; the paint storage tank vacuum valve is connected with a buffer through a pipe; the buffer is connected with a vacuum main valve through a pipe; the vacuum main valve is connected with a vacuum pump through a pipe; the vacuum pump is connected with a discharge tank through a pipe; the paint storage tank vacuum valve is connected with a dipping paint cylinder vacuum valve through a pipe; the dipping paint cylinder vacuum valve is connected with a dipping paint drying tank through a pipe; the dipping paint drying tank is connected with a dipping paint cylinder emptying valve through a pipe; the dipping paint dryingtank is connected with a heat conducting oil heater through a pipe; the heat conducting oil heater is connected with a heat conducting oil pump; the heat conducting oil pump is connected with an expansion tank through a pipe; and the expansion tank is connected with an oiling pump, and is connected with the pipe between the dipping paint drying tank and the heat conducting oil heater through a pipe.

Owner:CHANGCHENG VACUUM VARNISHING EQUIP MFG ZHANGJIAGANG CITY

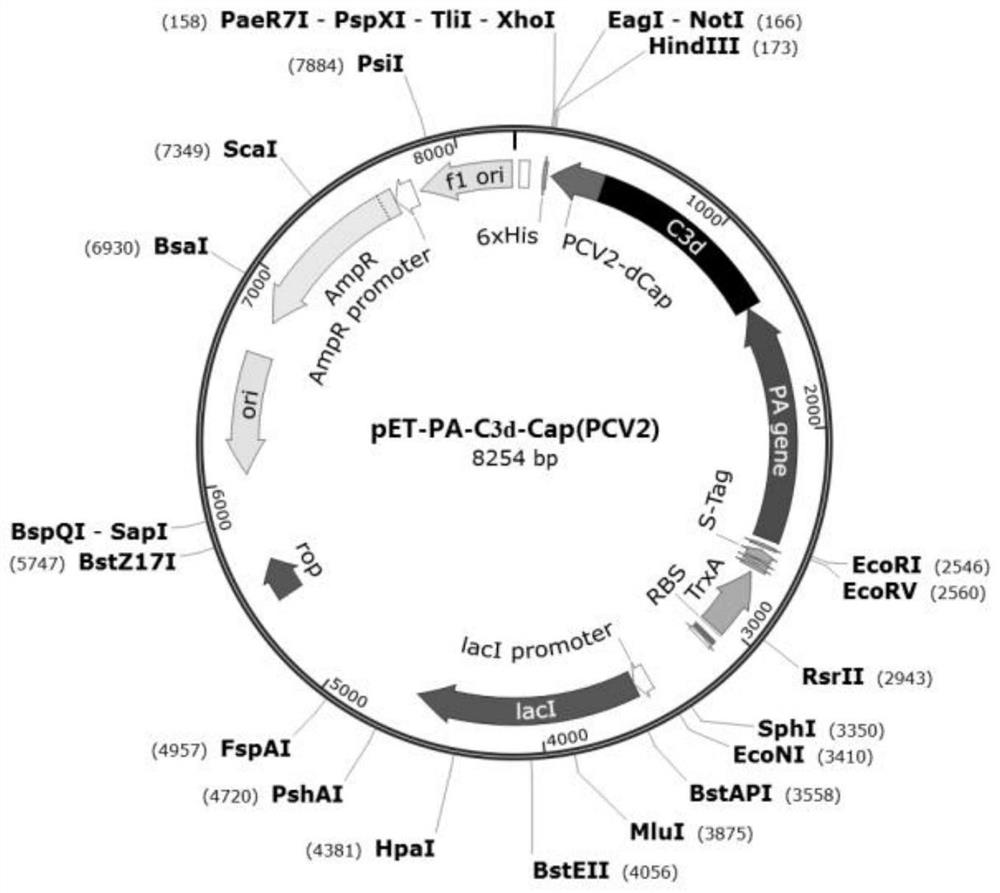

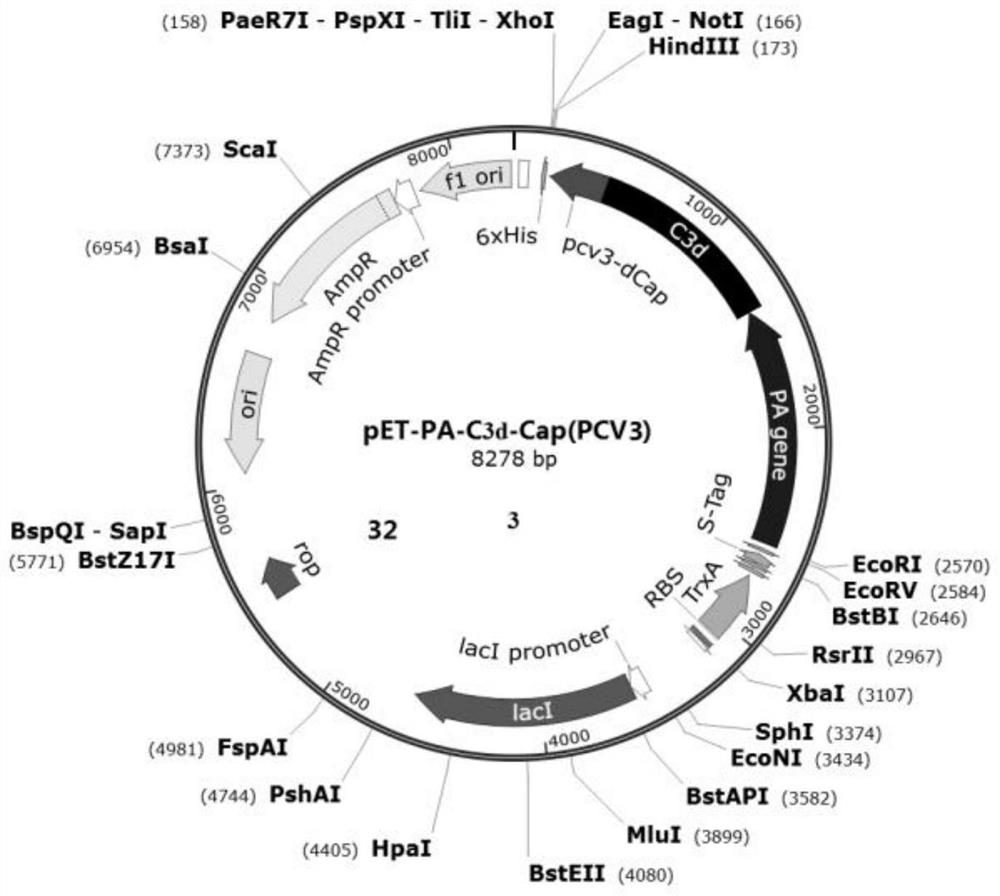

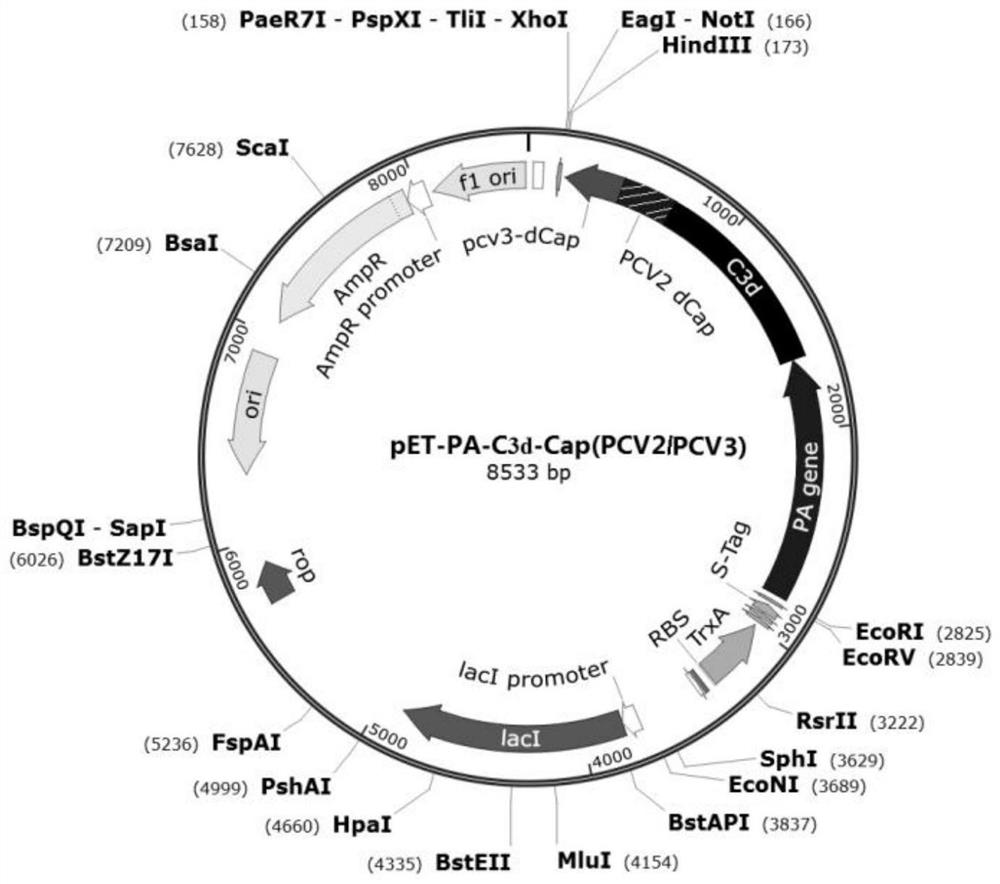

Fusion protein as well as preparation method, application, expression system and vaccine thereof

InactiveCN113527511ANot pathogenicImprove securityViral antigen ingredientsVirus peptidesAntigen epitopePseudomonas aeruginosa exotoxin A

The invention provides a fusion protein as well as a preparation method, application, an expression system and a vaccine thereof, and relates to the technical field of biology. The fusion protein provided by the invention comprises a pseudomonas exotoxin A structural domain segment, a porcine circovirus type 2 Cap protein dominant antigen epitope segment, a porcine circovirus type 3 Cap protein dominant antigen epitope segment and a carboxyl terminal part. According to the invention, dominant epitopes of PCV2 and PCV3Cap proteins are screened, the dominant epitopes are good in antigenicity and easy to highly express, then the dominant epitopes are fused with part of functional fragments of PEA, and meanwhile, carboxyl terminal sequences are added to the C terminal of the fusion protein and the immunogenicity is enhanced, so that the solubility of the fusion protein is improved. The obtained fusion protein has the advantages of targeting positioning, good antigenicity and high expression quantity. The vaccine prepared by taking the fusion protein as an antigen has the advantages of good safety, stable titer, no toxic or side effect and capability of activating cellular immune response.

Owner:TECON BIOLOGY CO LTD

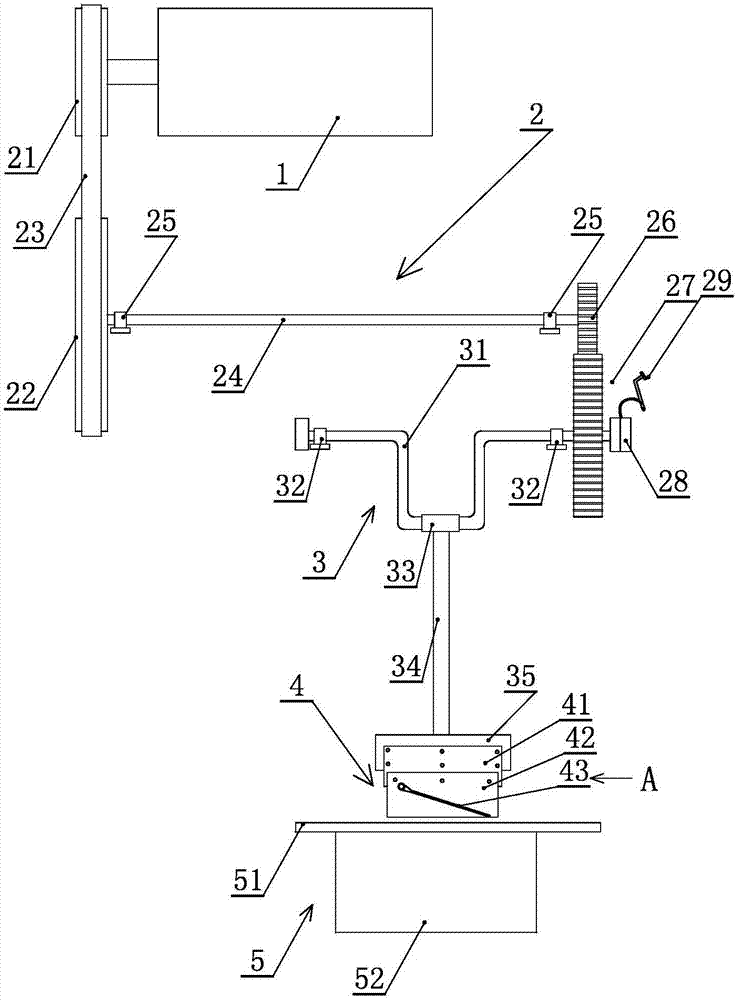

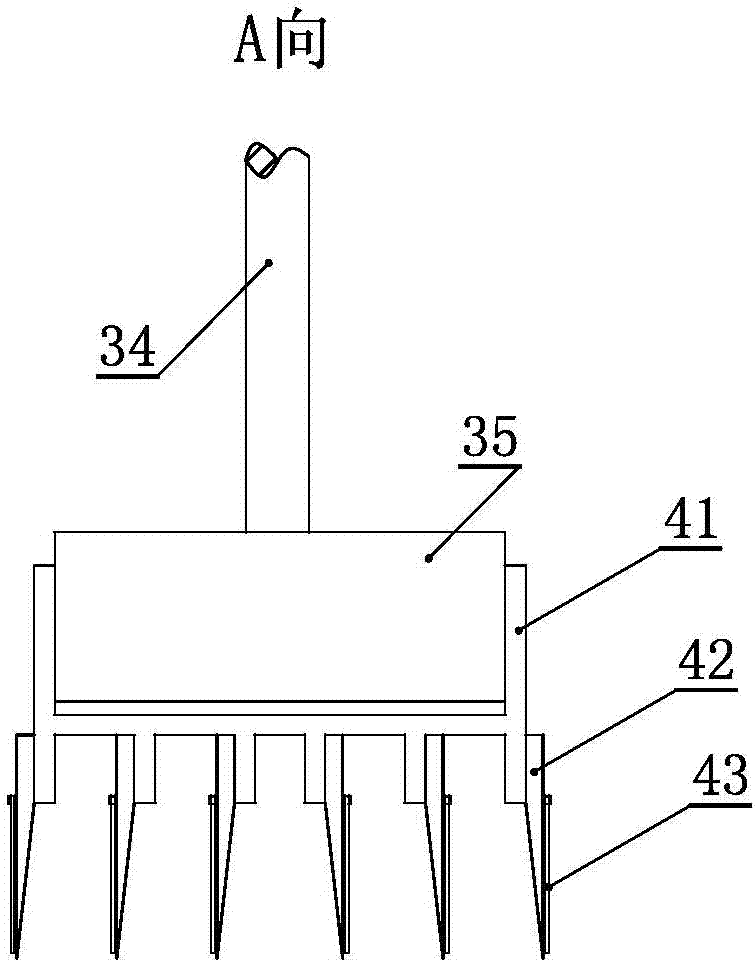

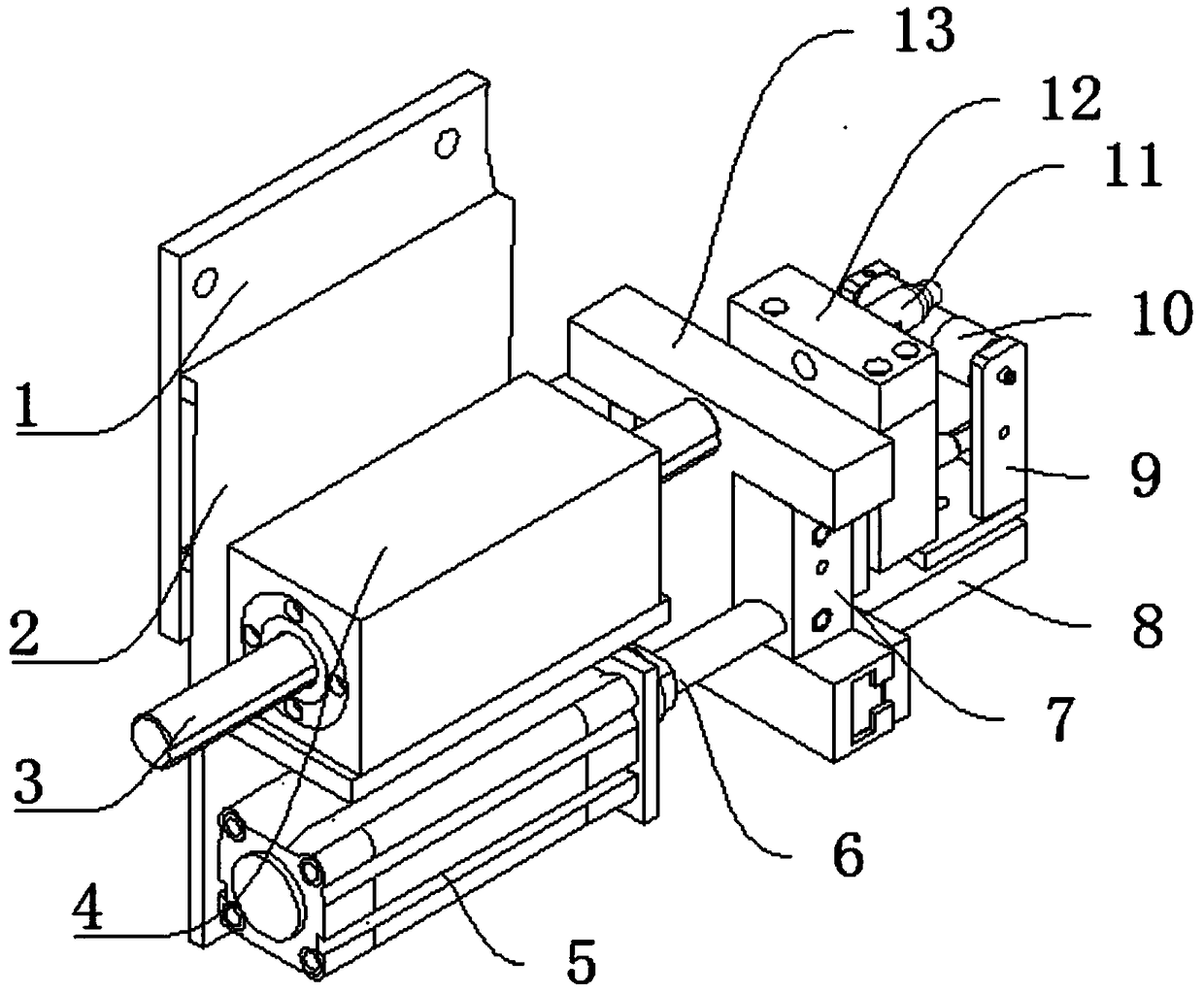

Machine capable of cutting integral mutton chop

InactiveCN107410431ABeautiful imageEasy to reprocessMeat shaping/cuttingNeighbor relationEngineering

The invention discloses a machine capable of cutting an integral mutton chop. An electric motor is used as a power source; the electric motor drives a transmission component to transmit power to a driving component; the driving component is fixedly connected with a cutting component, so that the cutting component can be driven to move up and down; the cutting component comprises a plurality of row cutters which are fixedly mounted side by side; the driving component drives the cutting component to move to the lowest position and cut the mutton chop at the same time; an elastic sheet is fixedly arranged on one side of each row cutter; one ends of the elastic sheets are hinged and fixed to one sides of the upper parts of the row cutters, and the other ends naturally oblique and extend downward to the blades of the row cutters; fresh mutton is integrally cut; though the mutton is cut into small cubes conforming to a specification, the neighboring relation of the bones and the mutton is not damaged, the overall shape is still preserved, and the product looks beautiful and tidy; after cutting is completed, the cut mutton chops are pushed onto a mutton chop placement table under the action of the elastic sheets and cannot stick to the row cutters; the condition that the cutters fall down to cut the mutton chop next time cannot be influenced; and mutton residues or bone residues produced by cutting the cut mutton chops again cannot be produced.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

Application of zeolite molecular sieve or modified zeolite molecular sieve in mosquito trapping and modifying method

InactiveCN106818675AImprove adsorption capacityStable desorption capacityInsect catchers and killersMolecular sieveTrapping

Owner:唐成康 +1

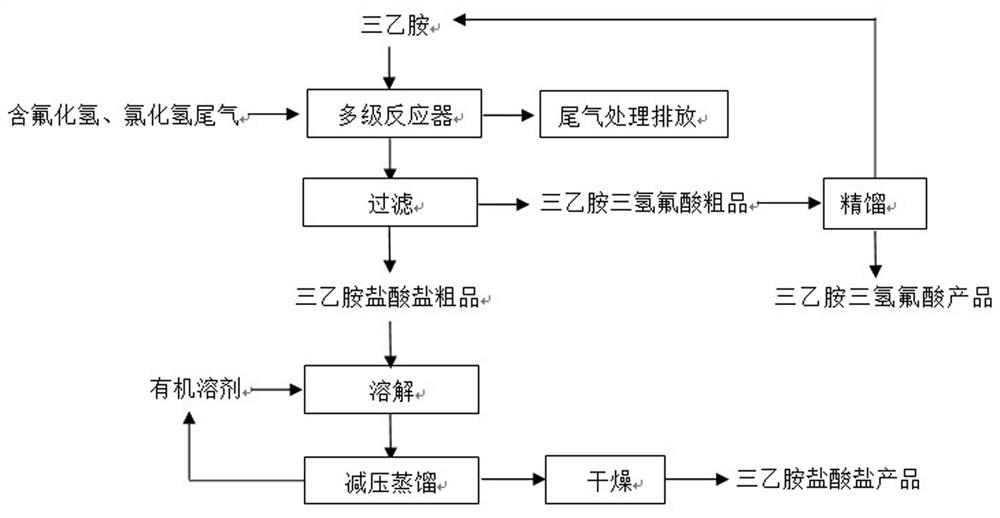

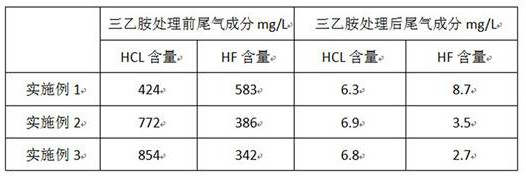

Comprehensive utilization method of mixed gas containing hydrogen fluoride and hydrogen chloride

ActiveCN111777514AMeet needsRealize closed loopAmino compound purification/separationOrganic compound preparationChemical industryHydrogen fluoride

The invention belongs to the technical field of fluorine chemical industry, and particularly relates to a comprehensive utilization method of mixed gas containing hydrogen fluoride and hydrogen chloride. Triethylamine is used for multistage absorption of mixed gas containing hydrogen fluoride and hydrogen chloride; the generated triethylamine hydrochloride is a precipitate, and triethylamine trihydrofluoride is a solution, so that the separation of the product can be realized through simple solid-liquid separation, and then the conversion from low-value hydrogen fluoride and hydrogen chlorideto high-value triethylamine trihydrofluoride and triethylamine hydrochloride products is completed through a subsequent refining process. The method has the advantages of simple process, strong operability, high added value of products, capability of meeting the requirements of the organic fluorine industry, closed cycle of the process, no secondary pollution and the like.

Owner:DO FLUORIDE CHEM CO LTD

A plastic film extruder filter device with automatic slag discharge

The invention belongs to the technical field of plastic film extruders, and relates to a filter device of an automatic-deslagging plastic film extruder. The filter device comprises a shell, a filter disc, a rotating device, filter sheets, a filter sheet replacement window, a window cover, a feed port and a discharge port, wherein a feed channel positioned between the feed port and one filter sheet is provided with a deslagging channel; the discharge port of the deslagging channel is dead against the filter sheet which is not dead against the feed port; the deslagging channel or the feed channel is provided with a pressure sensor and a one-way valve; one side of the feed port is provided with a deslagging pipe communicated with the opposite surface of the filter sheet which is dead against the outlet of the deslagging channel; and a controller receives a pressure signal transmitted by the pressure sensor and controls the opening and closing of the one-way valve to achieve automatic deslagging. The filter device disclosed by the invention has the advantages of stability in product quality, long service life of the filter sheets, no raw material waste, non-stop automatic deslagging, time saving, high efficiency, low cost and suitability for plastic extrusion equipment of various types.

Owner:浙江瑞宏塑胶有限公司

Long-acting antibacterial silicone rubber and preparation method thereof

The invention discloses a long-acting antibacterial silicone rubber and a preparation method thereof, the surface of the silicone rubber is bonded with a compact cross-linked network-shaped polyimidazole layer, and the thickness of the cross-linked network-shaped polyimidazole layer is 1-30 [mu] m. According to the long-acting antibacterial silicone rubber and the preparation method thereof, the problem that the biocompatibility and the long-acting antibacterial property of existing antibacterial silicone rubber are difficult to consider in a physiological environment is solved, and the long-acting antibacterial silicone rubber has a relatively good application prospect.

Owner:SUZHOU DOBIOM MEDICAL TECH CO LTD

An Online Optimal Shearing Method for Steel Plates with Defects

The invention relates to an online optimal shearing method for defective steel plates. The shearing method is characterized in that areas of a mother plate are divided, and at least one sub-plate is divided in each mother plate area, so that coordinates of a defect position on a rolling big plate are searched; edge coordinates of all the mother plate areas are inquired, so that the mother plate areas in which defects are distributed can be determined; different shearing strategies are formulated for sequence-type A group plates, partition-type S group plates and flame-cutting type G group plates; and all the defective sub-plates are avoided. In this way, the yield rate of the defective steel plates can be increased, and the feeding cost can be reduced. The method solves the problems in the prior art that the steel plate becomes shorter during shearing if the defect position is far from the head and tail of the rolling big plate; a lot of scrap plates can be generated; defects cannot be processed effectively; and the yield rate of the steel plates is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Automatic cleaning and blow-drying equipment for storage battery

ActiveCN111618023AProtect the working environmentSave cleaning fluidDrying gas arrangementsDrying machines with progressive movementsDrive wheelElectric machine

The invention belongs to the technical field of storage battery cleaning and blow-drying, and particularly relates to automatic cleaning and blow-drying equipment for a storage battery. The automaticcleaning and blow-drying equipment comprises a supporting mechanism, a cleaning supporting shell, a mounting shell, a belt, driving wheels and a blow-drying supporting shell. When the designed storagebattery cleaning and blow-drying device is used by people, a driving motor works, the driving motor can drive one of the two driving wheels connected with the driving motor to rotate through an output shaft; the driving wheel rotates to drive the belt to move; the belt moves to drive the supporting mechanism installed on the belt to move; the supporting mechanism moves to drive the storage battery to move; in the moving process of the storage battery, the storage battery is cleaned and blow-dried through a first spray head, a second spray head, a third spray head and an air blowing opening, and cleaning liquid is saved; meanwhile, irritant gases such as SO2 and the like are not generated in the heating decomposition process of the sulfuric acid; and the working environment around the conveying belt is protected.

Owner:ZHEJIANG JUST ELECTRICAL APPLIANCES CO LTD

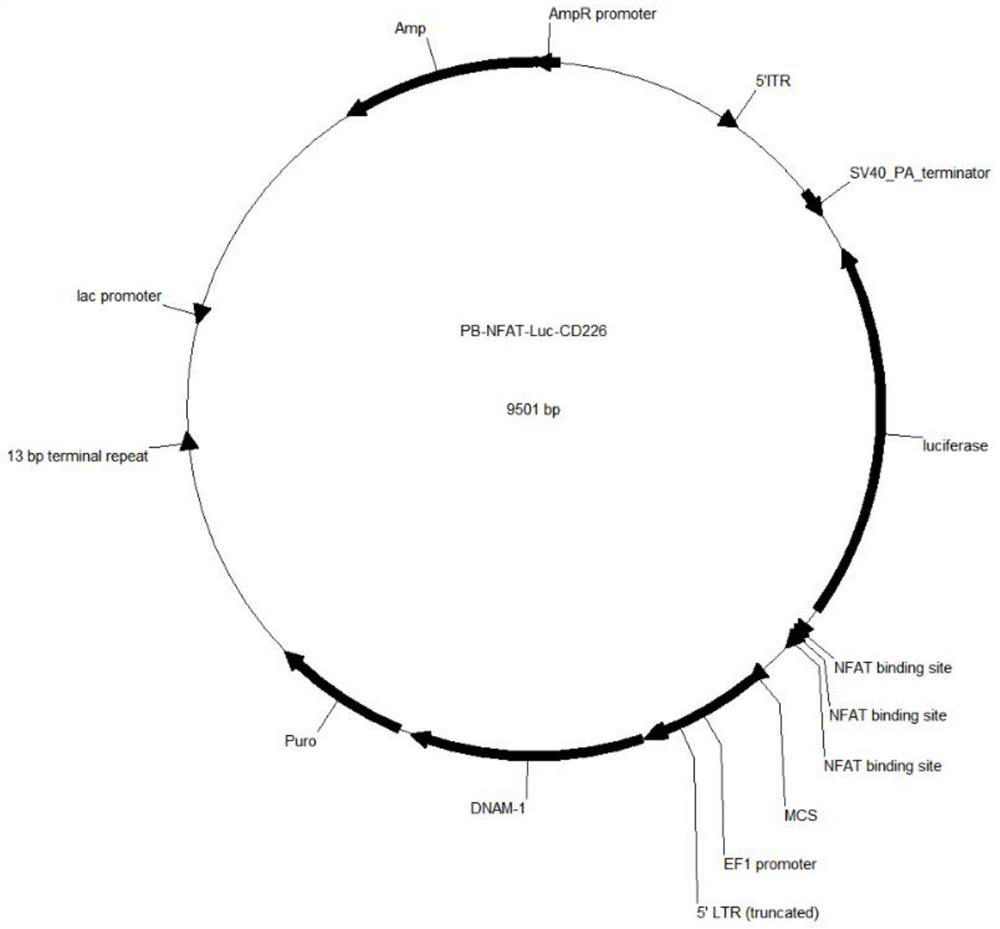

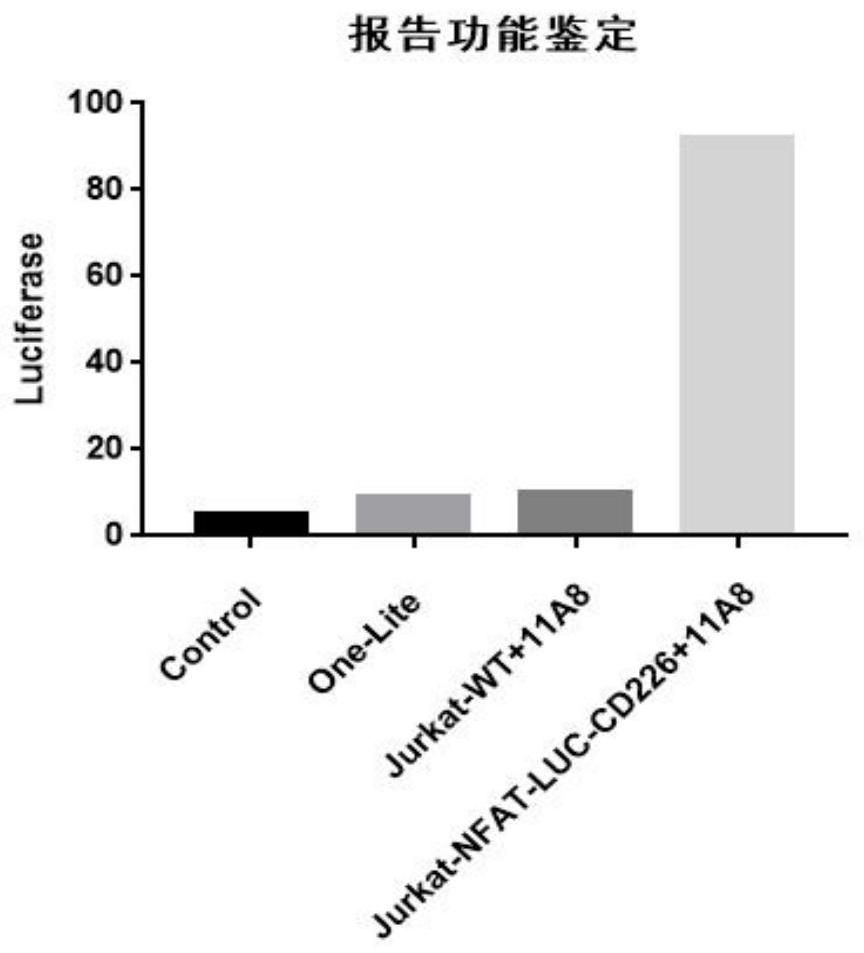

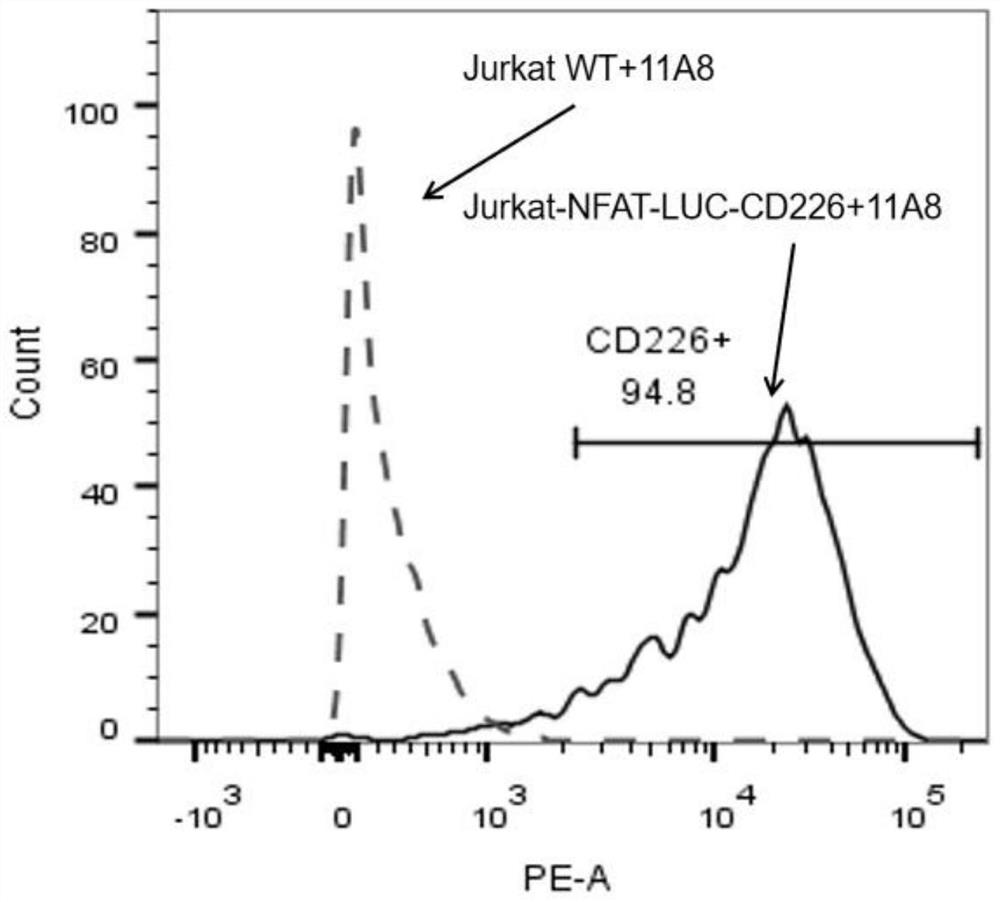

A recombinant plasmid co-expressing NFAT and human dnam-1 protein, recombinant cell and its construction method and application

ActiveCN113308491BWill not causeLess prone to operational errorsImmunoglobulins against animals/humansNucleic acid vectorHumaninNatural Killer Cell Inhibitory Receptors

The invention provides a recombinant plasmid co-expressing NFAT and human DNAM‑1 protein, a recombinant cell and its construction method and application, and relates to the technical field of biomedicine. The invention provides a method for constructing the recombinant plasmid and the constructed recombinant plasmid, and constructs recombinant cells and monoclonal recombinant cells based on the recombinant plasmid. The bidirectional promoter of the recombinant plasmid described in the present invention promotes the expression of the DNAM-1 gene and the NFAT-Luciferase gene, and the gene expression does not affect each other. The recombinant cells of the present invention are constructed based on Jurkat, a human immune type cell, which is closer to the NK cell model, and when constructing the recombinant cells, no virus is introduced, nor does it cause inflammation-related pathways in cells, and the operation is simple. Anti-human DNAM‑1 antibodies can also be detected and / or screened using the recombinant cells or monoclonal recombinant cells of the present invention.

Owner:BEIJING DCTY BIOTECH CO LTD

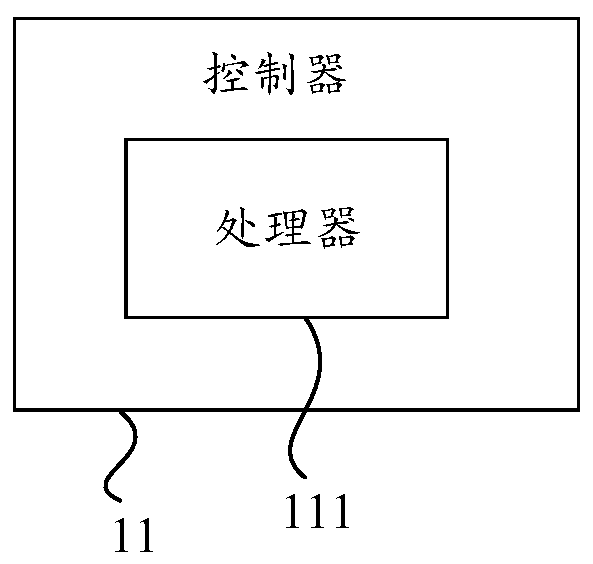

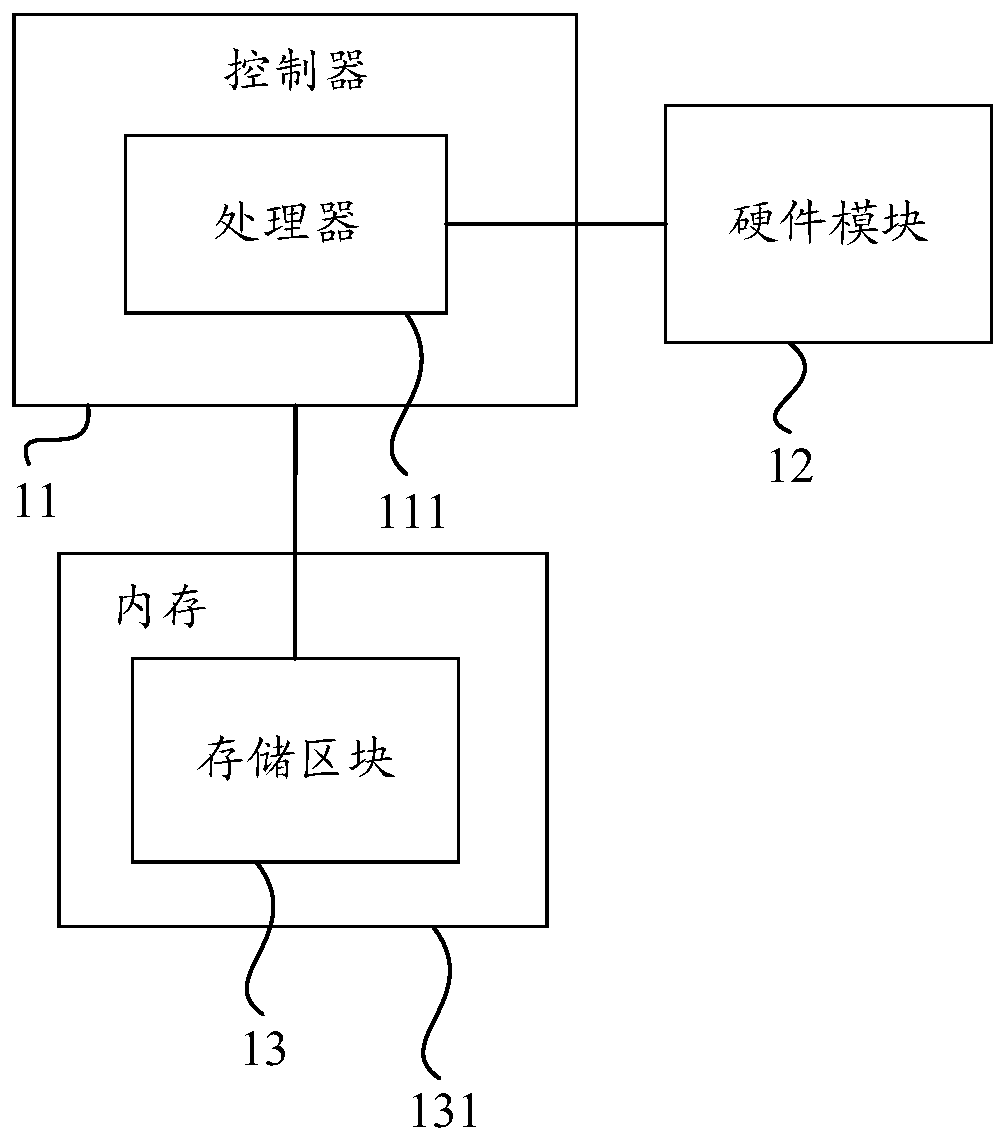

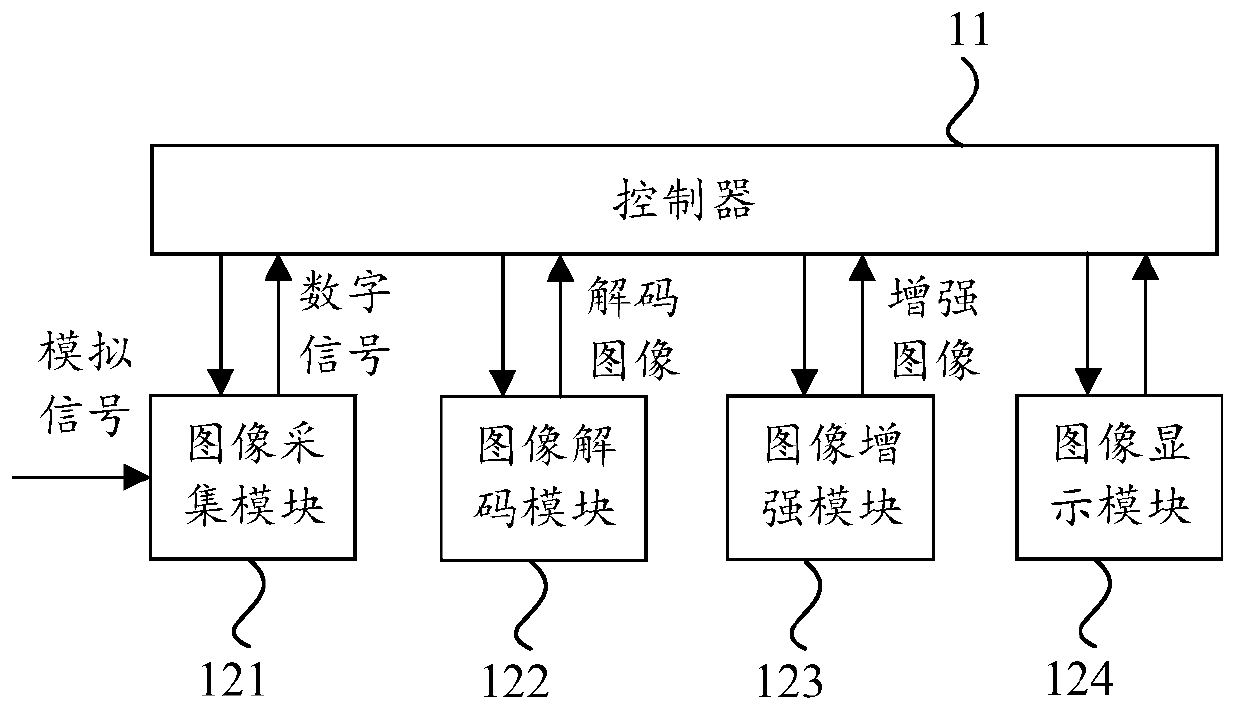

Control method, controller, system and storage medium of reversing image system

The invention discloses a control method, a controller, a system and a storage medium of a reversing image system. The method comprises the following steps of receiving an application request of one of a plurality of hardware modules; inquiring a memory block in an available state capable of being used by a certain hardware module from a plurality of memory blocks; allocating the memory block in an available state to a certain hardware module to allow the certain hardware module to writing and / or reading a reversing picture to the allocated memory block; the available state means that a certain hardware module has completed the writing and / or reading operation to the memory block at the next higher level hardware module in the time sequence. According to the mode, any memory block can be guaranteed to be used only in a single hardware module, garbage data cannot be generated between two adjacent hardware modules, and the reversing picture is normally displayed.

Owner:AUTOCHIPS

Weaving paper spray flame retardant

InactiveCN108797203AHigh heat resistanceImprove cooling effectPaper coatingPaper/cardboardFiberPolyethylene glycol

The invention mainly relates to the technical field of weaving article processing, and discloses a weaving paper spray flame retardant which is prepared from silicone modified phenolic resin, modifiedhigh density polyethylene, sodium silicate, sodium selenite, magnesium hydroxide, nano-graphene fibers, phytic acid and polyethylene glycol. The weaving paper spray flame retardant is green, healthy,safe and environmentally friendly, the heat resistance of paper can be increased, heat dissipation of the paper is accelerated, the carbonization time of the paper is prolonged, paper water absorption and toxic gas generation are avoided, the structures of the paper and a woven product are kept complete, and loss generated by combustion is avoided. The silicone modified phenolic resin is rapidlyheated and molten, slow heating and stirring are continued after the magnesium hydroxide is added, melt polymerization of the silicone modified phenolic resin and the magnesium hydroxide is promoted,the flexibility and flame resistance of the silicone modified phenolic resin are improved, excessive paper hardness caused by the flame retardant is avoided, and folding and weaving performances of the paper are kept.

Owner:阜南县猛发工艺品有限公司

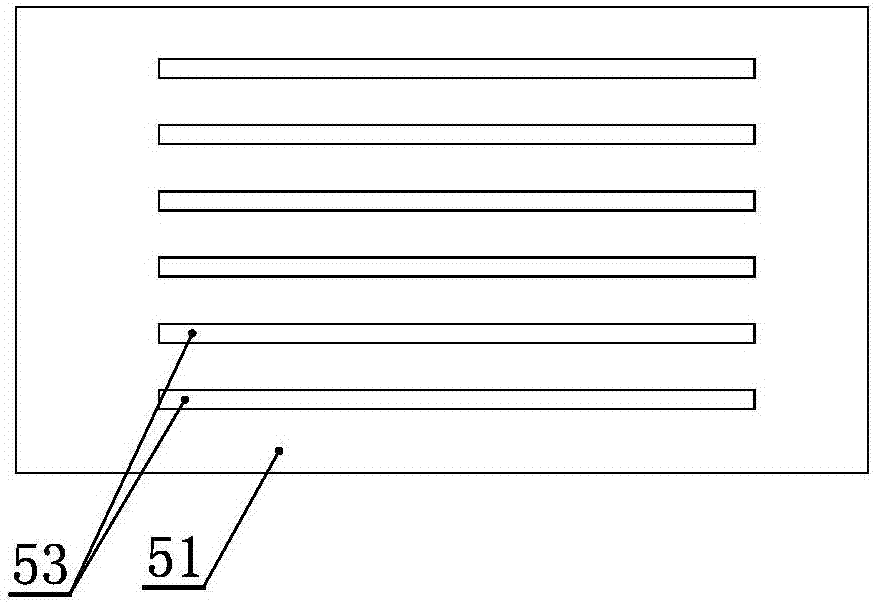

Automatic support structure for rewinder

The invention discloses an automatic support structure for a rewinder. The automatic support structure comprises a base, a connecting plate, a cylinder and a support shaft; the connecting plate is arranged beside the base, a linear bearing seat is arranged beside the connecting plate, a guide rod is arranged beside the linear bearing seat, the cylinder is arranged beside the guide rod, a push rodis arranged beside the cylinder, a guide seat is arranged beside the push rod, a movable plate is arranged beside the guide seat, a fixed plate is arranged beside the movable plate, a probe base is arranged beside the fixed plate, a shaft bracket is arranged beside the probe base, the support shaft is arranged beside the shaft bracket, and a detection probe is arranged beside the support shaft. The automatic support structure has the beneficial effects that the detection probe is additionally arranged, and the thickness of rolled paper can be detected, so that the support shaft maintains pressure the same as that of a paper surface all the time through action of the cylinder, waste products are not generated, and the enterprise economic benefits are improved.

Owner:徐州傲扬自动化科技有限公司

A battery automatic cleaning and drying device

ActiveCN108636906BProtect the working environmentSave cleaning fluidDrying gas arrangementsDrying machines with progressive movementsDrive wheelElectric machinery

The invention belongs to the technical field of battery cleaning and drying, and particularly relates to an automatic battery cleaning and drying device, which includes a support mechanism, a cleaning support shell, a mounting shell, a belt, a driving wheel, and a drying support shell. During the process of cleaning and drying the battery, when the driving motor is working, the driving motor will drive one of the two driving wheels connected to it to rotate through the output shaft; the driving wheel rotates to drive the belt to move; the belt moves to drive the The support mechanism moves; the movement of the support mechanism will drive the battery to move; during the battery moving process, the battery is cleaned and dried through the first nozzle, the second nozzle, the third nozzle and the air outlet, saving cleaning fluid; It will not cause sulfuric acid to generate SO2 and other irritating gases during the thermal decomposition process; it protects the working environment around the conveyor belt.

Owner:浙江杰斯特电器有限公司

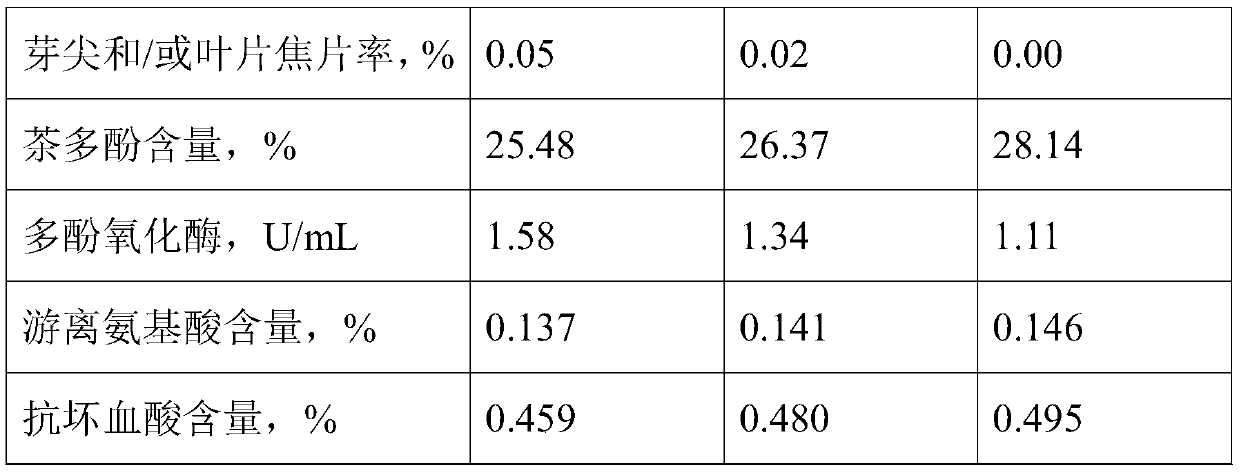

Granular round kidney-shaped green tea far-infrared fixation technology

PendingCN111165607AIncrease moisture contentStrong enzyme activityPre-extraction tea treatmentHorticultureMouthfeel

The invention discloses a granular round kidney-shaped green tea far-infrared fixation technology. The technology comprises the following steps: picking a fresh leaf raw material containing one bud and one leaf, uniformly spreading the raw material on a bamboo basket, then, carrying out withering at 20-25 DEG C at a withering humidity of 66%-70% for 4-6 h; sending the withered tea in a rolling machine to be ground back and forth until the tea forms balls by slight holding and disperses by slight pressing, then, dispersing the tea, and repeatedly covering the tea in the same direction to form granular round kidney-shaped tea with buds as cores and leaves covering bud tips; performing far-infrared fixation on the granular round kidney-shaped tea, increasing the temperature from the room temperature to 340-380 DEG C at a speed of 1-3 DEG C / min, carrying out fixation for 2-4 min, then, increasing the temperature 400-450 DEG C at a speed of 2-4 DEG C / min continuously, performing fixation for 1-2 min and baking, and slowly decreasing the temperature to room temperature to obtain the granular round kidney-shaped green tea. The technology can damage the activity of passivation oxidase, sothat the tea has stronger aroma, clearer color and mellower taste.

Owner:ANHUI JINZHAI JINLONG YUZHU TEA IND

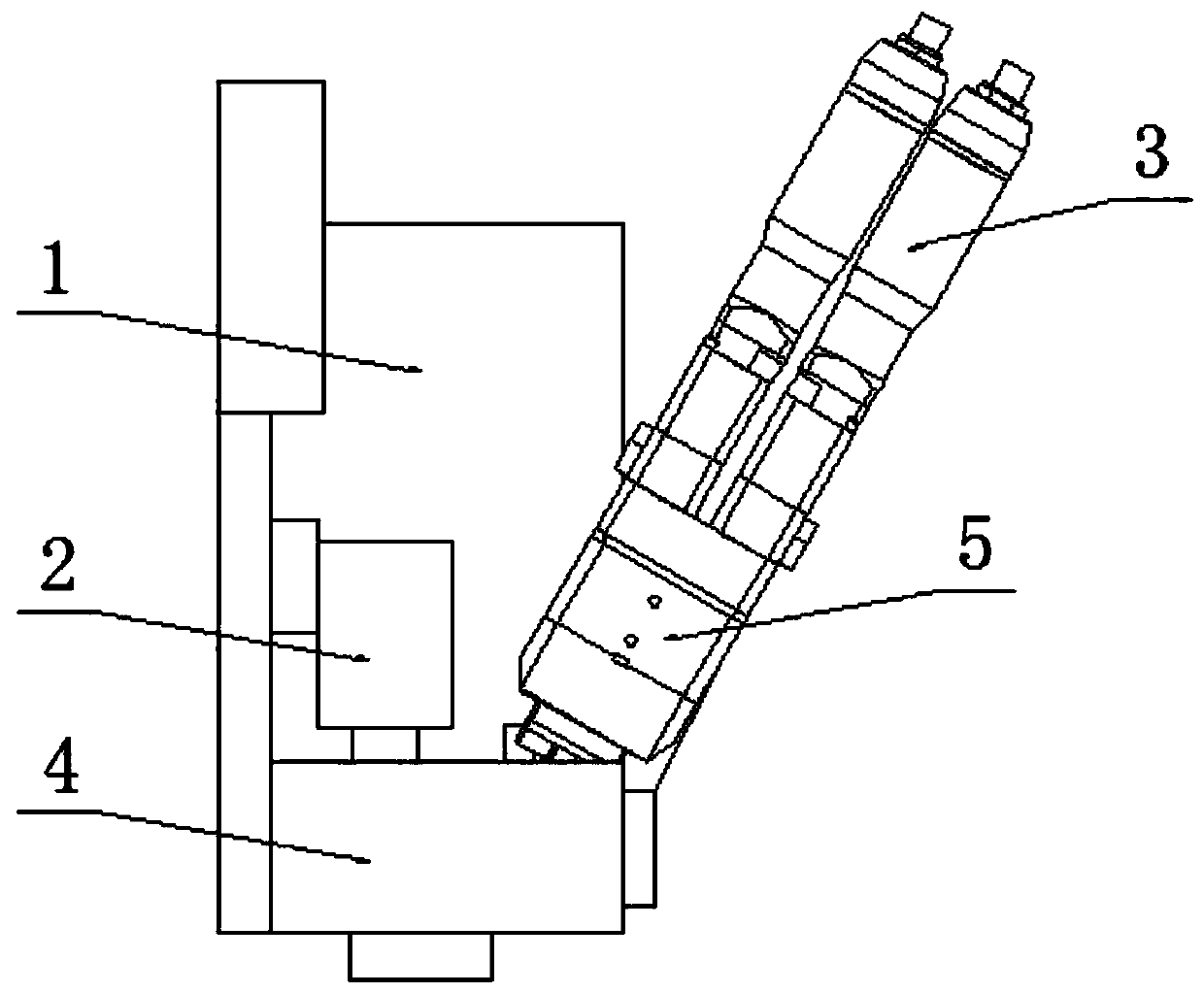

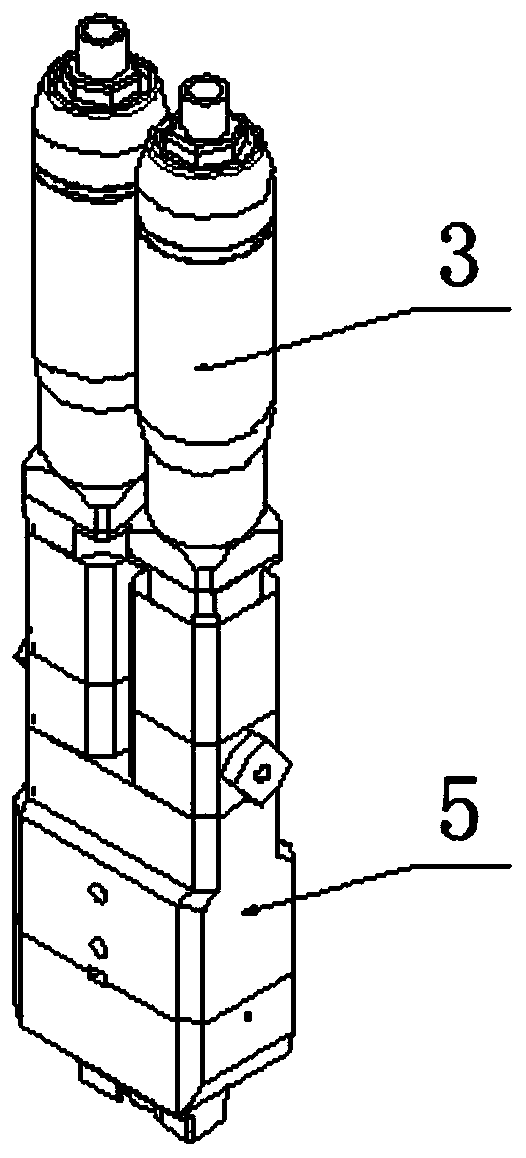

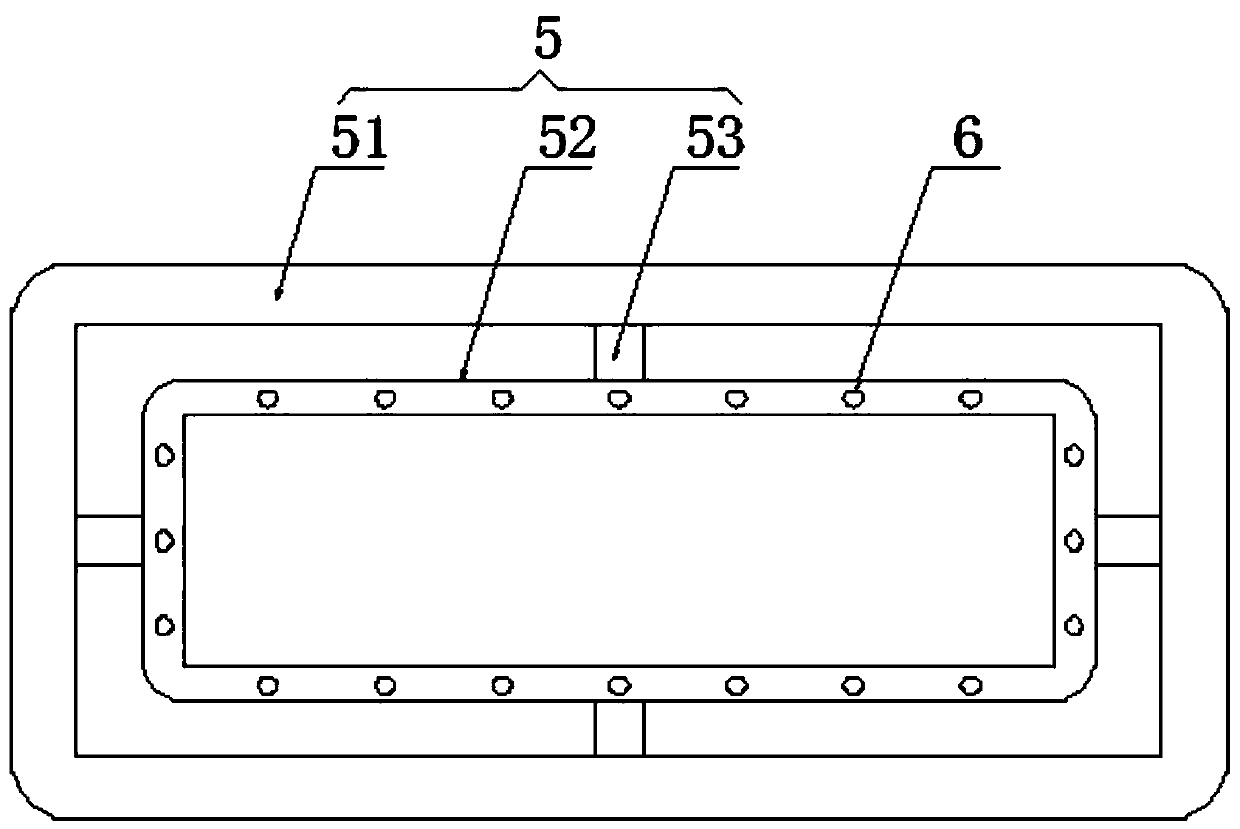

Dispensing system with condensing device

PendingCN110813654AExtend curing timeGuaranteed efficiencyLiquid surface applicatorsCoatingsPhysicsEngineering

The invention discloses a dispensing system with a condensing device, and belongs to the technical field of fast-response type AB glue ultra-precision dispensing. The dispensing system with the condensing device comprises a mounting bracket. A mixing pipe is arranged on the outer wall of the right side of the front part of the mounting bracket, and two sets of screw valves are arranged at the topend of the mixing pipe; and the bottom end of the mixing pipe is fixedly connected with an ADV leak-stopping valve, the outer wall of the left side of the front part of the mounting bracket is fixedlyconnected with a proportional valve, an outlet of the ADV leak-stopping valve is in communication with an inlet of the proportional valve, a wrapping layer sleeves the outer wall of the mixing pipe,and the outer wall of the bottom of the front side of the mounting bracket is fixedly connected with a condensing tank. According to the dispensing system with the condensing device, cold water is sent to a cooling layer through a water pump, so that the temperature of the cooling layer is reduced, the temperature of AB glue is reduced, the curing time after the AB glue is mixed is conveniently prolonged, and stable and precise dispensing of the AB glue is achieved; and the cooling layer is separated from an insulation layer by a supporting block, so that when the temperature is lowered, no water droplet is generated on the surface of the insulation layer, the situation that manual wiping is required due to generation of water droplets is avoided, and the efficiency of dispensing is ensured.

Owner:苏州研创自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com