Patents

Literature

215results about How to "Easy to reprocess" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

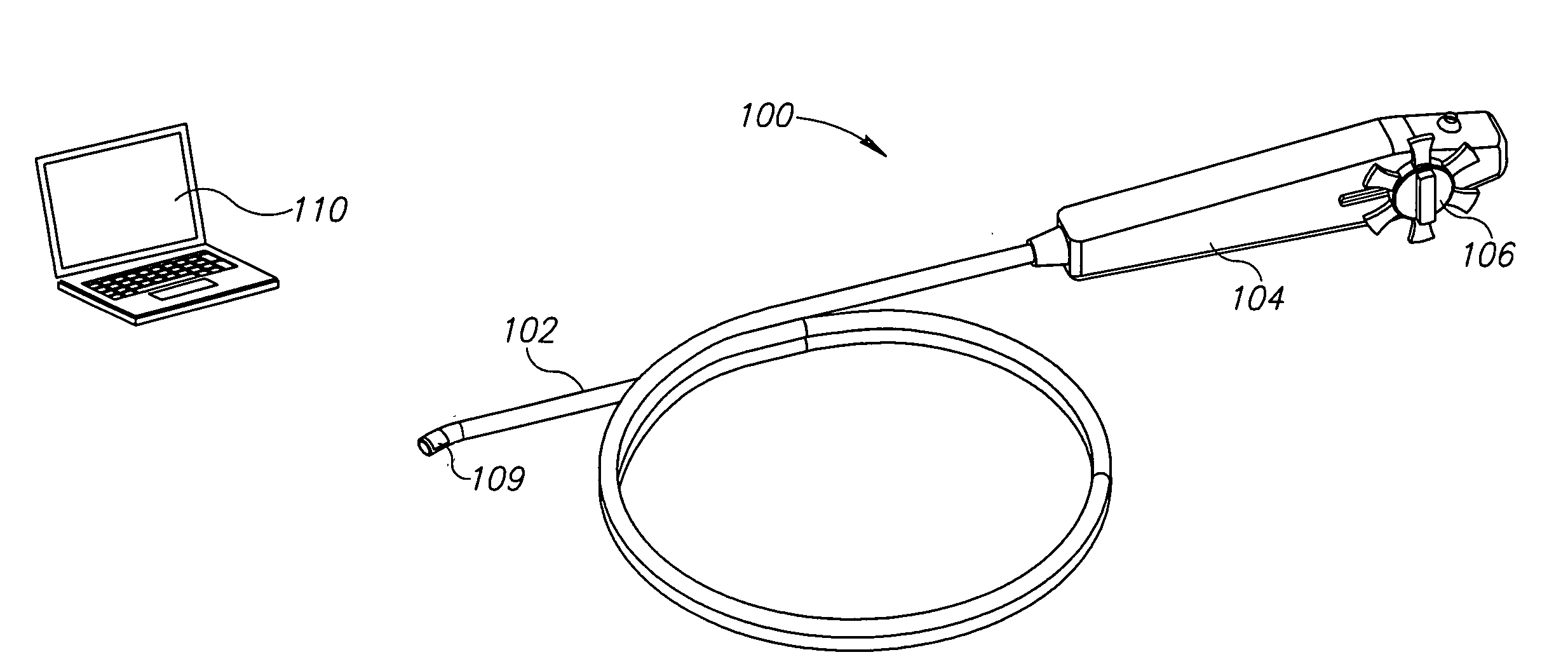

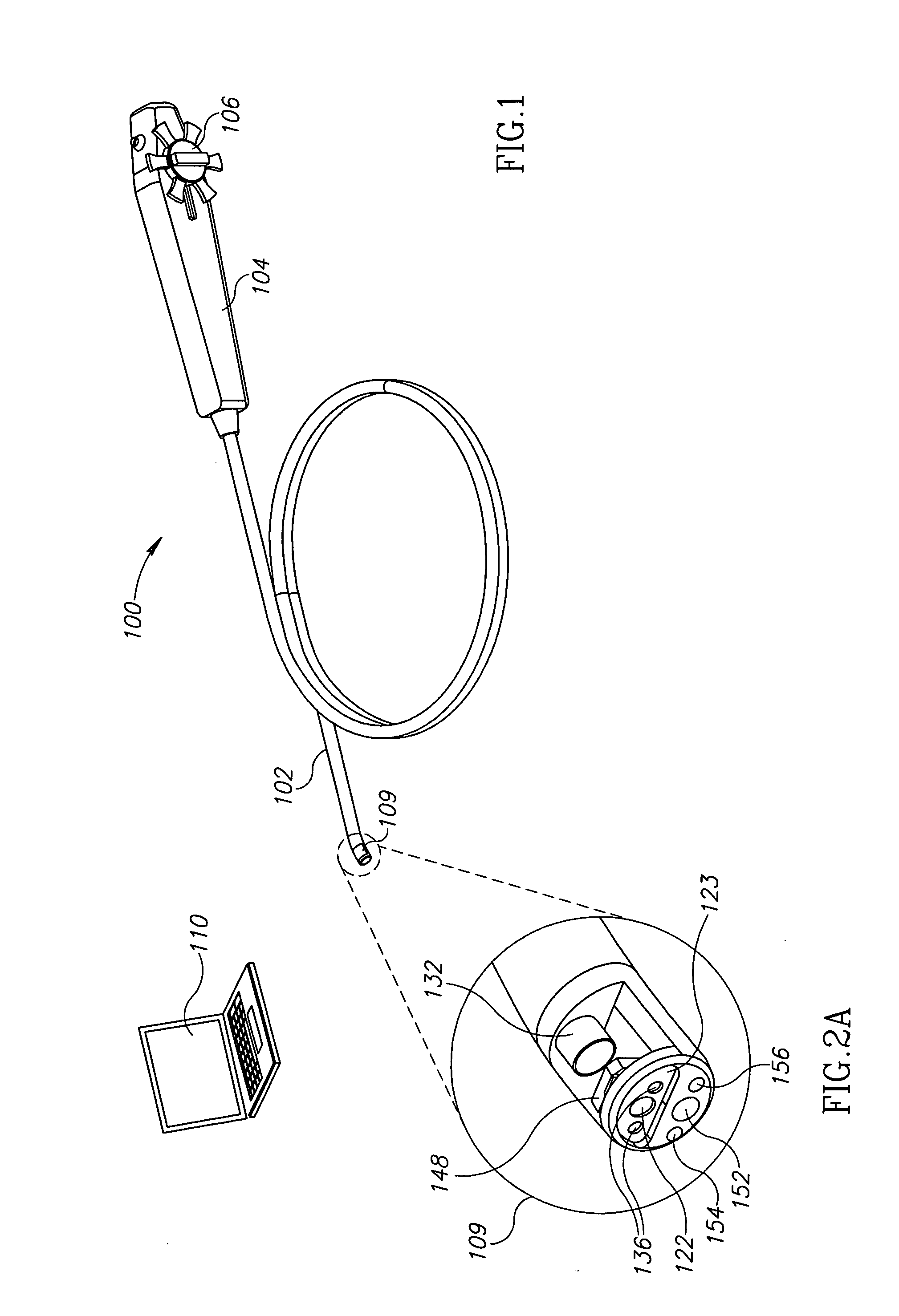

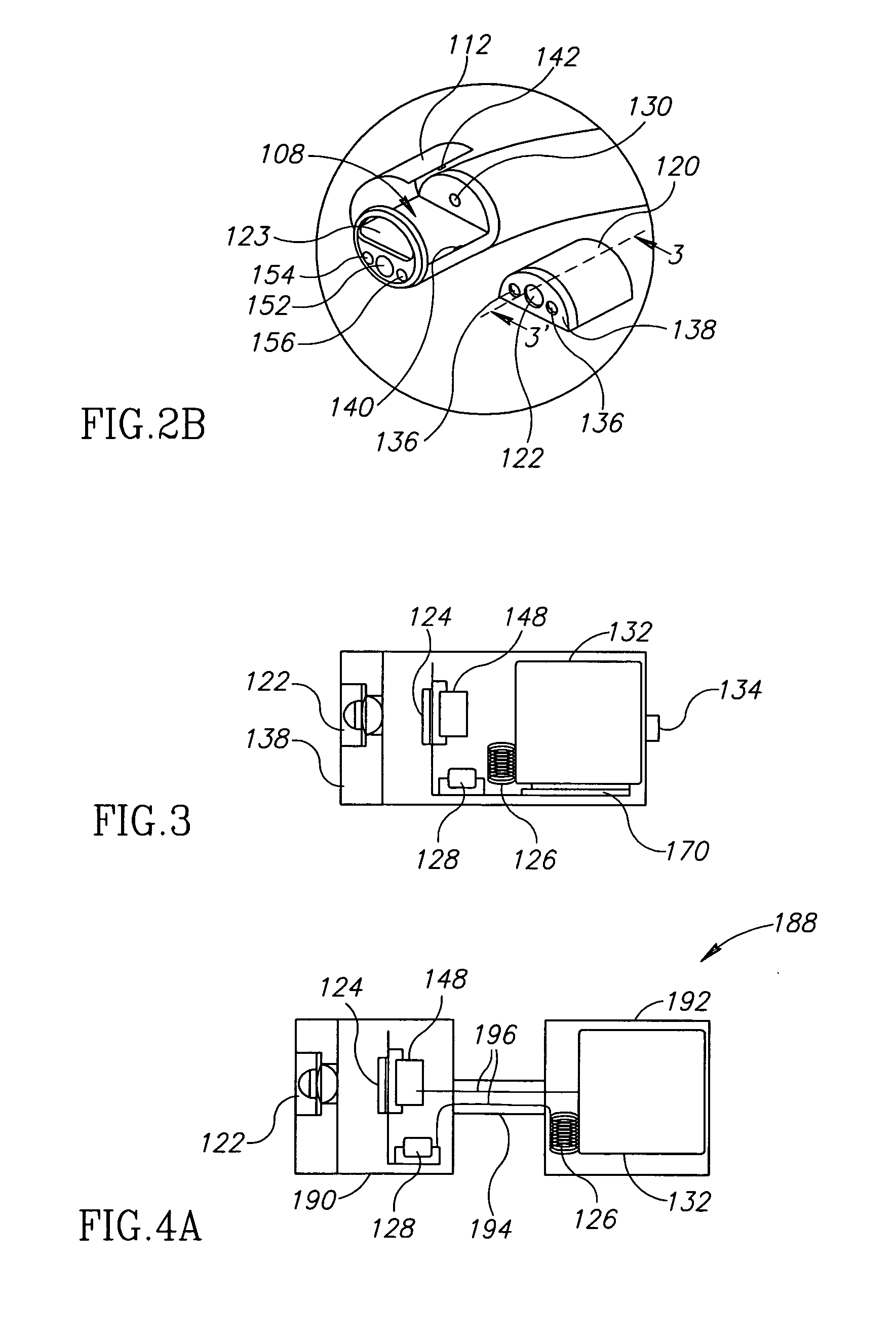

Endoscope With Imaging Capsule

A method of examining internal body portions of patients. The method includes providing an imaging capsule including an image capturing unit, mounting the imaging capsule on a first elongate tube suitable for insertion into a body cavity, in a manner which prevents release of the imaging capsule from the first elongate tube within a body cavity, inserting the first elongate tube with the capsule mounted thereon into a patient, retracting the first elongate tube from the patient, separating the imaging capsule from the first elongate tube, disposing of the first elongate tube, mounting the imaging capsule on a second elongate tube and inserting the second elongate tube with the imaging capsule mounted thereon into a patient.

Owner:COGENTIX MEDICAL

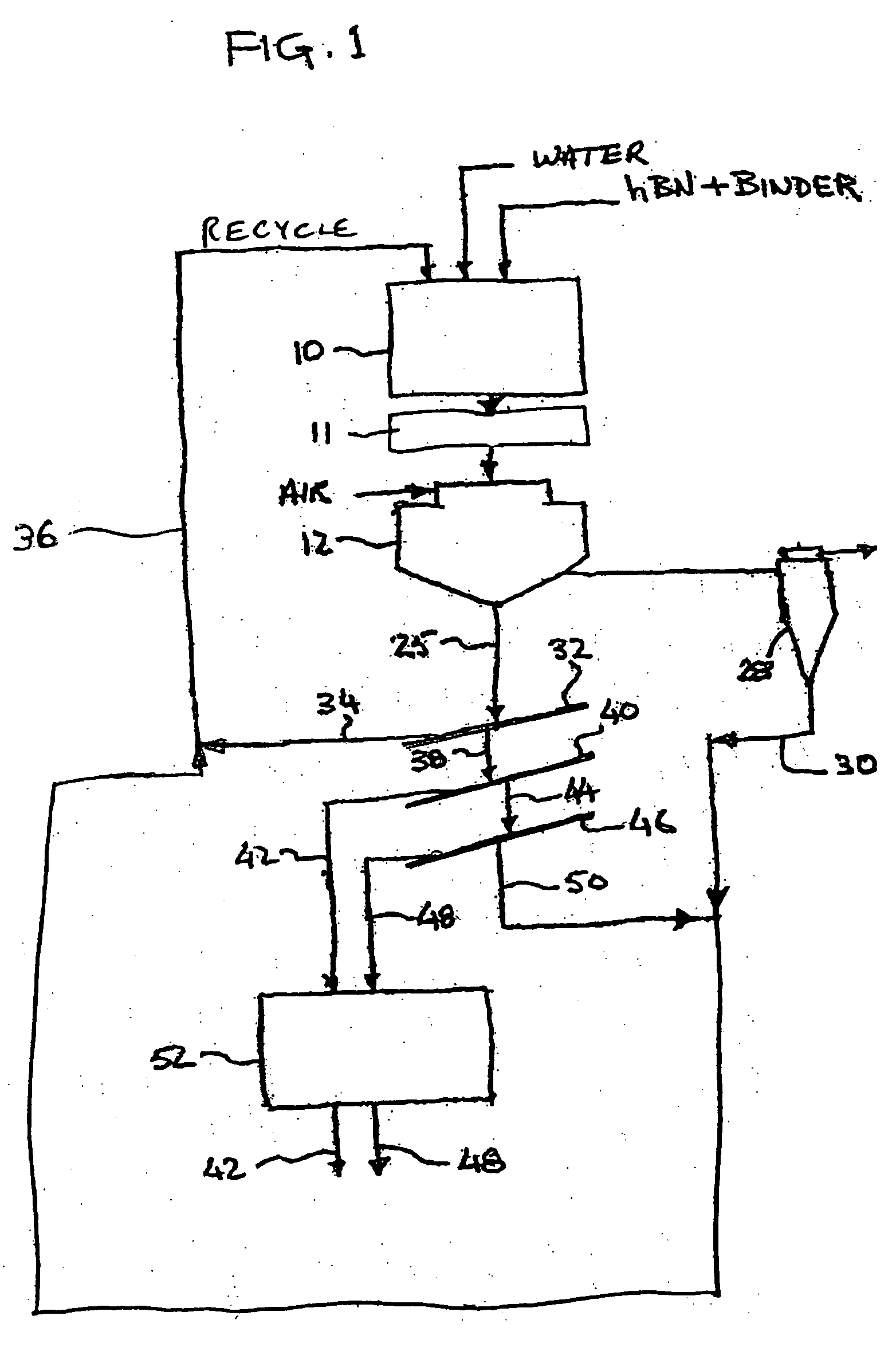

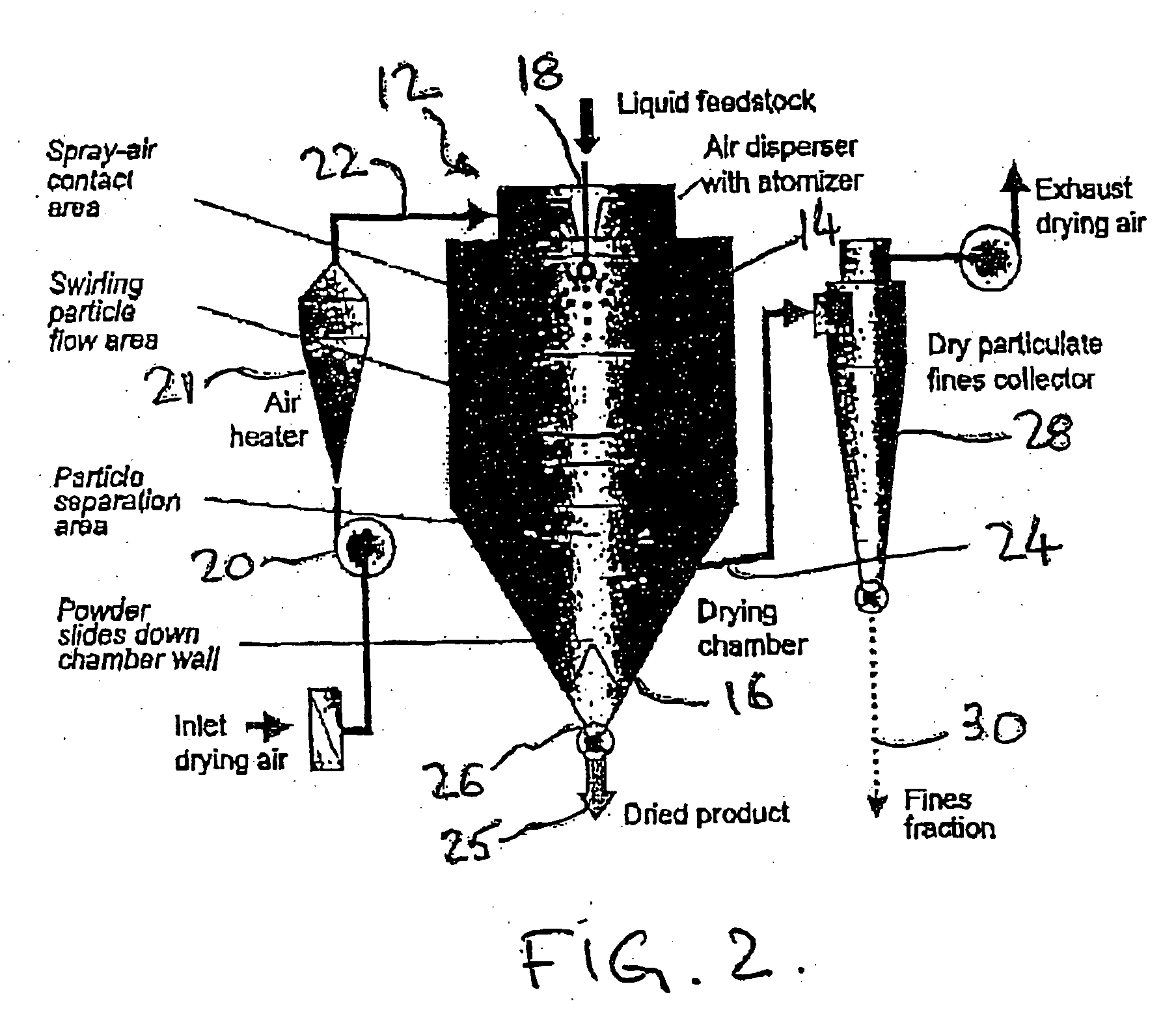

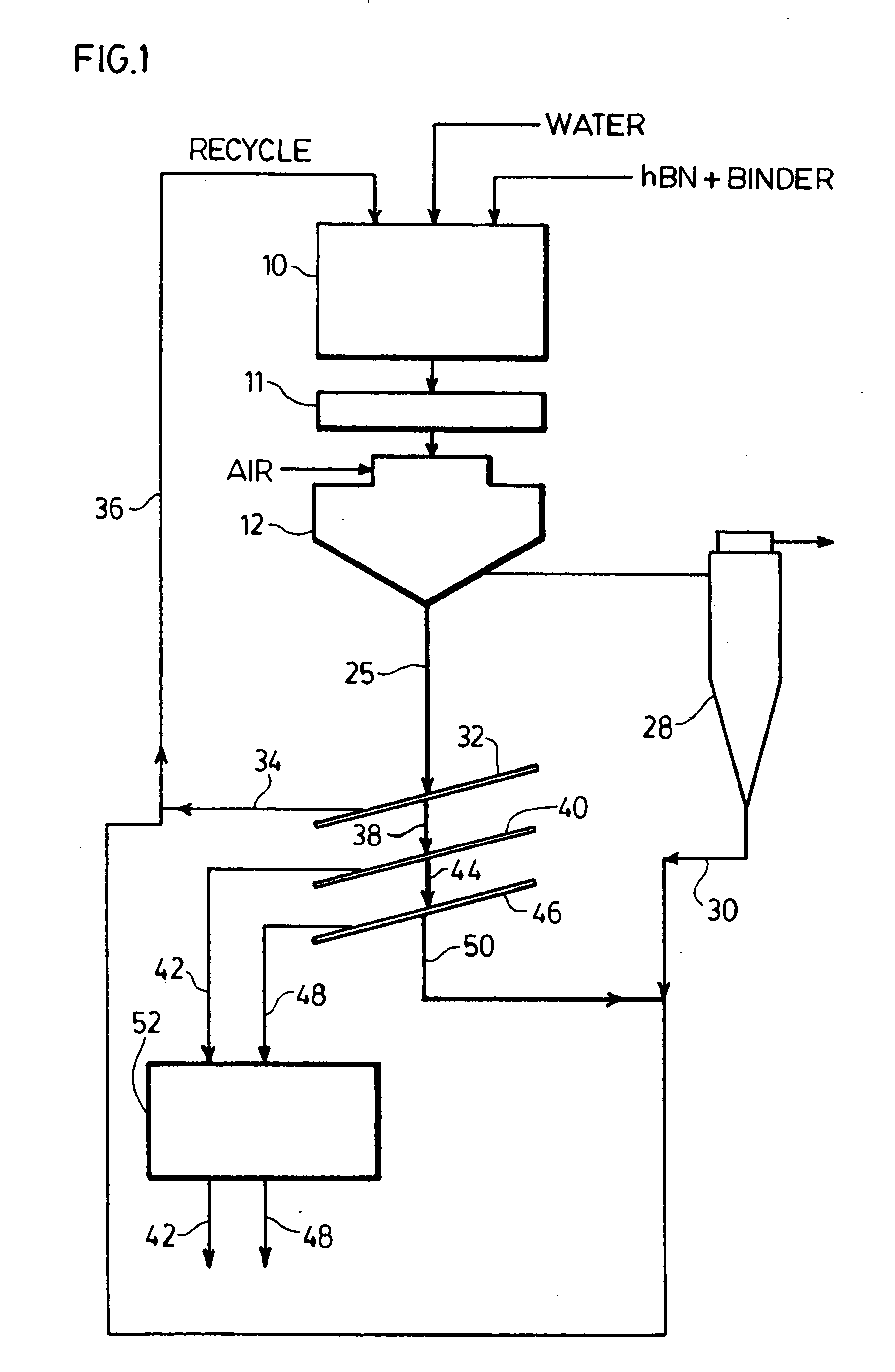

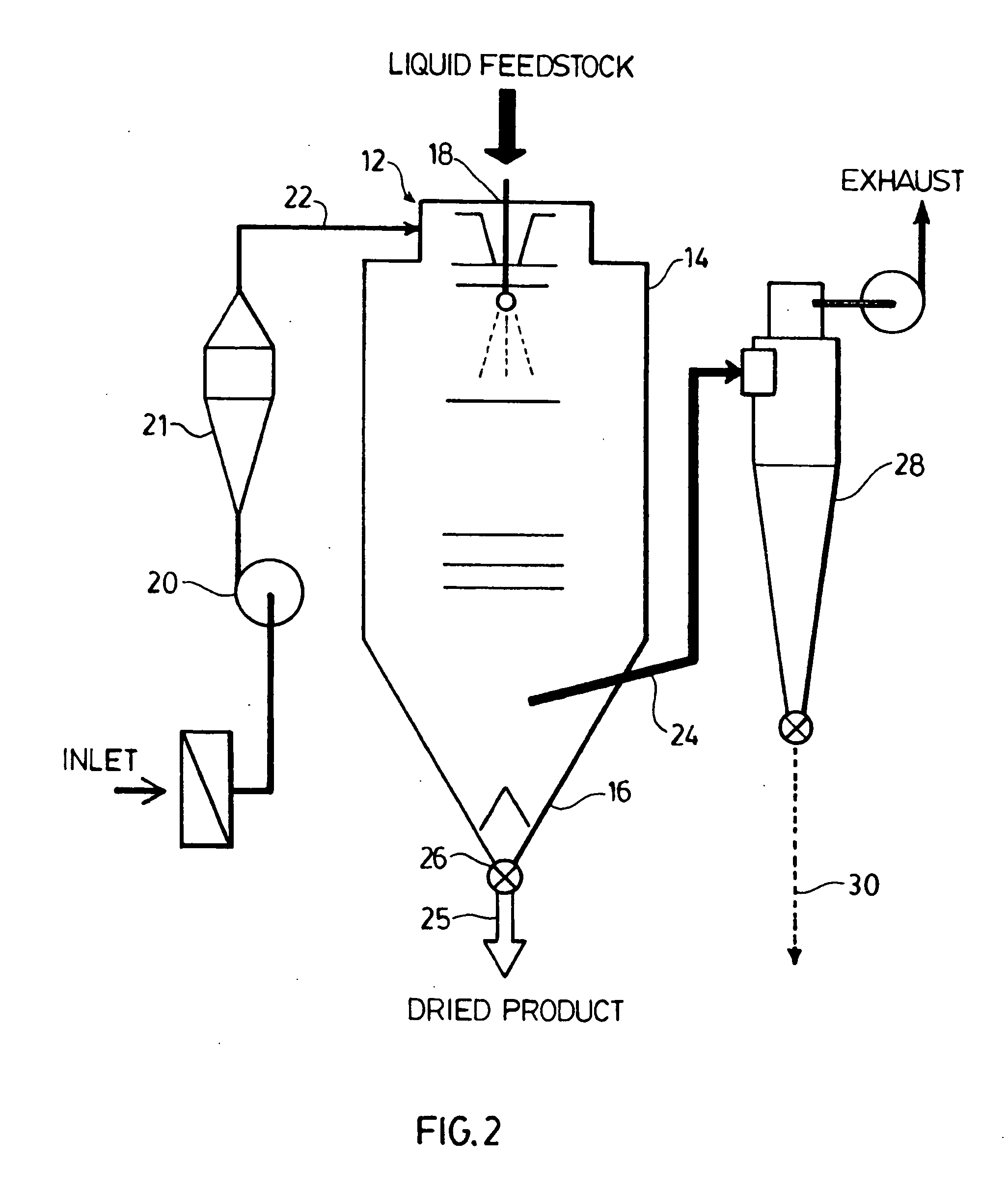

Method for producing composite material for coating applications

ActiveUS20050124505A1Low costHigh and more controllable deposit efficiencyLiquid surface applicatorsMixingMetallurgyLubricant

The production of solid lubricant agglomerates by combining solid lubricant powder, an inorganic binder, other fillers if optionally desired, and a liquid to form a mixture, and driving off the liquid to form dry agglomerates which are subsequently classified by size or milled and classified by size to yield agglomerates of a desired size range. These agglomerates are then treated to stabilize the binder, thereby strengthening the binder and rendering it nondispersible in the liquid. The undesired size ranges can be readily recycled because the agglomerates with untreated binder can be reprocessed, thereby promoting high recovery rates.

Owner:SULZER METCO CANADA INC

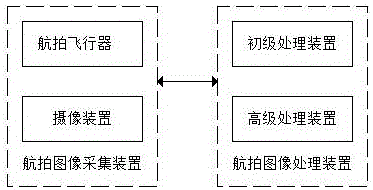

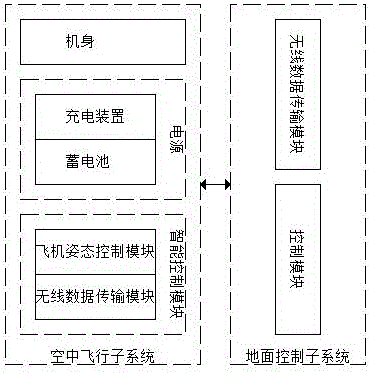

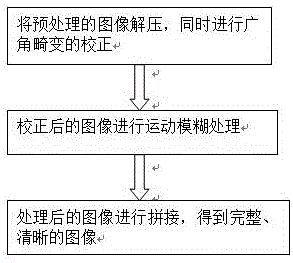

Intelligent aerial photographing system

InactiveCN105872413AImprove battery lifeReduce data transferTelevision system detailsGeometric image transformationFlight vehicleAutomatic control

The invention discloses an intelligent aerial photographing system. The intelligent aerial photographing system is characterized by comprising an aerial photographing image collecting device and an aerial photographing image processing device; the aerial photographing image collecting device comprises an aerial photographing aircraft and a camera device; the aerial photographing processing device comprises a primary processing device on the aircraft and an advanced processing device on the ground; an unmanned aerial vehicle is adopted as the aerial photographing aircraft and comprises an air flying subsystem and a ground control subsystem; the camera device comprises a high-definition camera installed on the lower portion of an unmanned aerial vehicle body. The invention further discloses a method for carrying out primary processing on images with the primary processing device and a method for carrying out advanced processing on images with the advanced processing device. The aerial photographing system comprises the unmanned aerial vehicle which is capable of achieving automatic flying continuation and automatic control; meanwhile, high-definition images are automatically collected and processed multiple times, and complete and clear images can be obtained.

Owner:CHENGDU DESHANNENG TECH CO LTD

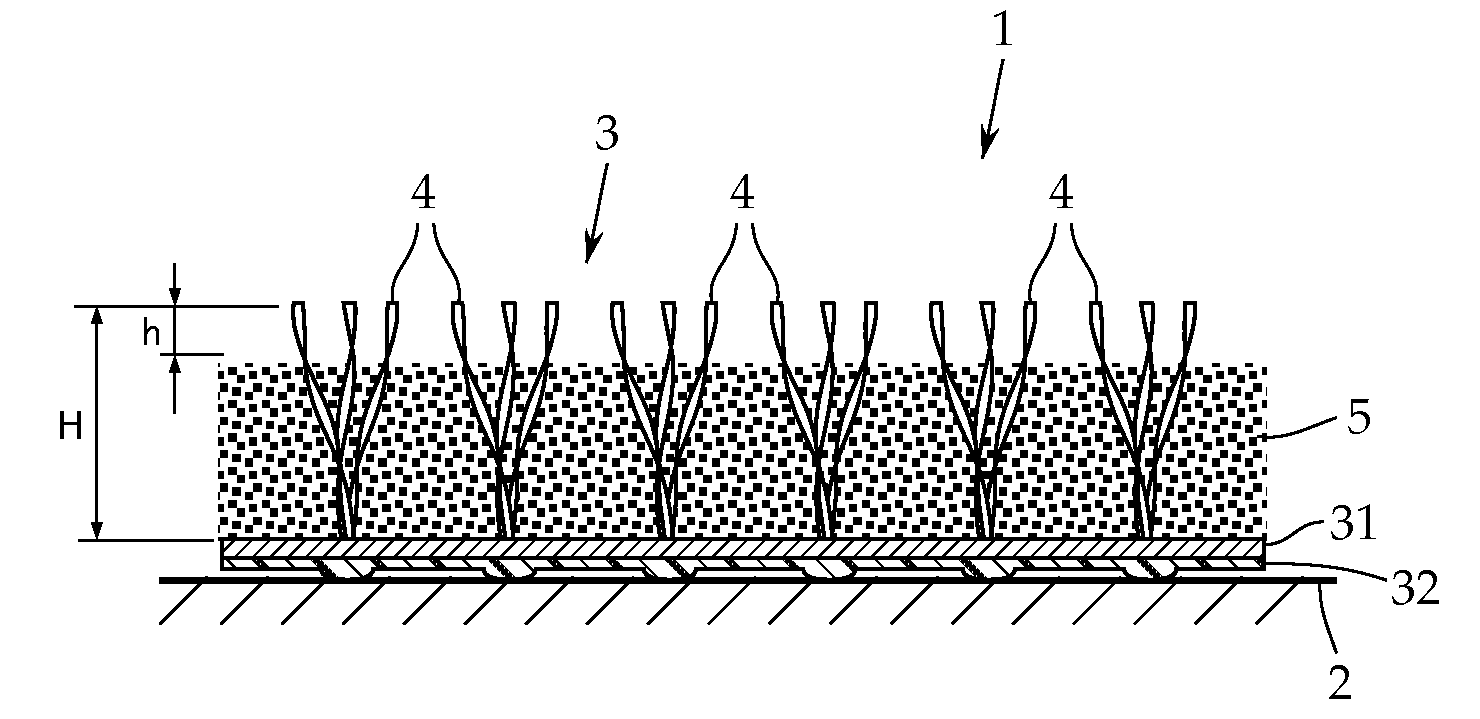

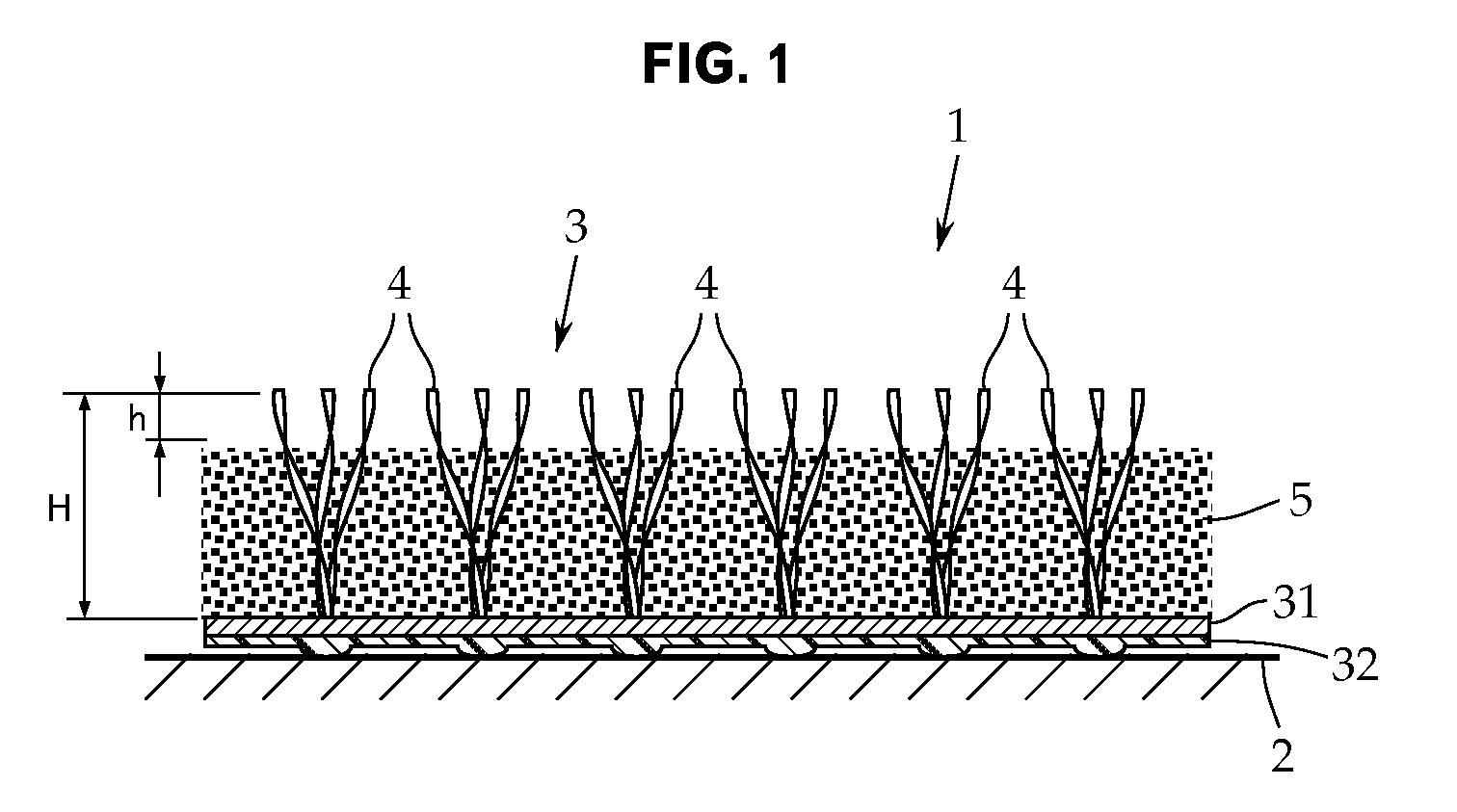

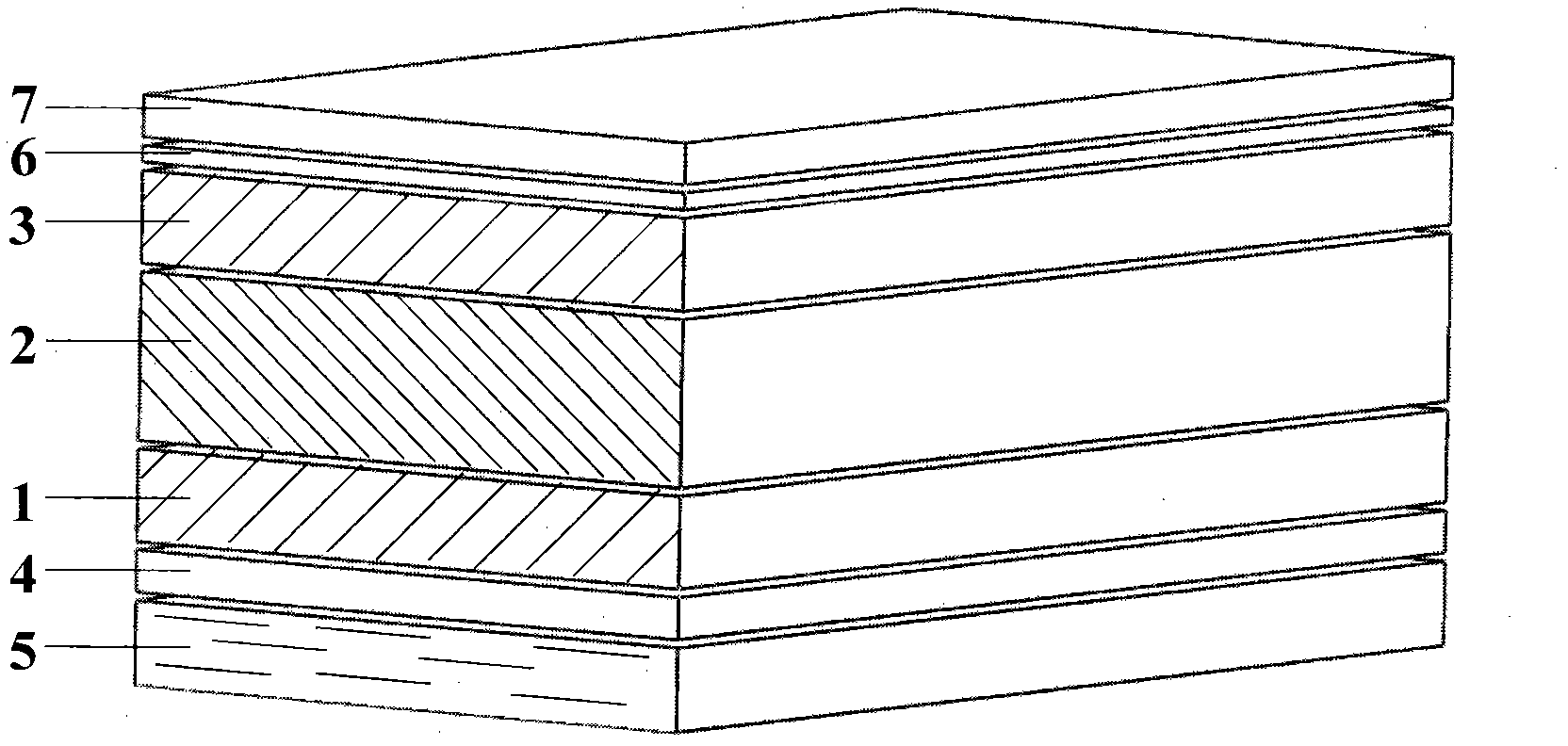

Artificial turf structure, artificial turf facilities employing the artificial turf structure and system for recycling artificial turf structure

InactiveUS20100247814A1Improve recycling efficiencyIncrease contentDead plant preservationArtificial flowers and garlandsParticulatesArtificial turf

A circulation type technique for recycling an artificial turf structure, in which a spent artificial turf is used as a filler for a fresh artificial turf. A spent artificial turf (3) is melted and formed into a particulate filler (5) for recycling. An artificial turf (3) newly laid on a roadbed is filled with the filler for recycling.

Owner:SUMITOMO RUBBER IND LTD

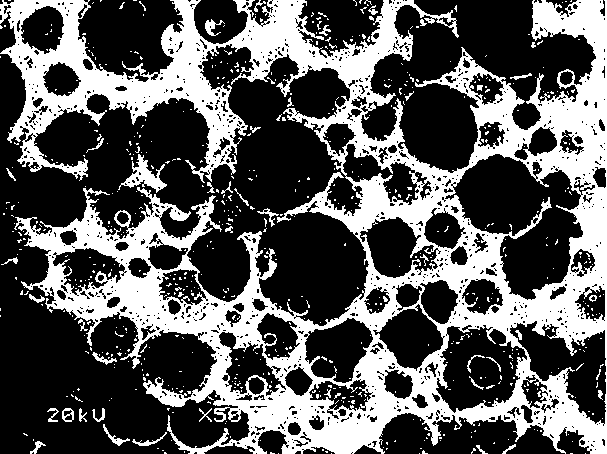

Lightweight foamed ceramics and preparation method thereof

The invention relates to lightweight foamed ceramics and a preparation method of the lightweight foamed ceramics. The lightweight foamed ceramics are prepared by the steps as follows: mechanically agitating raw material, curing agent and foam based on a certain ratio, so as to obtain uniform ceramic size; moulding the ceramic size by casting; and curing and drying same at a certain temperature; and finally sintering the dried blank body to obtain the lightweight foamed ceramics. The lightweight foamed ceramics are important for efficiently utilizing the solid waste, reducing the pollution of the industrial solid waste to the environment, and reducing the production cost; the produced lightweight ceramics have the advantages of being more in closed air pores, relatively low in heat conductivity, relatively high in strength, and relatively low in sintering temperature; and the lightweight foamed ceramics are suitable to be applied to the fields of lightweight decorative material, building insulation wall material, sound insulating material, fireproof material and sinking preventing material.

Owner:GANSU WANTE TECH DEV

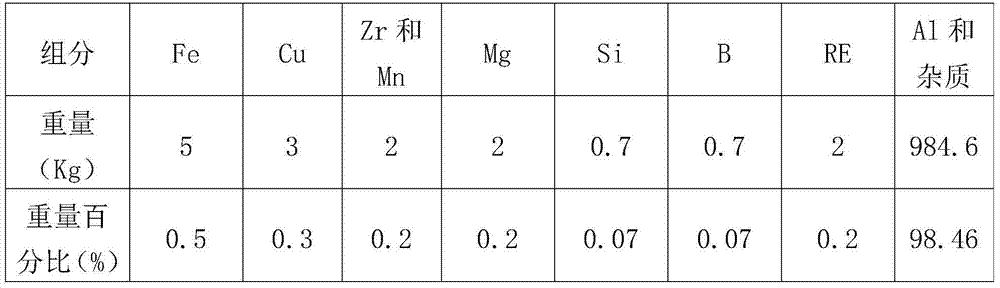

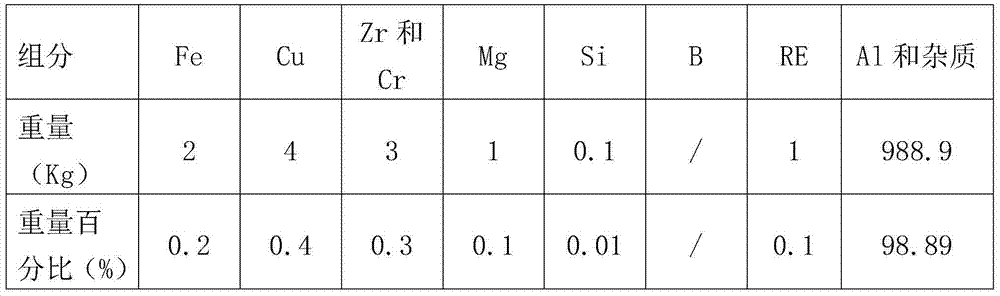

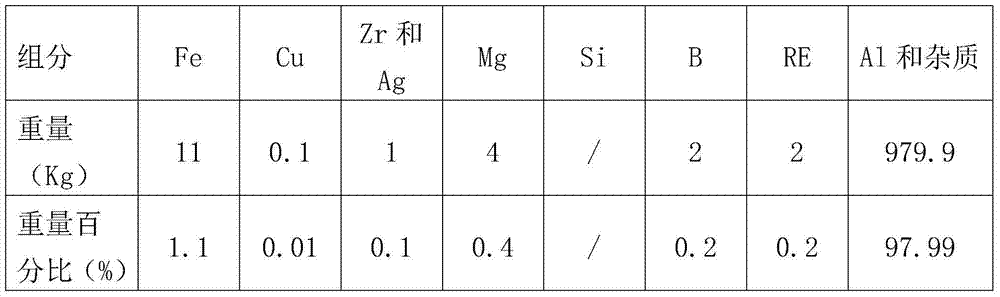

Al-Fe-Cu-Mg aluminum alloy for cables for coal mines, aluminum alloy cable and preparation method of alloy cable

PendingCN104294093AImprove performanceImprove mechanical strength, tensile propertiesMetal/alloy conductorsCable/conductor manufactureCoalOmega

The invention discloses an Al-Fe-Cu-Mg aluminum alloy for cables for coal mines, which comprises 0.2-1.1% of Fe, 0.01-0.4% of Cu, 0.01-0.4% of Mg, 0-0.1% of Si, 0-0.2% of B, and the balance of Al and impurities, wherein the electrical resistivity of the aluminum alloy is not greater than 0.028264 Omega.mm<2> / m, the elongation at break is not less than 10%, and the number of times of 90-degree fatigue bending is greater than or equal to 30. An aluminum alloy cable is prepared by the steps of melting, casting and rolling the aluminum alloy material so as to obtain an aluminum alloy rod, carrying out drawing, bunch-stranding and softening on the aluminum alloy rod so as to obtain an aluminum alloy cable core, and carrying out extruded insulation, cabling, extruded sheathing or armoring on the cable core; and the prepared aluminum alloy cable has the characteristics of high strength, high electric conductivity, good bending performance and the like, and can satisfy the requirements on the properties of cables in the field of coal mines.

Owner:ANHUI JOY SENSE CABLE

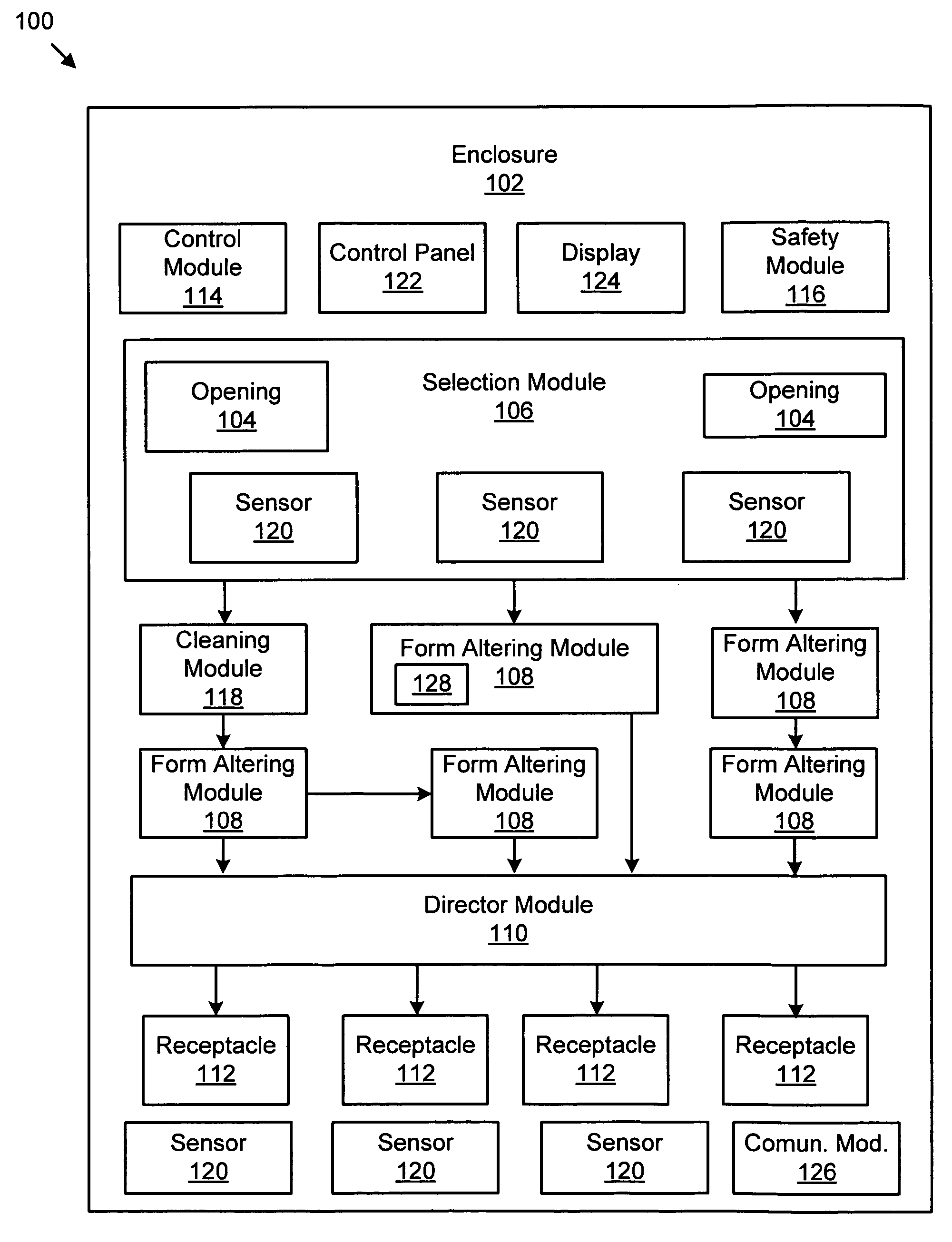

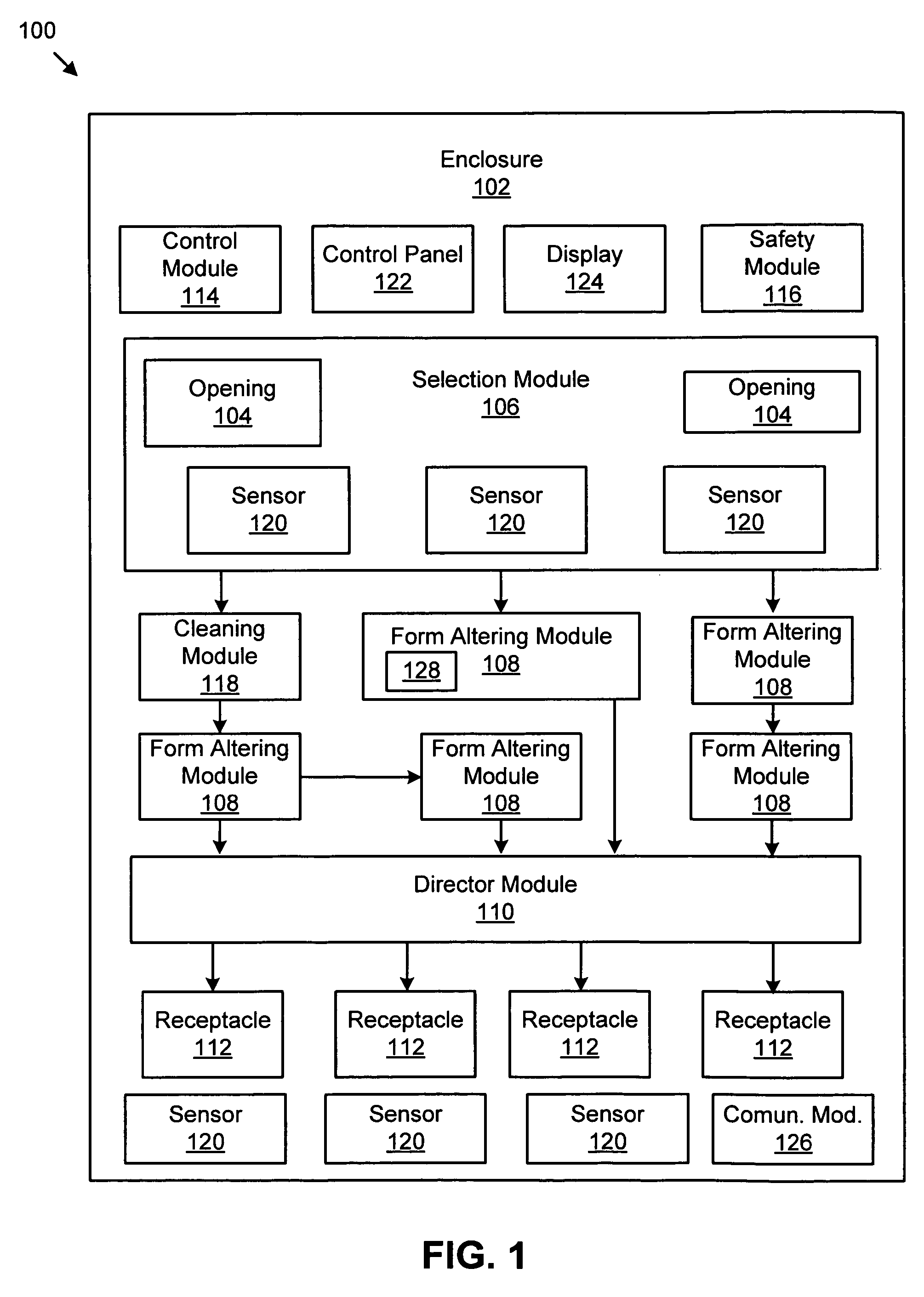

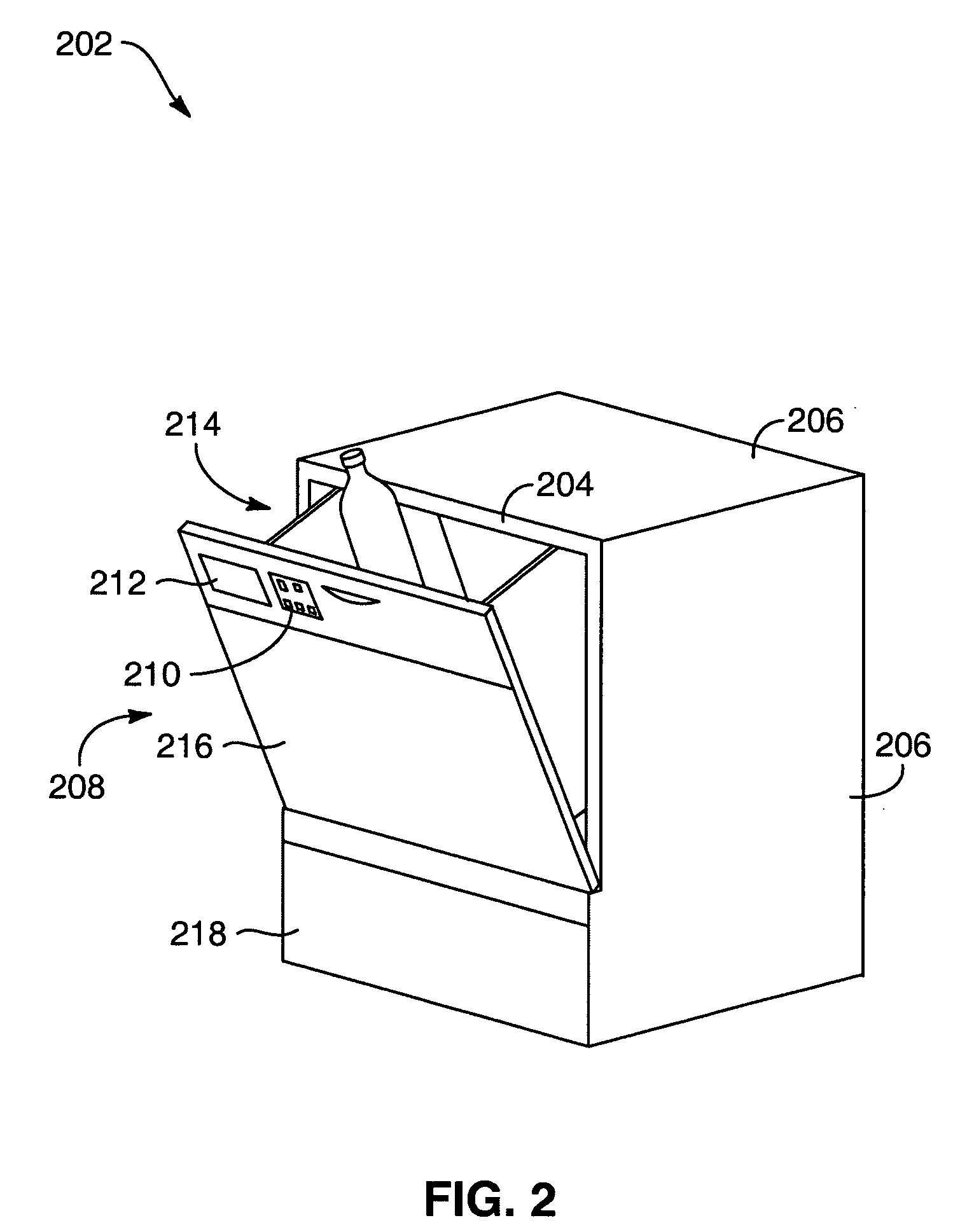

Apparatus, system, and method for condensing, separating and storing recyclable material

InactiveUS7562836B2Easy to installEasy to removePlywood pressesWaste collection and transferEngineeringAutomatic guidance

An apparatus, system, and method are disclosed for condensing, separating and storing recyclable materials. The apparatus, in one embodiment, selects a type of recyclable material, alters the recyclable material to a condensed form and stores the recyclable material in a designated receptacle. The apparatus may include an enclosure with one or more openings to receive an item made from a recyclable material, a selection module, a plurality of form altering modules, a plurality of receptacles, and a director module to automatically direct a recyclable material, responsive to a selection made with the selection module, to one of a plurality of receptacles according to the type of material selected. A system, in one embodiment, includes a recycling appliance and one or more modular form altering devices. The modular form altering devices may be interchangeable.

Owner:LANGSTON JODY

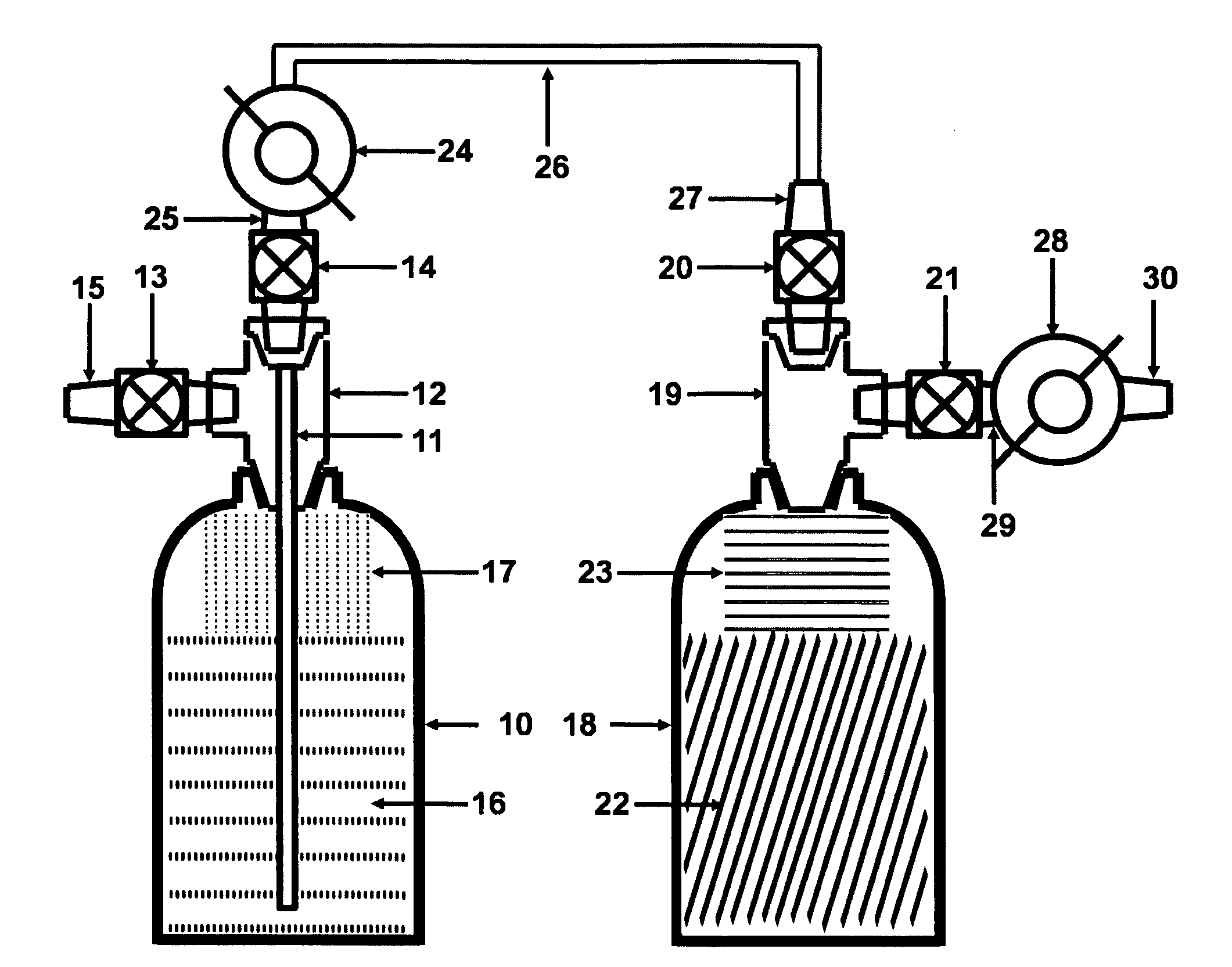

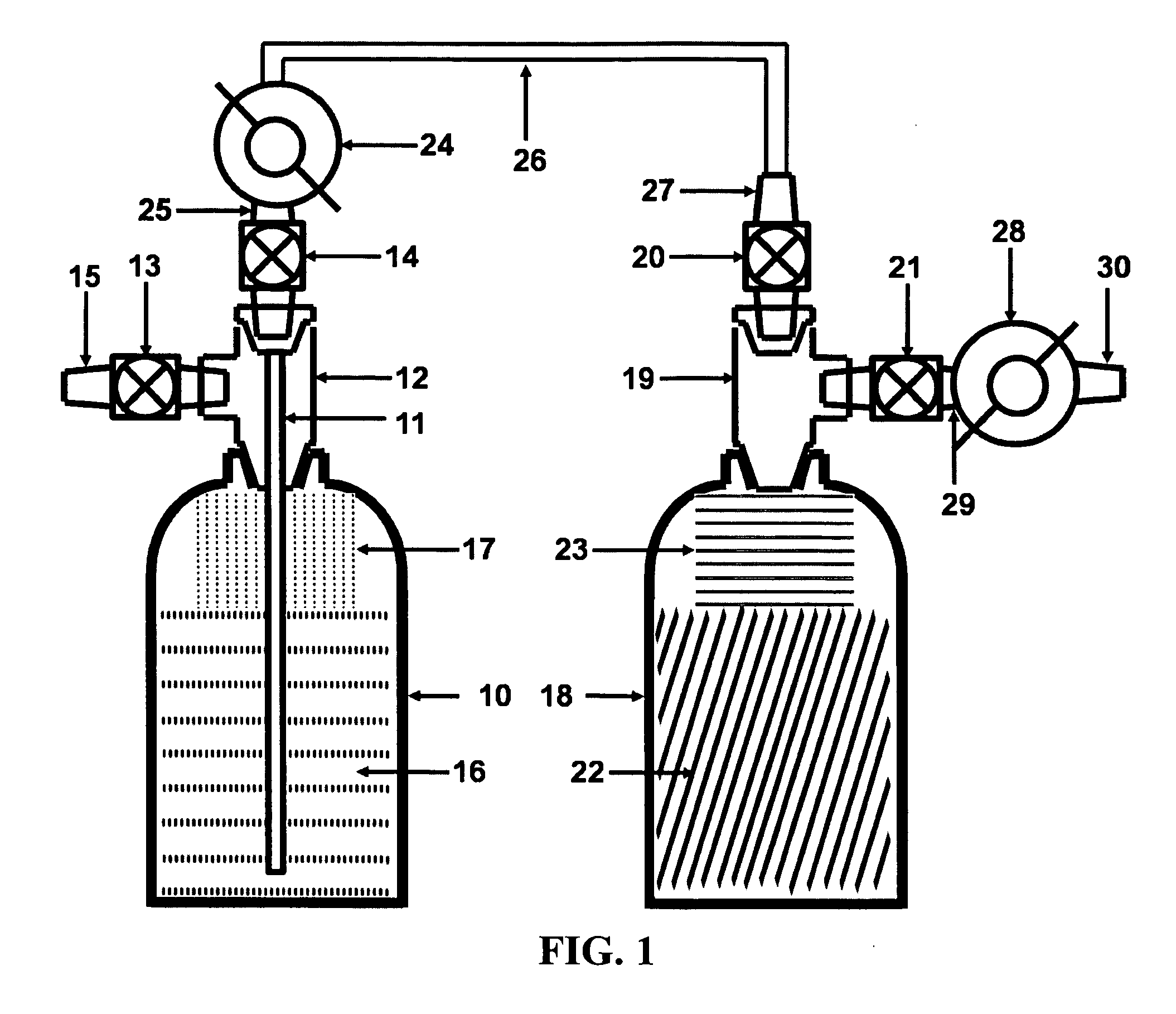

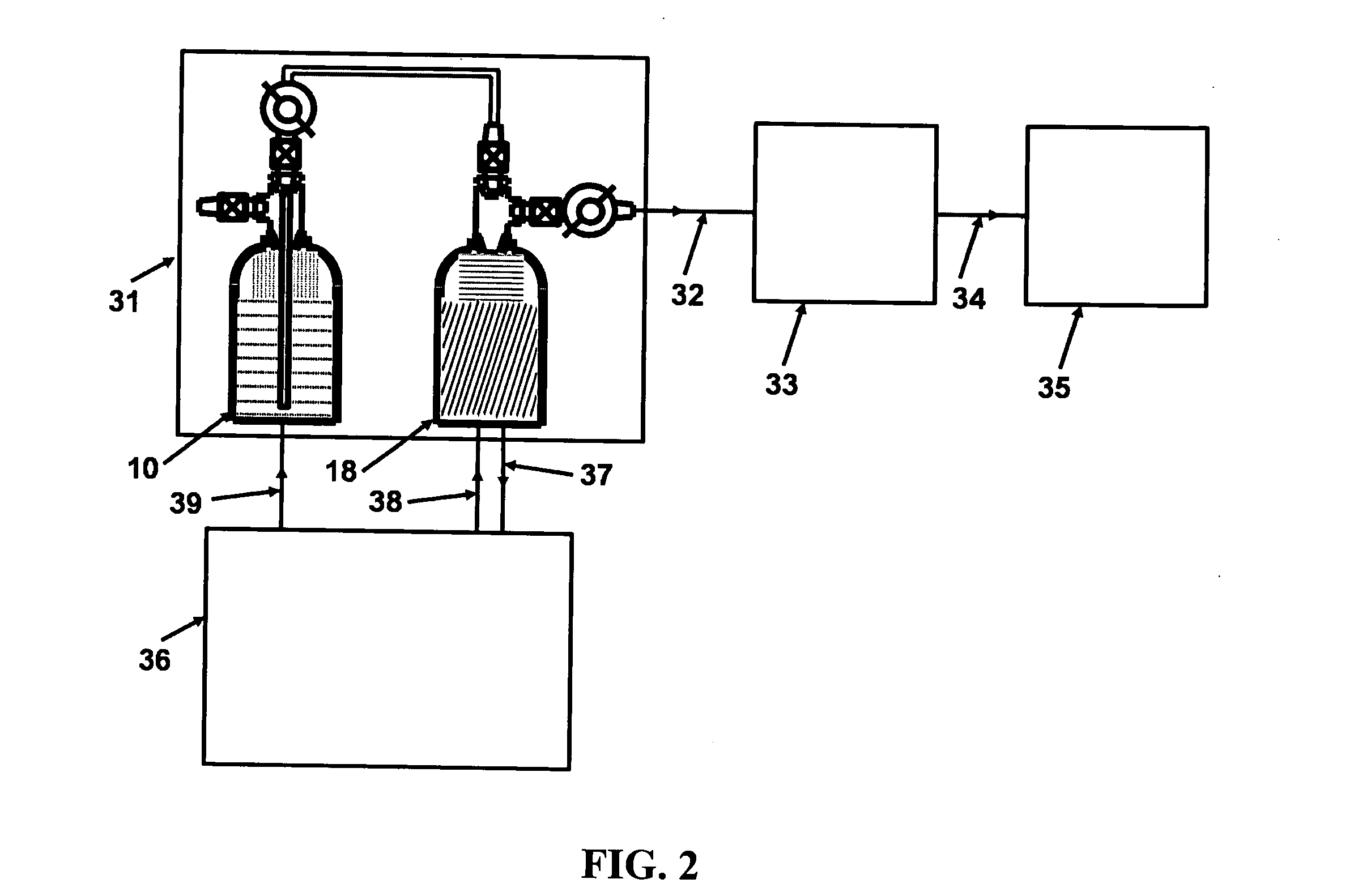

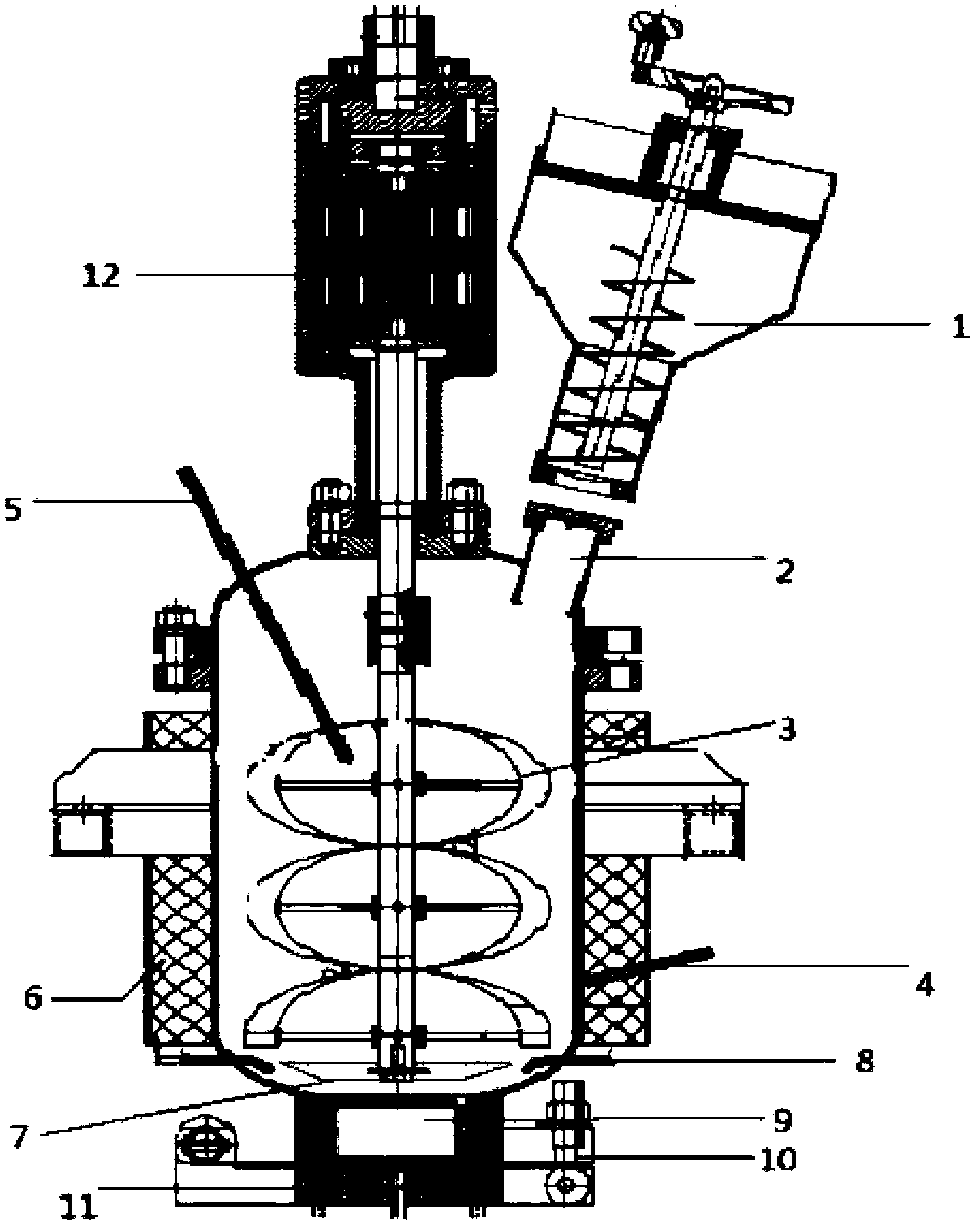

Compact, safe and portable hydrogen generation apparatus for hydrogen on-demand applications

ActiveUS20130115139A1Less hydrogenEasy to reprocessHydrogen productionGas generation devicesChemical reactionElectrolysis

A compact, chemical-mechanical apparatus, having no electrical components, for storing and generating hydrogen safely, on-demand, at the time and point of use in small or large quantities using the environmentally clean chemical reaction between sodium metal and water to generate hydrogen (H2) gas and sodium hydroxide (NaOH) byproduct is presented, for powering electricity generating fuel cells for large scale commercial and private electric motor vehicle transport. The apparatus of the present invention supports hydrogen gas generation by the controlled addition of liquid water to solid sodium metal to produce hydrogen gas and sodium hydroxide using only mechanical components without electrical components that require external power and can generate sparks or short circuits, producing catastrophic failure in hydrogen systems. The sodium hydroxide can be reclaimed and recycled by electrolysis using hydroelectric power to recover the sodium metal for reuse in generating hydrogen, thereby forming a complete clean energy hydrogen power cycle.

Owner:STERN ALVIN GABRIEL

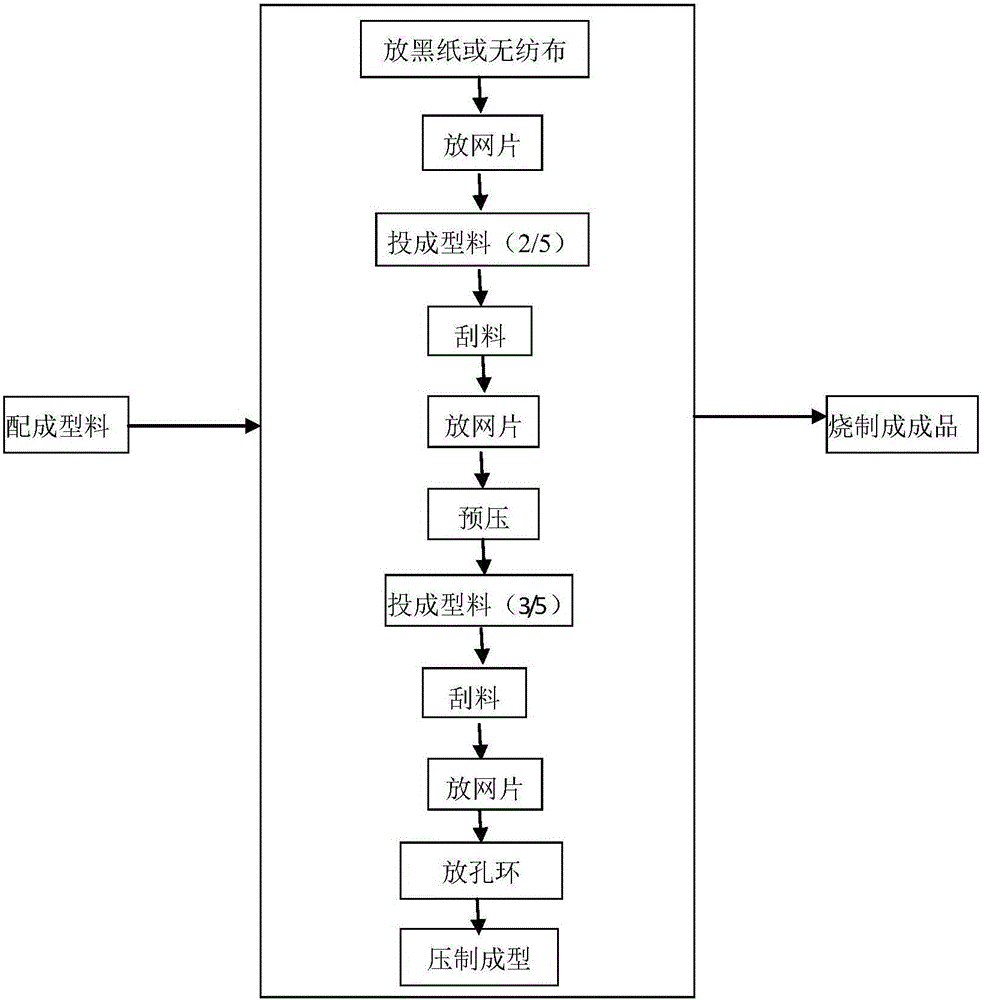

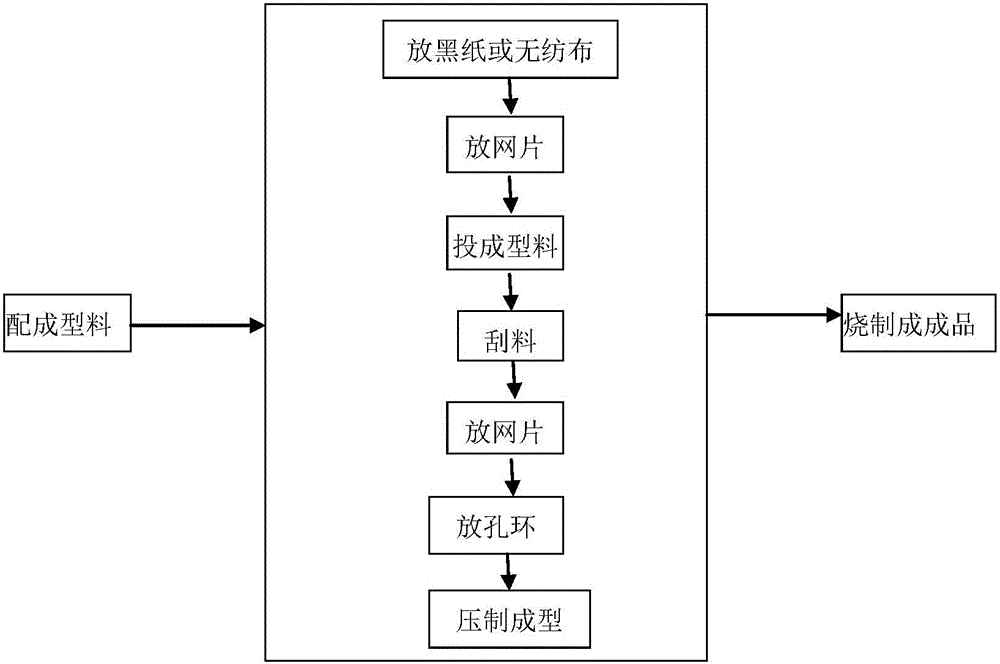

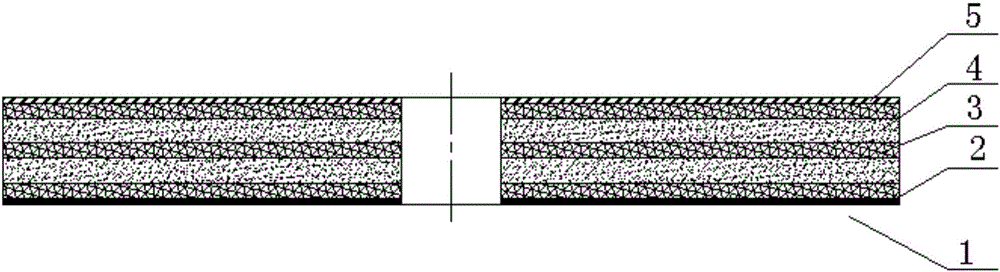

Manufacturing method of cutting and grinding resin wheel

InactiveCN106112840AReduce burnSave effortBonded abrasive wheelsGrinding devicesManufacturing technologyWork in process

The invention belongs to the technical field of resin grinding wheel manufacturing and relates to a manufacturing method of a resin grinding wheel for both cutting and grinding purposes. It includes the step of preparing the molding material, the step of molding the semi-finished resin grinding wheel blank and the step of firing the finished product. Among them, the molding material is made of phenolic resin material with high adhesion ability, and the molding material is poured in two times. The thickness of the grinding wheel is controlled below 2.5mm, so that Grinding wheels can both cut and grind. The beneficial effects of the invention are: convenience; avoiding the trouble of customers changing products back and forth, high processing efficiency; sharpness; saving labor and reducing burns to workpieces; saving energy; reducing thickness reduces the loss of workpieces; and is beneficial to workpieces. reprocessing; low cost and price, which is conducive to the promotion and application of the method of the present invention.

Owner:廊坊菊龙五金磨具有限公司

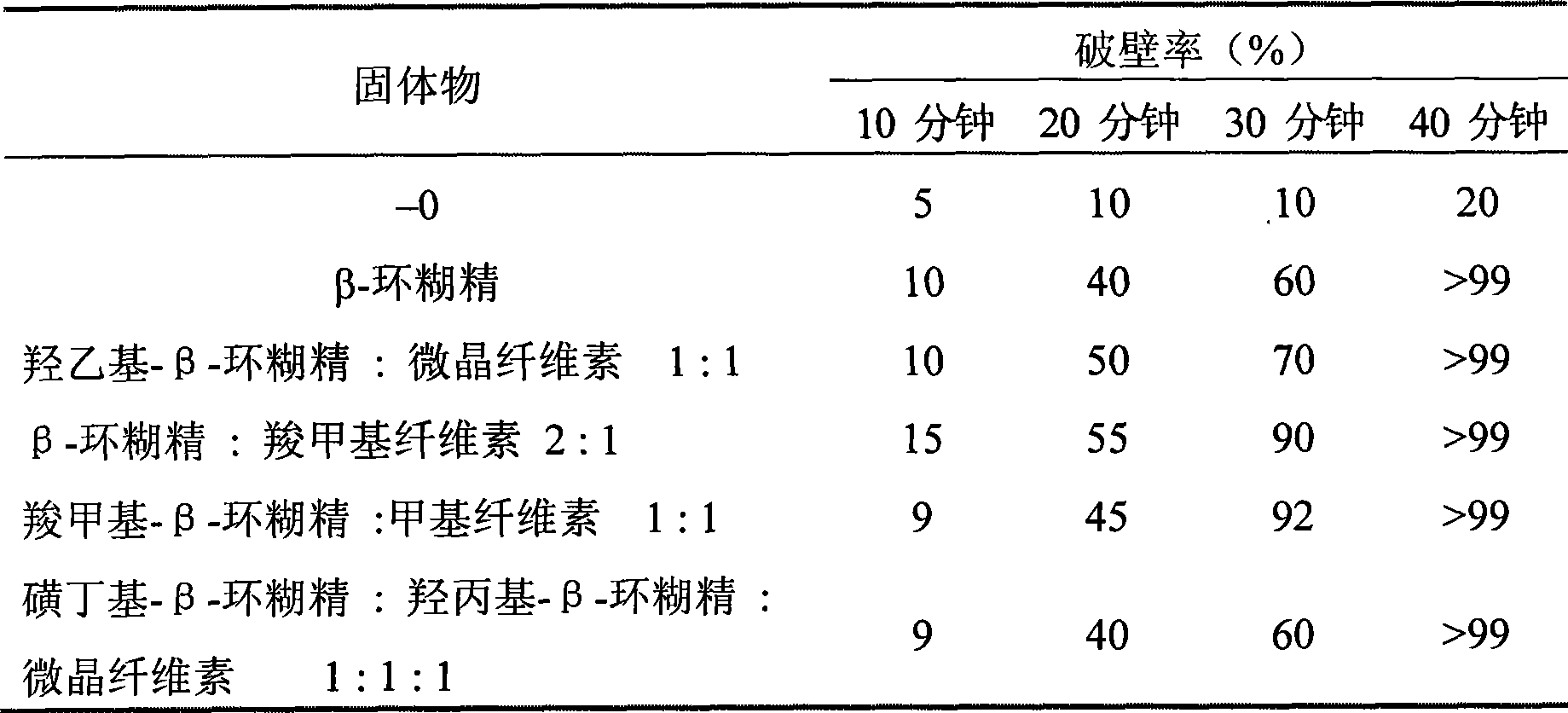

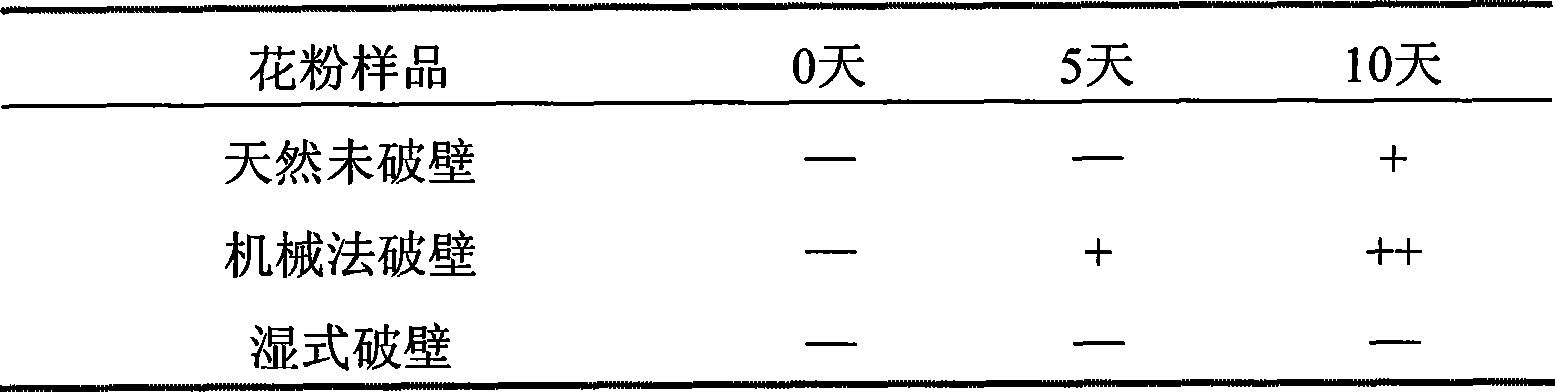

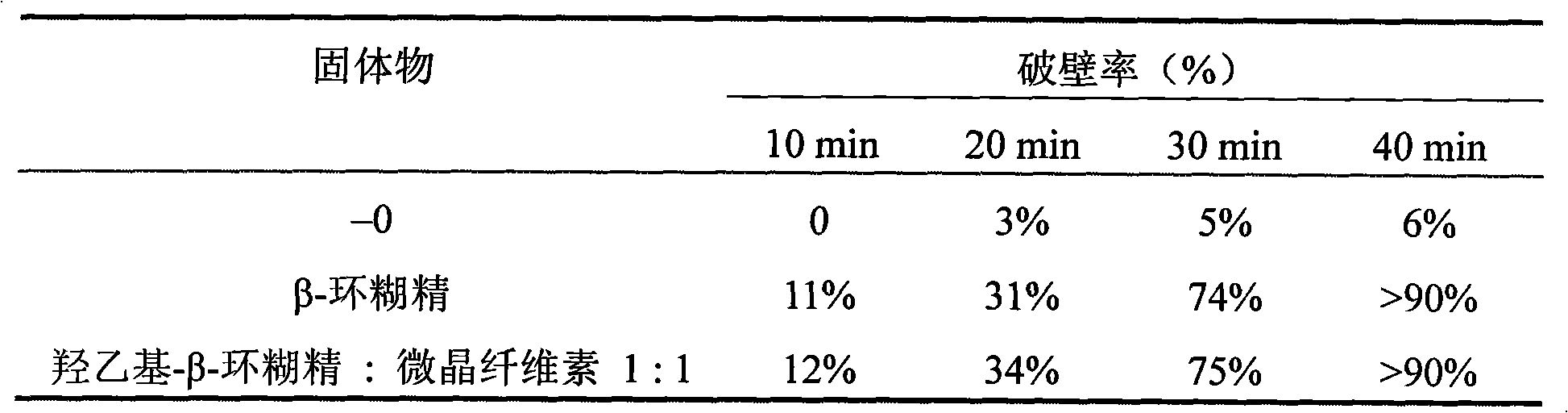

Wet-type wall-breaking method for pollen

InactiveCN101518303AReduce the possibility of infectionStrong photothermal stabilityFood preparationFlavorPollen

The invention relates to a wet-type wall-breaking method for pollen, which comprises the following steps of: (1), washing, layering and filtering the pollen to remove impurities; (2) soaking the pollen in ethanol and filtering the pollen for standby; (3) adding a mixed solid material to mix the pollen, adding water of which the mass is 1 to 3 times of the total mass of the solid material to obtain an uniform mixed suspension and grinding the suspension to make a paste, wherein the mass ratio of the pollen to the mixed solid material is 1:1.0-5.0; and (4) drying the paste under reduced pressure, and obtaining a product of wall-broken pollen through crushing and screening. The mixed solid material is orally-taken cyclodextrin or a mixture of the orally-taken cyclodextrin and an edible or pharmaceutical solid accessory, wherein the mass ratio of the orally-taken cyclodextrin to the edible or pharmaceutical solid accessory is 1:0.5-4.0. The method combines the pollen wall breaking and the protection of the wall-broken pollen, eliminates the possibility for the oxidization and bacteria infection of the wall-broken pollen and achieves high pollen wall breaking efficiency. The method ensures the stability of the active ingredients of the pollen and the natural flavor of the pollen.

Owner:NANJING NORMAL UNIVERSITY +1

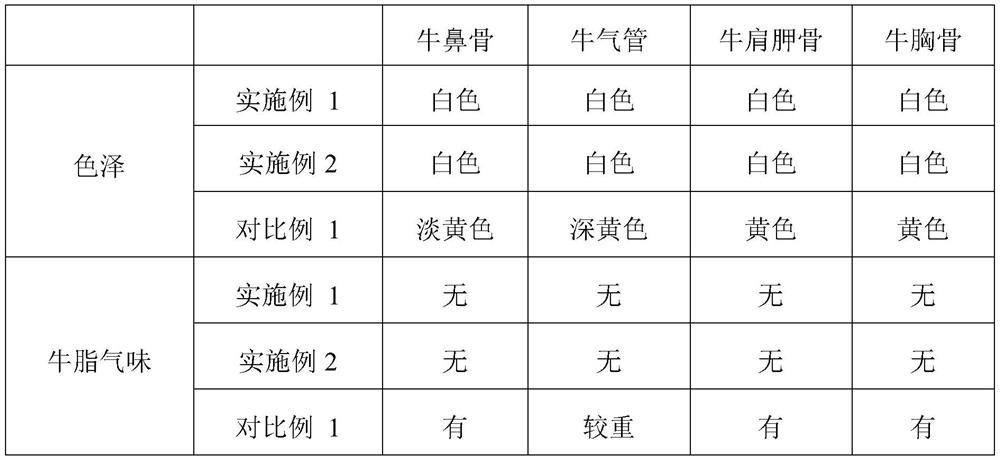

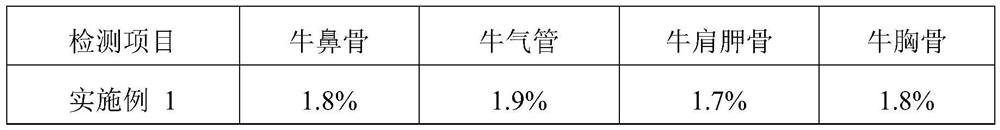

Process for improving quality and yield of collagen peptide coproduced from sodium chondroitin sulfate

PendingCN111793145AHigh extraction process requirementsReduce dosageConnective tissue peptidesPeptide preparation methodsUltrafiltrationIon exchange

A process for improving quality and yield of collagen peptide coproduced from sodium chondroitin sulfate comprises the following steps: (1) degreasing bovine cartilage by supercritical / subcritical extraction; (2) hydrolyzing, flocculating and separating endonuclease; (3) carrying out ultrafiltration to separate chondroitin sulfate sodium and collagen peptide; (4) refining the sodium chondroitin sulfate; and (5) refining the collagen peptide. The process is used for extracting the dried bovine cartilage chondroitin sulfate sodium and collagen peptide, meanwhile, the product yield and quality are improved, and the obtained product is white in color and luster and free of beef tallow smell. According to the process, the dried bovine bones are adopted, so that the problems that domestic bovinefeeding and slaughtering are scattered, and fresh bovine cartilage is high in storage, collection and transportation cost and high in difficulty are solved; and the process is simple in technologicalprocess, easy to filter, short in production time, capable of saving energy and reducing emission, low in production cost and remarkable in economic benefit and social benefit, and processes such asresin decoloration and ion exchange are not needed.

Owner:HUNAN WUXING BIOLOGICAL TECH CO LTD

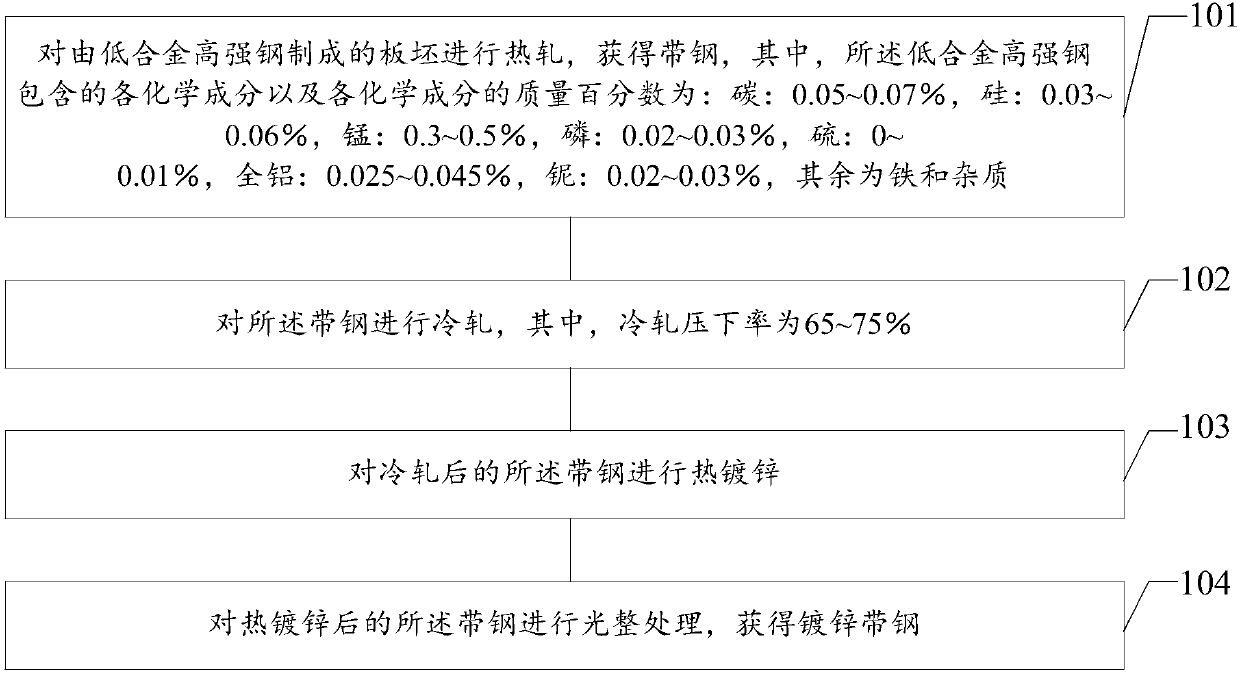

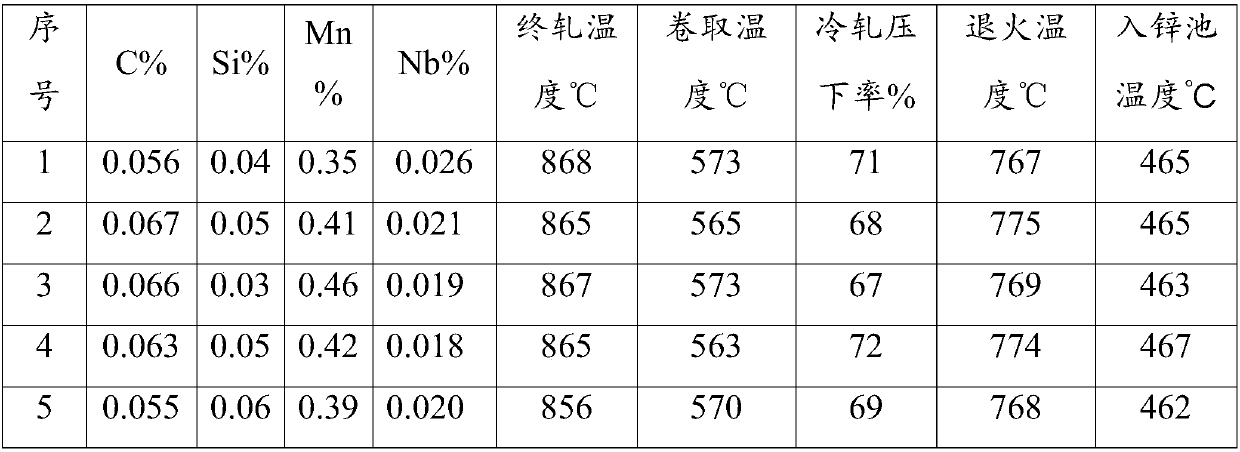

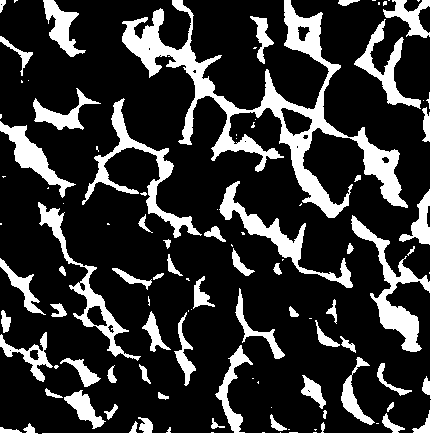

Production control method for low-alloy high-strength steel and galvanized strip steel

The invention relates to the technical field of hot galvanizing, in particular to a production control method for low-alloy high-strength steel and galvanized strip steel. The low-alloy high-strengthsteel comprises the chemical ingredients of, in percentage by mass, 0.05-0.07% of carbon, 0.03-0.06% of silicon, 0.3-0.5% of manganese, 0.02-0.03% of phosphorus, 0-0.01% of sulphur, 0.025-0.045% of total aluminum, 0.02-0.03% of niobium and the balance iron and impurities. The yield strength level of the strip steel obtained by machining the low-alloy high-strength steel can reach 300 MPa or aboveby adjusting the chemical ingredients and the contents of all the chemical ingredients of the low-alloy high-strength steel; and meanwhile, the strength and the forming property of the strip steel arefurther improved, and remachining is facilitated.

Owner:BEIJING SHOUGANG COLD ROLLED SHEET

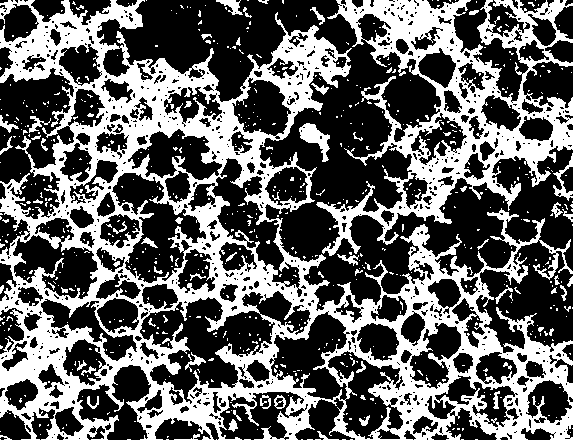

Light-weight closed-pore ceramic heat insulating board

InactiveCN102838377AHigh strengthLower sintering temperatureCeramic materials productionCeramicwarePorositySludge

The invention relates to a light-weight closed-pore ceramic heat insulating board, which is prepared by using the following main raw materials in percent by weight: 20-50 percent of phosphate tailing, 10-24 percent of sludge, 20-30 percent of feldspar, 4-15 percent of shale, 3-15 percent of kaolin, 10-20 percent of yellow sand and 1-2.5 percent of foaming agent, wherein the foaming agent is mixture of silicon carbide, calcium carbonate and ferric oxide, the grain size of the mixture is less than or equal to 0.045mm, and the weight percents of silicon carbide, calcium carbonate and ferric oxide are respectively 40-60 percent, 25-45 percent and 15-35 percent. The light-weight closed-pore ceramic heat insulating board has great importance on efficiently utilizing the phosphate tailing and reducing environmental pollution caused by industrial solid wastes so as to improve the natural environment, use cheap raw materials and decrease the production cost; and at the same time, the produced light-weight closed-pore ceramic heat insulating board has the advantages of higher porosity, higher strength and lower sintering temperature.

Owner:WUHAN UNIV OF TECH

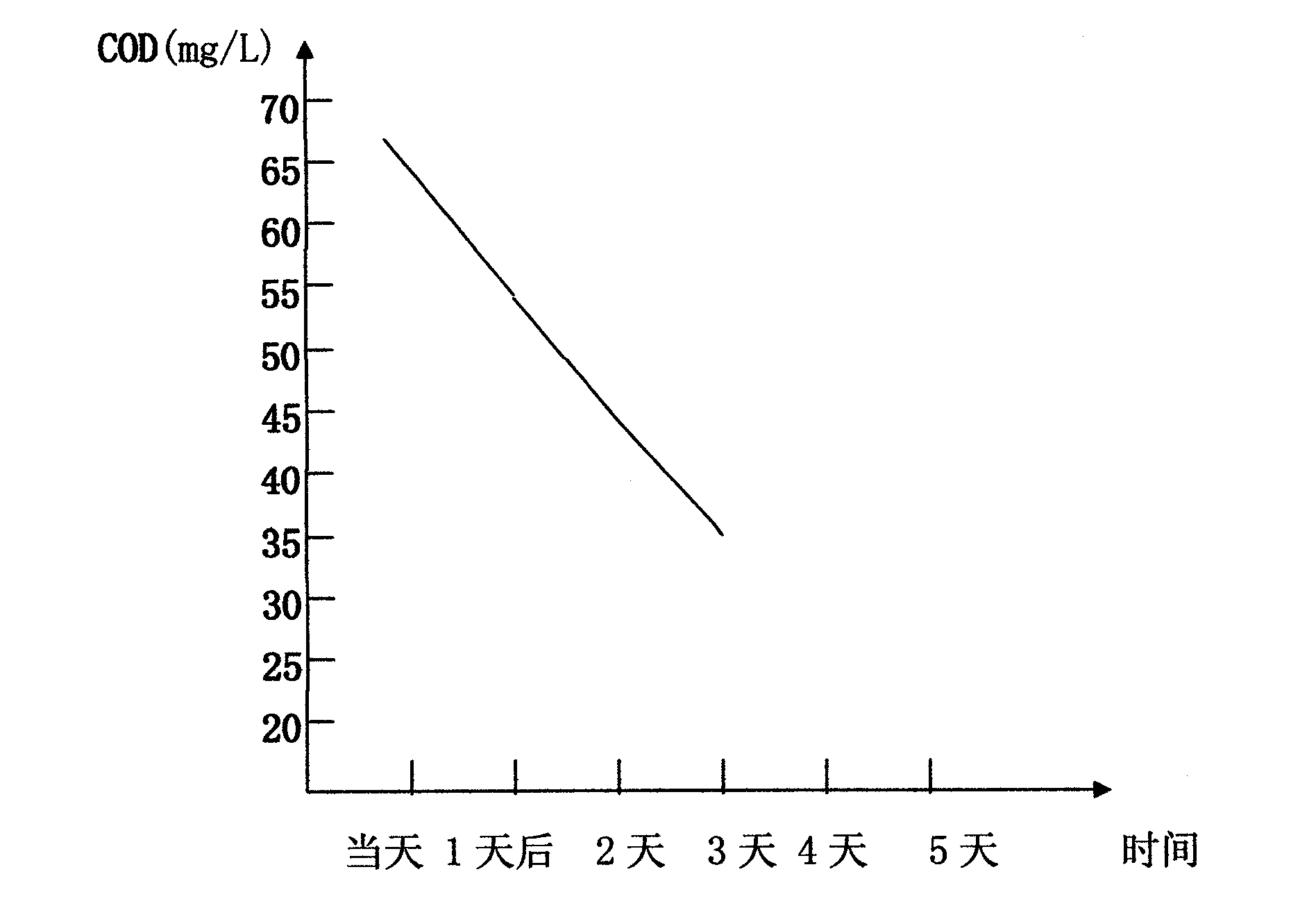

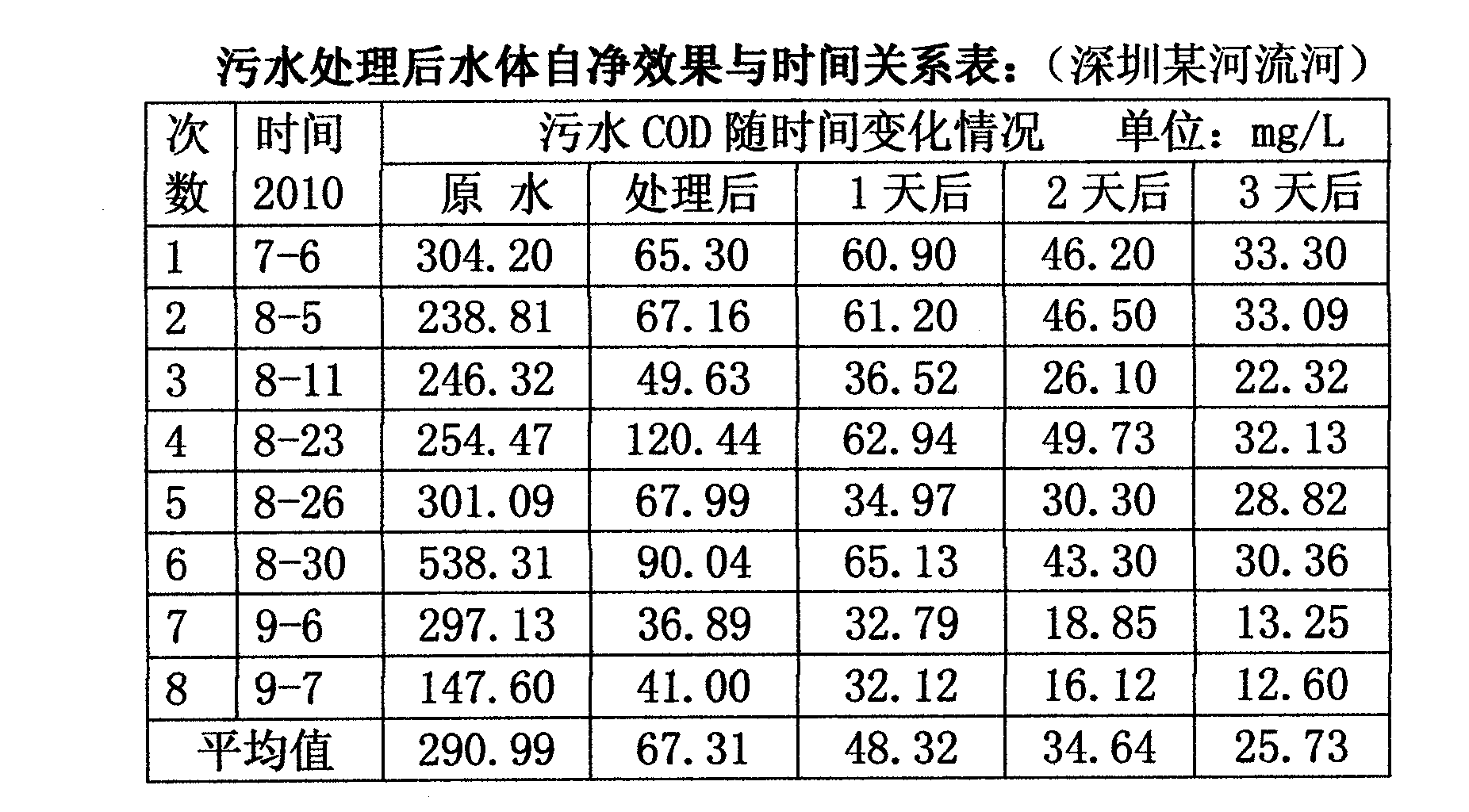

Sewage physical-chemical treatment method

InactiveCN102464420ALess investmentSimple handling and maintenanceSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentChemical treatmentGrating

The invention discloses a sewage physical-chemical treatment method, which comprises the following steps of: filtering sewage by gratings; adding an aluminum molysite dephosphorization agent and a modified china clay adsorbent on an inlet pipeline of a sewage pump sequentially, and adding a polyacrylamide organic high-molecule flocculating agent on an outlet pipeline of the sewage pump; performing solid and liquid separation in a sedimentation basin; adjusting the pH value of the sewage by using an inorganic acid or alkali solution after the sewage enters an ammonia nitrogen absorption tower and is subjected to ammonia nitrogen removal; and sterilizing the sewage by ultraviolet rays and discharging the treated sewage. The method is lower in investment of base facilities; the base facilities are easy to maintain and treat; the degree of a sewage treatment effect cannot be fluctuated greatly under the influence of factors, such as temperature, pollutants in the sewage, the sewage concentration, the pH value of the sewage and the like; the environment is protected because a bad smell is not produced during dephosphorization and ammonia nitrogen removal; and the dehydrated sludge has low water content and high heat value, and is easy to retreat.

Owner:陈学明

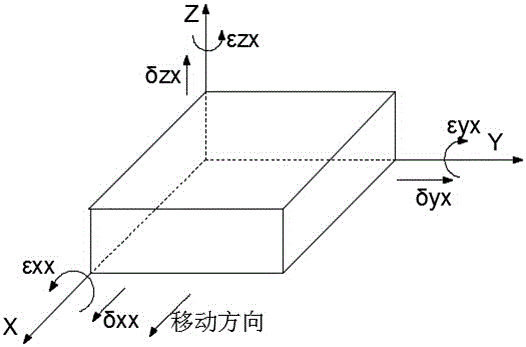

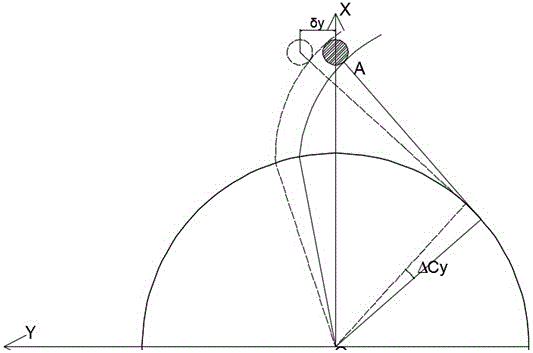

Tooth profile measuring method of numerical control gear grinding machine on-machine measuring system

ActiveCN105783845AAccurate measurementEasy to reprocessMeasurement devicesEngineeringObservational error

The invention discloses a tooth profile measuring method of a numerical control gear grinding machine on-machine measuring system. The tooth profile measuring method is characterized by comprising the following steps that firstly, a measuring error compensation model is established, wherein before gear grinding is carried out, the on-machine measuring system is adopted for measuring a standard gear corresponding to a gear to be measured, error values, at measuring points of the tooth profile of the standard gear, of the on-machine measuring system are obtained and converted into compensation values of the on-machine measuring system, and the measuring error compensation model is established; secondly, when measurement is performed on a working area of a gear workpiece, the compensation values in the measuring error compensation model are used for compensating for measuring values of the measuring points, and a measuring result of the tooth profile of the gear to be measured is obtained. The tooth profile measuring method has the advantages that compensation to measurement can be achieved according to measuring errors, the on-machine measuring precision is improved, and the qualified rate of gears can be easily increased.

Owner:CHONGQING UNIV

Method for producing composite material for coating applications

InactiveUS20060293194A1Low costInfluence on the cost of productionLiquid surface applicatorsBearing componentsThermal sprayingMetal alloy

The production of solid lubricant agglomerates by combining solid lubricant powder, an inorganic binder, other fillers if optionally desired, and a liquid to form a mixture, and driving off the liquid to form dry agglomerates which are subsequently classified by size or milled and classified by size to yield agglomerates of a desired size range. These agglomerates are then treated to stabilize the binder, thereby strengthening the binder and rendering it nondispersible in the liquid. The treated agglomerates are then blended or clad with a metal, metal alloy or a metallic composition, to produce a composition suitable for thermal spray applications.

Owner:SULZER METCO CANADA INC

Rare earth-iron-silicon-based magnetic refrigeration composite material and preparation method thereof

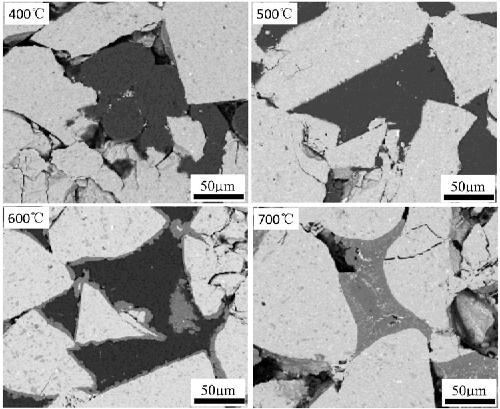

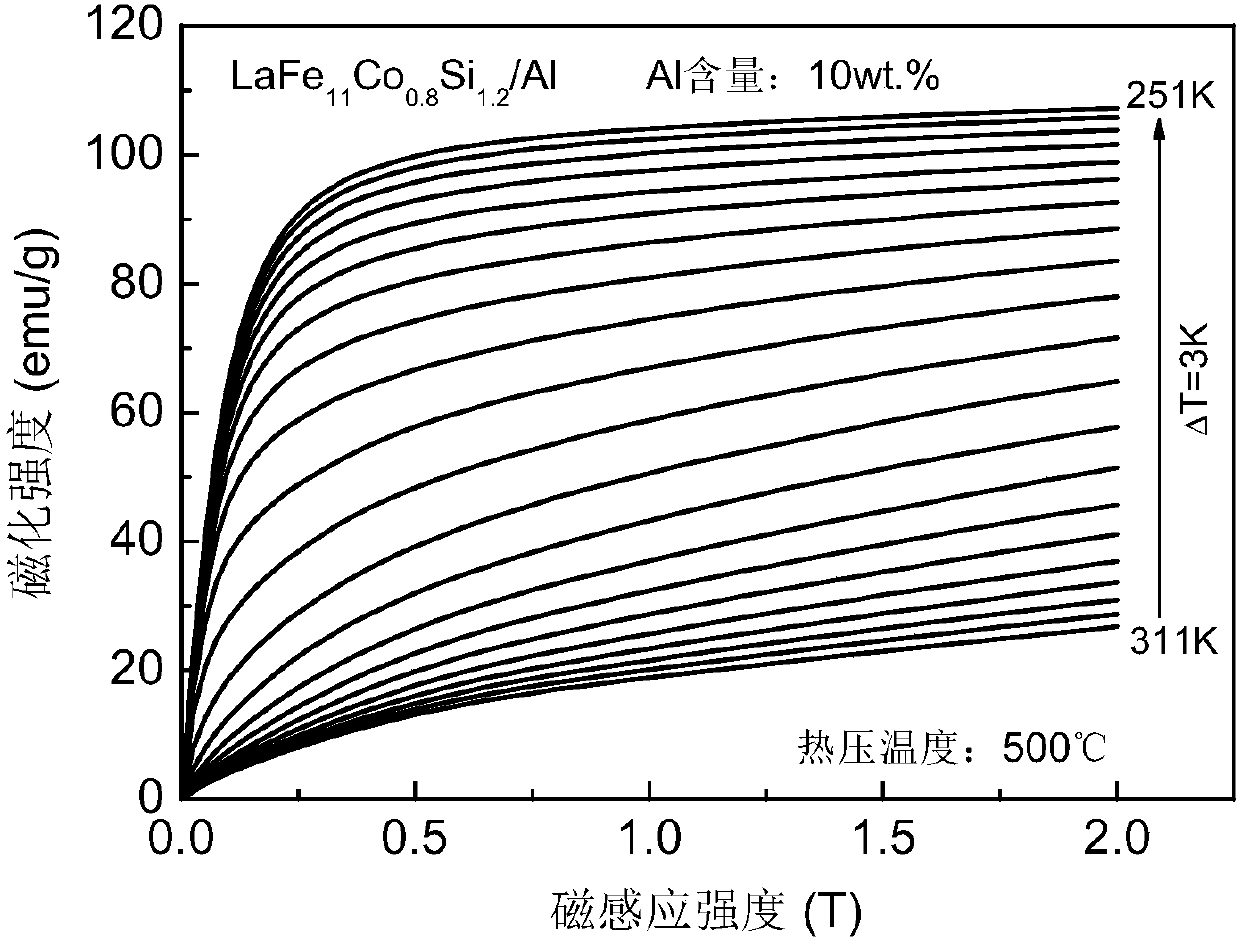

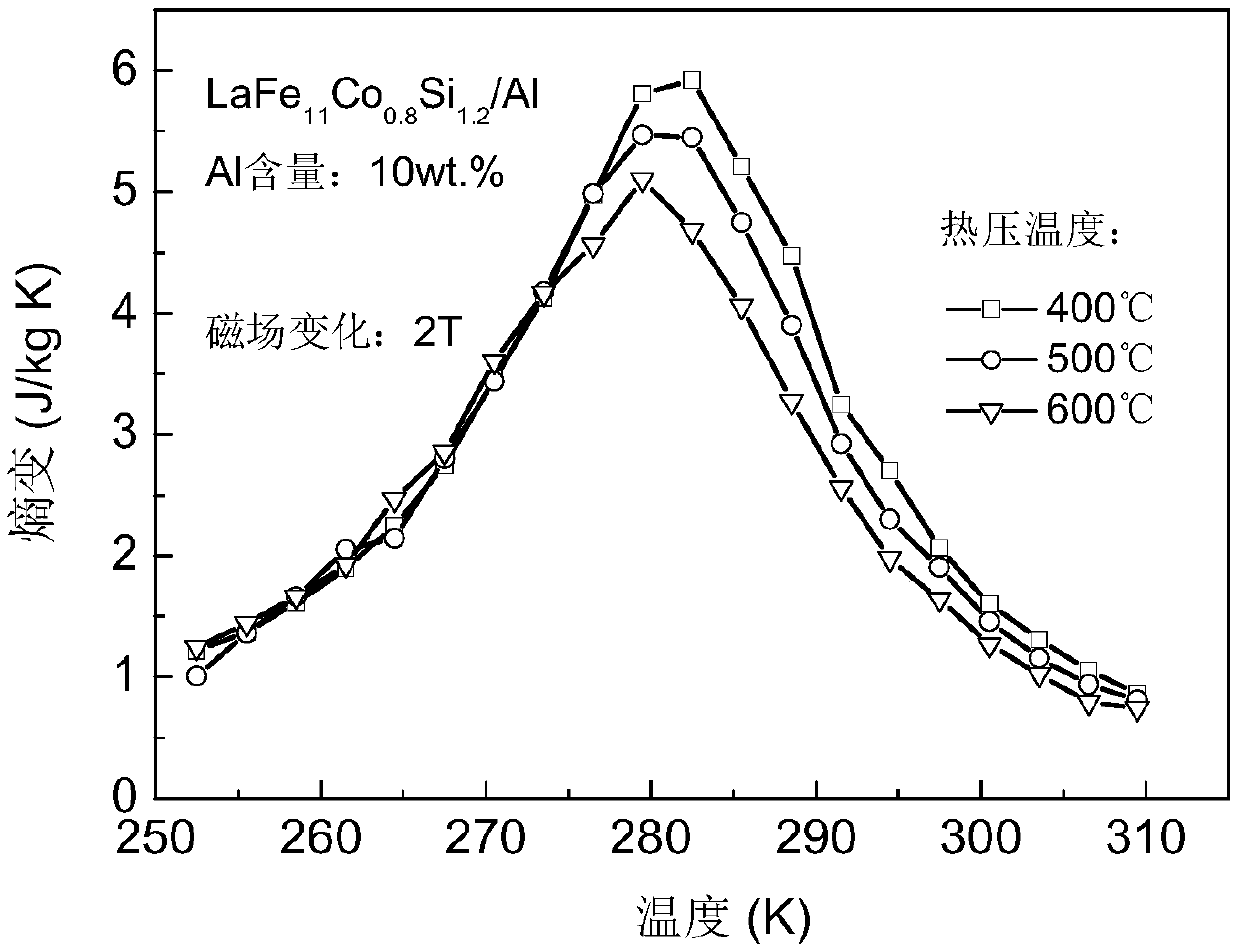

ActiveCN109524190AAbundant component raw materialsLow costInorganic material magnetismInductances/transformers/magnets manufactureRare earthAlloy

The invention provides a rare earth-iron-silicon-based magnetic refrigeration composite material and a preparation method thereof. The rare earth-iron-silicon-based magnetic refrigeration composite material comprises a functional body component and a matrix component. The functional body component comprises rare earth-iron-silicon-based alloy particles, the matrix component comprises an aluminum metal element or aluminum alloy, and the rare earth-iron-silicon-based alloy particles are bonded by the matrix component to form a bulk material or the reactant of the functional body component and the matrix component are bonded to form the bulk material. The composite material has the advantages that a high magnetocaloric effect, good thermal performance and god mechanical performance are simultaneously maintained, the machine shaping is facilitated, the composite material is not powdered in when the composite material is in hydrogenation processing or is used in a refrigerating machine, andthe shape remains intact.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

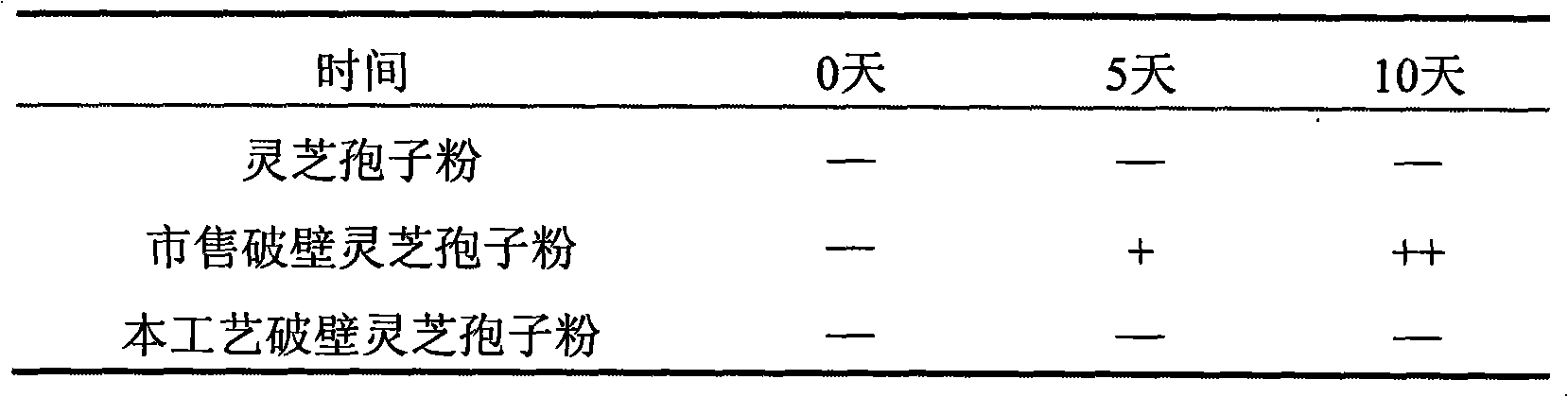

Wet-process wall breaking method of lucidum spore powder

InactiveCN101524375AImprove broken rateActive ingredients are stableNervous disorderMetabolism disorderProduction rateSpore

The invention relates to a wet-process wall breaking method of lucidum spore powder, comprising the steps of (1) soaking lucidum spore powder with ethanol and filtering; (2) washing with purified water and removing impurity; (3) adding mixing solids to mix with lucidum spore powder, and adding purified water 1-5 times of the total mass of solids into even mixed liquor, and grinding into mixed liquor and (4) drying, grinding and sieving to obtain solid spore powder products, wherein the mass ratio of the mixing solids and lucidum spore powder is 0.5-6:1;, the mixing solids are peroral cyclodextrin or mixture of peroral cyclodextrin and edible solid auxiliary materials or pharmaceutical solid auxiliary materials, and the mass ratio of the mixing solids and lucidum spore powder is 0.5-2:1. In the invention, the wall-broken rate of the lucidum spore powder is high, and stable effective ingredients in the lucidum spore powder are ensured. The invention has advantages of more convenient processing, sanitation, safety, short production period, few time consumption, high production rate, convenient operation, low investment of devices, and benefit for industrialized production.

Owner:NANJING NORMAL UNIVERSITY +1

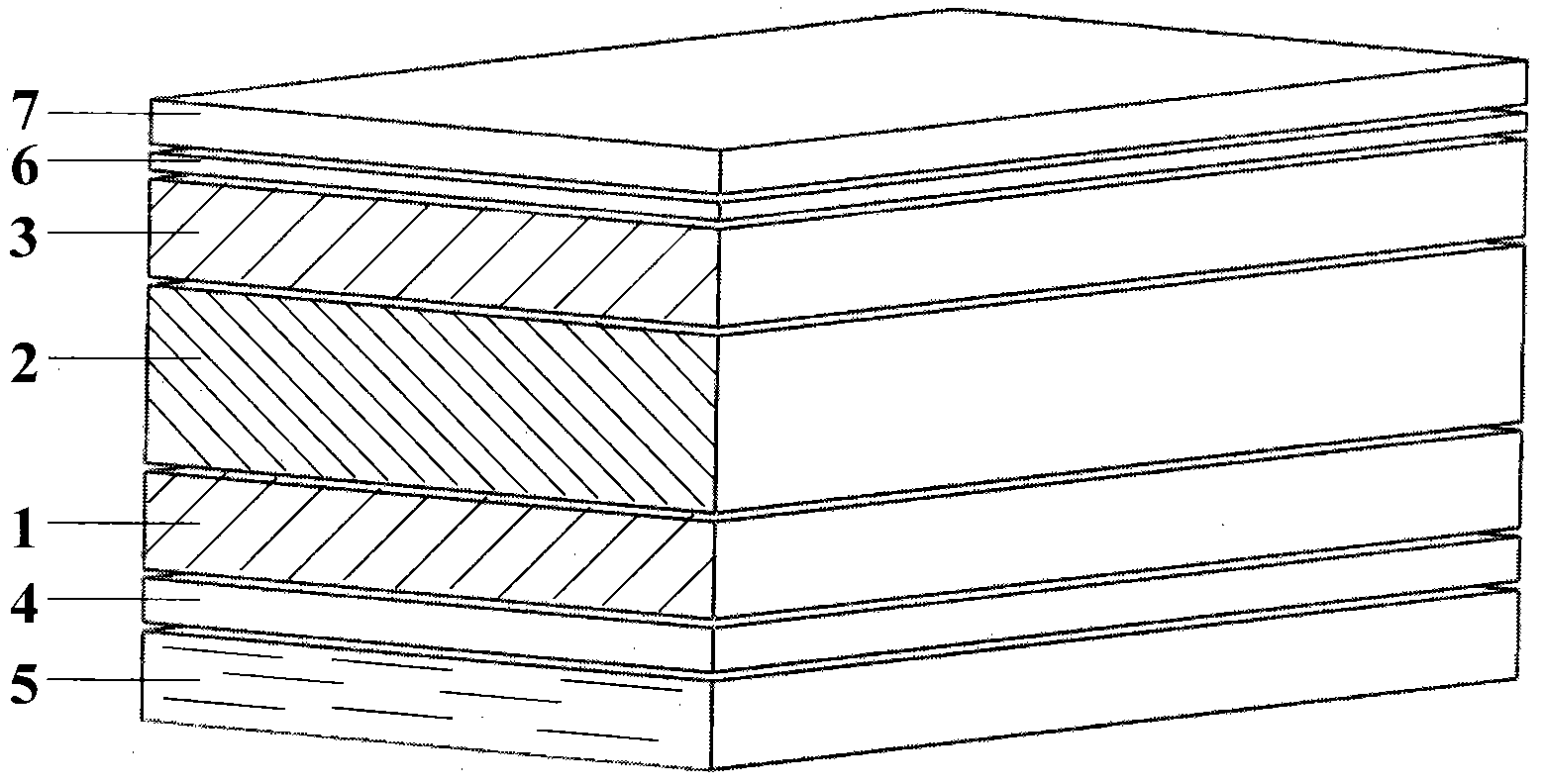

High-barrier flexible back film

InactiveCN102468352ALow costSolution to short lifeSynthetic resin layered productsPhotovoltaic energy generationTectorial membraneAdhesive

The invention provides a high-barrier flexible back film. The high-barrier flexible back film mainly comprises a substrate film, aluminum foil, an uvioresistant coating, a protection film layer, and an adhesive layer; two sides of the aluminum foil are compounded with the substrate film through an adhesive respectively; the uvioresistant coating can be directly coated or sputtered outside a compound film; the protection film layer can be directly coated or compounded on the uvioresistant coating; and the adhesive layer is coated on the inner side of the compound film, so the high-barrier flexible back film can be obtained. In the high-barrier flexible back film, the aluminum foil is used as an intermediate layer and has an extremely high barrier property, so the high barrier requirement of novel flexible thin-film solar products such as Cu(InGa)Se2 (CIGS), OPV and the like can be met, and the aluminum foil can reflect light to improve the conversion efficiency of solar energy; moreover, the high-barrier flexible back film is mainly prepared by a compound process. The obtained solar cell back film has the extremely high barrier property and mechanical strength, and can protect a solar cell well; and the compound process is mainly adopted, a production process is simple, production technologies for all the materials are mature, and all the materials are low in cost. Therefore, the back film is high in scale yield, the cost of the back film is far lower than that of similar products on market, and due to the advantage of the flexibility of the back film, the characteristics of flexibility, thinness and the like of a thin film solar cell can be exerted well.

Owner:武汉美格科技股份有限公司

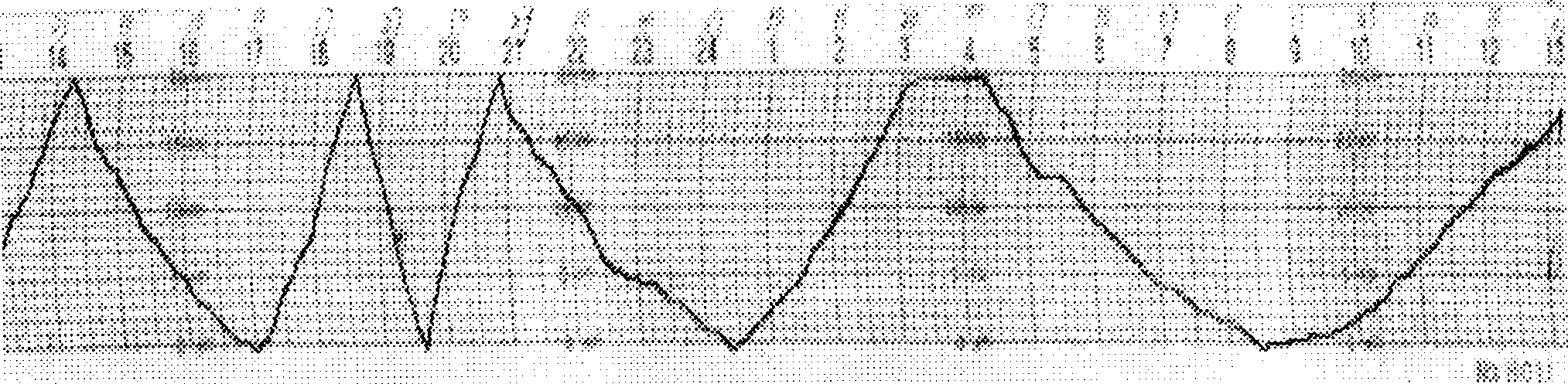

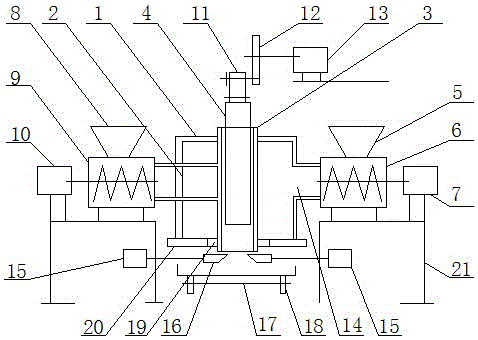

Method of abstracting data from curve function recorded on cooraination peper

InactiveCN1794268AAccurately reflectEasy to reprocessCharacter and pattern recognitionGraph readingPrimary standardSample length

This invention relates to a method for picking up data from curve functions recorded on the coordinate paper used in a roller automatic recording instrument in an image process technology including: first of all carrying out scanning process to coordinate paper recording curves to get the chart data of the curves then eliminating the profile of the background chart by the binary process based on the background of the chart data and profile of the target image, then carrying out median smooth process to the curve, then taking the hemline start position of the chart data as the primary standard and the sample length unit determined in advance as the step to fetch the vertical coordinate value Y on the curve section by section and store the length position X and the function value Y corresponding to said length value in a database.

Owner:LANZHOU UNIVERSITY +1

Pretreatment method of lignocellulose raw material

InactiveCN103849655AExtensive sources of raw materialsReduce dust contentBiofuelsWaste based fuelChemistryEnzymatic hydrolysis

The invention relates to a pretreatment method of a lignocellulose raw material. The pretreatment method comprises the following steps: (1) coarsely cutting a lignocellulose raw material, removing large impurities such as sands; (2) eliminating ash from the lignocellulose raw material obtained in the step (1); (3) subjecting the lignocellulose raw material obtained in the step (2) to a pretreatment; (4) subjecting the lignocellulose raw material obtained in the step (3) to an enzymatic hydrolysis or synchronous saccharification and fermentation. The pretreatment method has the advantages that: ash can be completely removed, thus the chemical catalyst will not be neutralized during the pretreatment process by the alkaline ash in the lignocellulose raw material, so the chemical reagent using amount in the pretreatment process is reduced, and the pretreatment effect and the cellulose conversion rate and hemicelluloses conversion rate of the lignocellulose raw material are all improved.

Owner:EAST CHINA UNIV OF SCI & TECH

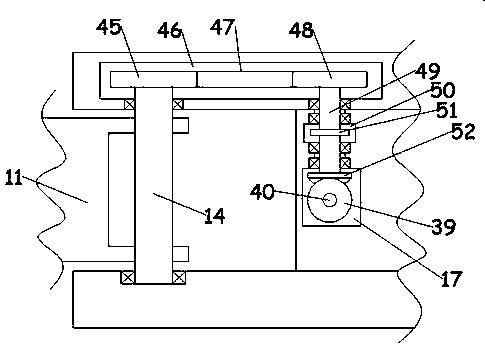

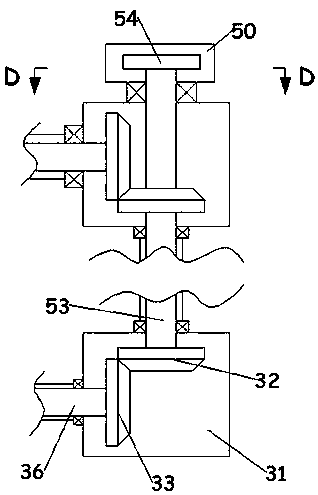

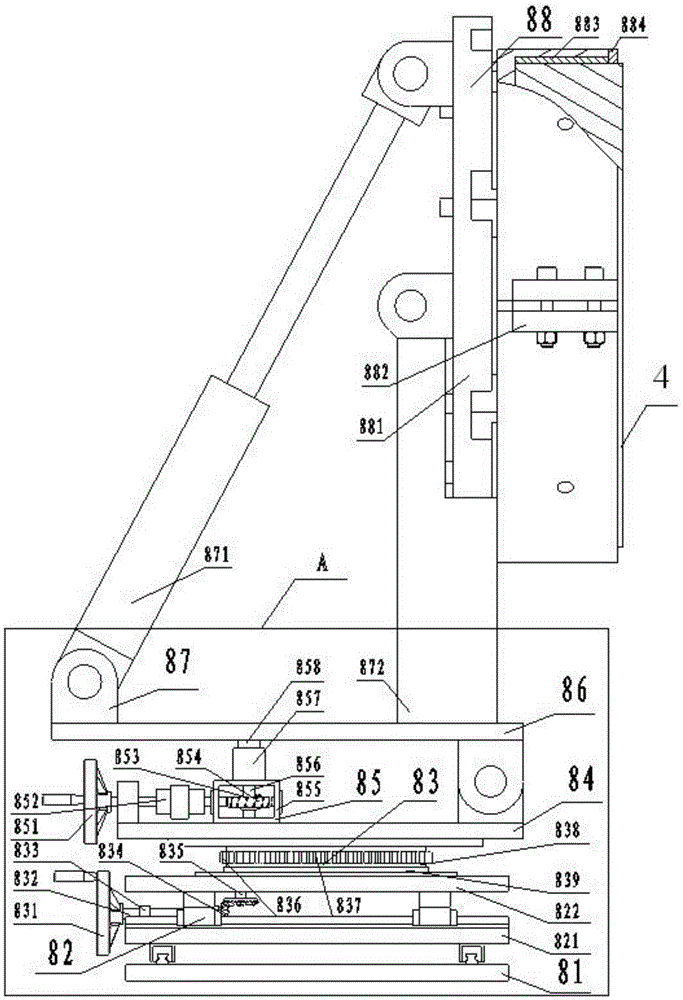

Automatic-stuffing food forming machine for clystering wrapper

The invention discloses an automatic-stuffing food forming machine for a clystering wrapper. The automatic-stuffing food forming machine comprises a rack, wherein the rack is provided with a stuffing squeezing feeding mechanism, a spiral wrapper extruding mechanism, a wrapper discharging barrel and a wrapper discharging disk; the wrapper extruding barrel is internally provided with a stuffing pushing cavity; the stuffing pushing cavity is internally provided with a piston rod; the cavity wall of the stuffing pushing cavity is provided with a material inlet which is communicated with the stuffing squeezing feeding mechanism through a stuffing connecting pipe; a wrapper extruding discharge hole is provided with a cut reforming knife; the cut driving machine drives the cut reforming knife. According to the technical scheme, a certain cavity wrapper is remained at the joint of the wrapper and the stuffing during cutting, so that the wrapper can not be stuffed easily after the product is cut off, the seal is firm in bonding and the reforming is easy, and thus the appearance of the product is beautiful, clean and tidy; the product can not easily crack to expose the stuffing during reprocessing; the product yield is improved, in the product appearance is good and the automatic-stuffing food forming machine is convenient to reprocess; the devices of the machine are low in cost and high in efficiency and are capable of saving time and labor, so that a reliable guarantee for automatic and continue production can be increased.

Owner:李建国

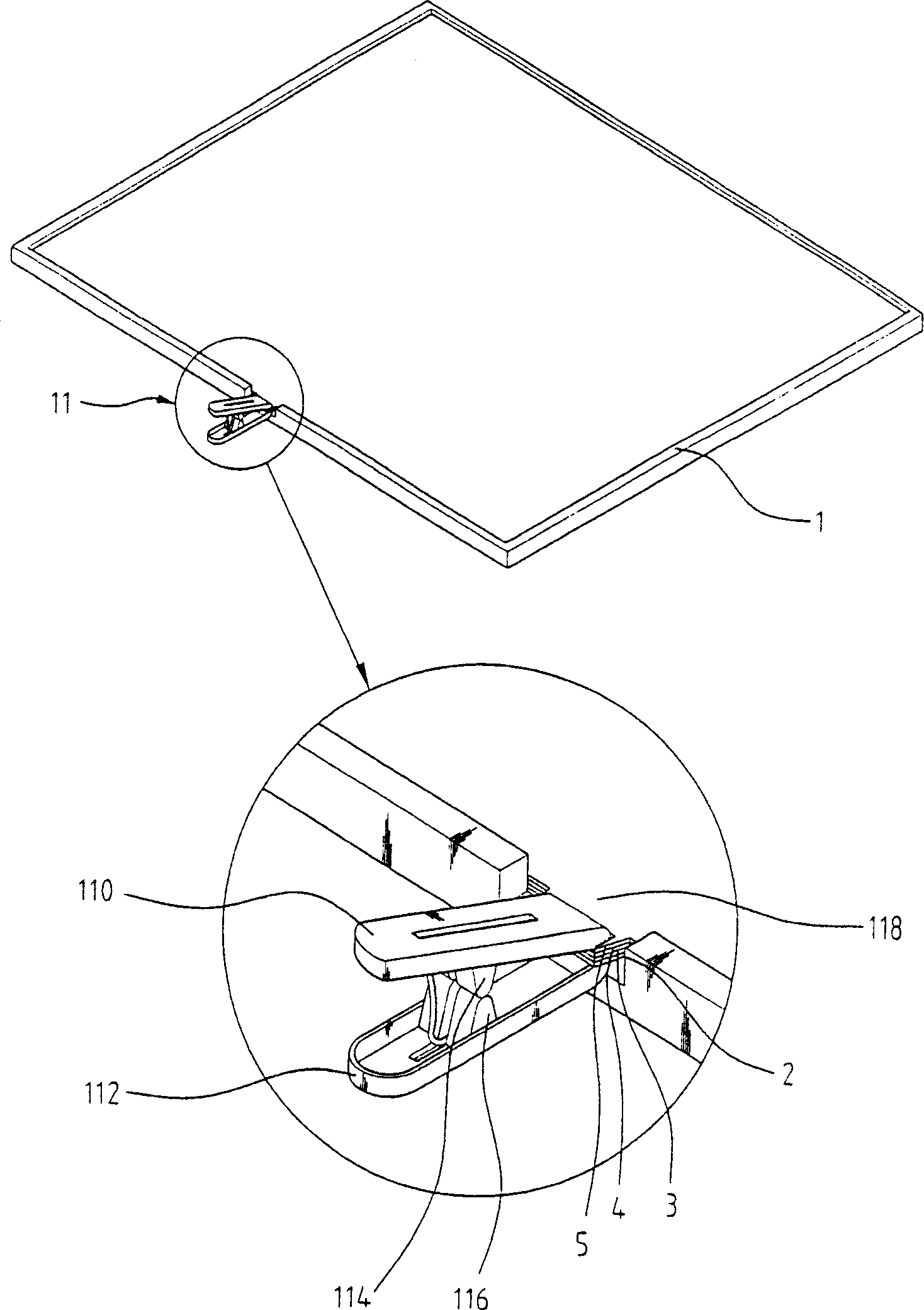

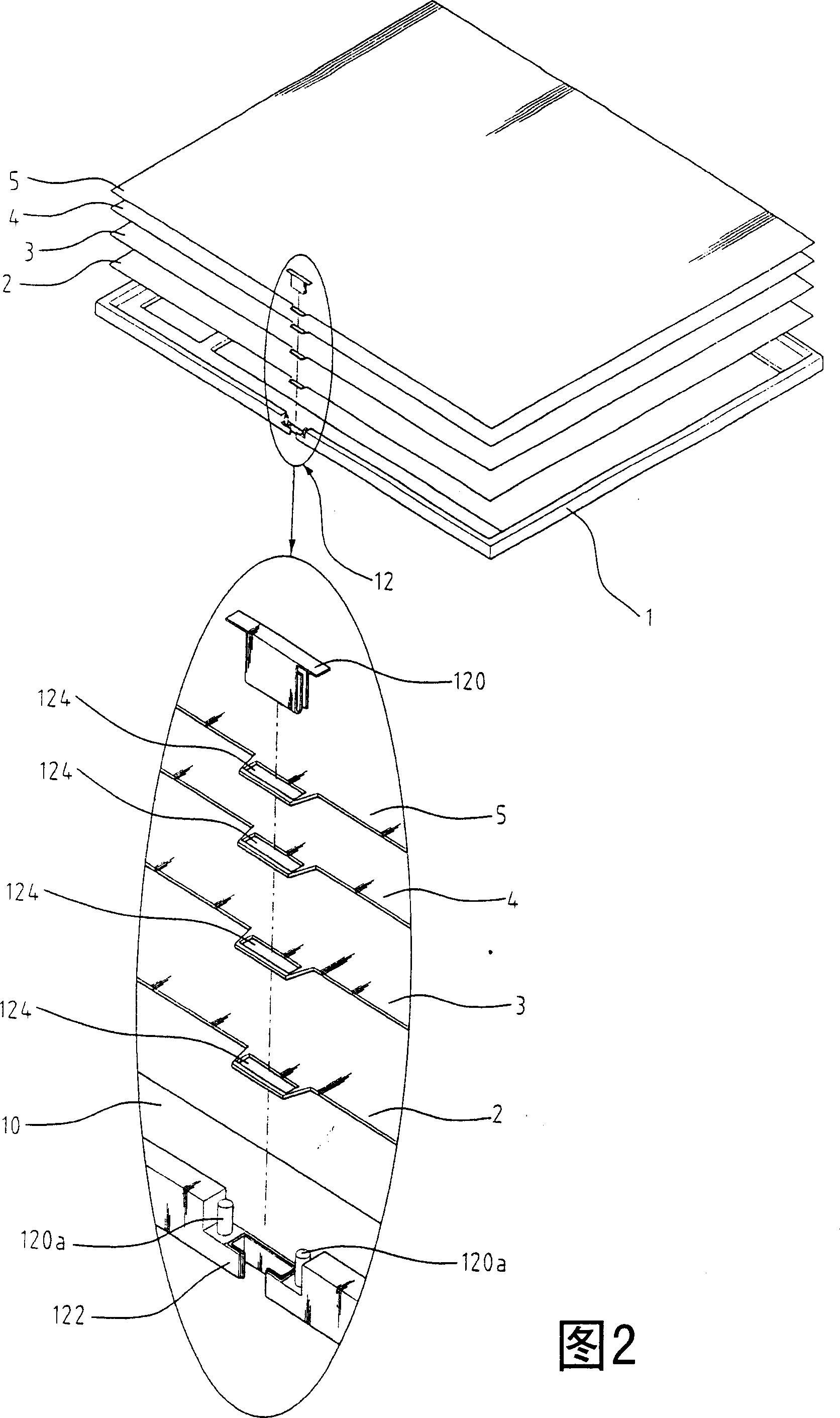

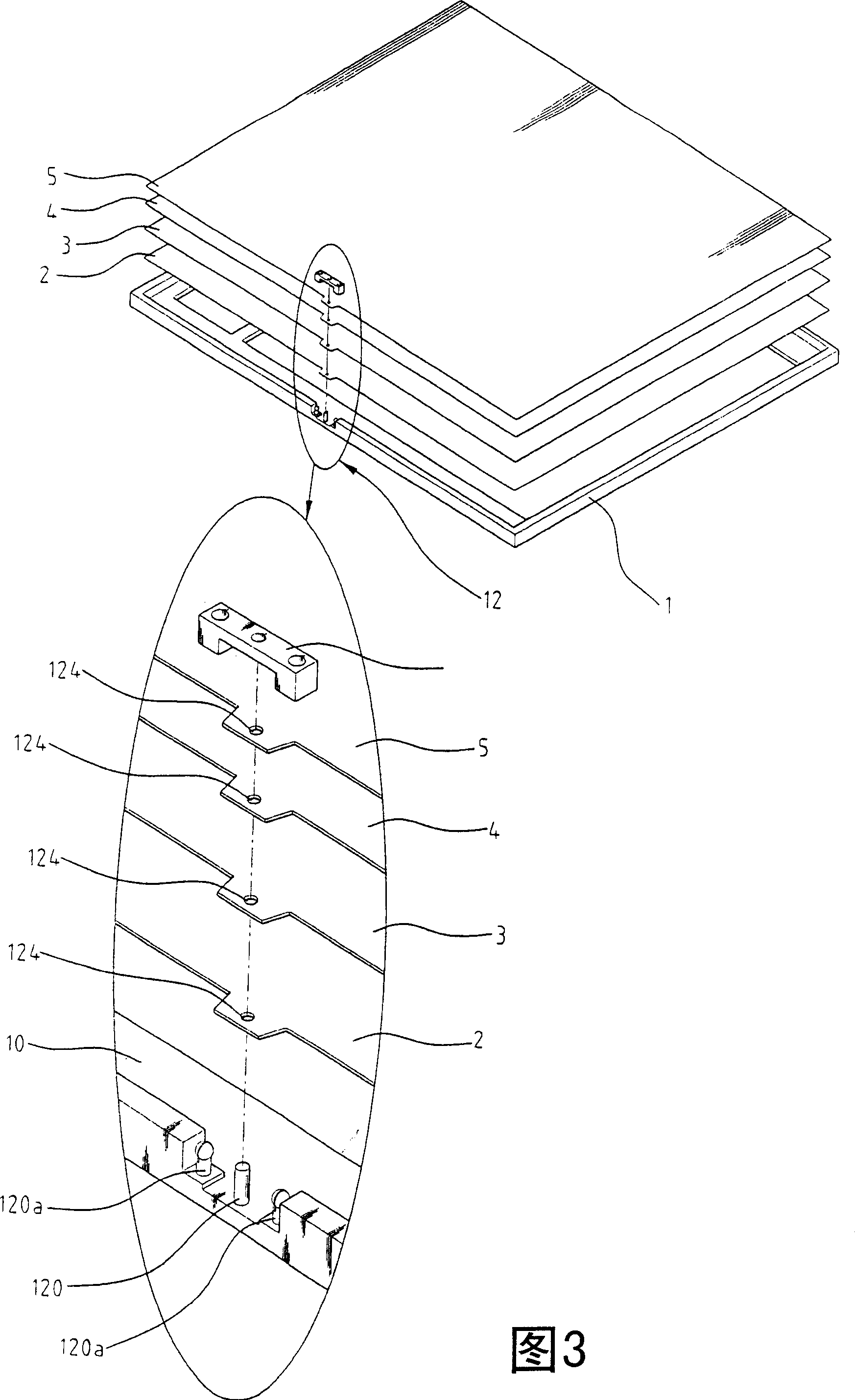

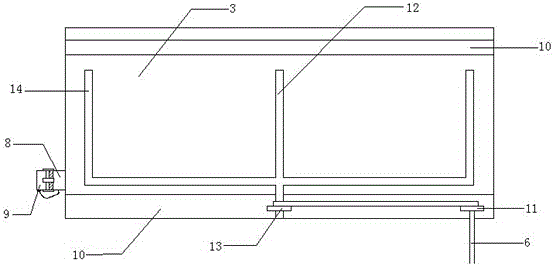

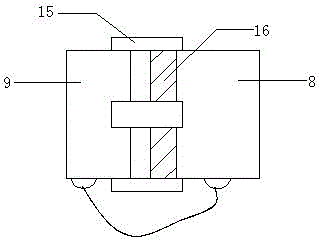

Front-light back-light film set fixed structure

InactiveCN1517758AEasy to reprocessSolve the wave problemNon-linear opticsOptical elementsLight valveLiquid crystal light valve

A fixing structure of front-light and back-light film set has a liquid crystal light valve and a lighting unit for lighting said LC light valve. It features that at least one film is fixed between baseplate and light source in non-adhering mode. In the following test process, the reliability of said film is not affected by high temp.

Owner:AU OPTRONICS CORP

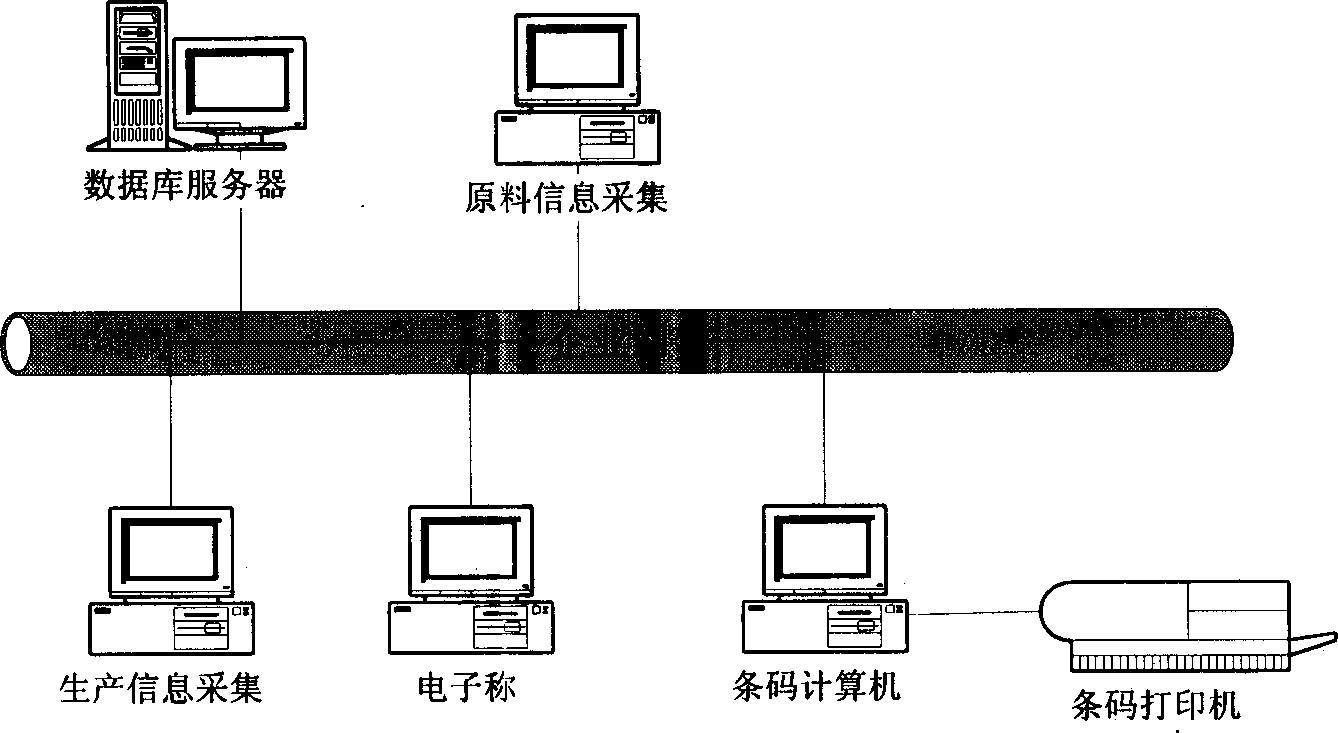

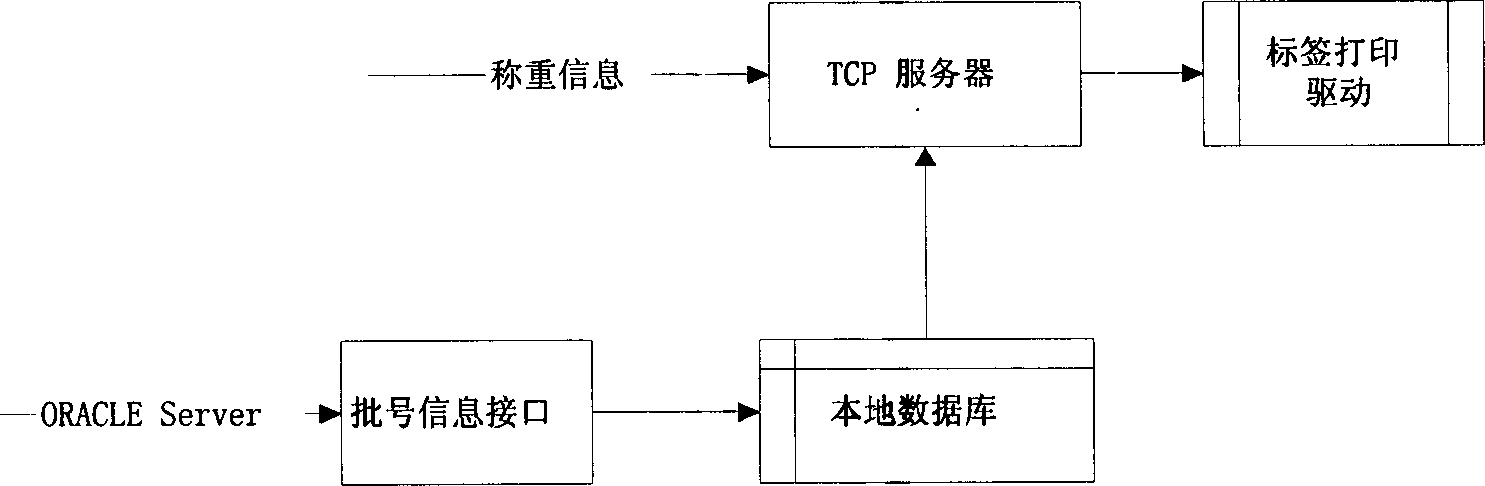

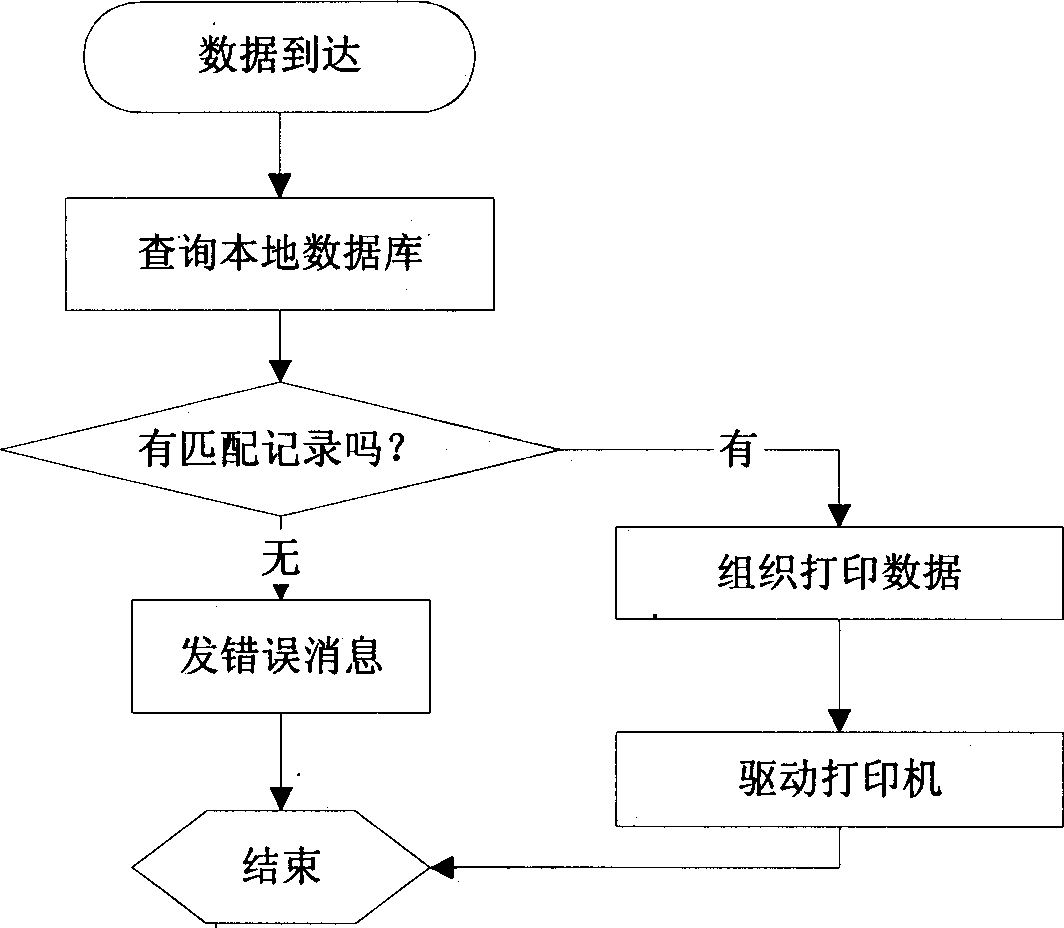

Wire label control system

InactiveCN1402148AEasy to reprocessRealize resource sharingDigital computer detailsTypewritersWire rodComputer architecture

A label control system for wire stocks is composed of a label print computer workstation, a thermal-transfer bar code printer controlled by said label print computer, and an electronic balance workstation, and is connected to the wire production management LAN in client / server mode. Its print software is a label print system consisting of TCP server, batch number information interface and local database.

Owner:ANGANG STEEL CO LTD

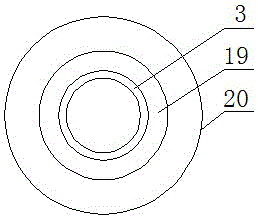

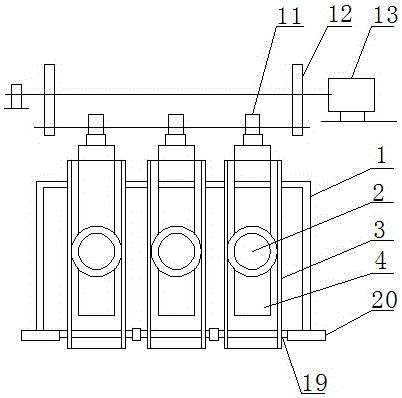

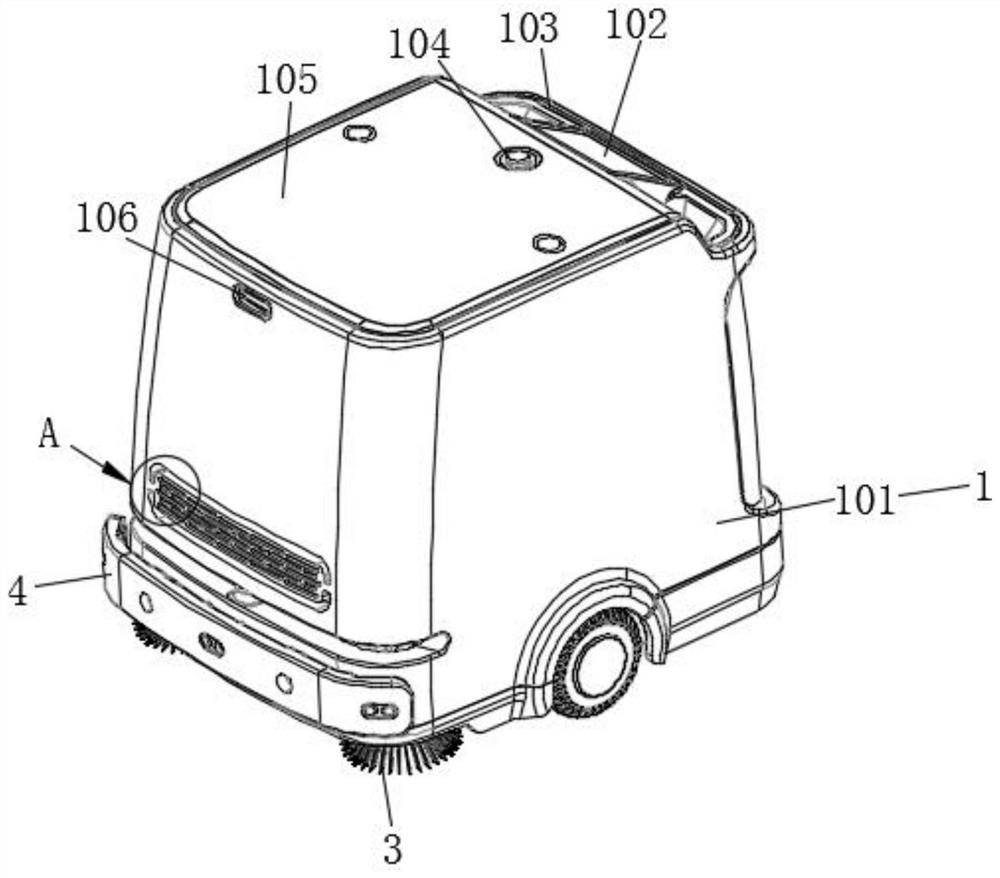

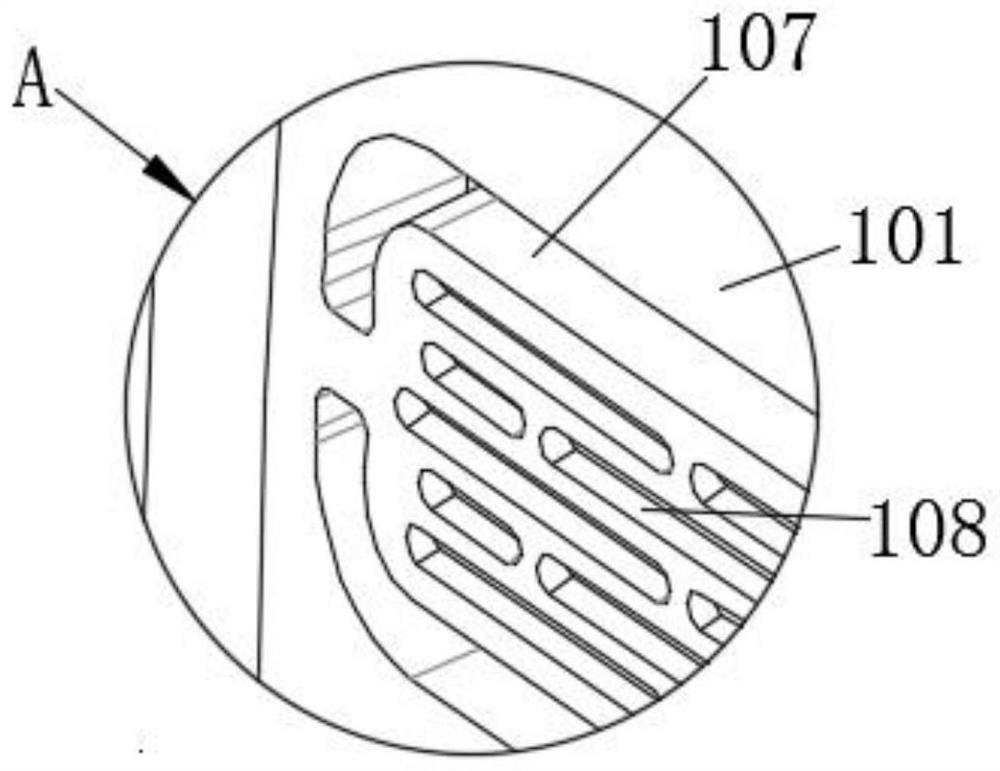

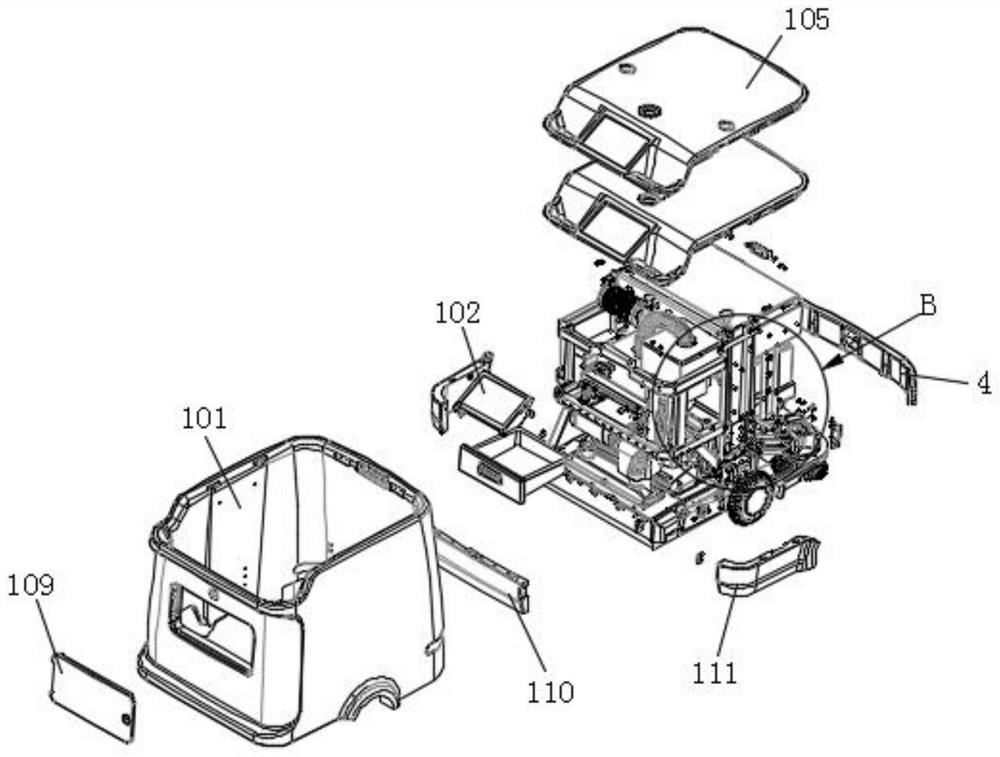

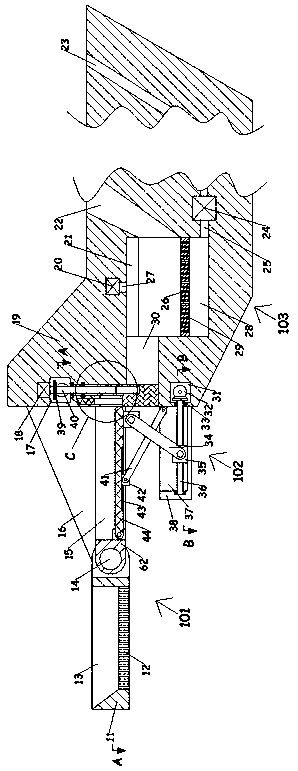

Sweeping robot

The invention discloses a sweeping robot which comprises a main brush assembly, a rack assembly and a side brush assembly. The side brush assembly and the main brush assembly are connected to the front end and the rear end of the rack assembly respectively. The main brush assembly comprises a main brush lifting assembly and a main brush roller. The main brush lifting assembly comprises a main brush steel wire rope and a main brush air cylinder. The main brush roller is connected to the output end of the main brush air cylinder through a flexible main brush steel wire rope. The side brush assembly comprises a side brush lifting structure and a side brush connecting piece. The side brush lifting structure comprises a side brush steel wire rope and a side brush cylinder; one end of the side brush connecting piece is rotationally connected to the rack assembly. The other end of the side brush connecting piece is connected to the output end of the side brush air cylinder through the flexible side brush steel wire rope. According to the invention, when the main brush assembly and the side brush assembly sweep bumpy ground, the robot is lifted, and the main brush steel wire rope becomes loose, so that damage to parts is reduced.

Owner:合肥哈工澳汀智能科技有限公司

River surface floating object recovery processing vessel

The invention discloses a river surface floating object recovery processing vessel. The river surface floating object recovery processing vessel comprises a garbage boat, supporting plates are fixedlyinstalled on the front side and the rear side of the garbage boat, a salvage mechanism capable of salvaging garbage on the river surface is arranged on the left side of the garbage boat, the salvagemechanism comprises a recovery box fixedly installed on the left side of the garbage boat, when a transmission rod rotates to drive a fourth gear to rotate, the fourth gear drives a connecting rod anda fourth bevel gear to rotate through a second chain and a third gear, and the fourth bevel gear drives a threaded rod to rotate through a third bevel gear. Floating objects on the river surface arecollected by the salvage mechanism, then the floating objects in a collecting chamber is poured in a recovery chamber through the rotation of a collecting box, the floating objects are conveyed into acompressor mechanism through a conveying mechanism, manual handling is not needed in the whole process, and the floating objects can be compressed by the compressor mechanism, the water in the floating objects is extruded, and then the water in a compressor chamber is discharged through a water pump.

Owner:泰兴市虹桥仓储有限公司

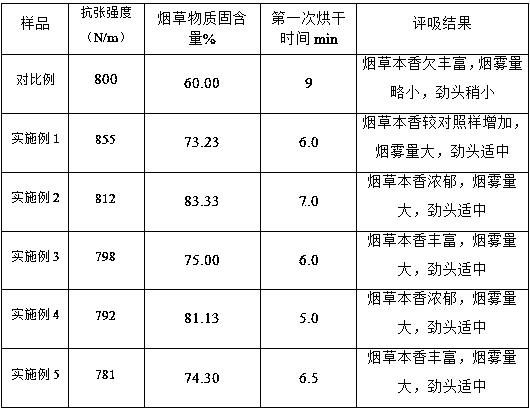

Production method of reconstituted tobacco special for heating cigarettes

The invention provides a production method of reconstituted tobacco special for heating cigarettes, and relates to the technical field of reconstituted cigarettes. The method comprises the following steps of (1) crushing, dividing the tobacco raw materials into two parts, including first tobacco powder and second tobacco powder; (2) grinding, grinding fibers with a grinding machine to prepare fiber slurry; (3) slurrying, uniformly mixing the first tobacco powder, the fiber slurry, water, an adhesive and a fuming agent to prepare a concentrated slurry; (4) coating, uniformly coating the concentrated slurry on a circulating metal belt to form a coating layer; (5) spraying, spraying the second tobacco powder on the coating layer; and (6) carrying out drying for the first time, roller pressing, peeling and drying for the second time to obtain the reconstituted tobacco for the heating cigarettes. The tobacco powder can be additionally added on the premise of ensuring the tensile strength ofthe reconstituted tobacco, so that on one hand, moisture in the concentrated slurry can be effectively absorbed, the drying time is shortened, and the fragrance loss rate is reduced; and on the otherhand, the content of tobacco substances in the reconstituted tobacco can be effectively increased, and the quality of the reconstituted tobacco is improved.

Owner:CHINA TOBACCO JIANGSU INDAL

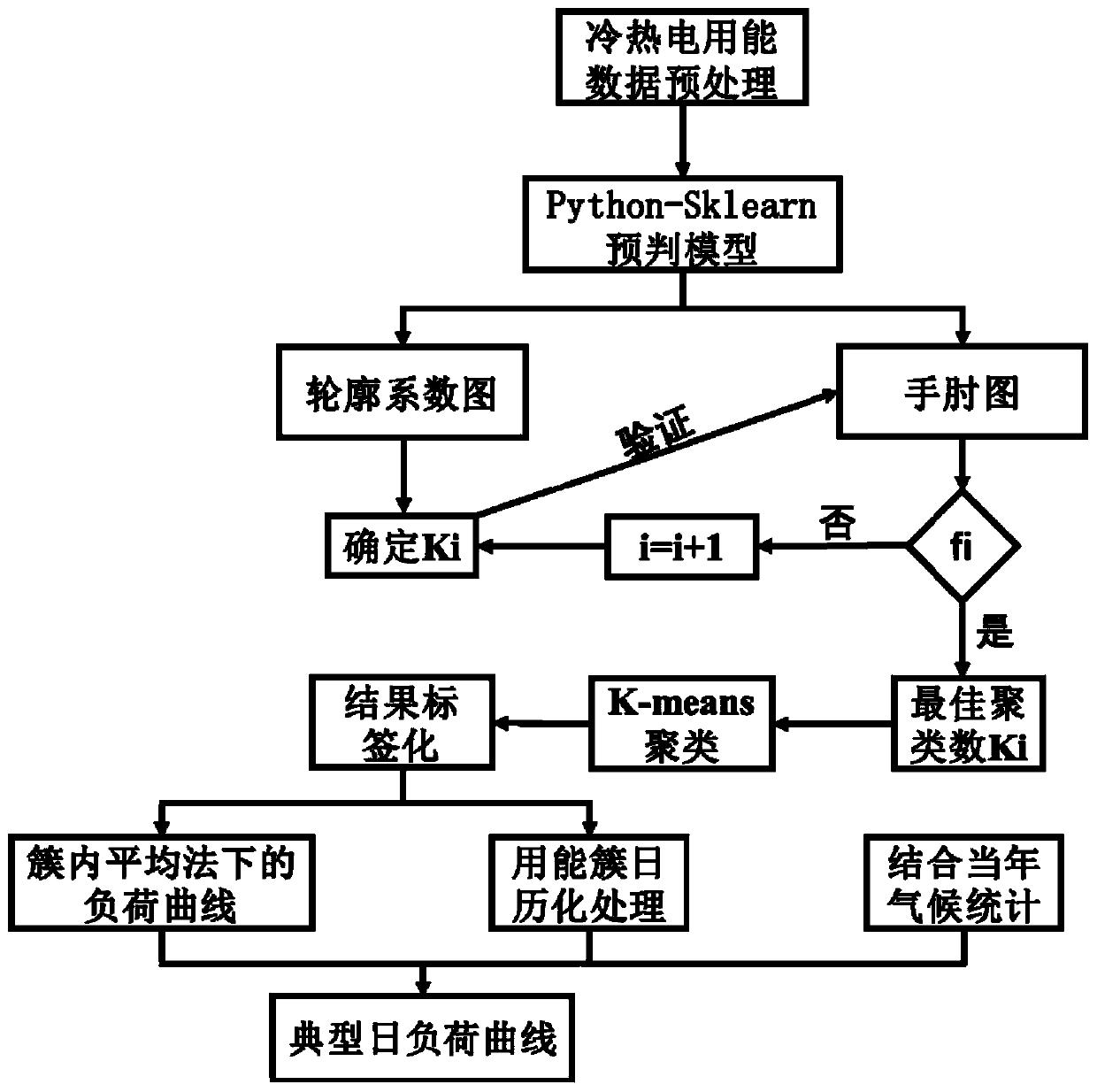

Method for determining typical daily load curve by using comprehensive energy system energy consumption big data

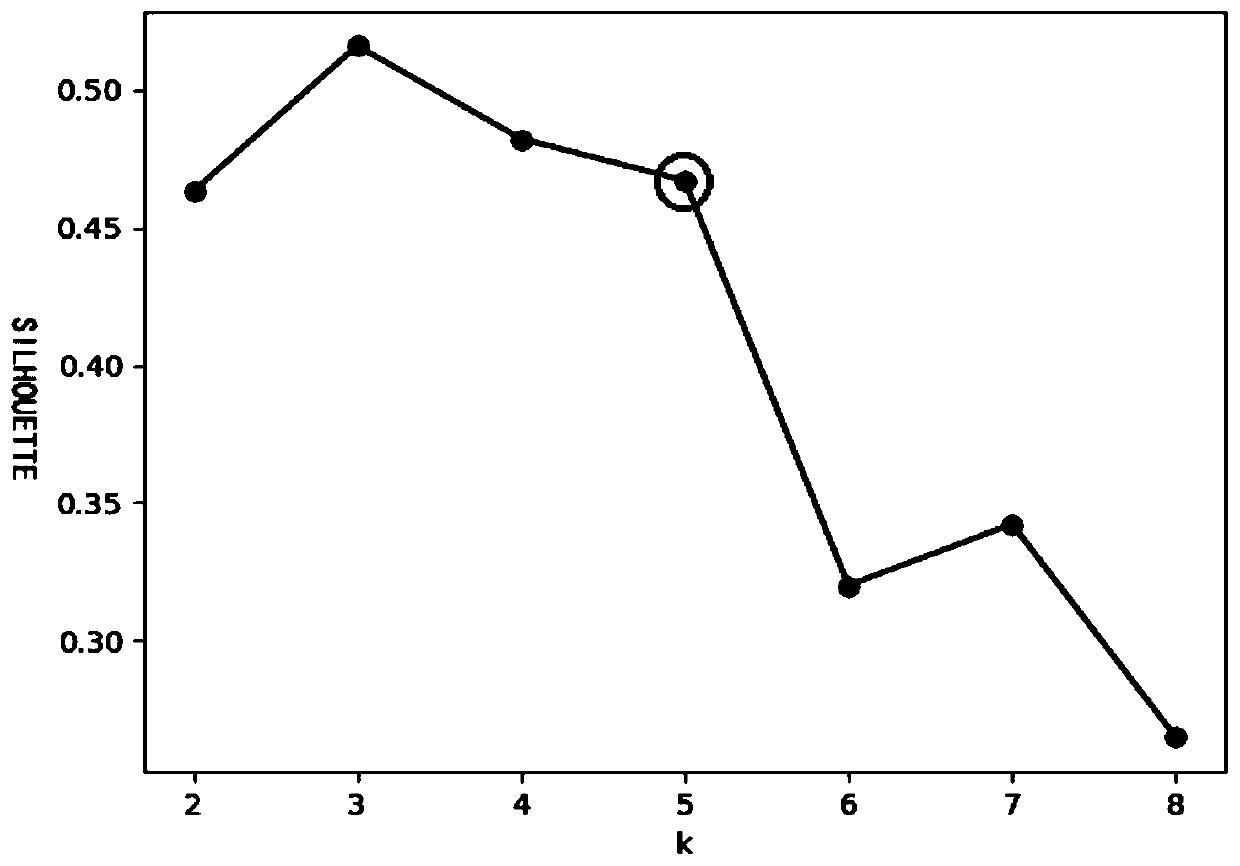

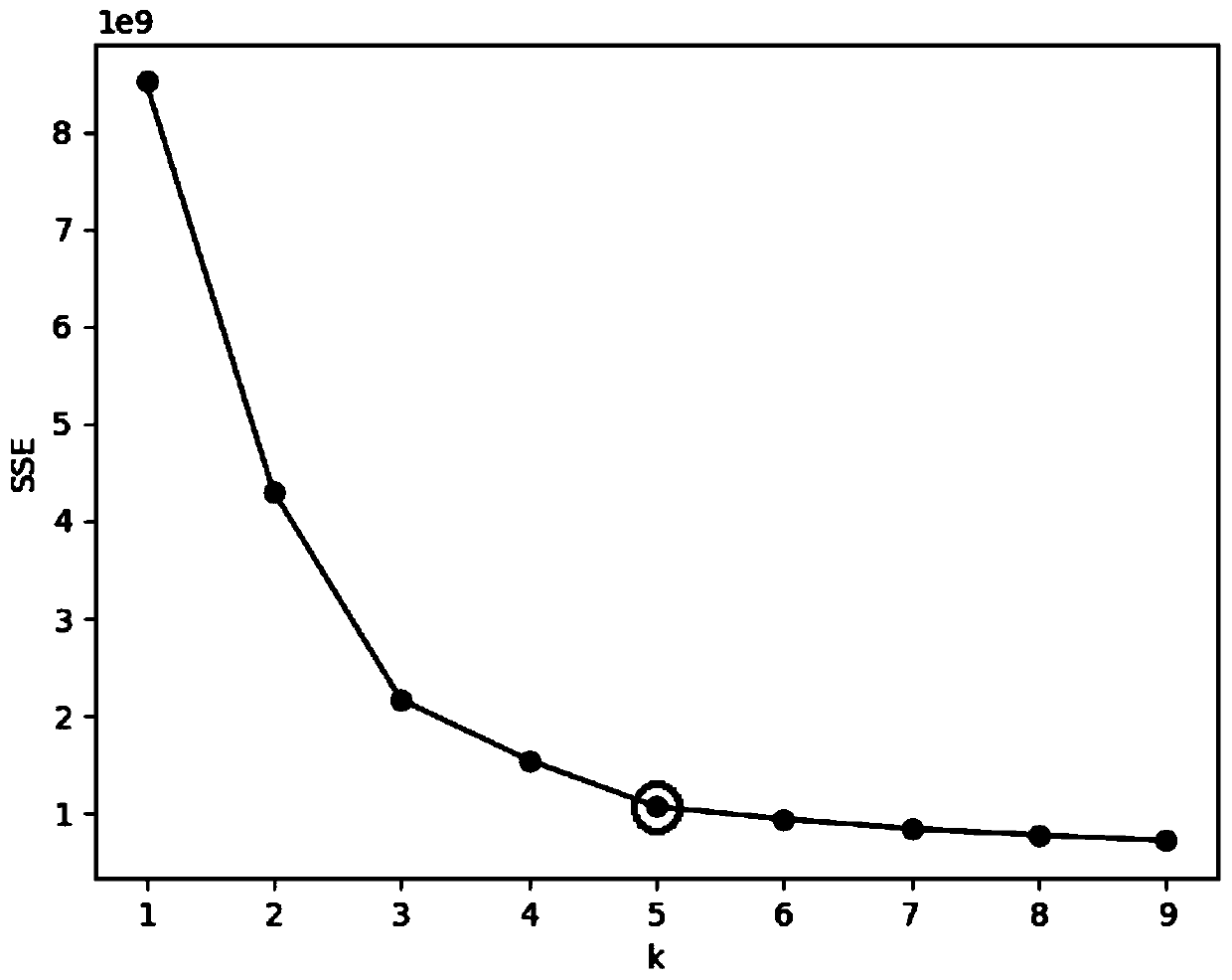

PendingCN110298567AEasy to reprocessGuaranteed accuracyCharacter and pattern recognitionResourcesData averagingResistance Factors

The invention relates to a method for determining a typical daily load curve by using comprehensive energy system energy consumption big data. According to the method, the original energy consumptionhistorical data is subjected to standardized preprocessing, so that the influence caused by large order-of-magnitude difference of data participating in clustering analysis is eliminated, abnormal data generated by human and other non-resistance factors are eliminated, and the accuracy and reasonability of a result are ensured. The optimal clustering number is determined by adopting a double-indexmutual verification method of a contour coefficient method SILHOUETTE index and an elbow method SSE index, so that the phenomenon of non-optimal result caused by self-calculation characteristics of asingle index is avoided. Compared with a typical daily load curve selected by a traditional peak load-apportionment proportional method, the method for solving the typical daily load by using the data averaging processing in the classification cluster has the advantages that the classification characteristics of the obtained energy consumption data are closer to the actual energy consumption demand characteristics, and the load prediction is more representative.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

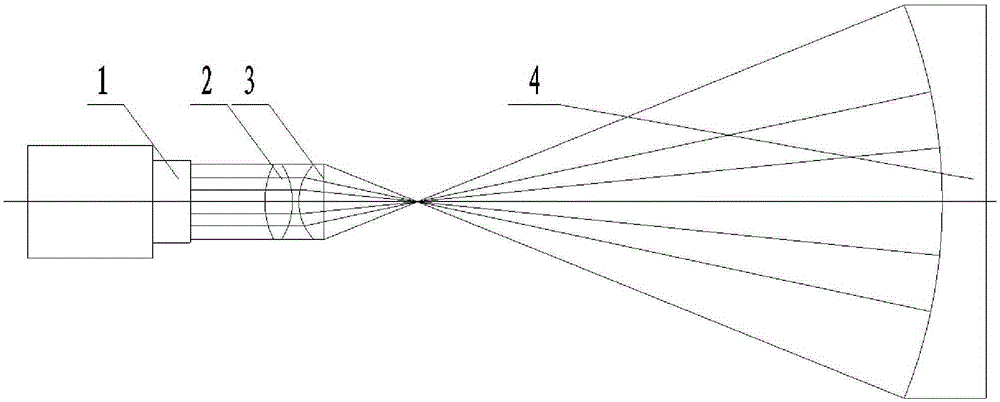

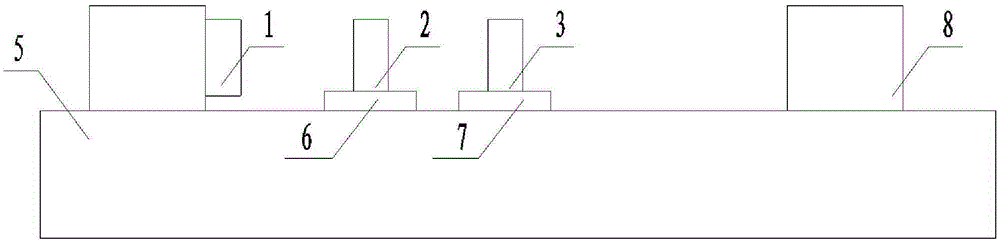

Device for interference detection device of surface precision of large-diameter concave aspheric lens

The invention relates to a device for the interference detection device of surface precision of a large-diameter concave aspheric lens, and belongs to a device for detecting surface quality of an aspheric lens. A laser interferometer, a first compensation lens adjustment support, a second compensation lens adjustment support and an aspheric lens adjustment device are placed on a vibration isolation platform. A first compensation lens is fixedly connected with the first compensation lens adjustment support, and a second compensation lens is fixedly connected with the second compensation lens adjustment support. The device is advantageous in that the device is novel in structure; the precision of linear movement is at the order of submillimeter; the precision of rotational motion is at the order of one second, thereby reducing the cost; the device can detect light short circuit under the condition that no jointing method is employed; the device is small in residual aberration; the device can achieve the high-precision detection of the surface of an optical element of a large-diameter rotational symmetric concave aspheric lens; the device is convenient to install and disassemble; and the device saves the manpower cost during detection.

Owner:CHANGCHUN EQUIP TECH RES INST

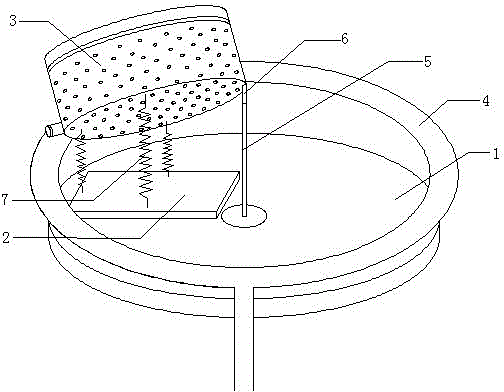

Feeding machine

A feeding machine comprises a supporting rotary plate, a vibration block, a feeding plate and a feeding trough, wherein the supporting rotary plate is in a shape of a circular ring, the bottom of the supporting rotary plate is fixedly provided with a rotary motor, and a support bar is fixed on center of the upper surface of the supporting rotary plate; the vibration block is fixed on the upper surface of the supporting rotary plate; a vibration motor is arranged in the vibration block; screening holes are formed in the bottom and side face of the feeding plate; a feeding plate support bar and springs are arranged on the bottom of the feeding plate; the furthest end, away from the feeding plate support bar, of the feeding plate is provided with a feeding plate discharging hole, and is connected with a discharging cover; the feeding trough is in a shape of an oblique circular ring, and the connection line of the center of the feeding trough and the center of the supporting rotary plate is perpendicular to the upper surface of the supporting rotary plate; the feeding plate discharging hole is positioned above the feeding trough. The raw material selection and feeding functions are integrated, so the quality of feeding is significantly improved; raw materials are screened in a way of centrifugal rotation and vibration, so screening is more efficient and fast; large size raw materials are screened, isolated and stored effectively, and the cost of production is reduced.

Owner:JIANGSU BOILN PLASTICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com