Wire label control system

A control system and label technology, applied in special data processing applications, printing, instruments, etc., can solve problems such as poor corrosion resistance and wear resistance, reduced label information accuracy, and inability to print successfully at one time, and achieve corrosion resistance. Strong ability, timely and accurate information transmission, and the effect of resource sharing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

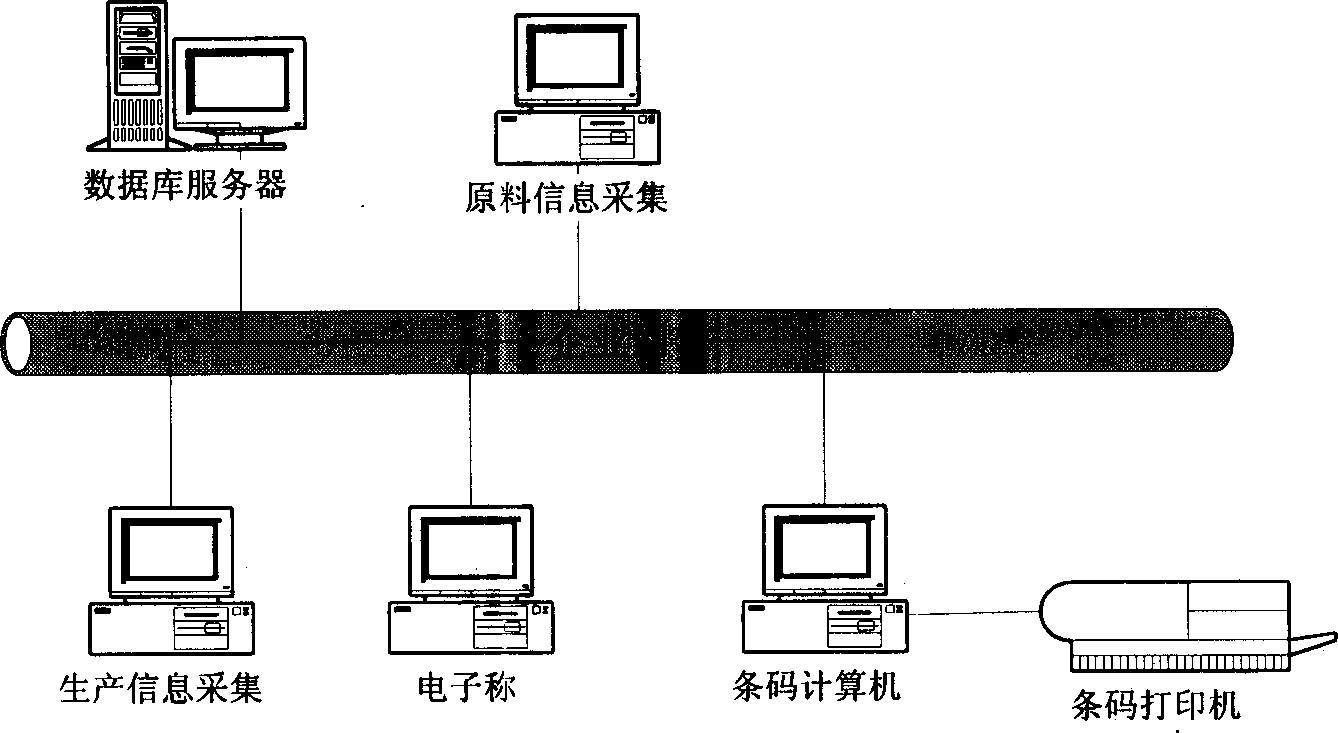

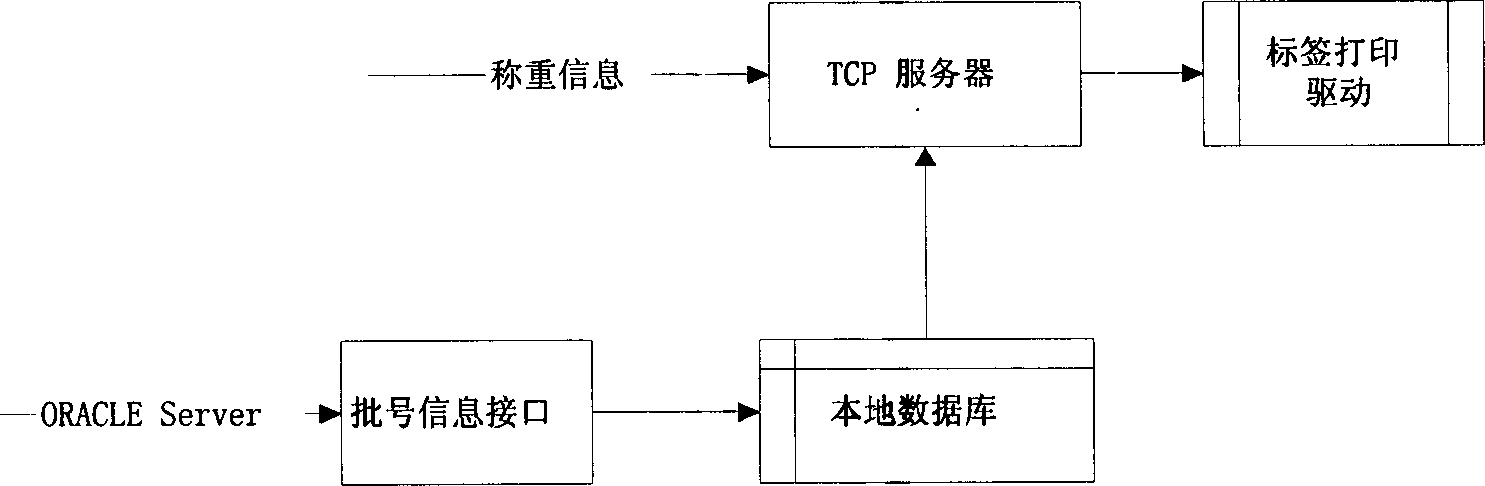

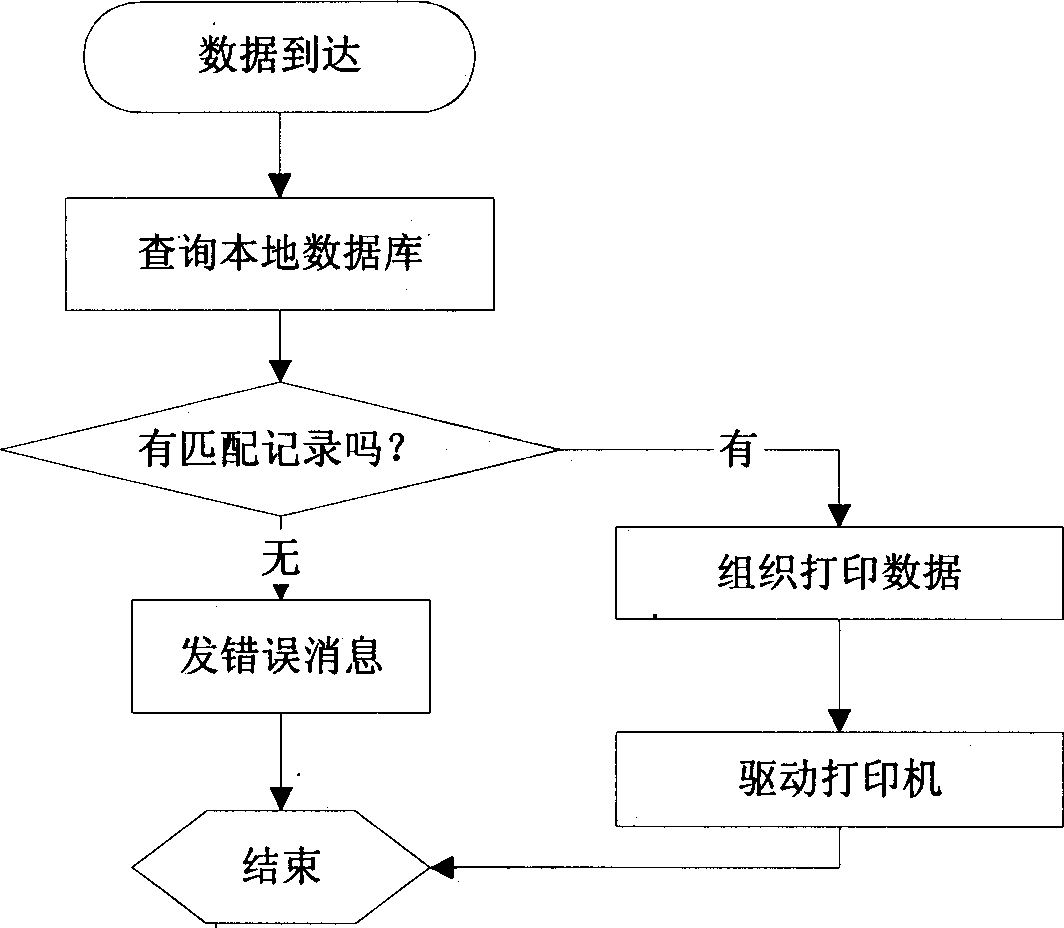

[0012] Such as figure 1 , 2 As shown, the wire label control system of the present invention is mainly composed of a label printing computer workstation (i.e. an industrial PC), a thermal transfer barcode printer controlled by the label printing computer and an electronic weighing computer workstation, and the Connected to the wire rod production and management LAN in Client / Server mode. In the bar code printer, the color crepe inkjet cloth is used as the medium of the information carrier of the wire label. The printing control software adopts a label printing system composed of a TCP server, a batch number information interface and a local database module. Such as figure 1 As shown, the batch number information in the present invention mainly includes: batch number, furnace tank number, steel number, specification, standard and chemical composition, etc....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com