Production method of reconstituted tobacco special for heating cigarettes

A technology for reconstituted tobacco leaves and production methods, which is applied in the field of reconstituted tobacco leaves for heating cigarettes, and can solve problems such as difficult processing, high water content, and reduced retention rate of tobacco flavor components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

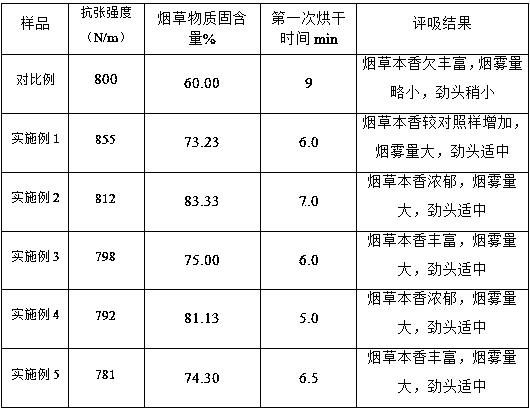

Examples

Embodiment 1

[0017] The invention is a method for producing reconstituted tobacco leaves specially for heating cigarettes, comprising the following steps:

[0018] (1) Pulverization: the tobacco raw material is pulverized into first tobacco powder and second tobacco powder. The first tobacco powder passes through a 80-mesh sieve, and the second tobacco powder passes through a 250-mesh sieve. The tobacco raw materials are tobacco leaves and tobacco stems mix;

[0019] (2) Refining: use a refiner to grind the fiber into fiber pulp, and the fiber is mixed with wood pulp and straw pulp;

[0020] (3) Pulping: mixing the first tobacco powder, the fiber pulp described in step (2), water, binder, and fuming agent to make a thick pulp, and the first tobacco 60 parts of powder, 10 parts of fiber, 5 parts of binder, 25 parts of fuming agent, the moisture content of thick stock is 75%, the binder is carboxymethyl cellulose, and the fuming agent is glycerin;

[0021] (4) Coating: uniformly coat the t...

Embodiment 2

[0028] The invention is a method for producing reconstituted tobacco leaves specially for heating cigarettes, comprising the following steps:

[0029] (1) Pulverization: the tobacco raw material is pulverized into the first tobacco powder and the second tobacco powder, the first tobacco powder is passed through a 200-mesh sieve, the second tobacco powder is passed through a 200-mesh sieve, and the tobacco raw material is a mixture of tobacco leaves and expanded shredded tobacco ;

[0030] (2) Refining: Grinding the fibers into fiber pulp with a refiner. Fiber can be hemp pulp;

[0031] (3) Pulping: mixing the first tobacco powder, the fiber pulp described in step (2), water, binder, and fuming agent to make a thick pulp, and the first tobacco Powder is 80 parts, fiber is 2 parts, binder is 2 parts, fuming agent is 16 parts, the moisture content of thick stock is 80%, binder is guar gum, fuming agent is glycerin, propylene glycol, ethyl alcohol One or more of diols;

[0032...

Embodiment 3

[0039] The invention is a method for producing reconstituted tobacco leaves specially for heating cigarettes, comprising the following steps:

[0040] (1) Pulverization: the tobacco raw material is pulverized into first tobacco powder and second tobacco powder. The first tobacco powder passes through a 150-mesh sieve, and the second tobacco powder passes through a 100-mesh sieve. The tobacco raw materials are tobacco leaves and expanded stems silk mix;

[0041] (2) Refining: use a refiner to grind the fibers into fiber pulp. The fiber is a mixture of wood pulp fiber and tobacco rod fiber;

[0042] (3) Pulping: mix the first tobacco powder, the defibrating solution described in step (2), water, binder, and fuming agent to make a thick pulp, and the first 70 parts of tobacco powder, 7 parts of fiber, 3 parts of binder, and 20 parts of smoking agent, the moisture content of thick stock is 76%, the binder is pectin, and the smoking agent is glycerin and propylene glycol;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com