Wet-process wall breaking method of lucidum spore powder

A Ganoderma lucidum spore powder and wet method technology, which is applied in the direction of medical formulas, medical preparations with non-effective ingredients, non-effective ingredients of polymer compounds, etc., can solve the problem of increasing the production cycle and cost of spore powder, unsatisfactory wall breaking effect, excessive Oxidation value exceeds the standard and other problems, to achieve the effect of facilitating technology promotion and industrial production, increasing disinfection, sterilization and impurity removal operations, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

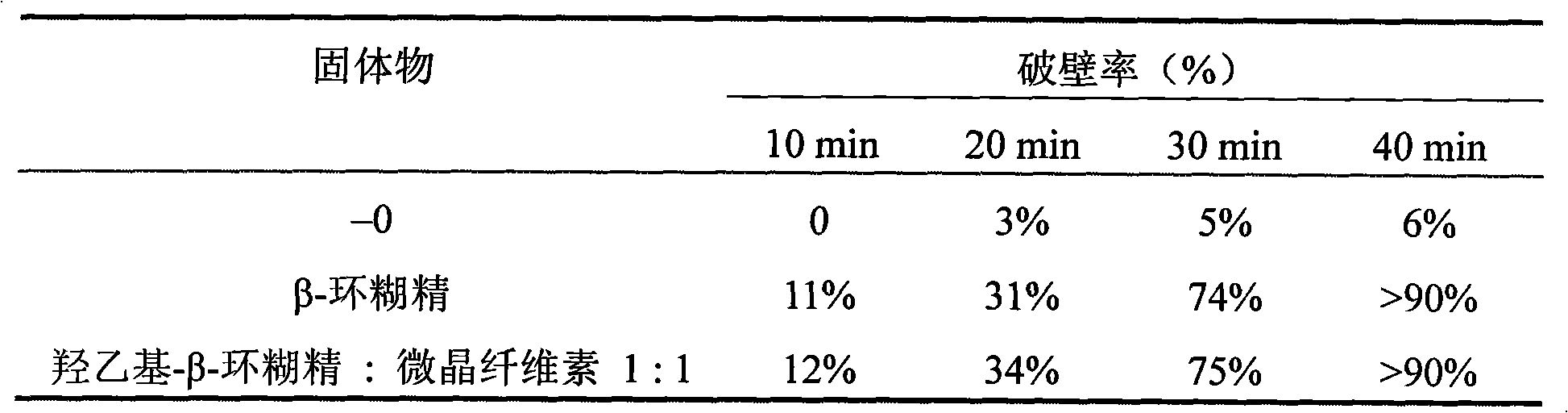

[0047]Example 1, soak 10 grams of natural Ganoderma lucidum spore powder with 75% ethanol for 10 minutes, filter with suction, wash with purified water twice for later use. Weigh 10 grams of hydroxyethyl-β-cyclodextrin and 20 grams of microcrystalline cellulose, add 30 milliliters of water, grind them evenly, add the processed spare Ganoderma lucidum spore powder, grind for 1 hour, and then place them in an oven at 50°C to dry , crushed through a 100-mesh sieve to obtain 40 grams of powdered product, and the wall-breaking rate of ganoderma lucidum spore powder is over 90%.

Embodiment 2

[0048] Example 2, weigh 500 grams of natural Ganoderma lucidum spore powder, soak it in 75% ethanol for 20 minutes, filter it with suction, wash it twice with pure water, add 250 grams of β-cyclodextrin and 1.5 liters of pure water to the Ganoderma lucidum spore powder, and mix well Then pour it into a colloid mill and grind it. The temperature of the system will naturally rise to 45°C. Grind it for 1 hour, then place it in an oven at 50°C and dry it under reduced pressure, and crush it through a 100-mesh sieve to obtain 740 grams of broken spore powder. The broken wall of Ganoderma lucidum spores The rate is above 90%.

Embodiment 3

[0049] Example 3 is basically the same as Example 2, but adding 500 grams of hydroxypropyl-β-cyclodextrin and 250 grams of microcrystalline cellulose and 2.0 liters of purified water to obtain 1250 grams of Ganoderma lucidum spore powder-broken inclusion complex product .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com