Automatic-stuffing food forming machine for clystering wrapper

A molding machine and enema technology, which is applied in the fields of dough processing, food science, baking, etc., can solve the problems of easy filling, difficult sealing and molding, etc., and achieve the effects of not easy opening, easy shaping, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples further illustrate the present invention.

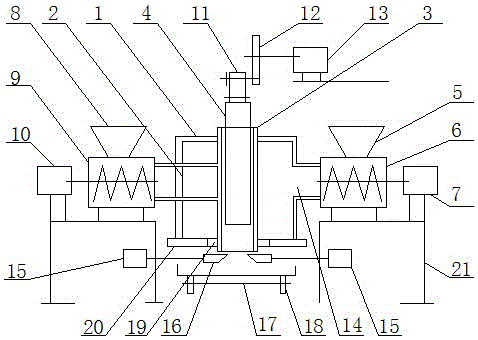

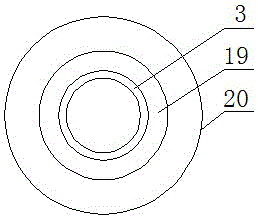

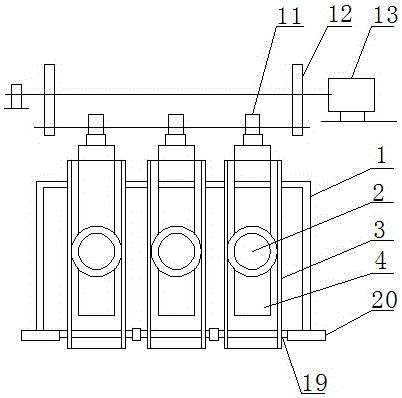

[0023] See figure 1 , figure 2 It can be seen that the automatic enema-type dough filling food forming machine of the present invention consists of a frame 21, a filling extrusion and feeding mechanism 9 arranged on the frame 21, a fabric spiral extrusion mechanism 6 and a filling pushing cavity 3. The frame 21 is provided with a fabric discharge cylinder 1, which is provided with a fabric feed inlet 14, a fabric discharge tray 20, and a fabric discharge tray 20 is equipped with a fabric extrusion discharge hole 19, and a fabric feed inlet 14 is in communication with the fabric spiral extrusion mechanism 6, the fabric discharging barrel 1 is provided with a stuffing pushing cavity 3, the outlet of the stuffing pushing cavity 3 is set at the fabric extrusion outlet hole 19, and the stuffing pushing cavity 3 A piston rod 4 is provided. The side wall of the filling pushing cavity 3 is provided with a feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com