Winding processing method of large-diameter FRPP finned pipe

A processing method and reinforced pipe technology, applied in the field of pipe processing, can solve the problems of inability to achieve bonding and easy cracking, and achieve the effects of good firmness, strengthening the bonding position of the sidewall of the coil, and improving ring stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A winding processing method for large-diameter FRPP reinforced pipes, comprising the following steps:

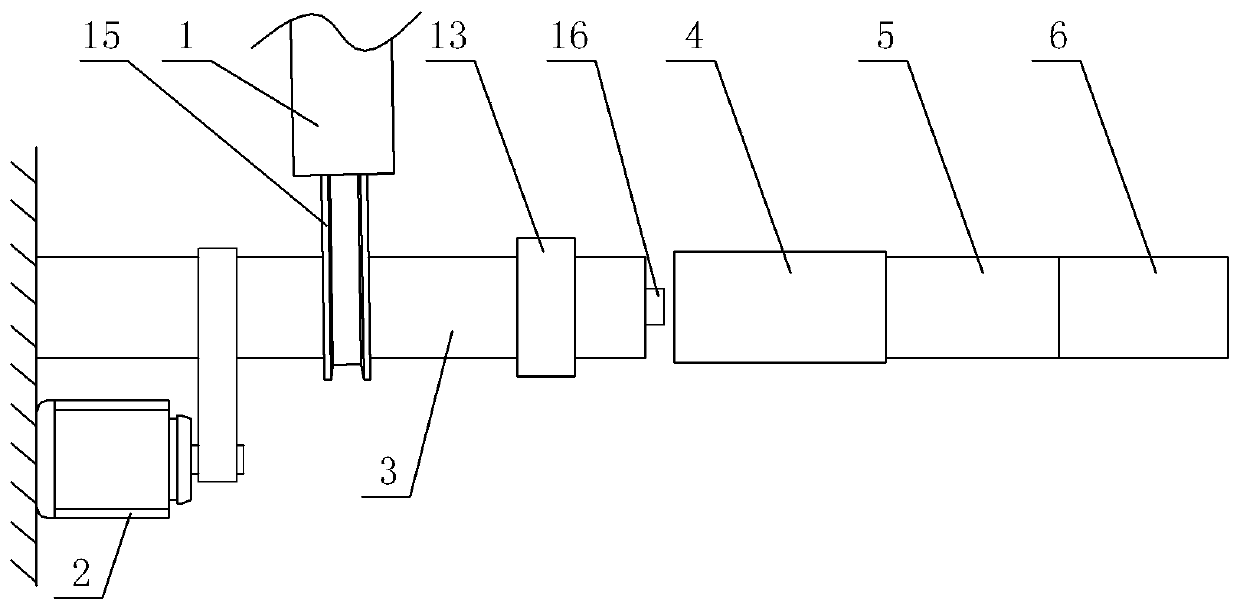

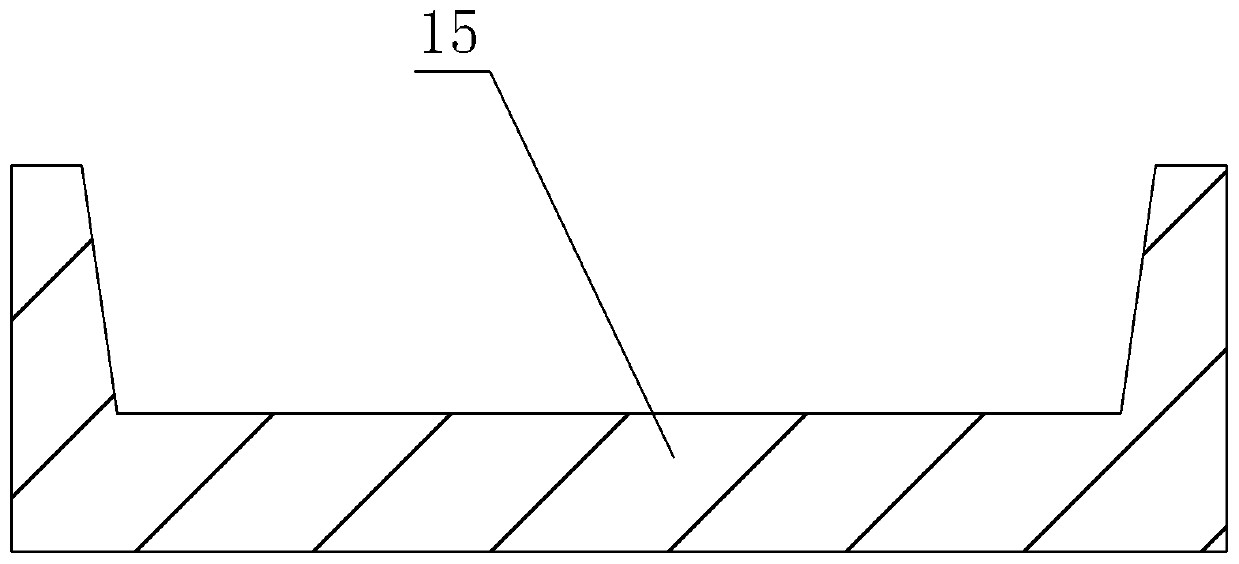

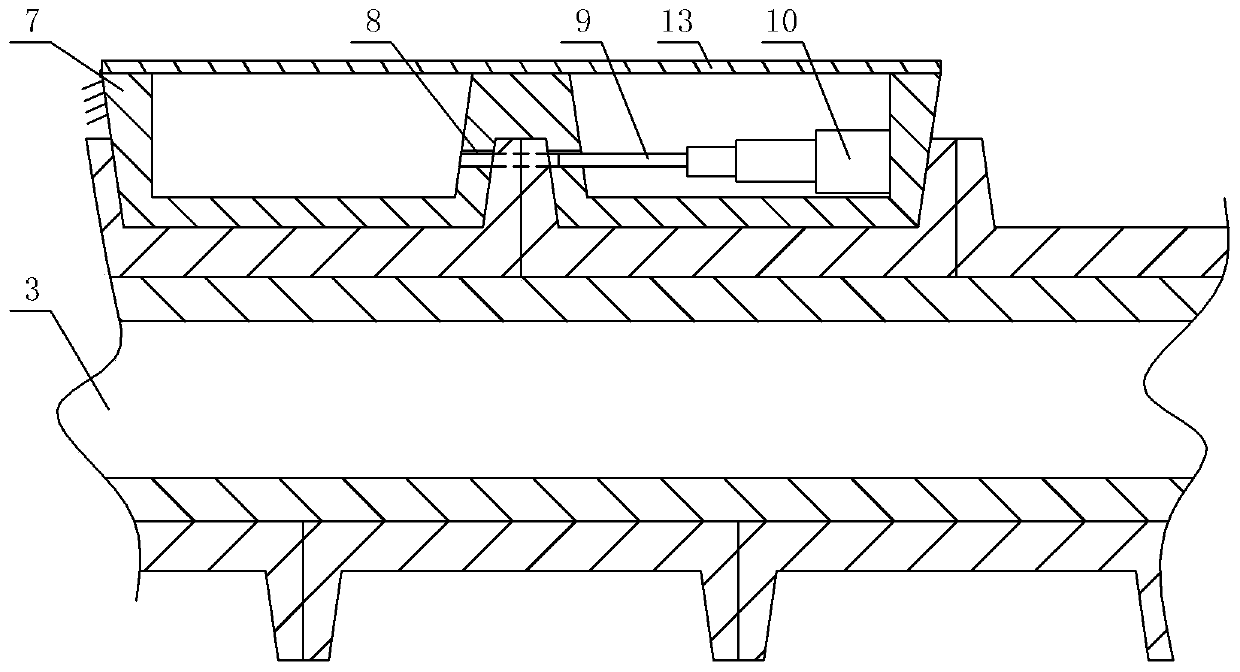

[0033] Step 1: Prepare as figure 1 A pipe winding processing system shown includes a frame, an extruder 1, a servo motor 2, a winding pipe 3, a cooling chamber 4, a cutting table 5 and an assembly table 6, and the extruder 1 is a twin-screw extruder 1 , and its extrusion port is in the shape of "U". The servo motor 2 is fixed on the frame by bolts, the model of the servo motor 2 is MR-J2S-700A, the left end of the winding pipe 3 is rotated and arranged on the frame, and the winding pipe 3 is connected with the output shaft of the servo motor 2 by a belt. Such as image 3 As shown, the frame is fixed with a "W"-shaped pressing box 7 by bolts, the side wall of the pressing box 7 is provided with a channel 8, and an opening strip 9 is slidably arranged in the channel 8; A cylinder 10 is fixedly installed by bolts in the box 7, and the perforated bar 9 is welded with t...

Embodiment 2

[0039] On the basis of embodiment one, from Figure 7 Viewed from the left side, the bottom of the press box 7 is arc-shaped, and both sides of the press box 7 bottom have material leakage ports. at the same time as image 3 As shown, the press box 7 is connected with a cover plate 13 through a hinge.

[0040] In addition, different from Embodiment 1, two automatic welding machines are arranged between the pressing box 7 and the cooling chamber 4, one is fixed on the frame outside the winding pipe 3 by bolts, and the other is installed on the The inner side of the winding pipe 3, specifically, the inner side of the winding pipe 3 is installed as figure 1 Shown support plate 16, the left end of support plate is welded with frame, and another automatic welding machine is fixedly installed on the support plate 16 by bolt, and the welding torch of this automatic welding machine is positioned at the right-hand end of winding pipe 3. The welding torches of the two automatic weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com