Front-light back-light film set fixed structure

A fixed structure, backlight film technology, applied in optics, optical components, nonlinear optics, etc., can solve the problems of optical film deformation, film displacement deformation of multi-layer optical film, etc., and achieve the effect of easy reprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

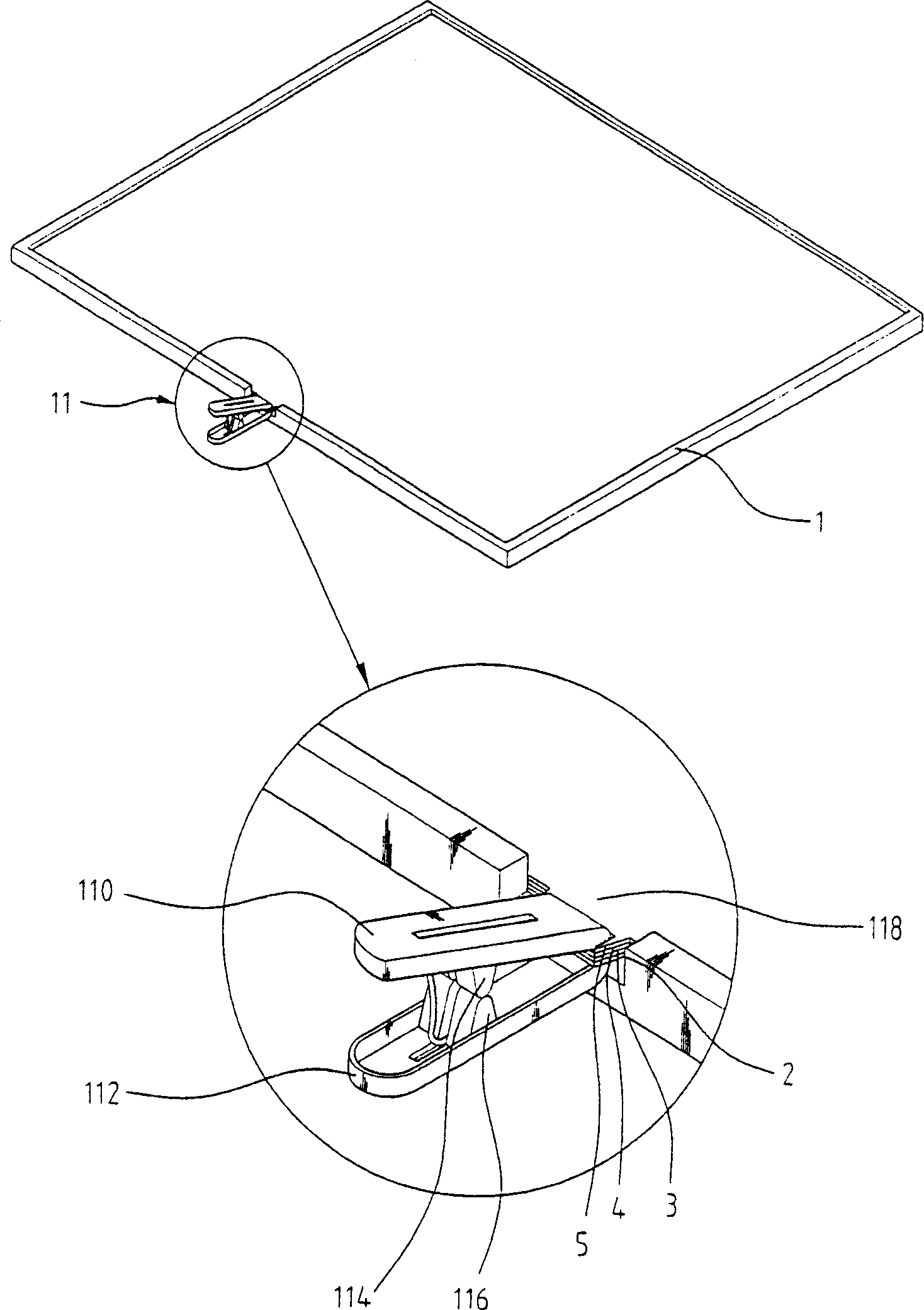

[0026] figure 1 According to the first embodiment of the present invention, the fixed structure diagram of the front light backlight diaphragm group mainly contains the parts mentioned below in this paper: a liquid crystal light valve (not shown in figure 1 ), an illumination mechanism 1, which is used to illuminate the liquid crystal light valve, and the illumination mechanism 1 itself has a planar light source (wave guide type plannar light source) of a waveguide type plate and a substrate (substrate) (not shown in figure 1 ), substrate figure 1 It is placed facing the light source, and has multi-layer optical films (multi-layer optical films) 2, 3, 4, 5 interposed between the substrates figure 1 Between the light source and the light source, in order to selectively reflect part of the light emitted by the planar light source of the waveguide type flat plate, without affecting the color filter, so that the light emitted from the light source has a small divergence range, an...

no. 2 example

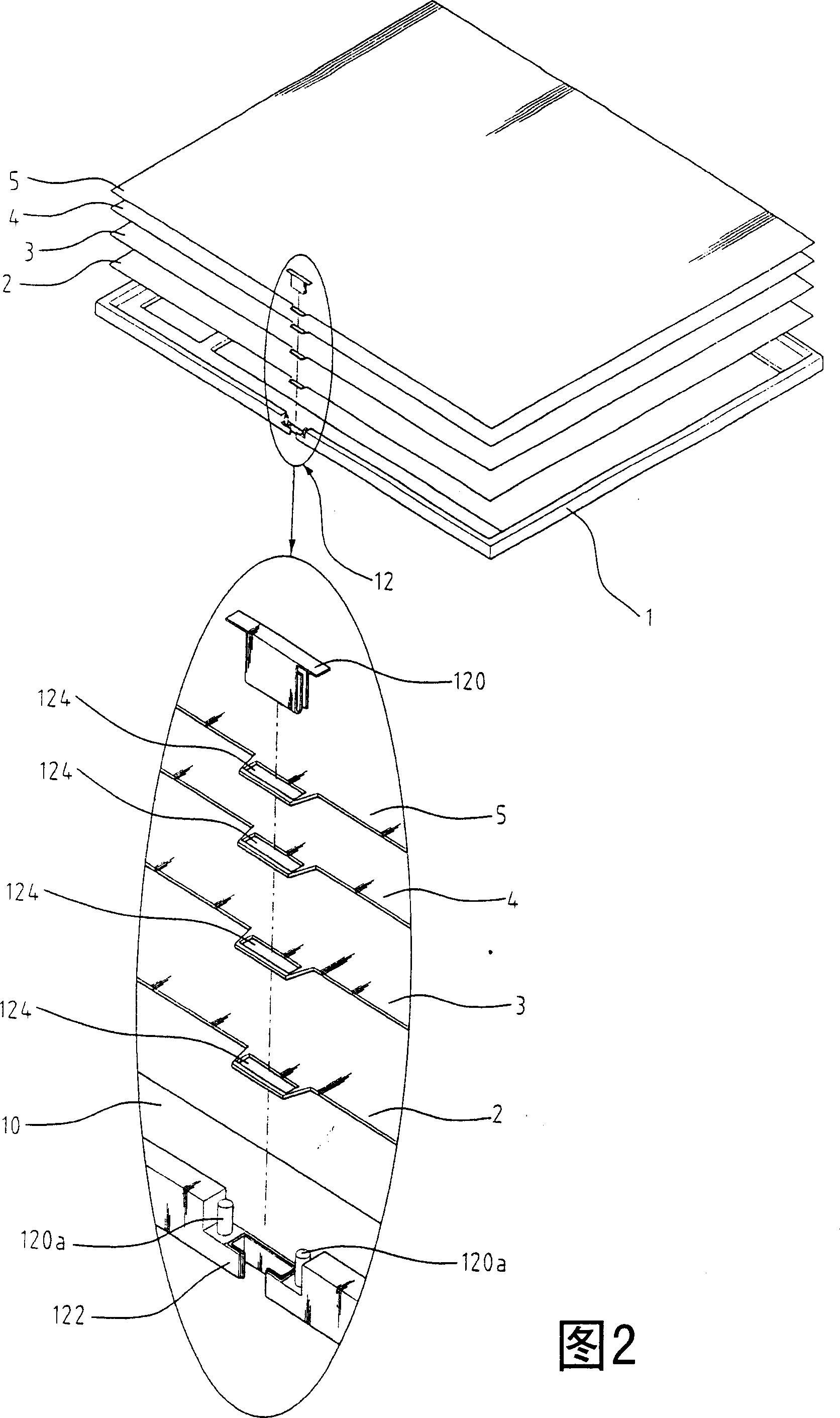

[0032] Fig. 2 is according to the second embodiment of the present invention, the fixing structure diagram of front light and back light film group, mainly contains the parts mentioned below in this text: a liquid crystal light valve (not shown in Fig. 2), a lighting mechanism 1, it is used for The liquid crystal light valve is illuminated, and the lighting mechanism 1 itself has a wave guide type planar light source (not shown in FIG. 2 ) and a substrate 10. The substrate 10 itself is placed as face towards the light source, and have multi-layer optical films (multi-layer optical films) 2, 3, 4, 5 interposed between the substrate 10 and the light source, so as to selectively reflect part of the light emitted by the planar light source of the waveguide type plate, and Does not affect the color filter, so that the light emitted from the light source has a small divergence range, and the multilayer optical film 2, 3, 4, 5 can be divided into multiple blocks, and the transmittance...

no. 3 example

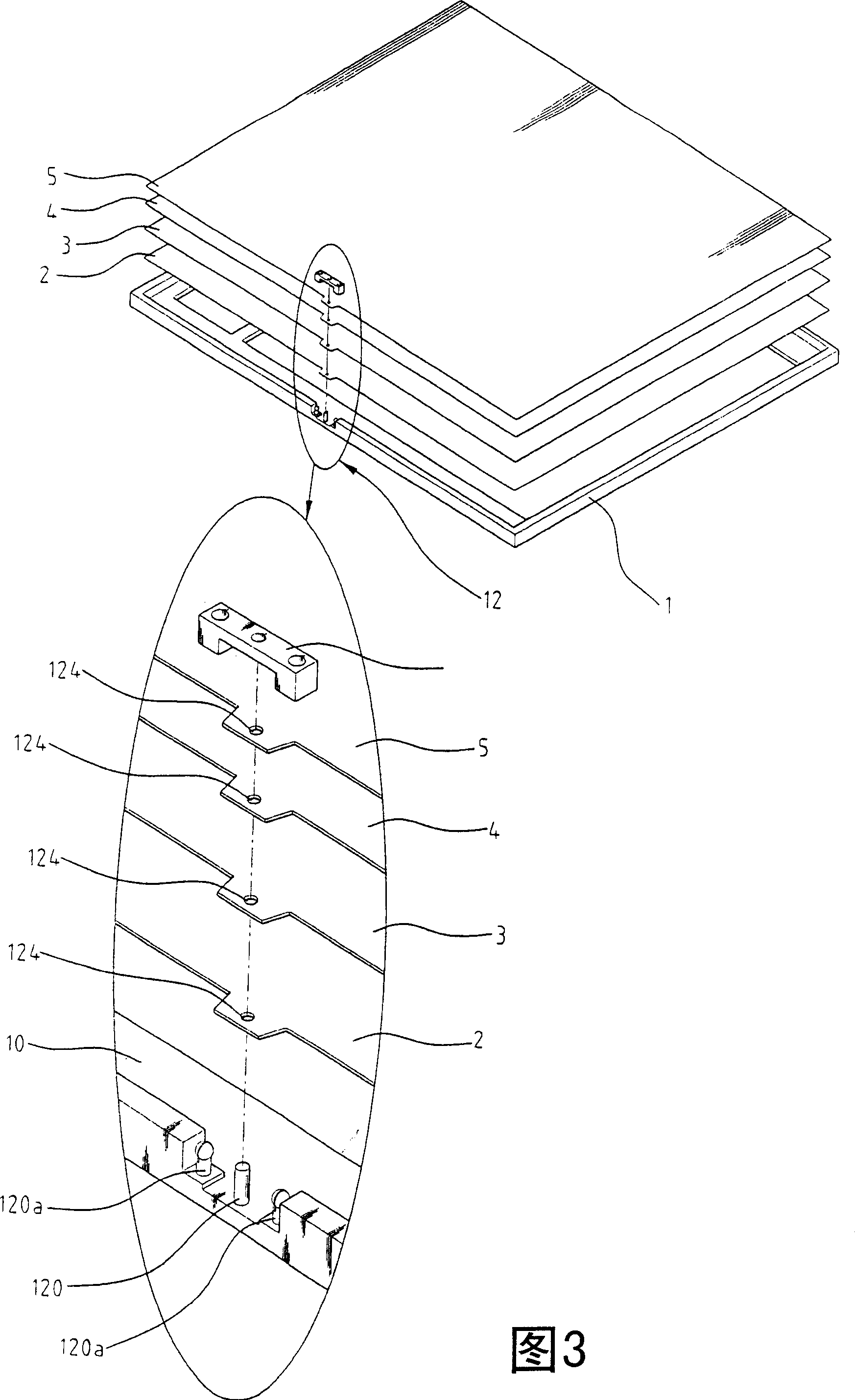

[0038] Fig. 3 is according to the 3rd embodiment of the present invention, the front light backlight film set fixing structure diagram, mainly contains the parts mentioned below in this text: a liquid crystal light valve (not shown in Fig. 3), a lighting mechanism 1, it is used for The liquid crystal light valve is illuminated, and the lighting mechanism 1 itself has a wave guide type planar light source and a substrate 10. The substrate 10 itself is placed to face the light source, and has multiple Multi-layer optical films (multi-layer optical films) 2, 3, 4, 5 are interposed between the substrate 10 and the light source, so as to selectively reflect part of the light emitted by the planar light source of the waveguide type flat plate without affecting the color filter, and The light emitted from the light source has a small divergence range, and multi-layer optical films (multi-layer optical films) 2, 3, 4, 5 can be divided into multiple blocks, and the transmittance between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com