Light-weight closed-pore ceramic heat insulating board

A thermal insulation board and closed-cell technology, which is applied in the production and application of ceramic products and ceramic materials, can solve the problems of high sintering temperature, long holding time, and difficulty in production. processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

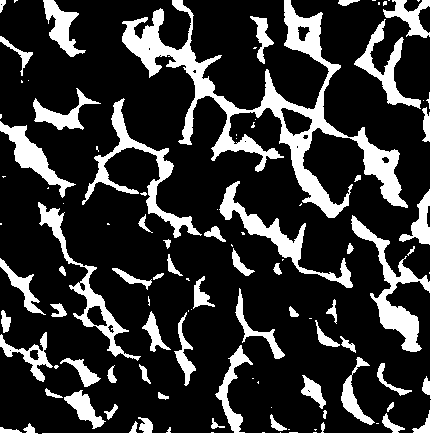

Image

Examples

Embodiment 1

[0022] The lightweight closed-cell ceramic insulation board is composed of the following raw materials: 25% phosphorous tailings, 17% silt, 25% feldspar, 10% shale, 9% kaolin, 12% yellow sand and 2% foaming agent, all in mass percentage The foaming agent is a mixture of silicon carbide, calcium carbonate and iron oxide, the particle size is ≤0.045mm, and the mass percentage is: silicon carbide 50%, calcium carbonate 28%, iron oxide 22%.

[0023] The light-weight closed-cell ceramic insulation board obtained by measuring the density by the Archimedes drainage method, the compressive strength by the rebound method, and the thermal conductivity by the flat-plate method has a density of 0.282g / cm 3 , the compressive strength is 12.26MPa, and the thermal conductivity is 0.089W / (m·K).

Embodiment 2

[0025] The lightweight closed-cell ceramic insulation board is composed of the following raw materials: 35% phosphorous tailings, 13% silt, 20% feldspar, 9.5% shale, 6% kaolin, 15% yellow sand, and 1.5% foaming agent, all of which are mass Percentage; foaming agent is a mixture of silicon carbide, calcium carbonate and iron oxide, particle size ≤ 0.045mm, mass percentage: silicon carbide 54%, calcium carbonate 26%, iron oxide 20%.

[0026] Test method is the same as embodiment 1, and the density of gained porous insulation board is 0.273g / cm 3 , The compressive strength is 11.60MPa, and the thermal conductivity is 0.076W / (m·K).

Embodiment 3

[0028] The lightweight closed-cell ceramic insulation board is composed of the following raw materials: 20% phosphorous tailings, 24% silt, 26% feldspar, 9% shale, 7.5% kaolin, 11% yellow sand, and 2.5% foaming agent, all in mass percentage The foaming agent is a mixture of silicon carbide, calcium carbonate and iron oxide, the particle size is ≤0.045mm, and the mass percentage is: silicon carbide 60%, calcium carbonate 25%, iron oxide 15%.

[0029] Test method is the same as embodiment 1, and the density of gained porous insulation board is 0.291g / cm 3 , the compressive strength is 13.07MPa, and the thermal conductivity is 0.095W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com