Pretreatment method of lignocellulose raw material

A technology of lignocellulose and raw materials, which is applied in the field of biorefinery and bioenergy, can solve the problems of poor hydrolysis efficiency of cellulase, reduce the ability to hydrolyze hemicellulose, weaken the acidic environment of pretreatment, etc., and achieve the effect of enhanced pretreatment , reduce energy consumption, reduce the effect of sulfuric acid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

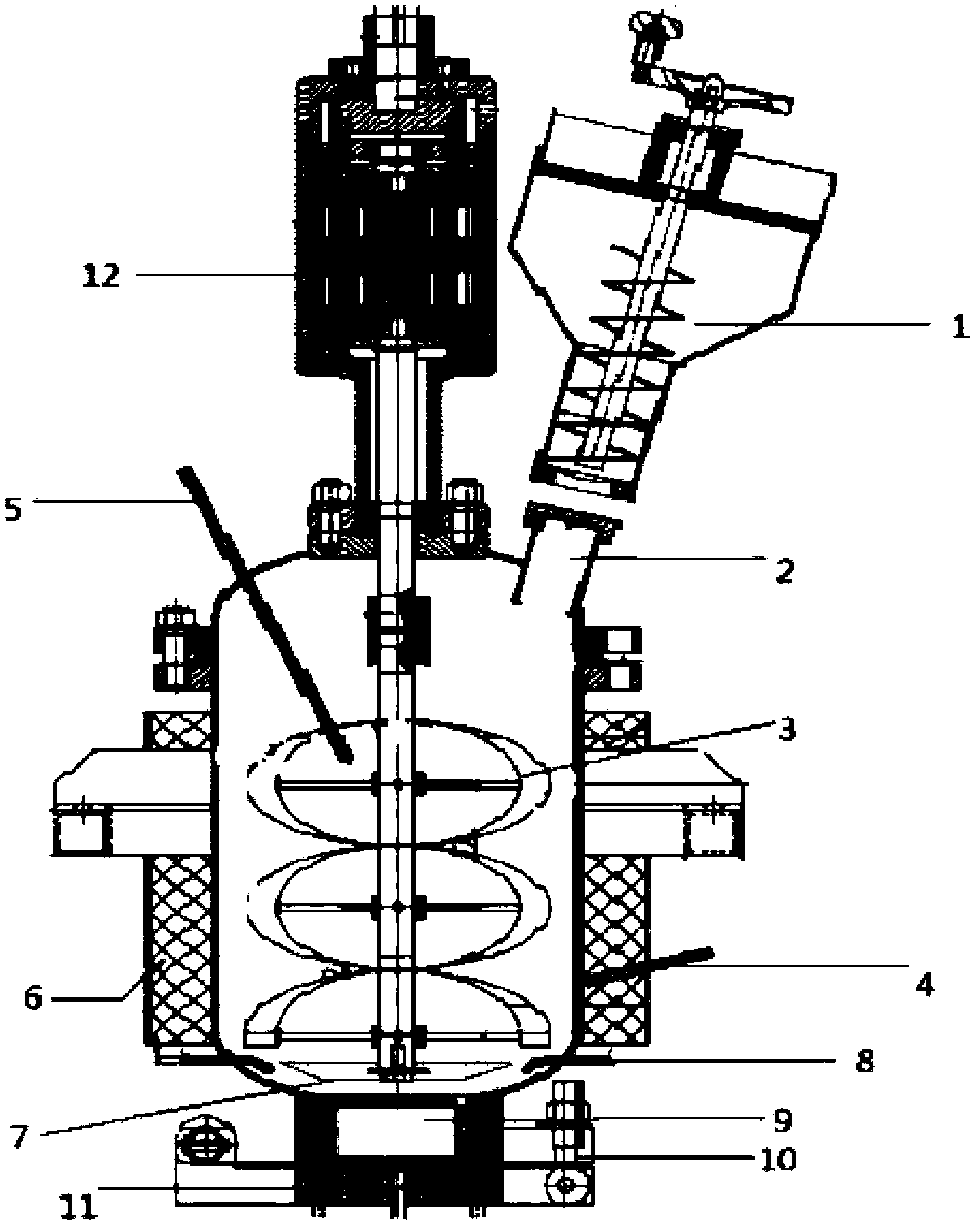

Embodiment 1

[0038] The air-dried corn stalks are roughly cut into 0.1-10 cm long, and directly pulverized with a hammer mill to a particle size of 0.1-0.5 cm without cleaning and dedusting. At this time, the pH value of the material is 9.1. Then material is through dilute acid high-temperature pretreatment (solid-to-liquid ratio 2: 1, sulfuric acid consumption 2.5% (w / w), 190 ℃ of reaction temperatures, 3 minutes), the used equipment of pretreatment is ribbon agitation type pretreatment reactor ( See attached for structure figure 1 ), the pretreated stalks were put into the Erlenmeyer shaker flask; the solid content reached 2% (w / w), and cellulase (Shanghai Youtel Company) was added, the enzyme amount was 15FPU / gDM, 50°C, 150rpm The conversion rate of cellulose was only 27% after 72 hours of enzymatic hydrolysis on a water bath shaker.

[0039] See attached figure 1 , a mechanical stirring device is installed on the still body of the described ribbon stirring type pretreatment reactor, ...

Embodiment 2

[0050] The air-dried corn stalks are roughly cut into 0.1-10 cm long, and directly pulverized in a hammer mill to a particle size of 0.1-0.5 cm without cleaning and dedusting, and the pH value of the material at this time is 9.1. Then material is through dilute acid high temperature pretreatment (solid-liquid ratio 1: 1, sulfuric acid consumption 5% (w / w), reaction temperature 190 ℃, 3 minutes), the used equipment of pretreatment is the ribbon stirring type pretreatment reactor, The structure is the same as in Example 1; the pretreated stalks are put into an Erlenmeyer shaker flask, and the solid content reaches 2% (w / w), and cellulase (Shanghai Youtel Company) is added, and the enzyme amount is 15FPU / gDM, 50°C, 150rpm water-bath shaker enzymolysis for 72h, the conversion rate of cellulose is 50%.

Embodiment 3

[0052] Roughly cut the air-dried corn stalks into 0.1-10cm lengths, add water to clean the stalks at a mass ratio of 200:1 (water:stalks), place them in an oven at 105°C for drying, and place them in a hammer mill after drying. Medium crushing until the particle size is 0.1-0.5cm, and the pH value of the material after cleaning and dust removal is 8.0. Then material is through dilute acid high temperature pretreatment (2: 1 solid-liquid ratio, sulfuric acid consumption 2.5% (w / w), 190 ℃ of reaction temperatures, 3 minutes), the used equipment of pretreatment is the ribbon stirring type pretreatment reactor, The structure is the same as in Example 1; the pretreated stalks are put into an Erlenmeyer shaker flask, and the solid content reaches 2% (w / w), and cellulase (Shanghai Youtel Company) is added, and the enzyme amount is 15FPU / gDM, 50°C, 150rpm water-bath shaker enzymolysis for 72h, the conversion rate of cellulose can reach 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com