High-barrier flexible back film

A high-barrier and flexible technology, applied in the field of solar cells, can solve the problems of low water vapor barrier requirements, difficulty in meeting barrier indicators, and high barrier requirements of packaging materials, achieving sufficient market supply, low cost, and fast production speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

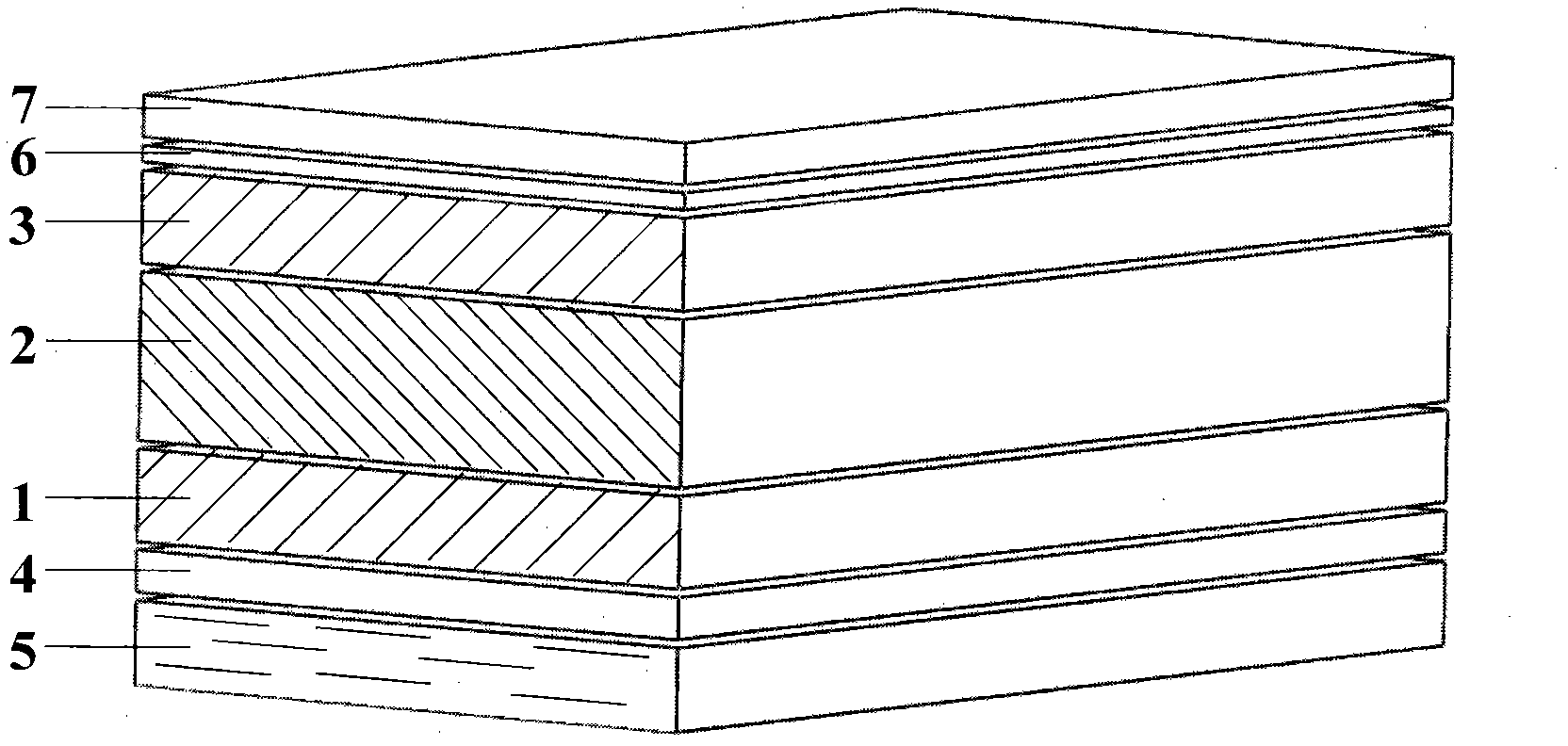

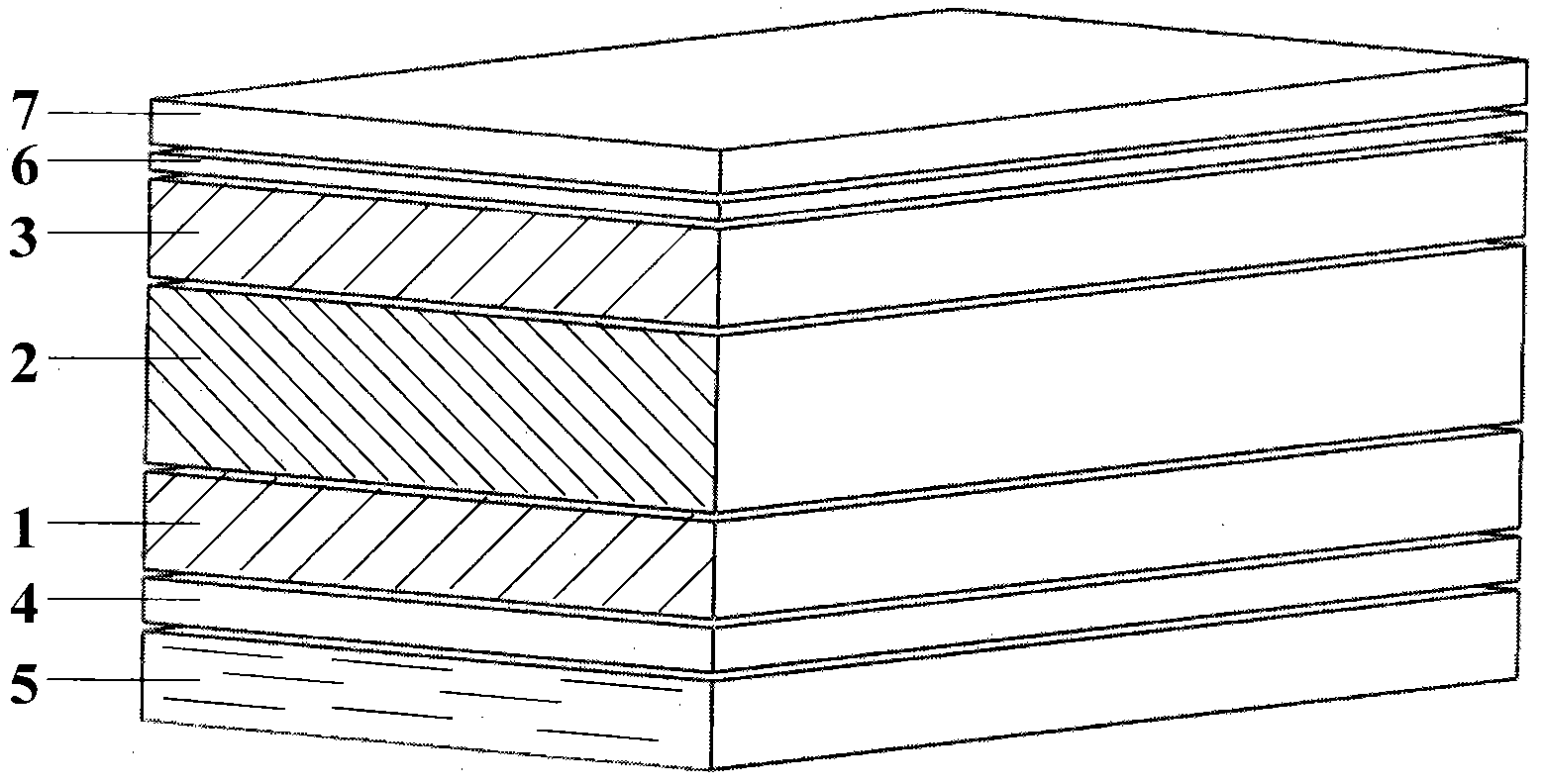

[0022] see figure 1 , a high barrier flexible back film, including base film I (1), aluminum foil (2), base film II (3), anti-ultraviolet layer (4), protective film layer (5) and adhesive layer (6 ), a temporary protective film (7), the base film I (1), II (3) is prepared into a composite film by a composite process through an adhesive and an aluminum foil (2), and the anti-ultraviolet layer (4) directly coated or sputtered onto the outside of the substrate film I (1), the protective film layer (5) is coated or compounded on the anti-ultraviolet layer (4), and the adhesive layer (6) is coated On the substrate film II (3), the temporary protective film (7) is pasted on the adhesive layer (6) to obtain a flexible transparent high-barrier packaging film with multiple barrier properties.

[0023] Preferably, the base film adopts a plastic film with high mechanical strength.

[0024] As a further preference, the substrate film is a film with sufficient supply and low price.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com