Process for improving quality and yield of collagen peptide coproduced from sodium chondroitin sulfate

A technology of chondroitin sulfate sodium and collagen peptides, which is applied in the direction of animal/human protein, peptide preparation methods, peptides, etc., and can solve the problems of affecting product yield and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

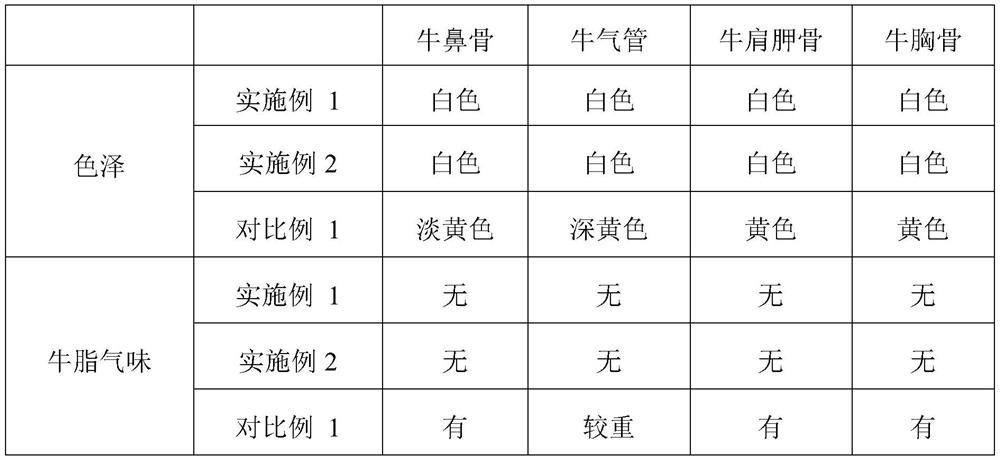

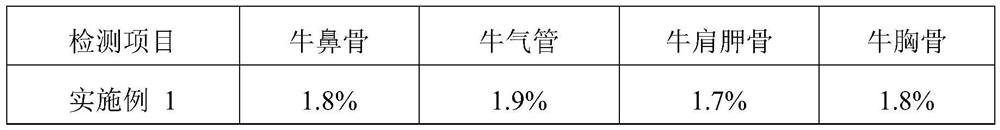

Examples

Embodiment 1

[0041] This embodiment includes the following steps:

[0042] A process for improving the quality of sodium chondroitin sulfate co-produced collagen peptides, comprising the following steps:

[0043] (1) Carbon dioxide supercritical extraction cartilage degreasing: crush 1000kg of dried bovine nasal bone to obtain cartilage coarse powder, use carbon dioxide supercritical extraction to crush the cartilage coarse powder, extract the lipophilic substances such as oil, choose continuous downstream extraction method, 200kg / Batch, flow rate 500 liters / hour, temperature 40 degrees, pressure 12mpa, 4 hours / batch, obtain defatted cartilage, receive 30 kilograms of grease.

[0044] (2) Hydrolysis: put the degreased cartilage obtained in step (2) into an extraction tank, add 8 tons of water, keep warm at 105°C for 2 hours; start stirring at a speed of 120 rpm, cool to 50°C; adjust the speed to 60 rpm , add 2709 alkaline protease with 0.9% cartilage mass (90 kg), and enzymatically hydro...

Embodiment 2

[0049] Example 2 is the same except that butane subcritical extraction is used to replace carbon dioxide supercritical extraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com