Sewage physical-chemical treatment method

A treatment method and sewage treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as inability to meet the requirements of effluent water quality, and achieve easy reprocessing and low investment The effect of small, low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

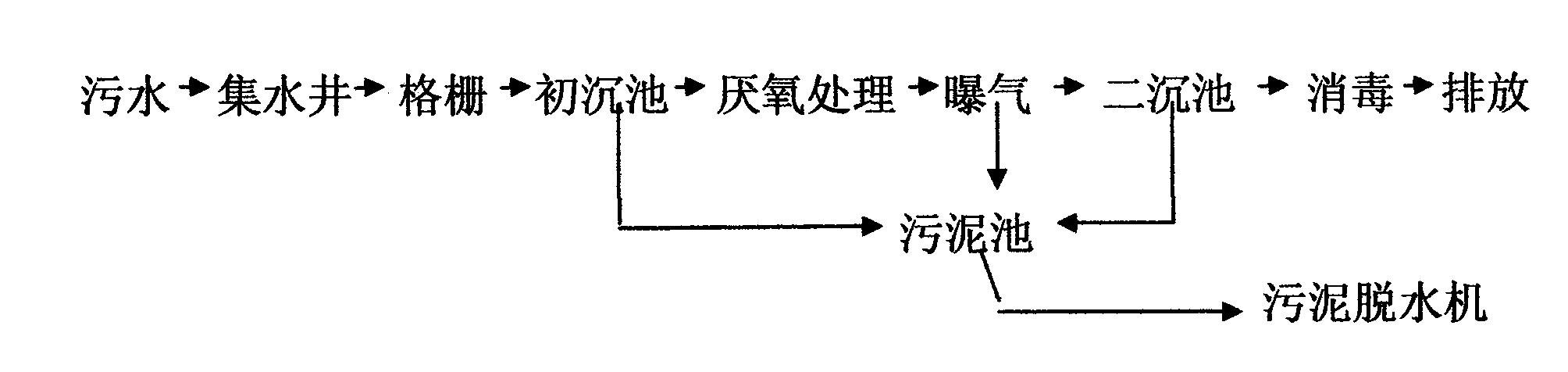

[0033] Embodiment 1, a kind of sewage physical and chemical treatment method is characterized in that comprising the steps:

[0034] A: In the water collection well, the conventional grid filter for sewage treatment is used to remove the coarse residue in the sewage and then use the sewage pump to send the sewage to the sedimentation tank;

[0035] B: Add 60ppm of aluminum-iron salt dephosphorization agent, 9ppm of modified china clay adsorbent to the inlet pipeline of the sewage pump, and 1.5ppm of polyacrylamide organic polymer flocculant to the outlet pipeline of the sewage pump.

[0036] C: After 20 minutes of sedimentation in the sedimentation tank, solid-liquid separation is realized;

[0037] D: The liquid sewage after the solid-liquid separation is completed through precipitation, enters the ammonia nitrogen absorption tower to remove ammonia nitrogen;

[0038] E: Sewage that has been deammonized and nitrogen-depleted is discharged after being sterilized by ultraviole...

Embodiment 2

[0041] Embodiment 2, a kind of sewage physical and chemical treatment method is characterized in that comprising the following steps:

[0042] A: In the water collection well, the conventional grid filter for sewage treatment is used to remove the coarse residue in the sewage and then use the sewage pump to send the sewage to the sedimentation tank;

[0043] B: Add 80ppm of aluminum-iron salt dephosphorization agent, 11ppm of modified china clay adsorbent to the inlet pipeline of the sewage pump, and 2.5ppm of polyacrylamide organic polymer flocculant to the outlet pipeline of the sewage pump;

[0044] C: After 20 minutes of sedimentation in the sedimentation tank, solid-liquid separation is realized;

[0045] D: The liquid sewage after the solid-liquid separation is completed through precipitation, enters the ammonia nitrogen absorption tower to remove ammonia nitrogen;

[0046] E: After the ammonia nitrogen has been removed from the sewage, first adjust the PH value to the ...

Embodiment 3

[0048] Embodiment 3, a kind of sewage physical and chemical treatment method is characterized in that comprising the following steps:

[0049] A: In the water collection well, the conventional grid filter for sewage treatment is used to remove the coarse residue in the sewage and then use the sewage pump to send the sewage to the sedimentation tank;

[0050] B: Add 70ppm of aluminum-iron salt dephosphorization agent, 10ppm of modified china clay adsorbent to the inlet pipeline of the sewage pump, and 2ppm of polyacrylamide organic polymer flocculant to the outlet pipeline of the sewage pump;

[0051] C: After 20 minutes of sedimentation in the sedimentation tank, solid-liquid separation is realized;

[0052] D: The liquid sewage after the solid-liquid separation is completed through precipitation, enters the ammonia nitrogen absorption tower to remove ammonia nitrogen;

[0053] E: Sewage that has been deammonized and nitrogen-depleted is discharged after being sterilized by ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com