Heating plate and method of manufacturing the same and electric heating kettle using the same

A technology of electric kettle and heating plate, which is applied in the direction of electric heating devices, electrical components, water boiling appliances, etc. It can solve the problems of large power consumption and environmental protection, and achieve the effect of high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The utility model is described in further detail below in conjunction with accompanying drawing and specific embodiment.

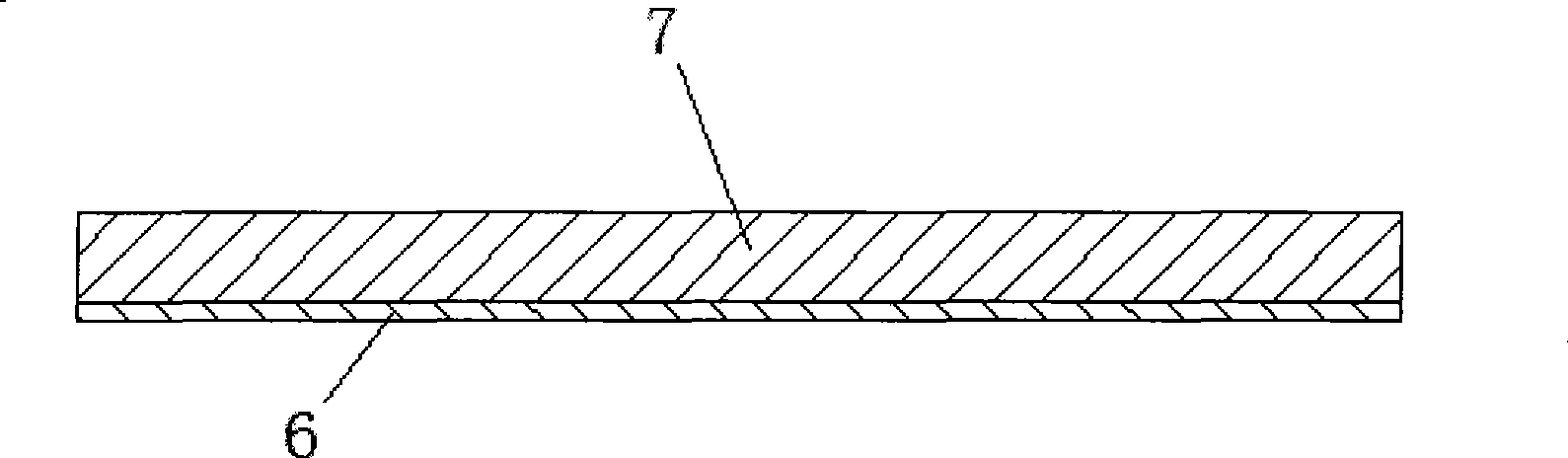

[0019] refer to figure 1 , a heating plate body 6, including a base plate 7, the base plate 7 is a glass plate or a ceramic plate, and a layer of electrothermal film 6 combined with it is attached to the base plate 7.

[0020] The manufacturing method of the heating plate body is as follows: a. Prepare the spray film liquid, and heat the substrate to 400°C; the spray film liquid can be prepared according to the existing spray film liquid formula, and will not repeat it again;

[0021] b. Spray the prepared spray film solution onto the substrate;

[0022] c. Bake the substrate sprayed with the spray film solution at a constant temperature of 400°C for 3 minutes and then cool it down.

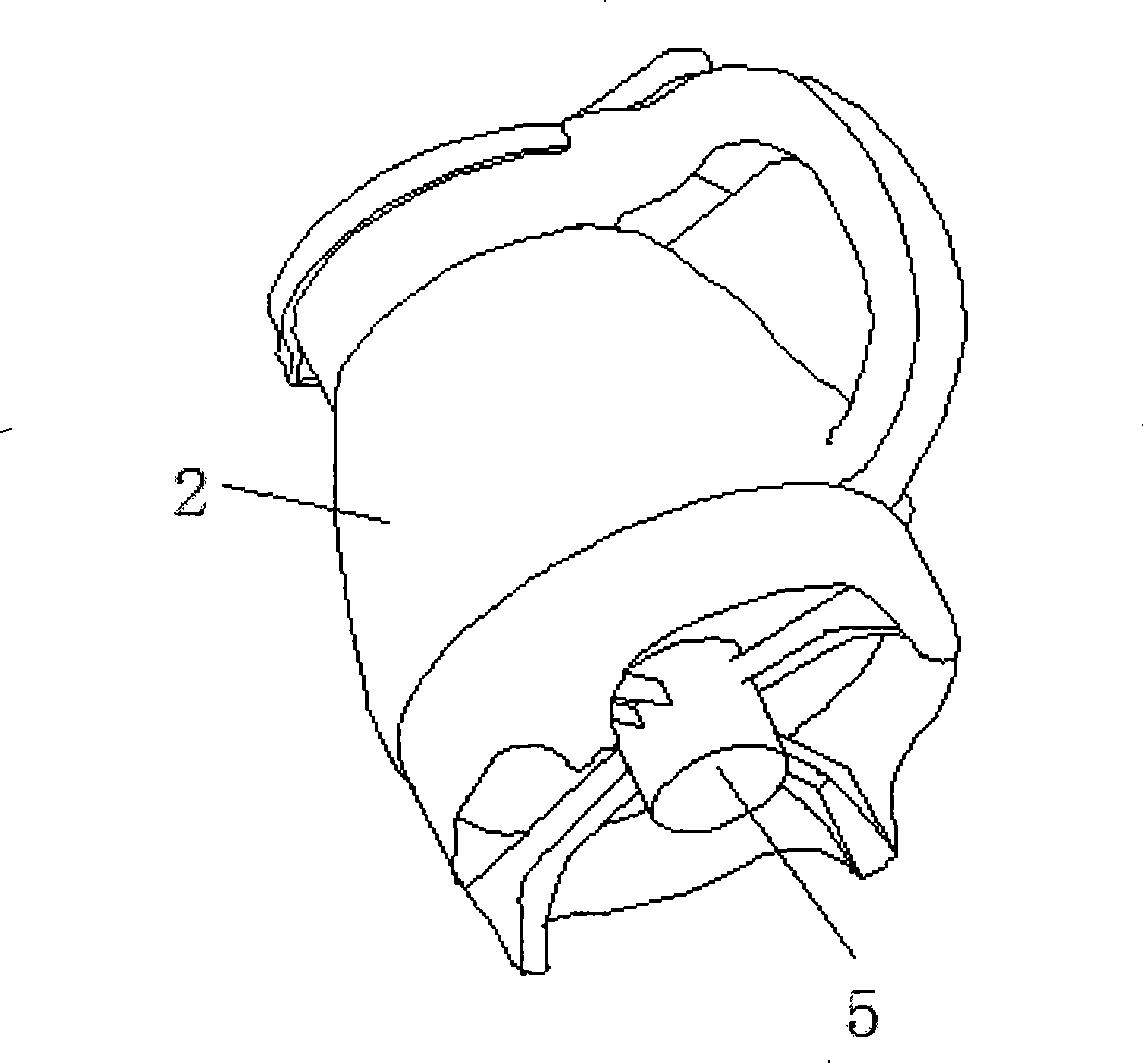

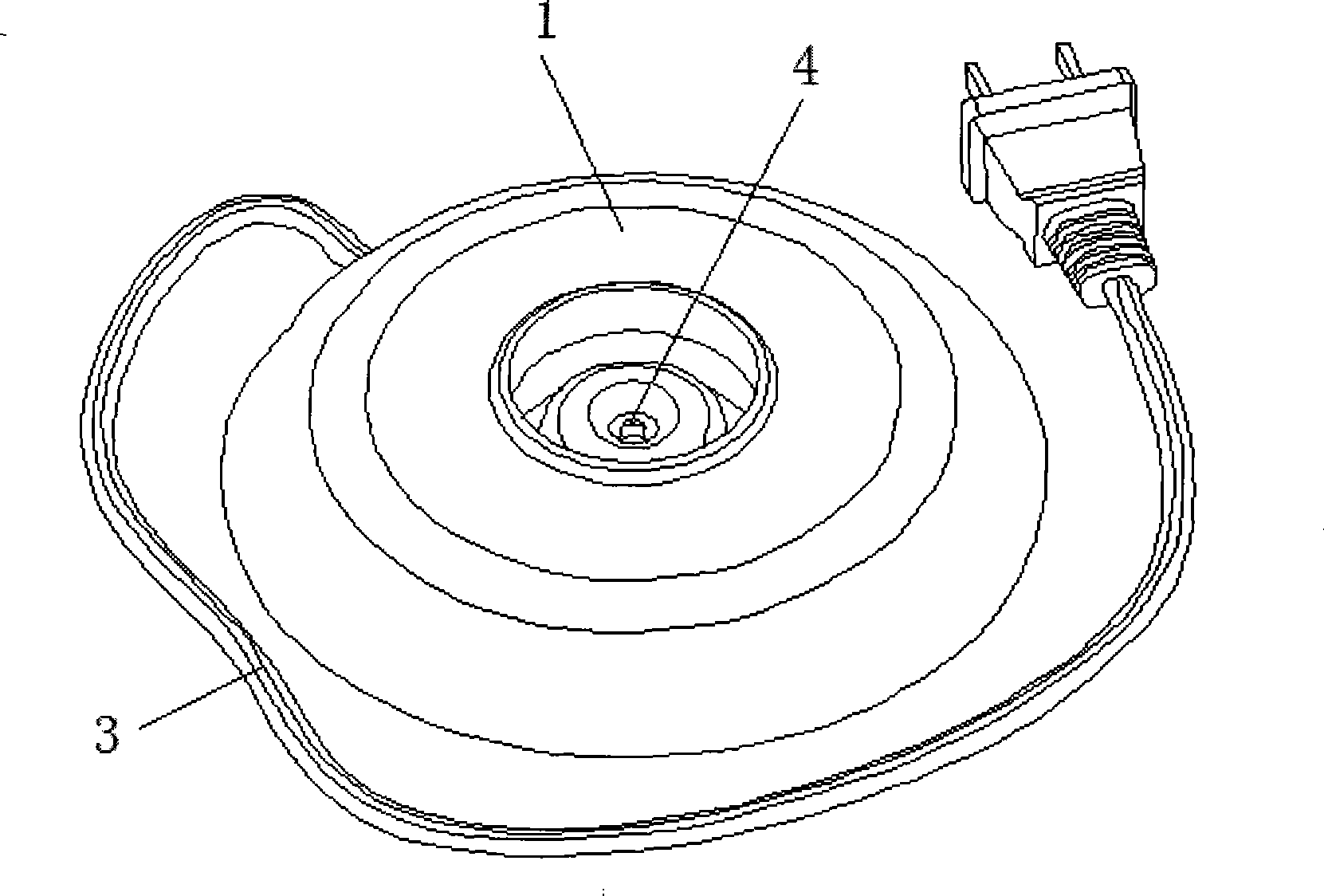

[0023] refer to figure 2 , image 3 , Figure 4 , an electric kettle, comprising a base 1 and a glass kettle body 2, the glass kettle body 2 is placed on the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com