Titanium based cathode material with uniform and dense TiB2 layer and preparation method of titanium based cathode material

A cathode material and dense technology, applied in the direction of coating, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems that the service life is difficult to meet the requirements, the titanium substrate is easy to be corroded, and boronizing cannot be realized, so as to eliminate the coating The problem of falling off, avoiding corrosion, and the effect of increasing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

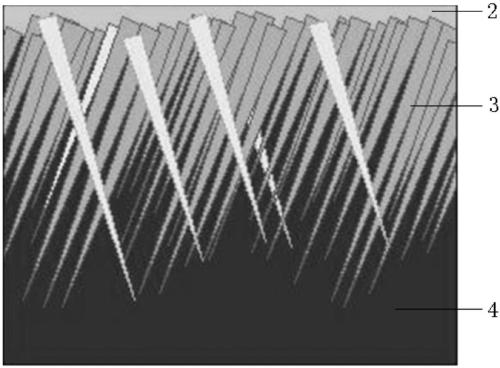

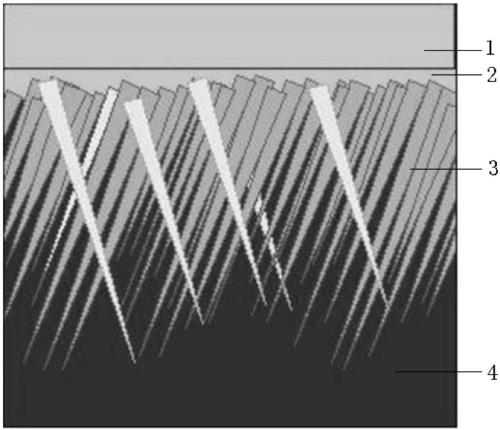

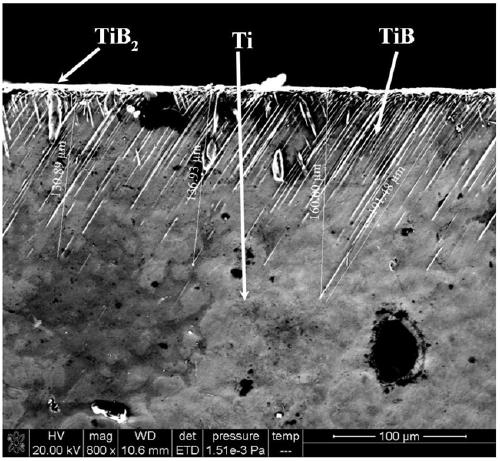

[0024] (1) Carry out boronizing treatment to the titanium base body that surface has been treated clean, electrolyte component and mass fraction are, the anhydrous borax of 70%, the anhydrous potassium carbonate of 15% and the B of 15% 4 C, with the graphite crucible as the anode and the metal titanium plate as the cathode, the cathode current density is controlled at 100mA / cm 2 , the temperature of the molten salt electrolyte is 850°C, and the electricity is energized for 5 hours, so as to obtain TiB 2 -TiB / Ti gradient composite material;

[0025] (2) TiB obtained in step (1) 2 -TiB / Ti gradient composite material is cleaned without damage, and the TiB 2 -TiB / Ti gradient composite material was boiled in 0.5mol / L sodium hydroxide solution for 75min, then soaked in clean water for 100min at room temperature, then treated in 0.5 / L hydrochloric acid for 6min at room temperature, and finally cleaned with ultrasonic waves in clean water.

[0026] (3) TiB after step (2) is cleaned...

Embodiment 2

[0028] (1) Carry out boronizing treatment to the titanium matrix that surface has been treated clean, electrolyte component and mass fraction are, the anhydrous borax of 75%, the anhydrous potassium carbonate of 15% and the B of 10% 4 C, with the graphite crucible as the anode and the metal titanium plate as the cathode, the cathode current density is controlled at 150mA / cm 2 , the temperature of the molten salt electrolyte is 800 °C, and the electricity is energized for 4 hours, so as to obtain TiB 2 - TiB / Ti gradient composites.

[0029] (2) TiB obtained in step (1) 2 -TiB / Ti gradient composite material is cleaned without damage, and the TiB 2 -TiB / Ti gradient composite material was boiled in 1mol / L sodium hydroxide solution for 60min, then soaked in clean water at room temperature for 120min, then treated in 1mol / L hydrochloric acid at room temperature for 5min, and finally cleaned with ultrasonic waves in clean water.

[0030] (3) TiB after step (2) is cleaned 2 -TiB / T...

Embodiment 3

[0032] (1) Carry out boronizing treatment to the titanium base body that surface has been treated clean, electrolyte component and mass fraction are, the anhydrous borax of 80%, the anhydrous potassium carbonate of 10% and the B of 10% 4 C, with the graphite crucible as the anode and the metal titanium plate as the cathode, the current density of the cathode is controlled at 200mA / cm 2 , the temperature of the molten salt electrolyte is 950°C, and energized for 0.5 hours, thus obtaining TiB 2 - TiB / Ti gradient composites.

[0033] (2) TiB obtained in step (1) 2 -TiB / Ti gradient composite material is cleaned without damage, and the TiB 2 -TiB / Ti gradient composite material was boiled in 3mol / L sodium hydroxide solution for 50min, then soaked in clean water at room temperature for 140min, then treated in 2mol / L hydrochloric acid at room temperature for 4min, and finally cleaned with ultrasonic waves in clean water.

[0034] (3) TiB after step (2) is cleaned 2 -TiB / Ti Gradien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com